Double-row chain pulley

A double-row sprocket and sprocket technology, which is applied in belts/chains/gears, portable lifting devices, hoisting devices, etc., can solve the problem that the weight of the finished product is less than one-third of the weight of the blank, the cutting volume is large, and the processing is complicated. problems, to achieve the effect of saving steel consumption, high pass rate, and reducing the amount of cutting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

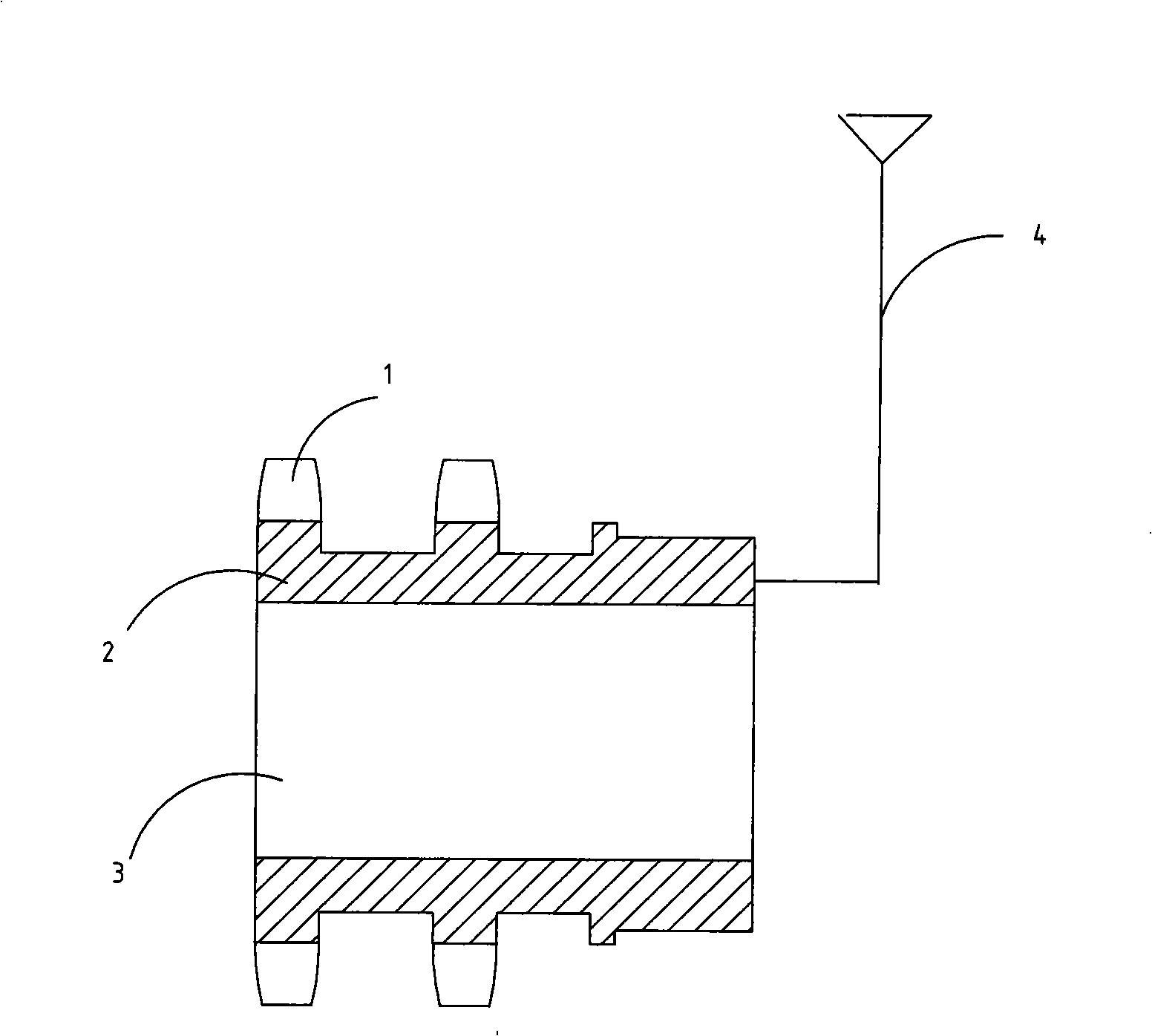

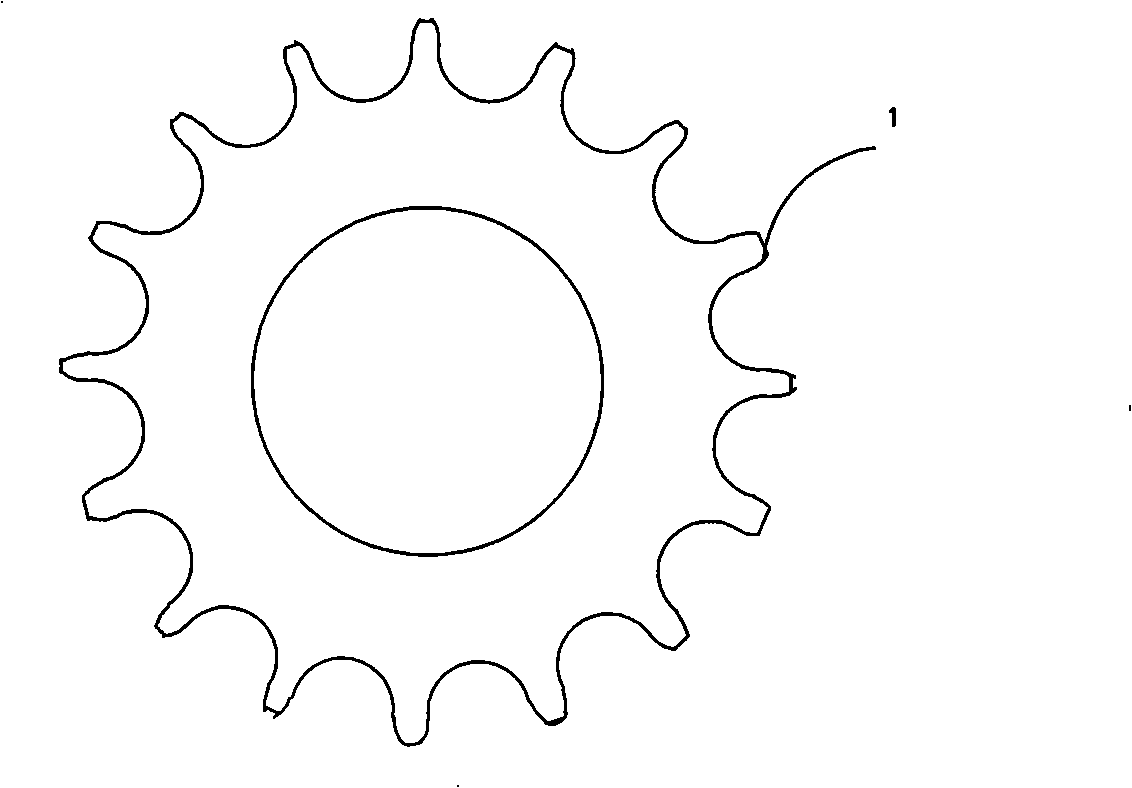

[0013] Depend on figure 1 and figure 2 As shown, a double-row sprocket of the present invention includes a sprocket body 2, a gear tooth 1 integrated with the body, and a shaft hole 3 in the center of the body; it is basically formed by No. 45 steel through lost wax casting, and the shaft The left end part of the hole is cut and processed into a hole that matches the bearing, and then the finished product is finished after the tooth surface is quenched; because the double-row sprocket has many teeth, taking the φ60 double-row sprocket as an example, the teeth are just As many as 28, the compactness of the casting is high, and the casting is difficult; the process and parameters used in the casting of the present invention are as follows:

[0014] a. The formwork needs to be cured at 800-850°C, and then cast after natural cooling to 600-650°C;

[0015] b. Heat the molten iron to 1650-1680°C, add expanded perlite powder to cover the molten iron, after 2-3 minutes, remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com