Lost-wax method associated with piezocrystallisation and a device for carrying out said method

A technology of pressure crystallization and lost wax casting, which is applied to casting molding equipment, metal processing equipment, casting molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

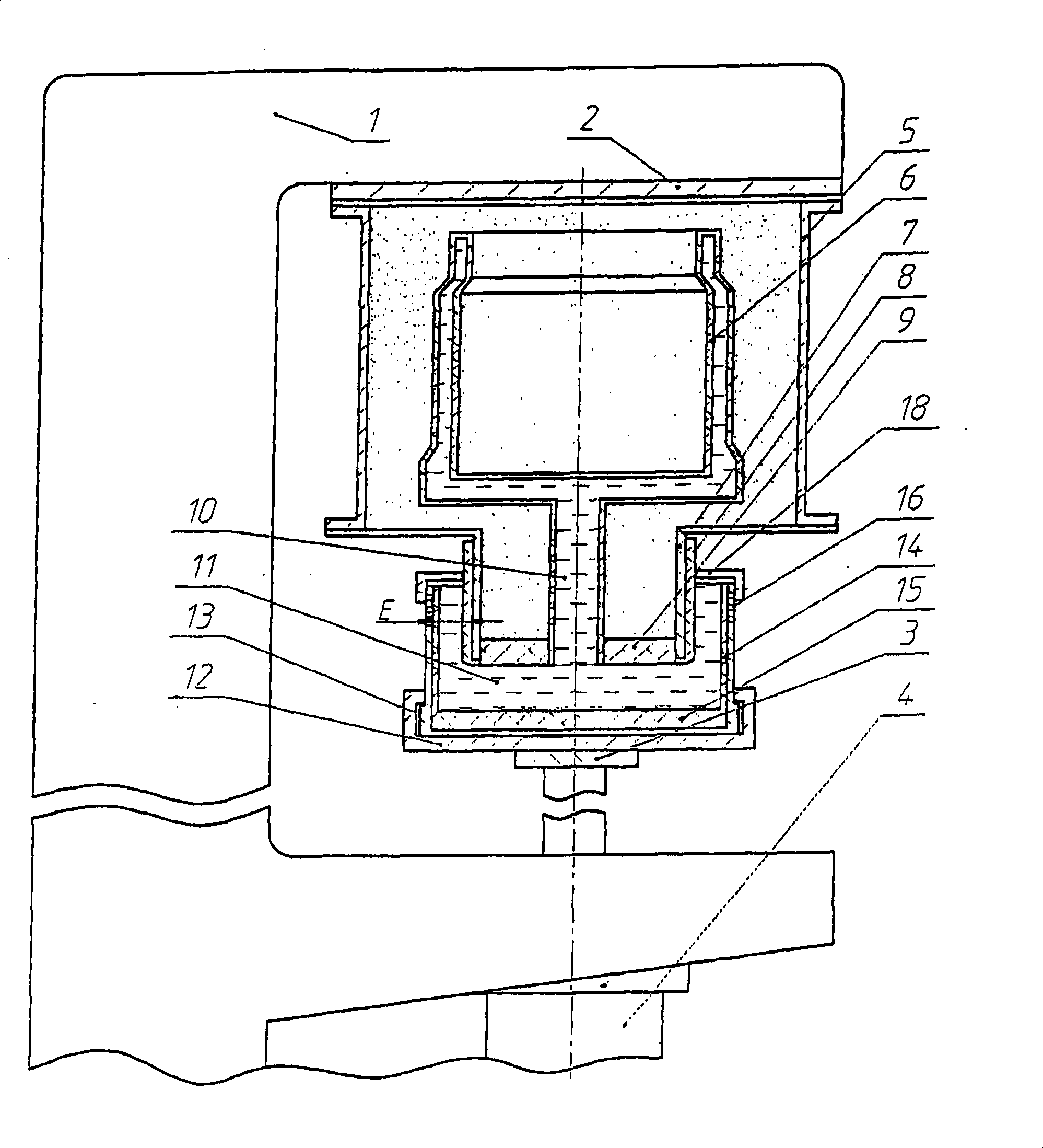

[0012] The apparatus for lost-wax casting under pressure crystallization comprises a column 1 with a fixed upper table 2 and a movable lower table 3 that can be driven by a fluid drive 4 . A mounting container 5 with a wax mold 6 molded with filling material is rigidly connected to the upper table 2 . Placed on the neck 7 of the receiving container 5 is a removable refractory sleeve 8 which is held fixed in a lower plane of the neck 7 by means of a closure 9 . The closure 9 is also responsible for accommodating the filling material in the container 5 and for a sprue with an opening in the wax mold 6 . On the lower worktop 3 there is a metal container 11 with a base 12 , in a groove 13 of the base 12 , with a guaranteed clearance, a removable cup 14 with an airtight inner lining 15 is arranged. The closure 9 and the inner lining 15 can consist of a mandrel compound or a water glass mixture. An opening 16 for the escape of gas is provided in the upper part of the housing of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com