Given force splitting mud jacking enhancement type composite foundation construction method

A composite foundation and reinforced technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of no theoretical system for processing design and construction, limitations on processing effects and benefits, and inconvenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

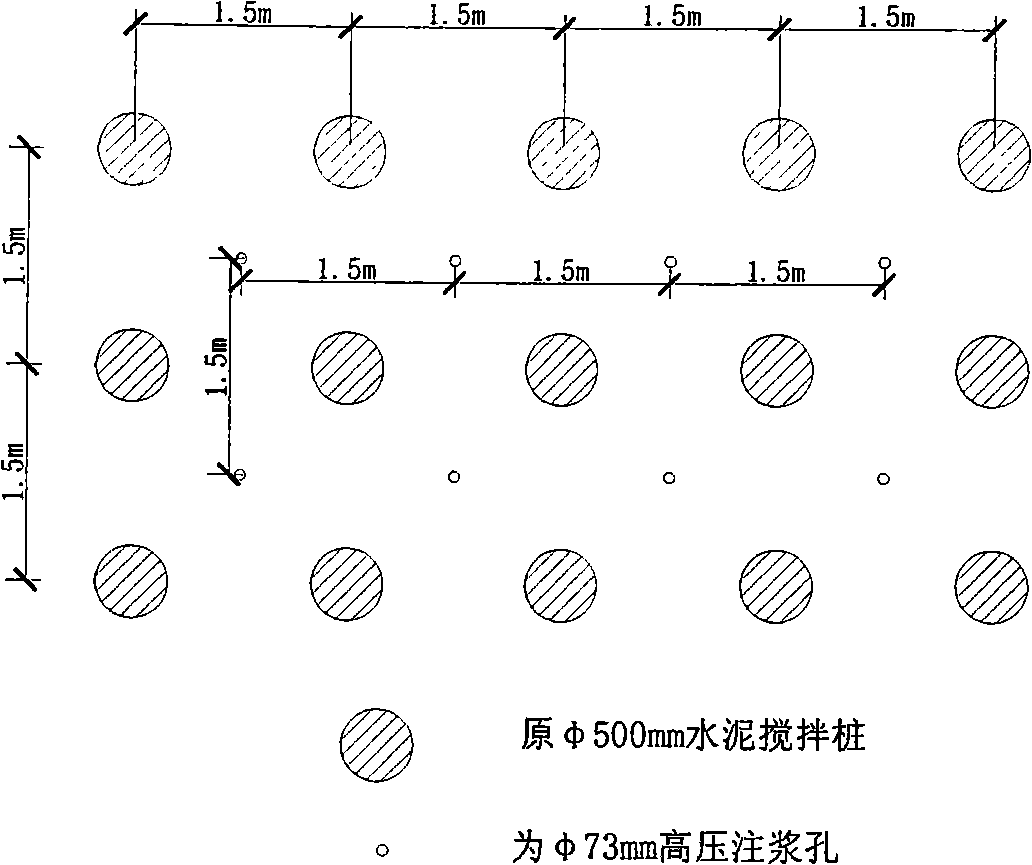

[0066] (1) Firstly, carry out detailed and comprehensive investigation and analysis, master the load standards and design requirements of the proposed site and roads and other building facilities, and clarify the reinforcement treatment grade standard of the proposed site (including various indicators required by the design). At the same time, be familiar with the engineering geological survey data of the proposed site and the technical conditions and construction process of dredging sandy soil layer and miscellaneous filling soil layer, recognize the soil properties and soil characteristics, master the treatment depth and treatment range, and formulate the process flow and Appropriate force control standard.

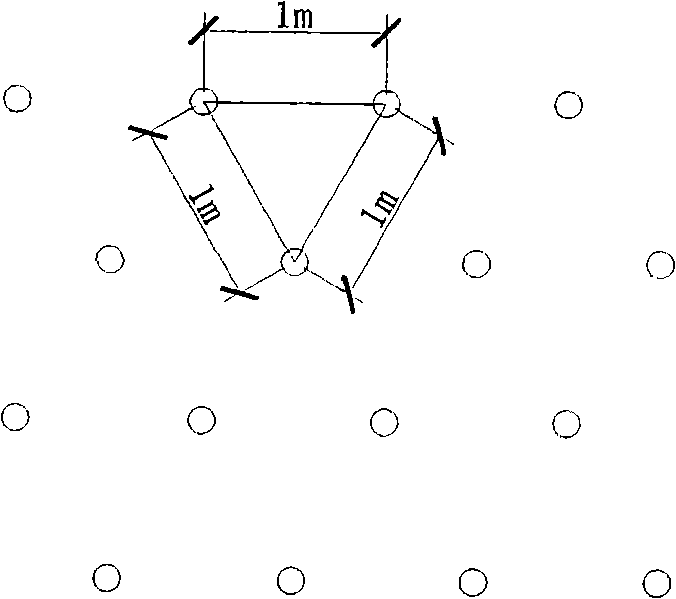

[0067] (2) The present invention utilizes the composition and ratio of the grout materials that have passed the laboratory test, and then matches with high-power high-pressure grouting mechanical equipment, and uses the force-giving technology to the reinforced soil skel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com