Patents

Literature

149 results about "Plaster Casts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A plaster cast is a copy made in plaster of another 3-dimensional form.

Method for creating a personalized digital planning file for simulation of dental implant placement

ActiveUS20090187393A1Provide informationAdvantageously avoidedImpression capsMechanical/radiation/invasive therapiesPersonalizationDental implant

The present invention provides a method for creating a personalized digital planning file for simulation of dental implant placement. After planning, the digital representation in a plaster model may be used to design and produce dedicated surgical templates to assist the surgeon in transferring the implant plan to a patient during medical intervention.

Owner:MATERIALISE DENTAL NV

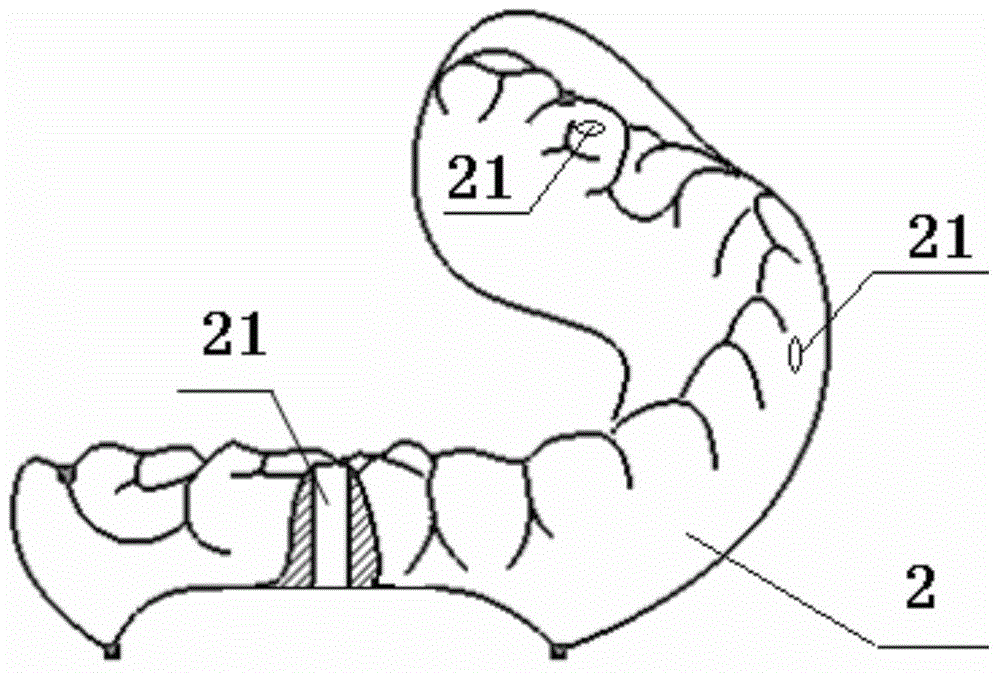

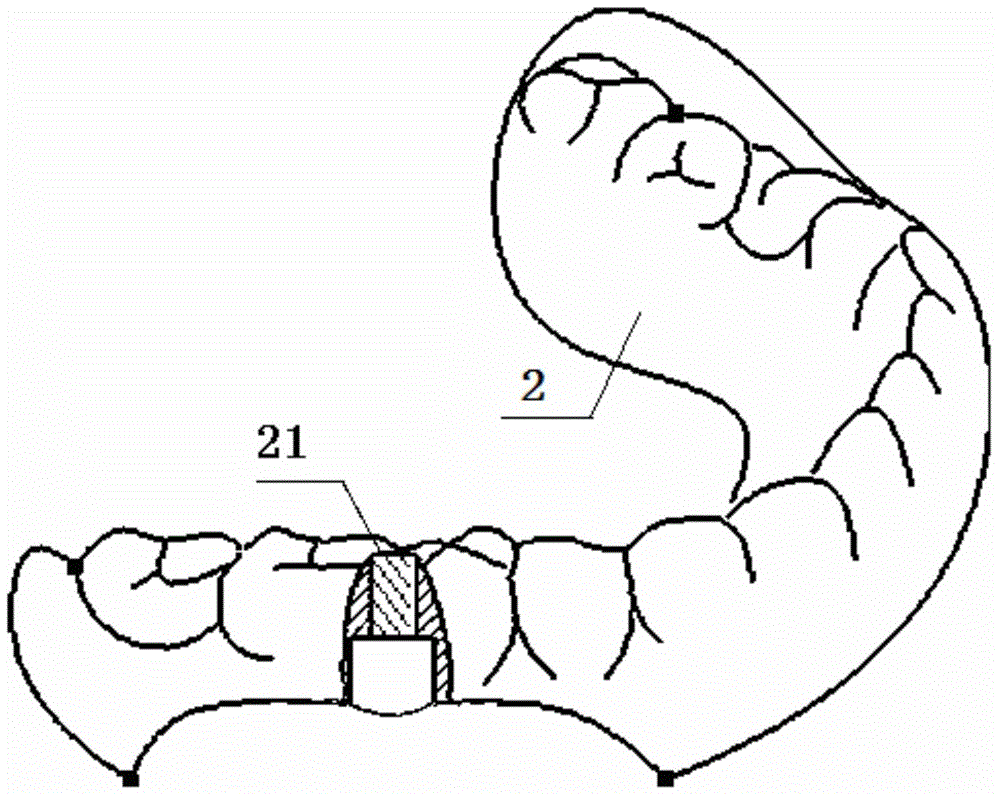

Whole-tooth lost dental implantation operation guide plate and making method thereof

Owner:6D DENTAL TECH

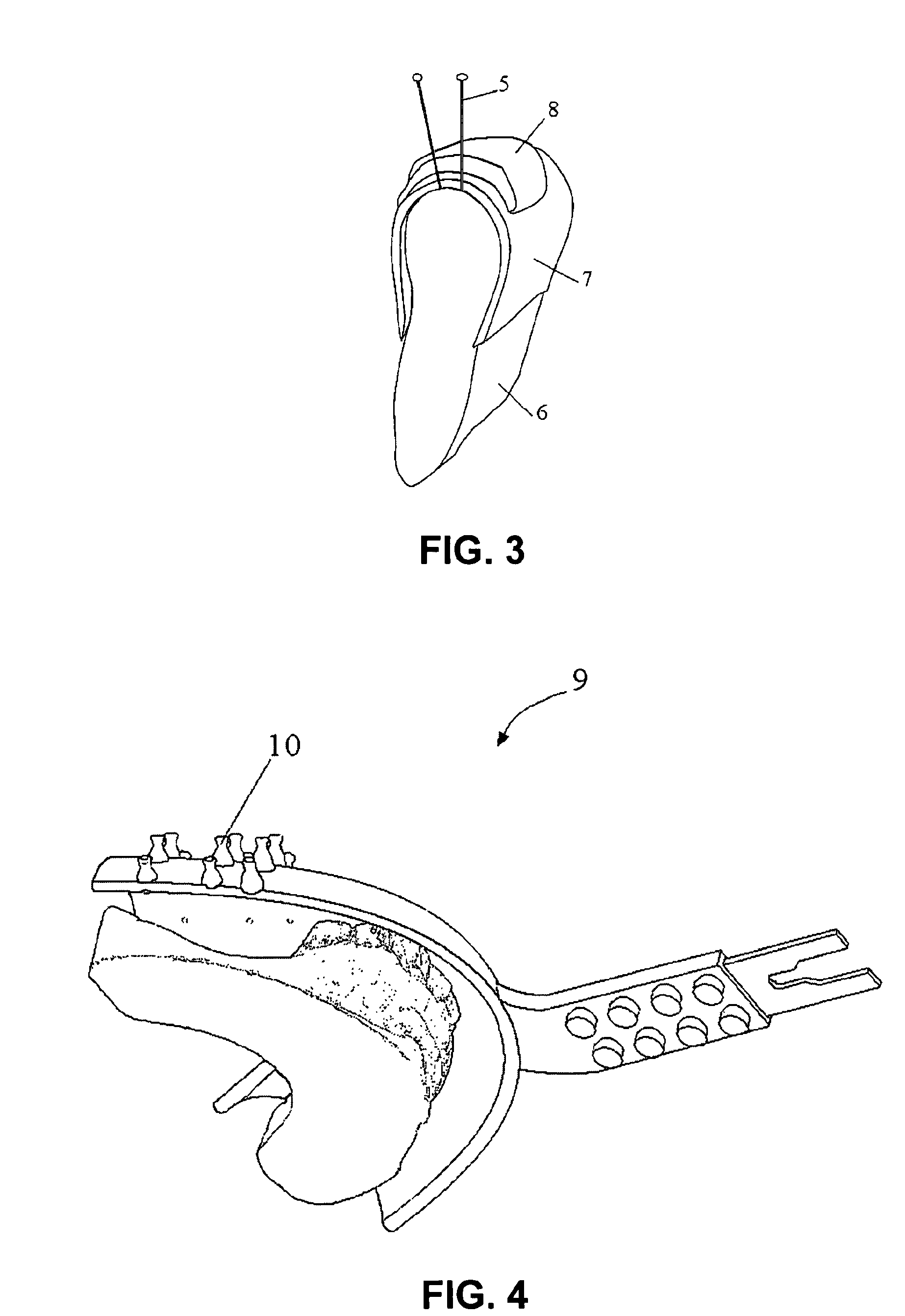

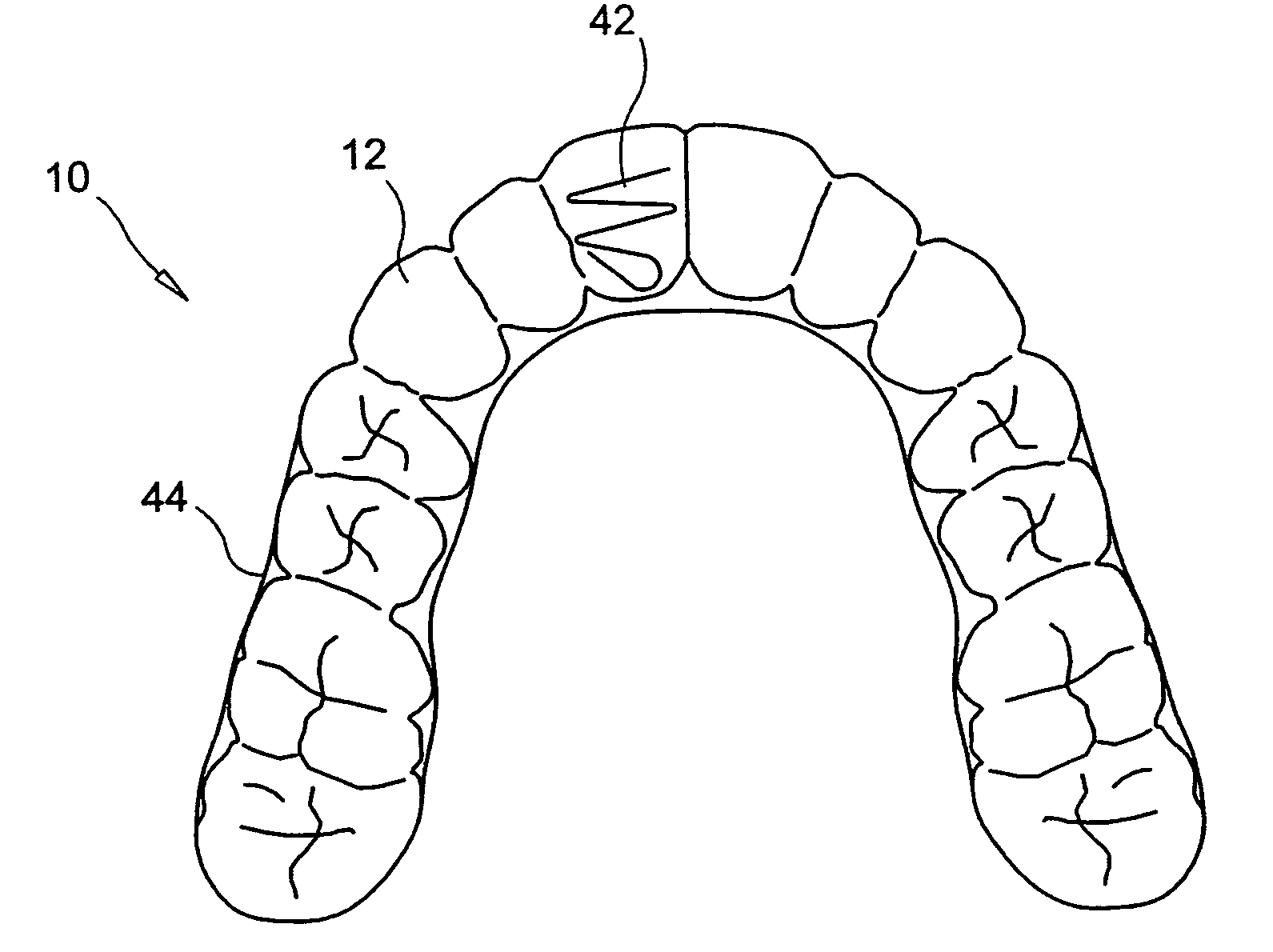

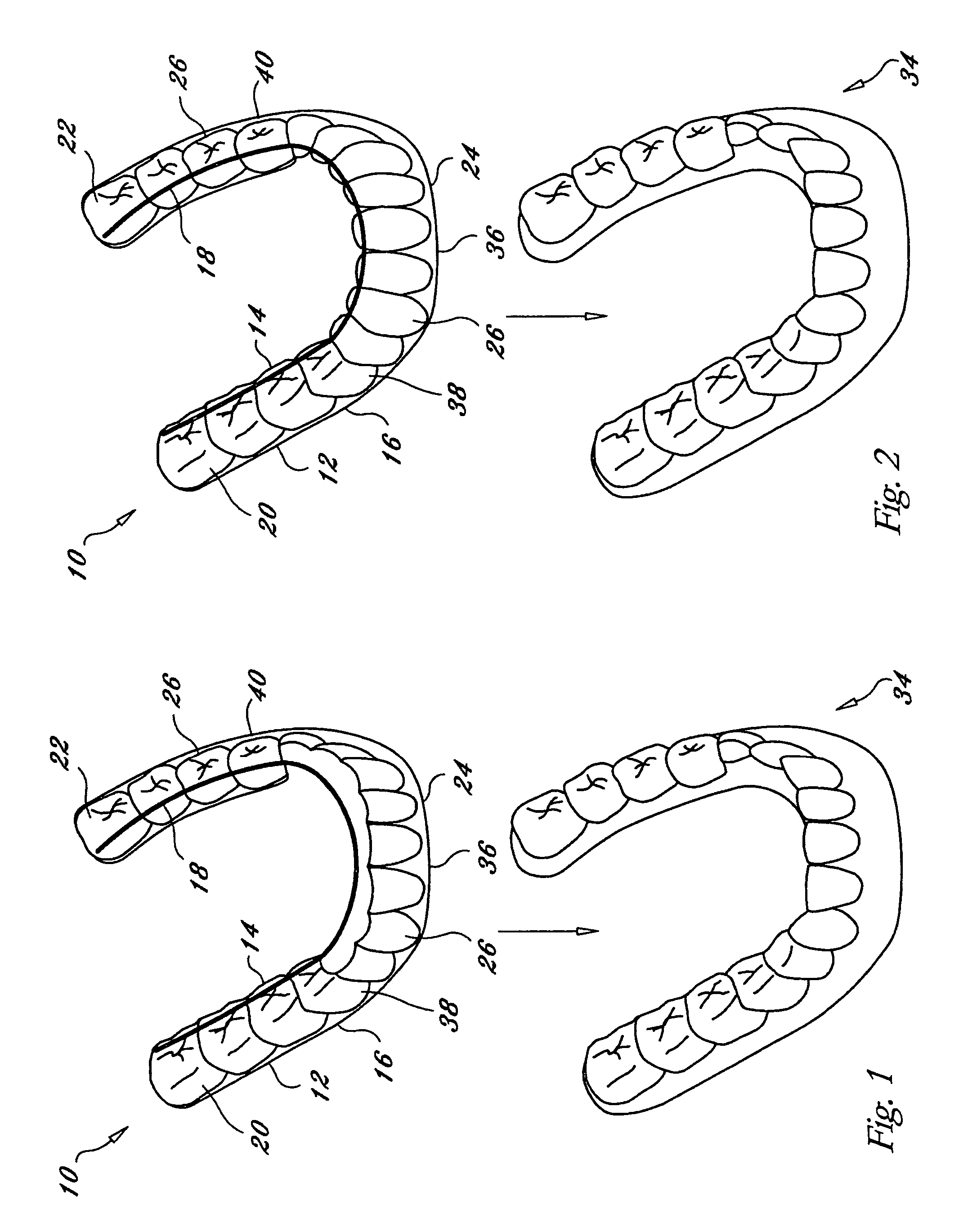

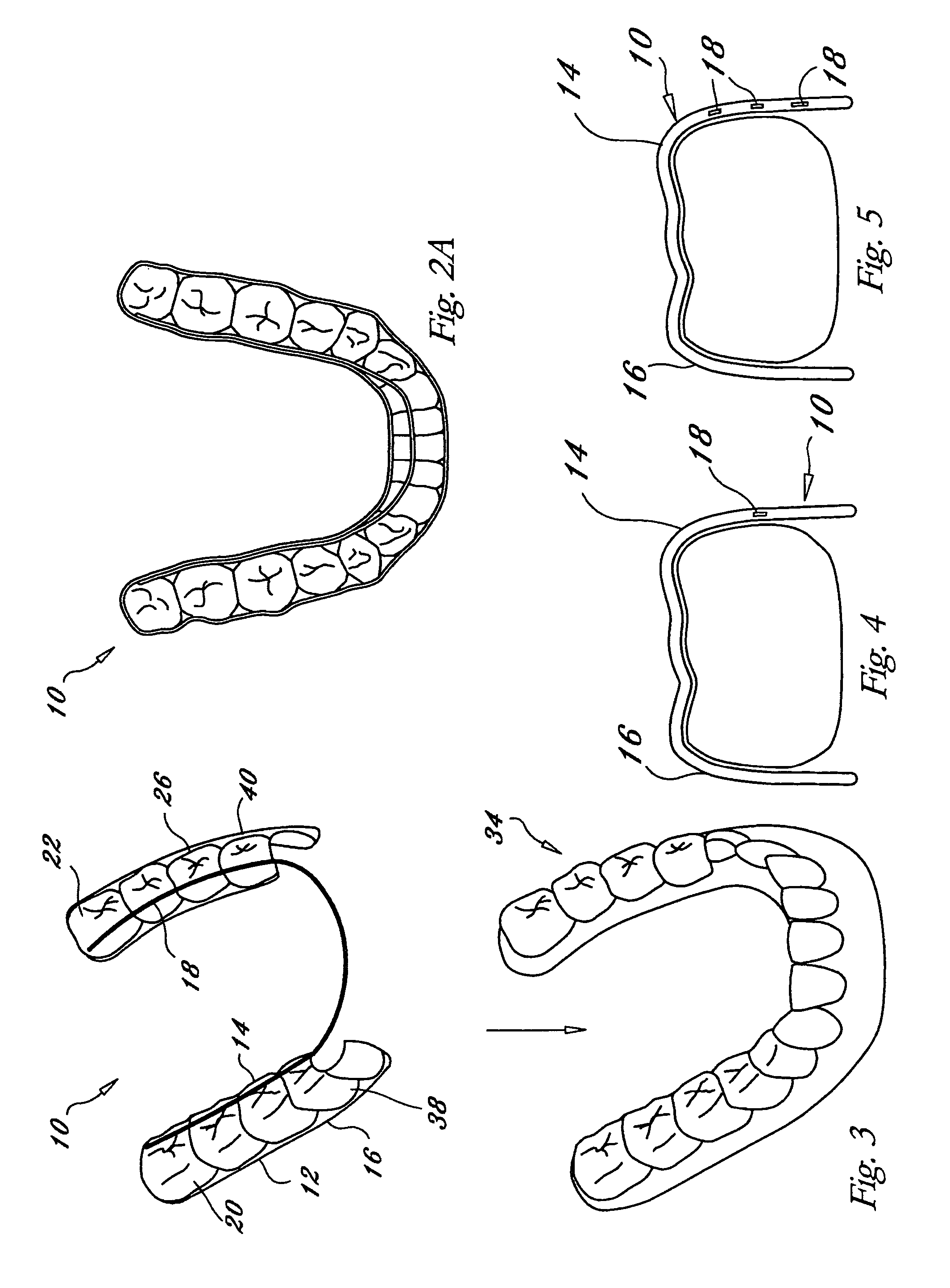

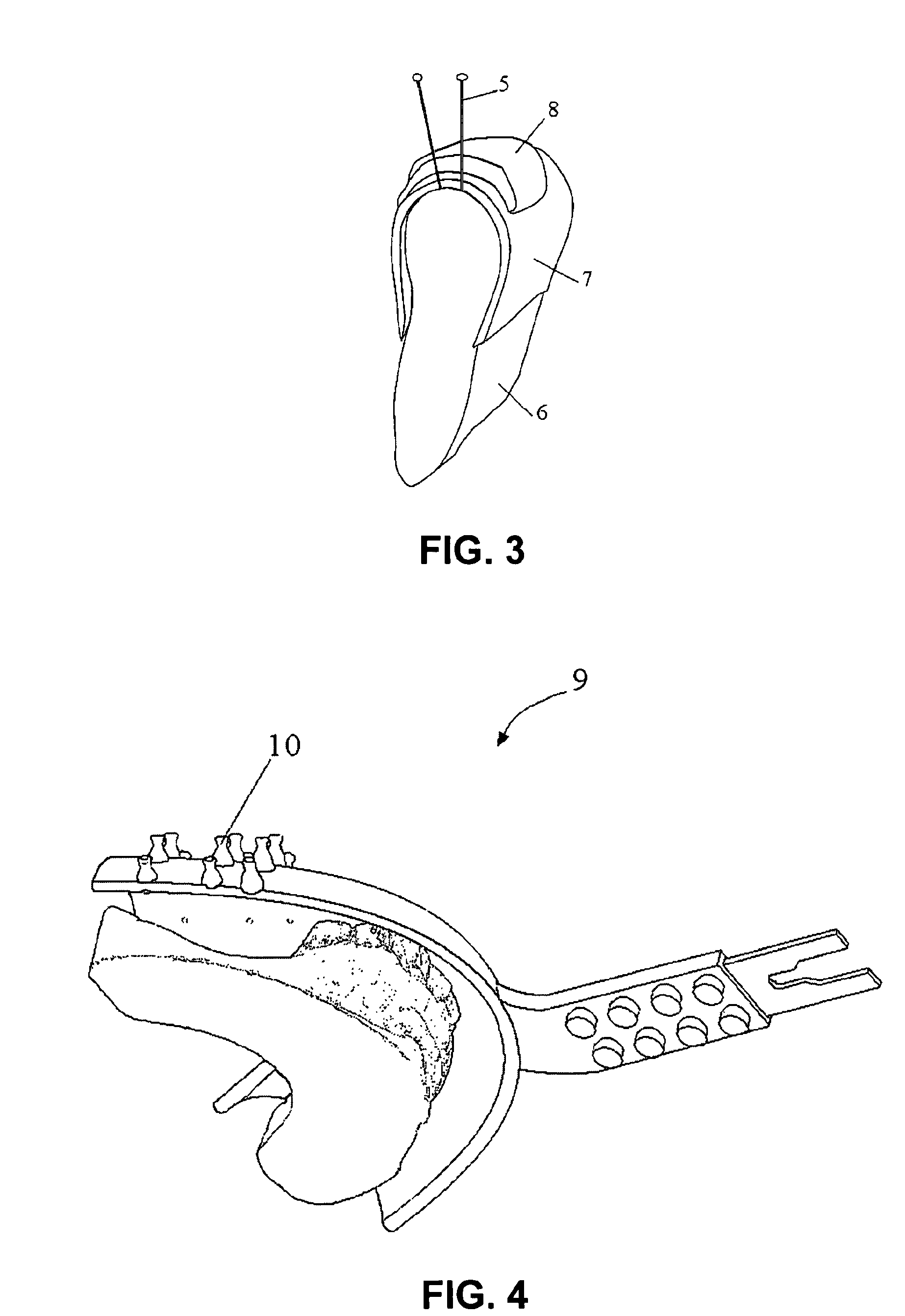

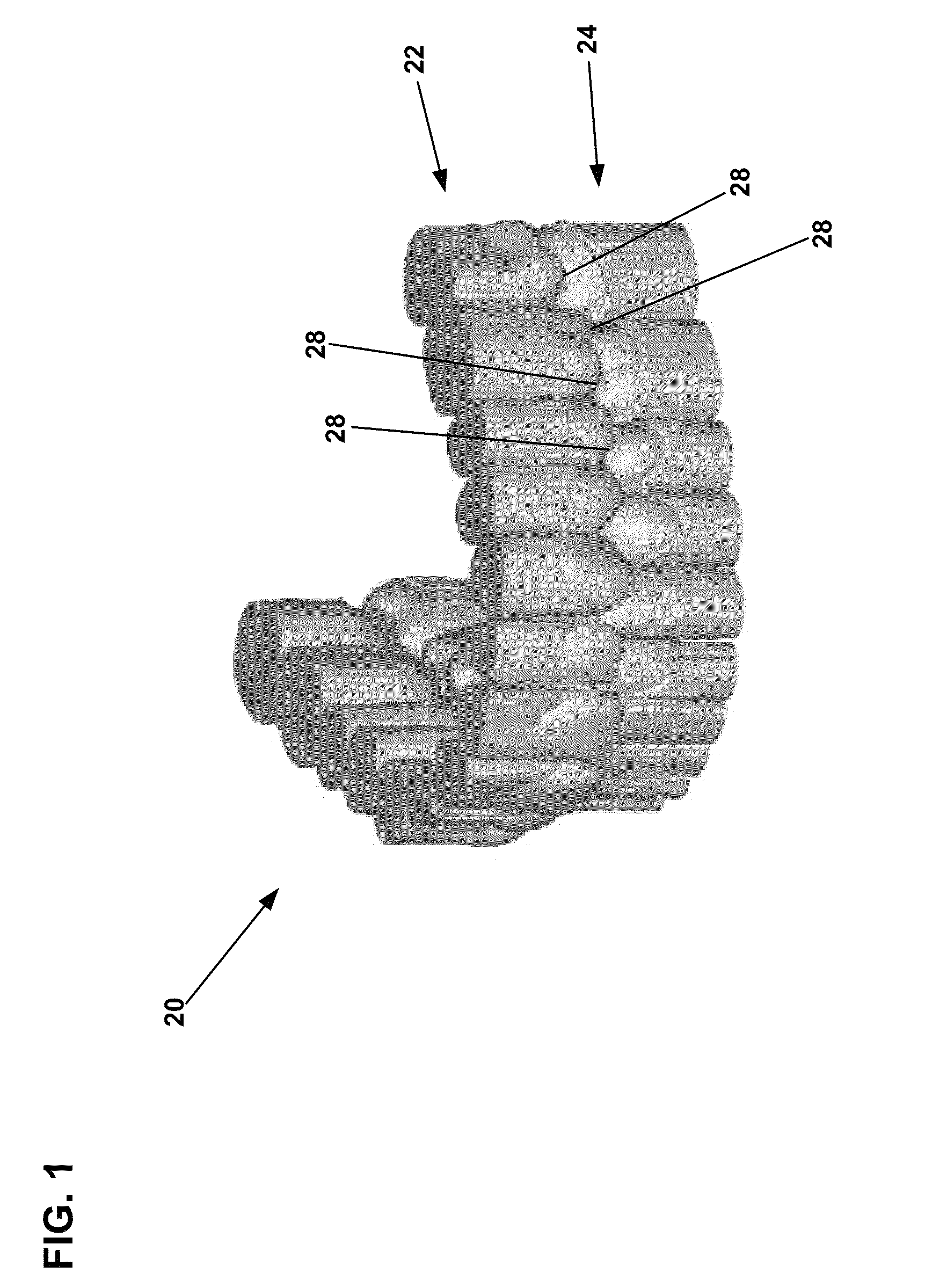

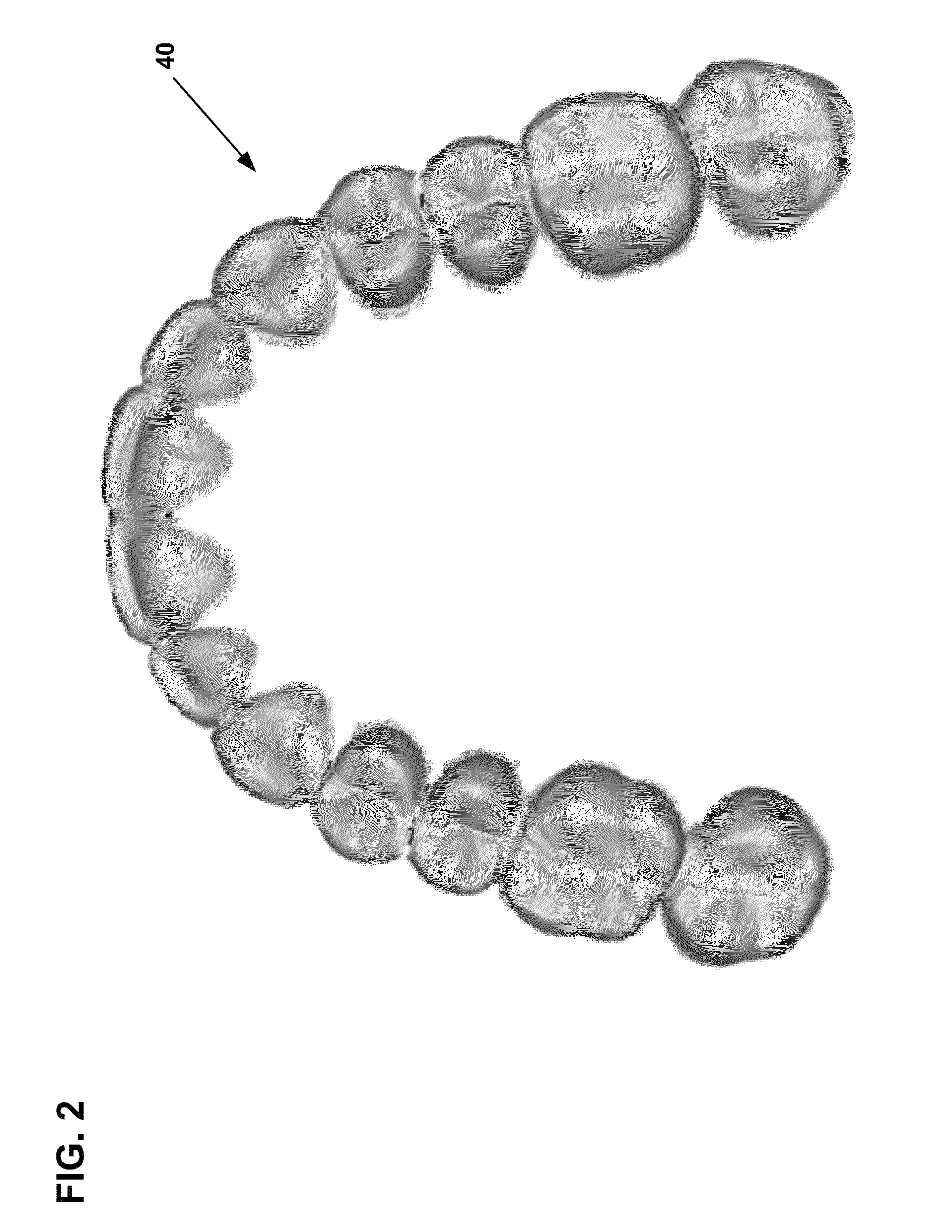

Orthodontic appliance with embedded wire for moving teeth and method

InactiveUS7416407B2Easy to manufactureMore forceful and less obtrusive movementOthrodonticsDental toolsPlastic forming machineWire rod

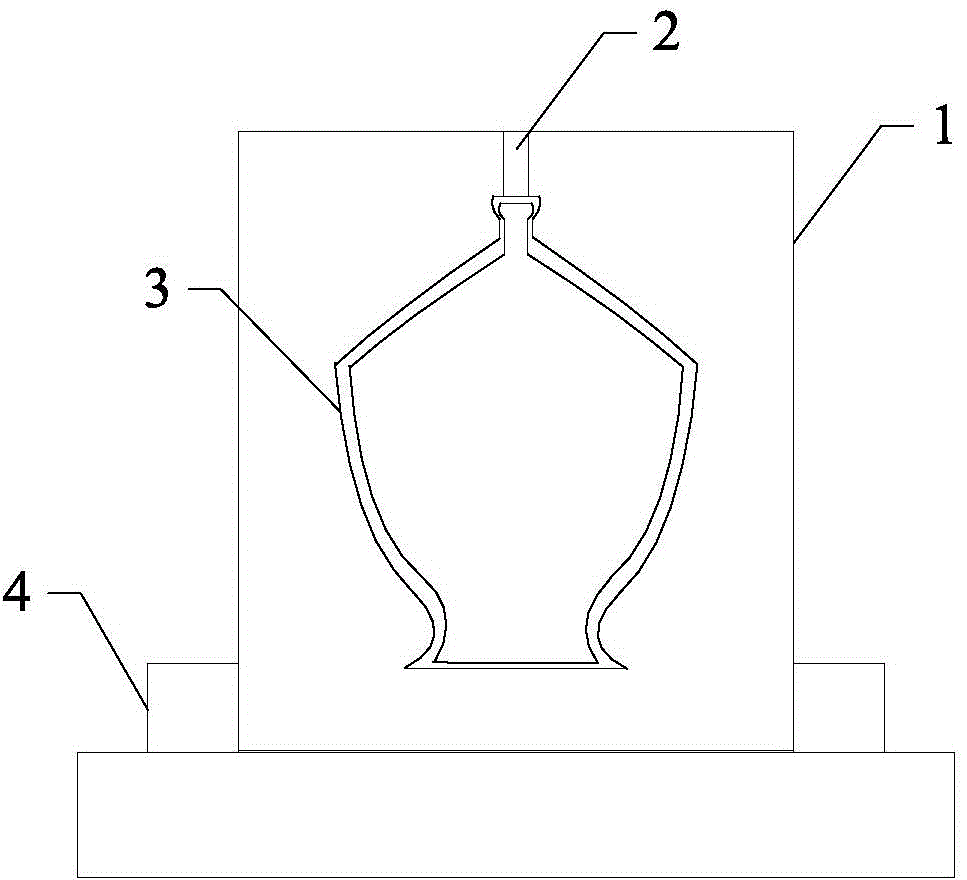

A generally horseshoe shaped clear flexible resilient plastic wire-imbedded orthodontic appliance is made with a plastic portion with contours on the lingual side and on the labial side, wherein the contours snugly cover the patient's teeth so that the appliance remains in place. One or more flexible wires are imbedded within the lingual side of the plastic portion from the left molar area to the right molar area of the plastic portion, whereby the wires apply force on the lingual side of the patient's bite. The appliance is formed by obtaining a plaster cast of the patient's teeth and gums, removing plaster teeth from the plaster cast of the gums, reattaching the plaster teeth to the plaster cast of the gums to form a cast of proper bite alignment, attaching one or more wires to the labial surface of the aligned plaster teeth so the wires become imbedded within thermosetting plastic placed over the cast, putting the cast in a thermosetting plastic molding machine, inserting thermosetting plastic in the machine, and heating the thermosetting plastic around the cast of the proper bite alignment, so the wires are imbedded within the formed appliance after the thermosetting plastic cools. A series of appliances may be used to shift a patient's bite to proper bite orientation.

Owner:CRONAUER EDWARD A

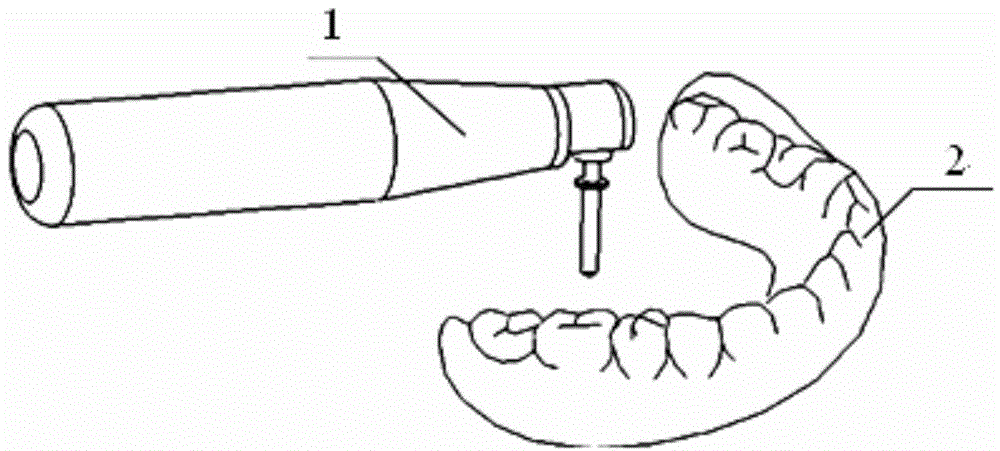

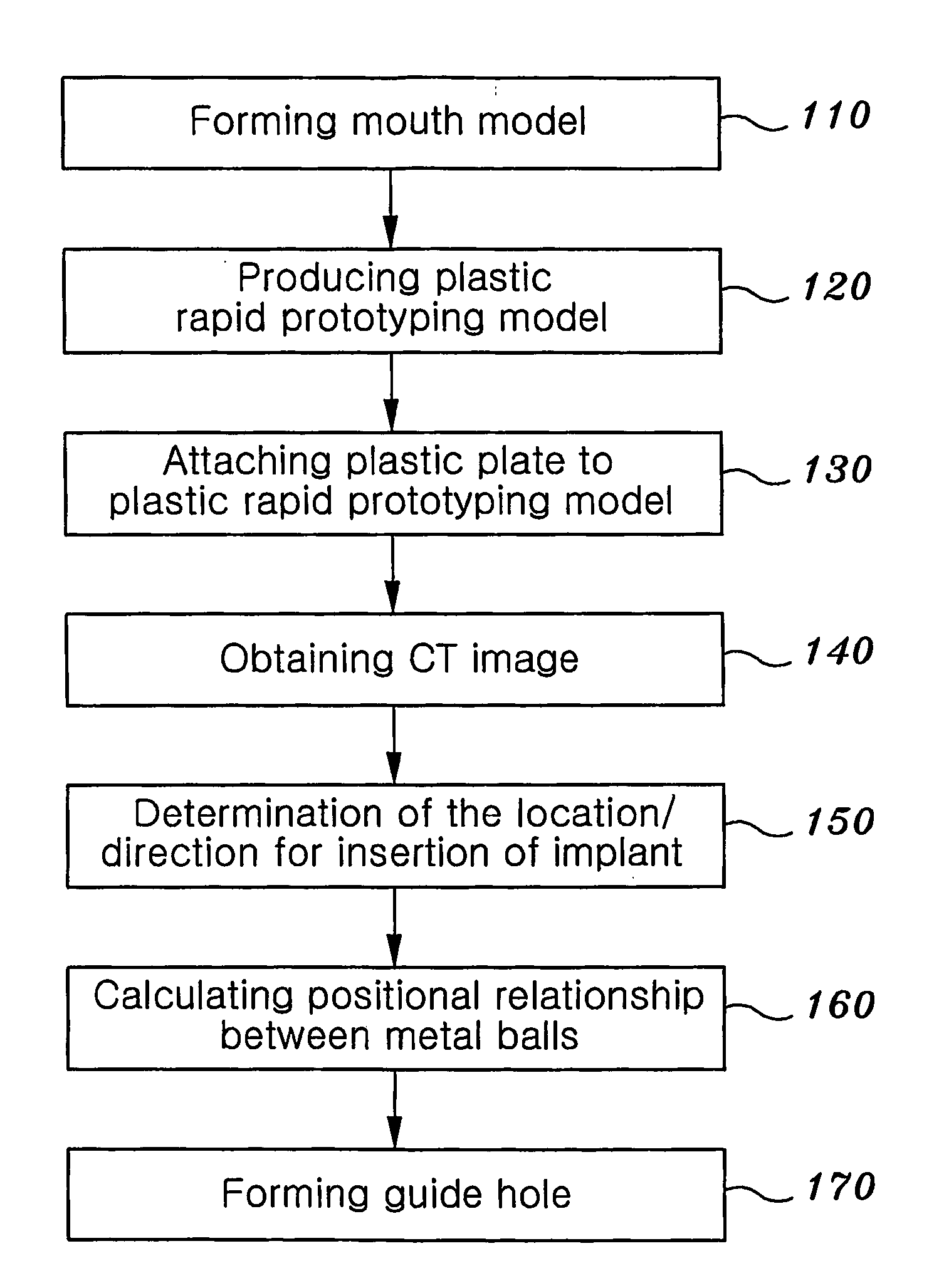

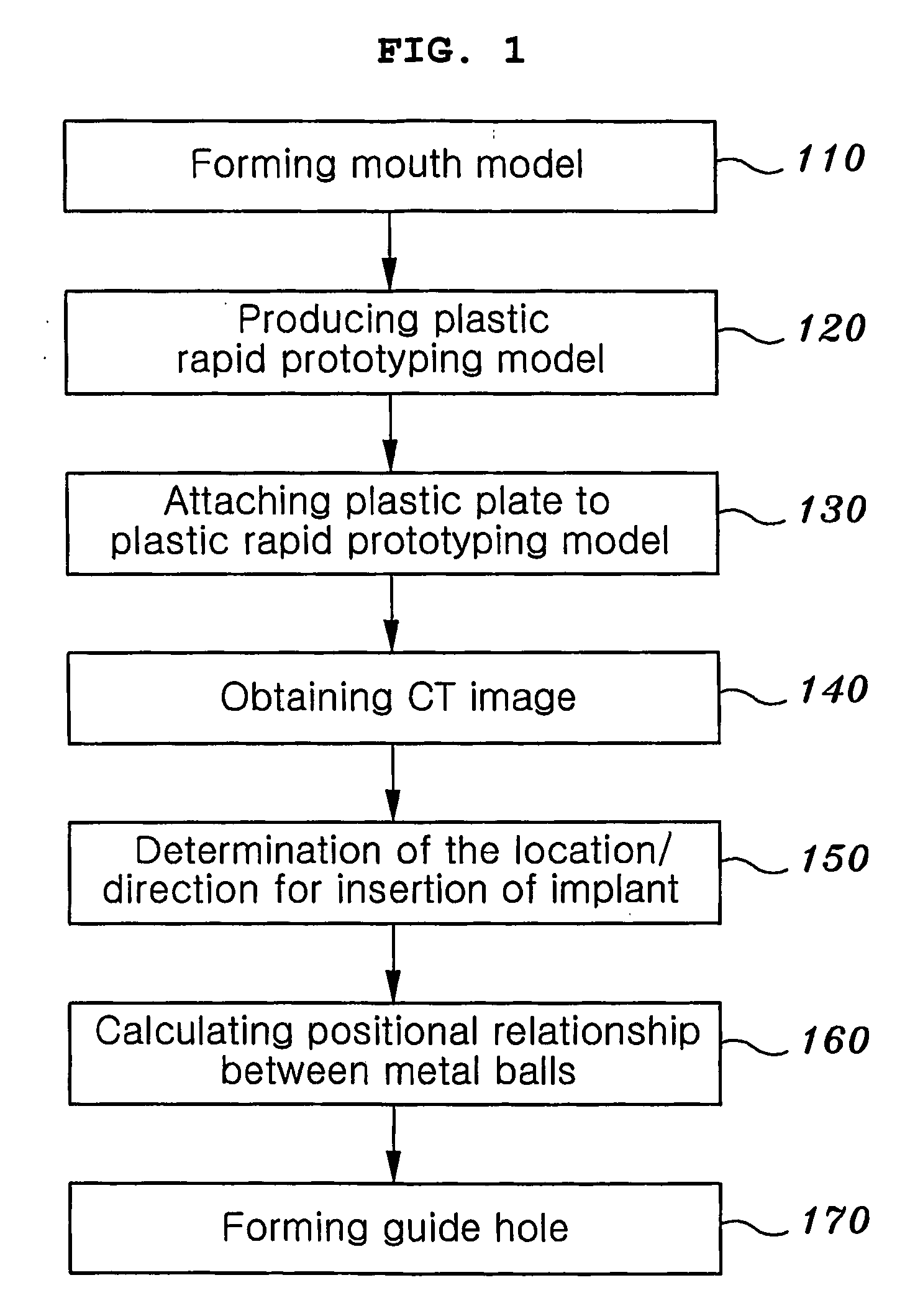

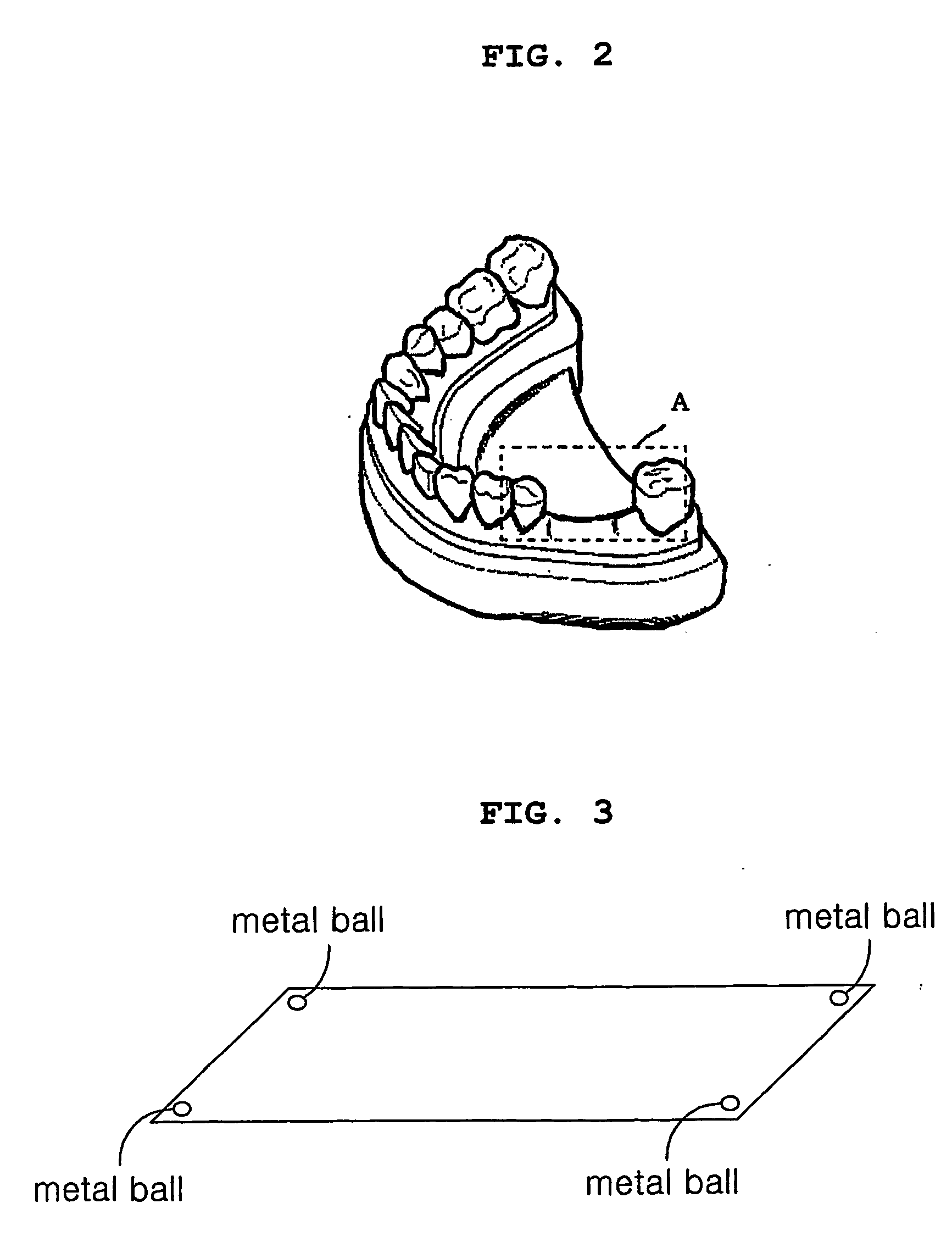

Stent for guiding the location/direction of implant, and production method thereof

The present invention is disclosed a stent for guiding the location / direction for the insertion of an implant a production method thereof. The method includes the steps of forming a plaster cast modeling of a mouth state using a plastic replica; and manufacturing a plastic cast model having an occlusal surface of the location for the insertion of the implant using the plaster cast; fastening a plastic plate having on corners thereof a plurality of metal balls to an upper end of the plastic cast model; and obtaining computed tomographic (CT) image of the mouth after placing the plastic cast model, on which the plastic plate is fastened, in the mouth, and forming a hole in a predetermined position in the stent to correspond to both a location and a direction of inserting the implant determined by a dentist based on the CT image.

Owner:MJRAD

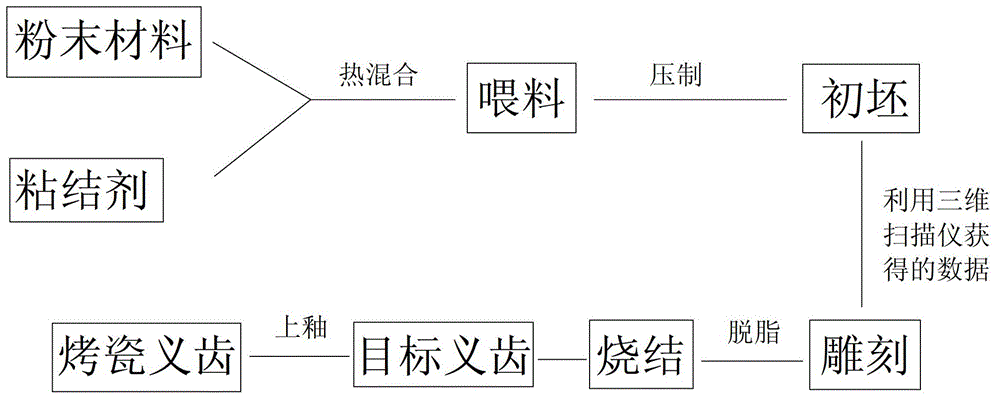

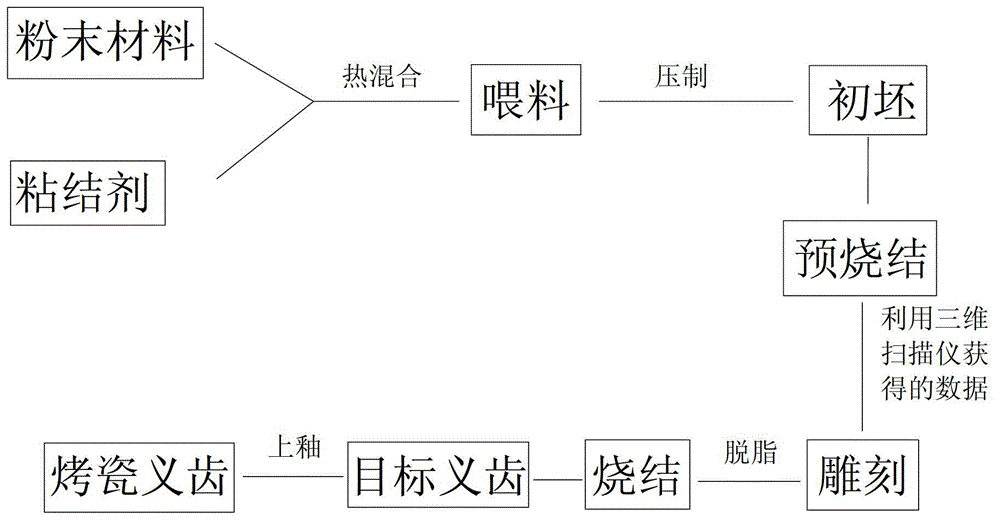

Artificial tooth and preparation method thereof

InactiveCN103143711AImprove edge fitImprove seatingArtificial teethNumerical controlCompression molding

The invention discloses an artificial tooth and a preparation method thereof, and belongs to the technical field of artificial tooth manufacturing. The preparation method comprises the following steps: (1) mixing metal powder with a binder to form homogeneous filling material, compression molding, and forming an initial blank; (2) obtaining data of the shape of a target artificial tooth through scanning a dental crown in an oral cavity or a plaster mold of a dental crown by adopting a three-dimensional scanner, and converting the data into a numerical control engraving file; (3) using a numerical control engraving machine to perform engraving to the initial blank; (4) sintering the engraved initial blank to obtain the target artificial tooth; and (5) carrying out porcelain sintering to the target artificial tooth. The technological processes of the method are automatically completed through the scanner, the engraving machine, a sintering furnace and other system machine and equipment, the sealing capability of the edge of the artificial tooth, the position, the thickness and the scientific consistency of the shape can be effectively improved, and the quality of the artificial tooth can be obviously improved; at the same time, due to the adoption of mechanical operation, the processing efficiency is obviously improved, the processing cost is reduced; and the method can be widely applied to the manufacturing of artificial tooth.

Owner:江西岳龙科技有限公司 +1

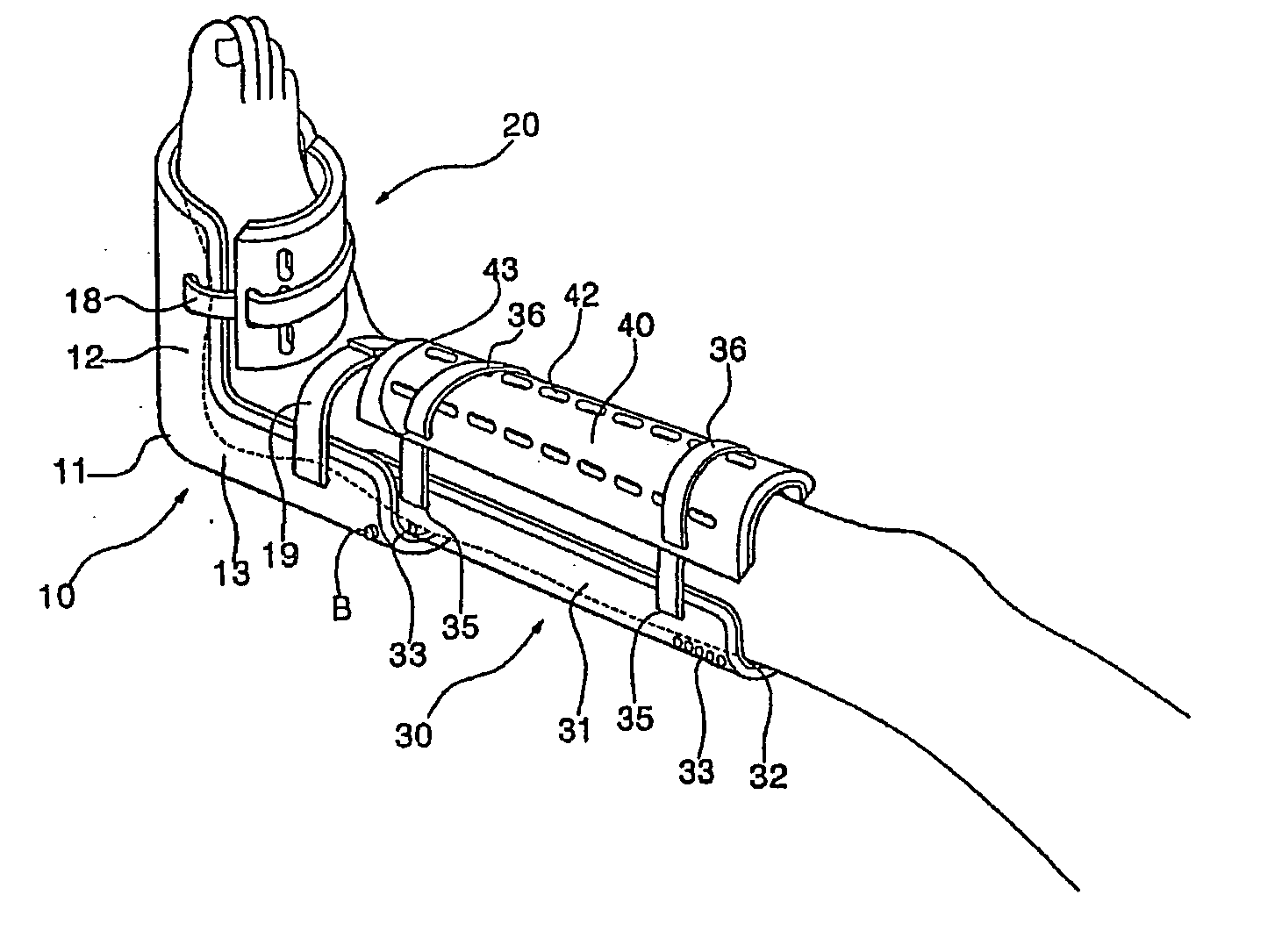

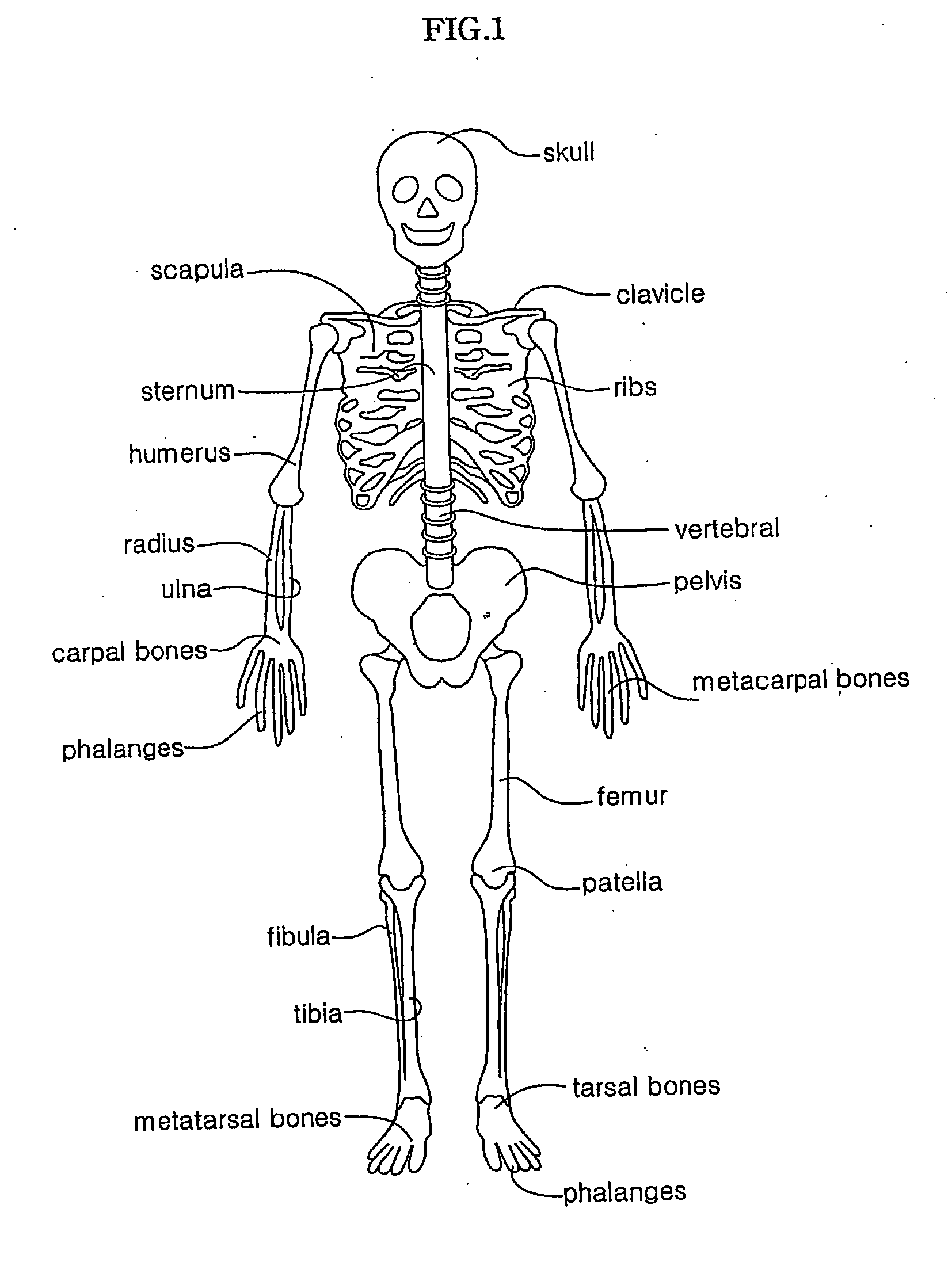

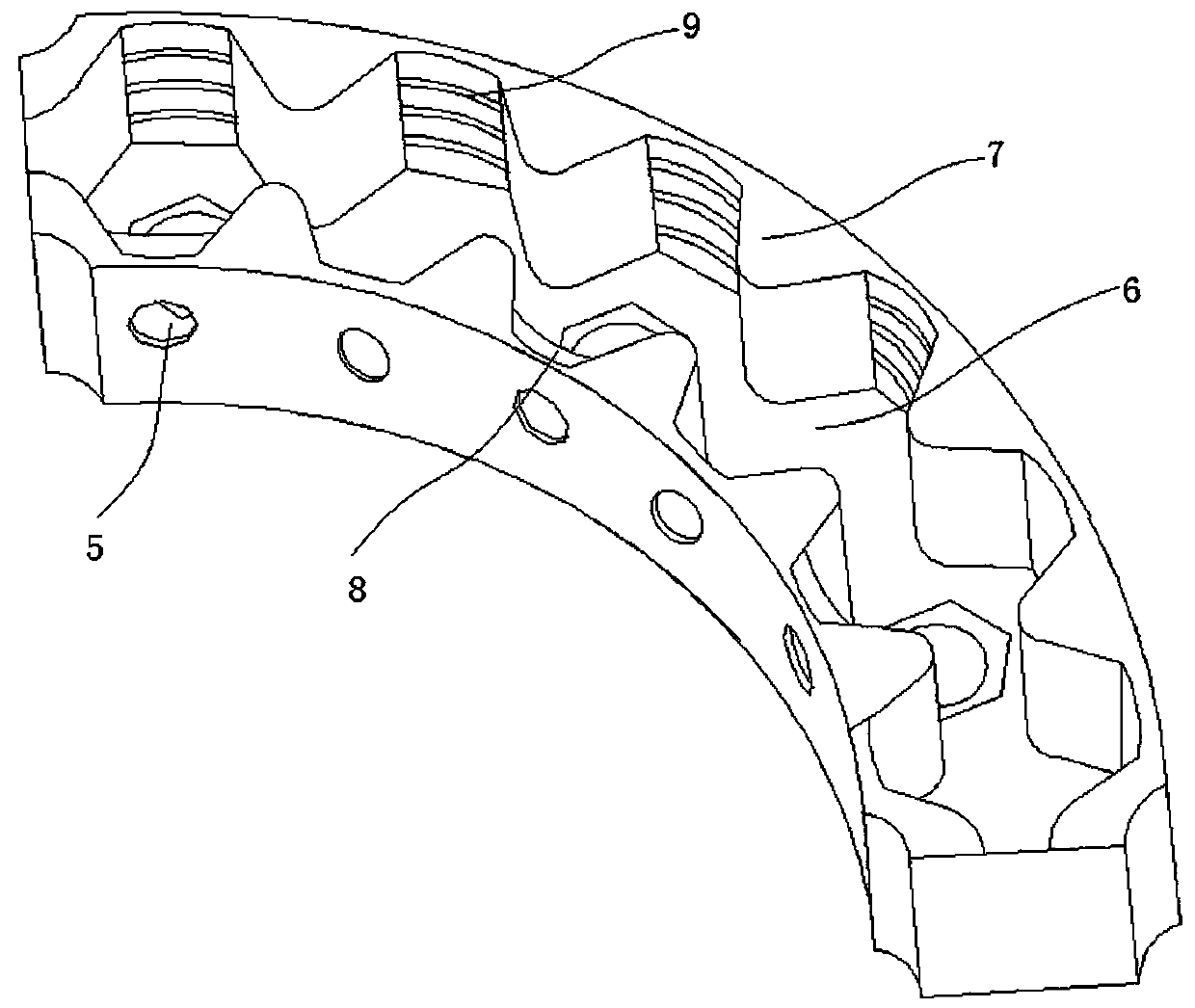

Splint combined use cast absence for bone fracture fixing

InactiveUS20050065458A1Easy to fixReduce time-consumed to apply castPlaster of paris bandagesFracturePlaster CastsDislocation

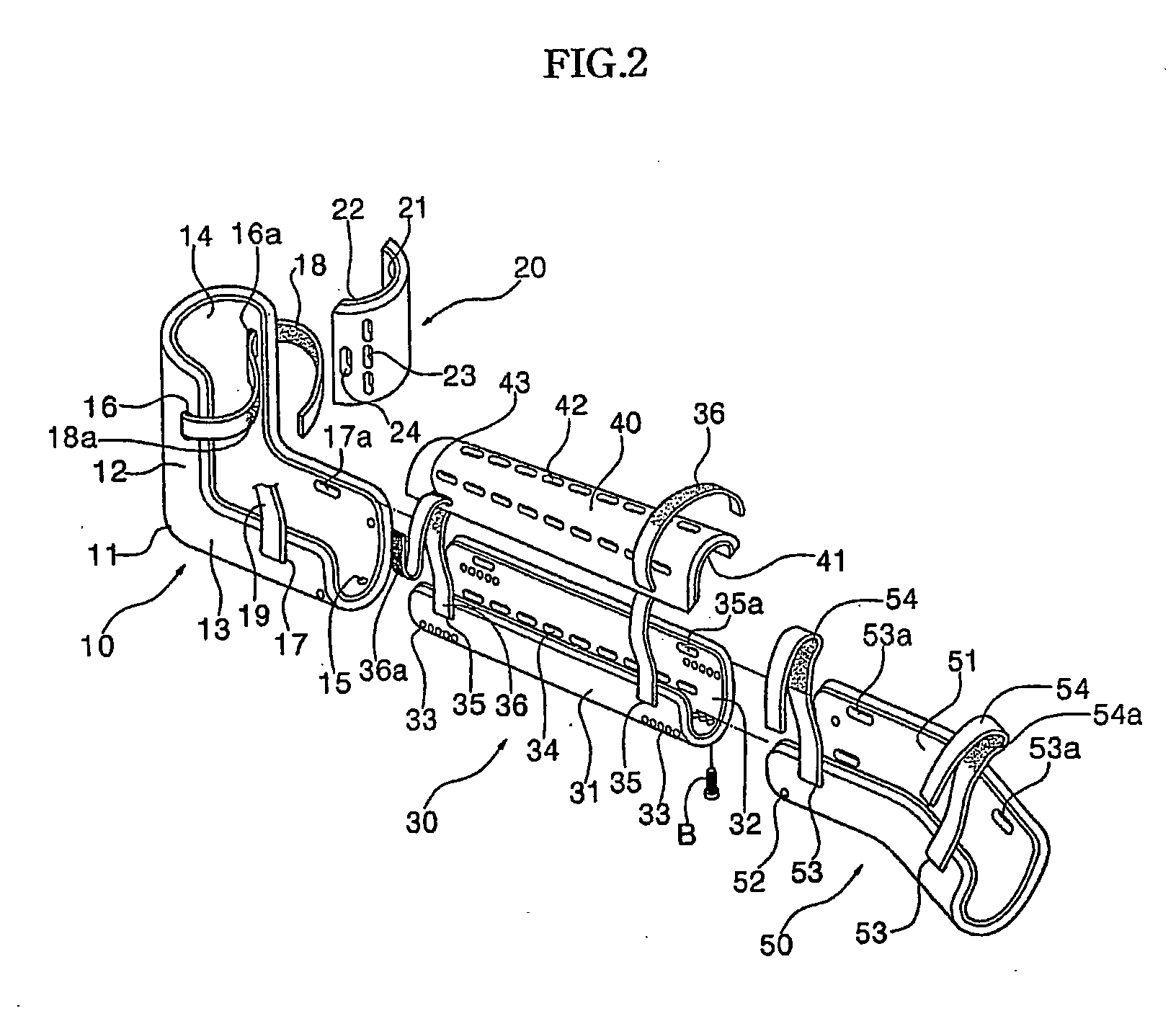

Disclosed is a combined splint and cast for immobilizing the injured body part due to fracture, ligament rupture, dislocation or the like. In particular, the present invention relates to a combined splint and cast for immobilizing fractured bones, in which a splint and a cast used for a predetermined period of time until a swelling in the injured body part subsides are injec-tion-molded to be combined into one. Therefore, the present invention can solve inconvenience of working with the conventional plaster cast member by using a foot fixing member, a connecting member and a knee fixing member of the combined splint and cast individually or cooperatively according to the use, for example, a short leg splint, a Patella Tendon Bearing (PTB) splint or a long leg splint, minimize the sequelae, such as joint contracture by making possible early joint movement, and correct an inaccurate reduction at its initial stage at any time and malunion by making intermediate inspections.

Owner:KIM KYUNG JIN

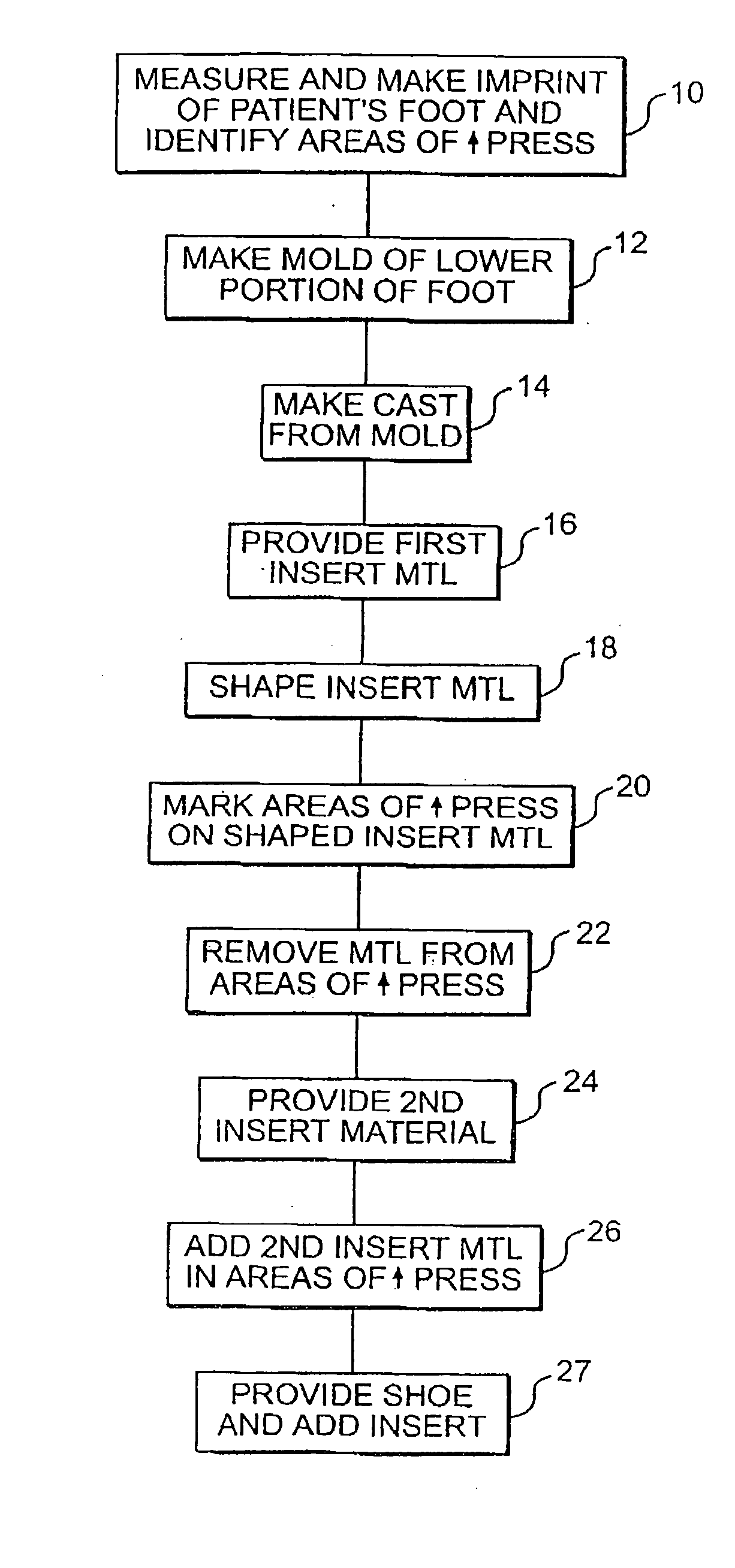

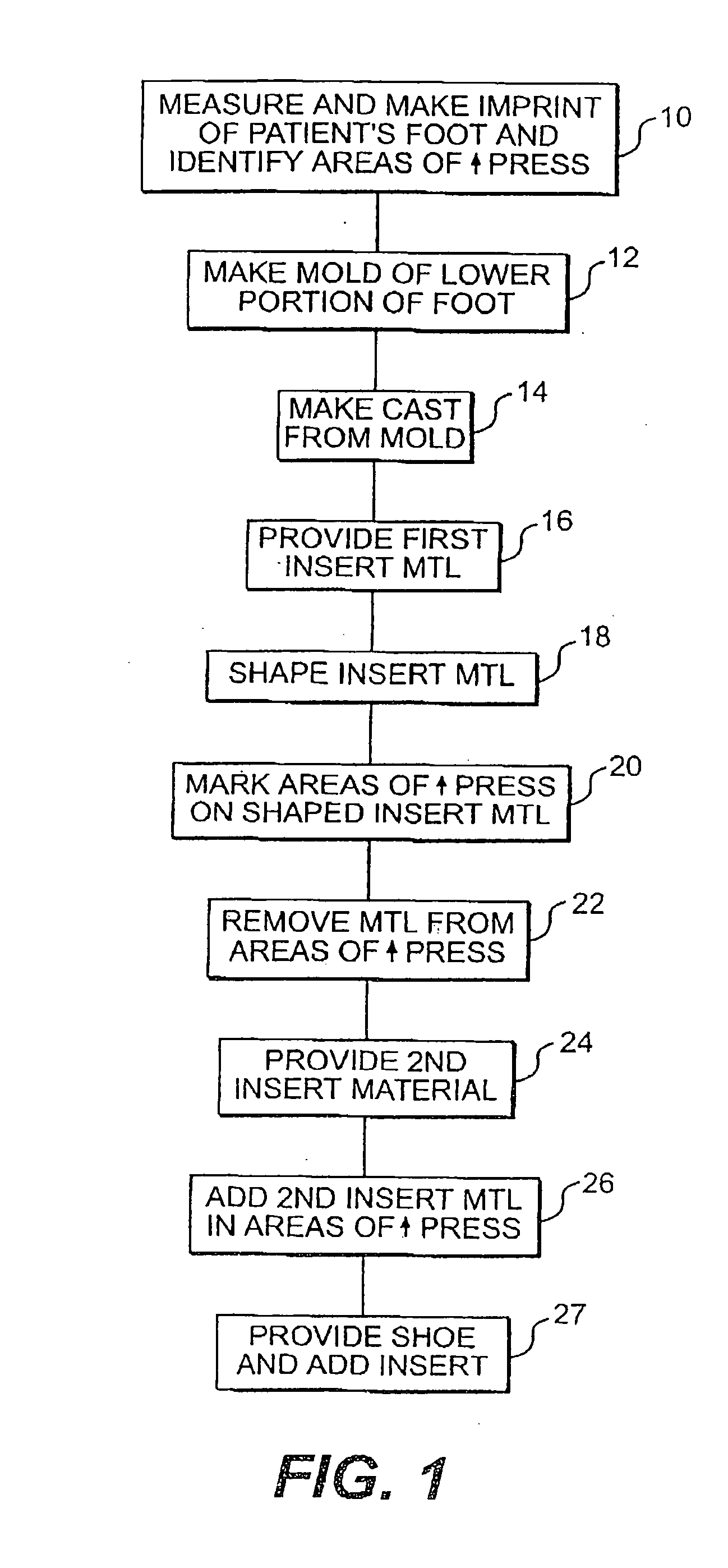

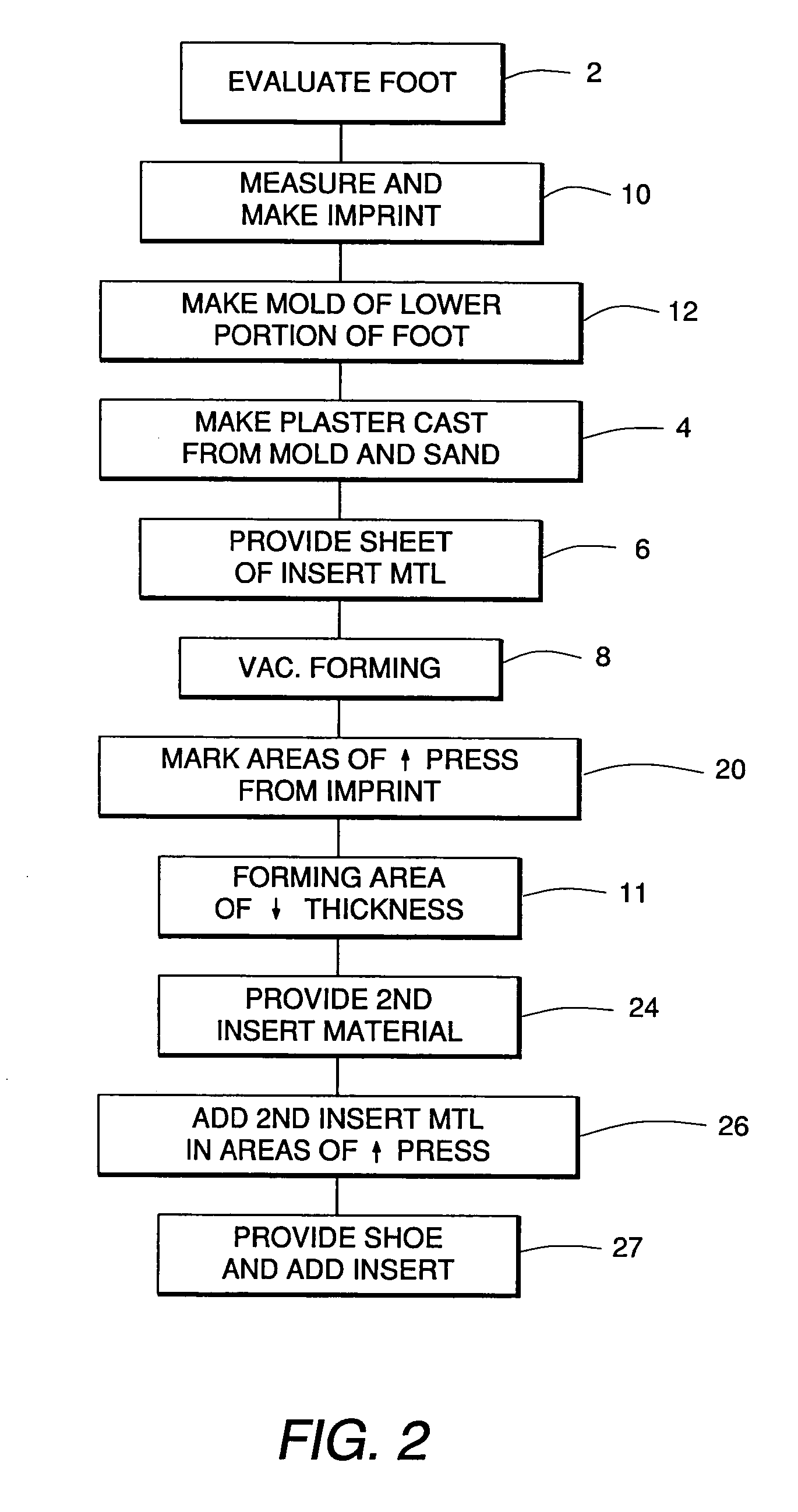

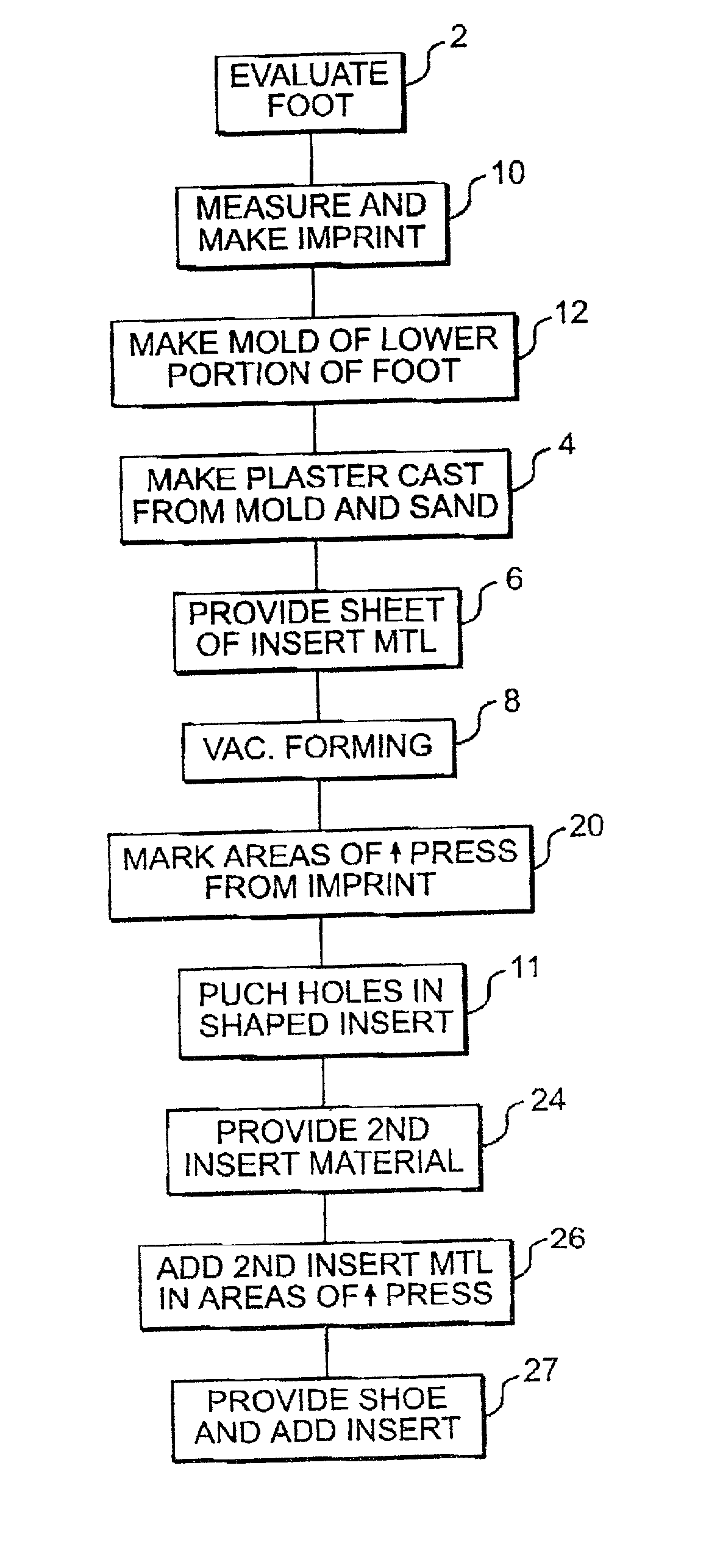

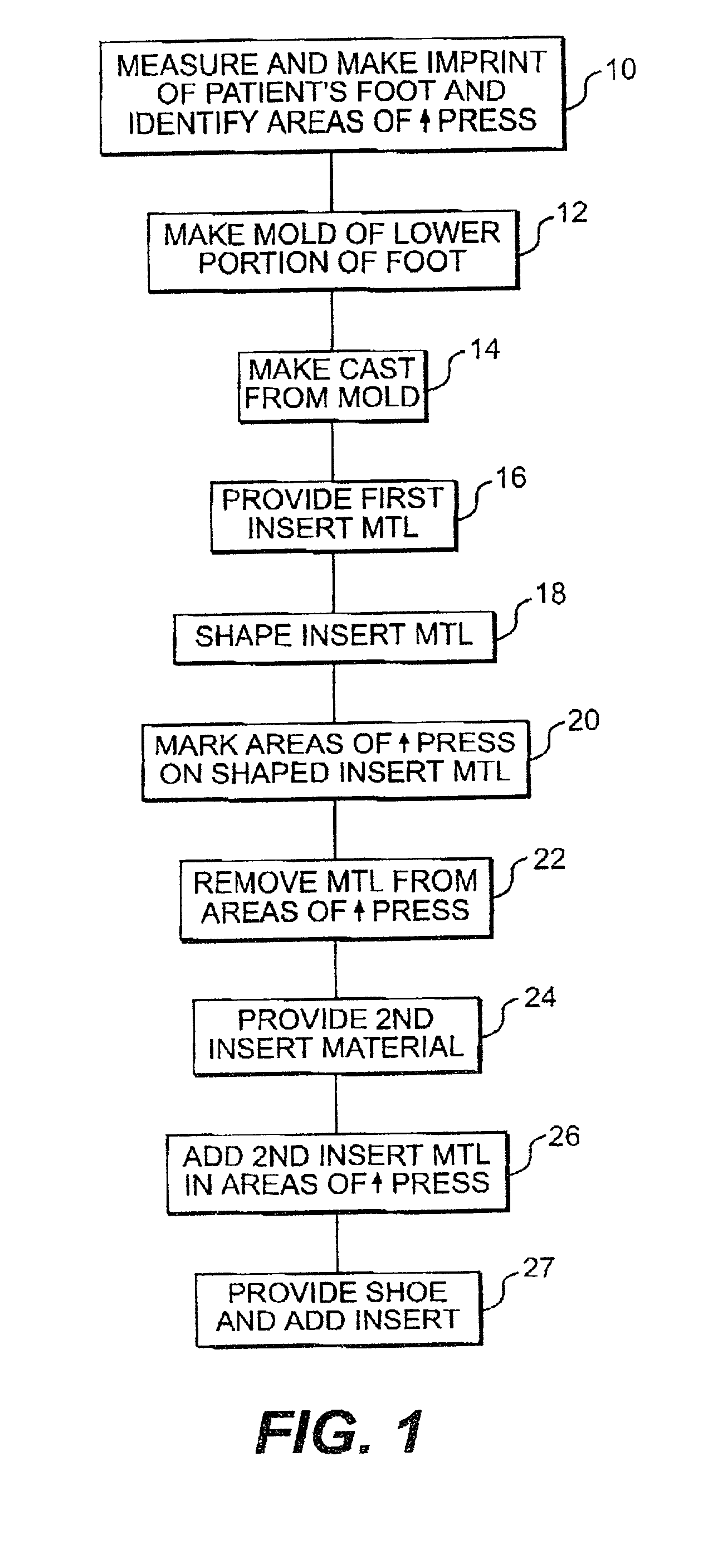

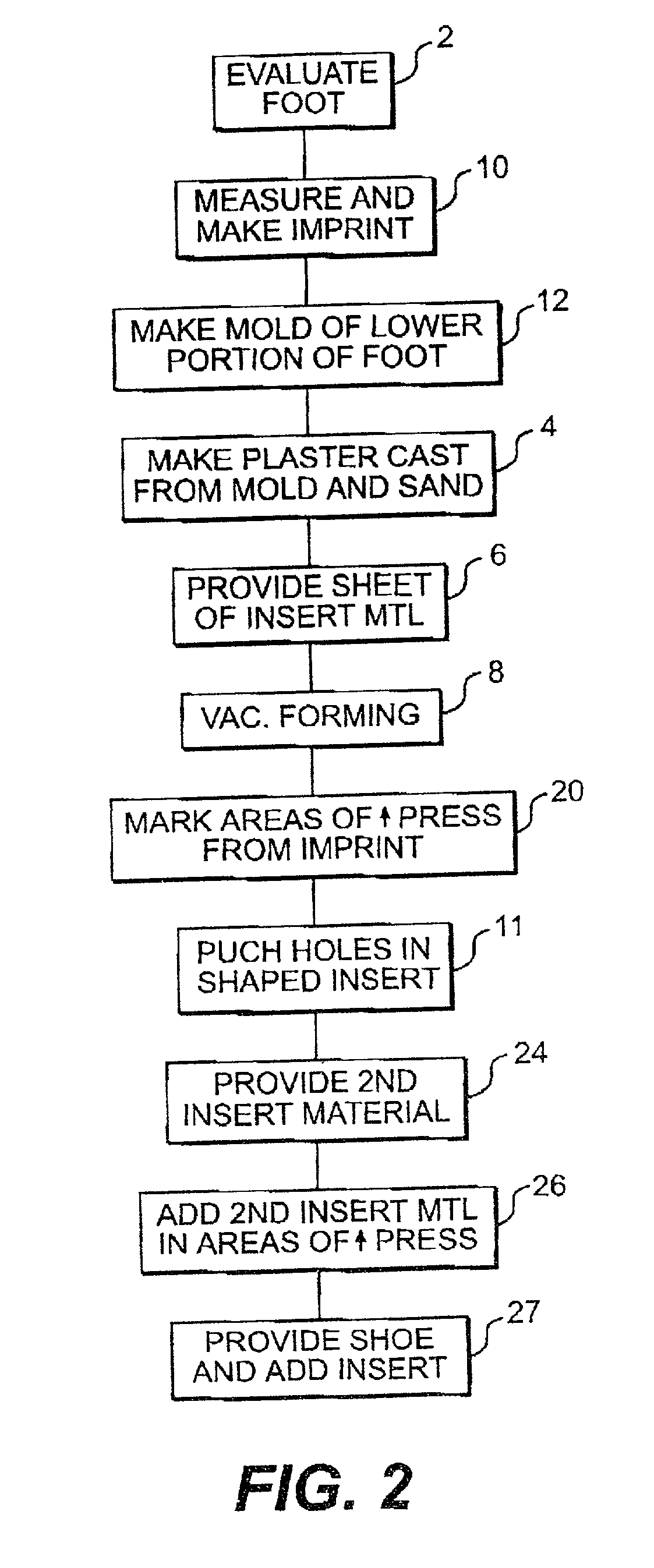

Method for providing custom fit therapeutic footwear

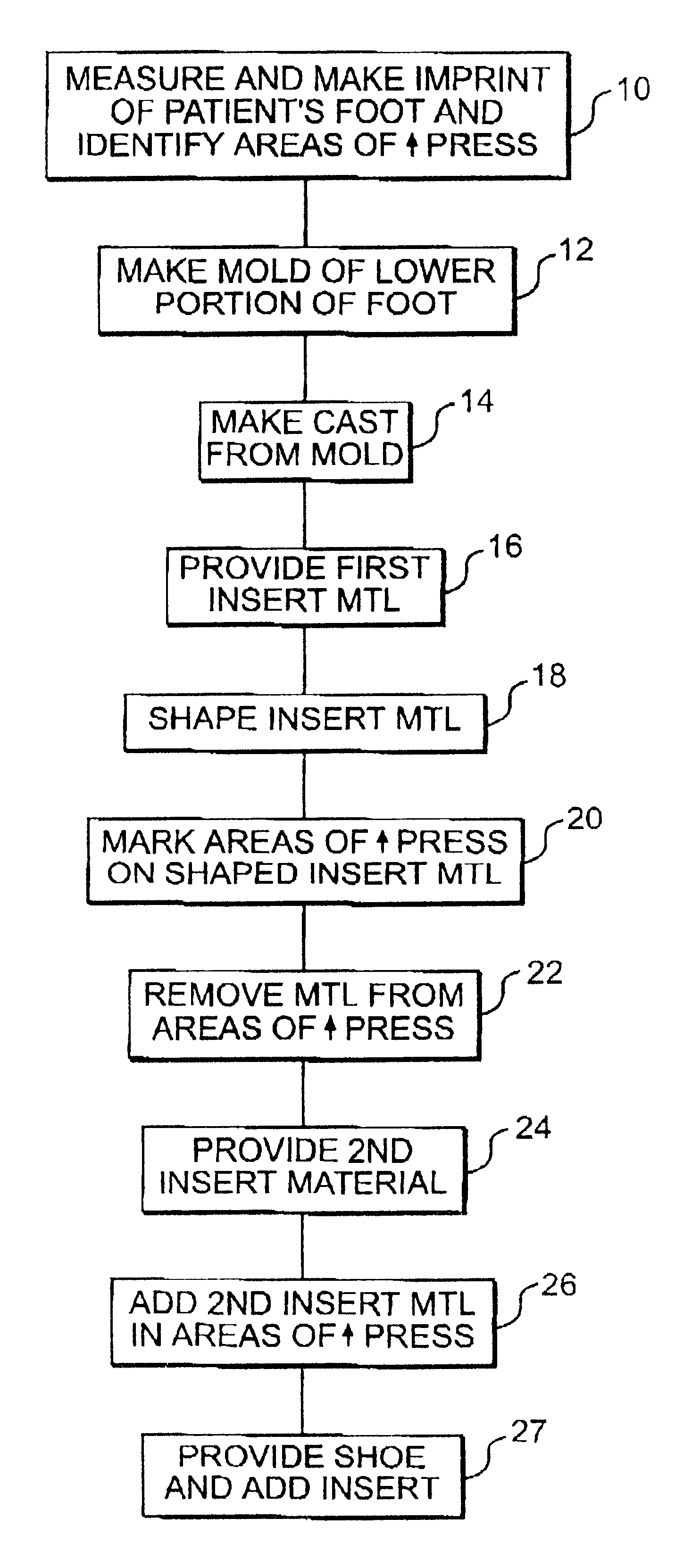

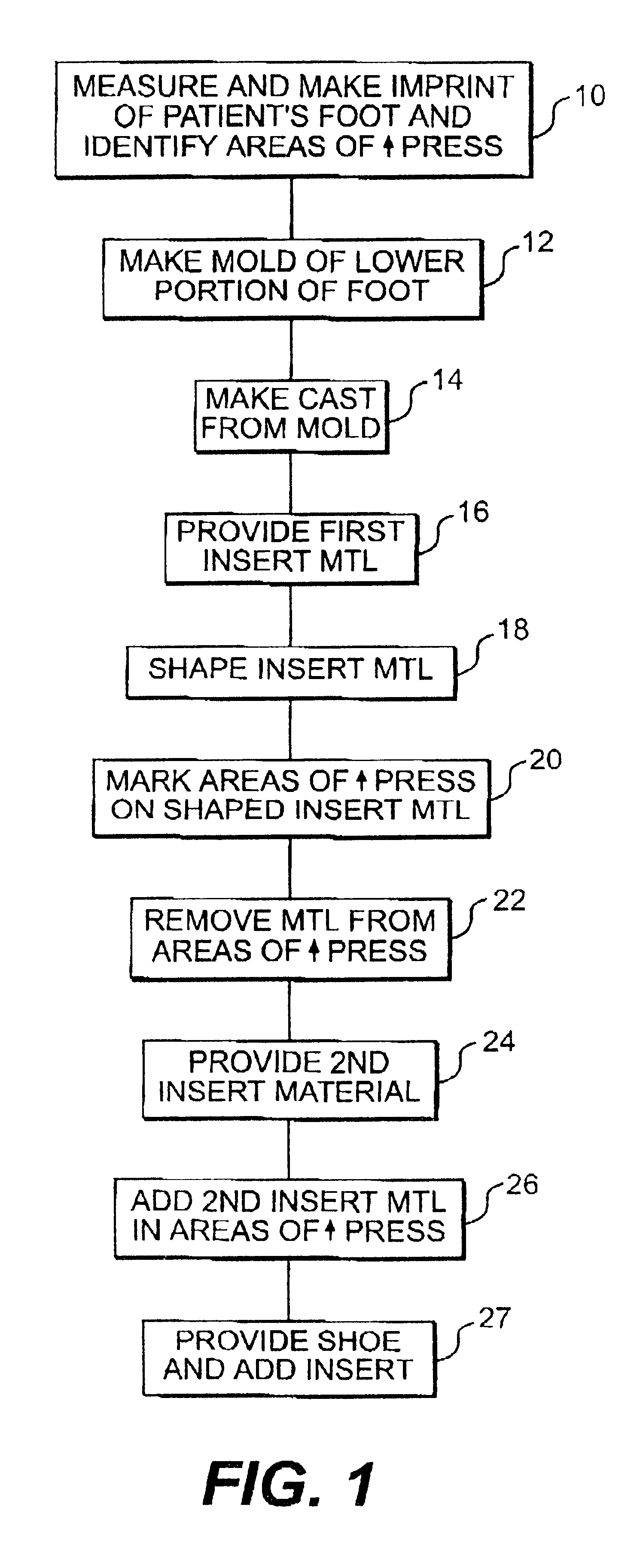

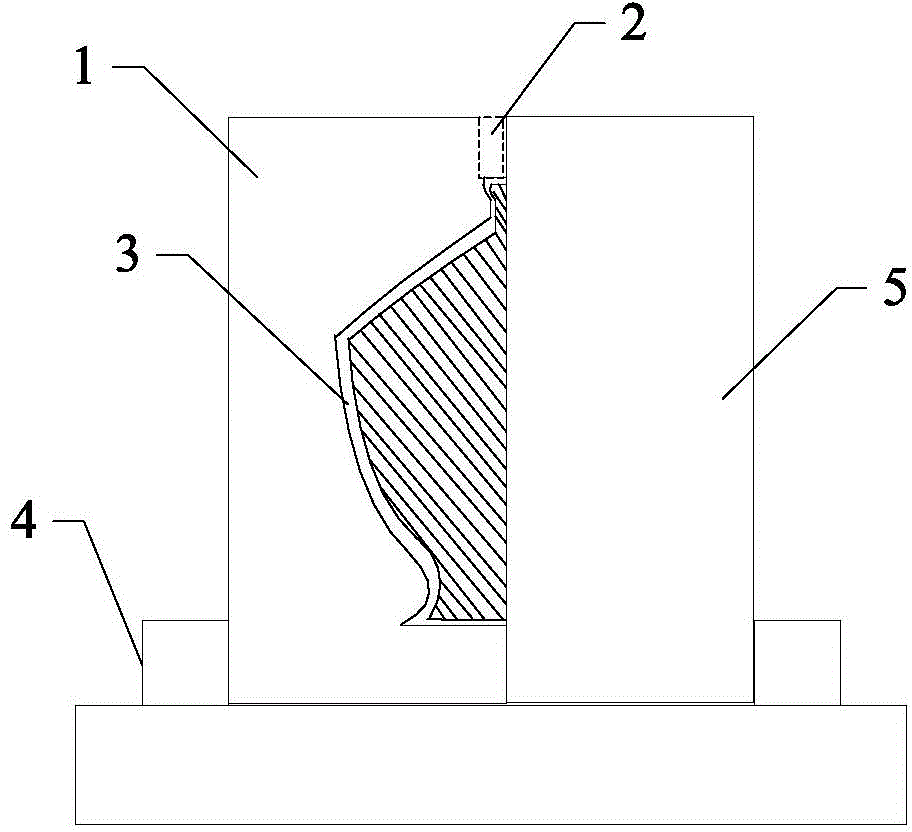

A method for manufacturing custom fit therapeutic footwear such as shoes and inserts includes the step of measuring a patient's foot and forming an imprint of a patient's foot to identify the patient's footprint and any high pressure areas on the bottom of the foot. The method also includes the step of making a mold of a lower portion of the patient's foot and subsequently making a plaster cast of the lower portion of the patient's foot. A multidensity sheet of insert material is provided and formed into a shape that corresponds to the lower portion of a patient's foot as for example by vacuum forming. The method also includes the step of providing a second insert material that is softer than the first insert material. The imprint of the patient's foot is then used to position any needed accommodations. The area to be accommodated is then punched out through the entire thickness of the insert and filled with a sheet of softer insert material. The final product may then be covered with a top coat or sheet of moldable polyethylene.

Owner:SOUTHERN PROSTHETIC SUPPLY

Oral beauty repair method used on 3D cast metal bottom crown

InactiveCN106420083ARapid productionInhibit sheddingArtificial teethDesign optimisation/simulation3d shapesDental cast

The invention relates to an oral beauty repair method used on a 3D cast metal bottom crown. The method includes the steps that S1, an impression silicone rubber material or gypsum model provided by a doctor is scanned, or the intra-oral portion of a patient is directly scanned to obtain scanning data; S2, the scanning data is received remotely by a computer and analyzed through dental CAD software, designing is conducted according to oral clinical actual conditions of the patient, and a virtual crown 3D shape is formed on the computer; S3, the formed virtual crown data is transmitted to a special dental metal laser fusing forming device and printed directly in a 3D mode, and a denture metal bottom crown green body is formed; S4, the top of the base bottom crown of a denture dental model is polished, so that the thickness of the occlusion portion is larger than that of a finger-shaped structure at the cut end in the middle of the crown top; S5, a protective coating is sintered on the portion, except the occlusion portion, of the bottom crown of the dental mode; S6, the sintered dental model is dyed and glazed. 3D printing is conducted on a denture crude body through the special dental metal laser fusing forming device, and the size and the shape of dentures can be adjusted at any time.

Owner:广州锦冠桥实业有限公司

Method for providing custom fit therapeutic footwear

A method for manufacturing custom fit therapeutic footwear such as shoes and inserts includes the step of measuring a patient's foot and forming an imprint of a patient's foot to identify the patient's footprint and any high pressure areas on the bottom of the foot. The method also includes the step of making a mold of a lower portion of the patient's foot and subsequently making a plaster cast of the lower portion of the patient's foot. A multidensity sheet of insert material is provided and formed into a shape that corresponds to the lower portion of a patient's foot as for example by vacuum forming. The method also includes the step of providing a second insert material that is softer than the first insert material. The imprint of the patient's foot is then used to position any needed accommodations. The area to be accommodated is then reduced in thickness and partially filled with a sheet of softer insert material. The area surrounding the area of reduced thickness may then be covered with a sheet of moldable polyethylene.

Owner:SOUTHERN PROSTHETIC SUPPLY

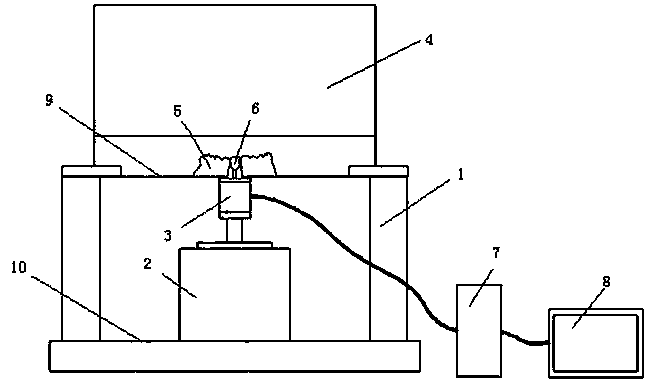

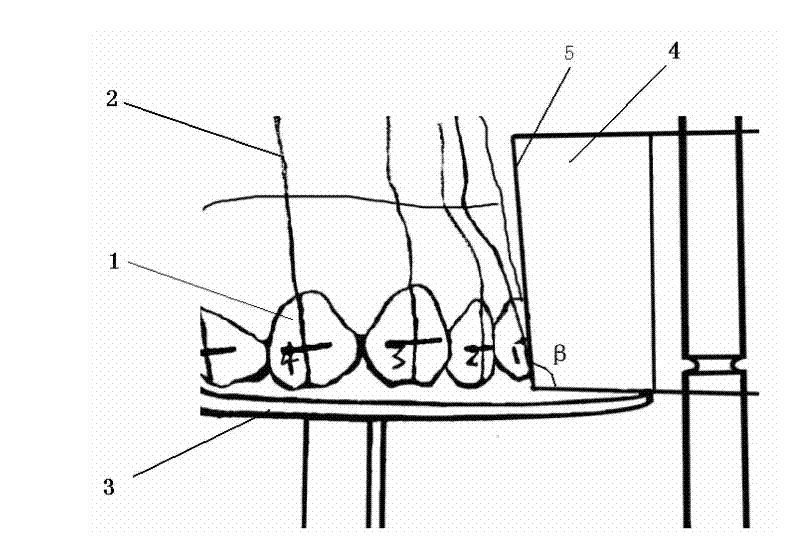

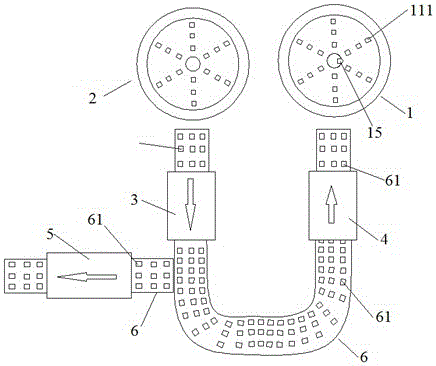

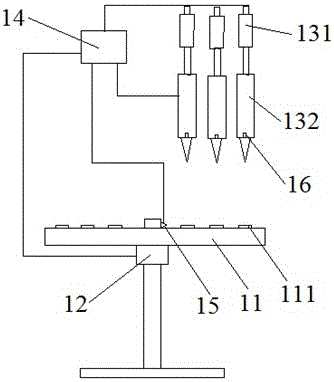

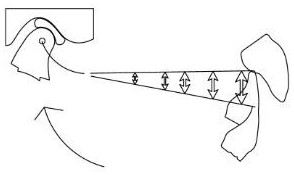

Three-dimensional force measure system of non-trace rectification device as well as measure method

The invention relates to a measure problem of dentistry no-orthodontic bracket no-trace rectification force in three dimensional coordinate, and provides a three-dimensional force measure system of non-trace rectification device as well as a measure method. The measure system and the measure method are characterized in that a single tooth to be straightened is separated from an integral jaw gypsum model, a six-dimensional force transducer is fixedly connected to the single tooth to be straightened, X, Y and R shafts displacement can be used for finely tuning a platform to simulate a straightening process, so that the position change of the single tooth to be straightened can be controlled, deformation of the non-trace rectification device is generated, deformation restoring force is generated, so that orthodontic force of non-trace rectification on the three dimensional coordinate can be determined. By researching the active force system and effect of the non-trace rectification device on the three dimensional coordinate, the orthodontic doctors can make a more reasonable and effective treatment scheme, and design staff can design a better customized non-trace rectification device. The method has the advantages of high measure precision, good real-time capability, simple and easy measure process.

Owner:FUZHOU UNIV

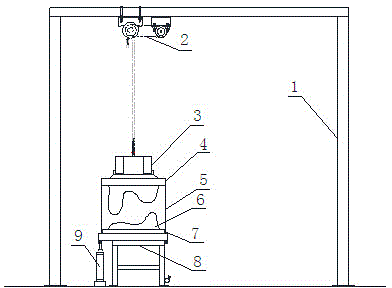

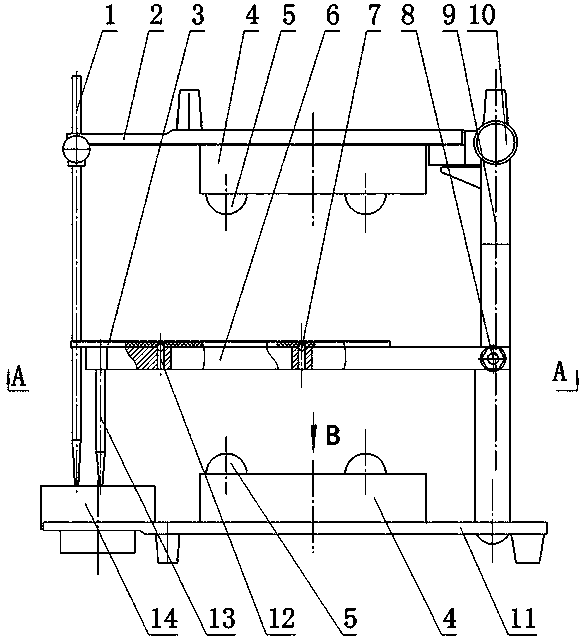

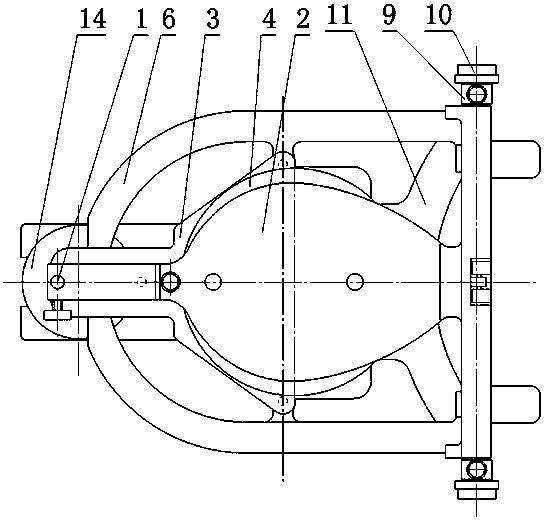

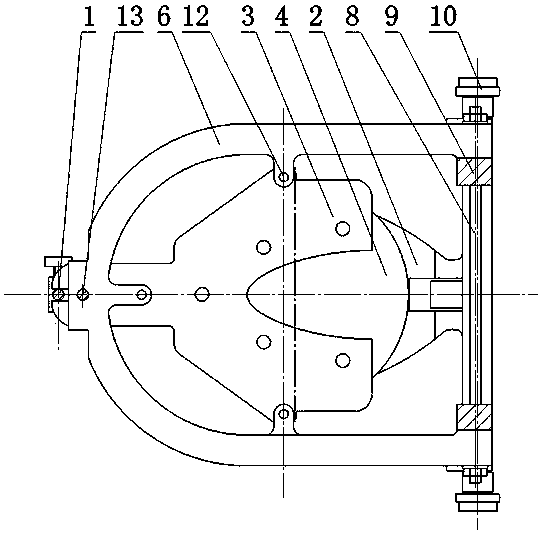

Automatic grouting machine of pedestal pan

ActiveCN104385438AReduce labor intensityPrevent leakageDischarging arrangementPlaster CastsClassical mechanics

The invention relates to a grouting machine, in particular to an automatic grouting machine of a pedestal pan. The automatic grouting machine is provided with an upper mold lifting mechanism, side mold pressing devices and a main line slanting device. An upper mold can ascend and descend vertically under control of the upper mold lifting mechanism, and achieves mold assembly of a bottom mold and side molds. The side molds move horizontally under driving of a motor, accordingly mold opening and closing of the side molds are achieved and wet blanks in plaster molds can be taken out conveniently. The side mold pressing devices are arranged on two sides of the side molds and abut tight the side molds to prevent slurry leakage during grouting. The main line slanting device ensures that plaster mold grouting and spoil disposal form a certain slanting angle, and accordingly grouting and spoil disposal are facilitated. The automatic grouting machine solves the problems of large labor intensity, poor safety, long operation time and too much chores for treating the wet blank as the mold opening and closing operation for the plaster molds needs to be completed manually in the existing production. The automatic grouting machine is advanced in technology, reasonable in structure, convenient to install and debug and low in worker labor intensity, and can be operated by only one person. In addition, the inclination angle of the main line is flexible and adjustable.

Owner:唐山森兰瓷科技有限公司

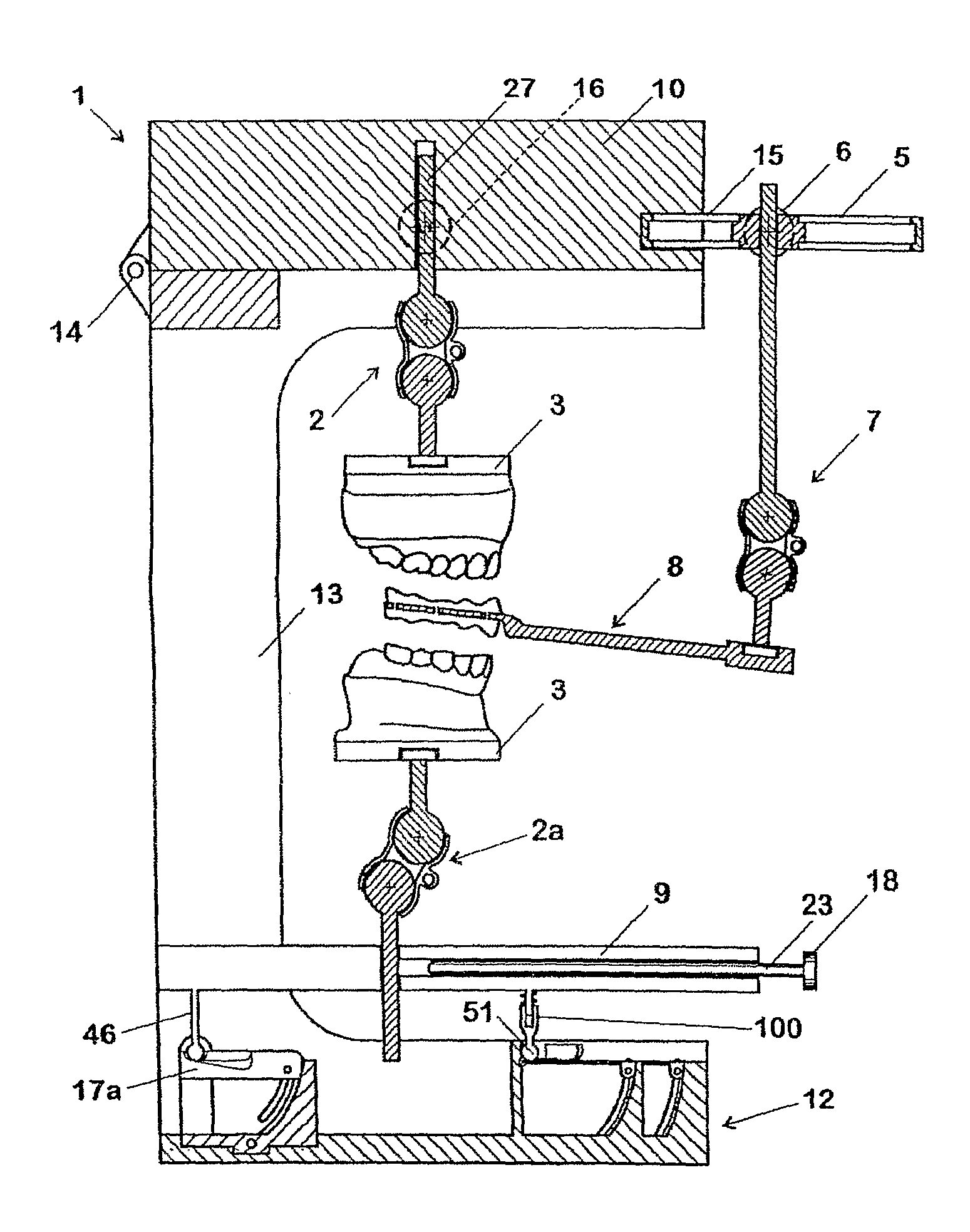

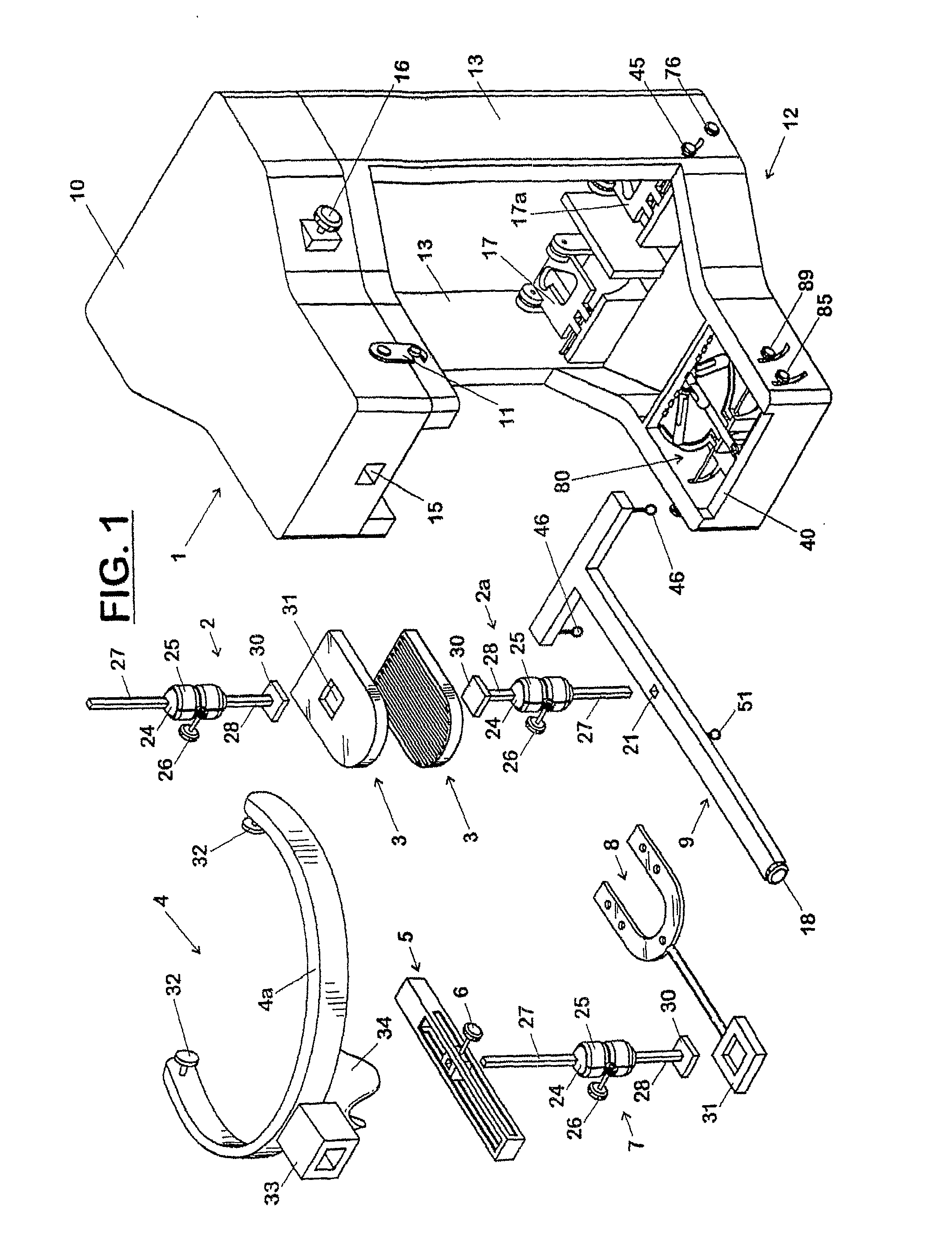

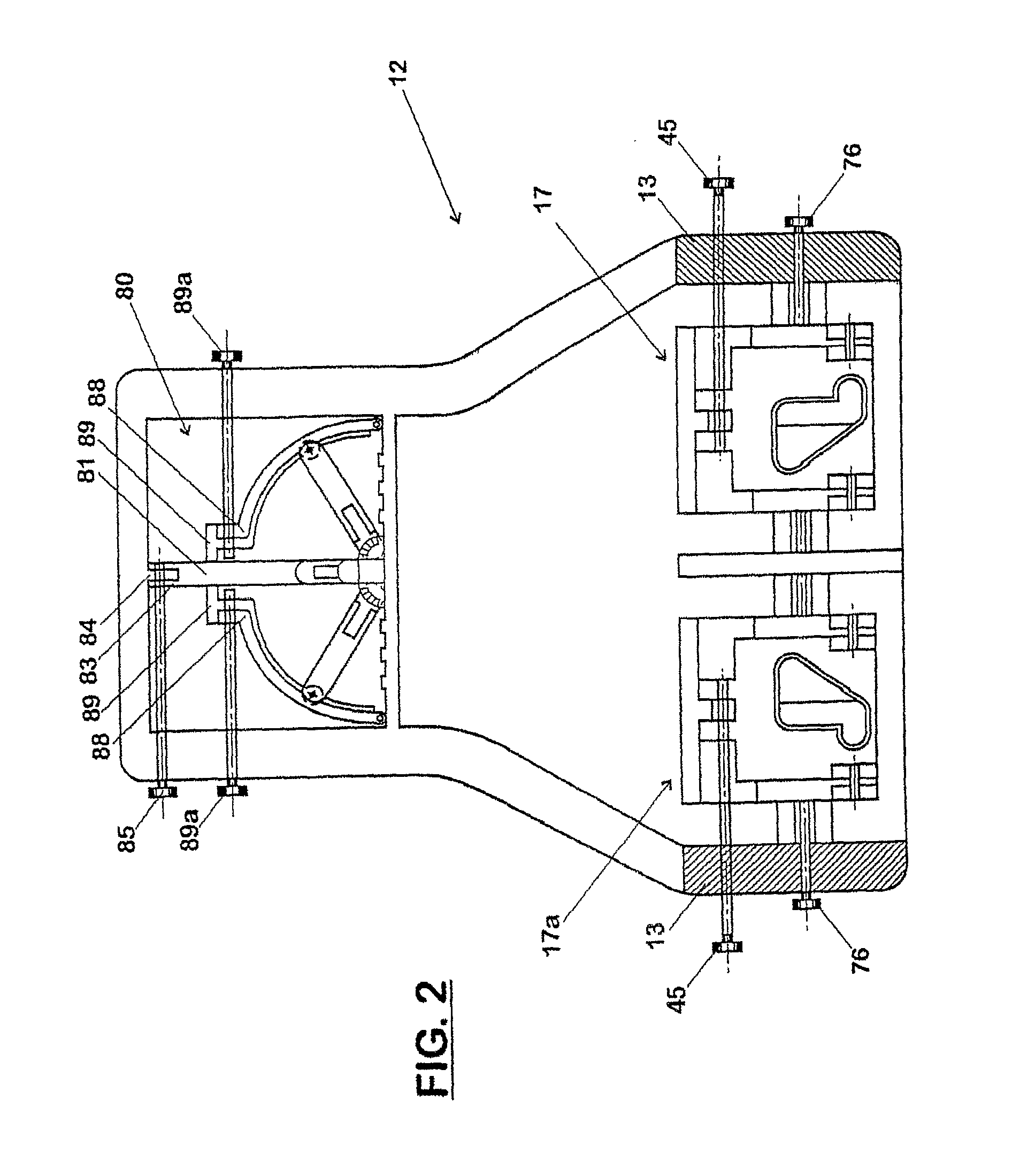

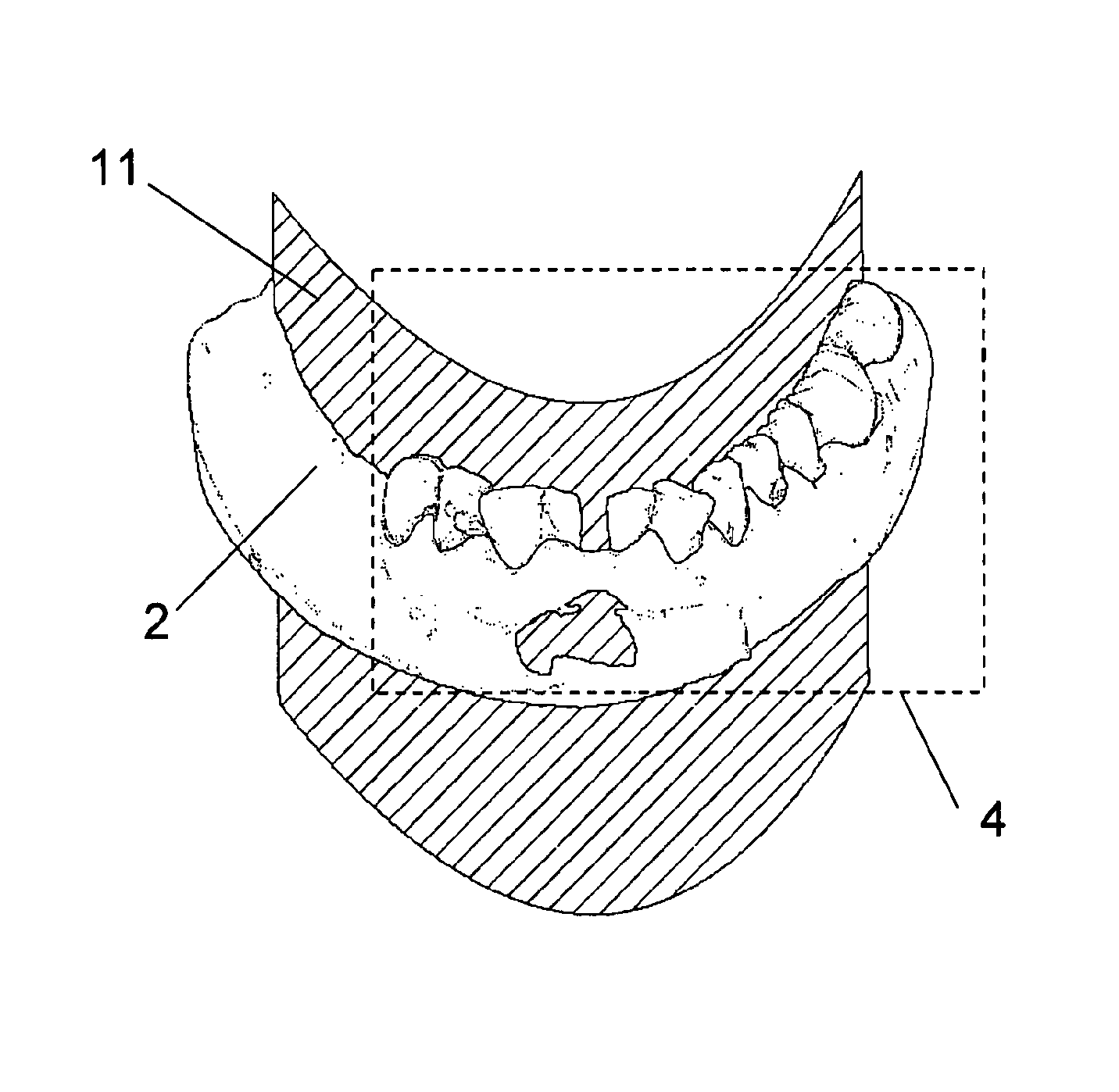

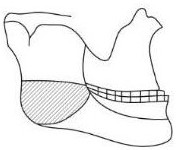

Dental articulator for positioning the arcades without the use of plaster

InactiveUS20120295219A1Improve fidelitySlow dynamicDental articulatorsEducational modelsDental ArticulatorsCombined use

This patent application refers to a mechanical equipment that, when used in conjunction with a device to determine the position of the superior arcade of the patient, based on landmarks on the skull of the same, allows accurate reproduction of the position of the dental arches, represented by plaster models and simulation of mandibular movements. These models are connected to the equipment, through a unique positioning mechanical system, eliminating the use of plaster to fix the same. The patent, now required, includes features of the equipment currently called “articulator” and “face-bow” and adds new features in an unprecedented and innovative way. The set of the equipment is light weighted, and easy to handle, allowing up to 50% reduction in the time required for assembly and adjustments when compared to the equipment market, and its guide system makes the reproduction of mandibular movements very accurate, avoiding errors in diagnosis and treatment.

Owner:MONTEIRO GERAS JORGE AVELINO +1

Method for creating a personalized digital planning file for simulation of dental implant placement

ActiveUS9579170B2Advantageously avoidedImpression capsMechanical/radiation/invasive therapiesPlaster CastsSurgical template

The present invention provides a method for creating a personalized digital planning file for simulation of dental implant placement. After planning, the digital representation in a plaster model may be used to design and produce dedicated surgical templates to assist the surgeon in transferring the implant plan to a patient during medical intervention.

Owner:MATERIALISE DENTAL NV

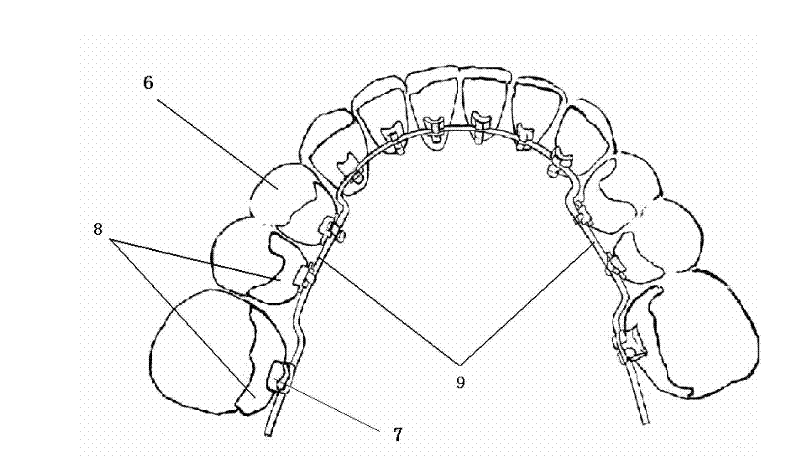

Method for manufacturing personalized tongue side corrector and tongue side corrector

ActiveCN102648875AMeet the correction requirementsImprove stabilityBracketsAnatomical structuresArch wires

The invention relates to a method for manufacturing a personalized tongue side corrector and a tongue side corrector. The method for manufacturing the personalized tongue side corrector comprises the following step of: 1) making a correcting plan; 2) manufacturing an impression, and manufacturing a plaster model to obtain a tooth arranging model; 3) according to the tooth arranging model, obtaining an ideal arch diagram; 4) selecting a bracket resin type and a bracket backplate model; 5) according to the ideal arch diagram, bending a full-size arch wire into an ideal arch; 6) manufacturing a personalized bracket; 7) resetting the personalized bracket on the tooth arranging model and manufacturing a transferring tray; and 8) according to the ideal arch diagram, manufacturing a series of arch wires. By the method for manufacturing the personalized tongue side corrector, a ribbon arch or an edgewise is selected according to requirements of different patients on torque and the width of the bracket is properly regulated according to a requirement on axis inclination; the personalized bracket backplate which is manufactured according to anatomical structure of a radula surface corresponds to the teeth of the patient one by one; and the bracket backplate is in complete fit with a cambered shape of the radula surface, so that the adhering stability and the positioning precision of the bracket are improved, the bracket can fit with the tooth surface to the maximum extent, the comfort and the attraction of the patient are ensured, and the clinical operation is facilitated.

Owner:张栋梁 +3

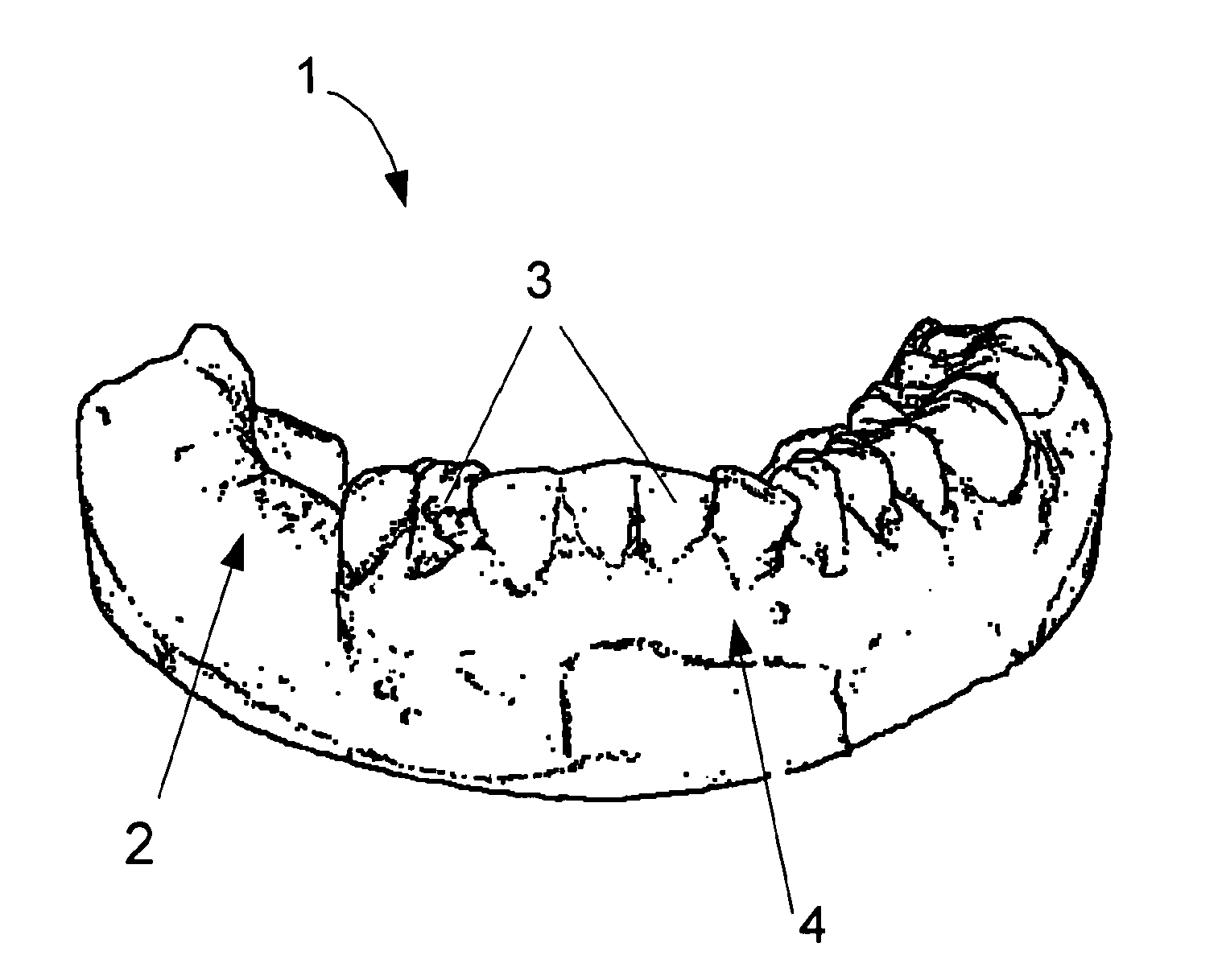

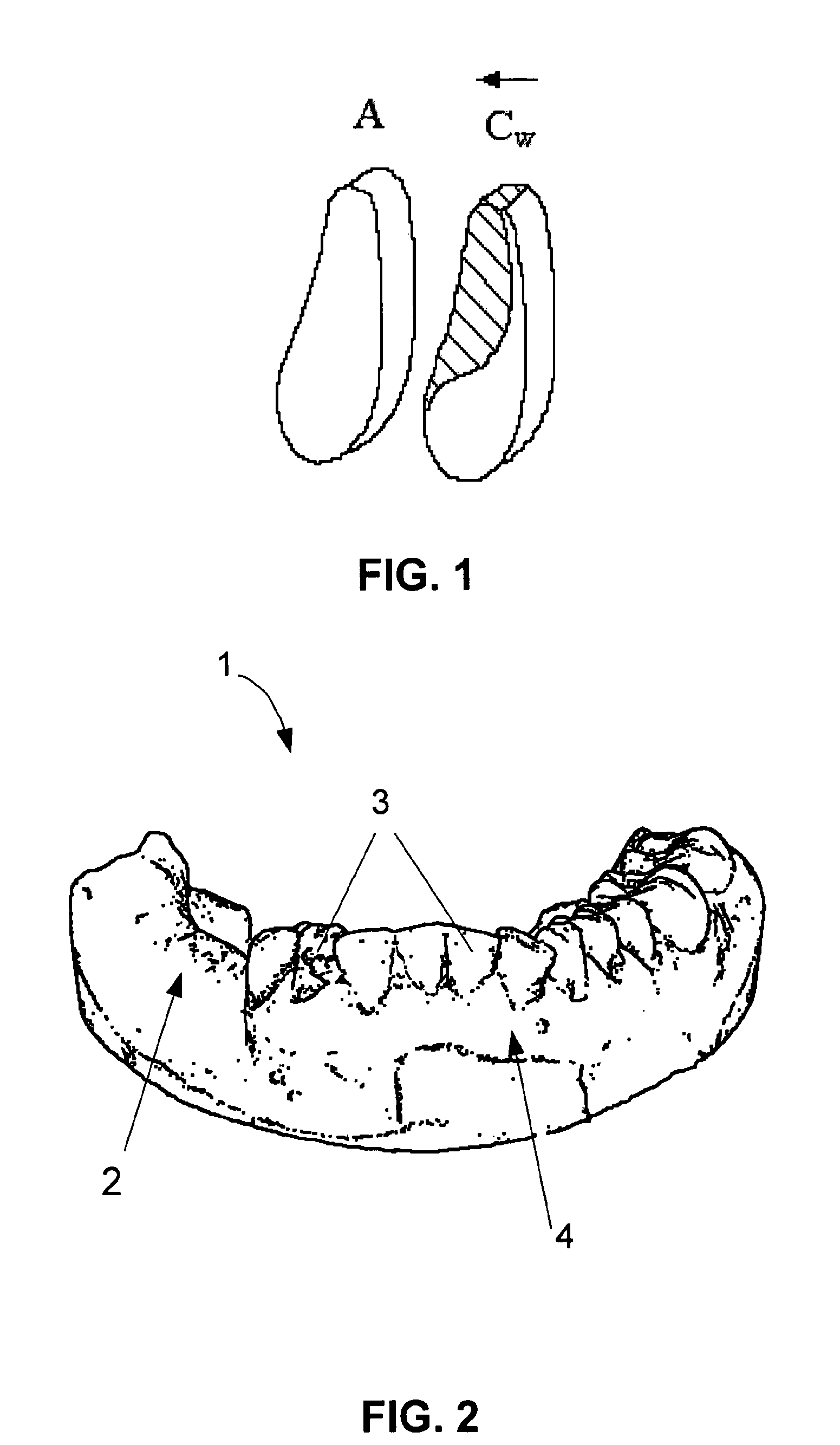

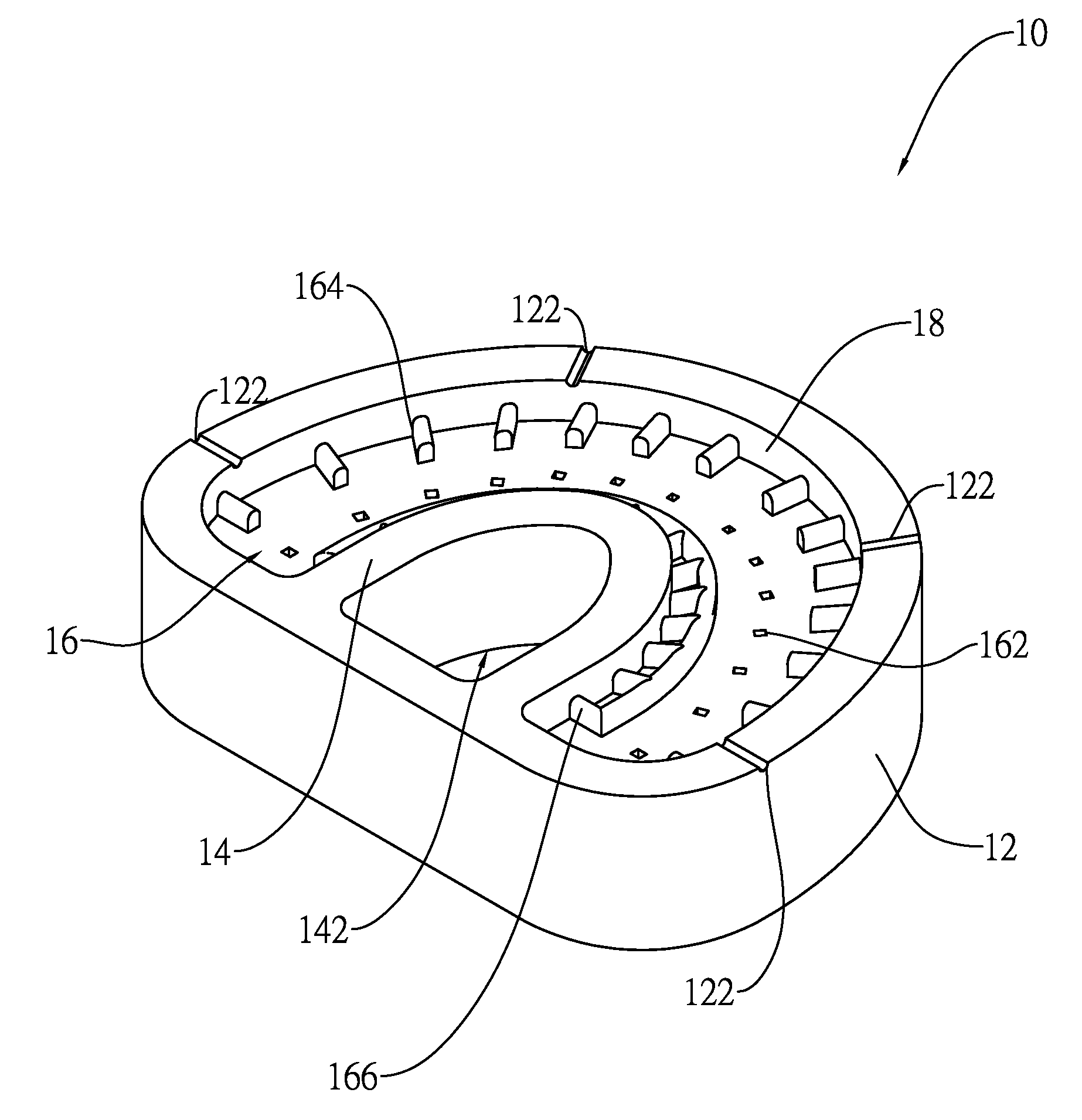

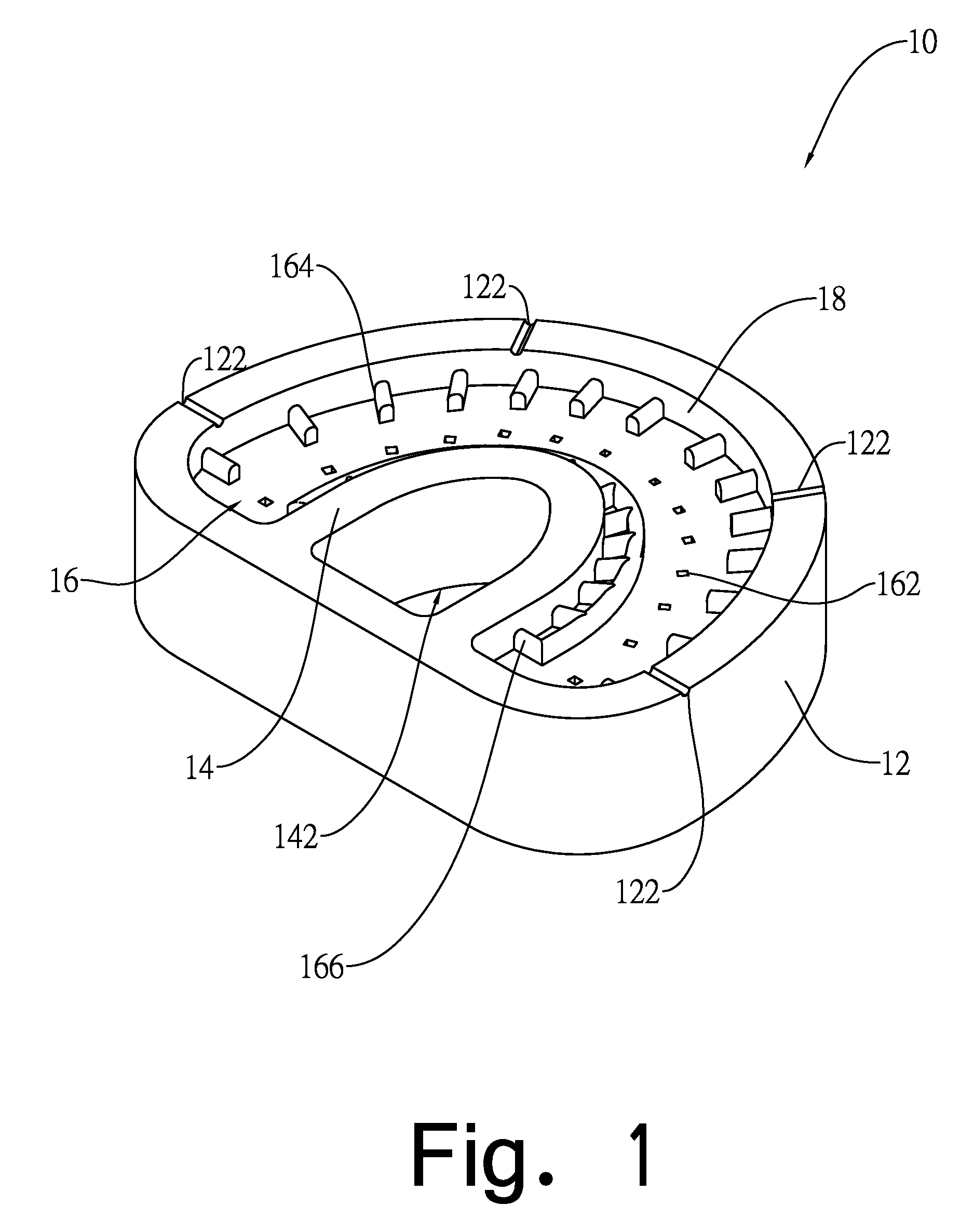

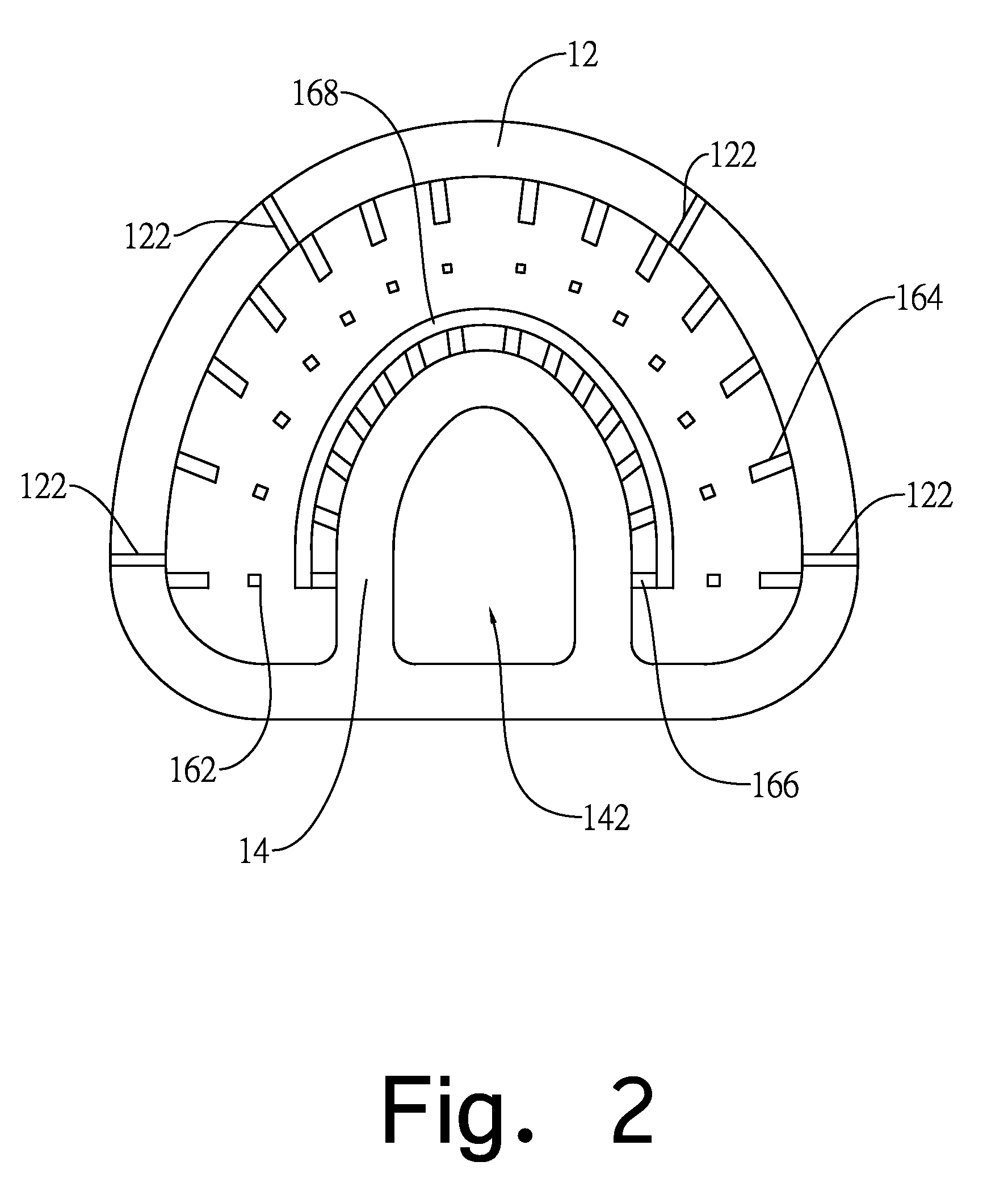

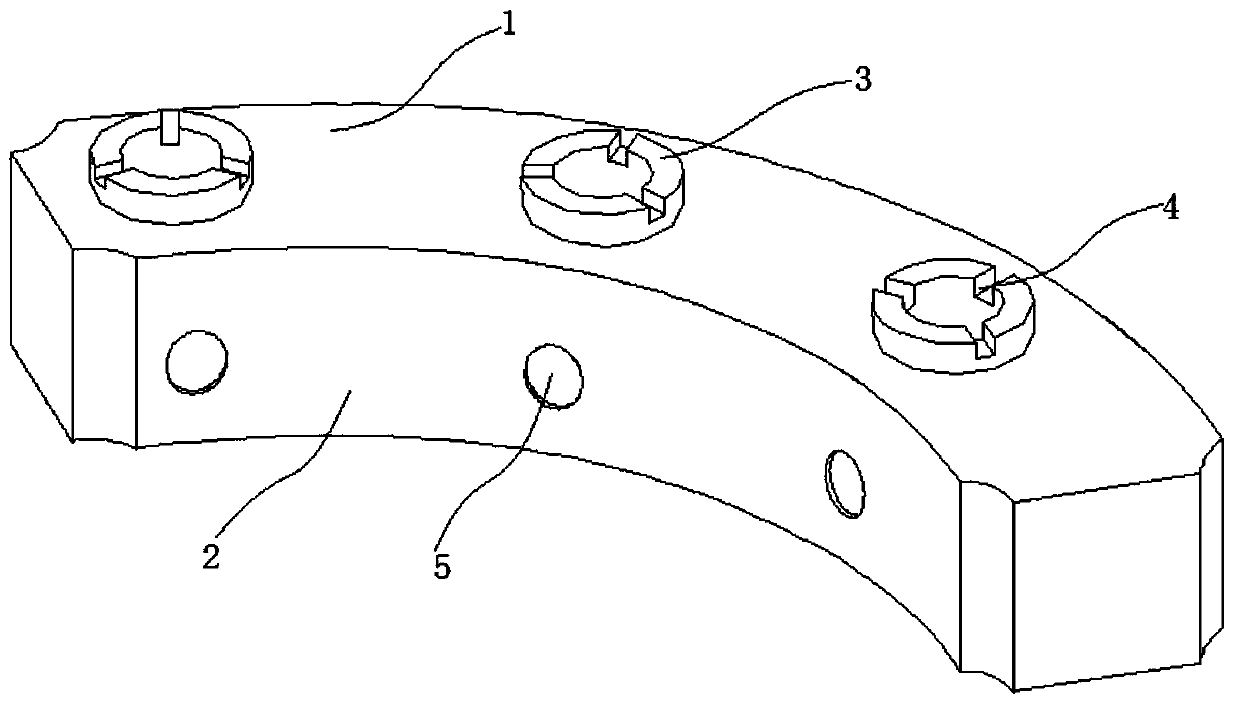

Plaster dental cast gum plate molding mold

InactiveUS20090208895A1Consume moreIncrease the amount of deformationImpression capsPlaster CastsDental cast

A plaster dental cast gum plate molding mold for molding a plaster dental cast gum plate having pins is disclosed. The body of the mold is made of an elastic material, having a cavity surrounded by a smoothly arched inner wall, a smoothly arched outer wall and a bottom wall, a plurality of insertion holes cut through the bottom wall for the insertion of a respective pin, and a plurality of alignment pegs respectively perpendicularly extending from the smoothly arched outer wall and suspending in the cavity so that the molded plaster cast gum plate has dents corresponding to the alignment pegs for quick recognition of the locations of the pins after positioning of the plaster cast gum plate on a base plate and bonding of a dental cast to the flat top surface of the plaster cast gum plate for enabling the dentist to cut one individual tooth model accurately.

Owner:SONG YOUNG INT

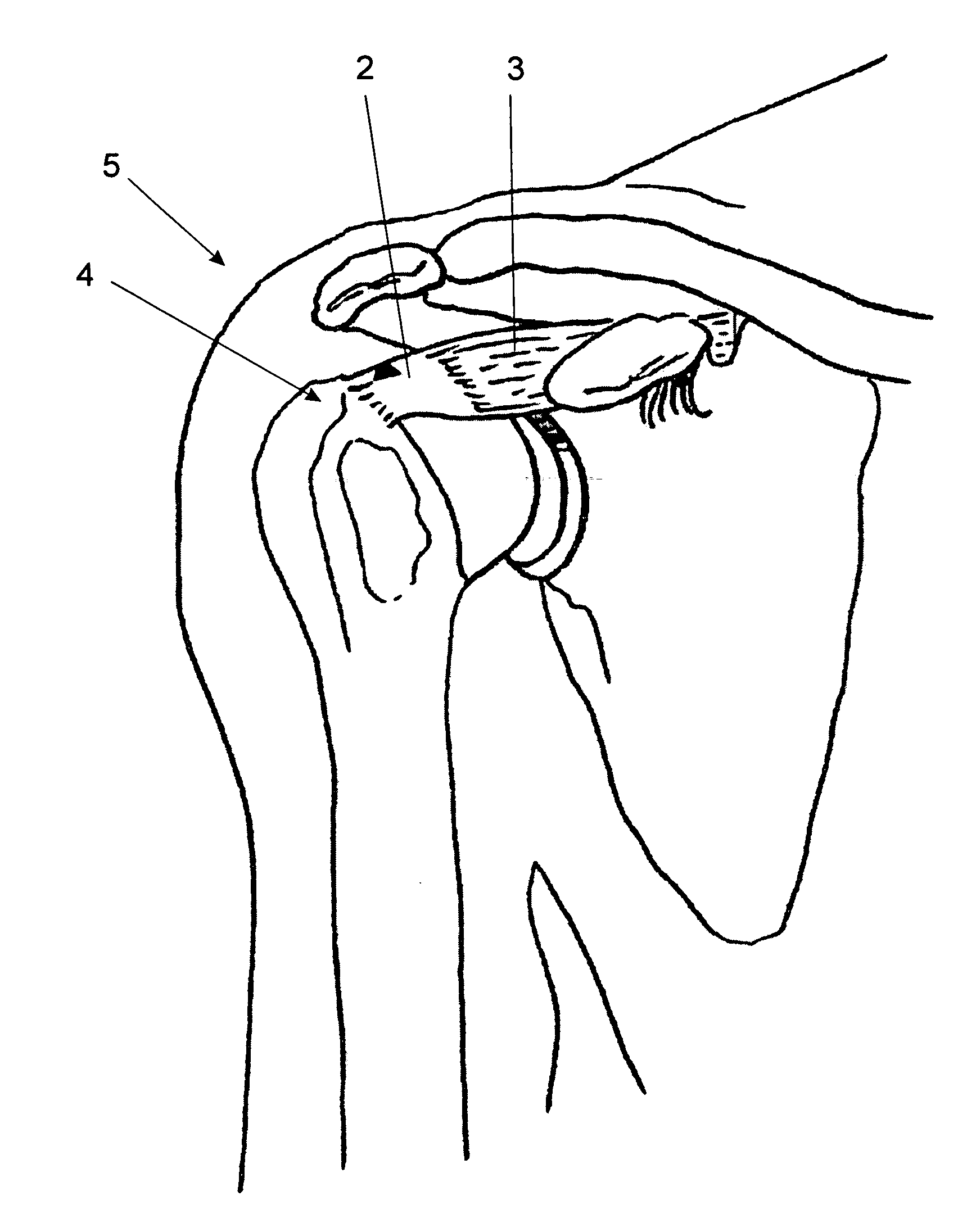

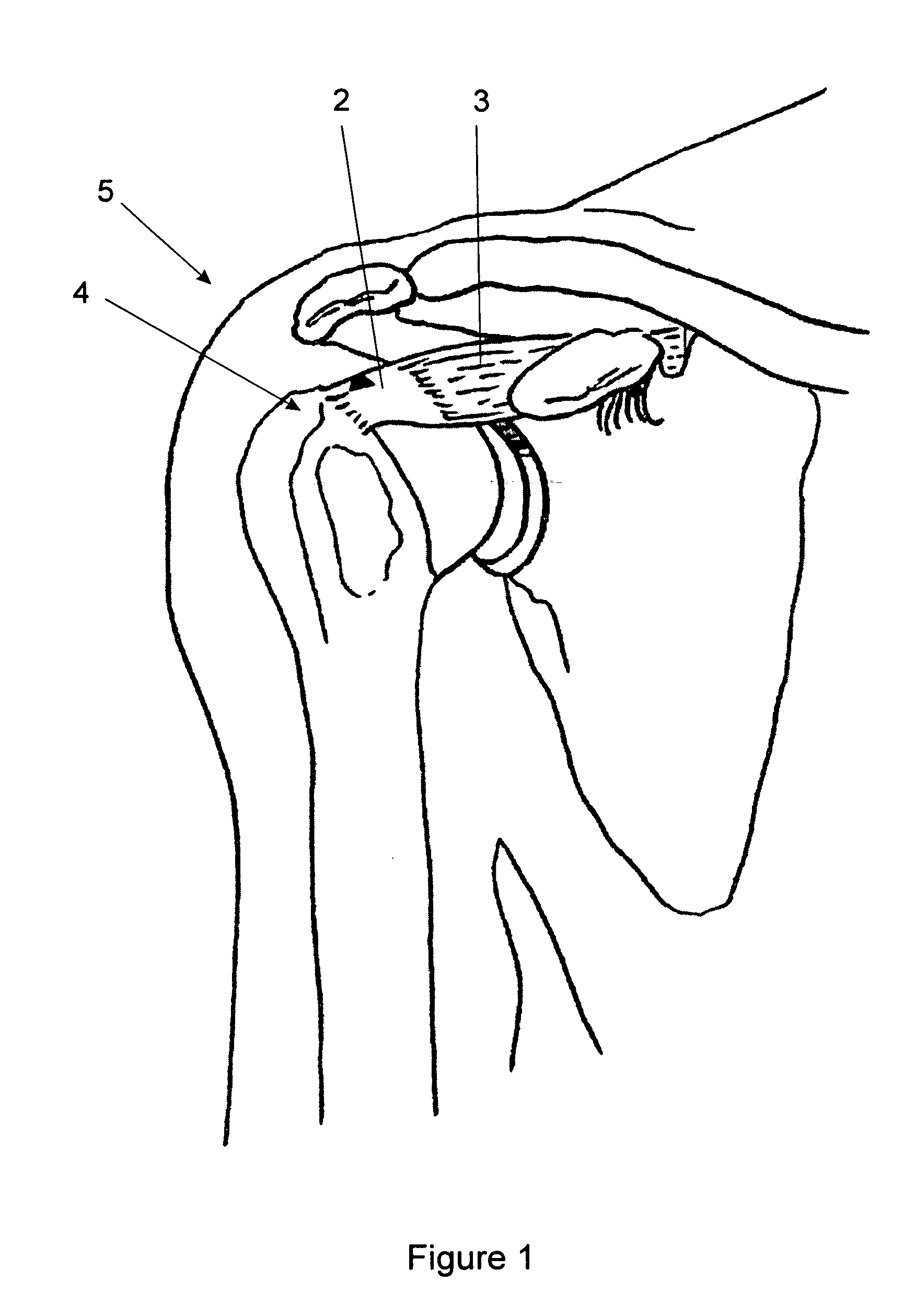

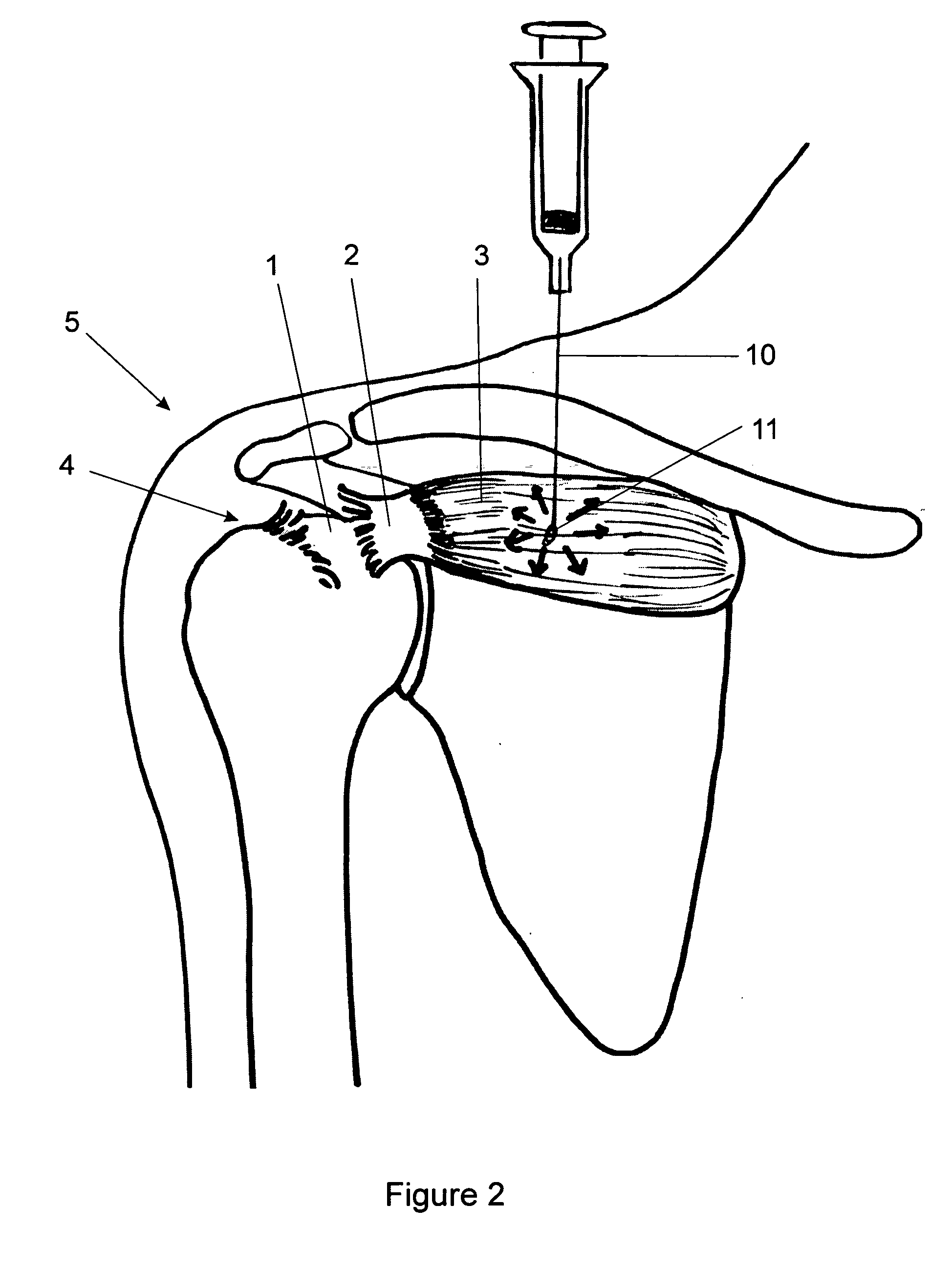

Method of repairing tendons by surgery

InactiveUS20060269574A1Inhibition of contractionBacterial antigen ingredientsPeptide/protein ingredientsPlaster CastsSurgery procedure

A method of repairing tendons by surgery is provided in which the muscle associated with the tendon to be repaired is treated with a predetermined dose of a neurotoxin sufficient to effectively cause temporary paralysis of the muscle. Any other muscle inextricably linked to that tendon may also be subjected to temporary paralysis. A sufficient period of time is allowed to elapse to enable said temporary paralysis of the muscle or muscles to set in prior to performing the necessary repair surgery on the relevant tendon in substantially conventional manner. The temporary paralysis of the relevant muscle or muscles obviates the necessity for postoperative immobilisation, typically by a sling or plaster cast, and ensures that the patient is not able to contract the relevant muscles during rehabilitation thereby possibly deleteriously affecting the repair.

Owner:HUIJSMANS POLYDOOR EMILE

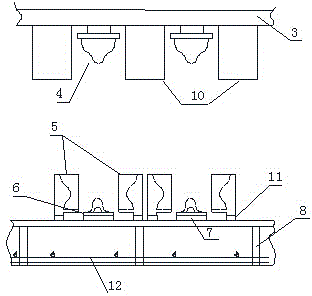

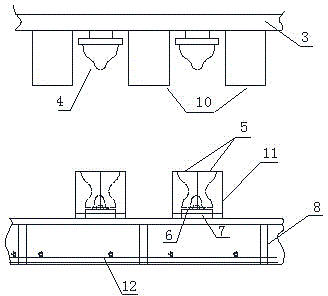

Ceramic grouting forming production line and production technique

ActiveCN106493850ASave quantitySave spaceCeramic shaping plantsFeeding arrangmentsProduction lineGypsum

The invention discloses a ceramic grouting forming production line. The ceramic grouting forming production line comprises a grouting workbench, a pouring workbench, a first drying chamber, a second drying chamber and a third drying chamber, wherein the grouting workbench is used for injecting grout into a plaster mold, the pouring workbench is used for pouring out redundant grout in the plaster mold, the first drying chamber is used for drying the plaster mold with a blank mud layer, the second drying chamber is used for drying the plaster mold, and the third drying chamber is used for drying a blank body; and the first drying chamber, the second drying chamber and the third drying chamber are each provide with a conveying device with a plurality of conveying stations; the input end of the first drying chamber is close to the pouring workbench, the input ends of the second drying chamber and the third drying chamber are connected with or close to the output end of the first drying chamber, and the output end of the second drying chamber is close to the grouting workbench. By installing the three drying chambers and the conveying devices, procedures such as grouting, pouring, drying and demolding can be conducted simultaneously, and time is greatly saved; and meanwhile, the plaster mold is recycled continuously in the whole process, a large space for placing the idle plaster mold is not needed, the number of plaster molds is reduced, and the spaced occupied by the plaster mold is reduced.

Owner:ZHIXINLONG TECH (GUANGDONG) CO LTD

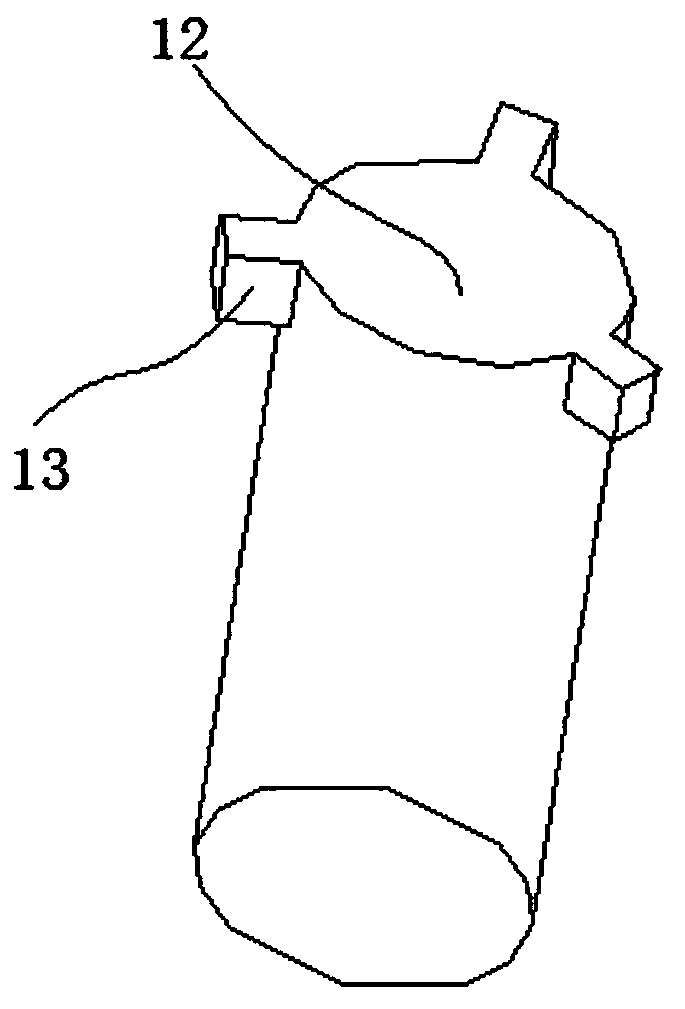

Dental implant guide plate based on 3D printing and manufacture method thereof

PendingCN110680529AImprove stabilityHigh positioning accuracyDental implantsAdditive manufacturing apparatusPlaster CastsDental implant

The invention relates to a dental implant guide plate based on 3D printing. The dental implant guide plate based on 3D printing comprises a base body and a guide hole. The base body comprises a positioning part for opening the guide hole and a fixing part integrally connected to the lower end of the positioning part. A planting point sleeve is arranged in the guide hole, a notch is formed in the guide hole, and an adapting block matched with the notch is arranged on the planting point sleeve. The planting point sleeve is fastened in the guide hole, in the process of a medical drilling tool penetrating through the guide hole to drill human bones in the gingival, drill bit displacement is avoided, and the positioning accuracy of the dental implant guide plate is improved. The invention further discloses a method for the implant dental guide plate based on 3D printing. The method comprises the steps that 1, a plaster model is manufactured; 2, three-dimensional models of the teeth and bones of the mouth and jaw region of a patient are reconstructed; 3, three-dimensional model data of the dental implant guide plate are obtained; and 4, the dental implant guide plate is printed. The 3D printing technology is adopted, the manufacturing cycle of the entire reconfigurable guide plate is shortened, and the rapid production of a base plate and the field reconstruction of the guide plate are achieved.

Owner:四川康铭智能装备科技有限公司 +1

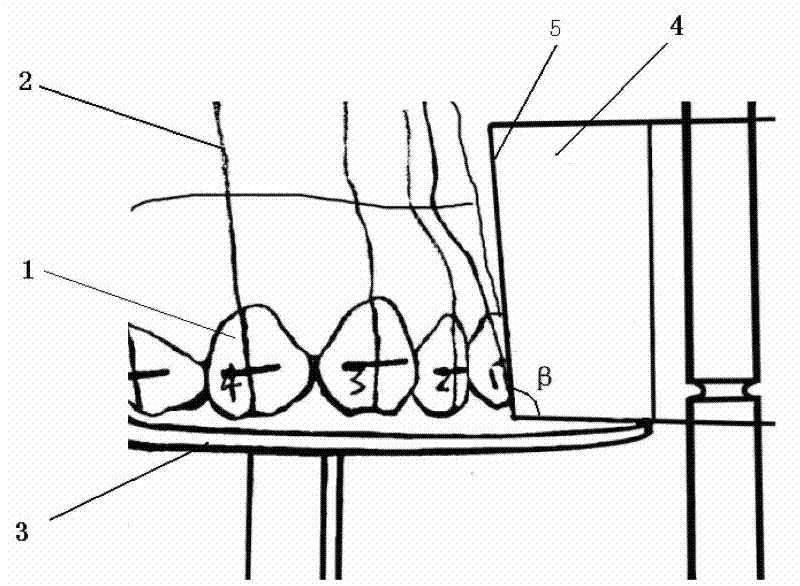

Method for fast making digital implantation guide plate and special positioning jaw frame for implementing method

The invention discloses a method for fast making a digital implantation guide plate and a special positioning jaw frame for implementing the method. The method for fast making the digital implantationguide plate comprises the following steps of wearing a barium-containing complete denture or a barium-containing partial denture and a positioning tray in the mouth of a patient, and acquiring three-dimensional oral image data of soft and hard tissue in the mouth of the patient through an oral CBCT or three-dimensional CT appliance; engaging a plaster cast with the positioning tray on the positioning jaw frame, enabling the plaster cast to be matched with a clamping apparatus of a five-axis cutting appliance, taking down the plaster cast, and making an implantation guide plate blank on the plaster cast through a compression molding or plastic coating method; importing the three-dimensional oral image data into an implantation guide plate designing device, carrying out coordinate positioning and coordinate matching, and designing an implantation position, direction and depth; importing three-dimensional position data of an implant designed by the implantation guide plate designing device into a control system of the five-axis cutting appliance, and making an implantation positioning guide hole according to the implantation position designed by the implantation guide plate designingdevice, so as to obtain the implantation guide plate.

Owner:张辉

Method for providing custom fit therapeutic footwear

A method for manufacturing custom fit therapeutic footwear such as shoes and inserts includes the step of measuring a patient's foot and forming an imprint of a patient's foot to identify the patient's footprint and any high pressure areas on the bottom of the foot. The method also includes the step of making a mold of a lower portion of the patient's foot and subsequently making a plaster cast of the lower portion of the patient's foot. A multidensity sheet of insert material is provided and formed into a shape that corresponds to the lower portion of a patient's foot as for example by vacuum forming. The method also includes the step of providing a second insert material that is softer than the first insert material. The imprint of the patient's foot is then used to position any needed accommodations. The area to be accommodated is then punched out through the entire thickness of the insert and filled with a sheet of softer insert material. The final product may then be covered with a top coat or sheet of moldable polyethylene.

Owner:SOUTHERN PROSTHETIC SUPPLY

Hand-shaping blank hollow-jun-porcelain grouting manufacturing method and mold used for grouting manufacturing

InactiveCN104669405AExquisite workmanshipShorten production timeSlip casting mouldsDual functionGypsum

Owner:XUCHANG UNIV

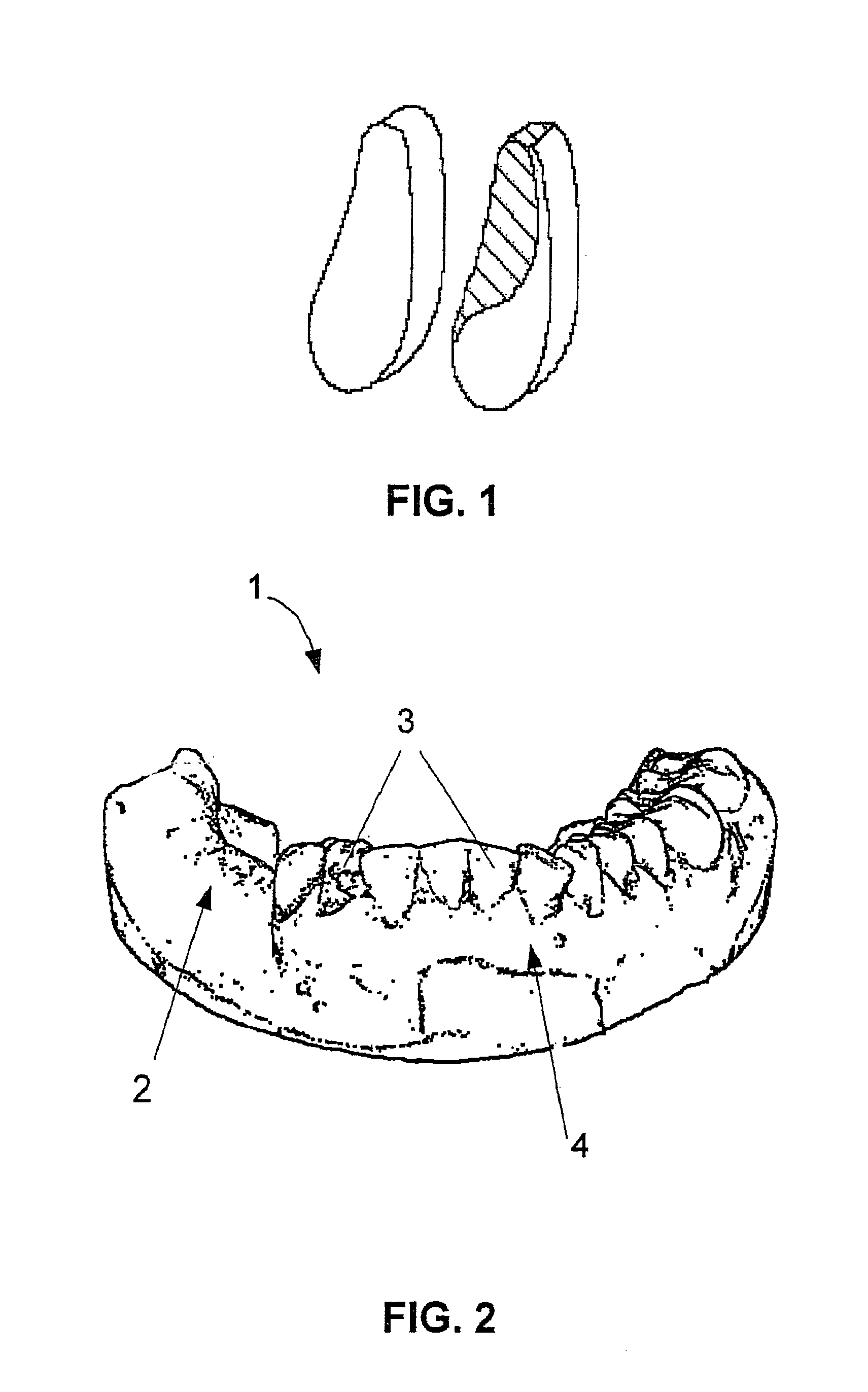

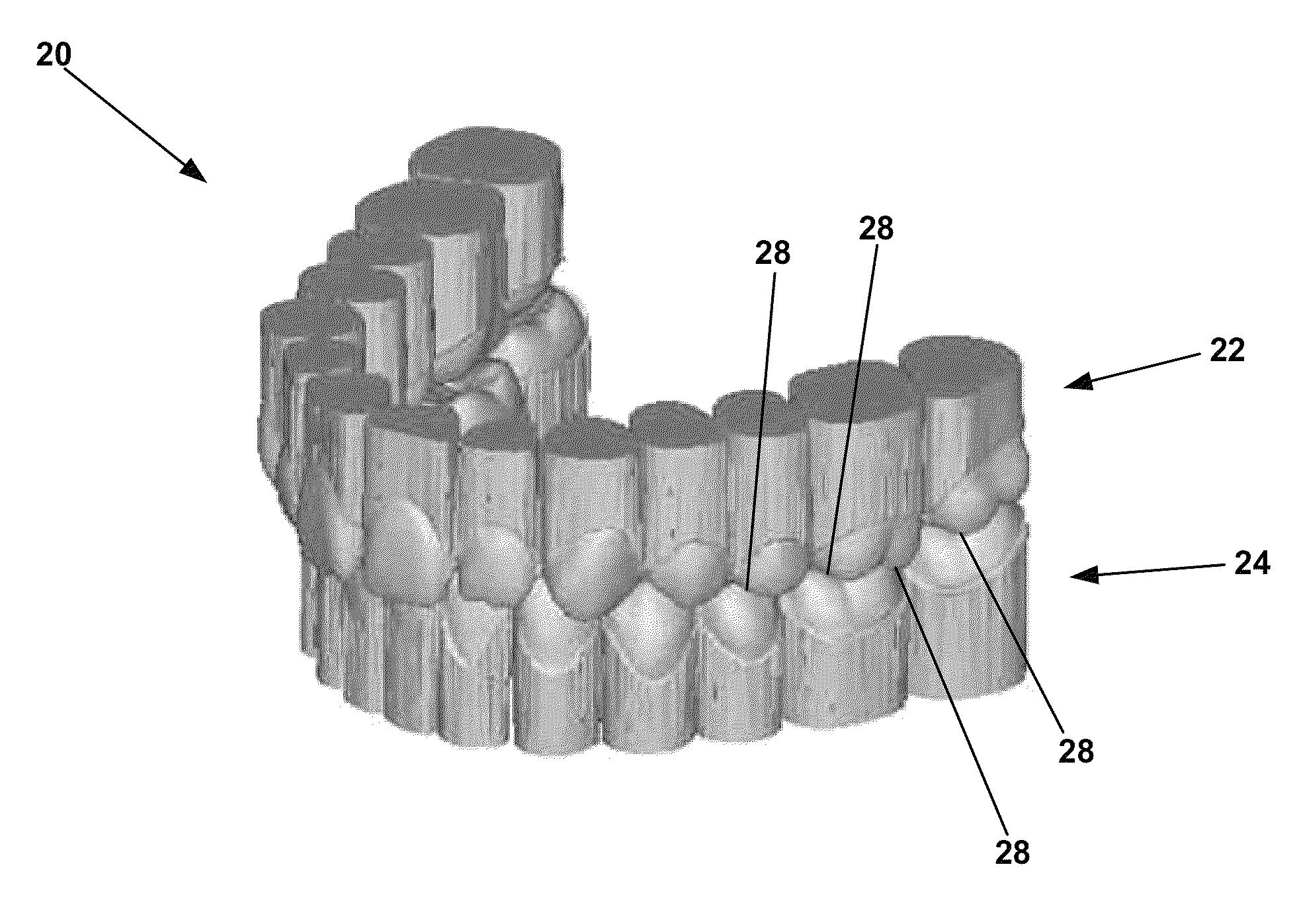

System and method for evaluating orthodontic treatment

A system and method for evaluating dental treatment utilizes virtual models created from scanned plaster casts. Patient's teeth are directly scanned with a three dimensional scanner or plaster casts of the patient teeth following treatment are scanned for evaluation. A planned configuration based on a plaster cast prior to treatment is created and the desired position and the two models are compared so that the actual position of the teeth may be compared to the desired position after treatment. Superimposition of the virtual models provides accurate and precise measurement of variances between the two virtual models. Difficulties due to superimposing the models, which are of the entire arch and evaluations based on individual teeth are overcome by applying an iterative closest point algorithm to correct the position and provide a truer measurement for evaluation. Differences between a preferred position of a patient's teeth and actual position of a patient's teeth may be assigned a score and the score may be compared to other patients to rank the patient needs.

Owner:HULTGREN DENTAL TECH LLC +1

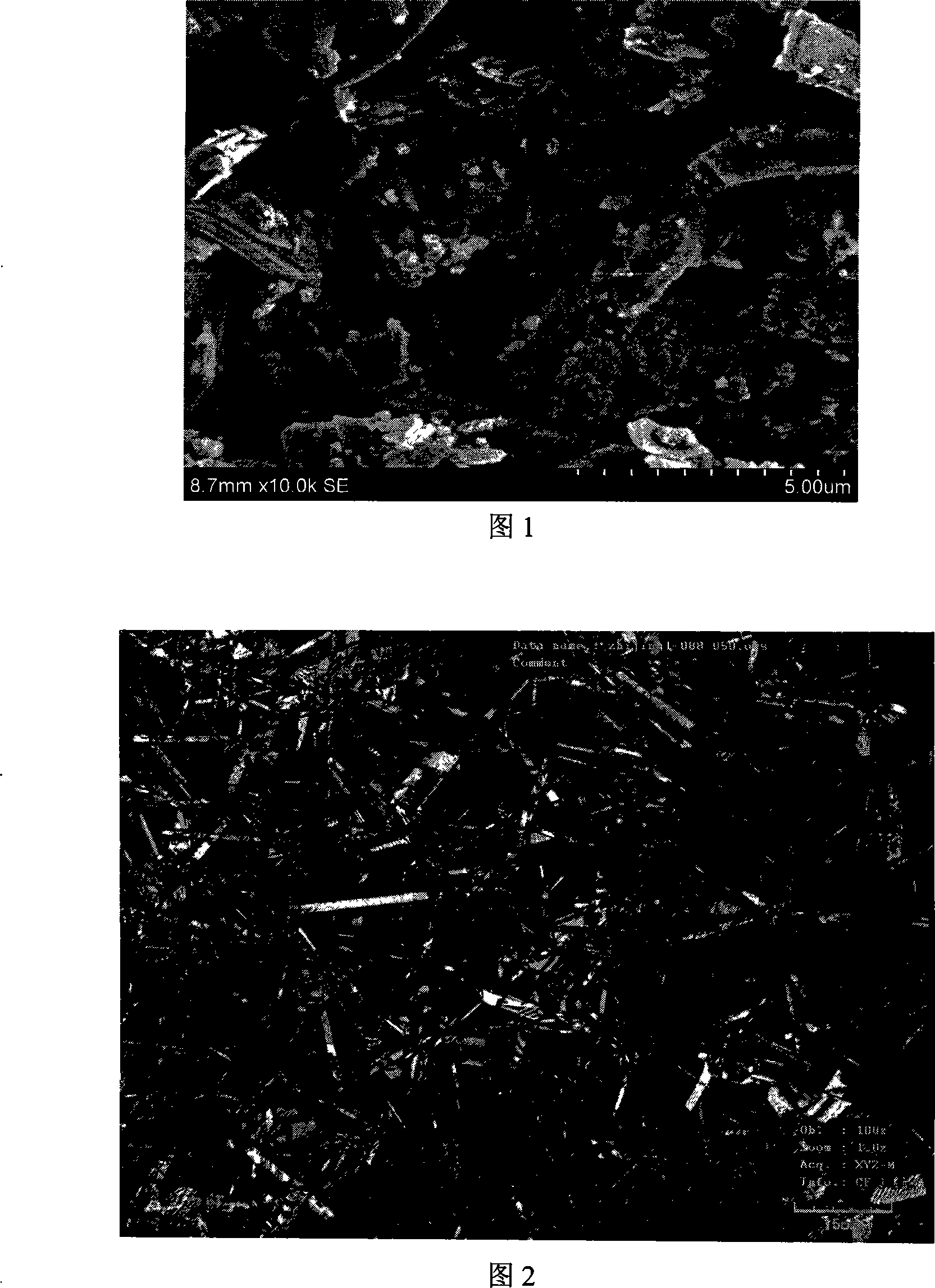

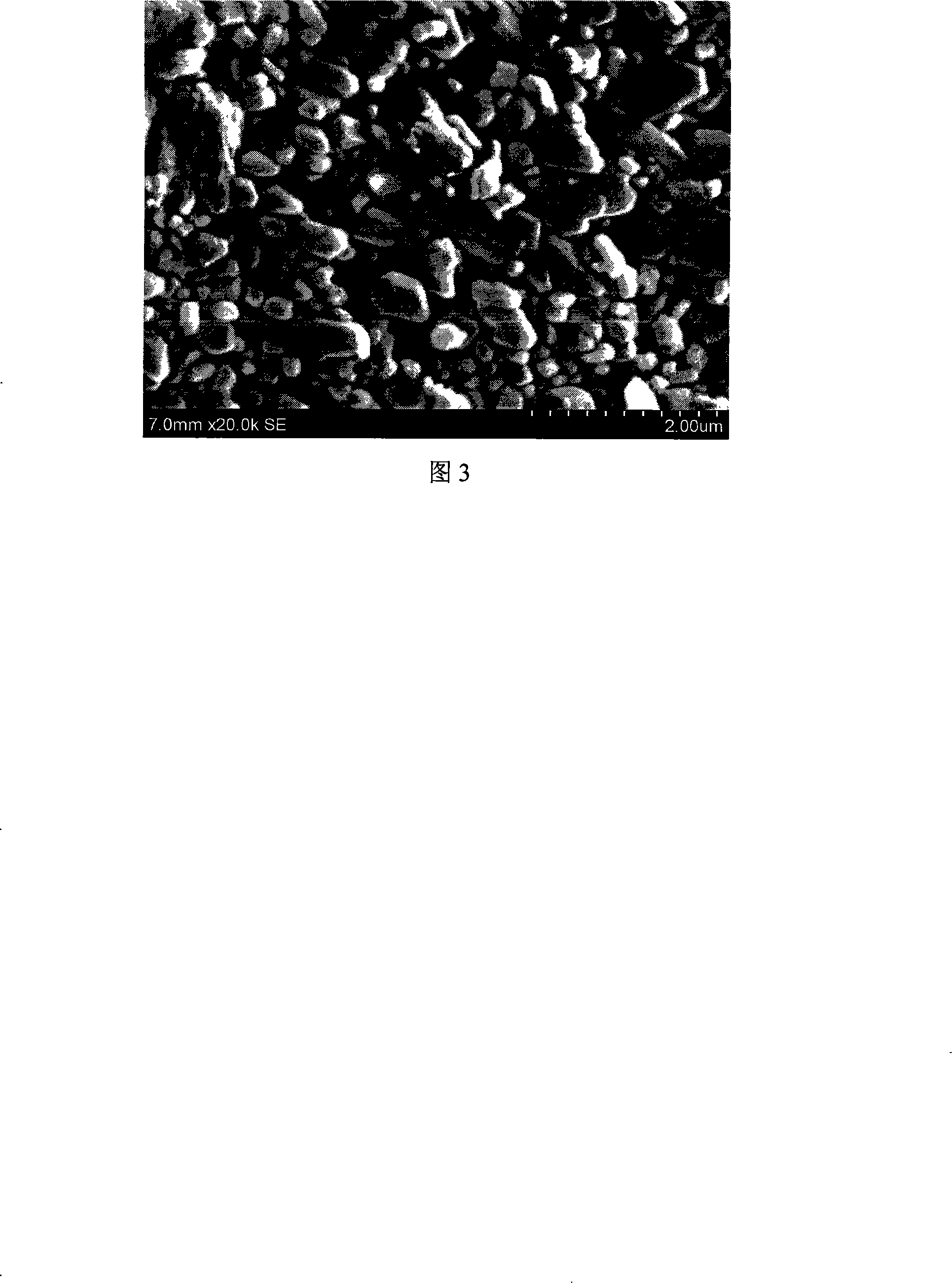

Preparation method of micro-welding mould quick used plaster casting mold

InactiveCN101204827ADoes not require prolonged clotting timeSmall sizeCeramic shaping apparatusClay processing apparatusPlaster CastsPhysical field

The invention relates to a preparation method of a gypsum mould for the precision casting of a micro-melting mold, pertaining to a gypsum mould preparation method. The invention solves the problem that: the gypsum mould produced by the current preparation method can not meet the requirements for the precision casting of micro-melting and be used for casting once-forming micro elements which have finish surface and high size accuracy. The preparation method is that: 1. Alpha or Beta semi-hydraulic gypsum and deionized water are mixed and stirred; 2. the gypsum slurry mixed and stirred in step one is poured into a water-proofing model and applied by ultrasonic field; 3. micro-melting investment casting gypsum mould is obtained after the ultrasonic field is stopped and the gypsum slurry is placed in the air and at room temperature. The method of the precision casting of the micro-melting gypsum mould adopted by the invention changes crystal microstructure of the solidified gypsum slurry by means of adding physical field and reduces the crystal size so as to produce the gypsum mould which meets the requirement of micro-melting investment casting, and cast once-forming micro elements with bright surface and high size accuracy.

Owner:HARBIN INST OF TECH

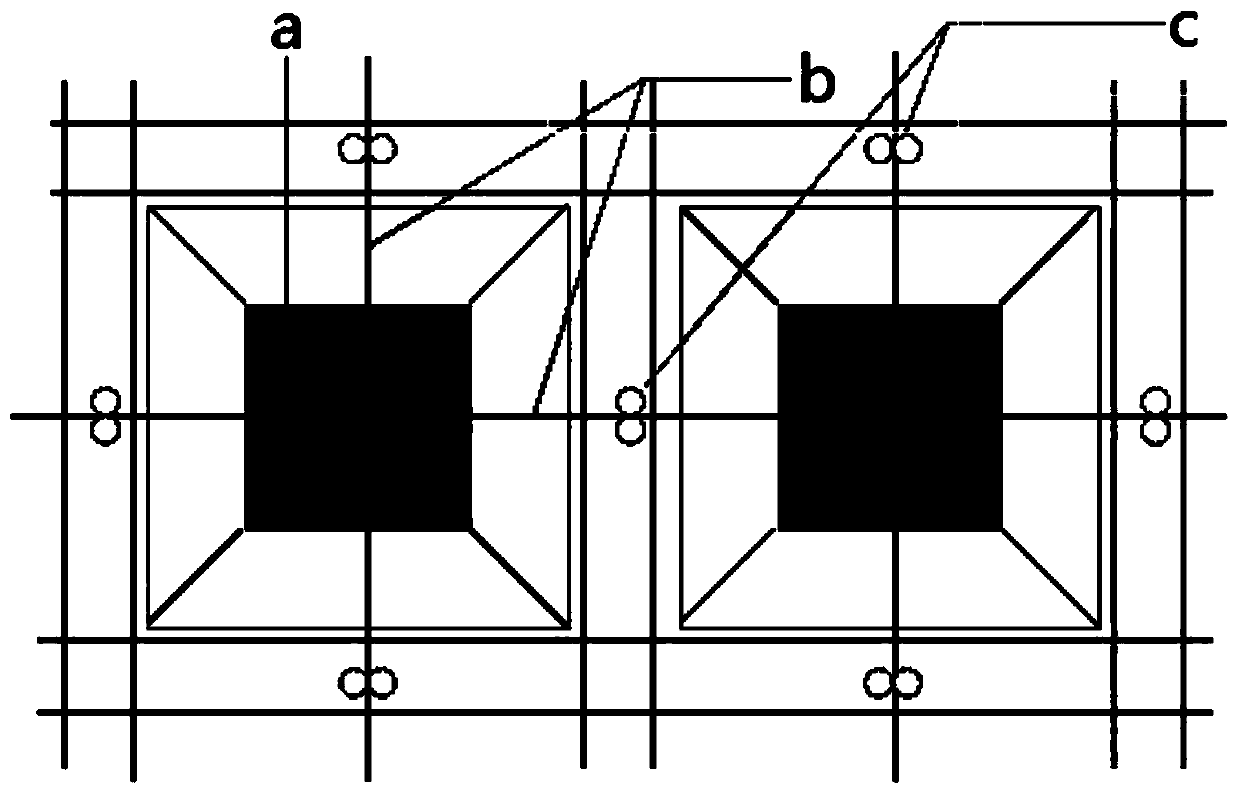

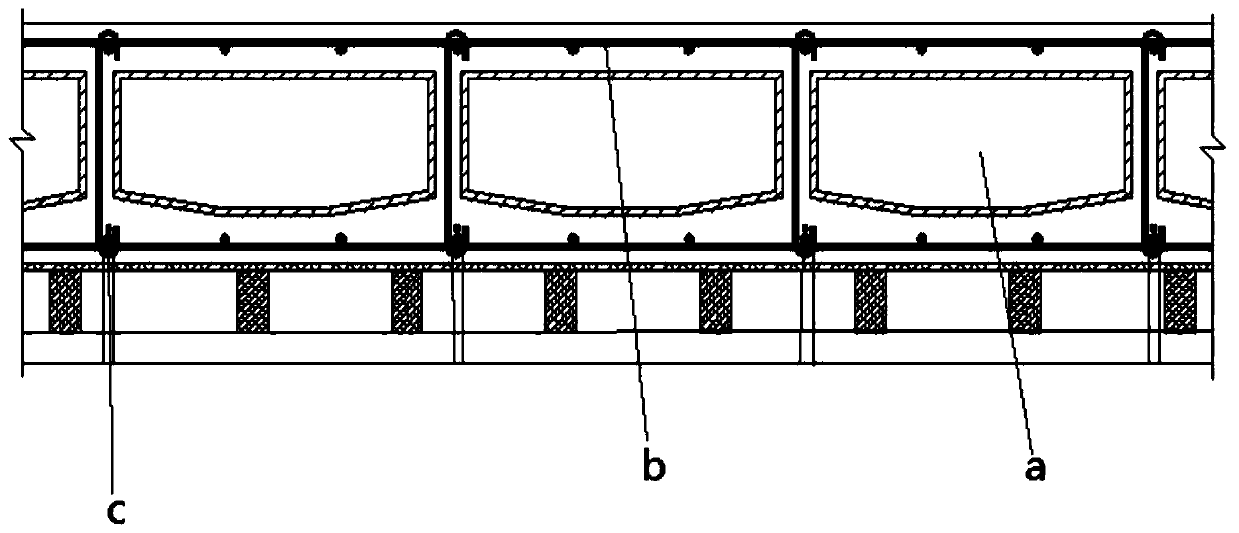

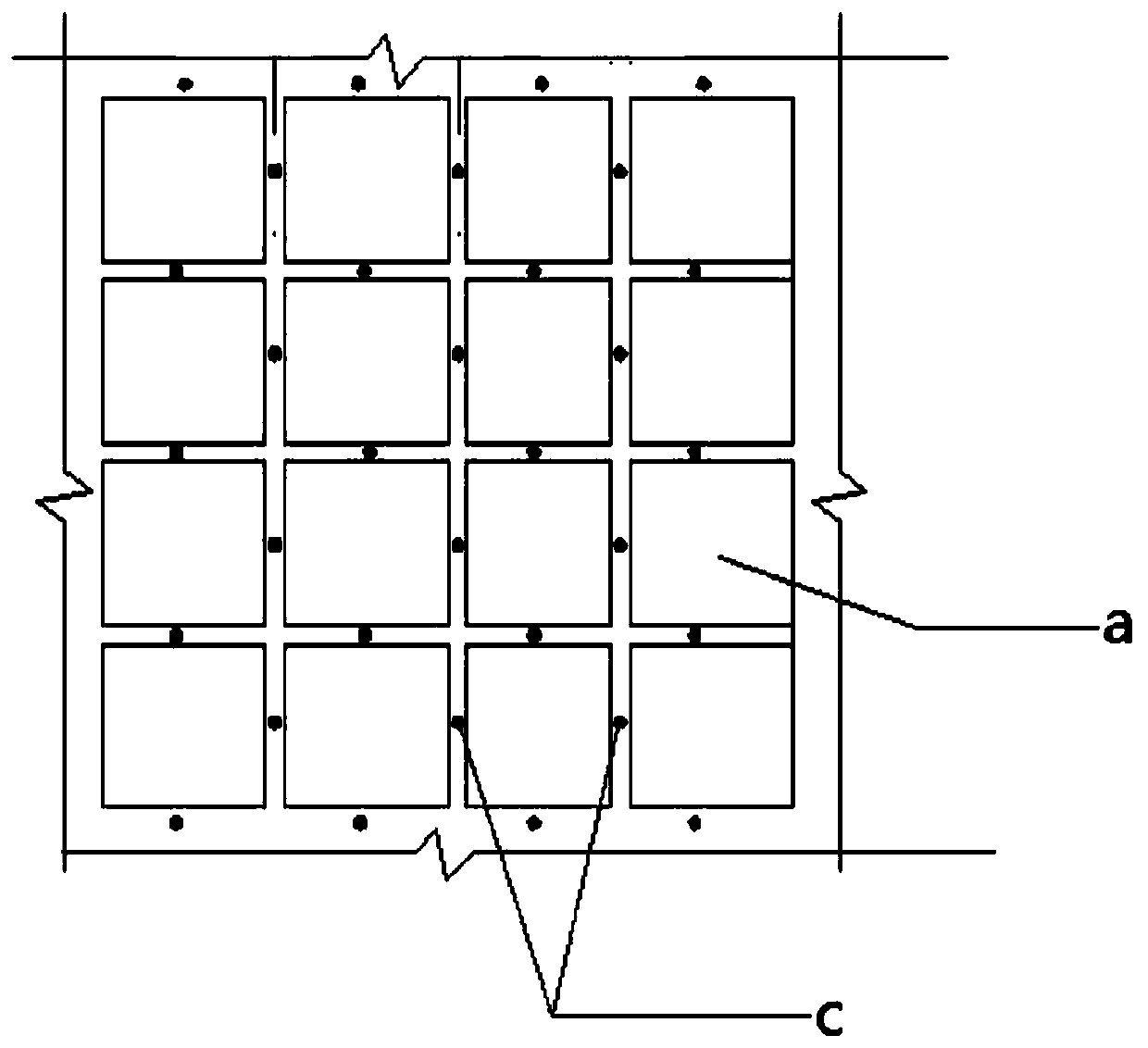

Hollow floor system construction method adopting plaster mold boxes and hollow floor system construction

PendingCN111379366ALight weightReduce usageFloorsBuilding material handlingPlaster CastsArchitectural engineering

The invention provides a hollow floor system construction method adopting plaster mold boxes, and relates to the technical field of buildings. The method comprises the following steps that S1, construction preparation is carried out, and the specification, the number and the reserved pre-burying condition of the plaster mold boxes are determined; S2, a support is arranged, and a formwork is laid on the support; S3, rib beam position lines, plaster mold box control lines, steel bar distribution lines and embedded reserved position lines of water and electricity installation pipelines are markedout on the formwork; S4, rib beam steel bars are bound according to the rib beam position lines, and then bottom plate steel bars are bound according to the steel bar distribution lines; S5, a plurality of cushion blocks are arranged at each plaster mold box control line on each bottom plate steel bar, and the plaster mold boxes are arranged on the cushion blocks; S6, the plaster mold boxes are subjected to anti-floating treatment; S7, floor system upper-layer steel bars and plate end support negative bars are bound; S8, concrete is poured, and vibration is carried out; and S9, after the concrete is shaped, the formwork is dismantled. According to the hollow floor system construction method adopting the plaster mold boxes, and the cost can be lower.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD

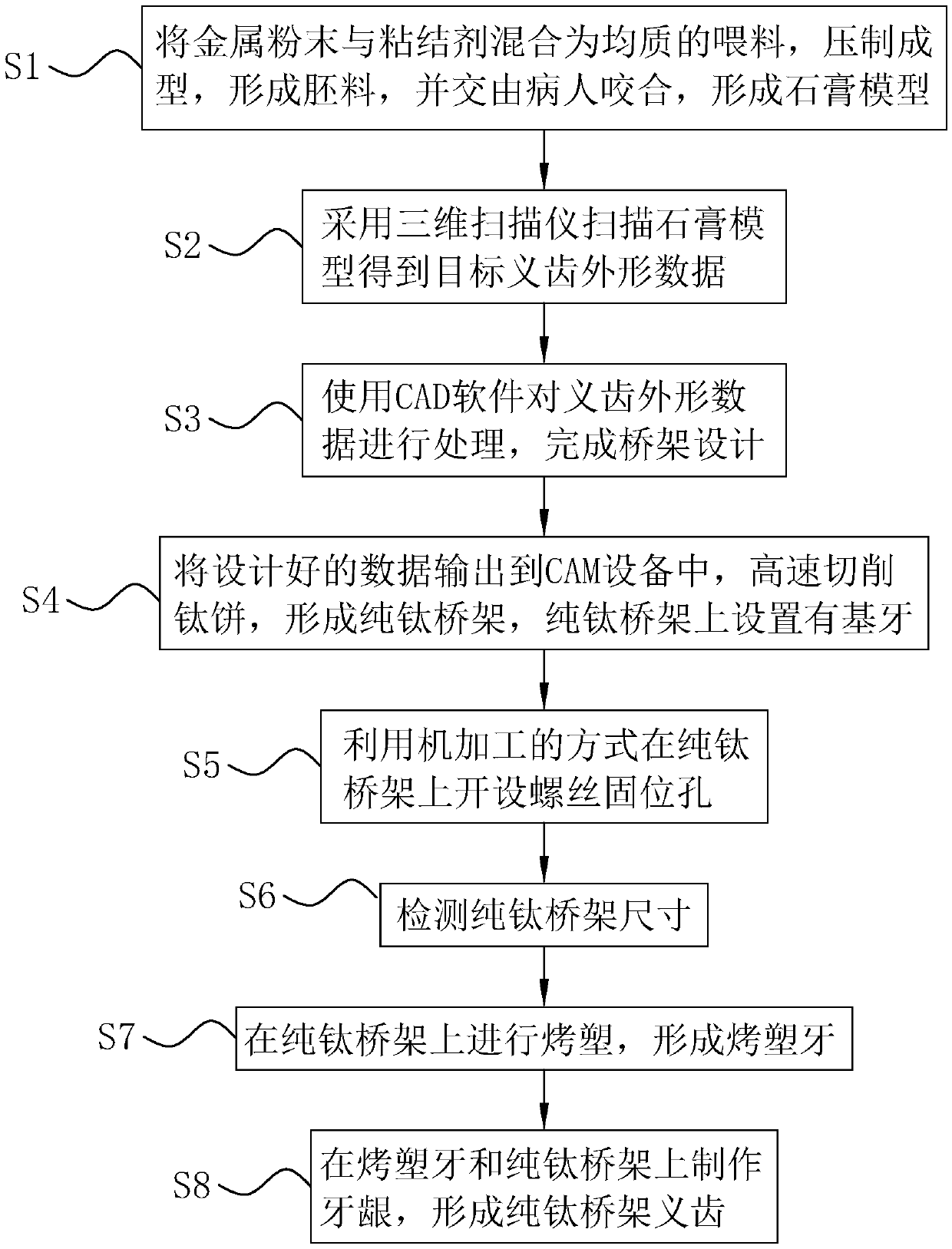

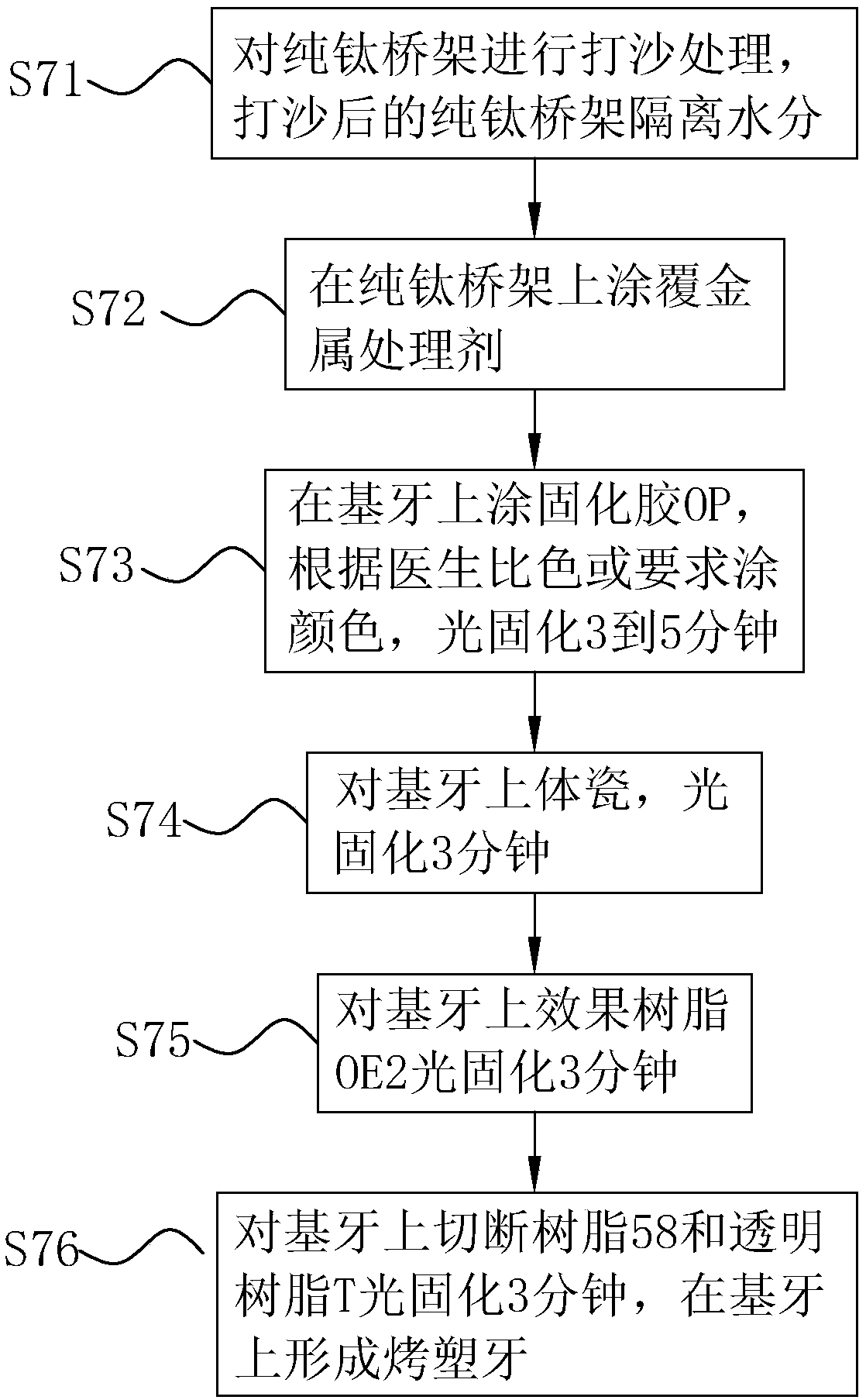

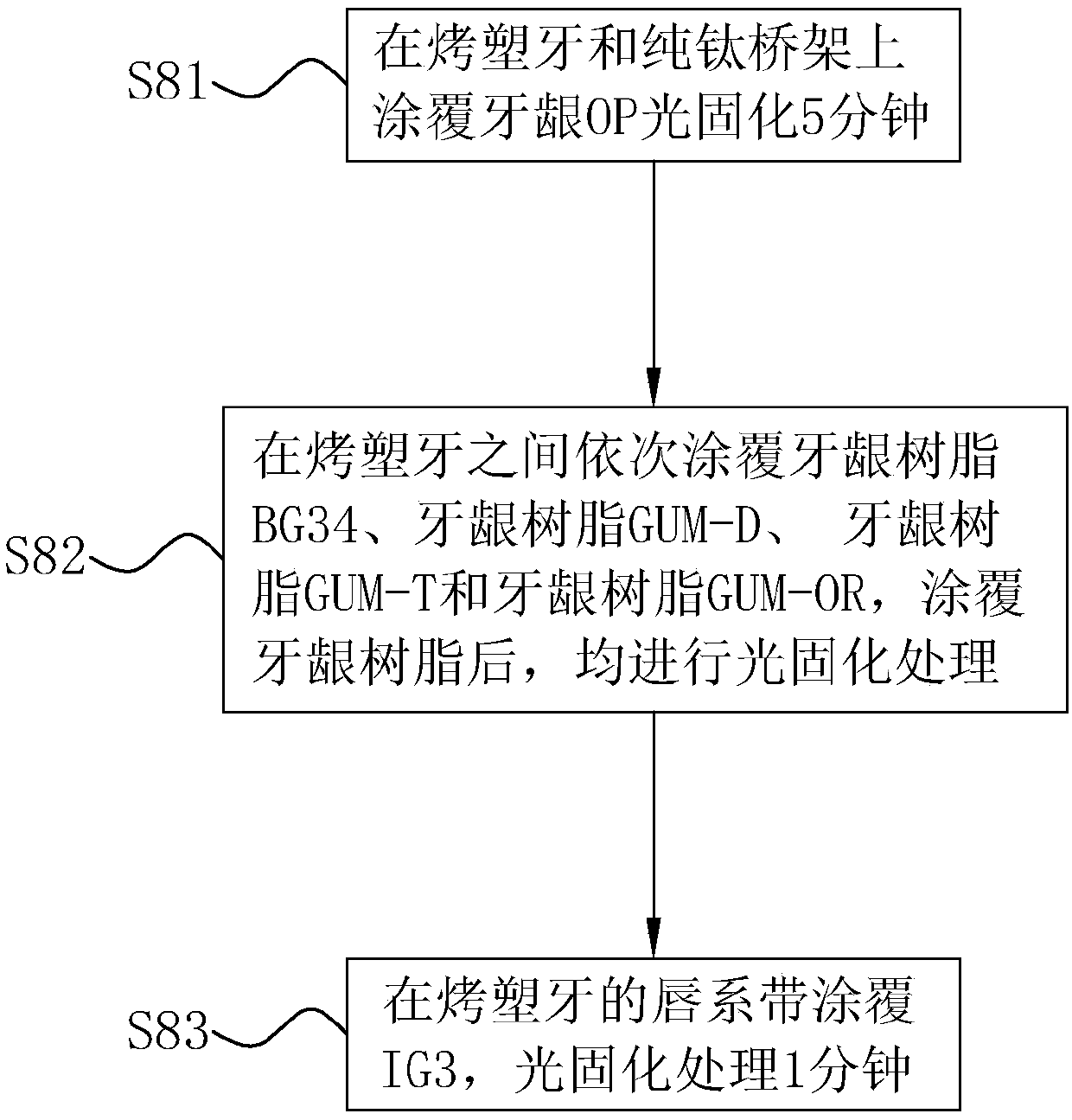

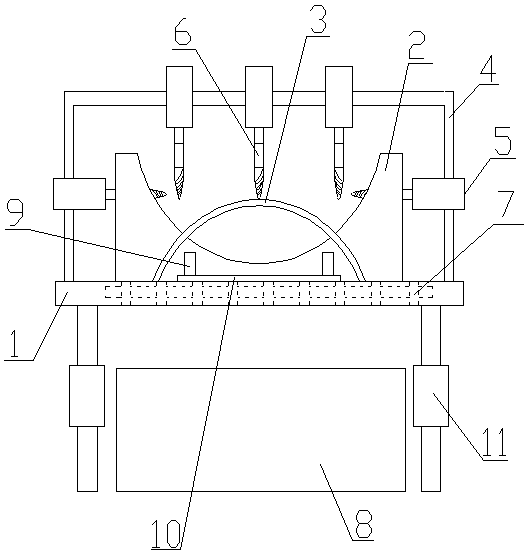

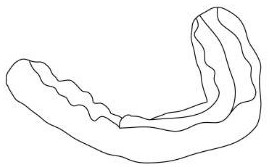

Preparation process of pure titanium bridge denture

The invention discloses a preparation process of a pure titanium bridge denture and relates to the technical field of production of complete dentures. The preparation process sequentially comprises the following steps: taking a model through occlusion by a patient; scanning the plaster model by a three-dimensional scanner to obtain target denture shape data; processing the denture shape data withCAD software and completing bridge design; cutting a titanium cake at high speed by machining to form a pure titanium bridge, and arranging abutment teeth on the pure titanium bridge; forming screw fixing holes in the pure titanium bridge; detecting the size of the pure titanium bridge; carrying out plastic fusion on the pure titanium bridge to form plastic fusion teeth; and producing gums on theplastic fusion teeth and the pure titanium bridge to form the pure titanium denture. Aiming at the problem that a pure titanium bridge in the prior art affects a following implantation process due toexistence of casting stress, the preparation process effectively avoids the problem of existence of casting stress in the bridge in a model taking and machining manner, meanwhile, the production speedis increased and the machining cost is reduced by a plastic fusion technology.

Owner:上海欧叶齿科技术有限公司

plaster removal device

The invention provides a gypsum removal device, which includes a base, a placing platform is arranged on the base, a fixing device is arranged on the placing platform, a bracket is arranged outside the placing platform, and a gypsum drill is arranged on the bracket. The gypsum drill is installed on the bracket through a telescopic cylinder, and the rear end of the drill bit of the gypsum drill is provided with an expansion mechanism, and the gypsum drill is driven into the gypsum to guide the expansion mechanism into the gypsum. The gypsum drill on the bracket is used to drill holes in the gypsum to destroy its original structure, and the expansion mechanism at the back of the drill bit is used to expand the gypsum from the inside to break the gypsum and improve the efficiency of gypsum removal, and through the support frame under the base The height adjustment makes the base inclined to the ground, making it suitable for various use situations.

Owner:WUHU RUIJIN MEDICAL EQUIP

Invisible correction method for treating class 2 and class 3 malocclusion by using occlusion repositioning device

The invention discloses an invisible correction method for treating class 2 and class 3 malocclusion by using an occlusion repositioning device, which comprises the following steps: respectively fixing the occlusion repositioning device on the mandibular or maxillary posterior tooth area on both sides, taking a maxillary and mandibular full-mouth model, filling a plaster model, scanning, transmitting an obtained STL file to invisible correction design software, performing multi-step invisible correction design, finally forming an STL design file, outputting the STL design file to a 3D printer to print a female mold, and pressing a transparent high polymer material on the female mold to form the bracket-free invisible corrector. The design process of the invention comprises the following steps: firstly, fixing an occlusion repositioning device to a back tooth area, connecting the back tooth area as a whole, not designing movement, only correcting an anterior tooth area, correcting the back tooth area, and finally finely adjusting the positions of upper and lower jaw teeth, thereby finishing orthodontic treatment of class 2 and class 3 malocclusion.

Owner:万善军

Homogeneous denture material and patternless manufacturing process

ActiveCN106074183AImprove mechanical propertiesImprove toughnessImpression capsDentistry preparationsPlasticizerAcrylic resin

The invention belongs to the technical field of denture preparation and particularly relates to a homogeneous denture material and a patternless manufacturing process. The material is mainly prepared from the following components in parts by weight: 100 to 120 parts of special water for a dental department, 95 to 105 parts of dental base acrylic resin powder, 0.8 to 2 parts of binding agent and 0.5 to 0.8 part of plasticizer. The patternless manufacturing process of the homogeneous denture material comprises the following steps: firstly, weighing all the components according to the weight parts; secondly, uniformly mixing all the components, then filling an injection pipe with a mixture, injecting the mixture into a plaster model with a denture female die cavity at a certain pressure by using a special injection molding machine; performing heat treatment under the condition that the temperature is 90 to 150DEG C and the pressure is 1 to 20MPa, and cooling to obtain a finished product. The denture material provided by the invention has the properties of high toughness and mechanical strength, good bacteria resistance, and the like.

Owner:珠海新茂义齿科技有限公司

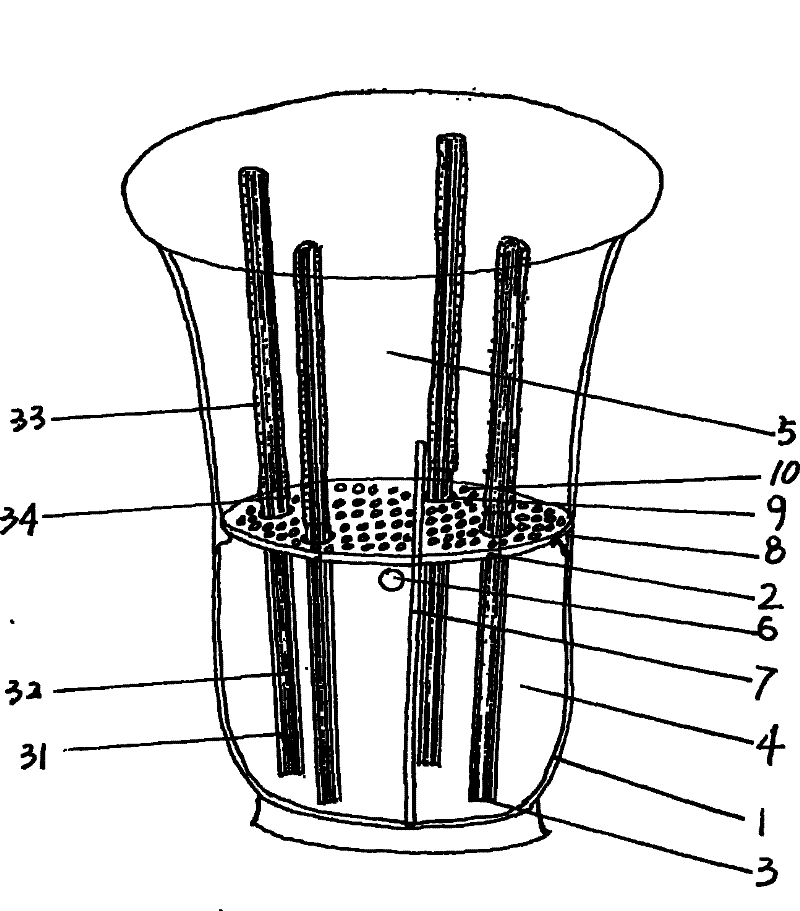

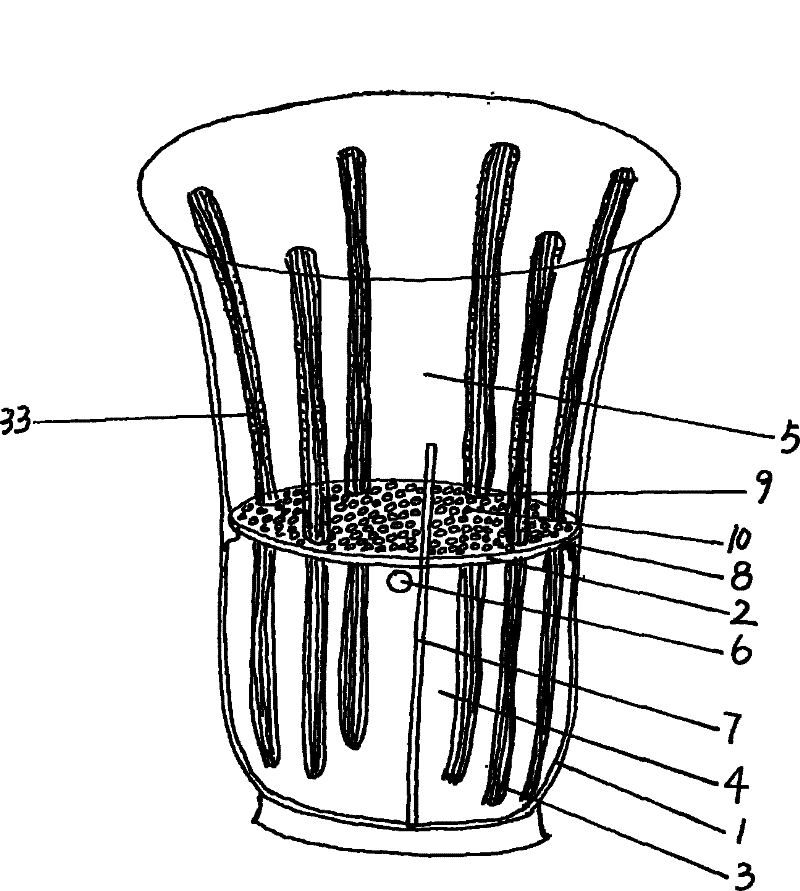

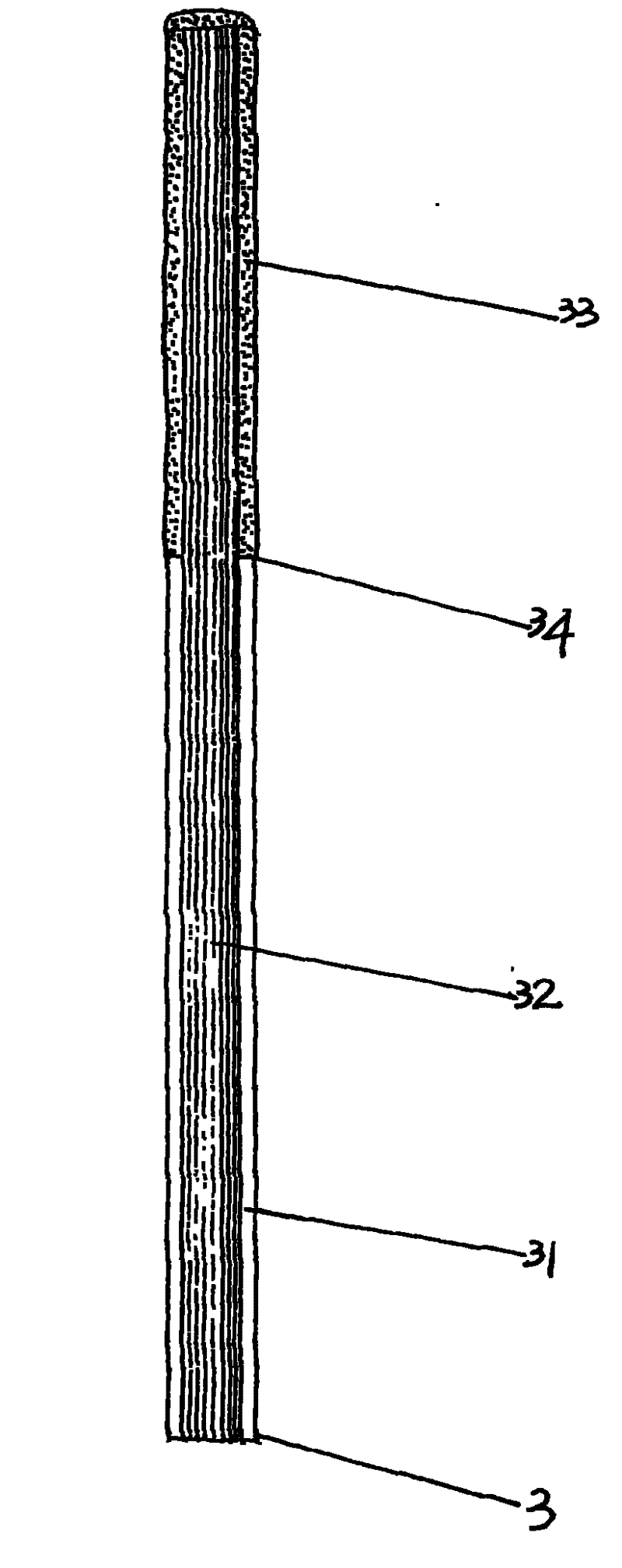

A water seepage flowerpot made of water seepage parts

InactiveCN102257929AEasy to observeMeet moisture needsSelf-acting watering devicesReceptacle cultivationYarnGlass fiber

The present invention is a water seepage flower pot made of water seepage parts, which is characterized in that a platen (2) is arranged at about half of the height inside the flower pot body (1) so that it is divided into two layers, and the upper layer is the belly of the flower pot ( 5) The lower layer is the water storage bin (4), and the water seepage parts (3) are inserted into several eyelets (9) provided on the top of the table (2), and are provided with sieve-shaped eyelets (10), and the upper opening of the water storage bin (4) It is equipped with irrigation air holes (6) and water level observation tubes (7), wherein the water seepage part (3) is penetrated by glass fiber filaments, yarns, cotton slivers, and flexible moisture guides (32) through a tube (31), and the tube Above the head (34), the belly section of the moisture guide flowerpot is sealed with a plaster casting layer (33). The water seepage flower pot with flexible water seepage parts attached inside can directly attach the flexible water seepage parts to the inner wall of the flower pot, and the top of the platen is sealed with a gypsum casting layer. It solves the problems of gypsum soaked in water and soaked by water, ceramic carbon mixed with calcium water shower stone, etc., which have poor water seepage performance and gradually fade away. The water seepage performance is good, balanced and long-lasting, and it is a new technology for natural water seepage flowers.

Owner:易美春

Plaster mould for ceramic slip casting and manufacturing method of plaster mould

ActiveCN103360012AHigh strengthImprove corrosion resistanceCeramic shaping apparatusBreaking strengthCompressive resistance

The invention provides a plaster mould for ceramic slip casting and a manufacturing method of the plaster mould. The plaster mould comprises the following materials: porous asphalt carbon and plaster slurry, wherein the plaster slurry is formed by dissolving plaster powder in water; the weight percentage of the porous asphalt carbon to the plaster powder is 1:(0.8-3). The invention further provides a manufacturing method of the plaster mould. The 2h-wet breaking strength, the 2h-wet comprehensive strength and the water absorption of the plaster mould obtained by the manufacturing method disclosed by the invention are obviously improved. Meanwhile, the plaster mould manufactured by the manufacturing method disclosed by the invention is excellent in corrosion resistance and abrasion resistance.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com