Artificial tooth and preparation method thereof

A technology of dentures and press molding, which is applied in the field of dentures, can solve the problems of reduced strength of metal inner crowns or full metal crowns, overheating of denture metal inner crowns, waste of casting head materials, etc., so as to improve the edge fit of dentures, improve the quality of dentures, The effect of energy saving and environmental protection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

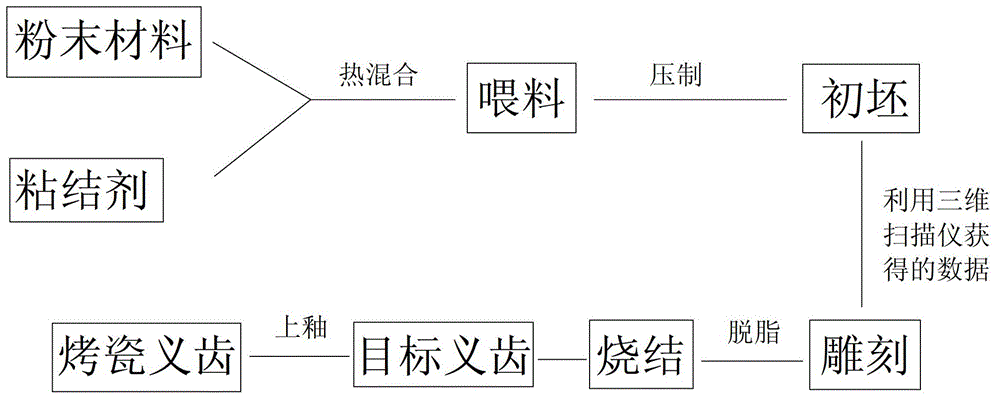

[0029] A method of manufacturing dentures such as figure 1 shown, including the following steps:

[0030] 1) Mix metal powder and binder into a homogeneous feed;

[0031] The metal powder is titanium powder with a particle size of 50 nanometers to 180 microns; the weight ratio of the titanium powder to the binder is 98:2, and the binder is composed of the following components by weight: edible peanut oil (Oil ): Polyethylene (PP): Polyethylene (PE): Stearic acid (SA): Polyoxymethylene (POM) = 10:13:0.5:0.8:1, put into the mixer, heat mix evenly, mixing temperature The feed is prepared at 100-220°C. Then adopt a 100-180 ton powder injection molding machine to make the above-mentioned feed material into a preform.

[0032] 2) The dentist uses a three-dimensional scanner (such as the 3SHAPE-D800 dental special scanner made in the United States) to scan the crown in the oral cavity to obtain the shape data of the target denture, and then uses dental software (such as the German...

Embodiment 2

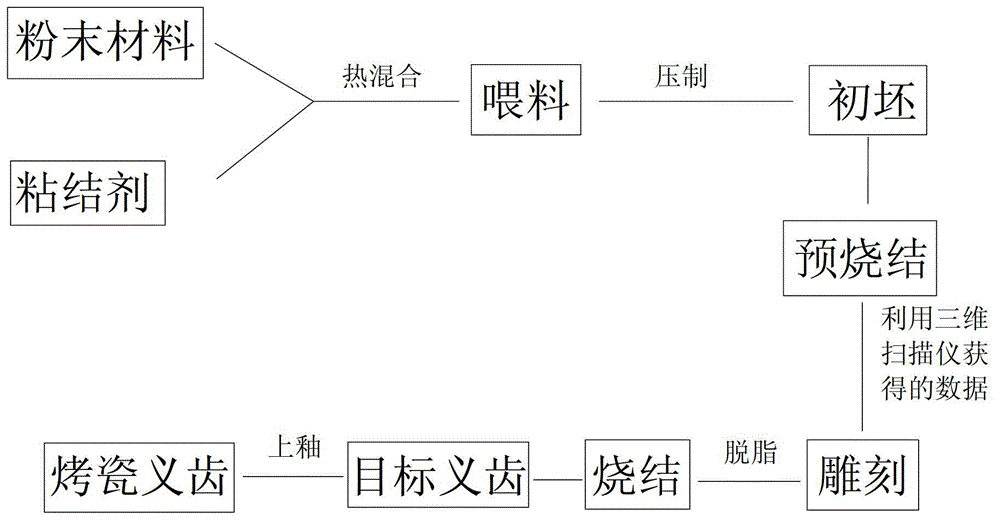

[0037] A method of manufacturing dentures, comprising the steps of:

[0038] 1) Mix metal powder and binder into a homogeneous feed;

[0039] The metal powder is cobalt chromium tungsten powder with a particle size of 50 nanometers to 180 microns; the weight ratio of the cobalt chromium tungsten powder to the binder is 67:33, and the binder is composed of the following components by weight ratio: High-density polyethylene (HDPE): polystyrene (PS): wax (PW): edible peanut oil (Oil): polybutadiene (PB): ethylene-vinyl acetate copolymer (EVA): dioctyl phthalate Ester (DOP) = 19:33:55:20:55:33:44; put the above metal powder and binder into a mixer and heat mix at a mixing temperature of 100-220°C to prepare the feed. Put the feed material prepared above into the mold of a two-way hydraulic press (such as the YS40-80 two-way hydraulic press produced by Foshan Dayongxing Hydraulic Machinery Co., Ltd.) for dry pressing. After the shape and structure of the feed are formed in the mol...

Embodiment 3

[0045] A method of manufacturing dentures, comprising the steps of:

[0046] 1) Mix metal powder and binder into a homogeneous feed;

[0047] The metal powder is nickel-chromium-tungsten powder with a particle size of 50 nanometers to 800 microns; the weight ratio of the nickel-chromium-tungsten powder to the binder is 80:20, and the binder is composed of the following components by weight: High-density polyethylene (HDPE): polystyrene (PS): wax (PW): edible peanut oil (Oil): polybutadiene (PB): ethylene-vinyl acetate copolymer (EVA): dioctyl phthalate Ester (DOP)=1:1:20:10:33:2:22; put the above metal powder and binder into a mixer and heat mix them at a mixing temperature of 100-220°C to prepare the feed. Put the feed material prepared above into the mold of a two-way hydraulic press (such as the YS40-80 two-way hydraulic press produced by Foshan Dayongxing Hydraulic Machinery Co., Ltd.) for dry pressing. After the shape and structure of the feed are formed in the mold, It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com