Preparation method of micro-welding mould quick used plaster casting mold

A gypsum and precision casting technology, used in clay preparation devices, chemical instruments and methods, manufacturing tools, etc., can solve the problem that it cannot be used for casting small parts with one-time forming, smooth surface and dimensional accuracy, and gypsum casting cannot meet the requirements of micro-investment molds. The requirements of precision casting, etc., to achieve the effect of prolonging the solidification time, small crystal size, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

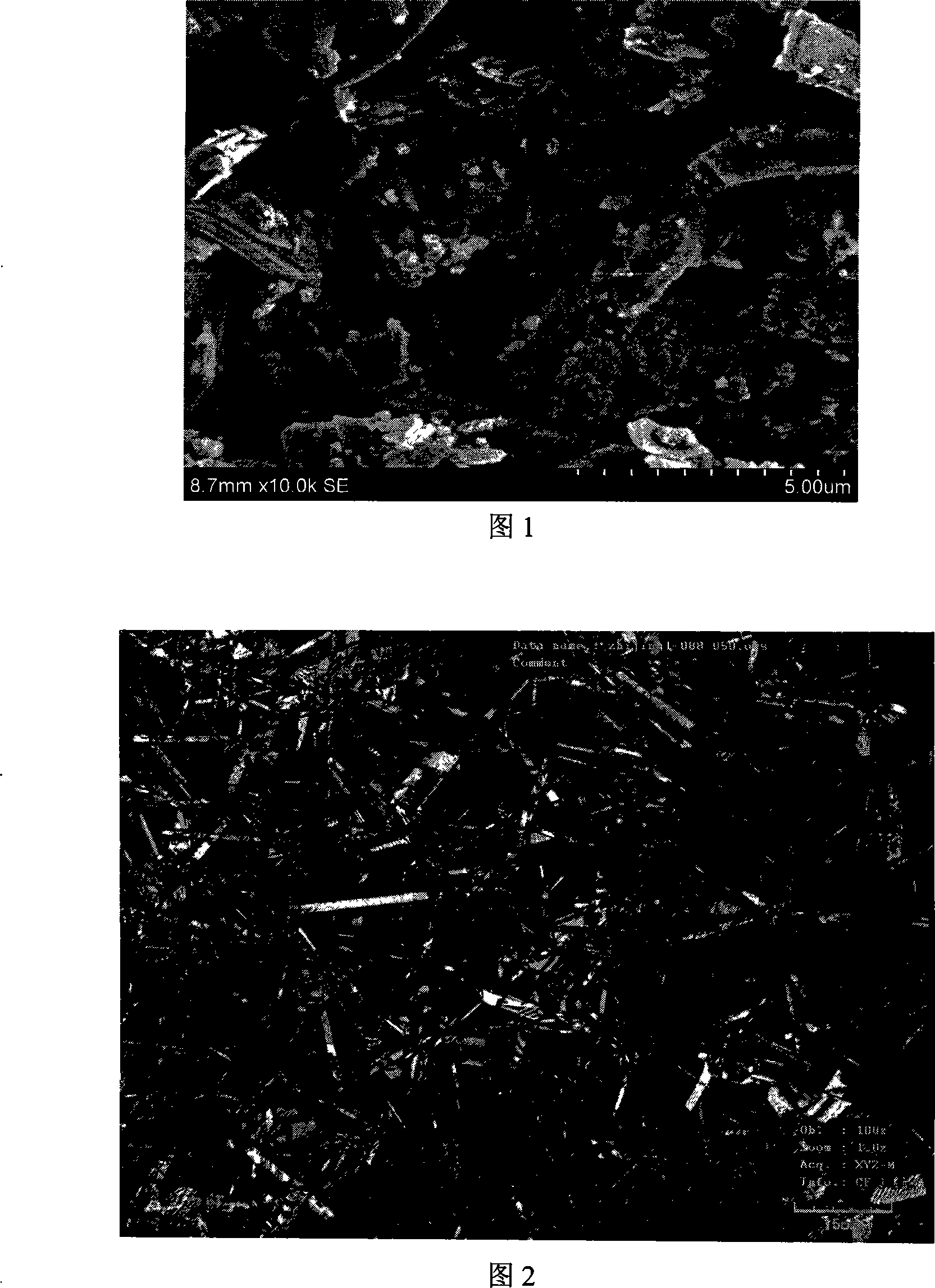

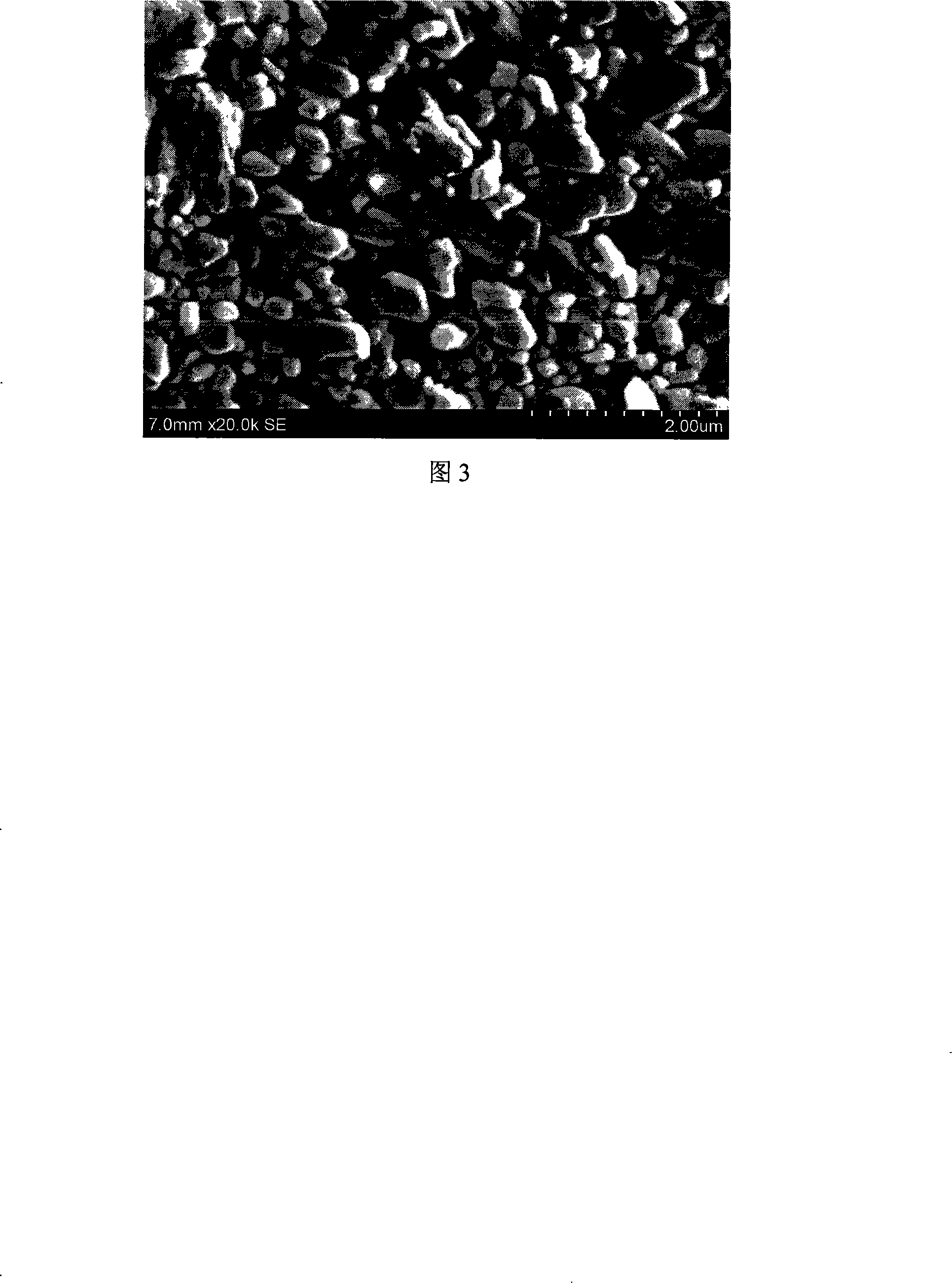

[0008] Specific embodiment one: In this embodiment, the gypsum casting mold for micro-investment casting is carried out according to the following steps: 1. Mix α or β hemihydraulic gypsum with a particle size of less than 200 meshes and deionized water at a mass ratio of 1:36 to 42 Stir for 10-20s, then stir for 15-40s under vacuum; 2. Inject the gypsum slurry mixed in step 1 into an impermeable model for ultrasonic force field action; 3. After stopping the ultrasonic force field, in air atmosphere, room temperature Place it for at least 48 hours under the same conditions to obtain the gypsum casting mold for micro-investment casting; wherein in step 2, the ultrasonic force field is introduced from the lower part of the slurry, the time for the ultrasonic force field to act is 4 to 10 minutes, and the introduction power of the ultrasonic force field is 50 ~500W, the action frequency of the ultrasonic force field is 20~100KHz.

[0009] At present, the preparation method of gyp...

specific Embodiment approach 2

[0016] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the temperature of α or β hemihydraulic gypsum in step 1 is 18-25°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the temperature of the deionized water in Step 1 is 18-25°C. Other steps and parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com