Patents

Literature

98 results about "Lost-wax casting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lost-wax casting (also called "investment casting", "precision casting", or cire perdue which has been adopted into English from the French) is the process by which a duplicate metal sculpture (often silver, gold, brass or bronze) is cast from an original sculpture. Intricate works can be achieved by this method.

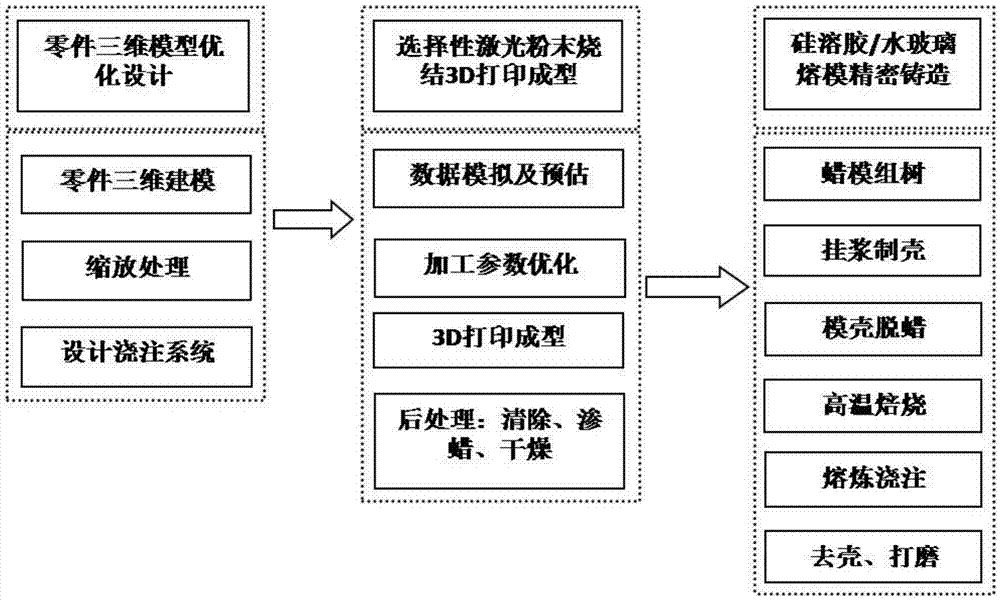

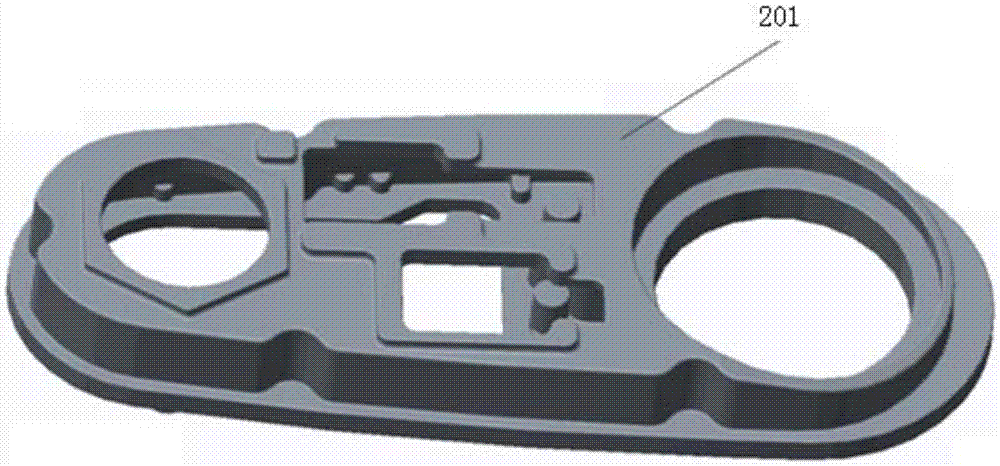

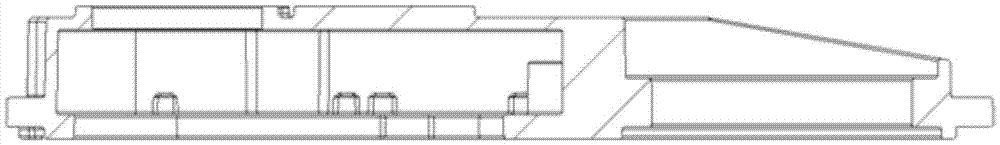

Precision lost wax casting technology based on selective laser powder sintering 3D printing

InactiveCN105436406AFast preparationCasting fastAdditive manufacturing apparatusFoundry mouldsInvestment castingOptimal design

The invention discloses a precision lost wax casting technology based on selective laser powder sintering 3D printing. The precision lost wax casting technology comprises the following steps that S101, a target part is subjected to optimal design of a CAD casting technology; S102, selective laser powder sintering 3D printing forming is carried out; and S103, silica sol / water glass precision investment casting is carried out. A wax mold of the part can be fast manufactured without molds, the metal part is fast manufactured, fast manufacturing of complex parts can be achieved, and integration, automation and fastness in the precision casting technology process can be achieved; and the development period of new products are greatly shortened, development cost is reduced, and the precision lost wax casting technology is especially suitable for production of single small-batch complex castings and trial-manufacturing of new products.

Owner:HUST WUXI RES INST +1

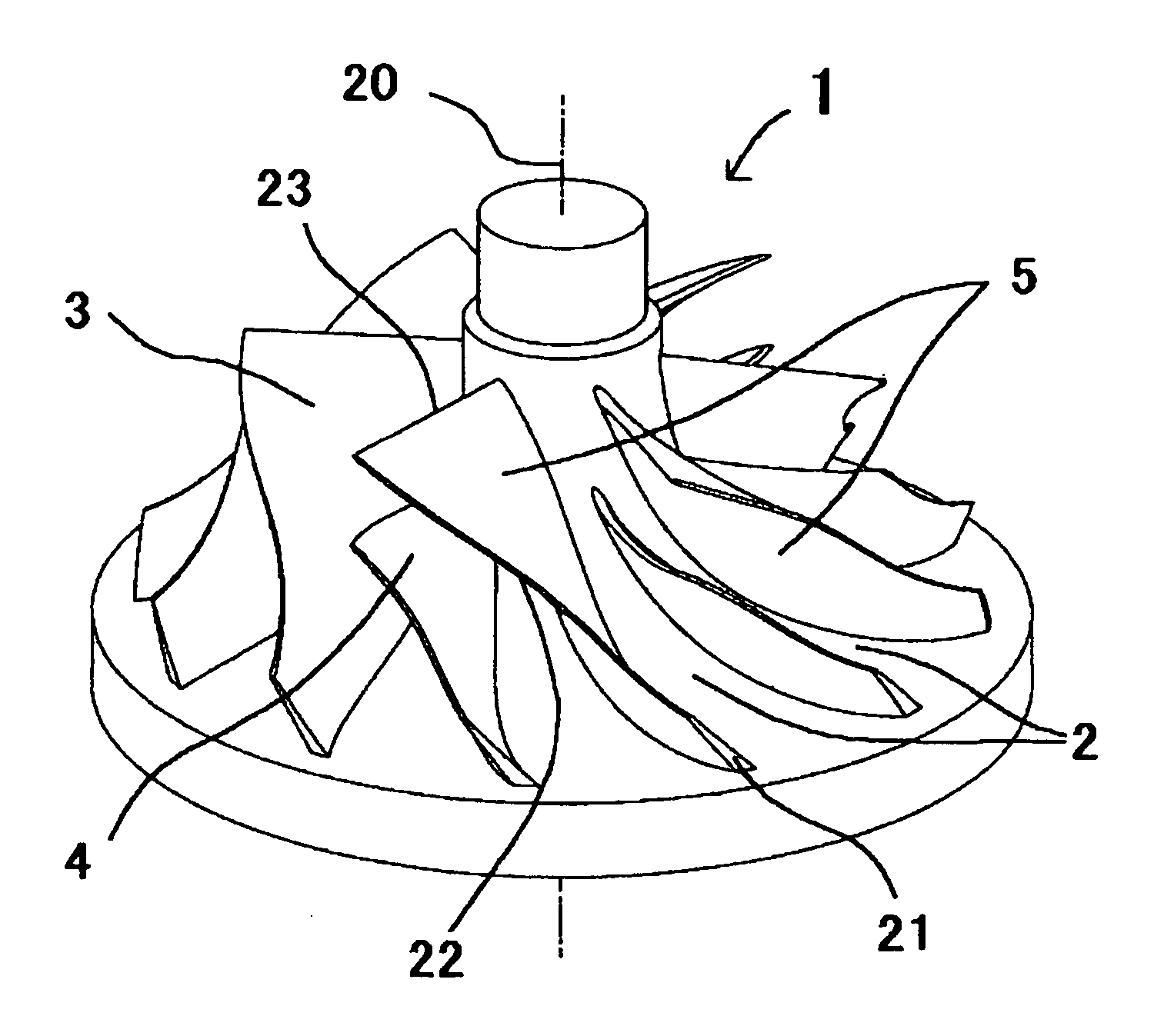

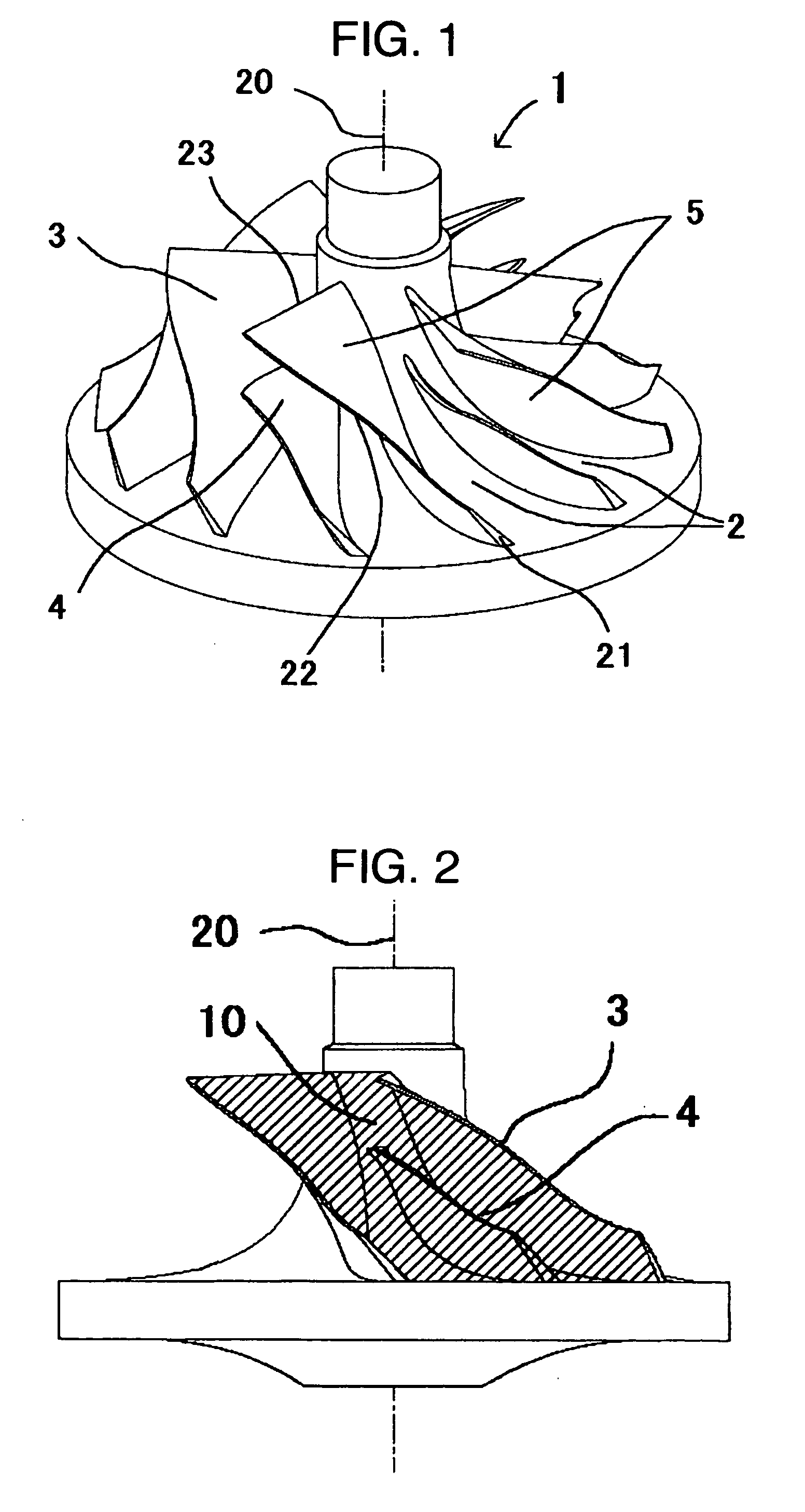

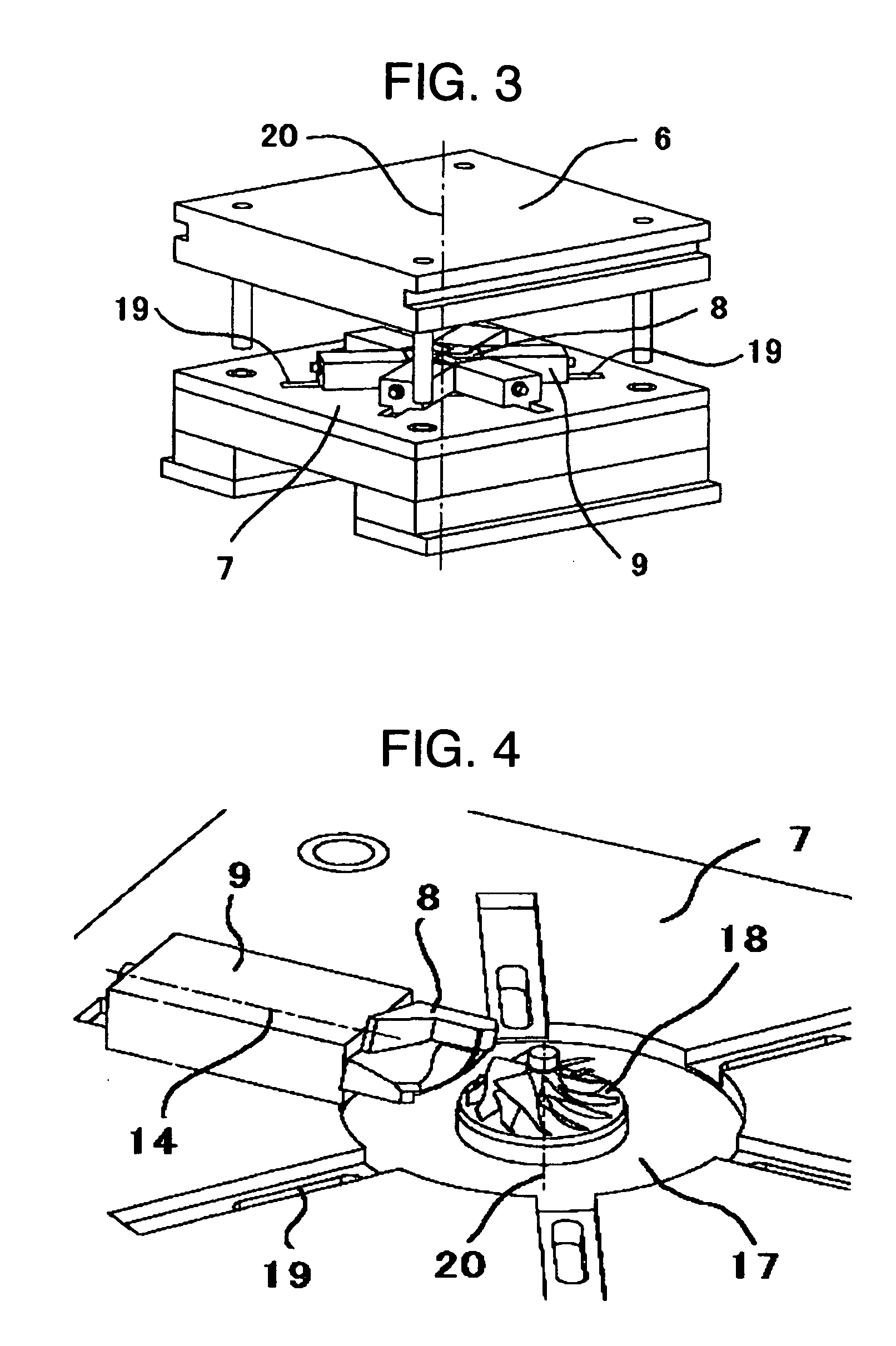

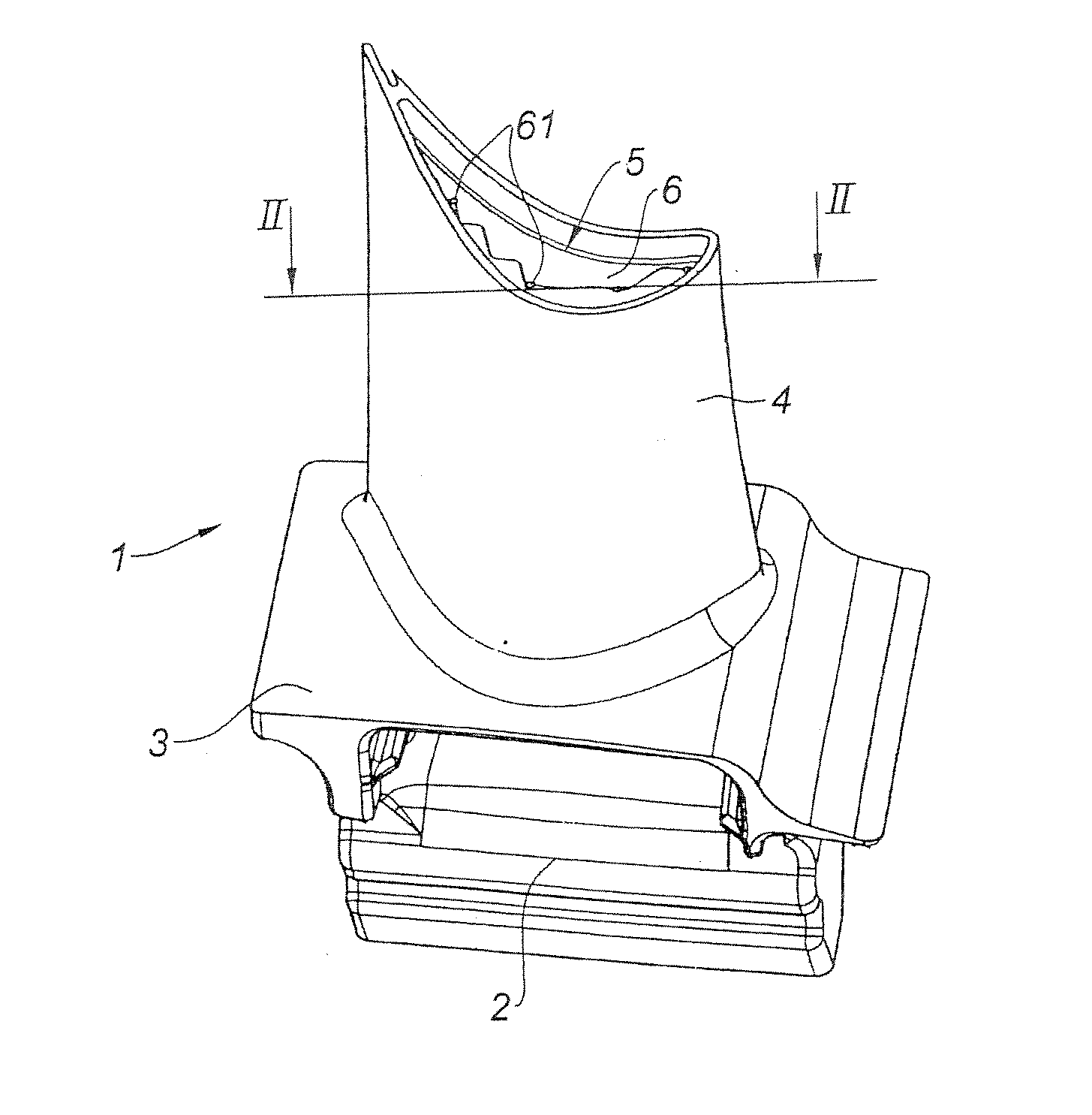

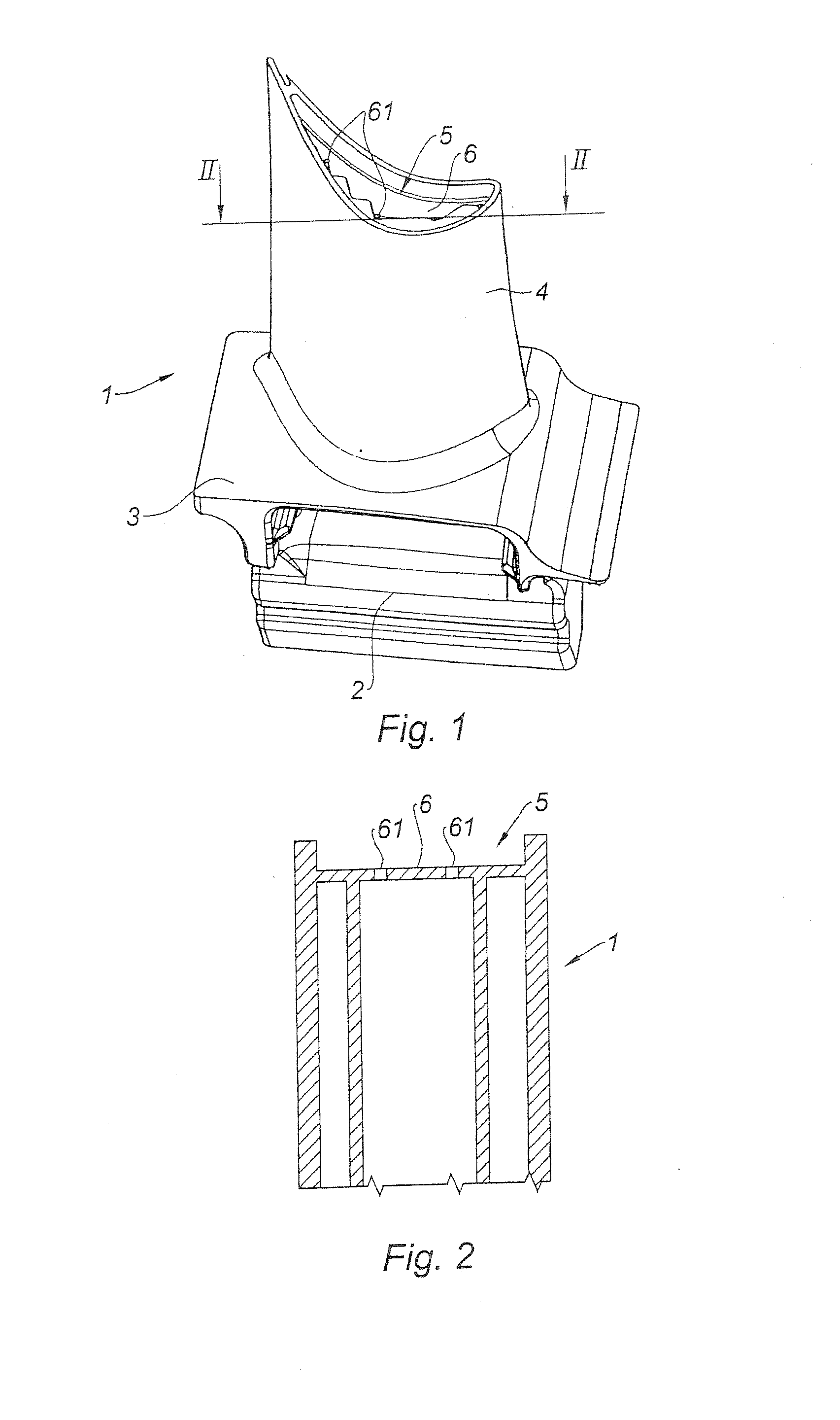

Impeller for supercharger and method of manufacturing the same

InactiveUS20060291996A1Improve aerodynamic performanceDifficult to obtainPump componentsBlade accessoriesImpellerRefractory

[Problems]To provide a lost-wax cast impeller for a supercharger having no parting line corresponding part on a hub surface and a blade surface in each space demarcated by pairs of long blades adjacent to each other and having excellent aerodynamic performance. [Means for Solving Problems]This method of manufacturing the impeller comprises a step for forming a lost form pattern formed in the substantially same shape as the impeller for the supercharger, a step for forming a mold by eliminating and removing the lost form pattern after the lost form pattern is coated with a refractory, and a step for pouring a molten metal in the mold for casting. In the step for molding the lost form pattern, a lost material is injection-molded in a space demarcated by radially arranging, toward a center shaft, a plurality of slide molds having short blade-shaped bottomed groove parts and space shapes between the pairs of long blades adjacent to each other, and the slide molds are released by moving in the radial direction of the center shaft while rotating. Thus, the parting line corresponding part is not present on any of the hub surface and the blade surface in the spaces demarcated by the pairs of long blades adjacent to each other.

Owner:HITACHI METALS PRECISION LTD +1

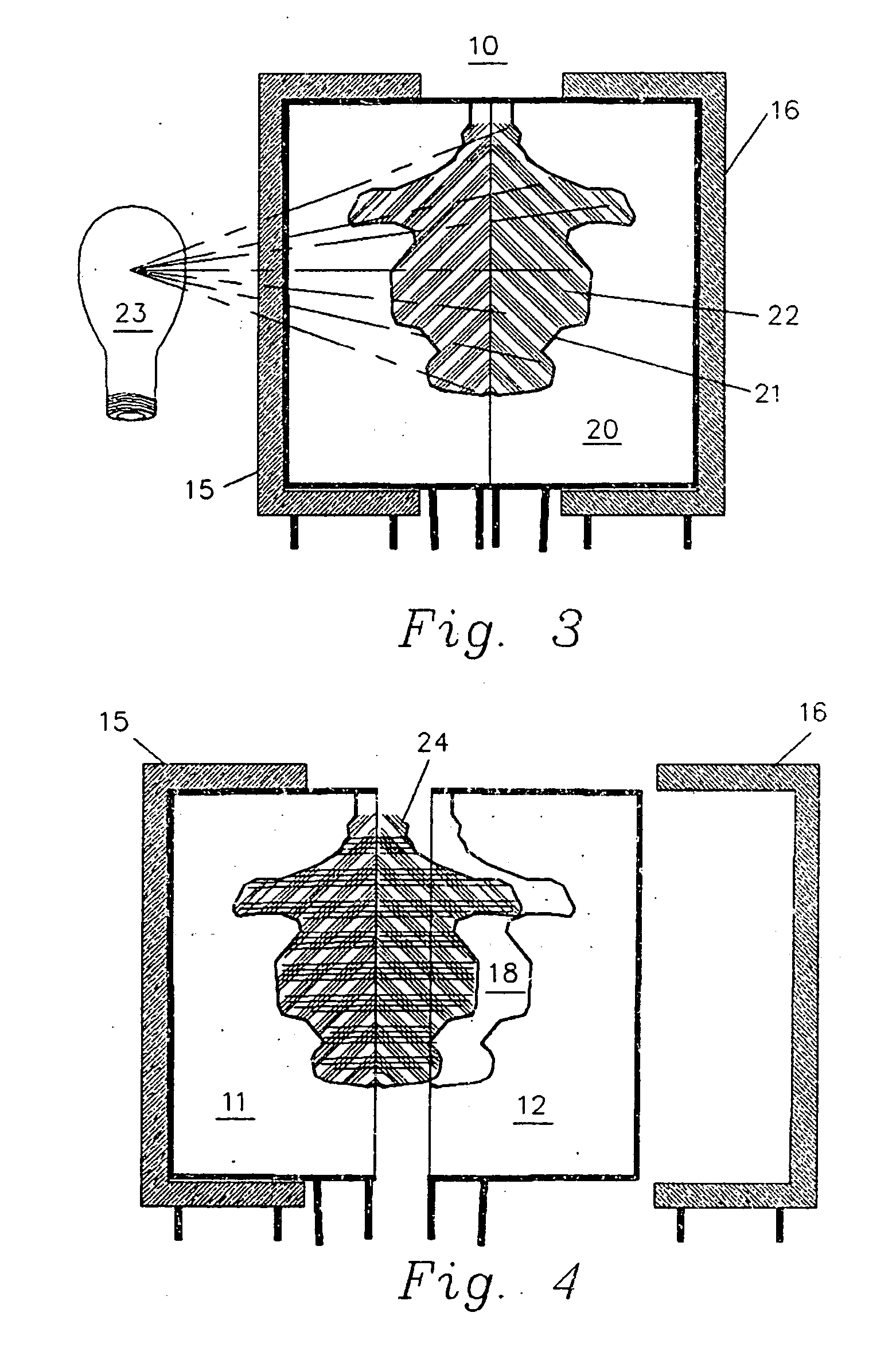

Method and apparatus for creating sacrificial patterns and cast parts

Owner:JOYNER VICTOR

Copolymer based powdered material for selective laser sintering and preparation method thereof

InactiveCN101319075AFormed parts with high strengthHigh dimensional accuracyVitrificationSelective laser sintering

The invention discloses a multipolymer base powder material used for SLS and a preparation method thereof. The multipolymer is a styrene-acrylonitrile (SAN) multipolymer. The preparation method comprises the following steps that: firstly, an SAN resin is subjected to deep cooling and crushing; secondly, the multipolymer powder with appropriate grain diameter and appropriate distribution of the grain diameter is selected by the sieve method; and finally, a certain proportion of the multipolymer powder, carbon soot and a flow aid are mixed evenly to produce the multipolymer base powder material. Because the SAN is an amorphous polymer, the vitrification temperature is low and the die shrinkage is small; therefore, the multipolymer base powder material has good sintering performance and high drip molding accuracy. Meanwhile, the SAN has appropriate melt viscosity and body intensity; therefore, the SLS die molding of the multipolymer base powder material also has high intensity. The multipolymer base powder material can be used to manufacture a wax pattern used for lost wax casting and a functional element meeting general requirements through SLS forming and appropriate post treatment.

Owner:武汉华科三维科技有限公司

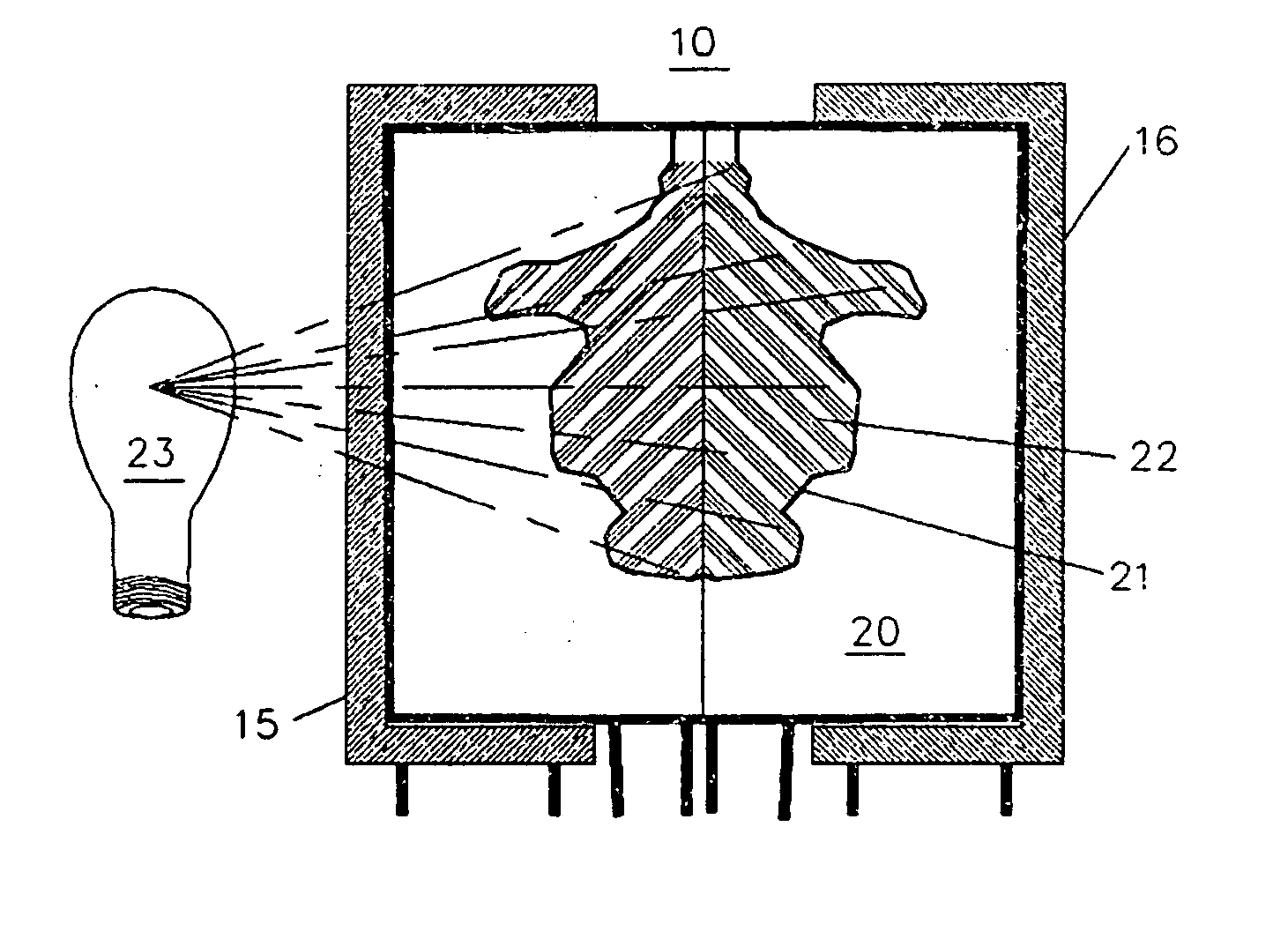

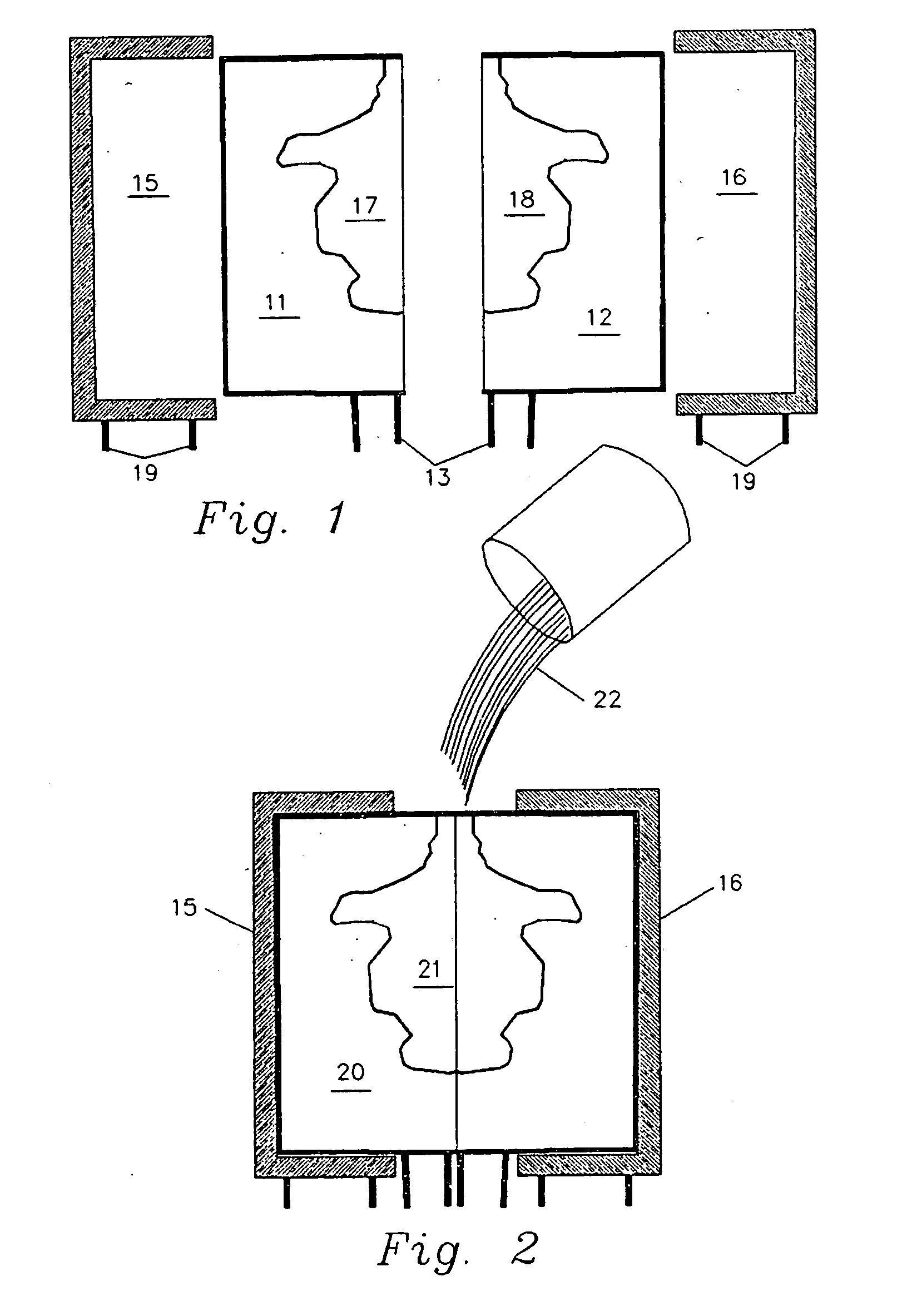

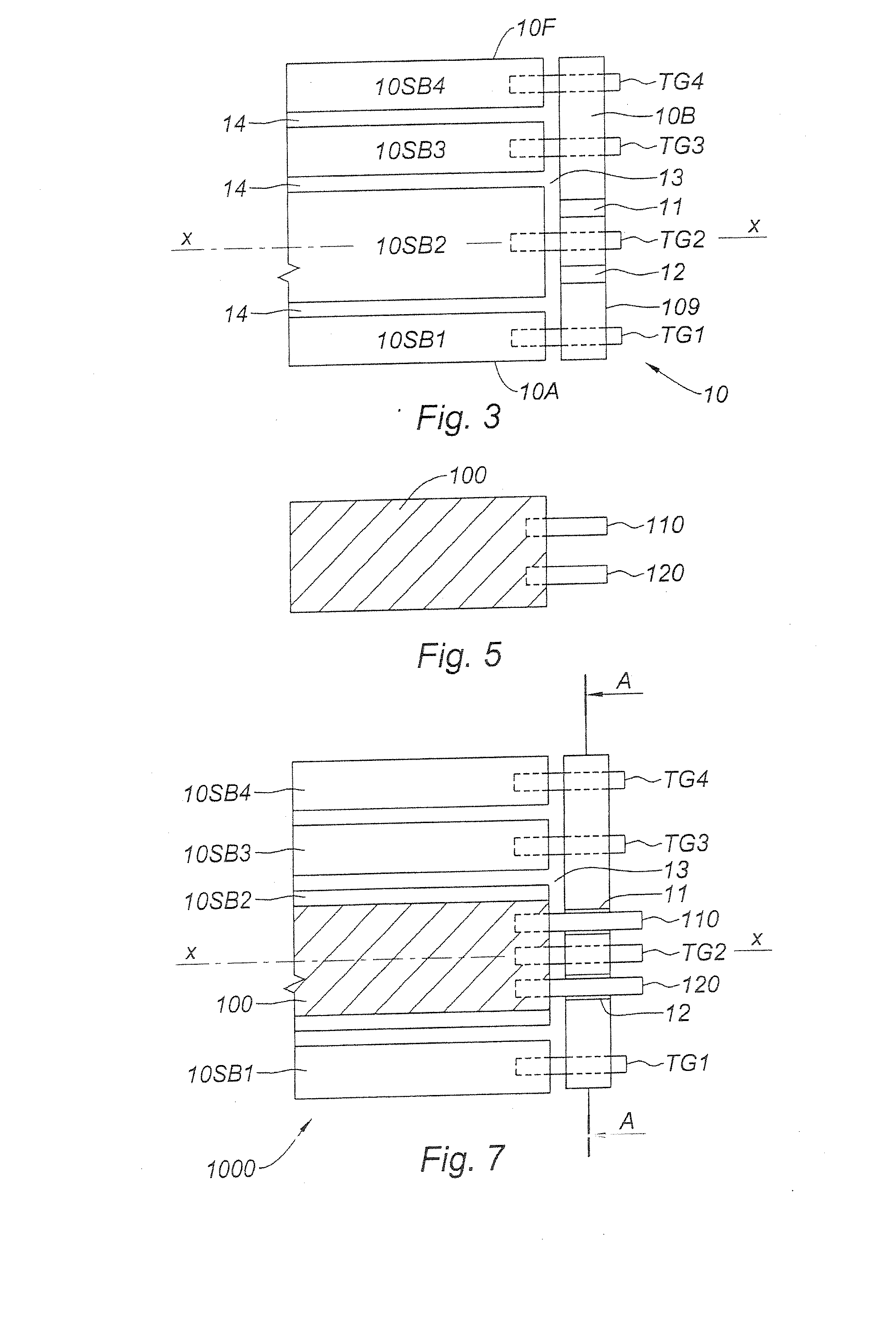

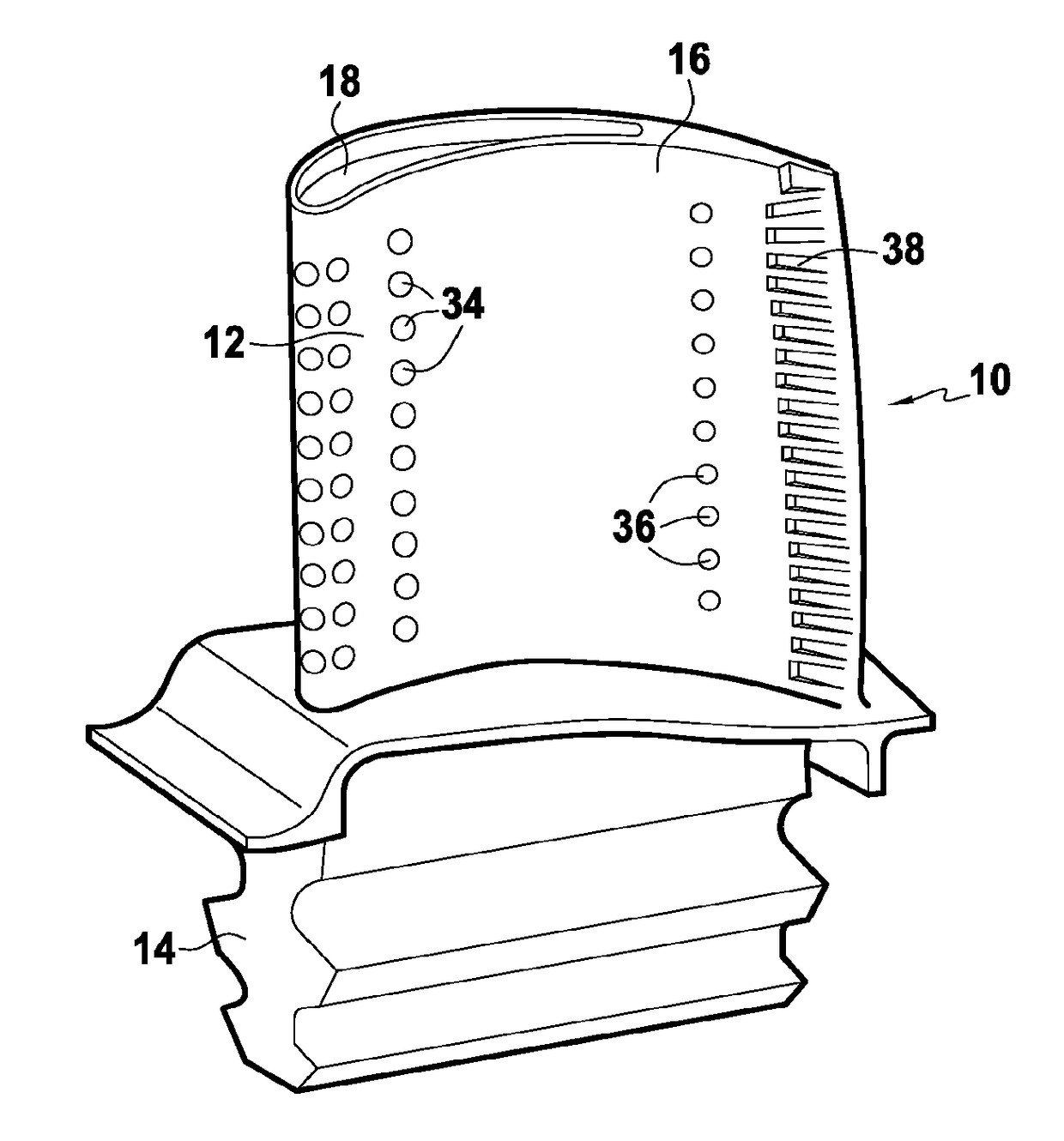

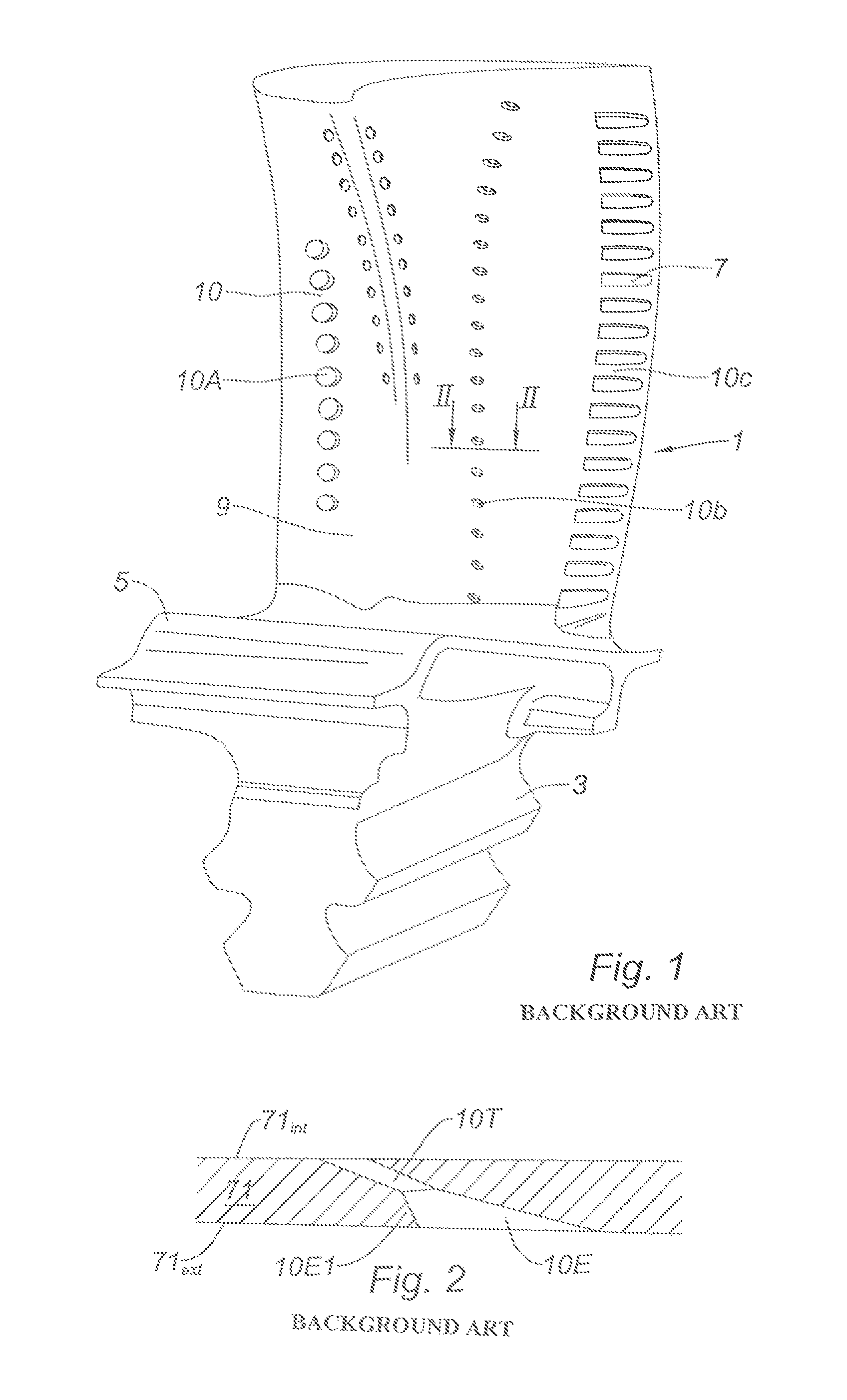

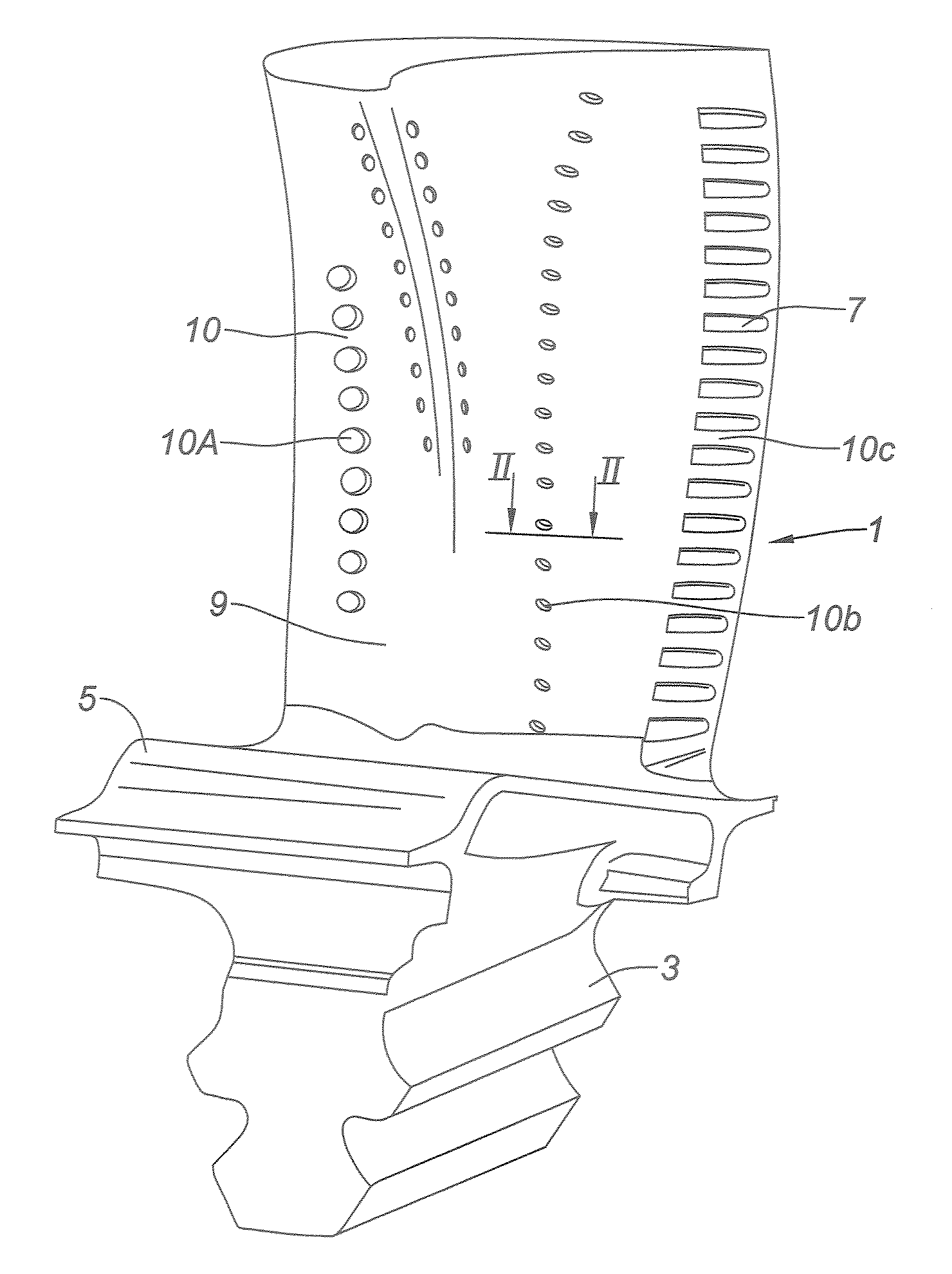

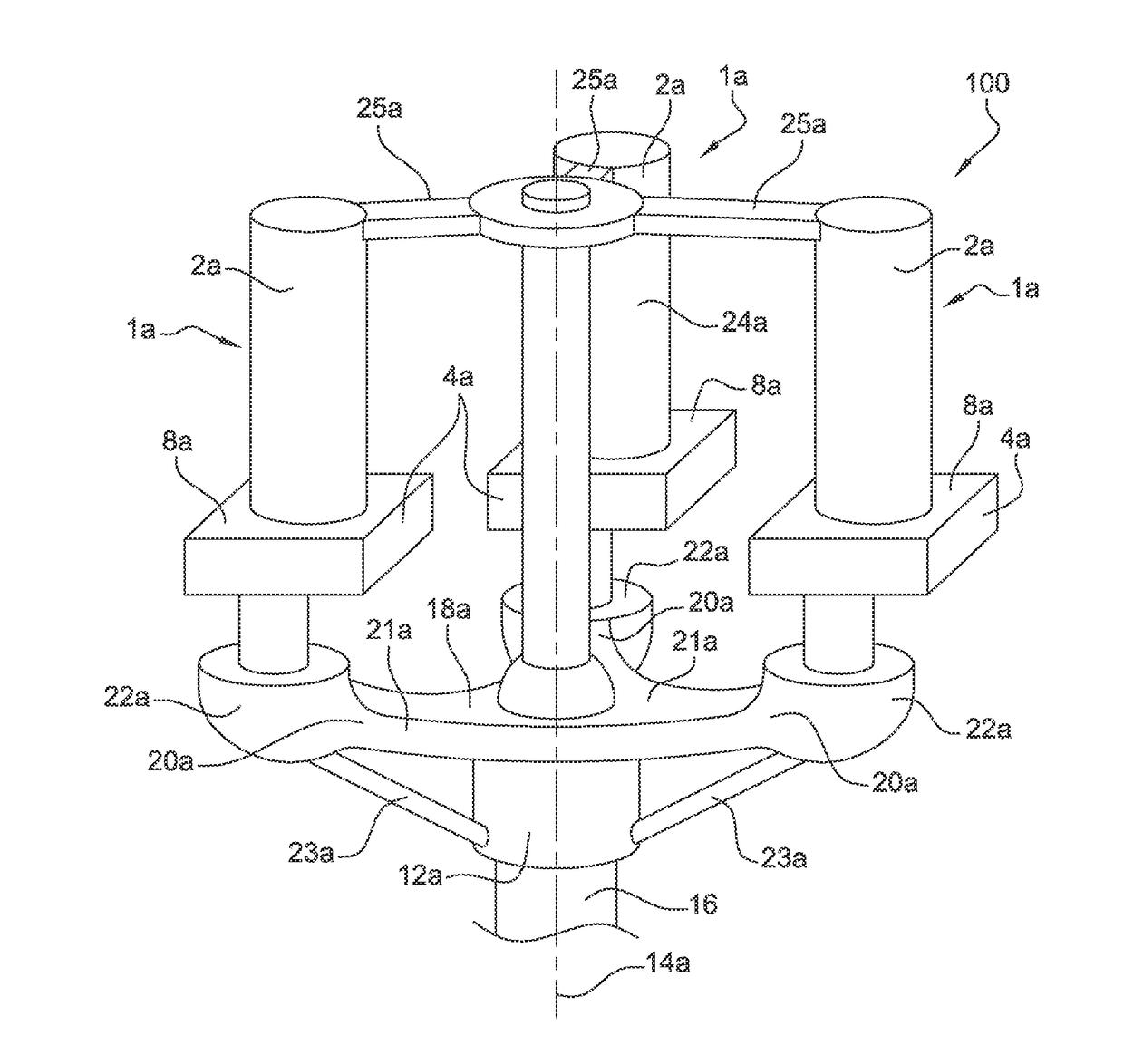

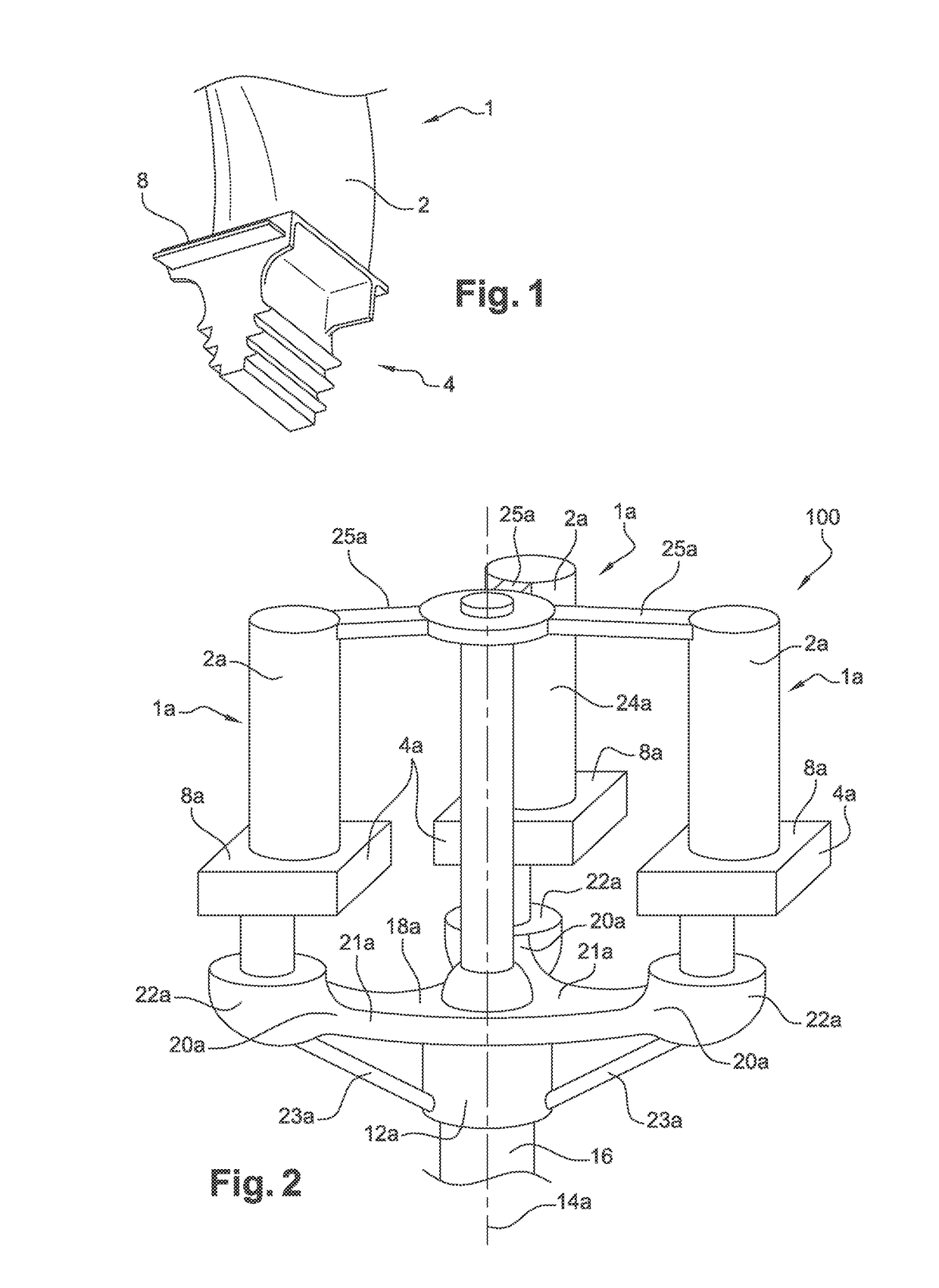

Core for turbomachine blades

ActiveUS20070025851A1The assembly position is accurateBlade accessoriesFoundry mouldsMechanical engineeringLost-wax casting

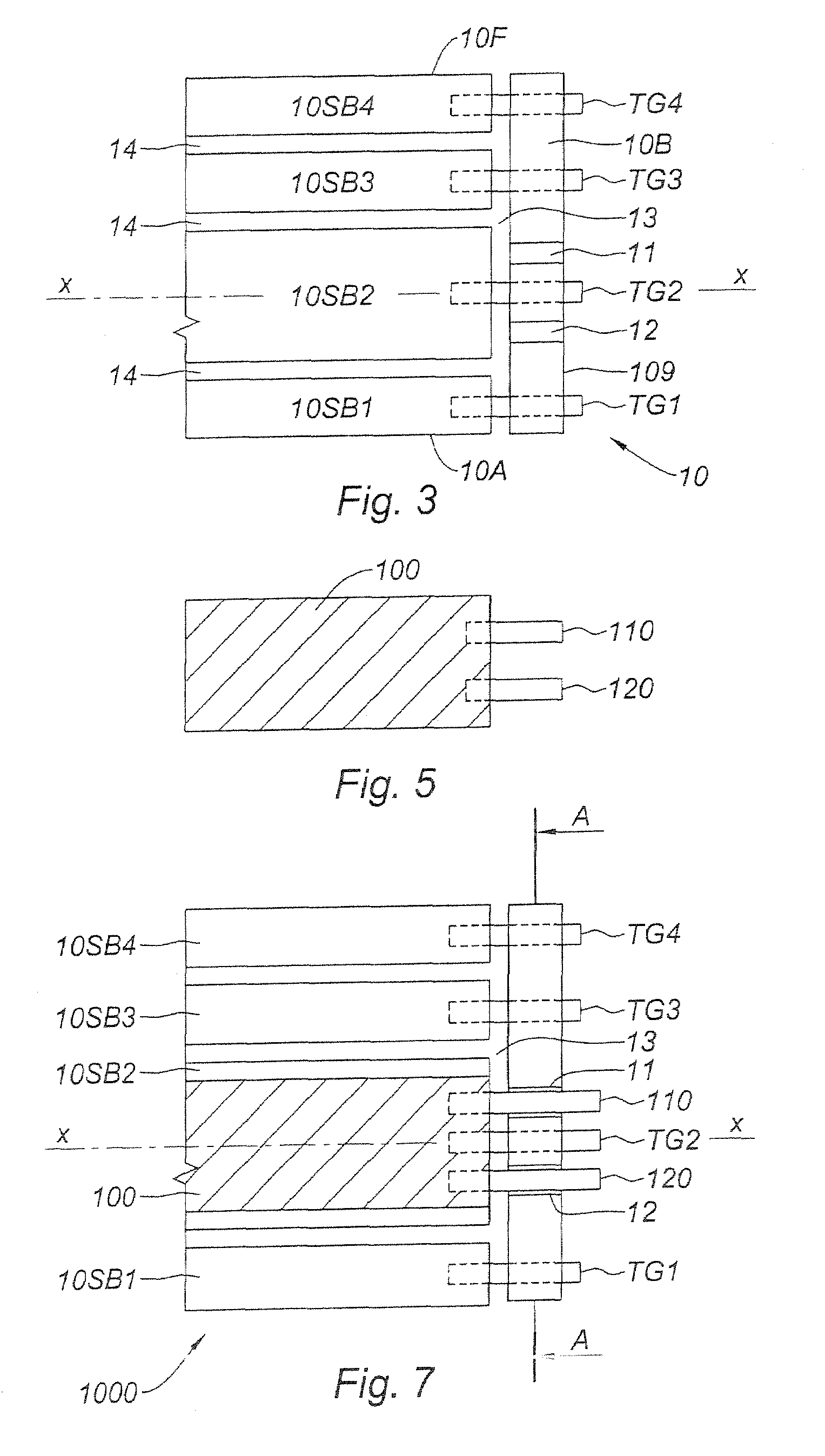

The present invention relates to a ceramic core used in the manufacture, by lost wax casting, of a turbomachine blade with cooling cavities and a squealer, comprising at least one main core, wherein the main core (10) comprises an element (10B) shaped so as to constitute the squealer and an element (10SB) shaped so as to constitute at least one cavity beneath the squealer, the two elements leaving between them a space (13) shaped so as to constitute, at least in part, the bottom wall of the squealer. In particular, the elements (10B and 10SB) are joined together by ceramic rods (TG).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

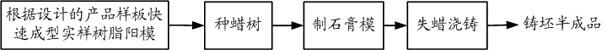

Simplified process method of lost wax casting

InactiveCN102248125ASimple processing methodSimple methodFoundry mouldsFoundry coresParaffin oilsProduct pattern

The invention discloses a simplified process method of lost wax casting, which comprises the following steps in sequence: wax tree planting, plaster mold preparation, and lost wax casting; before the wax tree planting step, the following steps are included: (1) directly molding a resin female mold by a rapid molding device, wherein the resin female mold comprises a mold cavity which has the same shape as the product to be prepared by the simplified process method of lost wax casting; (2) injecting a wax mold: melting paraffin and performing heat insulation, filling the resin female mold with the paraffin in a wax injector, cooling, and finishing to obtain a wax mold. The method of the invention omits a plurality of procedures for mold turnover, saves the cost, and prevents the problem that dimensions and styles deviates the initial design due to multiple male mould-female mold conversion; and the resin female mold is directly molded by the rapid molding device, and thus product pattern replacement is very flexible and rapid.

Owner:SHENZHEN INST OF TECH

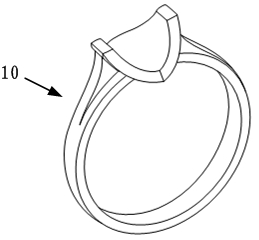

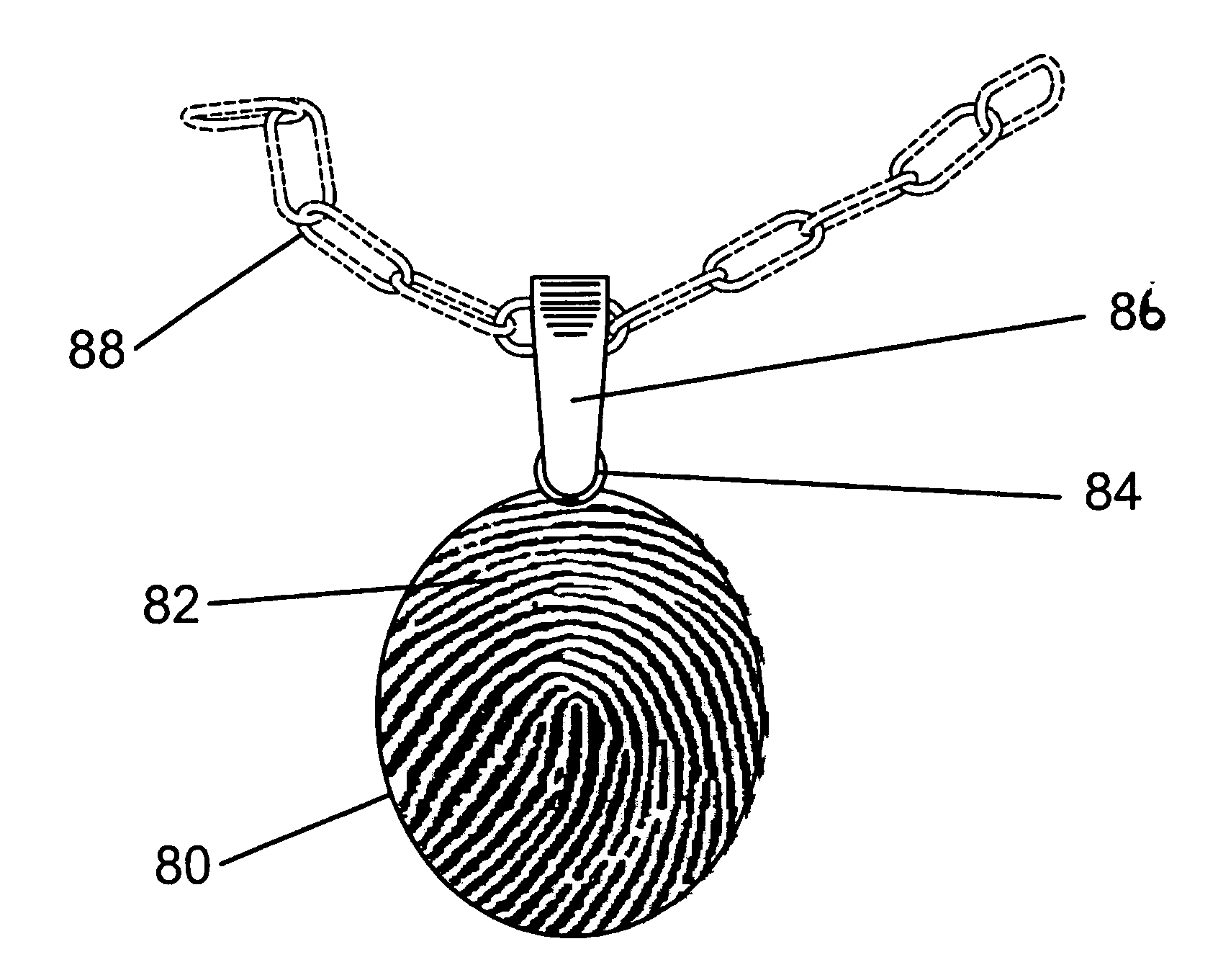

Article of jewelry and method of manufacture

A method and system for creating an article of jewelry that contains an anatomical image using a digital image of an anatomical body part such as a fingerprint, handprint, footprint, or the like to create a computer numeric controlled (CNC) software program that drives a machine for producing a wax model of the anatomical image. The wax model is used in a lost wax casting process to create a casting that is used in an article of jewelry. The present invention further provides an article of jewelry containing a novel bail assembly for attaching the article of jewelry to a chain or the like in an aesthetically pleasing manner that hides the attachment hole of the casting.

Owner:LEHMANN TODD P +1

CAD/CAM digital manufacturing method for bracket movable denture

ActiveCN109223218AQuality improvementReduce manual dependenceArtificial teethDenturesDigital manufacturing

Owner:邢浩

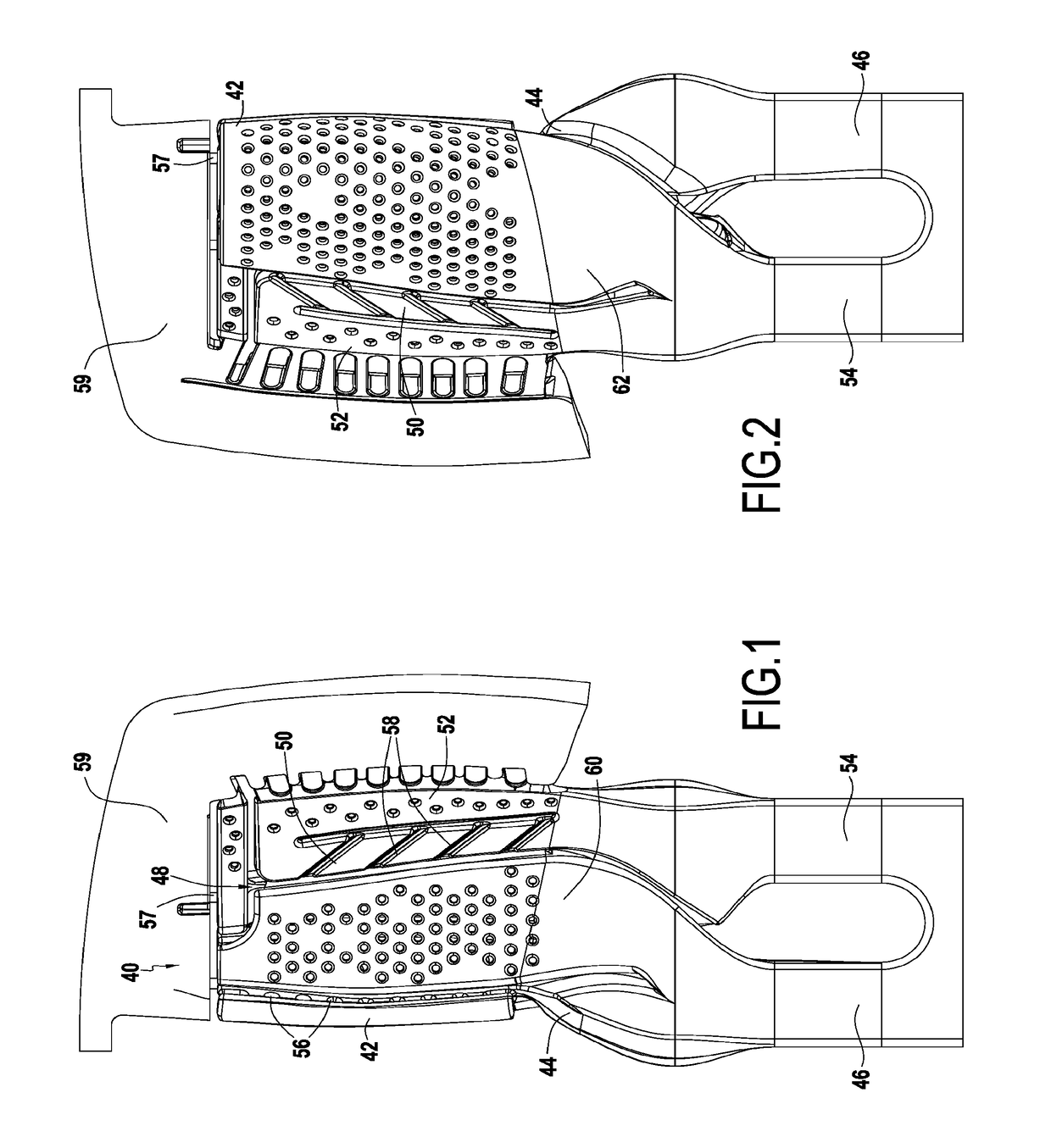

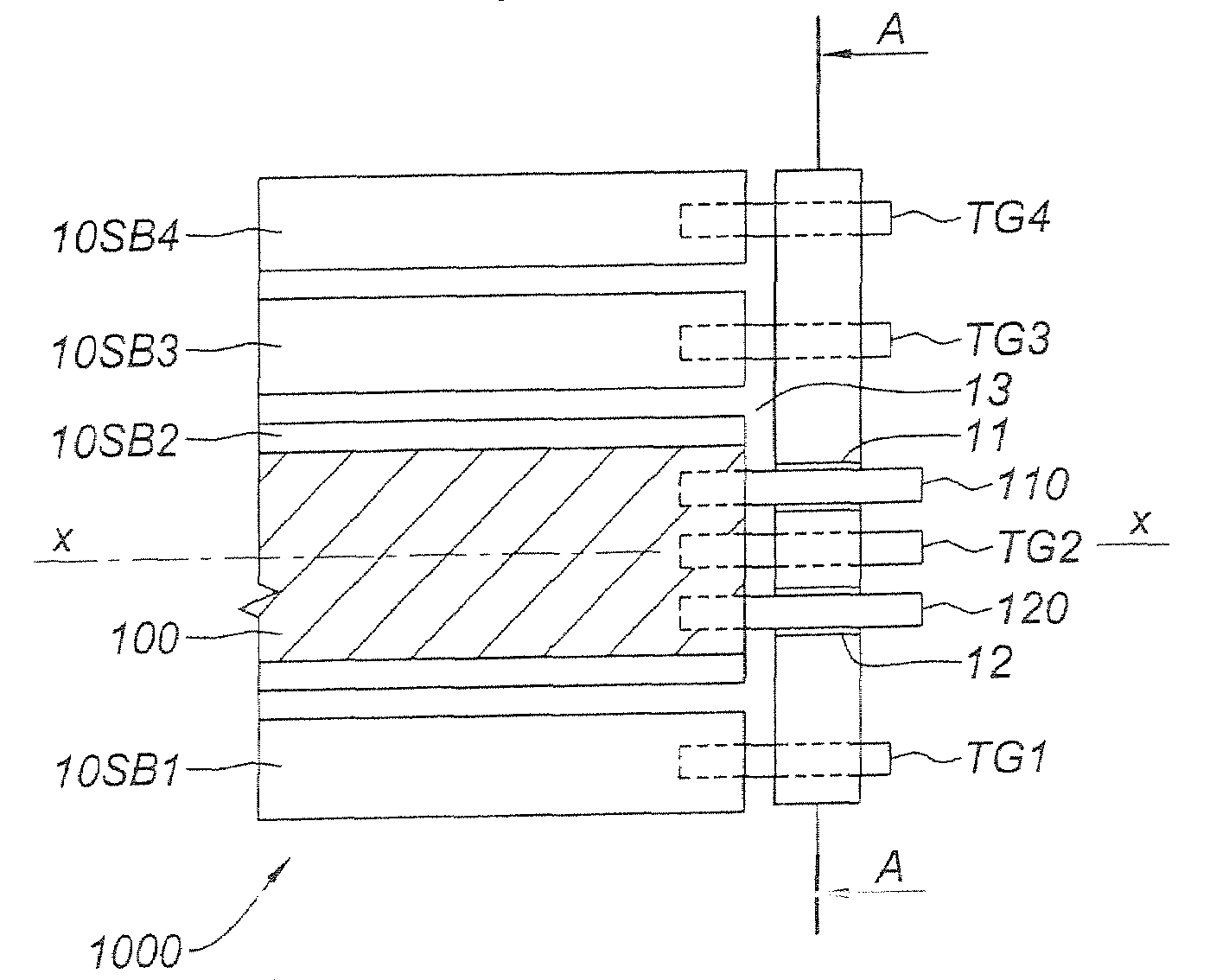

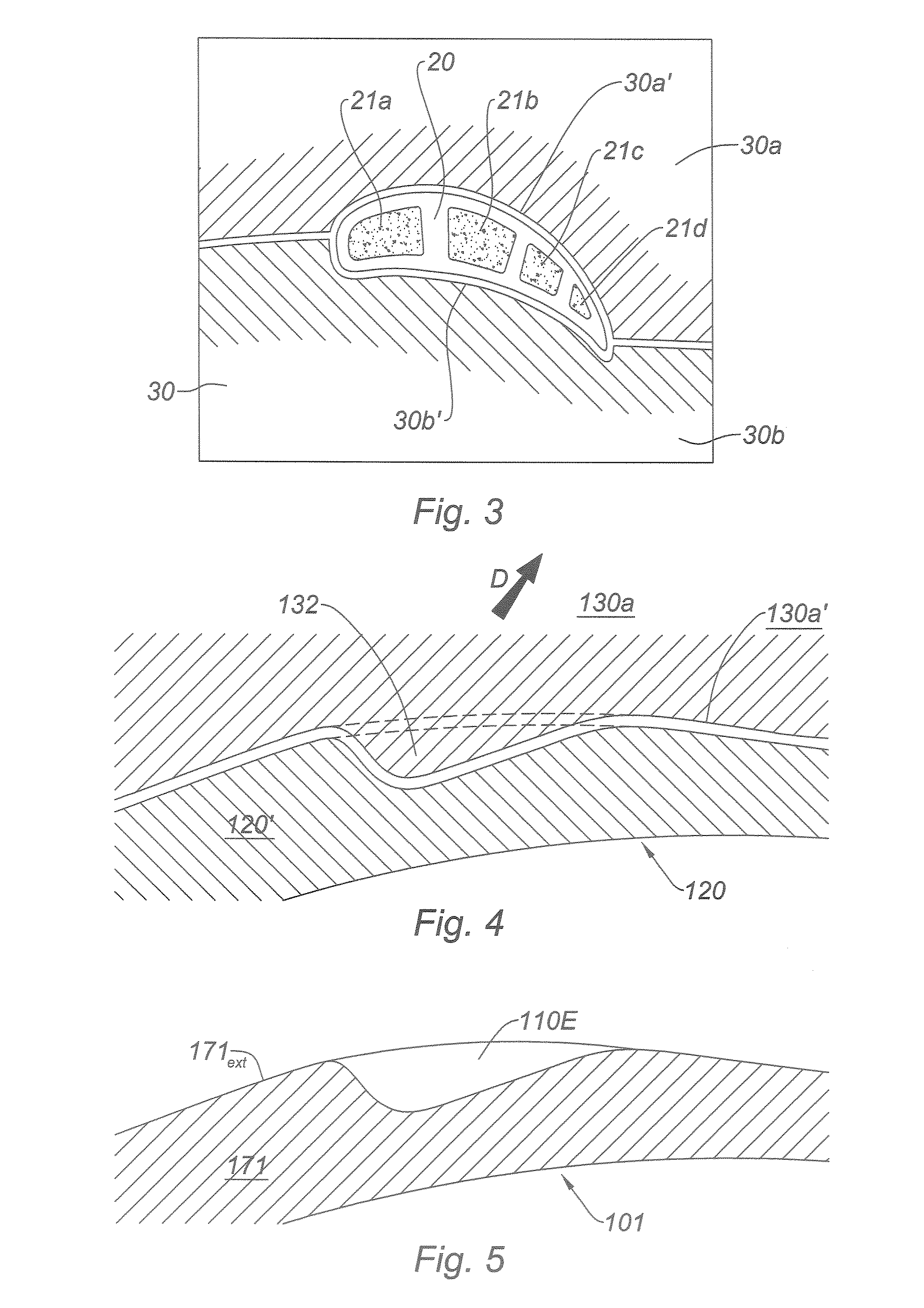

CERAMIC CORE FOR A MULTl-CAVITY TURBINE BLADE

ActiveUS20180073373A1Mitigate such drawbackEliminate operationBlade accessoriesFoundry mouldsSingle elementTurbine blade

A ceramic core used for fabricating a hollow turbine blade for a turbine engine by using the lost-wax casting technique and shaped to constitute the cavities of the blade as a single element, includes, in order to feed the insides of these cavities jointly with cooling air, core portions that are to form first and second lateral cavities and that are connected to a core portion that is to form at least one central cavity, firstly in the core root via at least two ceramic junctions, and secondly at various heights up the core via a plurality of other ceramic junctions of positioning that defines the thickness of the internal partitions of the blade, while also ensuring additional cooling air for predetermined critical zones of the first and second lateral cavities.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A +1

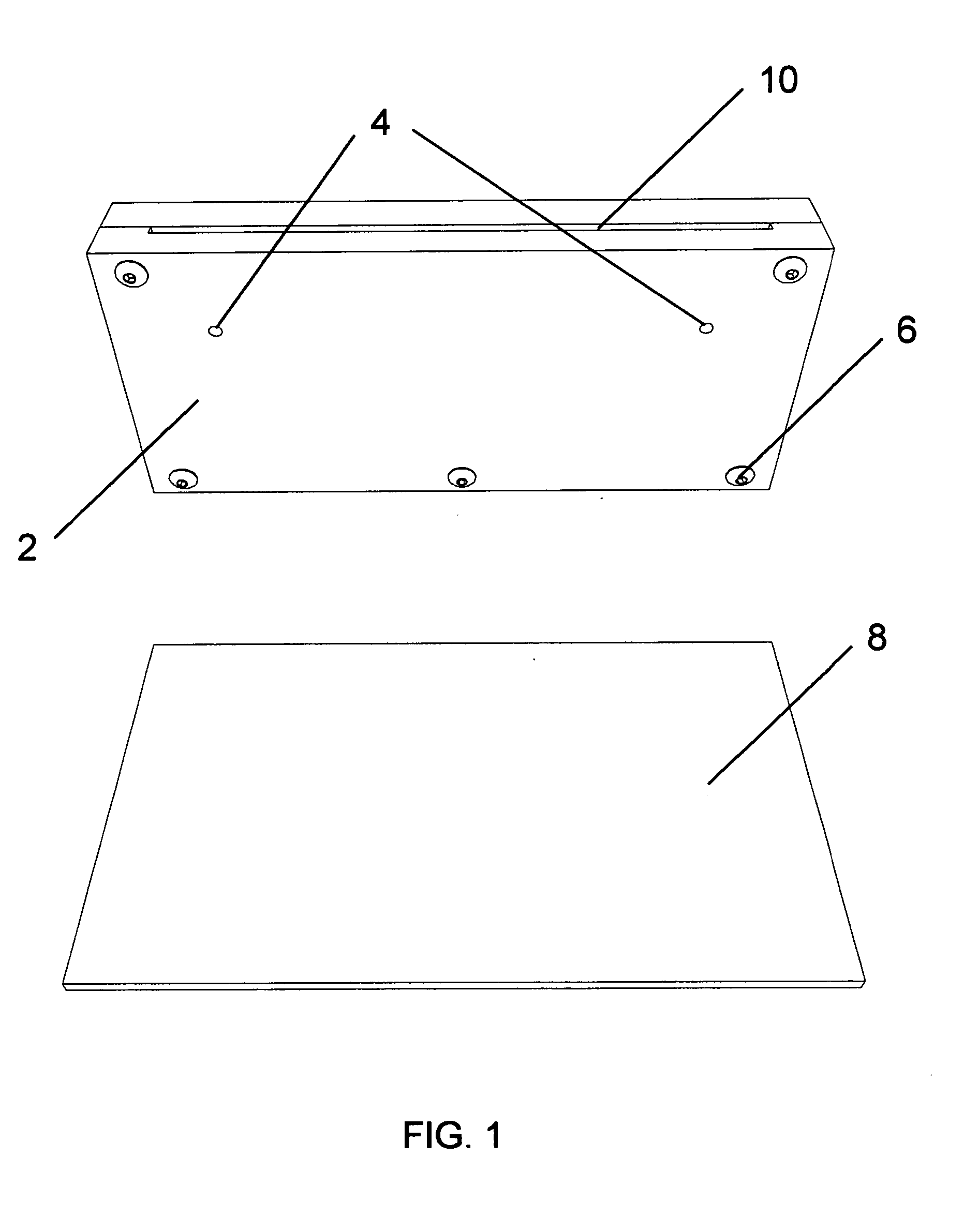

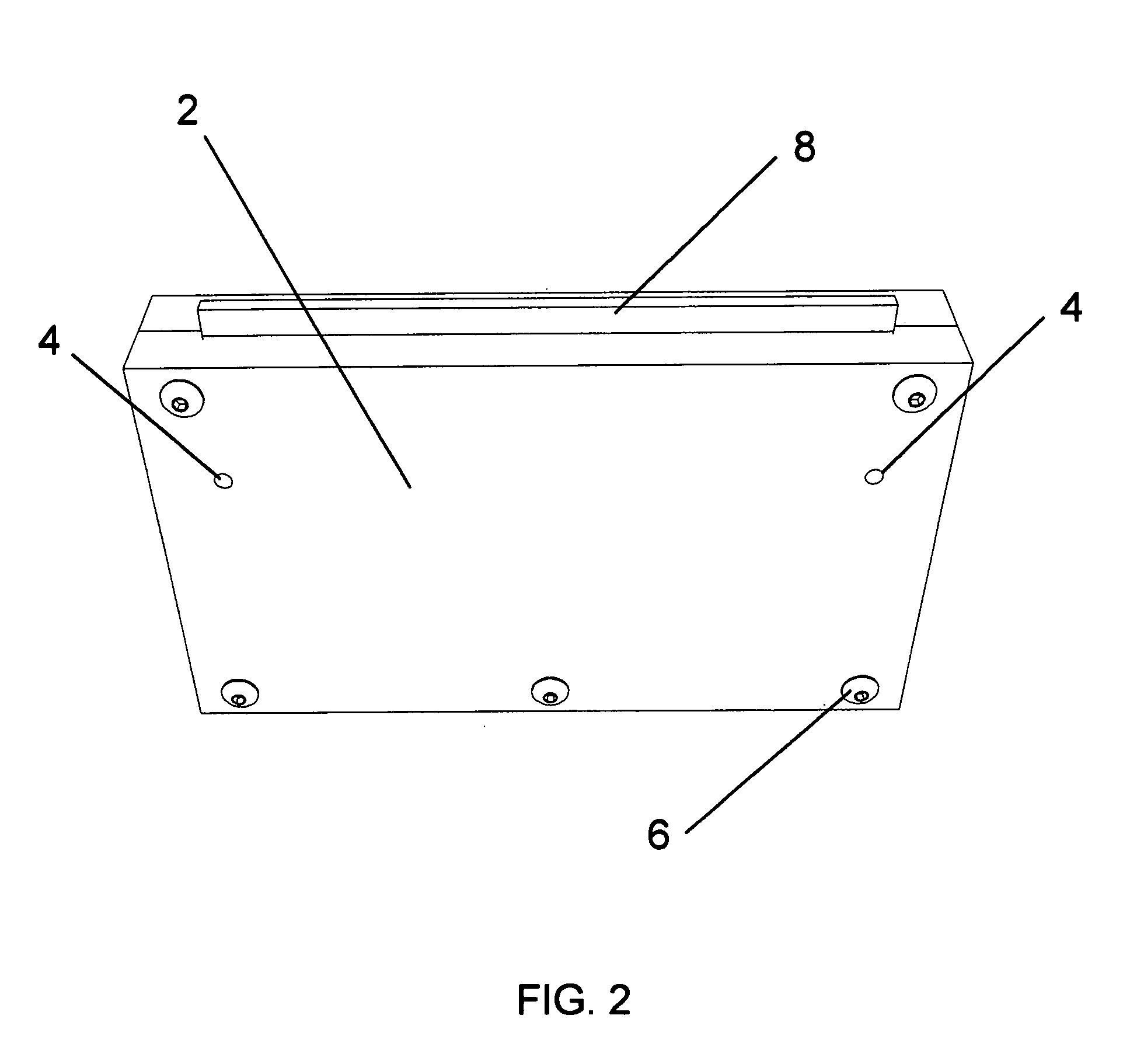

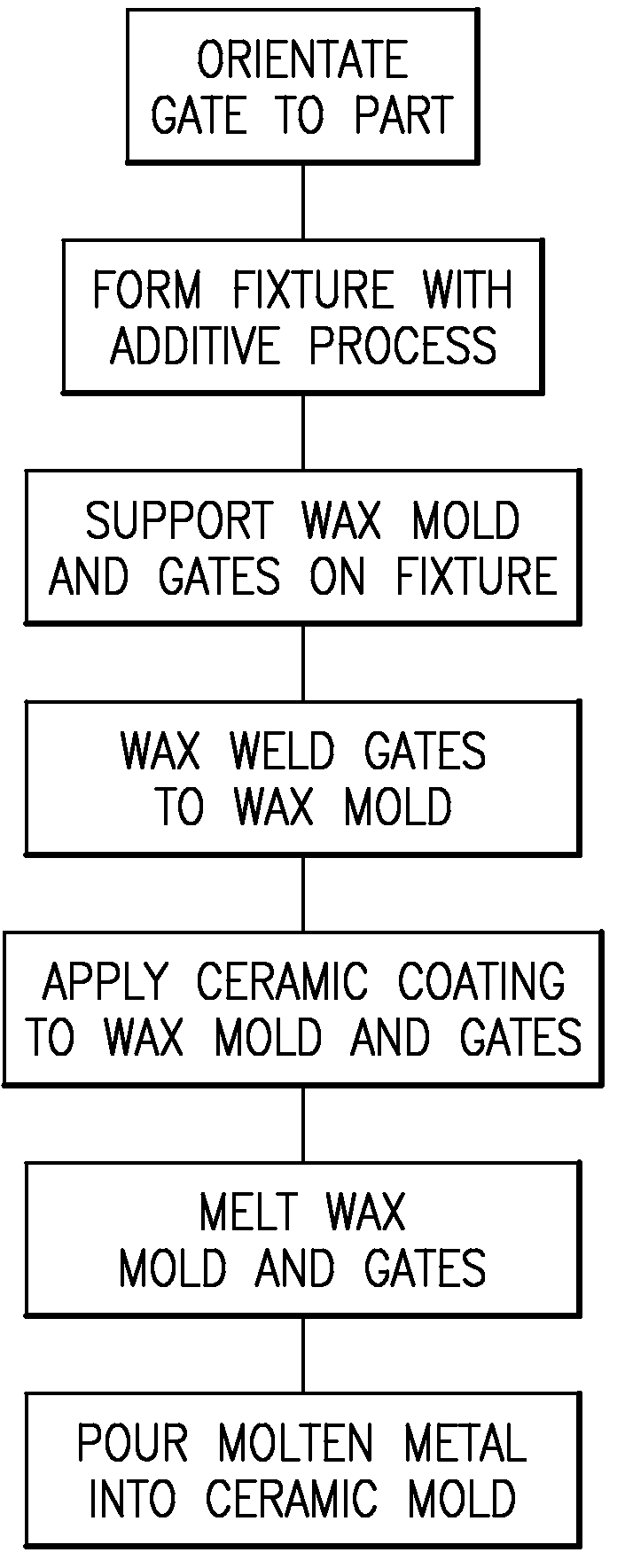

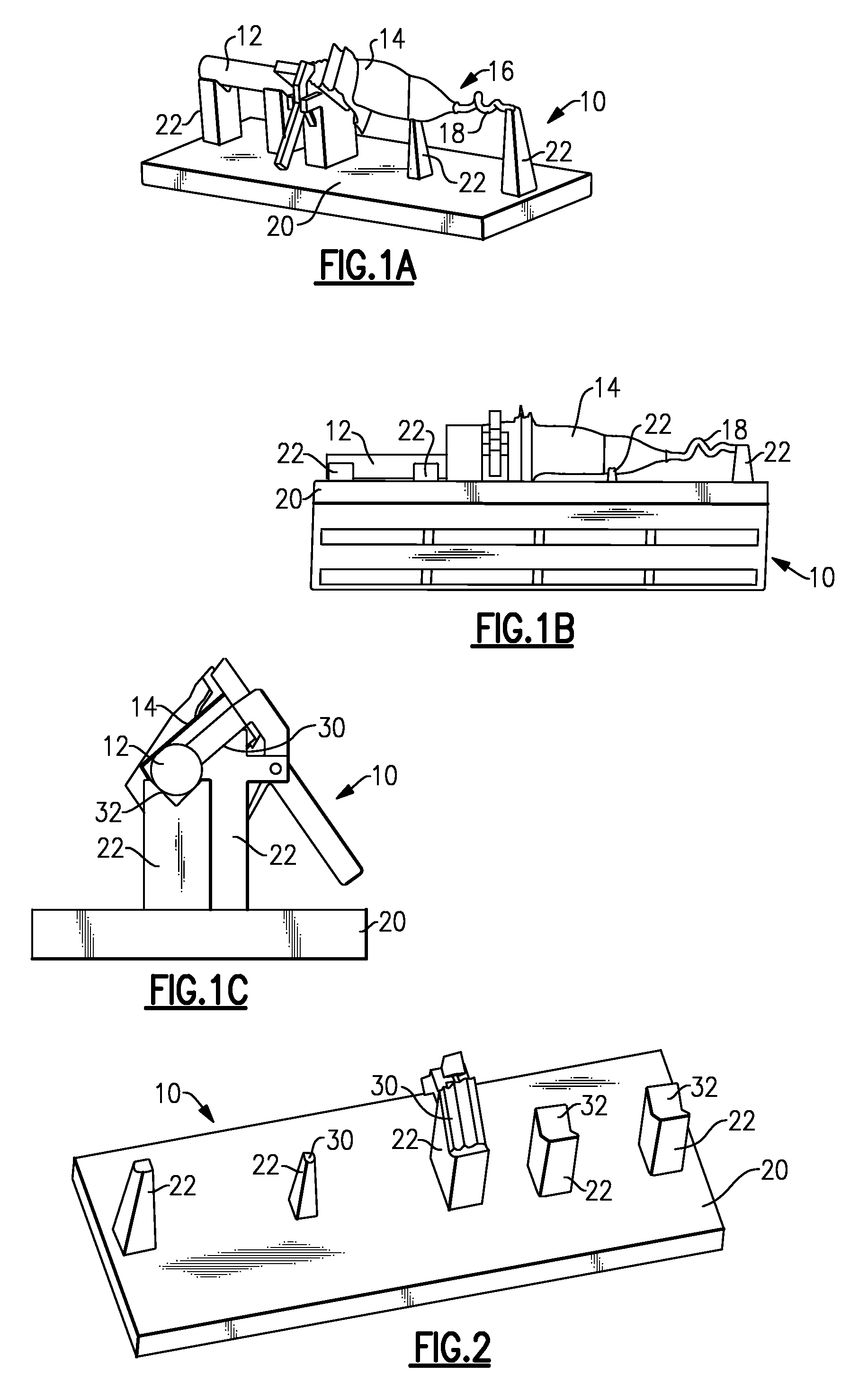

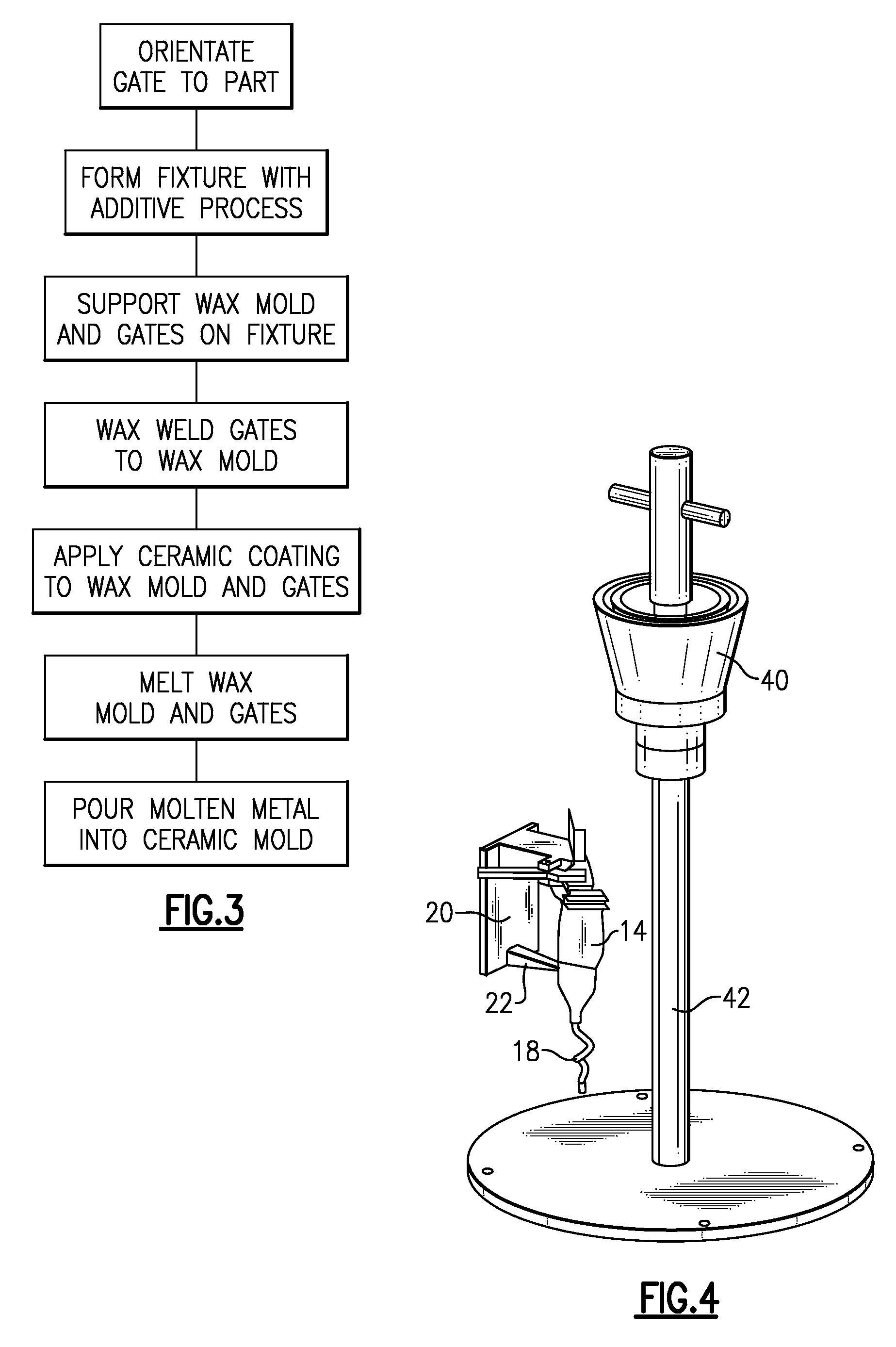

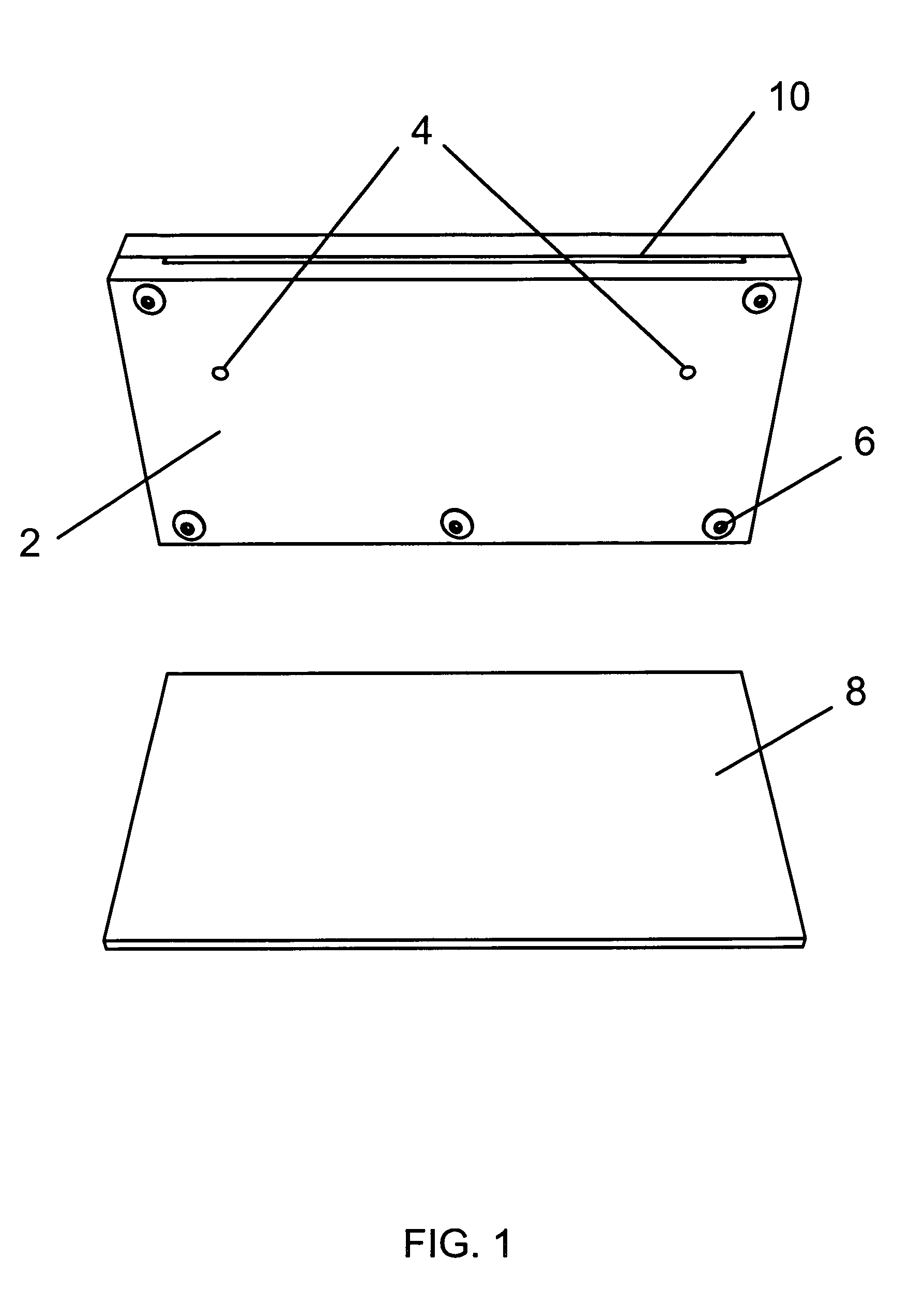

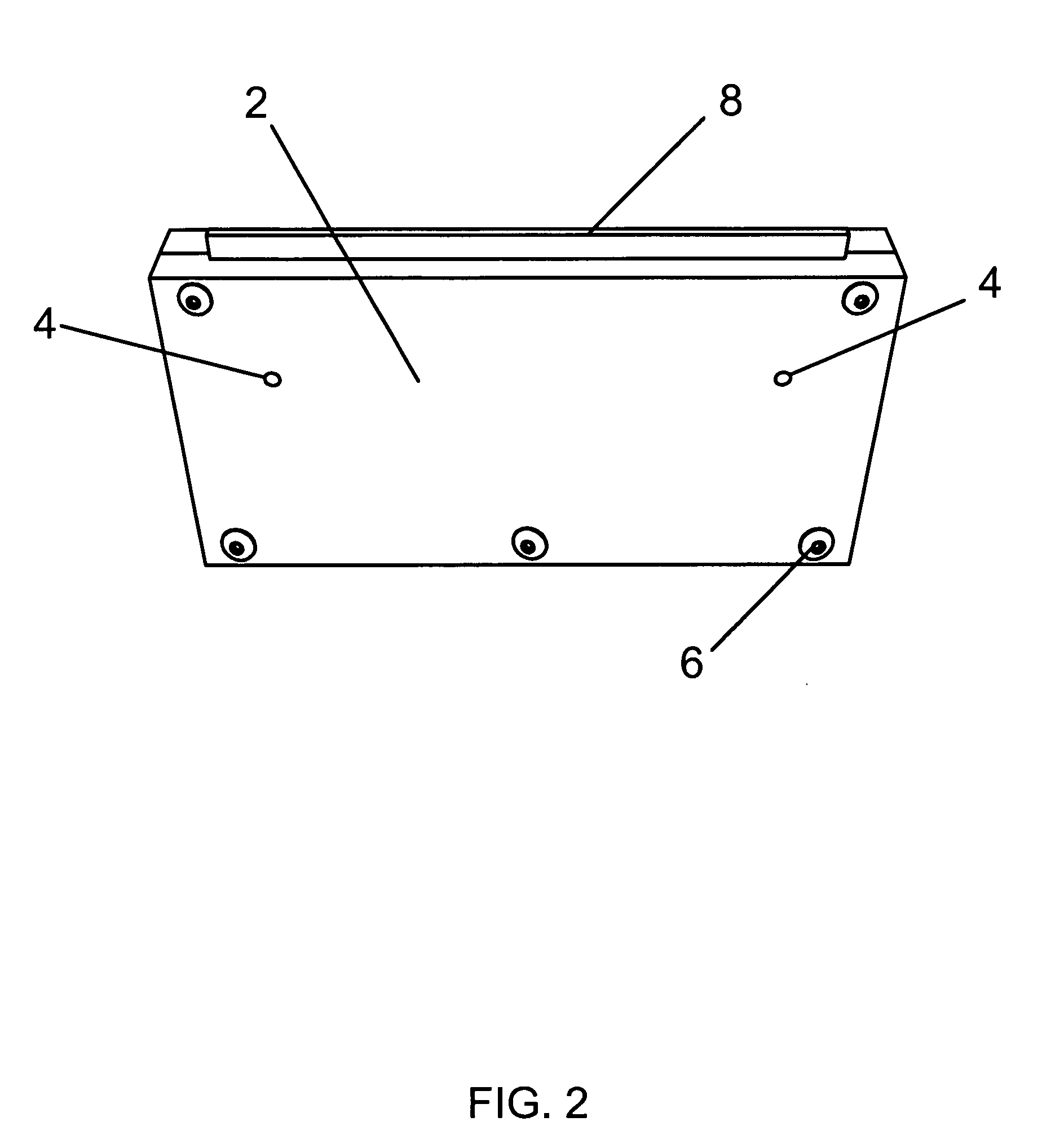

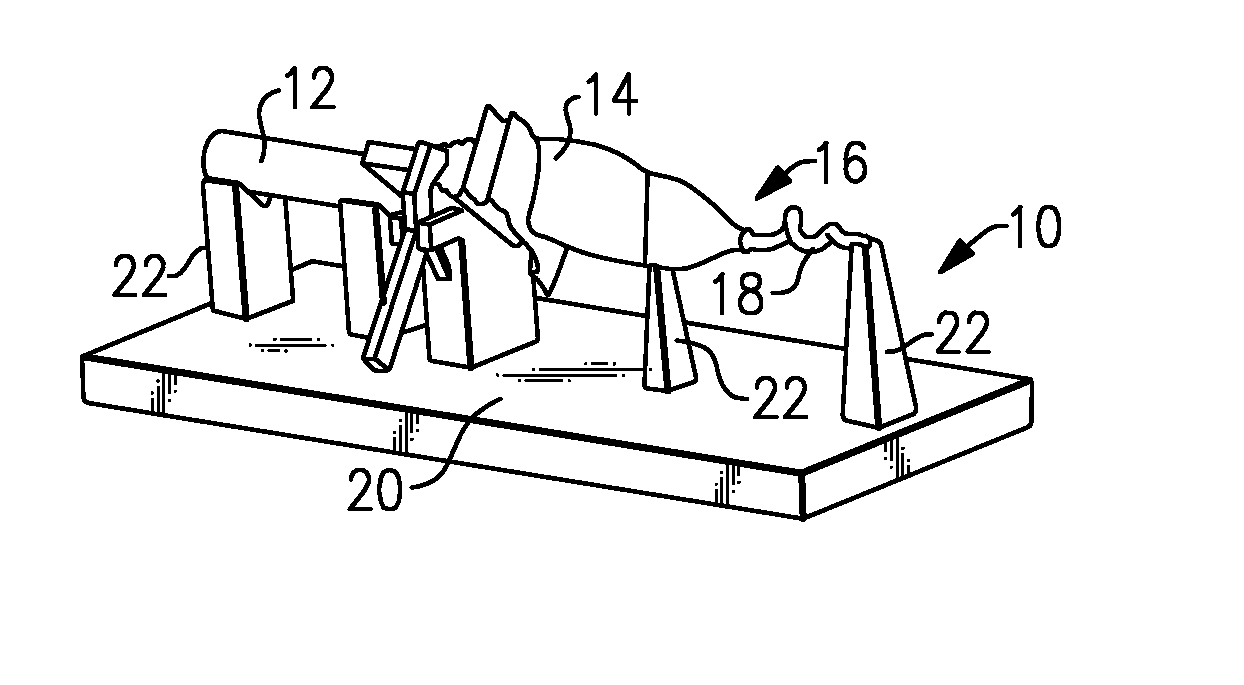

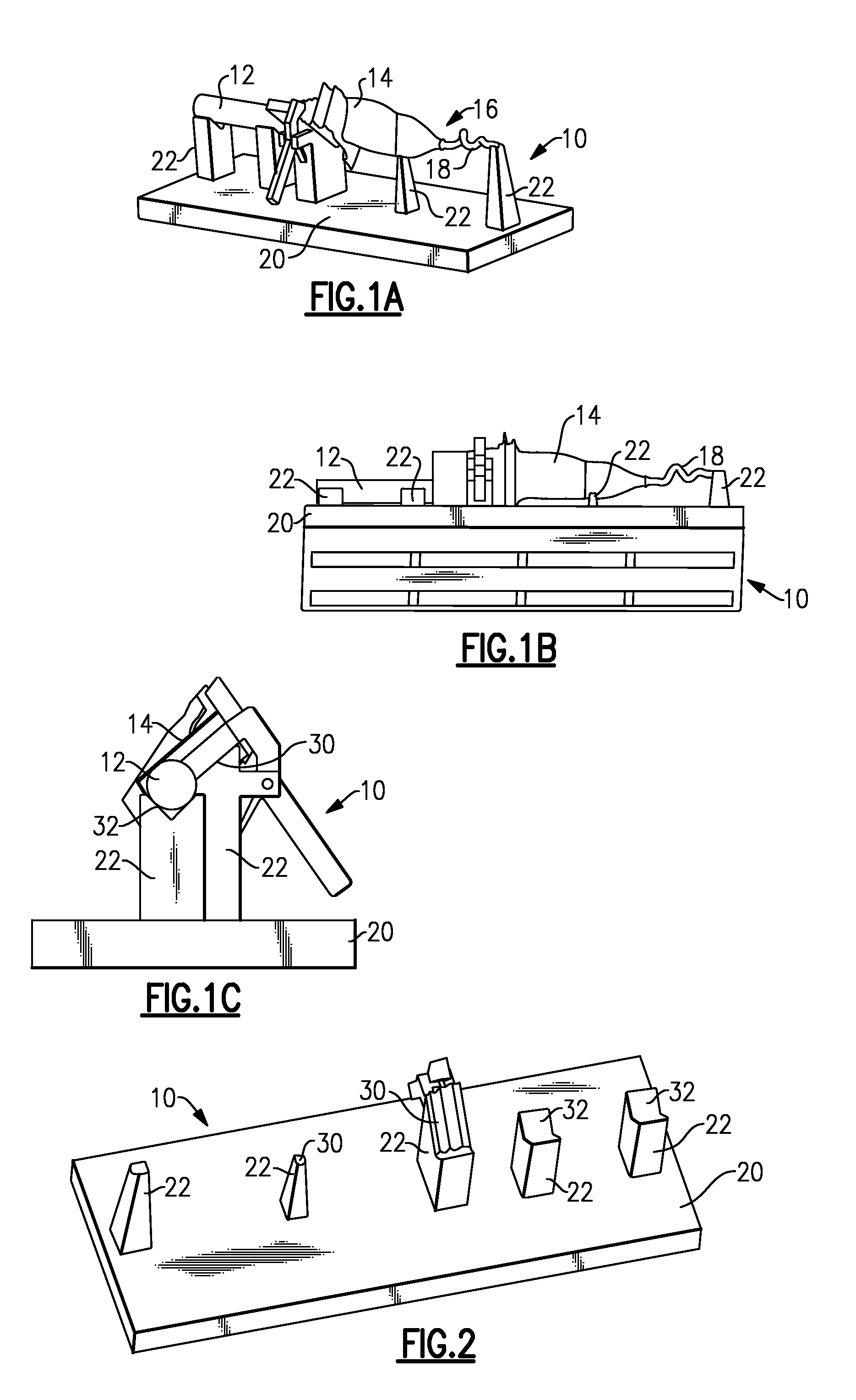

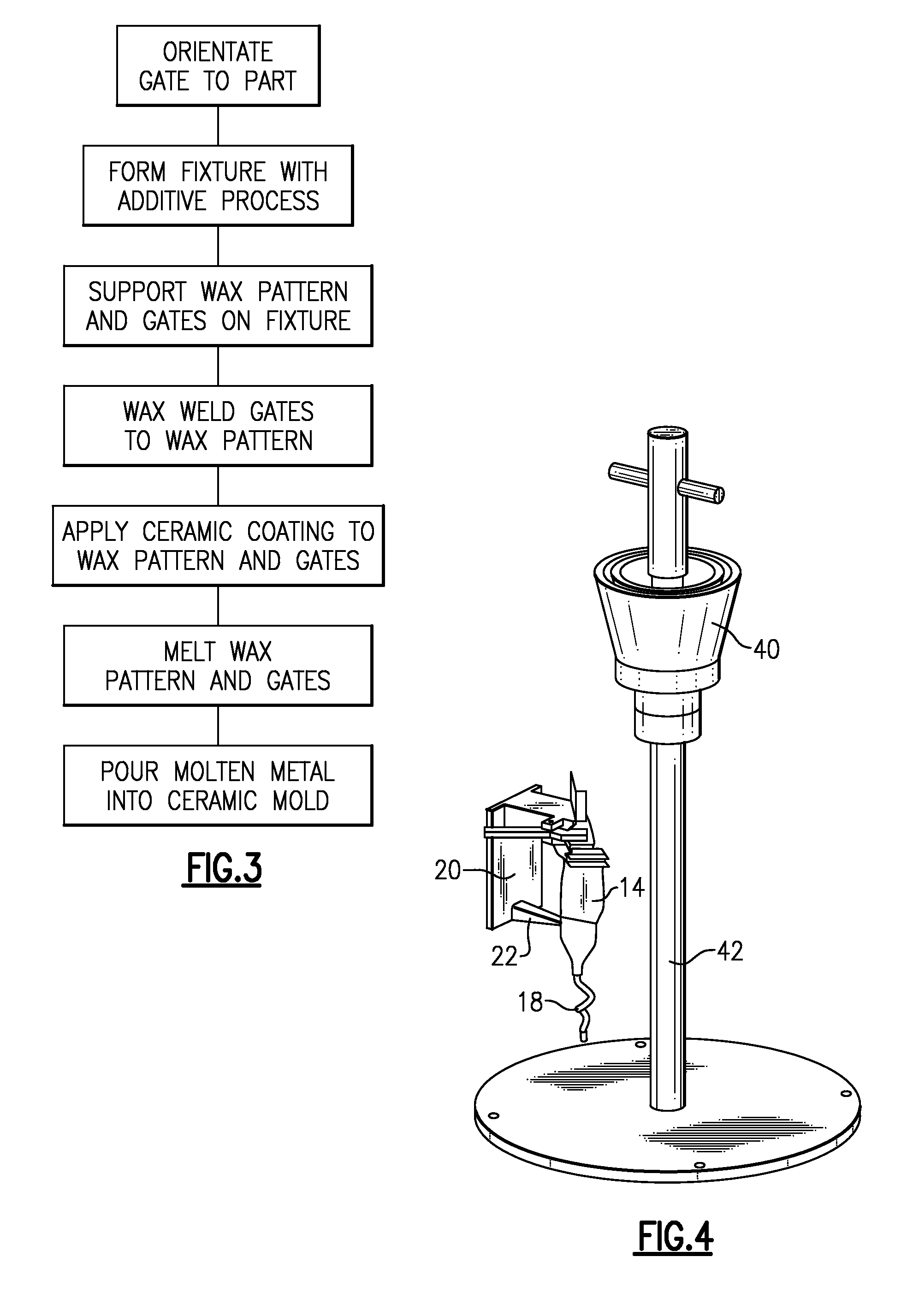

Lost wax investment casting gating fixtures

InactiveUS20090065168A1Additive manufacturing apparatusFoundry mouldsInvestment castingLost-wax casting

A method of forming a gating fixture for a lost wax casting process includes determining an optimal orientation of a gate in relation to a part, and forming a fixture that can repeatably be used to consistently locate the gate relative to the part. In one example, stereolithography is used to form the fixture.

Owner:RAYTHEON TECH CORP

Method of manufacturing a turbomachine component that includes cooling air discharge orifices

ActiveUS7841083B2Easy to optimizeExpensive and complicated to useEngine manufactureEngine fuctionsEngineeringCooling fluid

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Core for turbomachine blades

ActiveUS7562691B2The assembly position is accurateFoundry mouldsFoundry coresMechanical engineeringLost-wax casting

The present invention relates to a ceramic core used in the manufacture, by lost wax casting, of a turbomachine blade with cooling cavities and a squealer, comprising at least one main core, wherein the main core (10) comprises an element (10B) shaped so as to constitute the squealer and an element (10SB) shaped so as to constitute at least one cavity beneath the squealer, the two elements leaving between them a space (13) shaped so as to constitute, at least in part, the bottom wall of the squealer. In particular, the elements (10B and 10SB) are joined together by ceramic rods (TG).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

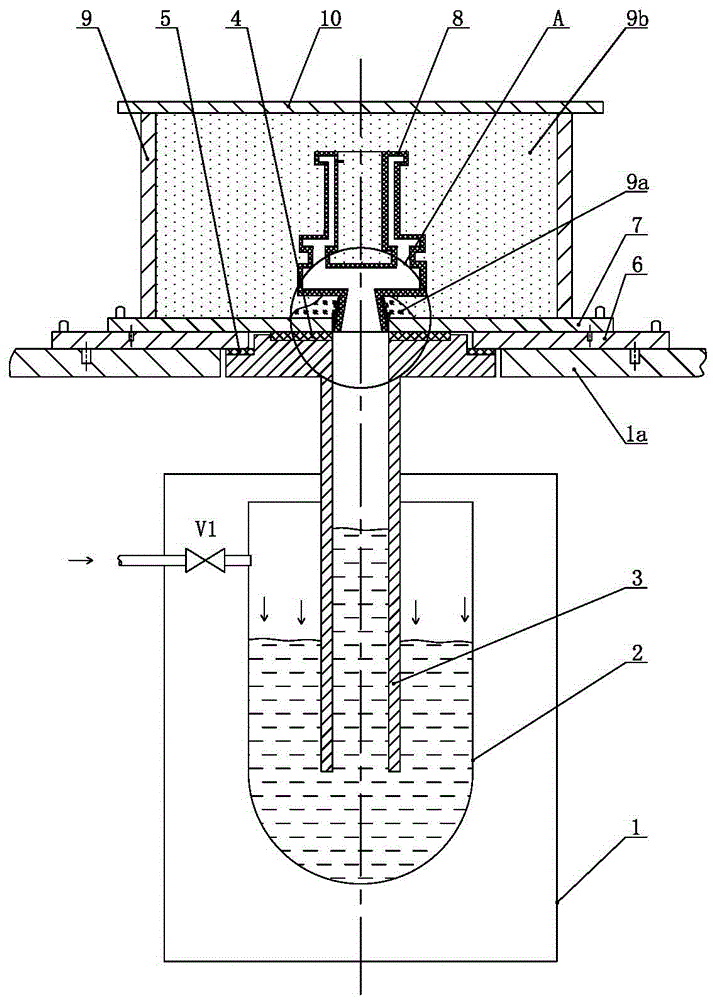

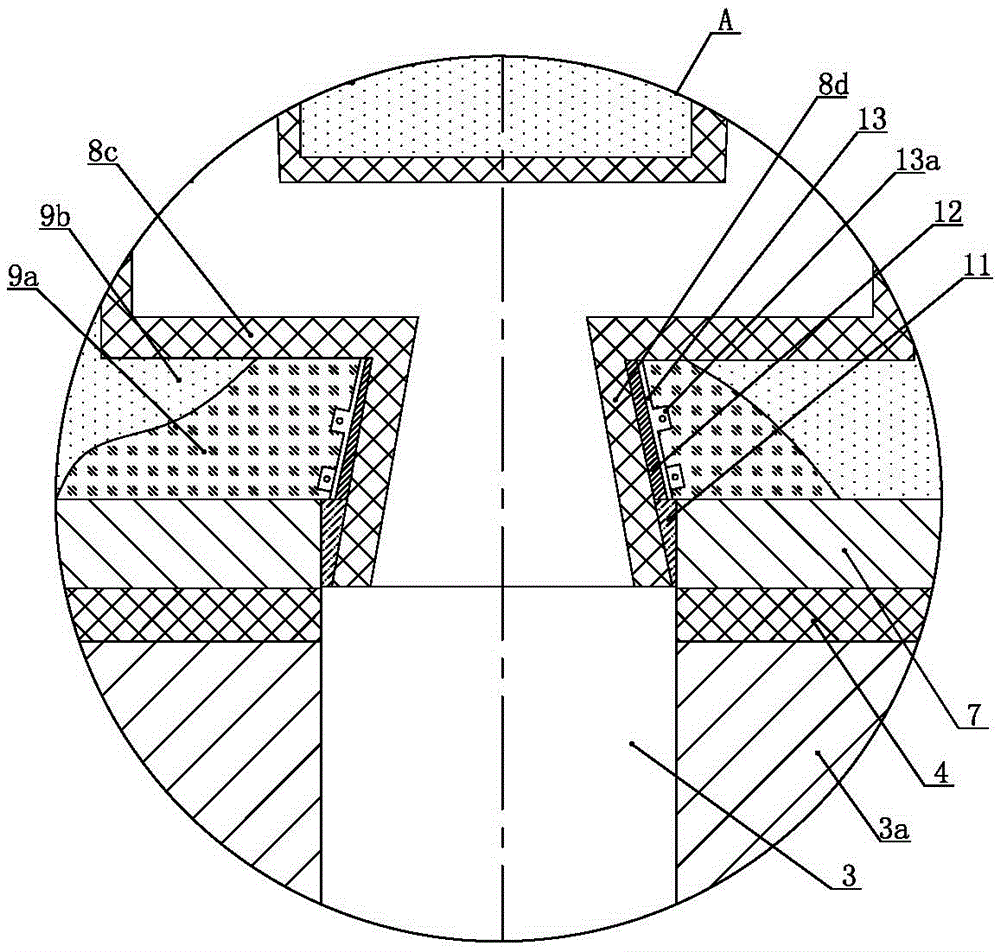

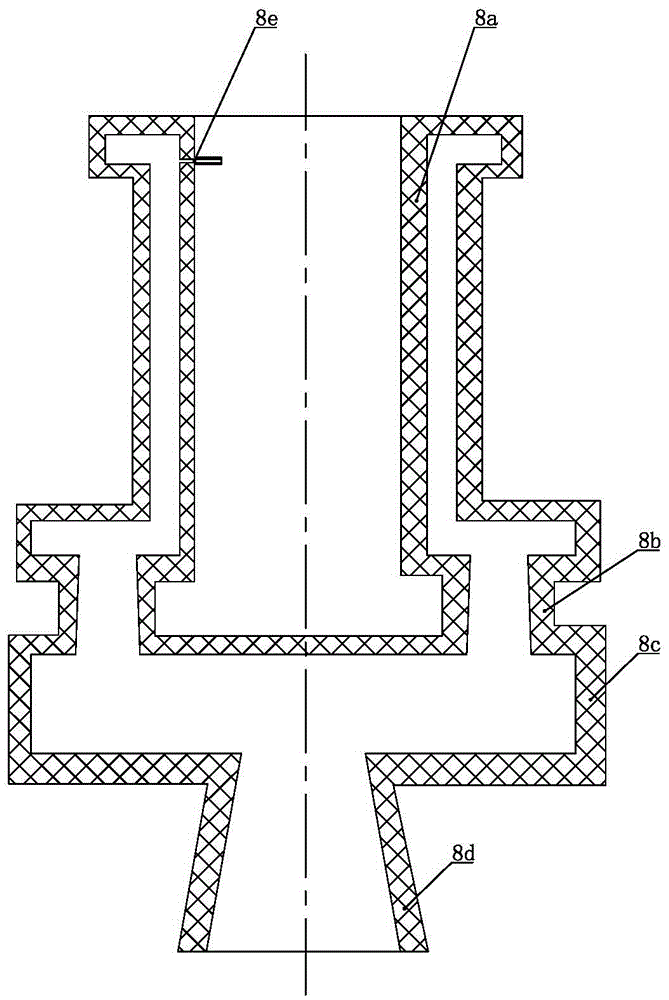

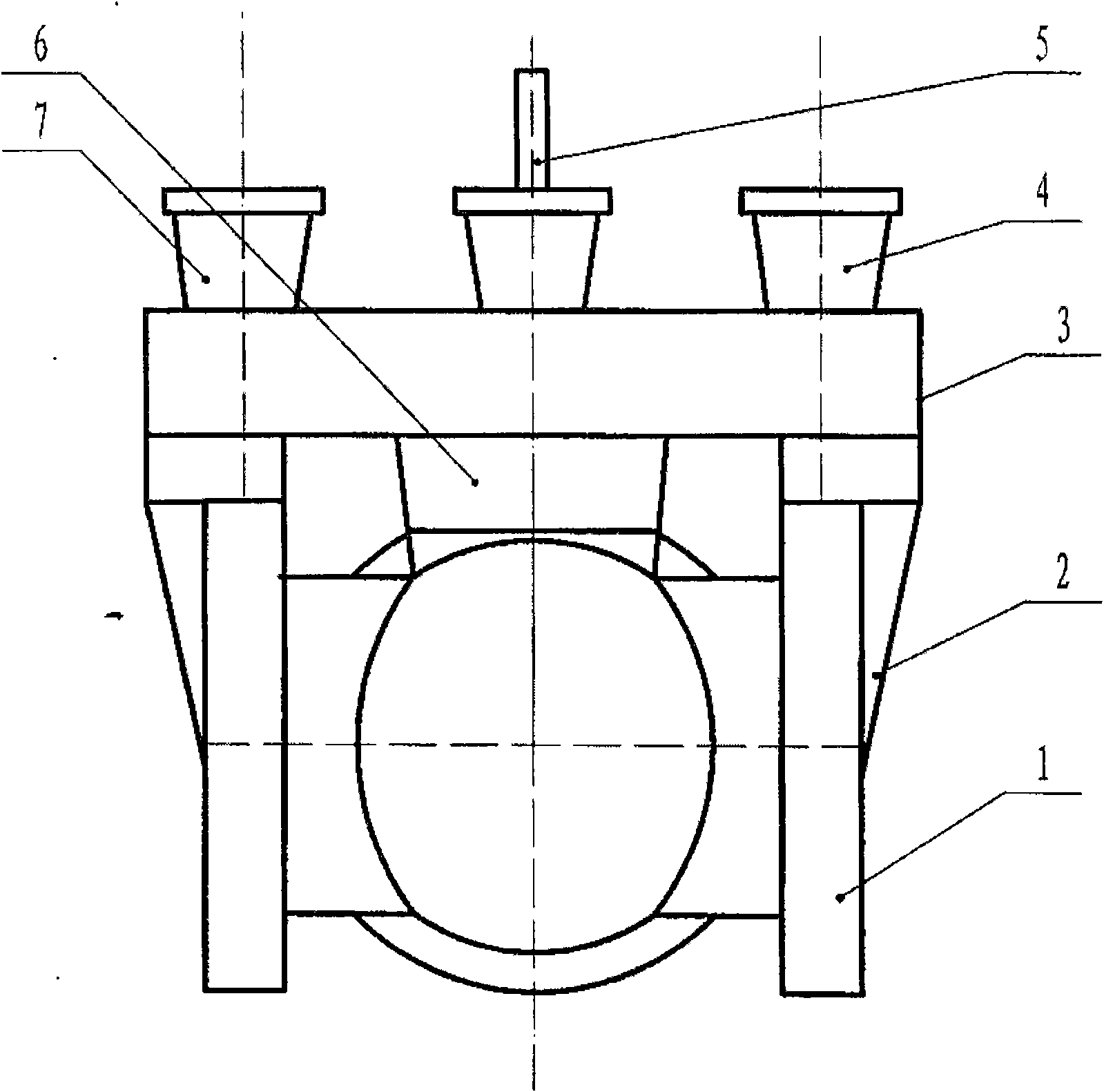

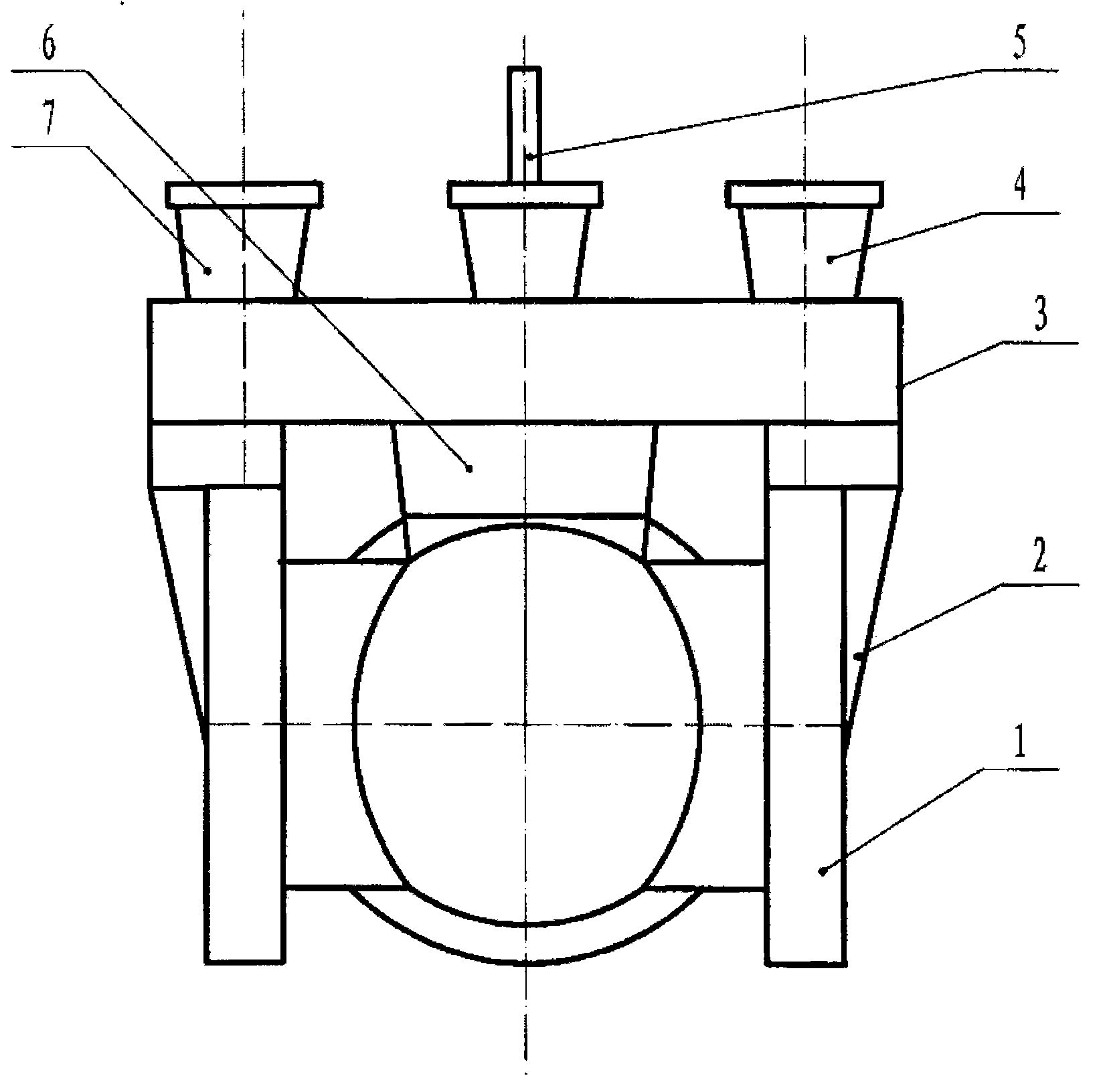

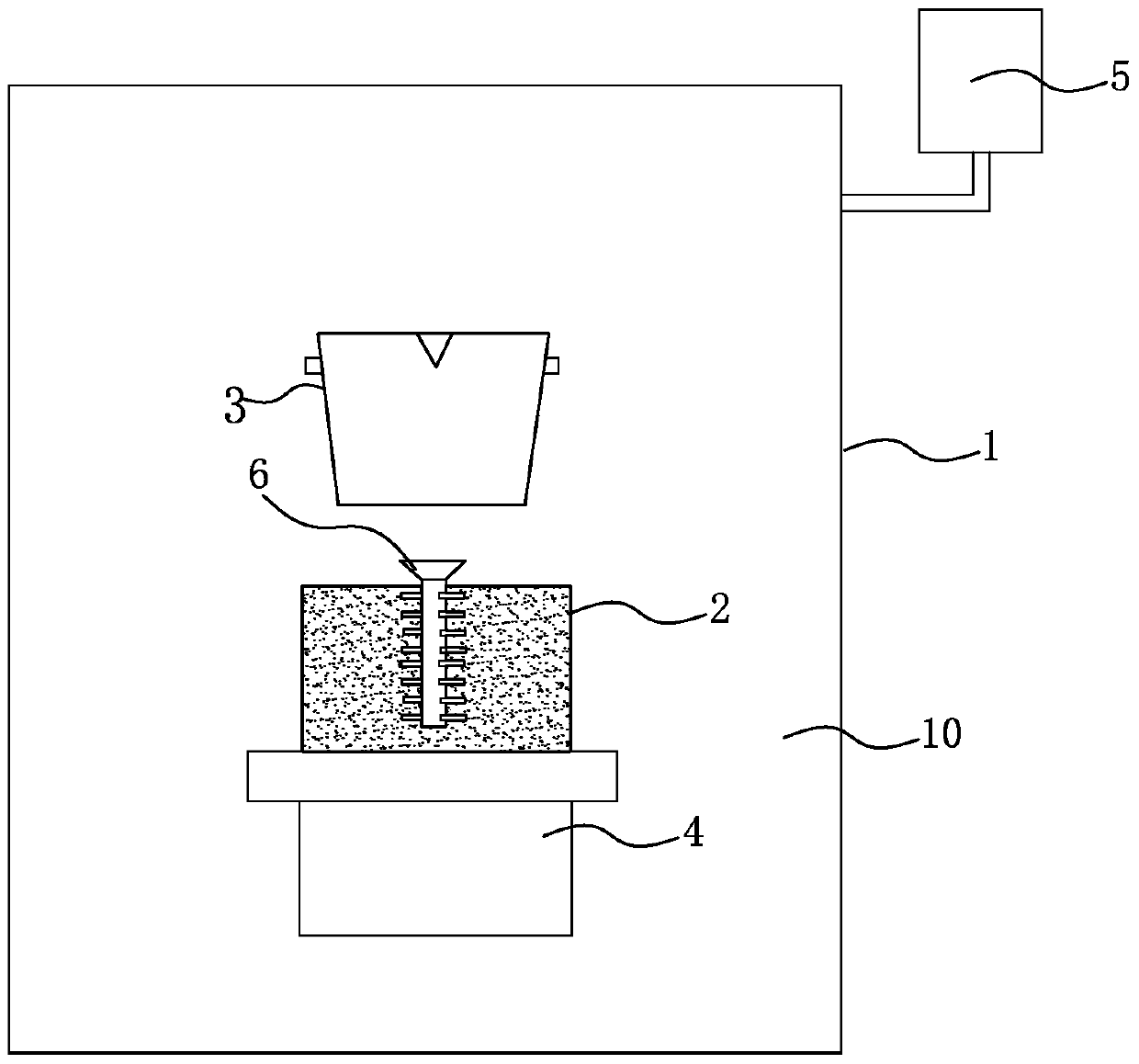

Precise low-pressure lost wax casting system

The invention discloses a precise low-pressure lost wax casting system, which comprises a heat holding furnace positioned in a low-pressure casting machine. A riser tube is inserted in the heat holding furnace. The top of the riser tube extends out of the heat holding furnace and is positioned in a center hole of a working table of the low-pressure casting machine. A hoisting steel plate is fixed on the working table of the low-pressure casting machine. A modeling steel plate is fixed on the hoisting steel plate. A sand box is fixed on the modeling steel plate. A pressing steel plate covers the top end of the sand box. A pressing device is pressed on the pressing steel plate. A combined shell is arranged in the center of the inner cavity of the sand box, is coaxial to the riser tube, and comprises a thin-wall product shell, an inner gate shell, a cross gate shell and a sprue cup shell, which are sequentially arranged from top to bottom in a penetrating manner. The lower end opening of the sprue cup shell is formed in the center hole of the modeling steel plate and is in butt joint with the upper end opening of the riser tube hermetically. The periphery of the combined shell and the inner space of the thin-wall product shell are filled with dry sand. The system has the advantages that a thin-wall product can be molded at high temperature, the cost is low, the efficiency is high, and defects are few.

Owner:YANGZHOU FENG MING METAL PROD

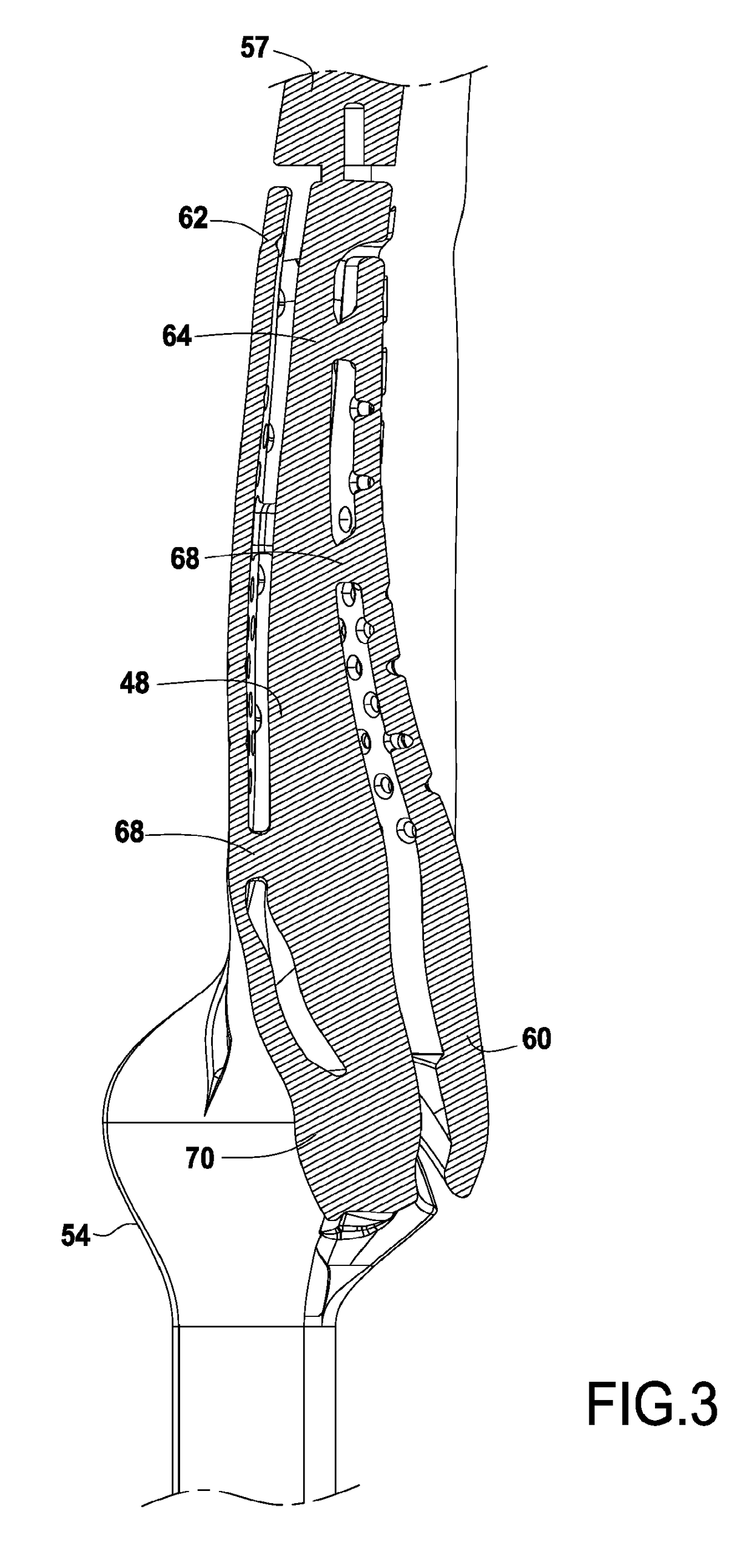

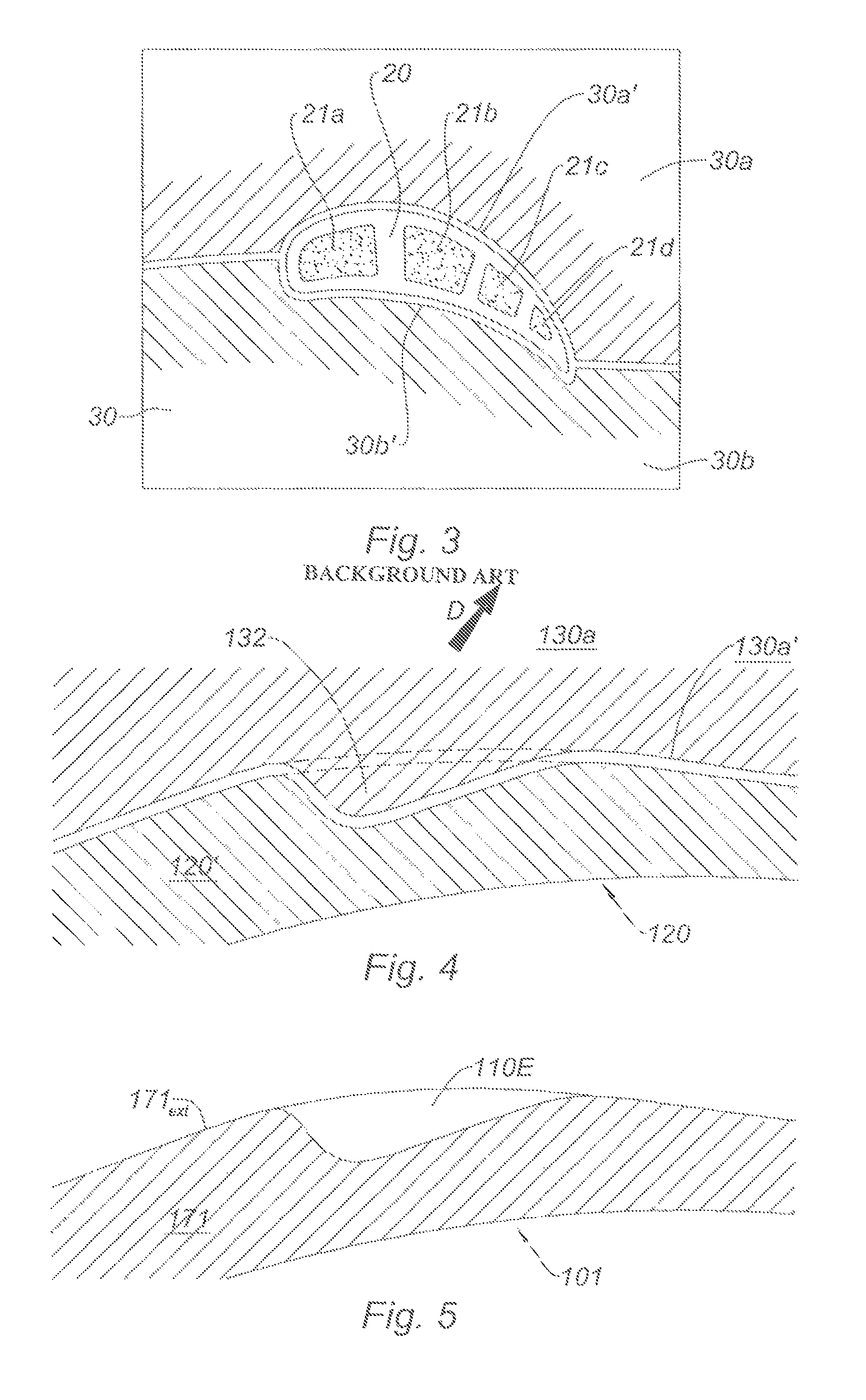

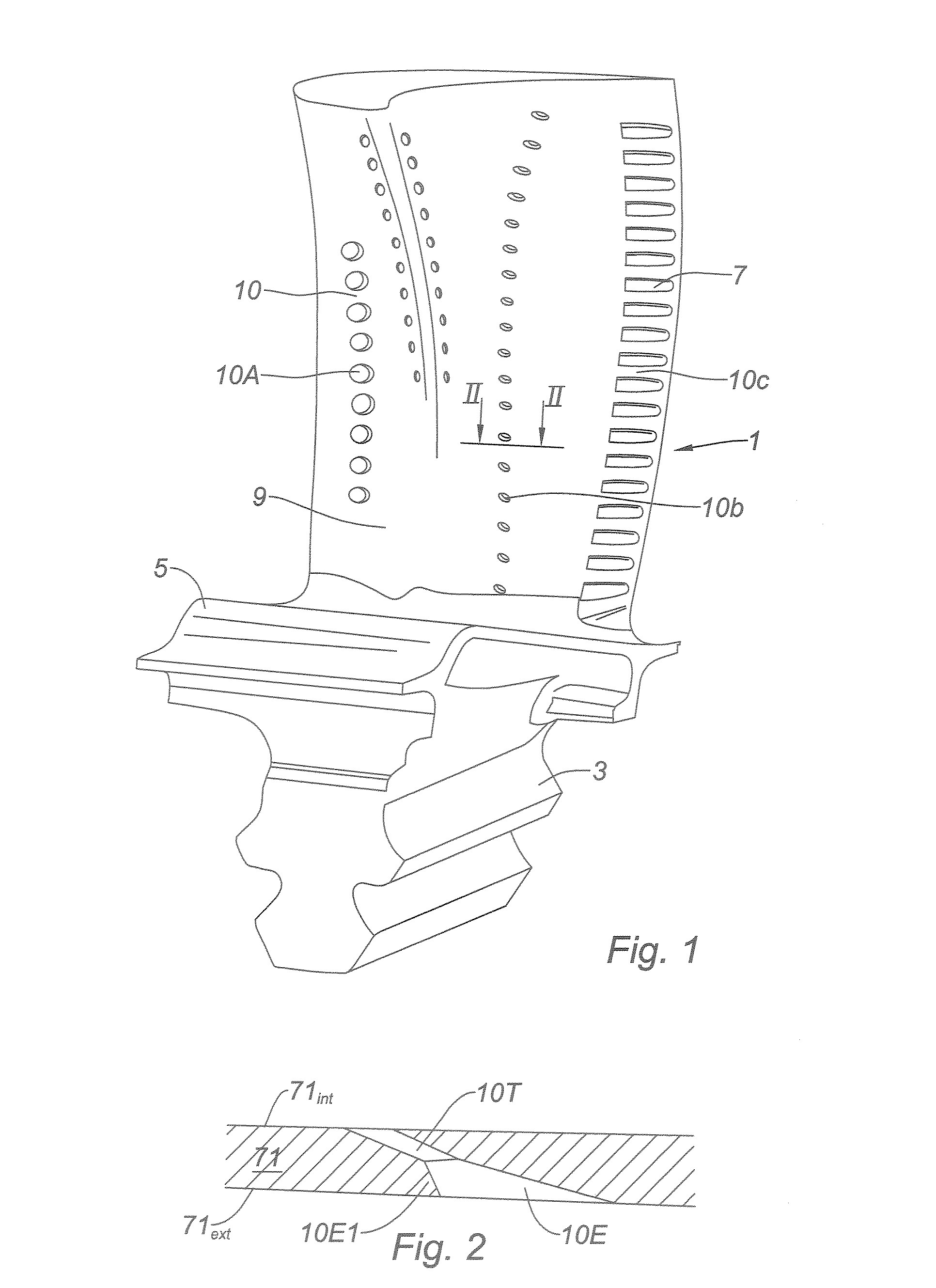

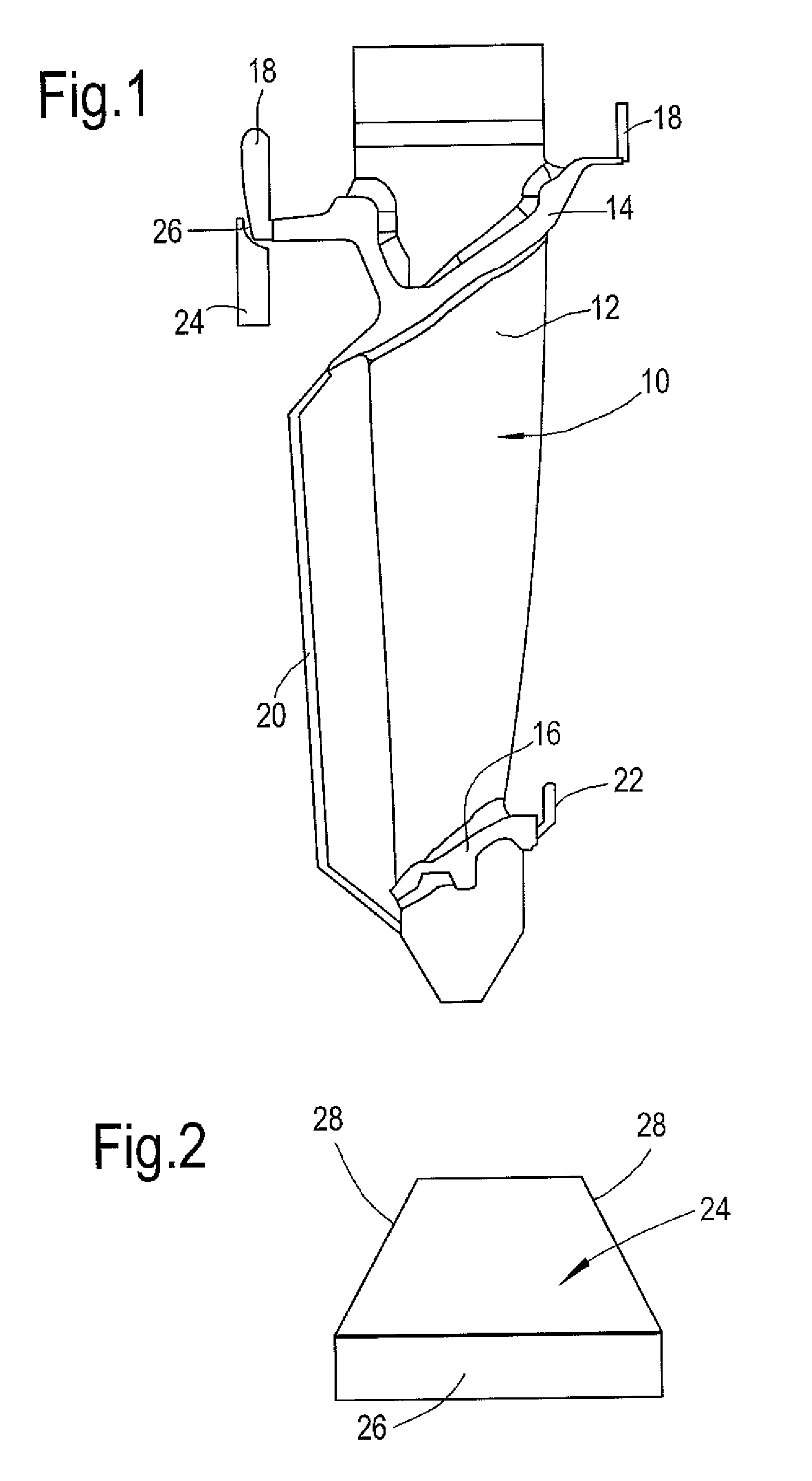

Method of manufacturing a turbomachine component that includes cooling air discharge orifices

ActiveUS20070175009A1Easy to optimizeExpensive and complicated to useEngine manufactureEngine fuctionsEngineeringCooling fluid

The present invention relates to a method of producing cooling fluid discharge orifices in the wall (171) of a part manufactured by the technique of lost wax casting in which a pattern of the part is produced in a wax mold, the orifices having a first portion (110E) emerging at the external surface (171ext) of the wall. The method consists in making cavities in the wax pattern that correspond to the first portions (110E) of said orifices of the part.Thus it is possible to produce cooling air discharge orifices without sharp edges.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Craft manufacturing flow for lost-wax casting value body with more than 8-inch caliber

ActiveCN101927320AEasy to manufactureImprove yieldFoundry mouldsFoundry coresEngineeringUltimate tensile strength

The invention provides a craft manufacturing flow for lost-wax casting a value body with a more than 8-inch caliber, aiming to solve the craft difficult problems that a wax form is heavy, is difficult to turn, is easy to be damaged by cracking and shedding and the like. The invention adopts reinforcing ribs to enhance the strength of the value body and enlarge a welding contact area of a running gate system. The invention has simple manufacturing, high finished product ratio, good quality and the like; the product has smooth and beautiful appearance, stable size and small morpheme error; and shooting shows that the inner part of the product has no crack and shrinkage porosity phenomena, thus reaching the over second-level RT requirement.

Owner:江苏万恒铸业有限公司

Article of Jewelry and Method of Manufacture

A method and system for creating an article of jewelry that contains an anatomical image using a digital image of an anatomical body part such as a fingerprint, handprint, footprint, or the like to create a computer numeric controlled (CNC) software program that drives a machine for producing a wax model of the anatomical image. The wax model is used in a lost wax casting process to create a casting that is used in an article of jewelry. The present invention further provides an article of jewelry containing a novel bail assembly for attaching the article of jewelry to a chain or the like in an aesthetically pleasing manner that hides the attachment hole of the casting.

Owner:LEHMANN TODD PHILIP +1

Lost-wax casting technology for thin-wall pressure-bearing casting

InactiveCN109175232AQuality improvementFeed lessFoundry mouldsFoundry coresCasting defectLost-wax casting

The invention discloses a lost-wax casting technology for a thin-wall pressure-bearing casting. The lost-wax casting technology comprises the following steps of according to technology design requirements, placing patches on an inner cavity of an air cylinder casting from bottom to top by employing a hot spot incircle rolling method, changing an iso-wall thickness structure of the air cylinder casting into a structure which is gradually thickened from bottom to top, thus being in favor of forming progressive solidification, designing two risers at the thickest part of an upper part patch of the air cylinder casting, making the risers perform feeding on the thickest part, placing a riser neck at a hot spot position of the air cylinder casting, determining the risers and a gate stick according to the size of the riser neck, and then, manufacturing a mold according to the technology requirement; molding: opening the mold, checking whether a mold cavity is intact or clean or not, sprayinga mold releasing agent to a position comparatively tiny and complicated in shape in the mold cavity, then, injecting wax into the mold cavity by utilizing a wax injector, after wax injection is finished, opening the mold after a wax piece is cooled, and taking out a wax mold. The lost-wax casting technology disclosed by the invention is capable of increasing quality of the casting and reducing casting defects.

Owner:安徽应流铸业有限公司

Lost wax investment casting gating fixtures

A method of forming a gating fixture for a lost wax casting process includes determining an optimal orientation of a gate in relation to a part, and forming a fixture that can repeatably be used to consistently locate the gate relative to the part. In one example, stereolithography is used to form the fixture.

Owner:RAYTHEON TECH CORP

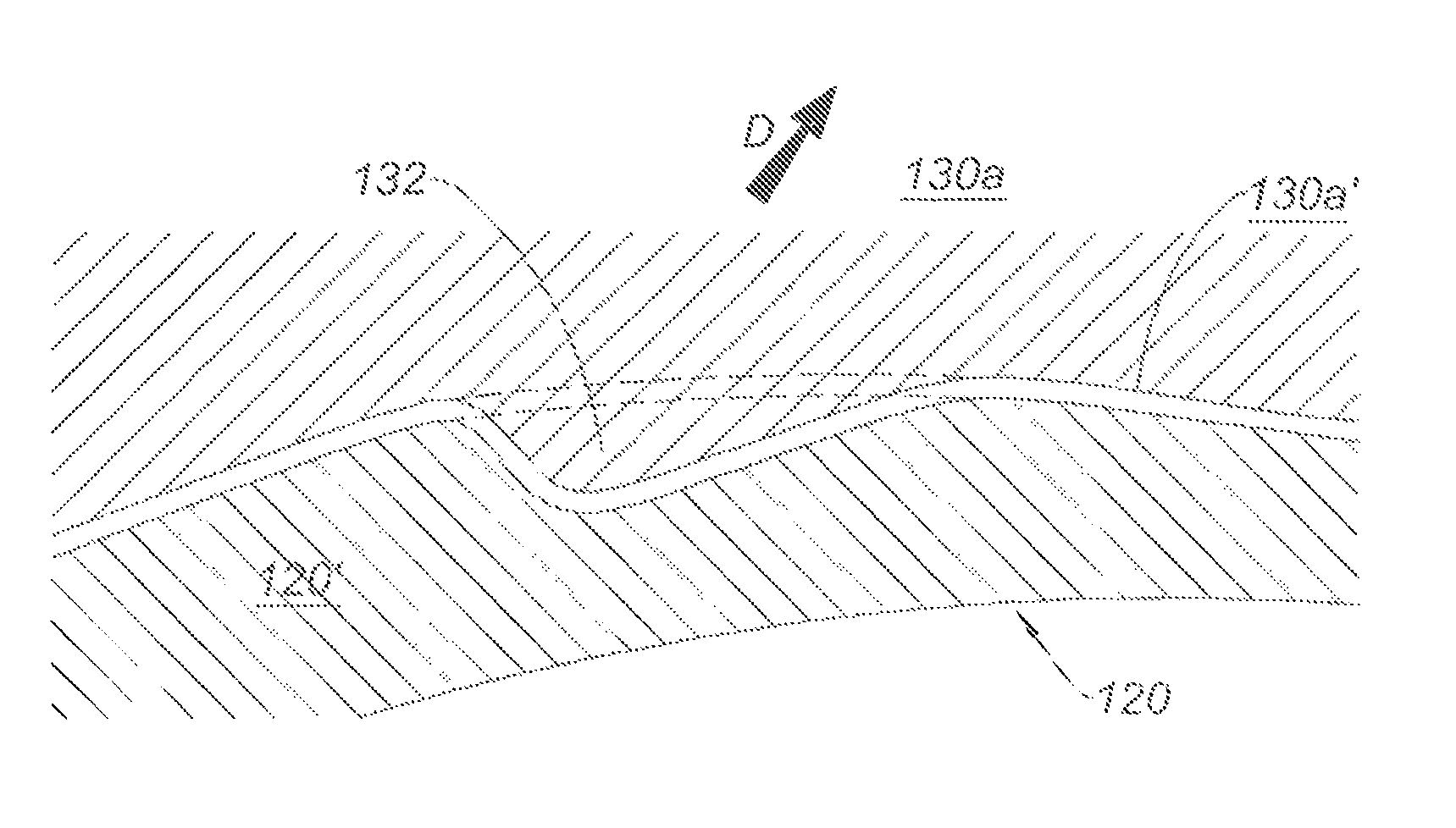

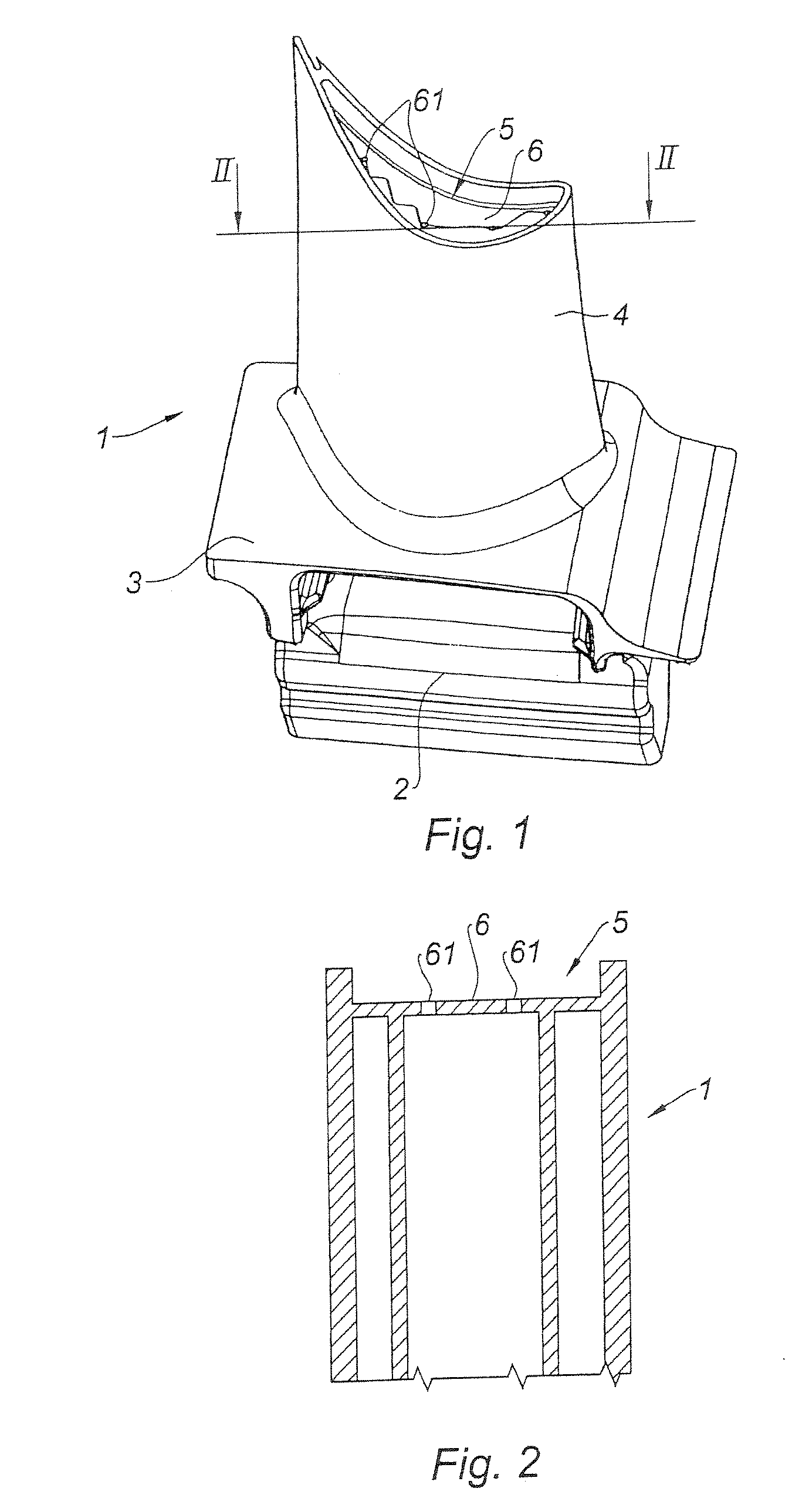

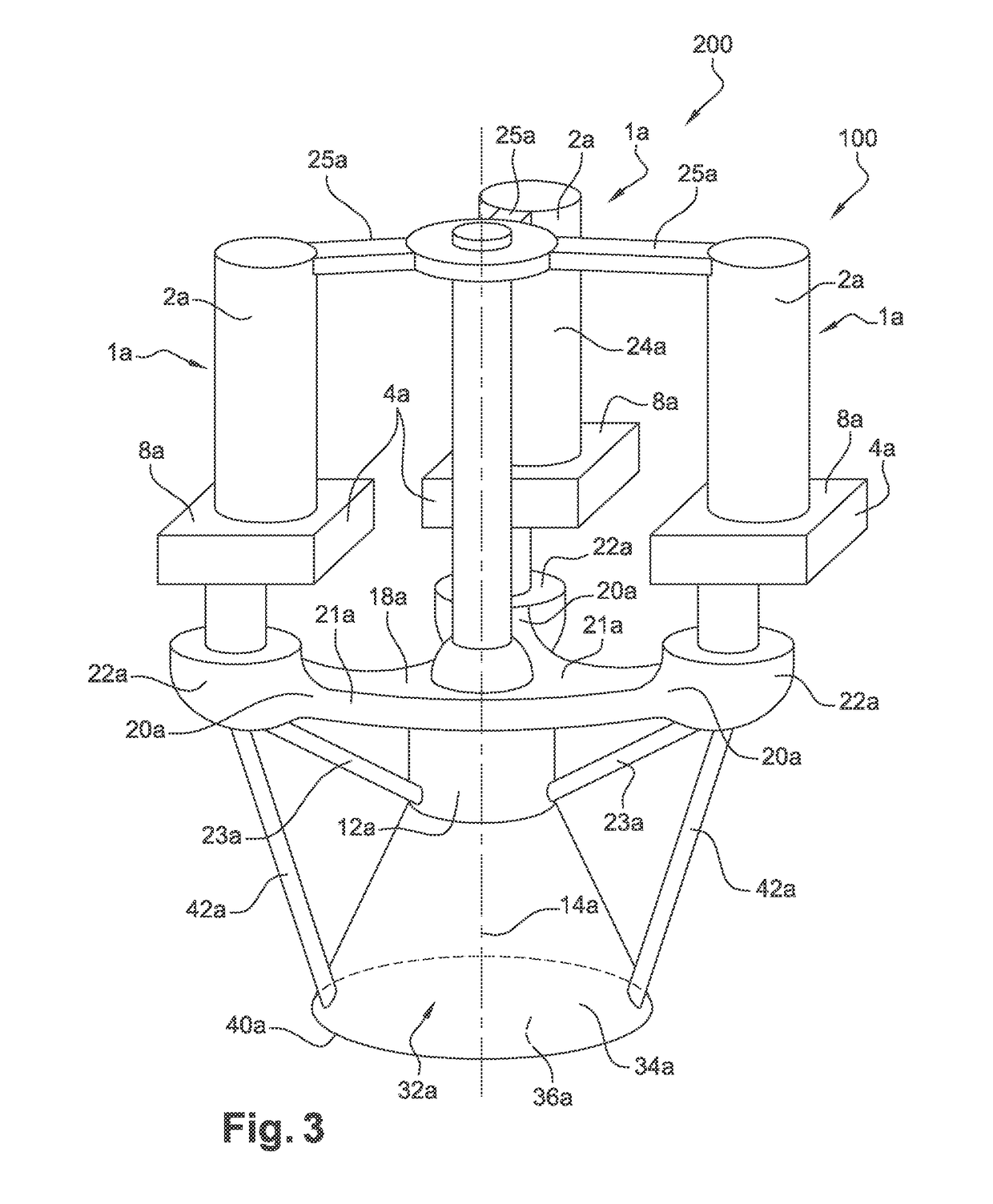

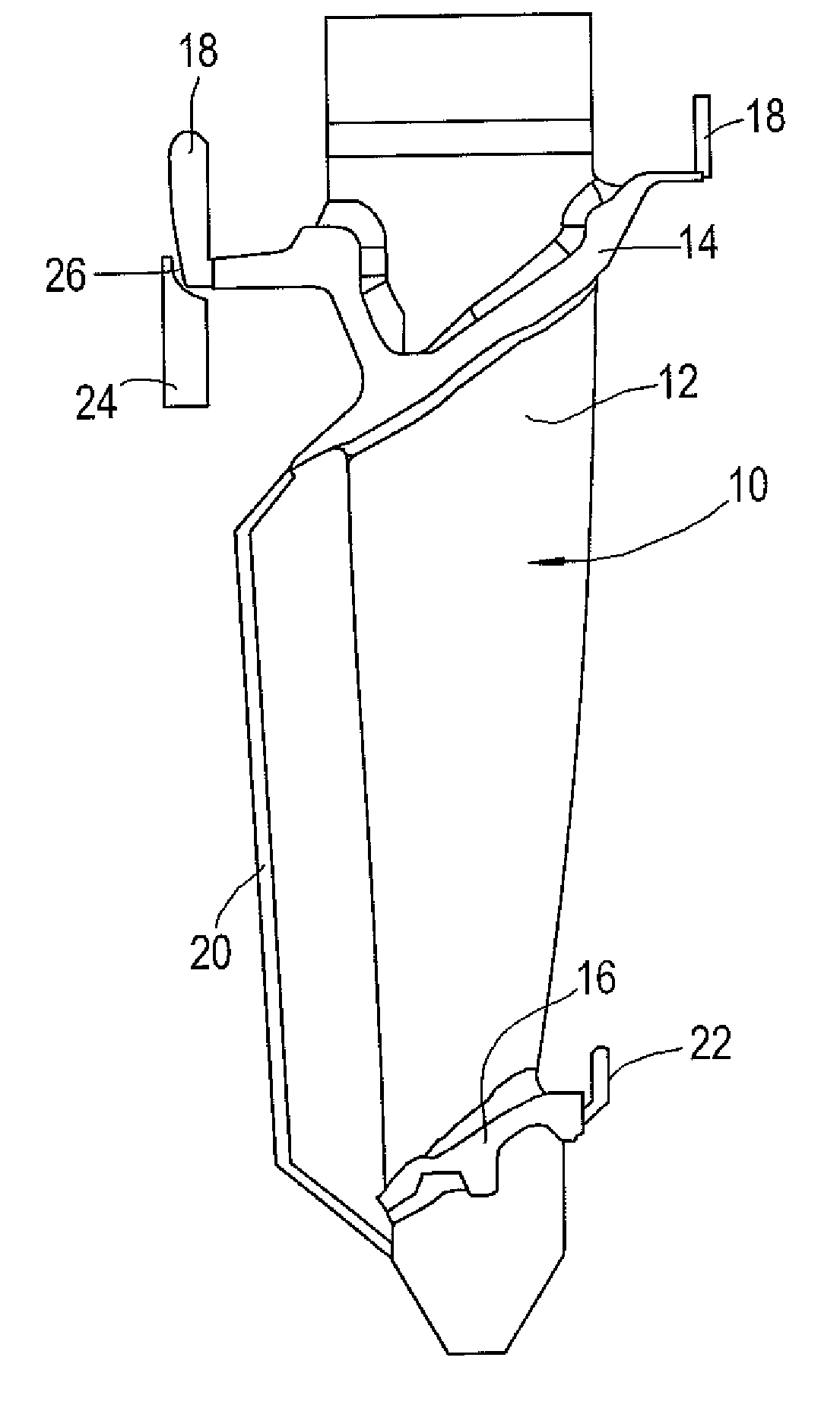

Improved method for manufacturing a shell mold for production by lost-wax casting of bladed elements of an aircraft turbine engine

ActiveUS20170151605A1Low costReduce riskLiquid surface applicatorsPump componentsImproved methodTurbine

A method for manufacturing a shell mold for the production by lost-wax casting of bladed elements (1) of an aircraft turbine engine, including the following steps: creating an assembly (200) including a wax pattern (100) as well as a device for forming a cup for pouring metal (32b) and having an end surface (40a); depositing a hot wax coating layer on at least one portion of the end surface (40a); forming the shell mold around the assembly (200). In addition, the method includes, between steps b) and c), the implementation of a step of structuring the coating layer intended for reinforcing the adhesion between the layer (46) and the shell mold, and including the production of recesses (62) and projections (60) on the still-malleable coating layer.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Casting method

In the casting of a single crystal component, such as a turbine blade, by the lost wax casting technique, one or more ceramic pieces are positioned on a wax pattern at locations corresponding to parts of the cast component where relatively quick solidification of molten metal may occur during casting. A coating is subsequently formed around the wax pattern to define a mould, whereupon the wax is removed to leave the one or more ceramic pieces within the formed mould.

Owner:ROLLS ROYCE PLC

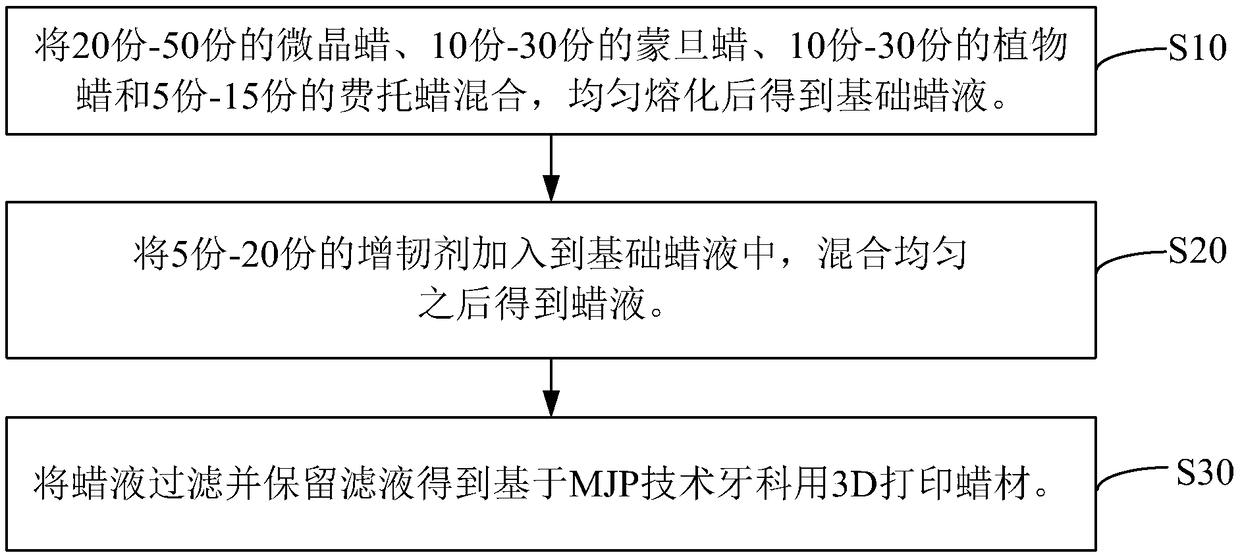

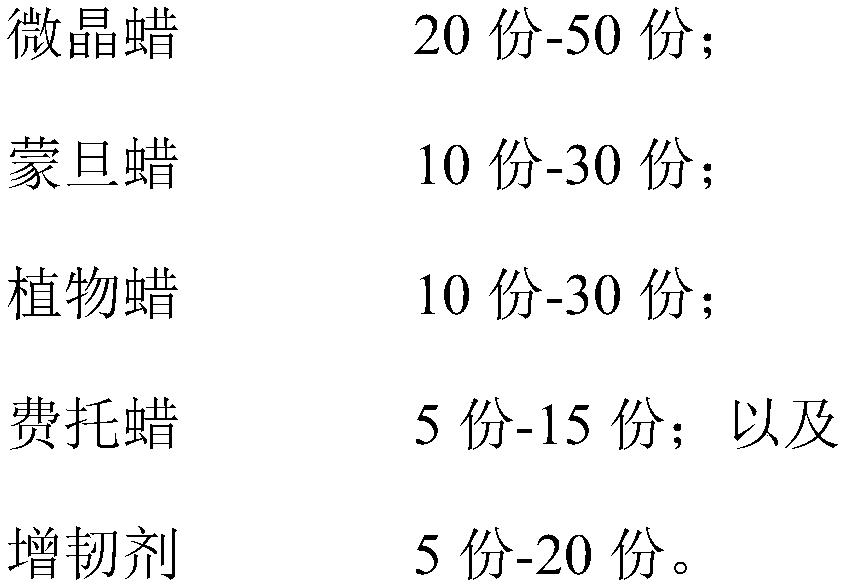

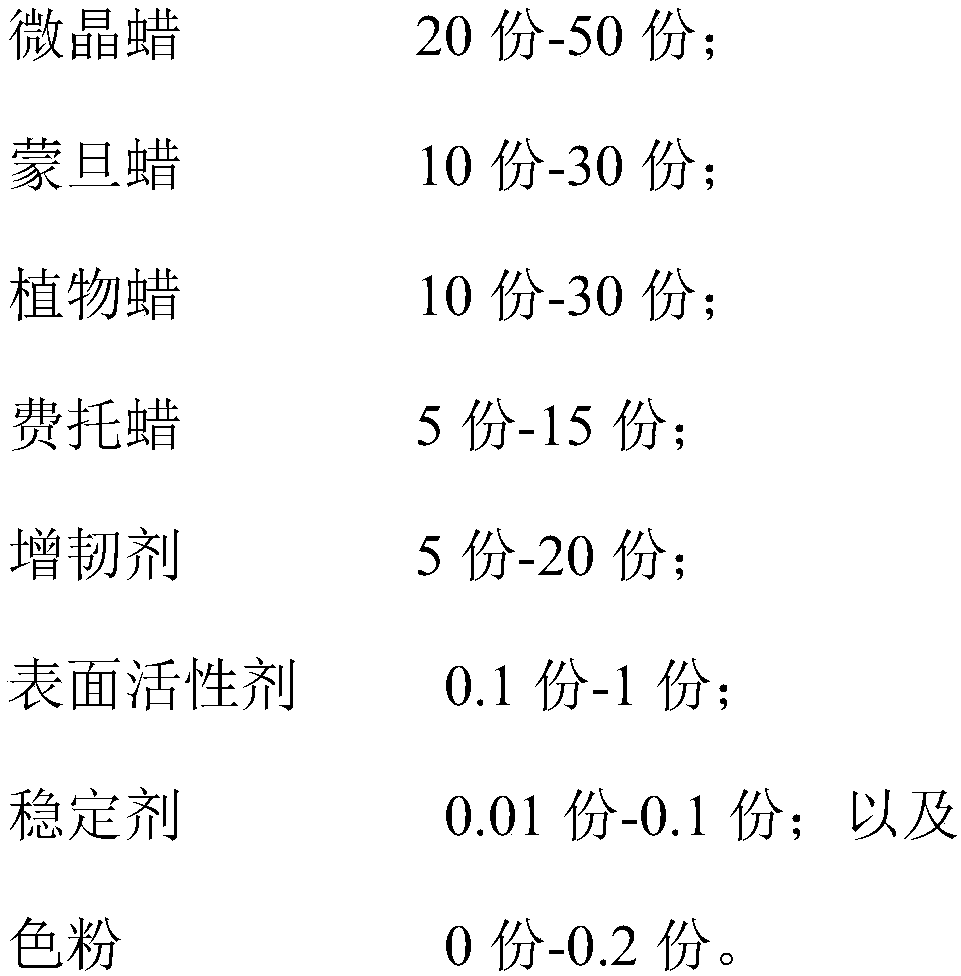

Dental 3D printing wax material based on MJP (multi-jet printing) technology and preparation method of dental 3D printing wax material

ActiveCN109438999AHigh precisionModerate kinematic viscosityAdditive manufacturing apparatusMicrocrystalline waxViscosity

The invention relates to a dental 3D printing wax material based on MJP (multi-jet printing) technology. The dental 3D printing wax material is prepared from the following raw materials in parts by mass: 20-50 parts of microcrystalline wax, 10-30 parts of montan wax, 10-30 parts of vegetable wax, 5-15 parts of Fischer-Tropsch wax and 5-20 parts of a toughening agent. The dental 3D printing wax material based on the MJP technology has the characteristic of balanced rigidity and toughness, high precision, moderate kinematic viscosity and good film forming performance; plugging, limpness and ashresidues in lost wax casting cannot occur when the dental 3D printing wax material is applied to the MJP technology, the requirements of high printing speed and high precision of the MJP technology are met, and lost wax performance in casting is good. Besides, the dental 3D printing wax material based on the MJP technology can meet the requirement of 3D printing dentistry for high precision.

Owner:GUANGZHOU DEXIN WAX PROD

Lost-wax casting waste shell total regeneration utilization new process

InactiveCN101758162AReduce manufacturing costImprove efficiencyFoundry mouldsMould handling/dressing devicesEnvironmental resistanceEngineering

The invention discloses a technological process of a Lost-wax casting waste shell total regeneration utilization new process. The new technological process of the invention comprises the following steps: waste shell collection -roll-polishing and impurity removal-de-ironing by magnetic force -refining and crushing-laying screening - measurement and package, the technological process produces regeneration sand particles by adopting a mechanical matching coordinated process. The invention is energy-saving and environment-protective, thereby bringing good overall economic efficiency.

Owner:江苏万恒铸业有限公司

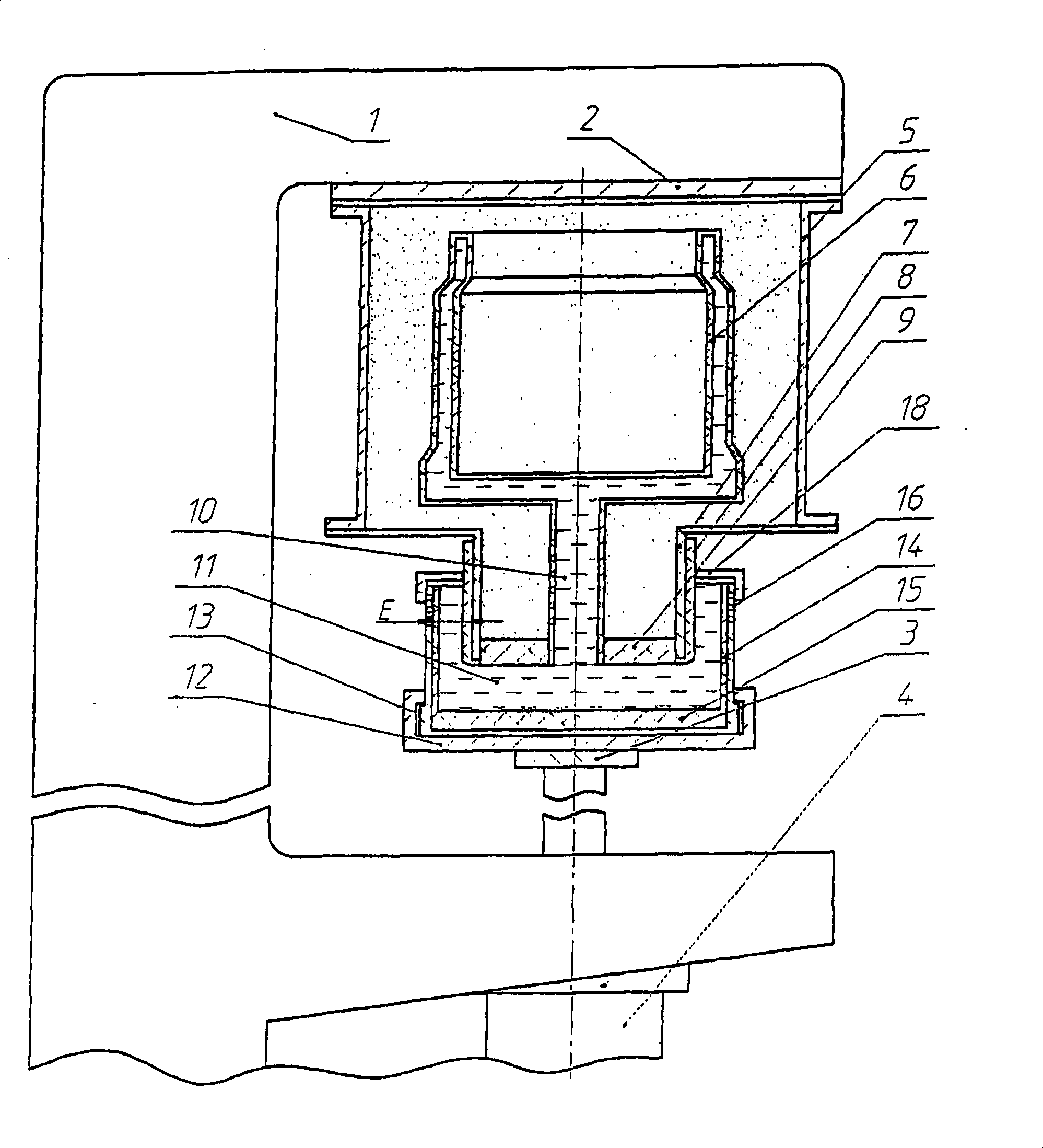

Lost-wax method associated with piezocrystallisation and a device for carrying out said method

The invention relates to a lost-wax casting method associated with piezocrystallisation, which comprises pressing a melt from a metal receiver into the cavity of a shaped investment mould at a temperature which is greater than a liquidus line and a pressure which enables a maximum splash-free liquid metal flow and which is increasable along with the melt crystallisation to a pressure sufficient for filling the mould to a quantity of a casting shrinkage volume. The inventive device for carrying out said method comprises a metal receiver embodied in the form of a removable cylinder, which is coated inside thereof and provided with an annular flange, and a container which, comprises the shaped investment mould and whose hollow throat is provided with a removable fire-resistant sleeve. The flange is mounted in such a way that the internal diameter thereof mates with the external diameter of the sleeve, wherein the internal diameter of the flange is smaller than the internal diameter of the cylinder.

Owner:OTKRYTOE AKTSIONERNOE OBSHCHESTVO NOVOSIBIRSKIJ ZAVOD KHIMKONTSENTRATOV

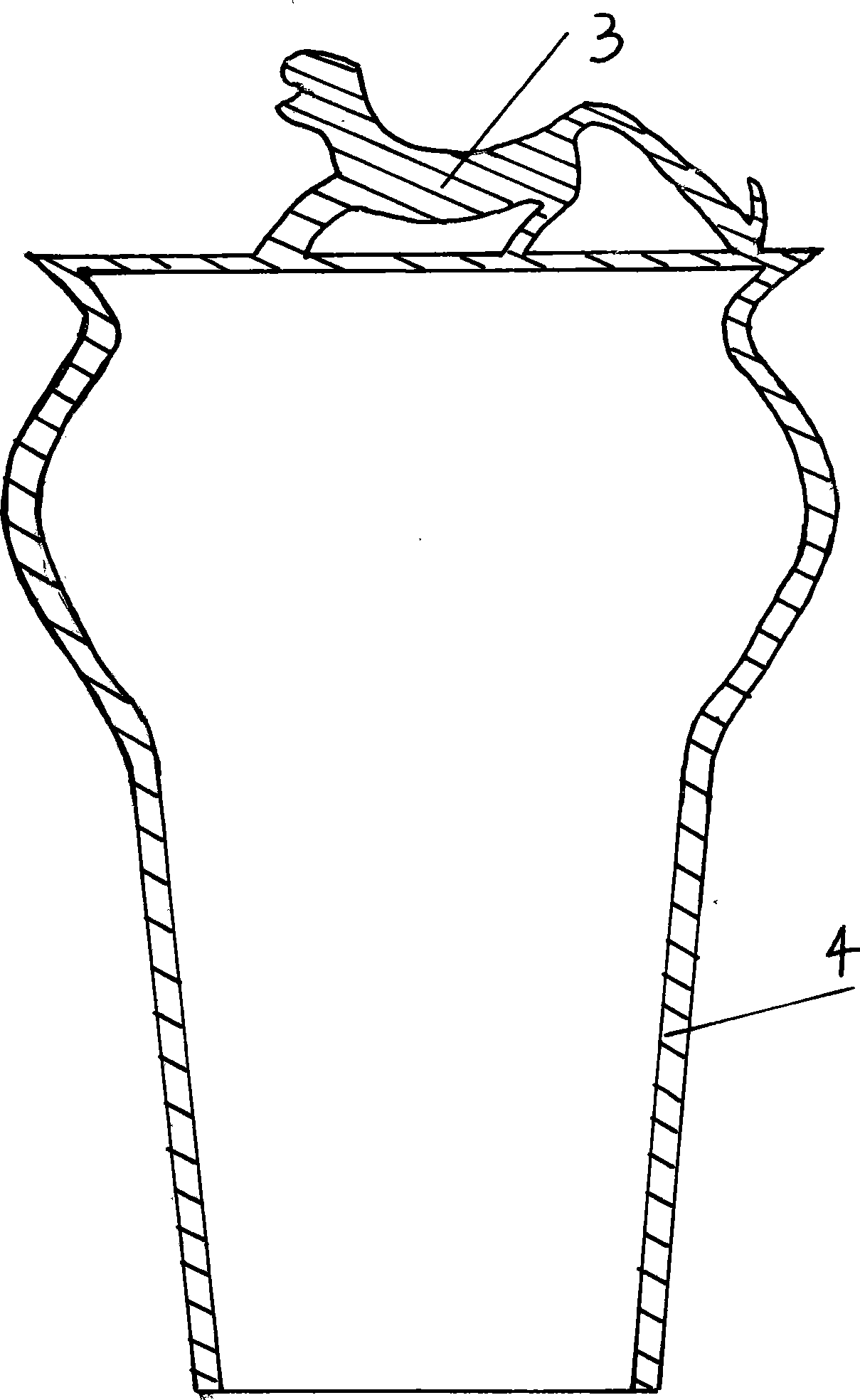

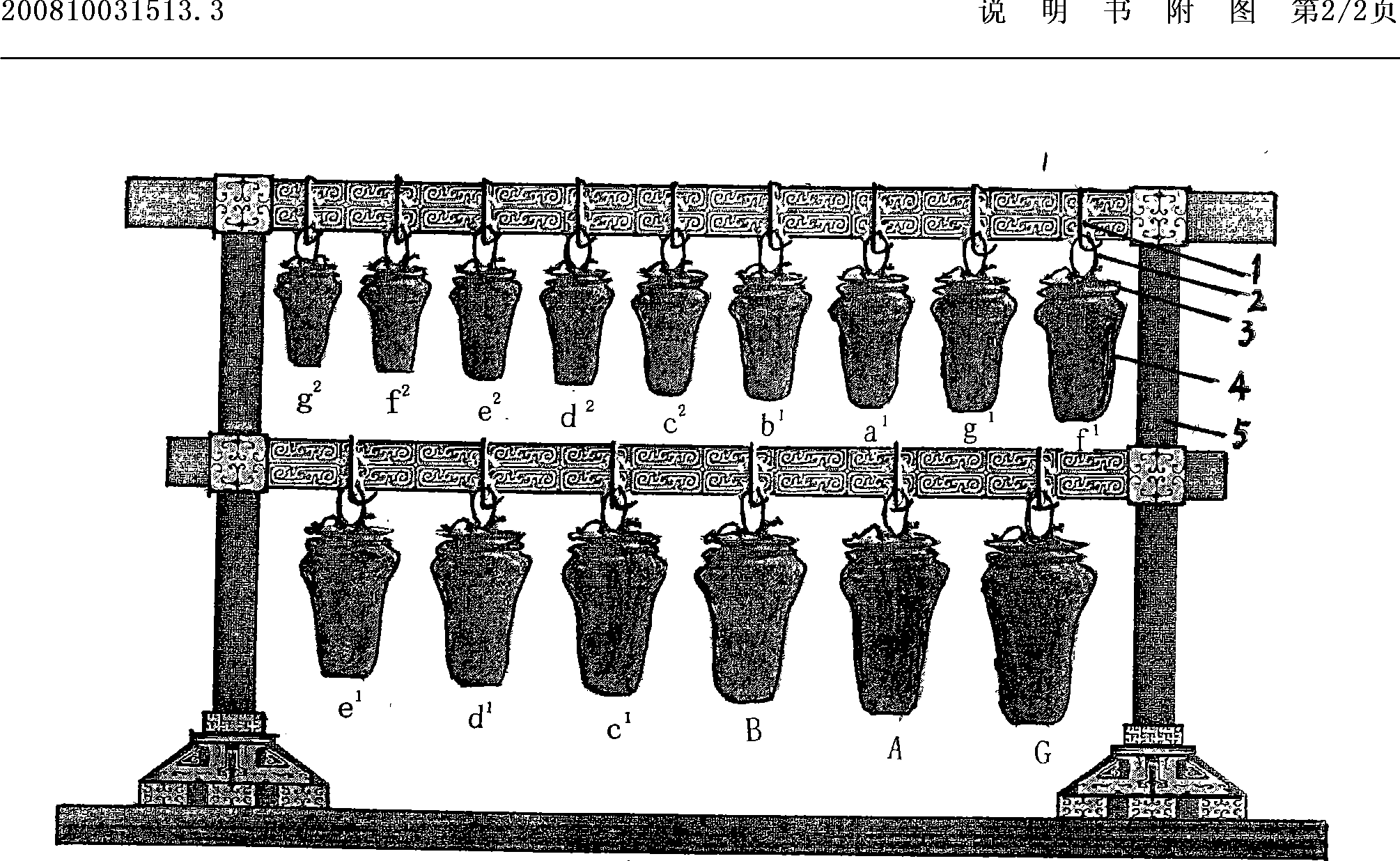

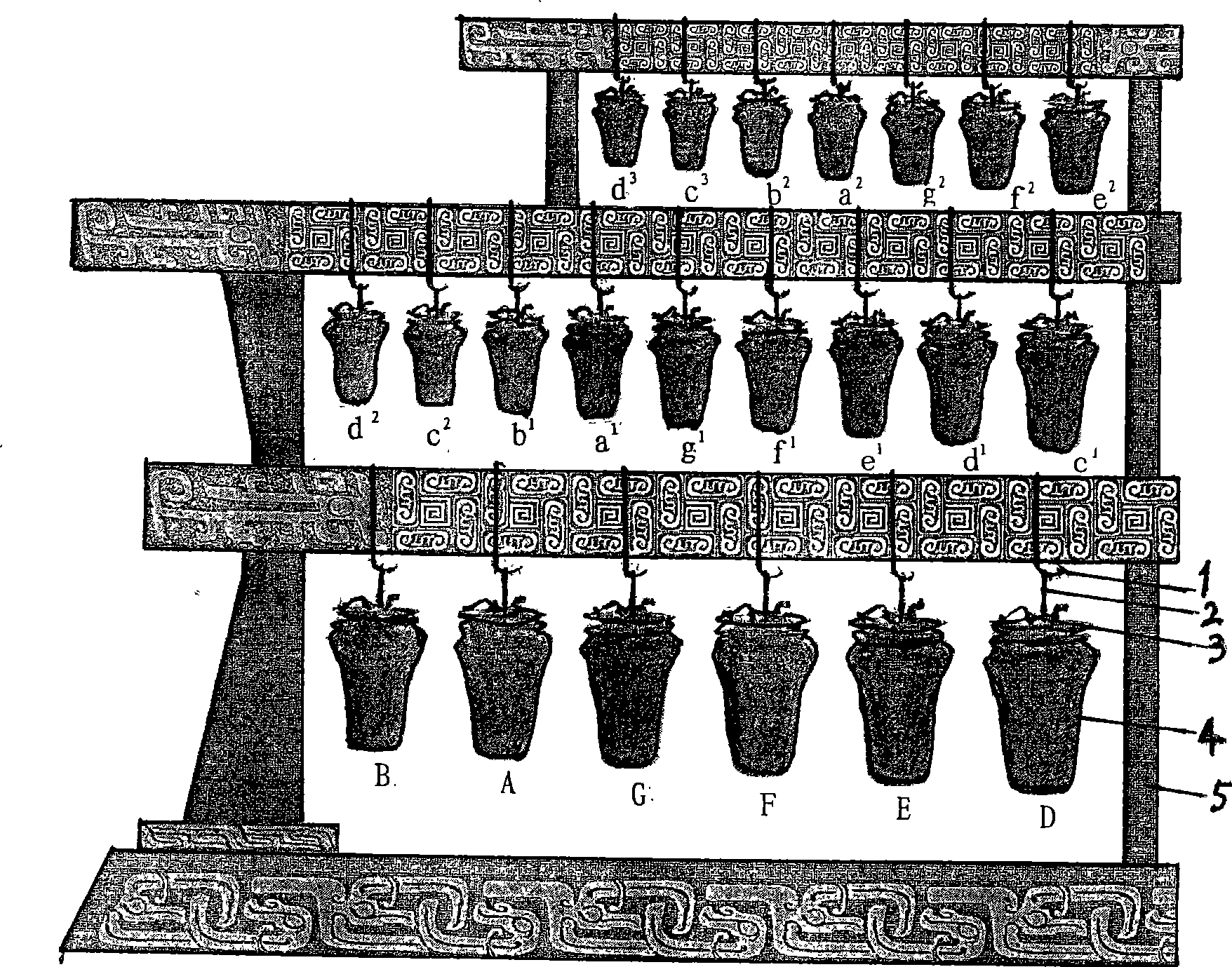

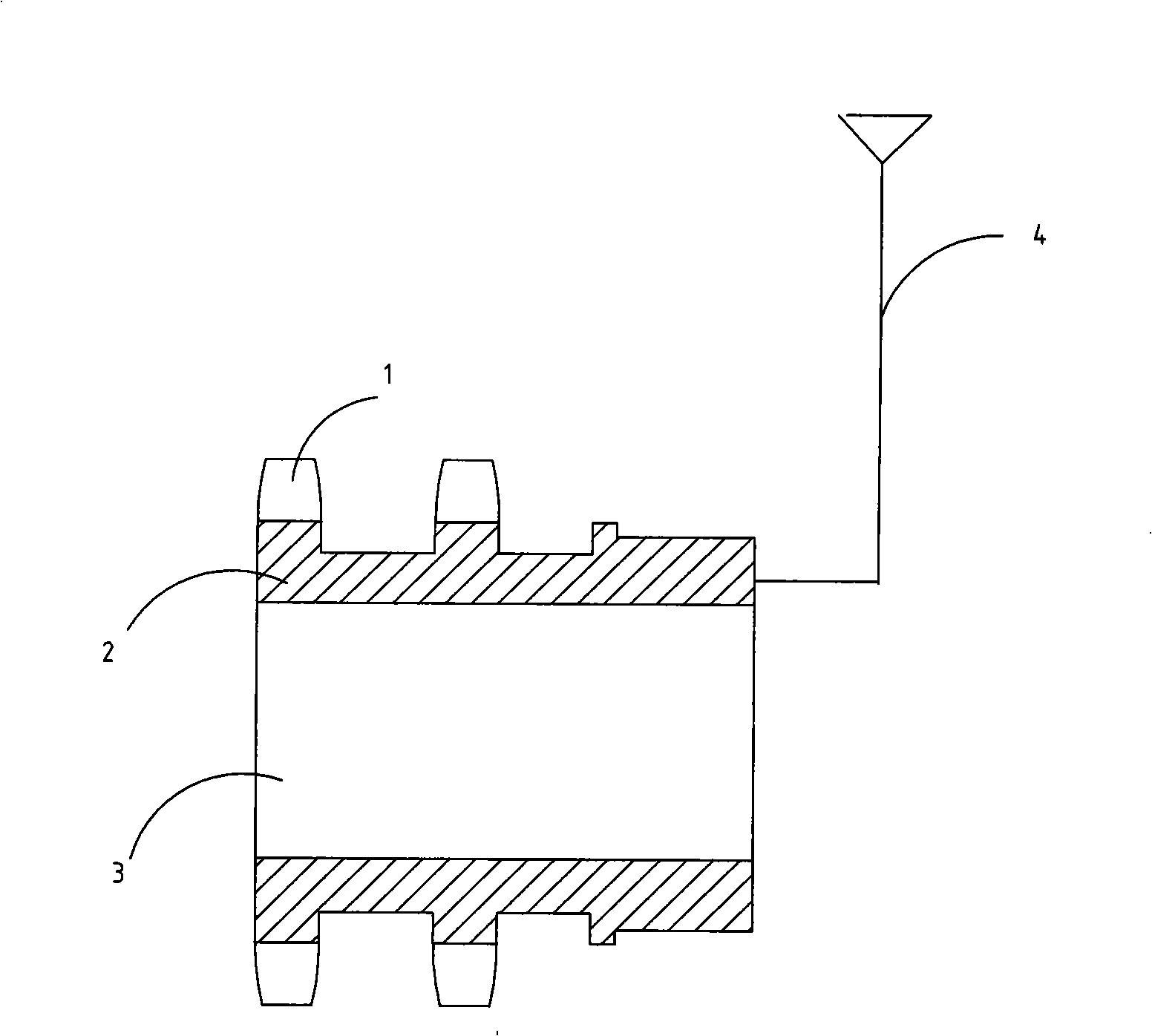

Percussion instrument made of Chunyu

A percussion instrument made from Chunyu (an ancient musical instrument) belongs to the technical field of musical instruments. The percussion instrument consists of a plurality of Chunyu instruments, a mallet, a hook, a sling and a bracket and is characterized in that each Chunyu instrument has the same shape and material but is different in height, diameter and the thickness of supporting wall. Each Chunyu instrument is arranged into 1-4 layered structure capable of being used for music performance according to the respective height and the mode, scale of produced sound and each layer of the Chunyu instrument is hung on the bracket by the hook and the sling. Each Chunyu instrument is respectively cast from bronze by adopting a lost wax casting process and accords with the note arrangement from pitch to bass according to produced sound. One scale is remained among every Chunyu instrument, so an executant can fix the tone independently and can play music of different scores by using the mallet to beat different Chunyu instruments. The percussion instrument not only remains the advantages of resonant sound, exaggerated performance and generous shape of an ancient Chunyu instrument, but also richens the variety of percussion instruments and can be used as a main or auxiliary musical instrument.

Owner:刘朝阳

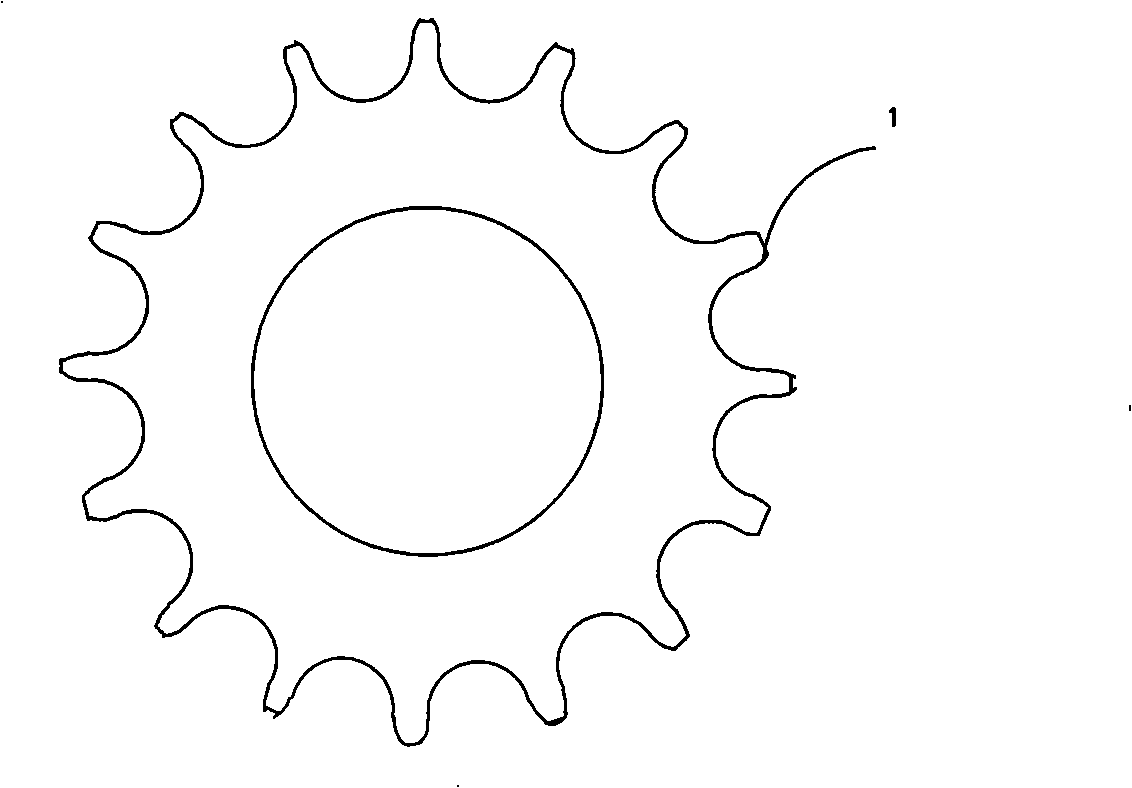

Double-row chain pulley

InactiveCN101354075AReduce consumptionReduce the amount of machiningFoundry mouldsPortable liftingFree coolingEngineering

The invention discloses a double-row sprocket wheel which is used as a component for transmission movement and comprises a sprocket wheel body, wheel teeth and a shaft hole. The finished product of the sprocket wheel is obtained by steps that: the product is basically formed by No. 45 steel by the lost-wax casting; the left end part of the shaft hole is cut and processed into the hole that is matched with a bearing; then tooth surface is quenched to obtain the finished product. The technology adopted by the lost-wax casting and the parameters are as follows: a. a formwork needs to be cured at 800 DEG C to 850 DEG C and is cooled to the temperature of 600 DEG C to 650 DEG C naturally so as to carry out casting; b. iron melt is heated to the temperature of 1650 DEG C to 1680 DEG C and expanded perlite powder is added for covering the iron melt; after 2 to 3 minutes, scum in a furnace is removed by a mechanical way; then appropriate amount of SiC is added for deoxidation, after that the casting is carried out; c. only one sprue runner is provided. The double-row sprocket wheel uses the lost-wax casting to replace the manufacturing method of using roughcast round steel for cutting and processing, thus greatly reducing the cutting capacity and reducing the product cost; meanwhile, the technological parameters of the sprocket wheel are reasonable and the qualification rate is high, therefore, the quality of the manufactured product can fully accord with the actual use requirements.

Owner:象山爵溪明嘉机械厂

Copolymer based powdered material for selective laser sintering and preparation method thereof

The invention discloses a multipolymer base powder material used for SLS and a preparation method thereof. The multipolymer is a styrene-acrylonitrile (SAN) multipolymer. The preparation method comprises the following steps that: firstly, an SAN resin is subjected to deep cooling and crushing; secondly, the multipolymer powder with appropriate grain diameter and appropriate distribution of the grain diameter is selected by the sieve method; and finally, a certain proportion of the multipolymer powder, carbon soot and a flow aid are mixed evenly to produce the multipolymer base powder material. Because the SAN is an amorphous polymer, the vitrification temperature is low and the die shrinkage is small; therefore, the multipolymer base powder material has good sintering performance and highdrip molding accuracy. Meanwhile, the SAN has appropriate melt viscosity and body intensity; therefore, the SLS die molding of the multipolymer base powder material also has high intensity. The multipolymer base powder material can be used to manufacture a wax pattern used for lost wax casting and a functional element meeting general requirements through SLS forming and appropriate post treatment.

Owner:武汉华科三维科技有限公司

Cold mold casting method of rubber

InactiveCN104550700AReduce manufacturing costMeet the requirements of precision castingFoundry mouldsFoundry coresConventional castingSand casting

The invention discloses a cold mold casting method of rubber. The cold mold casting method is a novel technique which is completely different from the conventional casting technique. The casting cost of the cold mold casting method is reduced by 35-50% when being compared with that of lost wax casting and lost foam casting, so that cast parts of which the cost is equivalent to that of ordinary sand casting and the quality can completely meet the requirements of precise casting can be produced through cold mold casting. Metals which can be applied to cold mold casting at present are gray cast iron, spheroidal graphite cast iron, cast steel, aluminum alloy, copper alloy and the like.

Owner:QINGDAO WUYANG CASTING MACHINE

Casting method for shell mold made by 3D printing

The invention relates to the technical field of lost-wax casting technology, in particular to a casting method using 3D printing shell molds. The casting method of the 3D printing shell mold includes the following steps. First, draw the drawings by computer according to the products to be processed; second, input the drawn drawings into the 3D printer for 3D printing of the shell mold; Carry out sintering treatment to sinter and solidify the printed shell mold; fourthly, the shell mold after sintering is used as a casting cavity, and molten raw materials are injected into the shell mold to shape it, and finally the entire shell mold is taken out and the shell is broken The molded product can be taken out of the mold; fifthly, the finished product is obtained after post-processing the molded product; the printing material used in the above-mentioned 3D printing is mixed with a liquid mixture of photosensitive resin and ceramic powder. After adopting the above technical scheme in the present invention, the shell mold is directly printed by a 3D printer, thus eliminating the shell mold manufacturing process in the traditional process and improving production efficiency.

Owner:LIANYUNGANG YYU PROD

Lost-wax casting process with contact layer

A dewaxing casting technology using contact layer for preparing the multi-layer ceramic shell mould including a mother mould made of wax or its similar material and at least one contact layer includes such steps as dipping said mother mould in a modeling paint containing ceramic particles and adhesive to form a contact layer, depositing black particles on said contact layer, and drying.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method for bonding chillers in lost wax casting process

InactiveCN109396341AImprove process yieldFulfil requirementsFoundry mouldsFoundry coresInvestment castingSteel bar

The invention discloses a method for bonding chillers in a lost wax casting process. The method includes the steps: 2) determining hot spot regions on castings according to casting drawings, determining bonding positions of the chillers, and calculate the area of the hot spot regions; 2) preparing cast steel bars, determining the sizes of the chillers according to the area of the hot spot regionsacquired in the step 1), machining the cast steel bars into the chillers meeting size requirements by the aid of a sawing machine, machining more chillers with the same specification sizes by the aidof chiller molds, and preparing the chillers meeting requirements by an investment casting mode; 3) preparing installed and welded wax molds, cleaning the outer surfaces of the chillers and the regions on the wax molds for bonding the chillers, removing sand grains and oil stain, and ensuring bonding firmness of the chillers. According to the method, the inner quality and the machining requirements of the castings can be ensured, and production cost is reduced.

Owner:安徽应流铸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com