Dental 3D printing wax material based on MJP (multi-jet printing) technology and preparation method of dental 3D printing wax material

A 3D printing and dental technology, applied in the field of 3D printing materials, can solve the problem of scarcity of dental 3D printing wax materials, and achieve the effect of good wax loss performance, fast speed and moderate kinematic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

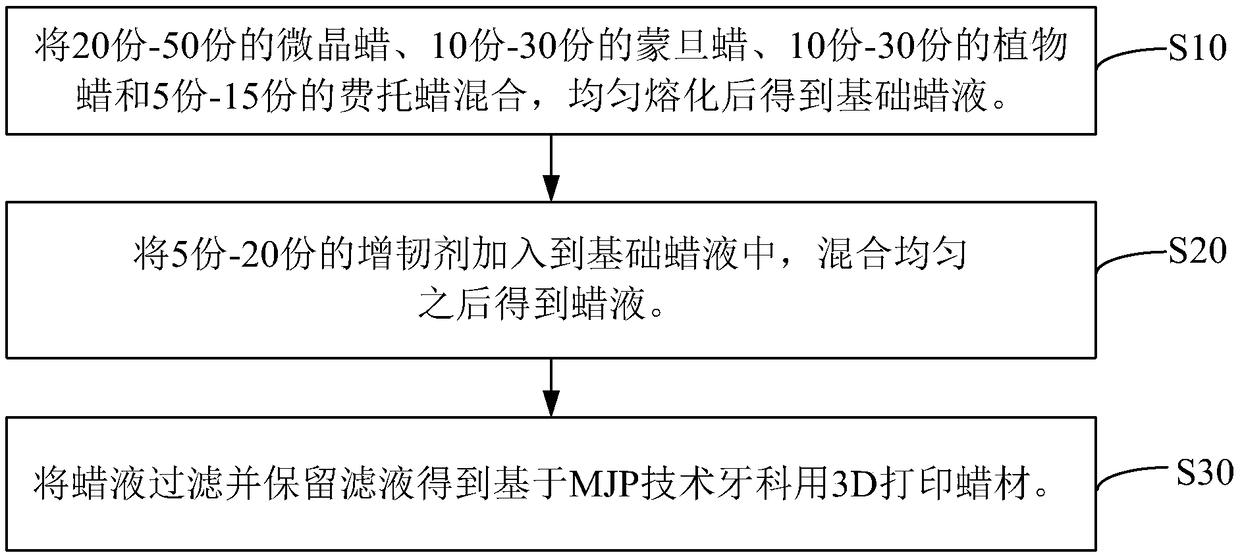

[0041] See figure 1 , the preparation method of dental 3D printing wax material based on MJP technology in one embodiment of the present invention, comprises the following steps:

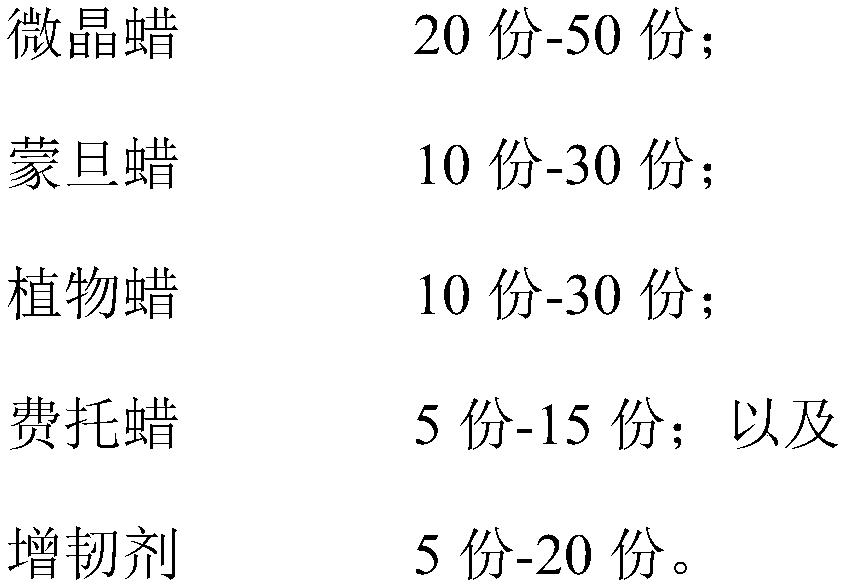

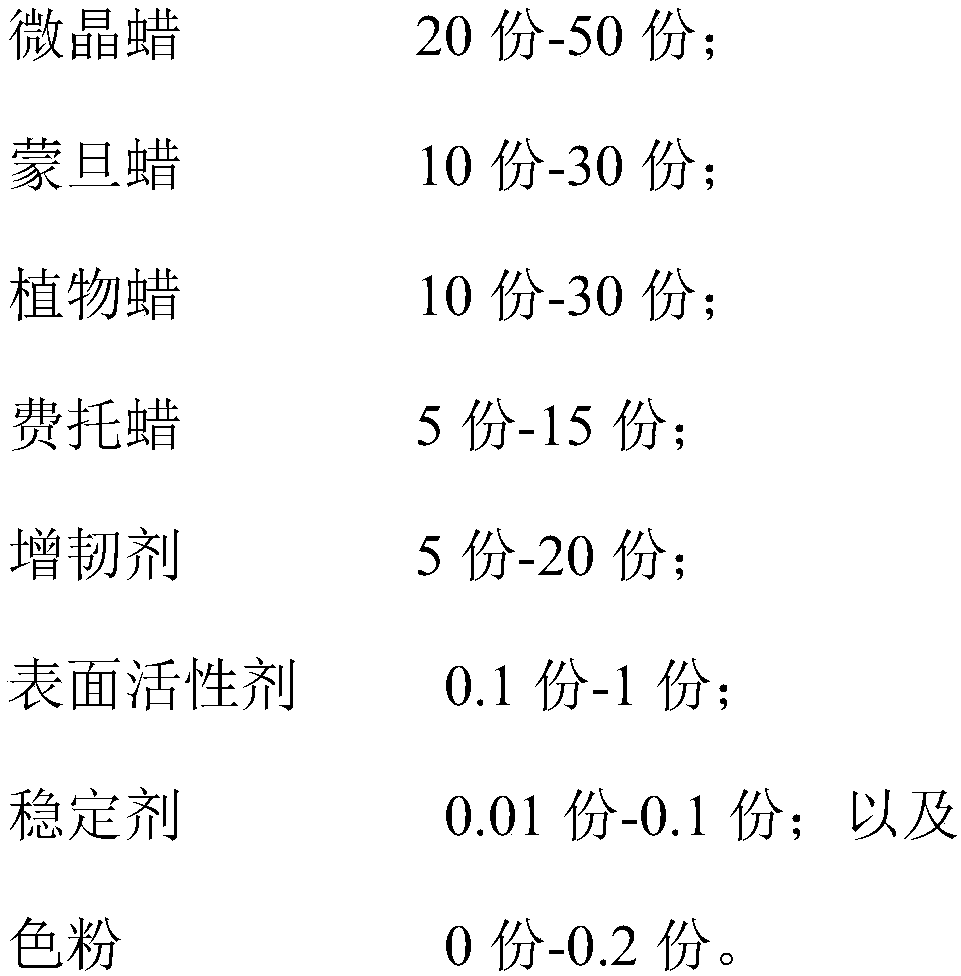

[0042] S10, according to the mass parts, mix 20-50 parts of microcrystalline wax, 10-30 parts of montan wax, 10-30 parts of vegetable wax and 5-15 parts of Fischer-Tropsch wax, and evenly melt Afterwards, the basic wax liquid is obtained.

[0043] Preferably, according to the number of parts by mass, 20-50 parts of microcrystalline wax, 10-30 parts of montan wax, 10-30 parts of vegetable wax and 5-15 parts of Fischer-Tropsch wax are mixed evenly During melting operation: maintain the mixing temperature at 100°C-110°C. The above raw materials are all solid, and the mixing temperature is maintained at 100°C-110°C, which can melt each raw material and make it better evenly mixed.

[0044] S20. According to the parts by mass, 5 parts to 20 parts of the toughening agent are added to the basic wax liqu...

Embodiment 1

[0060] Add 20g 85# microcrystalline wax, 30g montan wax, 20g wood wax, 5g rice bran wax and 5g Fischer-Tropsch wax into the reaction kettle, control the temperature at 100°C, and obtain the basic wax liquid after uniform melting.

[0061] Add 19.3g of ethylene-vinyl acetate copolymer, 0.5g of sorbitan monostearate, 0.1g of dibutyl hydroxytoluene and 0.1g of Xinbo SB3602 into the above-mentioned basic wax liquid, control the temperature at 110°C, and use 800r / After stirring for 1.5 h at a stirring speed of min, a wax liquid was obtained.

[0062] Filter the above wax liquid through suction filter bottles with 100 μm, 20 μm and 5 μm filter elements while it is hot, and fill the filtrate to obtain dental 3D printing wax based on MJP technology.

Embodiment 2

[0064] Add 48.7g 70# microcrystalline wax, 12g montan wax, 18g 3# carnauba wax and 6.5g Fischer-Tropsch wax into the reaction kettle, control the temperature at 100°C, and obtain the basic wax liquid after uniform melting.

[0065] Add 8g of polyethylene with a molecular weight of 3000-5000, 6.2g of amorphous α-olefin copolymer, 0.45g of polysorbate-80, 0.05g of 2,6-di-tert-butyl-p-cresol and 0.1g of Xinbo SB3422A Into the above basic wax liquid, control the temperature at 100°C, stir at a stirring speed of 650r / min for 2h, and obtain the wax liquid.

[0066] Filter the above wax liquid through suction filter bottles with 100 μm, 20 μm and 5 μm filter elements while it is hot, and fill the filtrate to obtain dental 3D printing wax based on MJP technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com