Hollow floor system construction method adopting plaster mold boxes and hollow floor system construction

A technology of gypsum mold box and hollow floor cover, which is applied in the direction of building structure, floor slab, building components, etc., can solve the problems of high construction cost and more concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

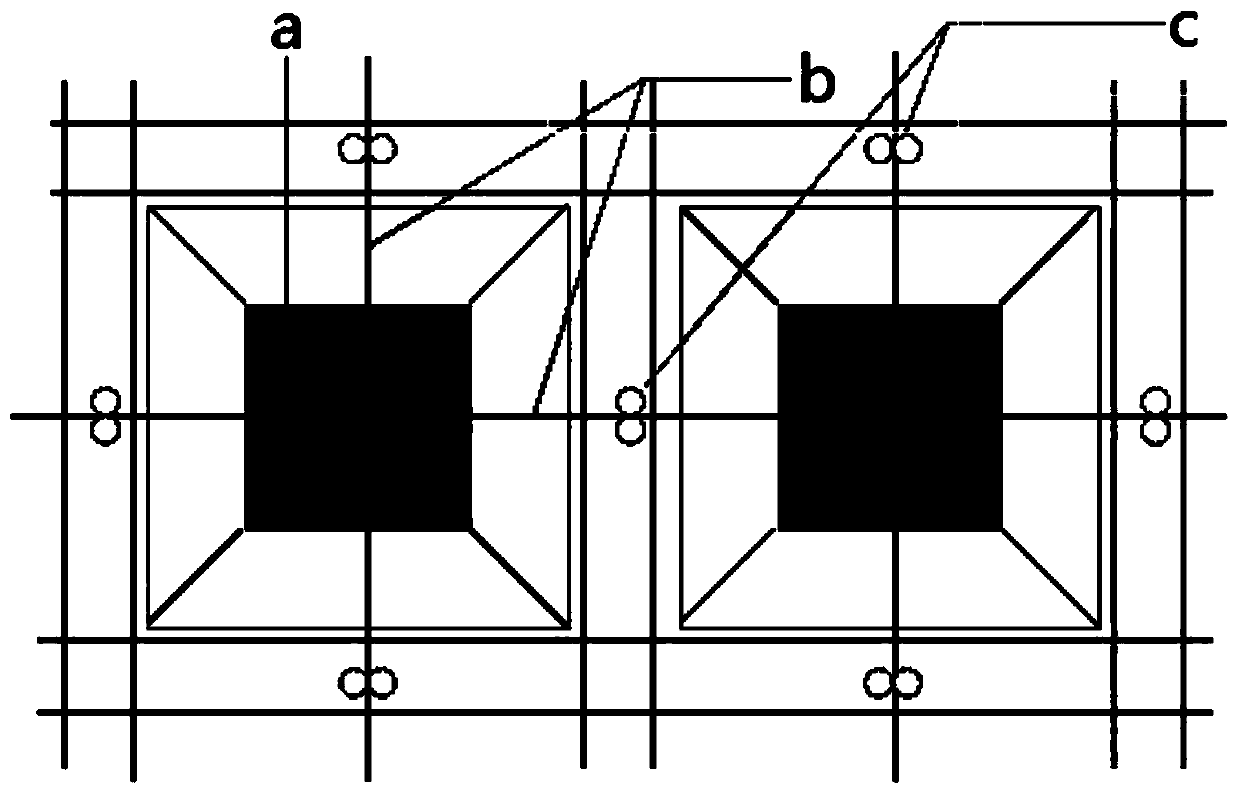

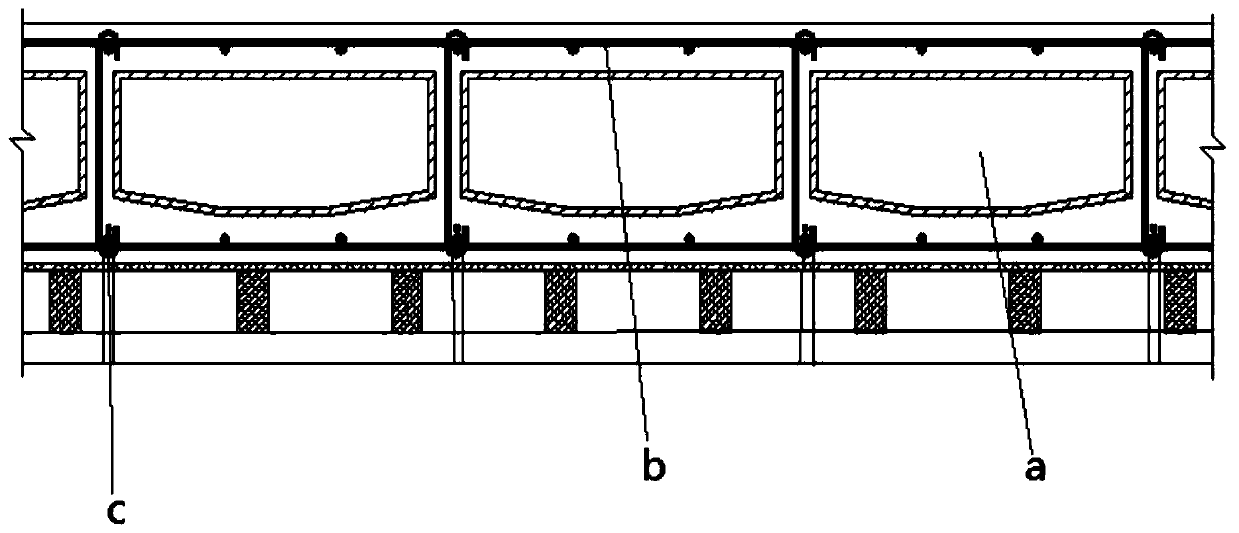

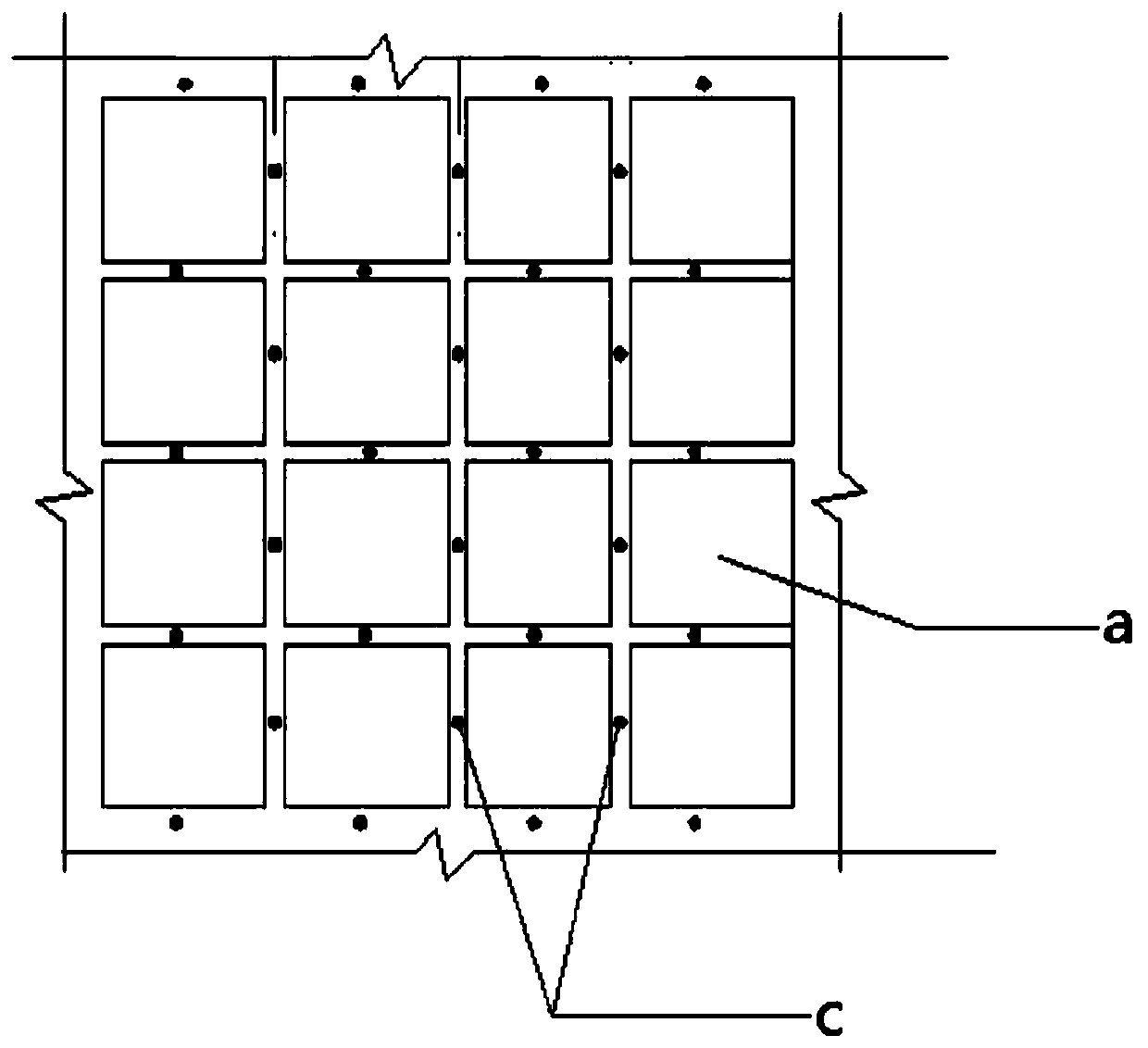

[0042] see Figure 1 to Figure 4 , the application provides a hollow floor construction method using a gypsum mold box, comprising the following steps:

[0043] S1, construction preparation, determine the specifications, quantity and reserved embedding of plaster mold boxes;

[0044] S2, setting up a support and laying a formwork on the support;

[0045] S3, draw rib beam position lines, gypsum mold box control lines, steel bar distribution lines and pre-embedded reserved position lines for water and electricity installation pipelines on the formwork;

[0046] S4, first bind the rib beam reinforcement according to the rib beam position line, and then bind the floor reinforcement according to the reinforcement distribution line, and bind the short-span reinforcement first, and then bind the long-span reinforcement;

[0047] S5, set several pads (for protecting the steel bars) at each control line of the gypsum mold box on the bottom plate reinforcement, and set the gypsum mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com