Patents

Literature

86results about How to "The assembly position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

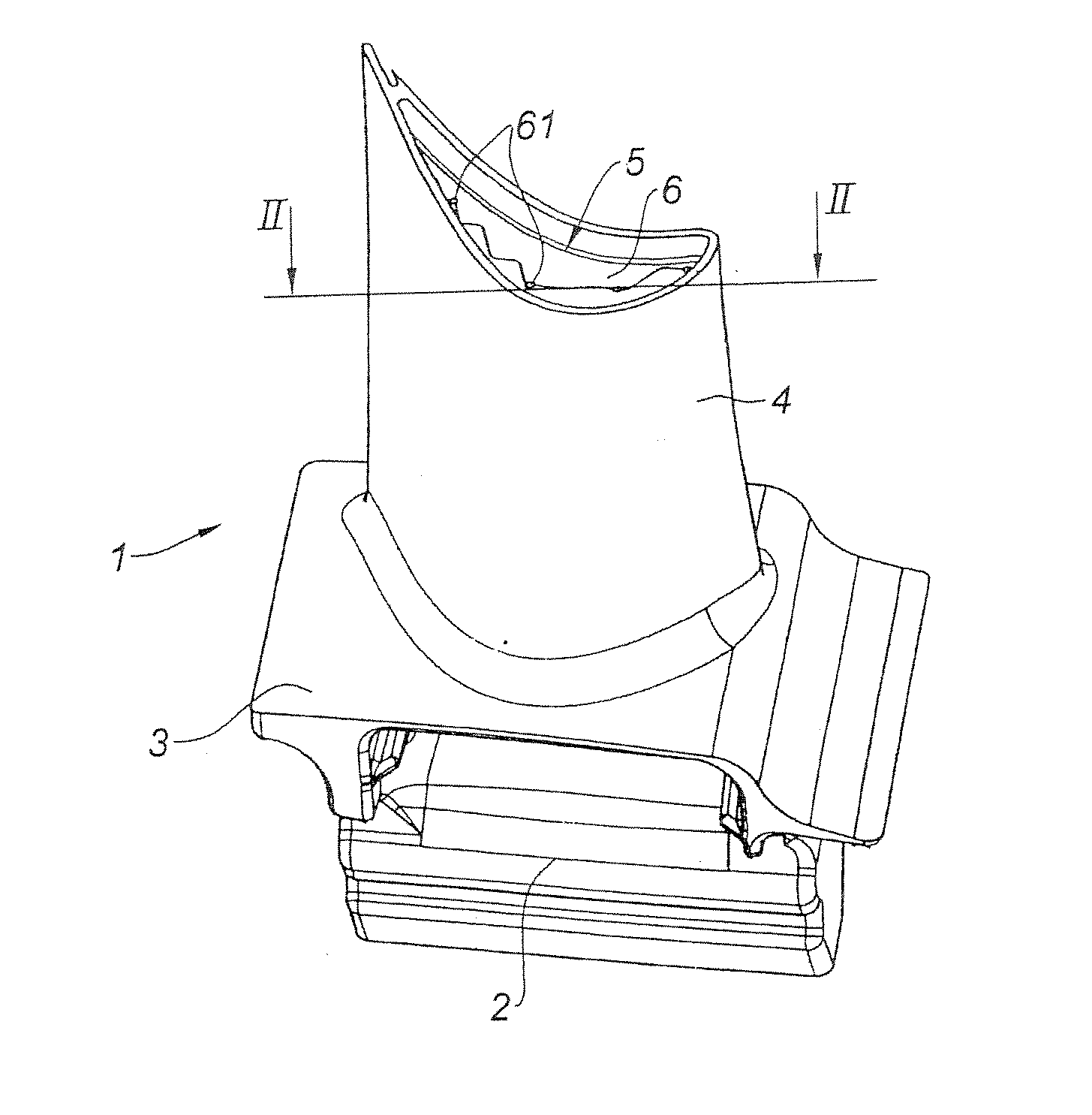

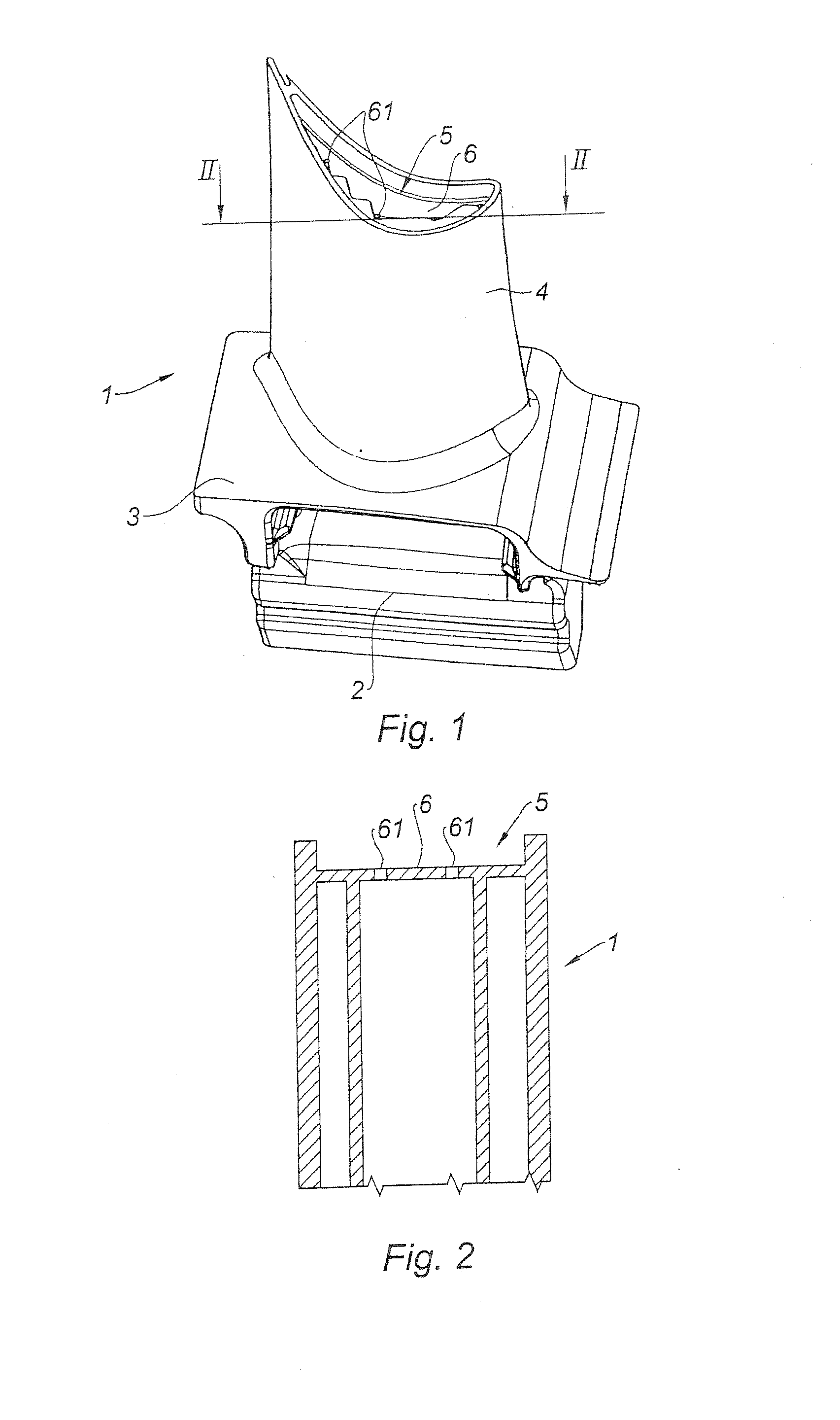

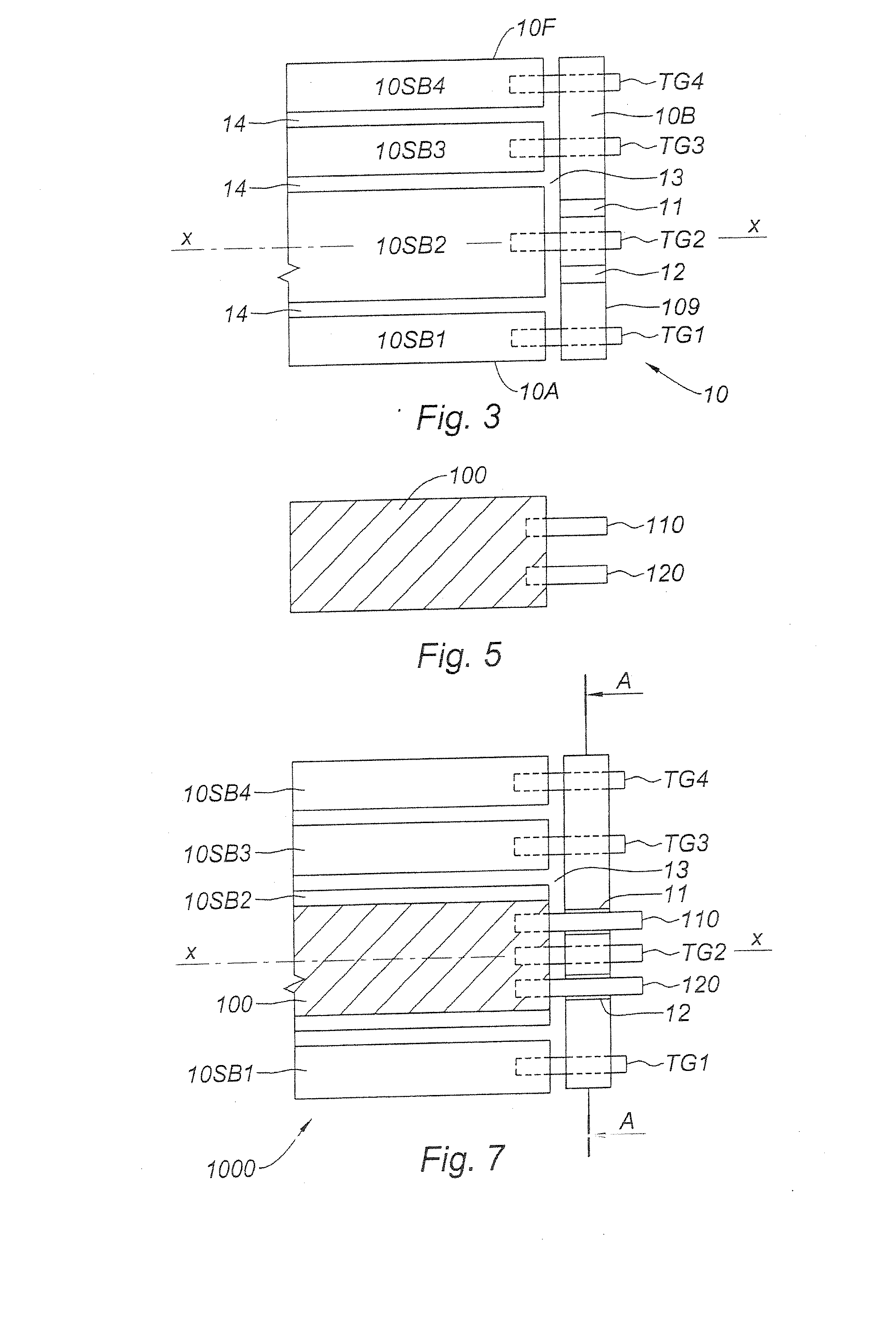

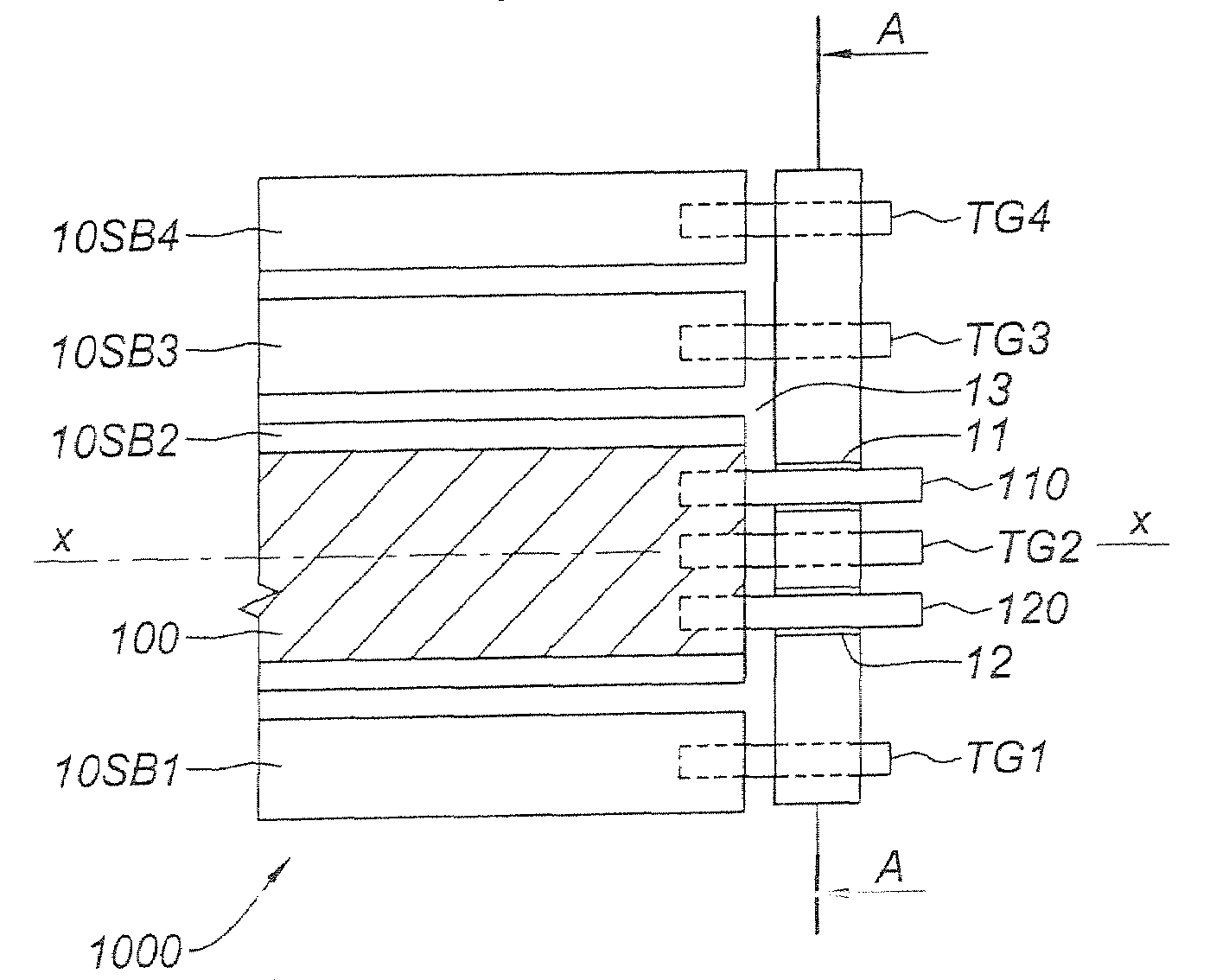

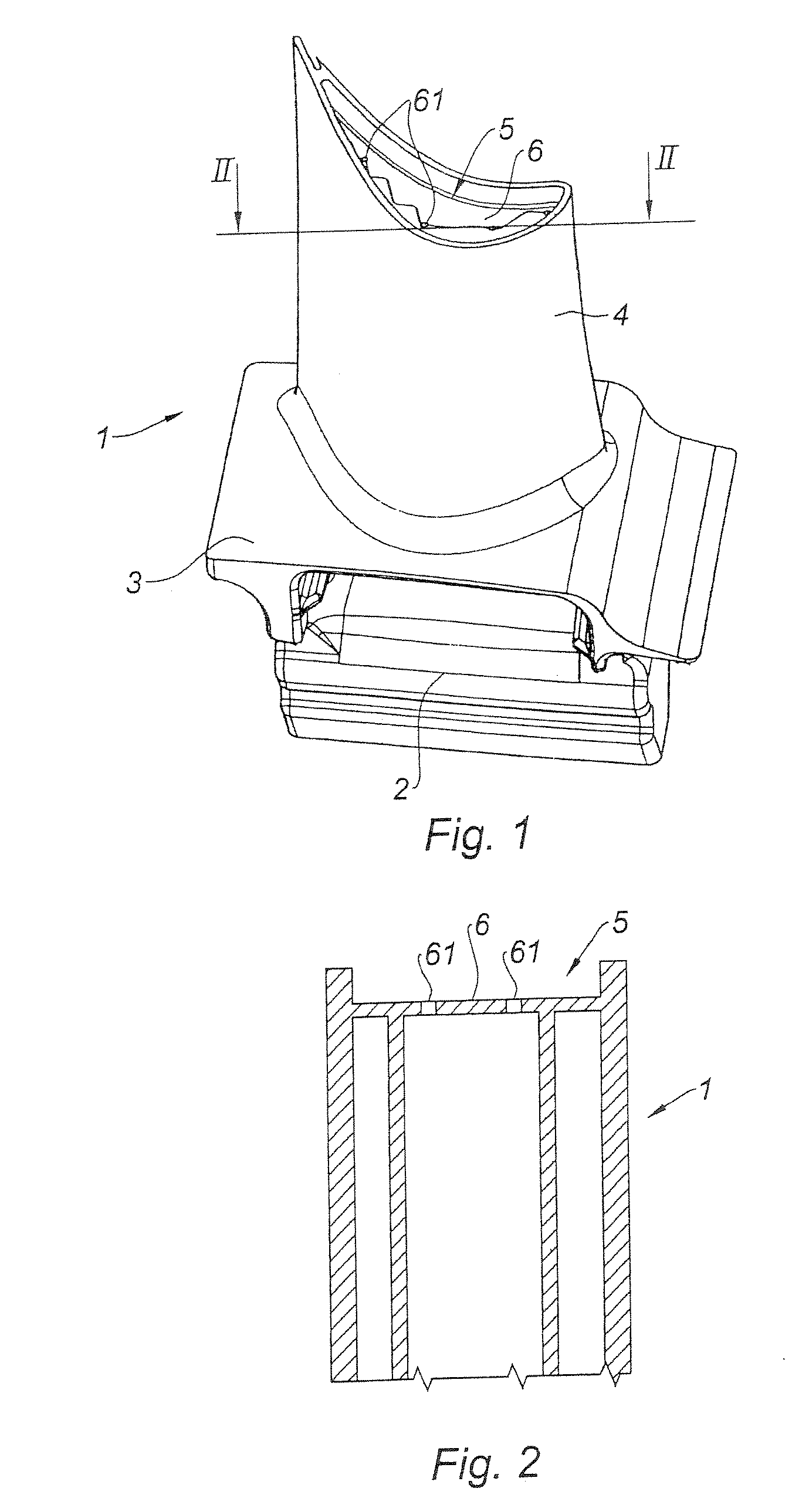

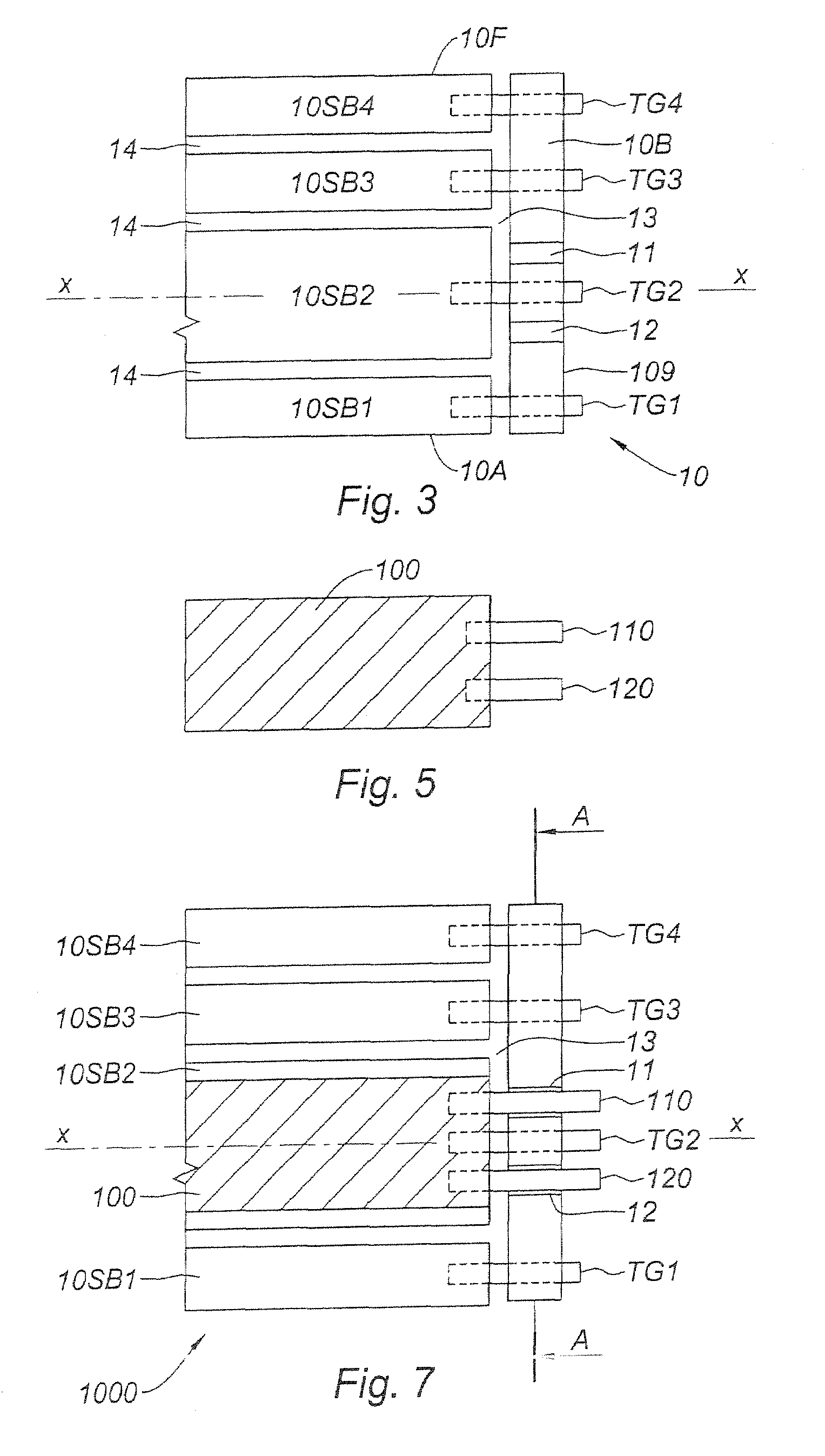

Core for turbomachine blades

ActiveUS20070025851A1The assembly position is accurateBlade accessoriesFoundry mouldsMechanical engineeringLost-wax casting

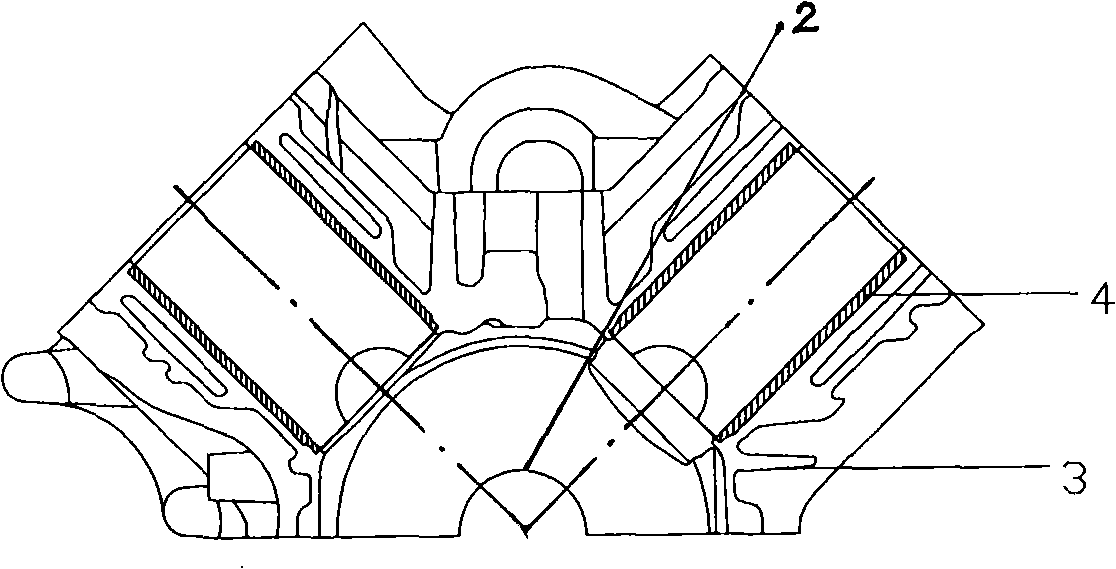

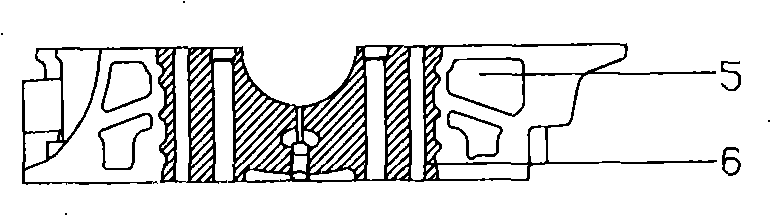

The present invention relates to a ceramic core used in the manufacture, by lost wax casting, of a turbomachine blade with cooling cavities and a squealer, comprising at least one main core, wherein the main core (10) comprises an element (10B) shaped so as to constitute the squealer and an element (10SB) shaped so as to constitute at least one cavity beneath the squealer, the two elements leaving between them a space (13) shaped so as to constitute, at least in part, the bottom wall of the squealer. In particular, the elements (10B and 10SB) are joined together by ceramic rods (TG).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

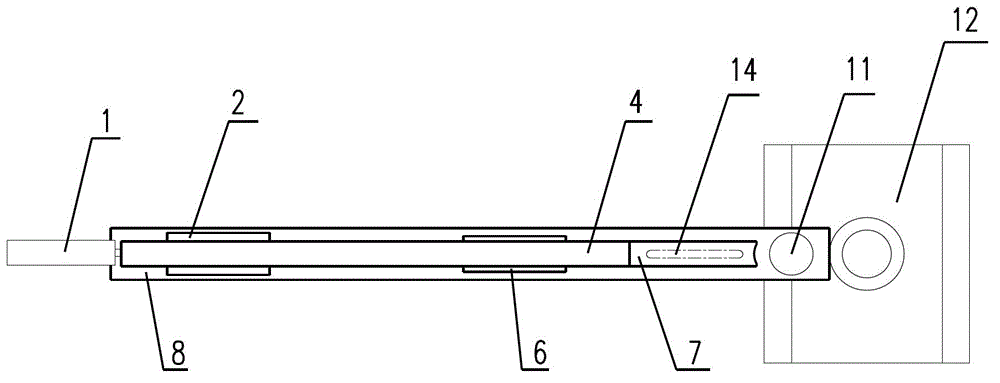

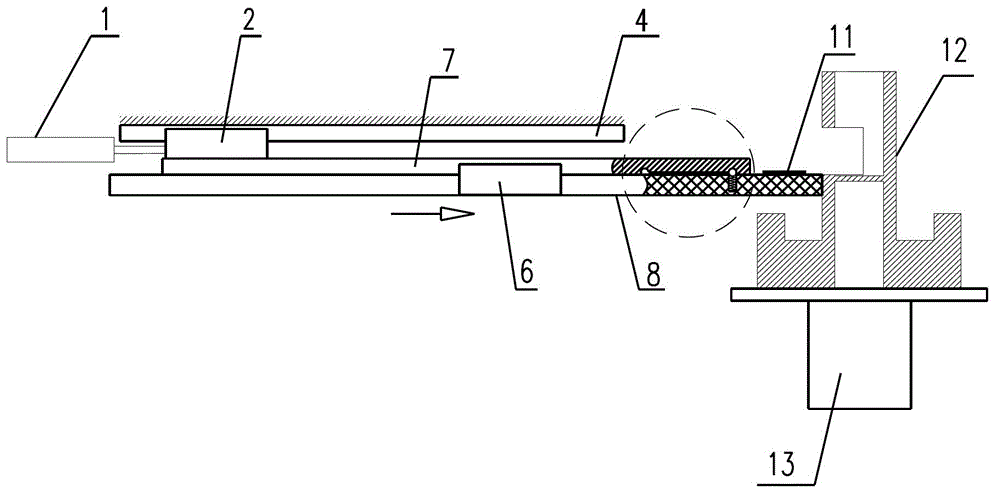

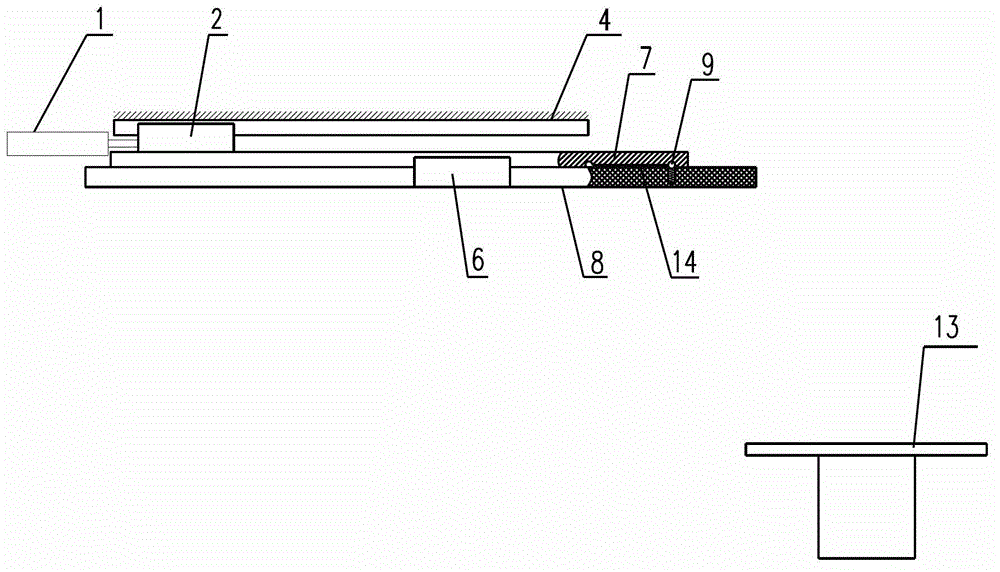

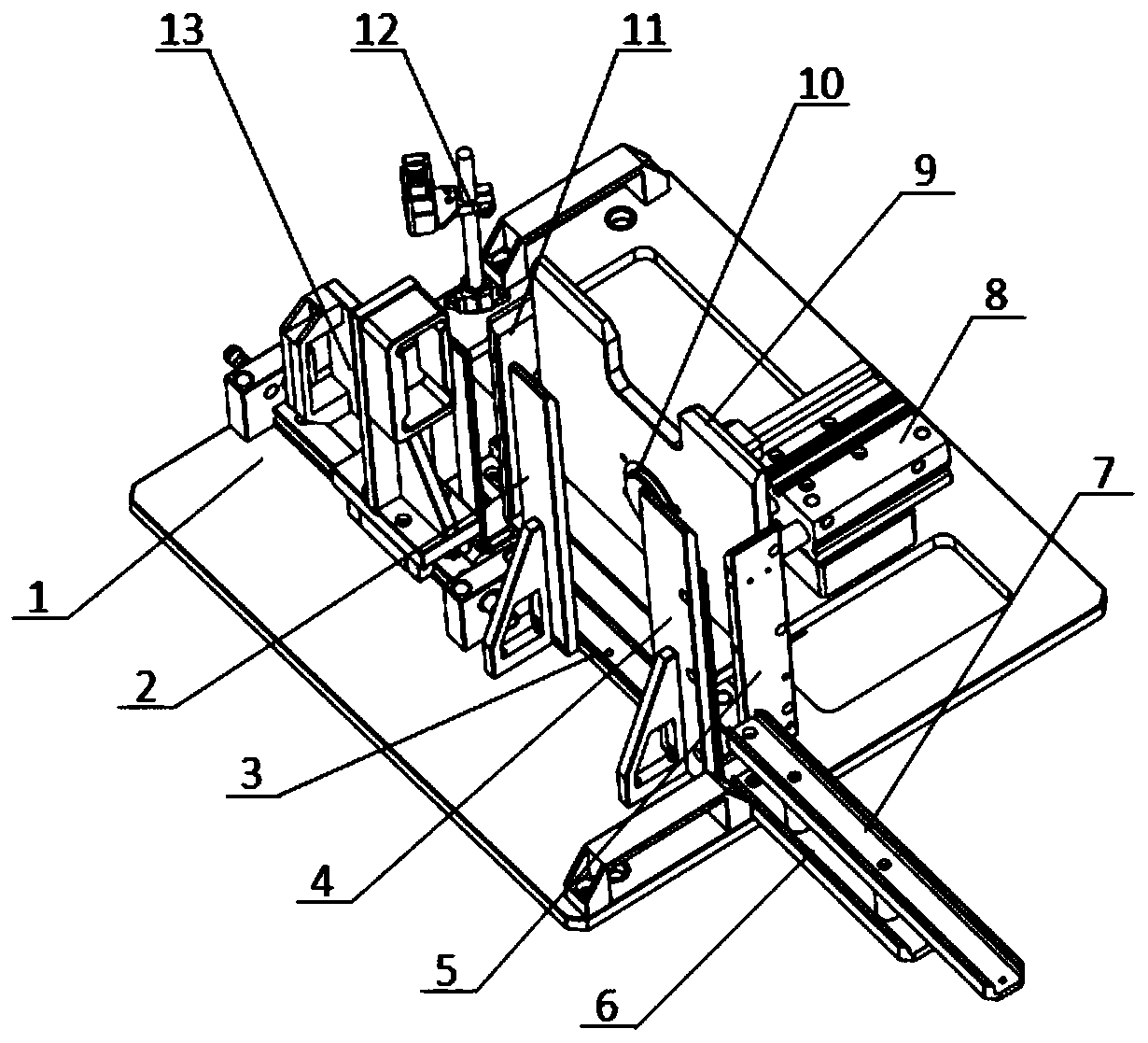

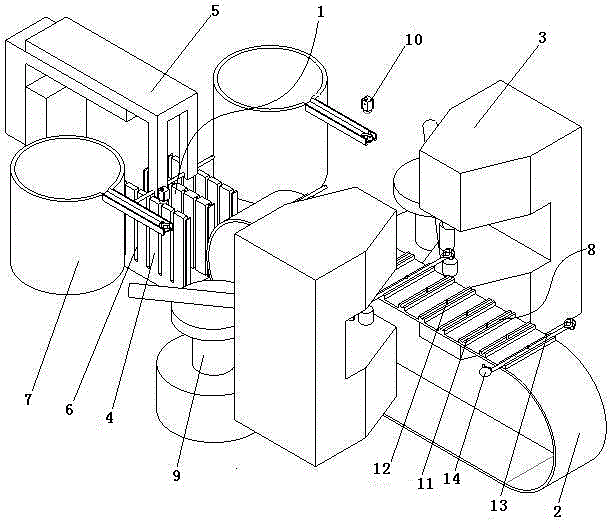

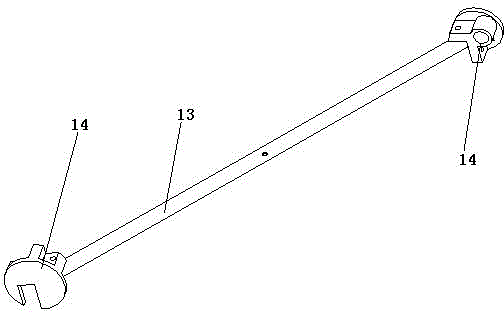

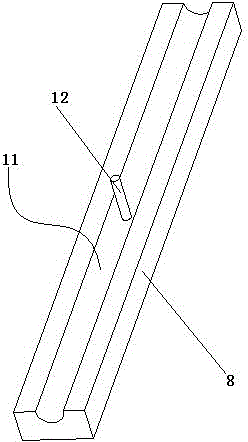

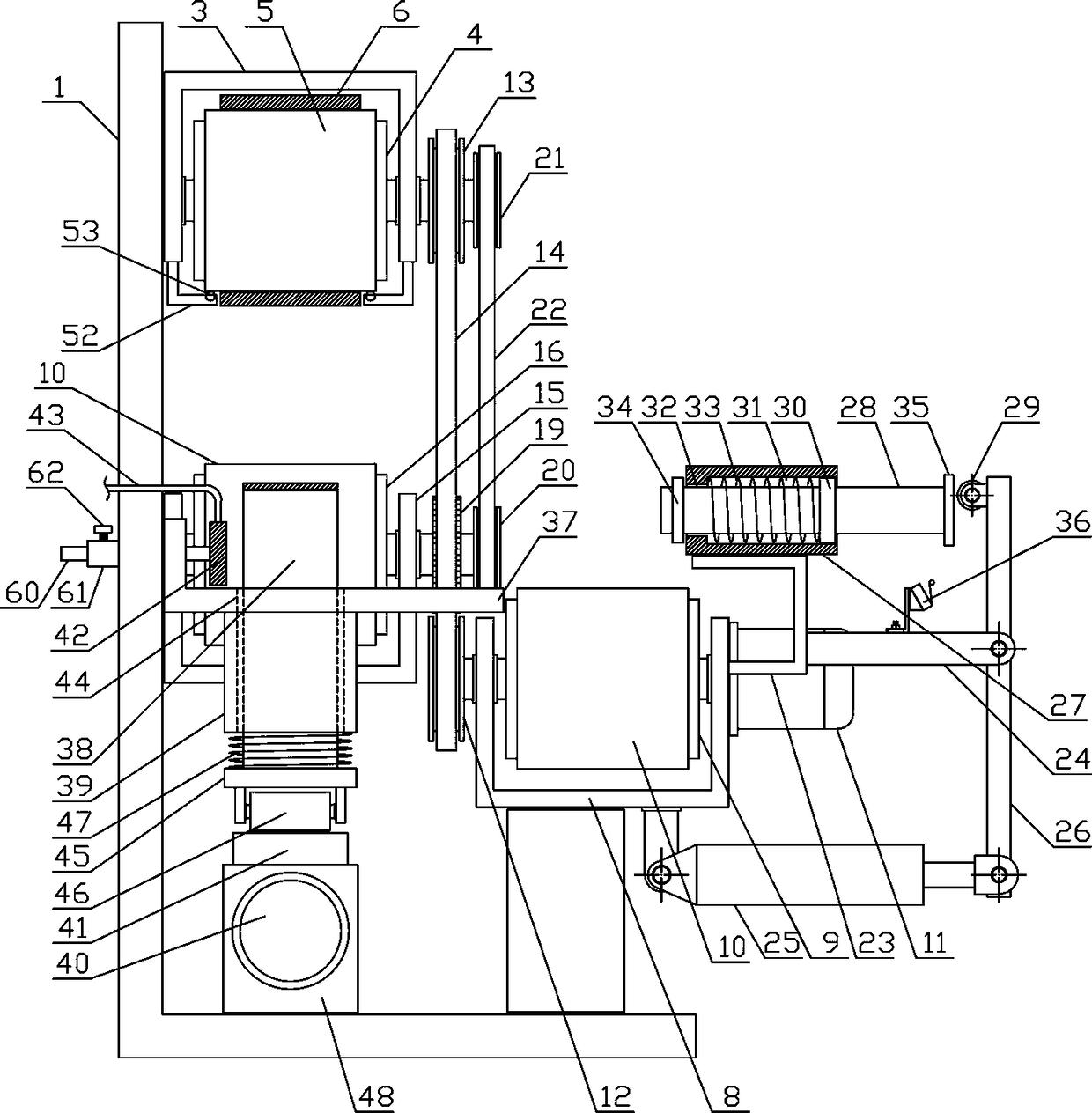

Gasket assembling mechanism

The invention provides a gasket assembling mechanism. The mechanism comprises upper and lower slide rails, which are horizontally and transversely arranged, wherein a first slide rail is fixed on a base; a second slide rail is mounted on the first slide rail by a slide block; a horizontal long bottom plate is placed close to the lower surface of the second slide rail; the bottom plate is mounted on the second slide rail by a slide block; a locating groove and a locating hole matched with each other are respectively formed in the second slide rail and the bottom plate; a spring and a locating block are pressed into the locating hole in sequence; the locating block is impelled upward by the spring; a compression cylinder is placed on one side of the second slide rail; a rack for bearing parts is arranged on the right side of the bottom plate; the rack can lift up and down; and by a double-slide-rail moving mechanism, a gasket is pushed to enter a narrow part recess of a mounting space; full mechanical operation of the whole assembling process can be achieved, manual assembling is not needed and high assembling efficiency is achieved; moreover, the gasket assembling mechanism provided by the invention has the advantages of simple structure, good reliability, accurate assembling position and comparatively low production and machining cost.

Owner:SHANGHAI UNIV OF ENG SCI

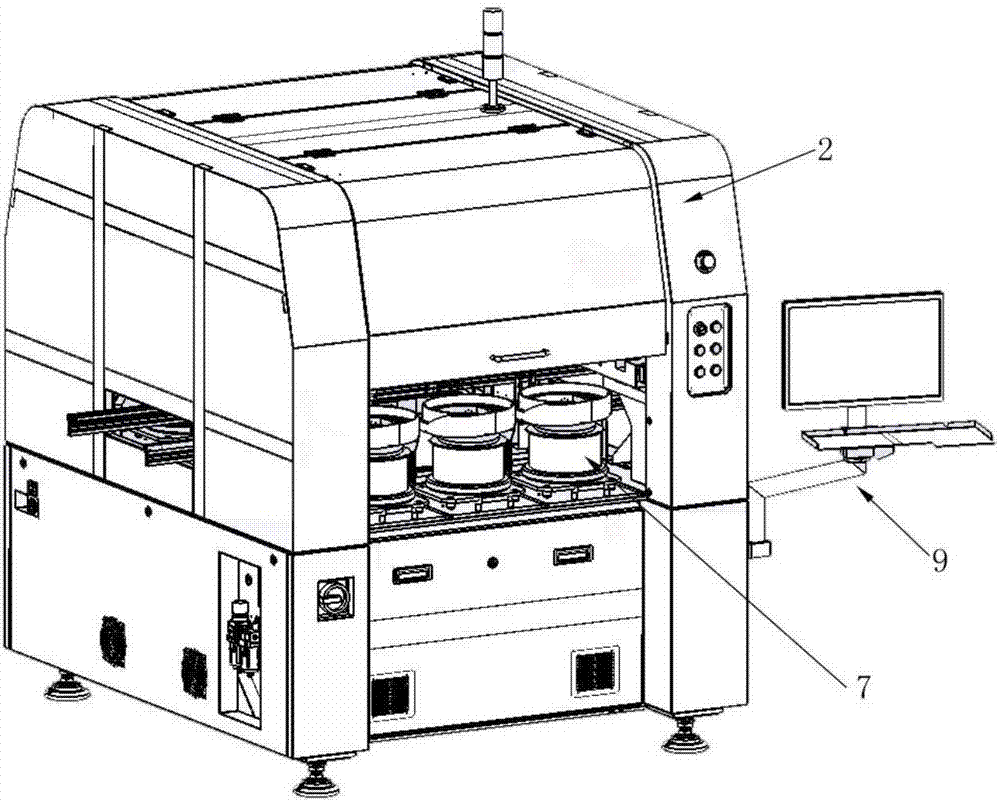

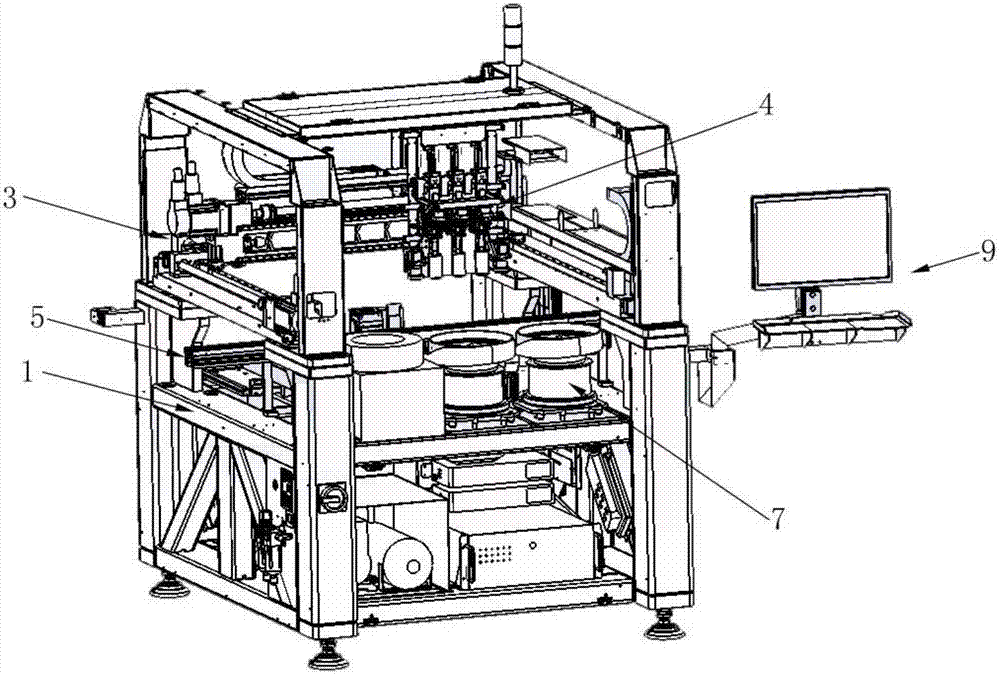

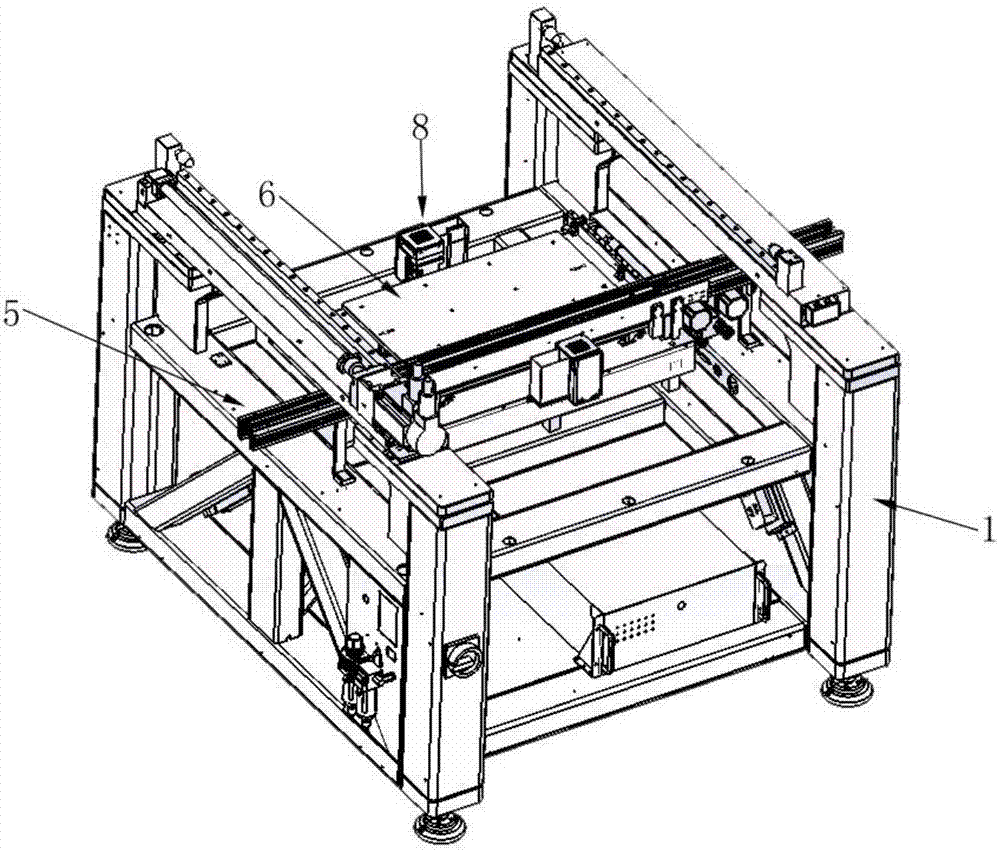

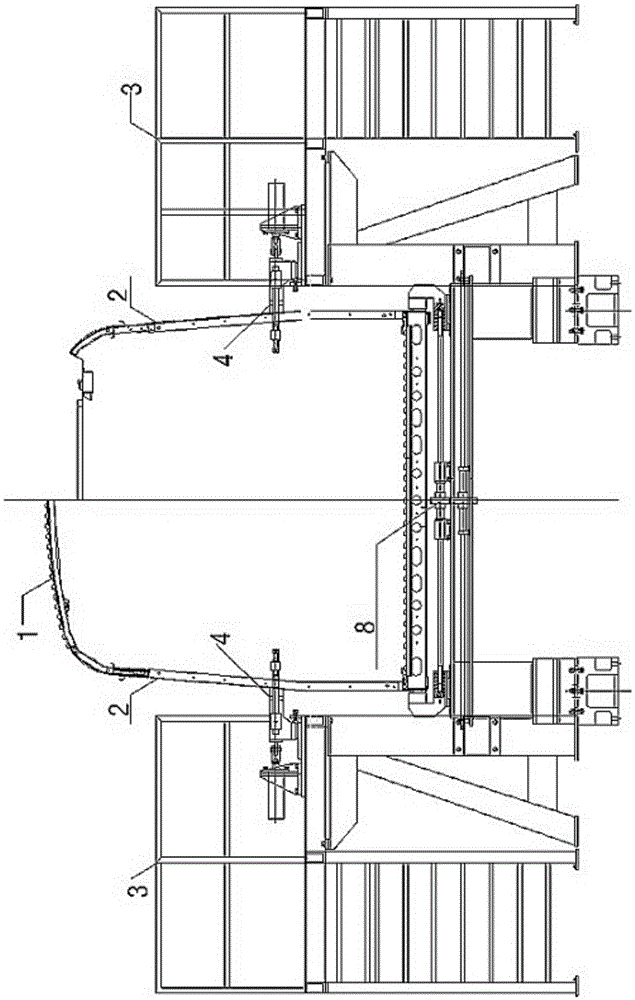

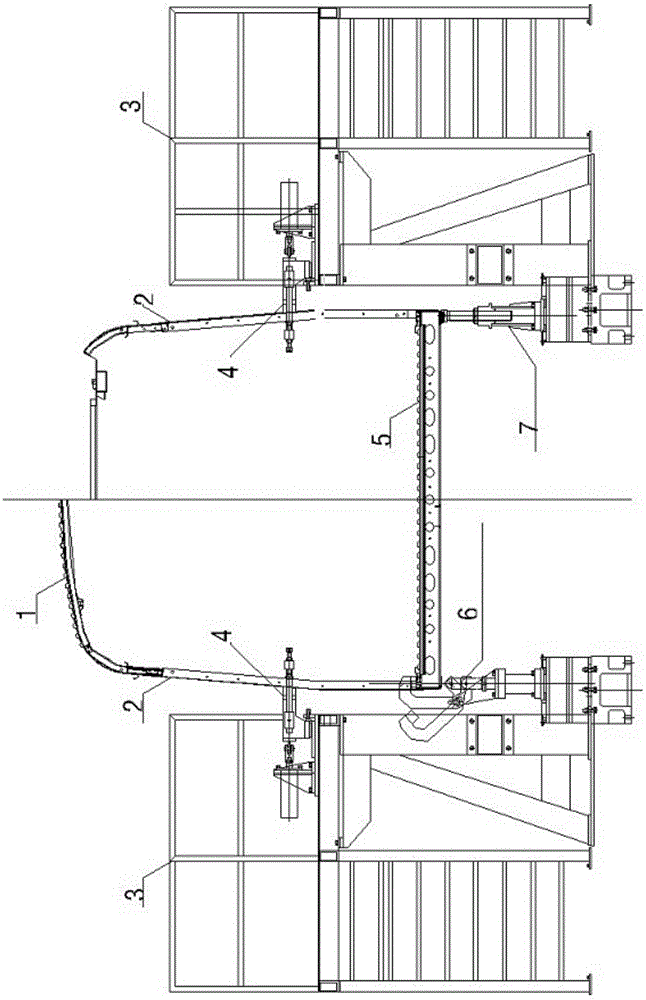

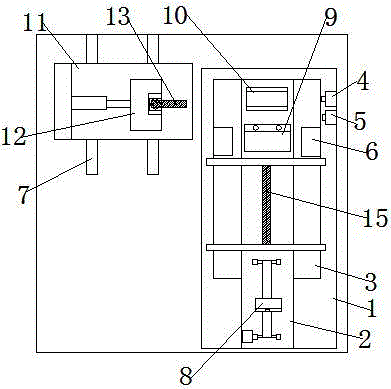

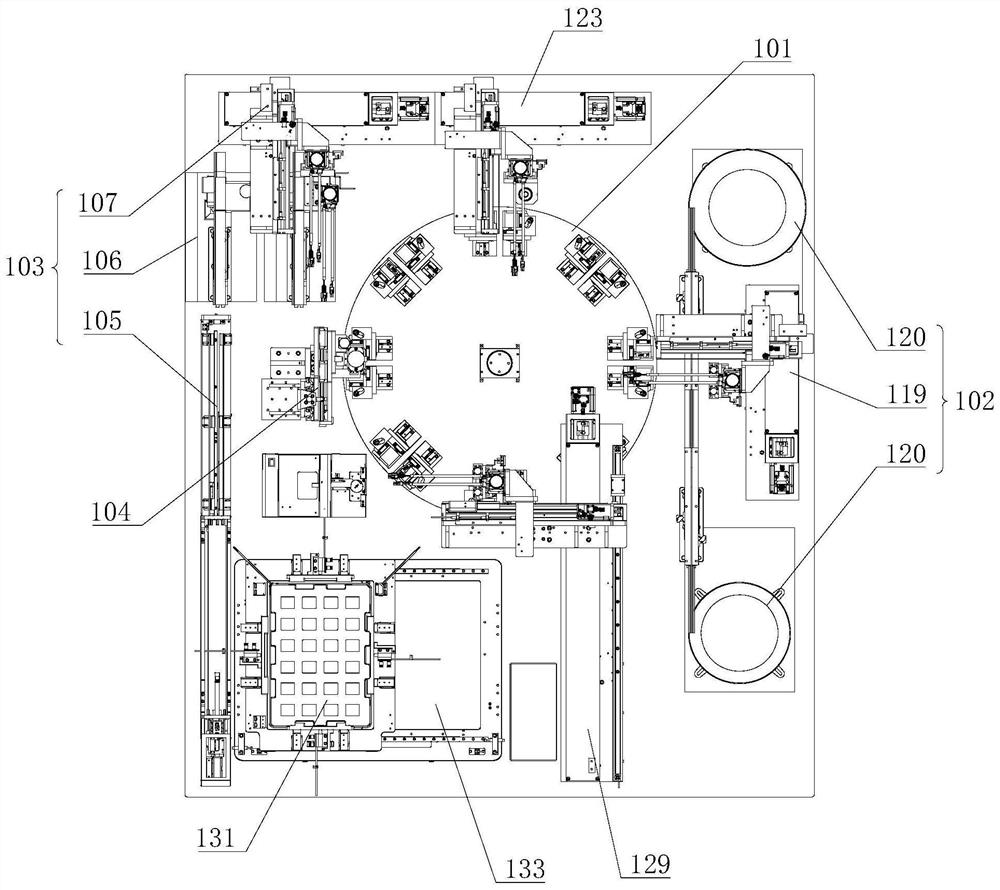

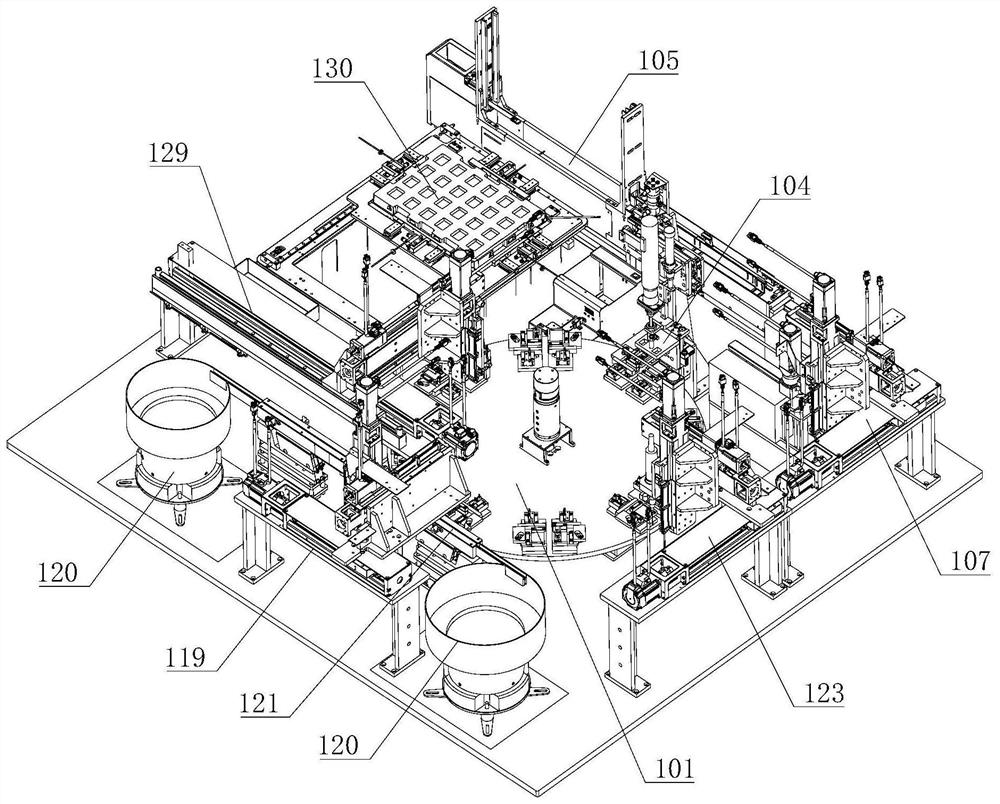

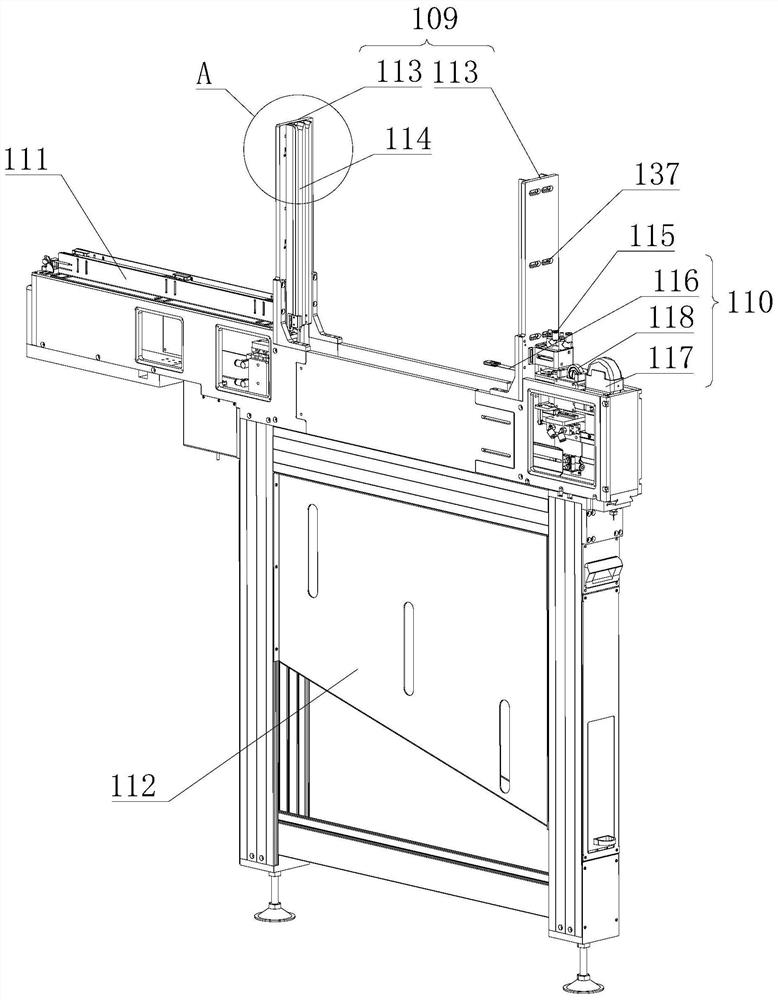

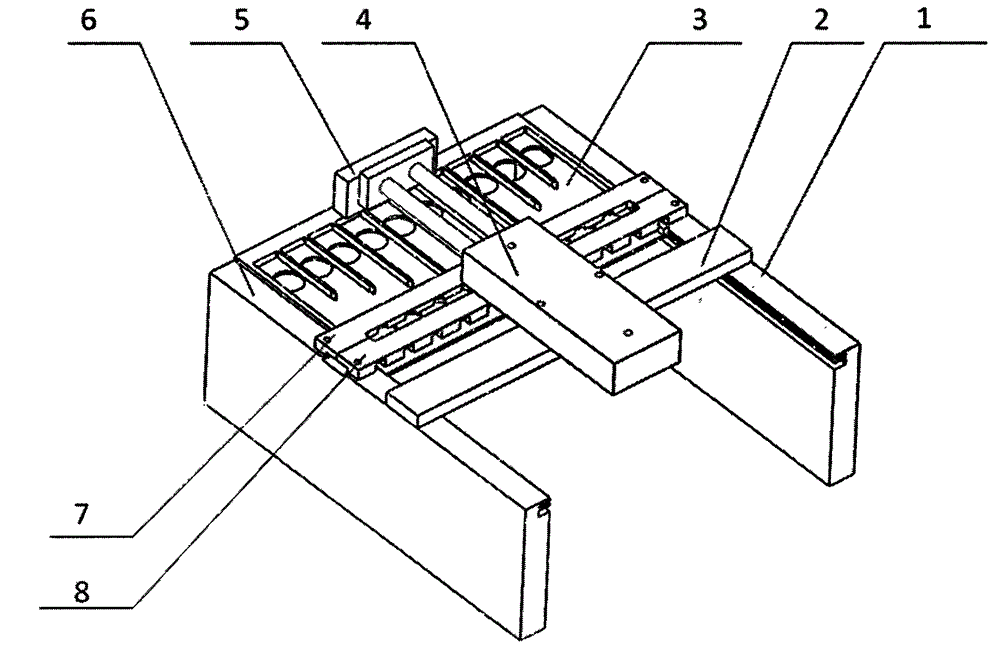

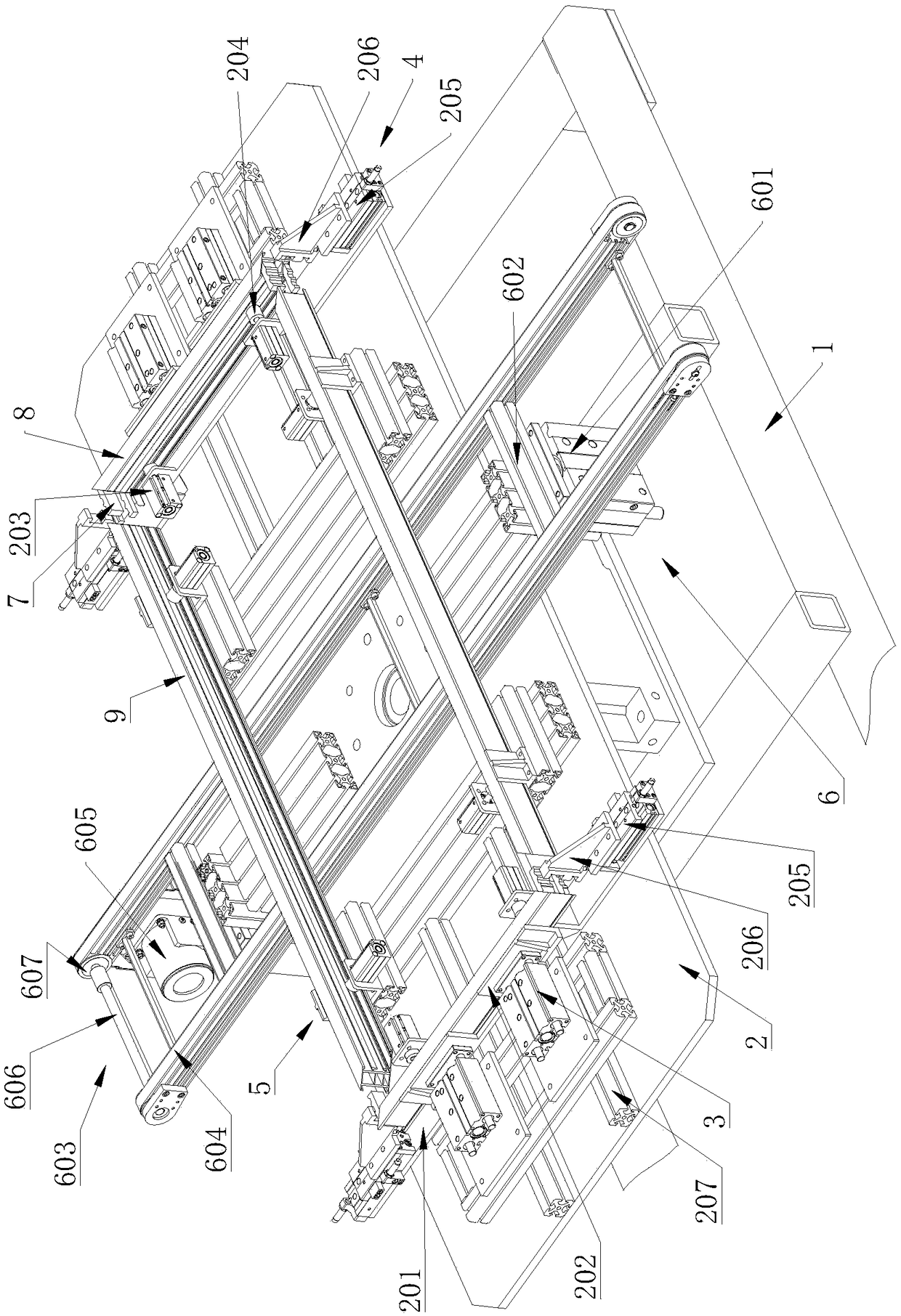

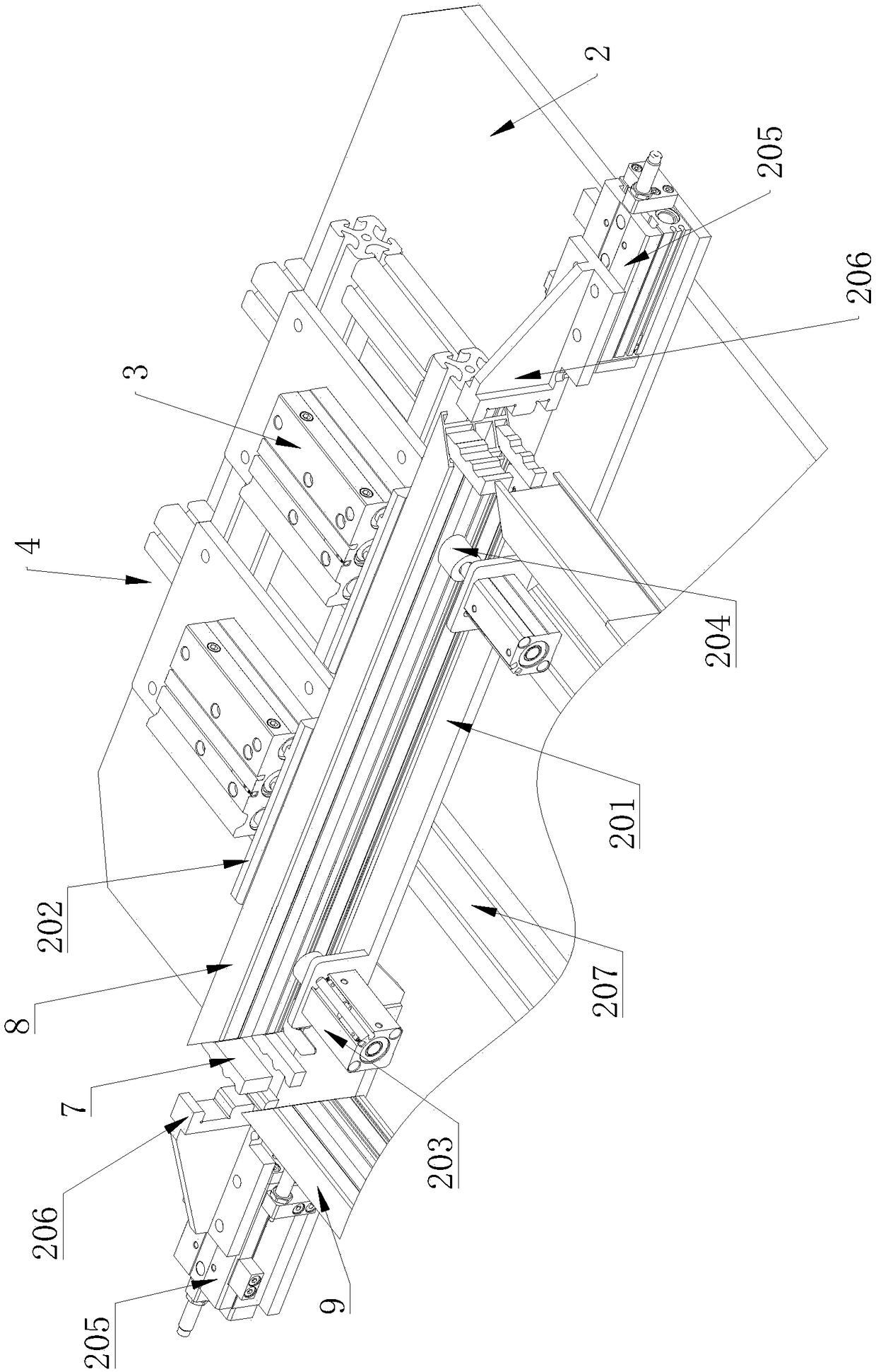

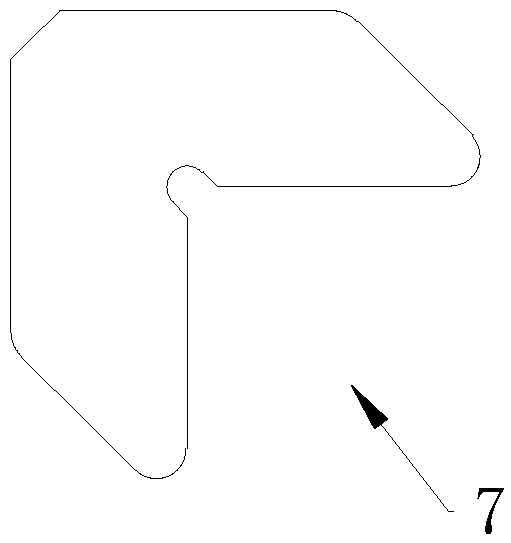

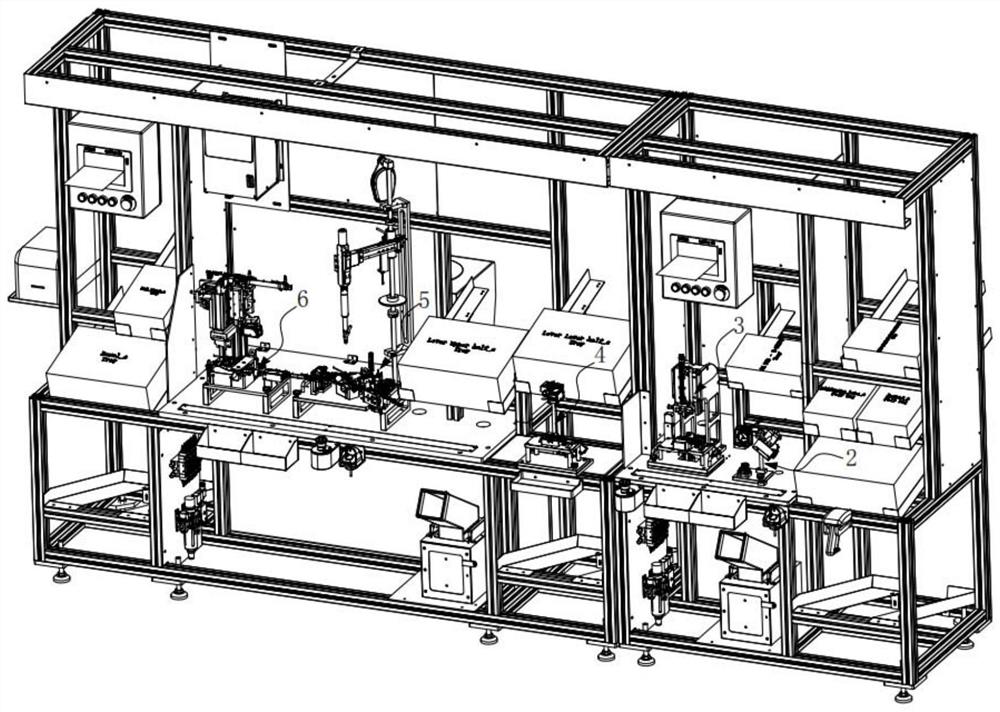

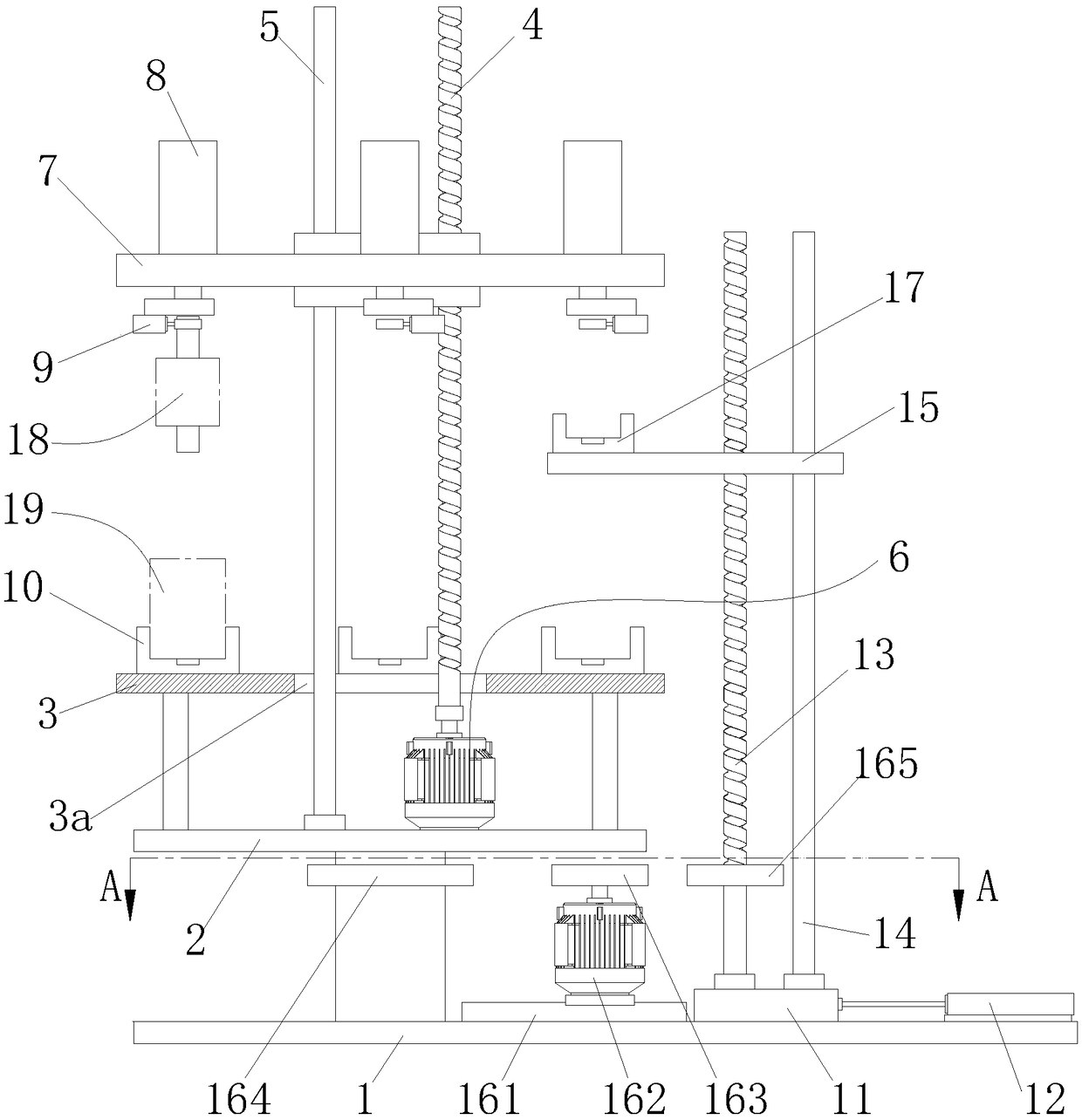

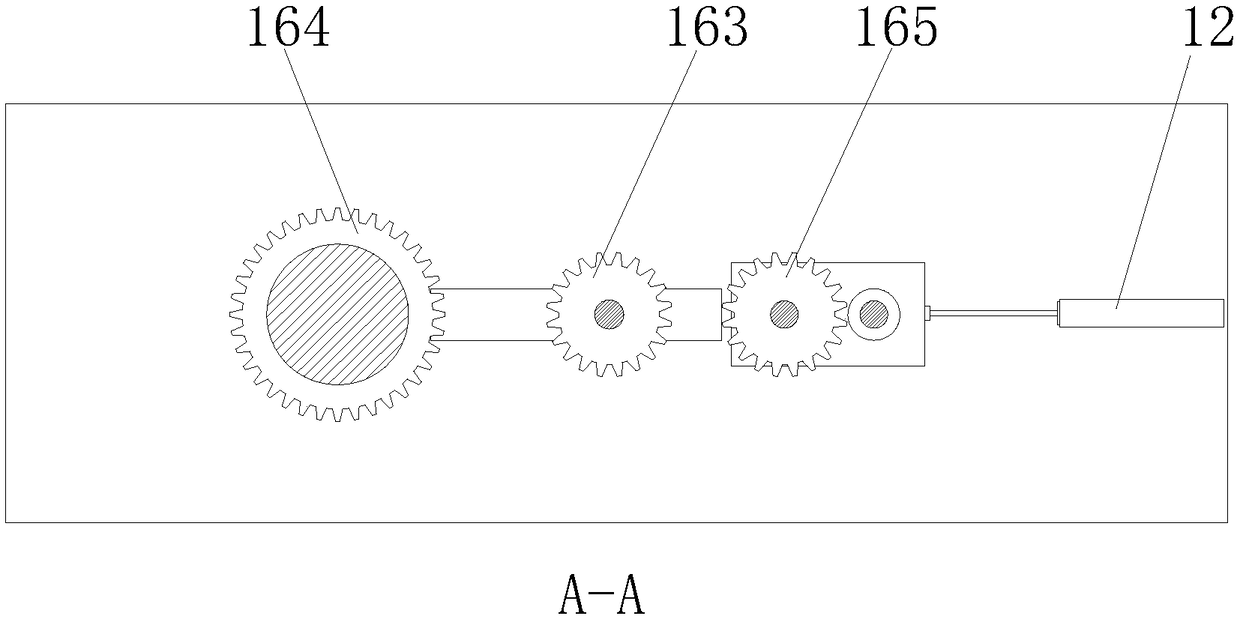

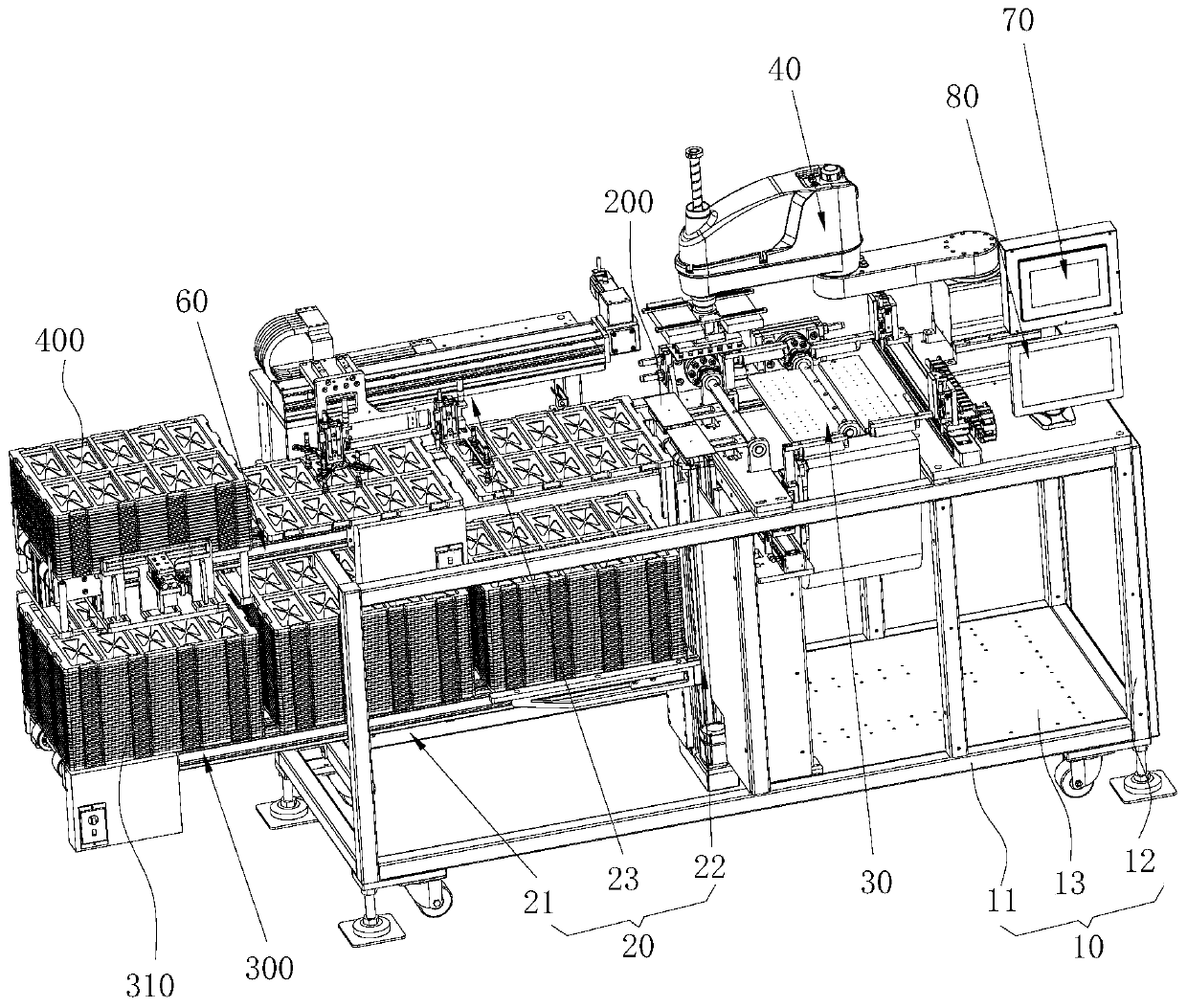

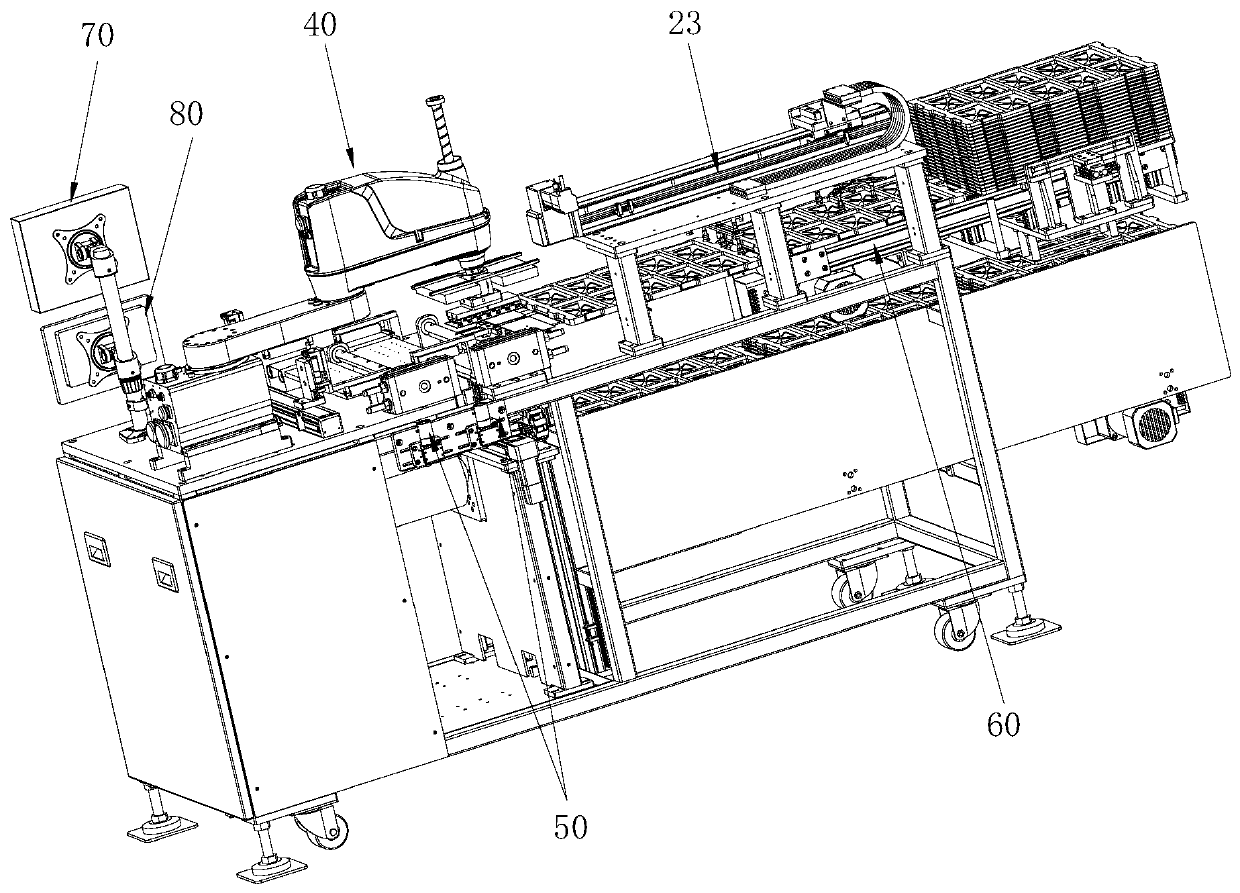

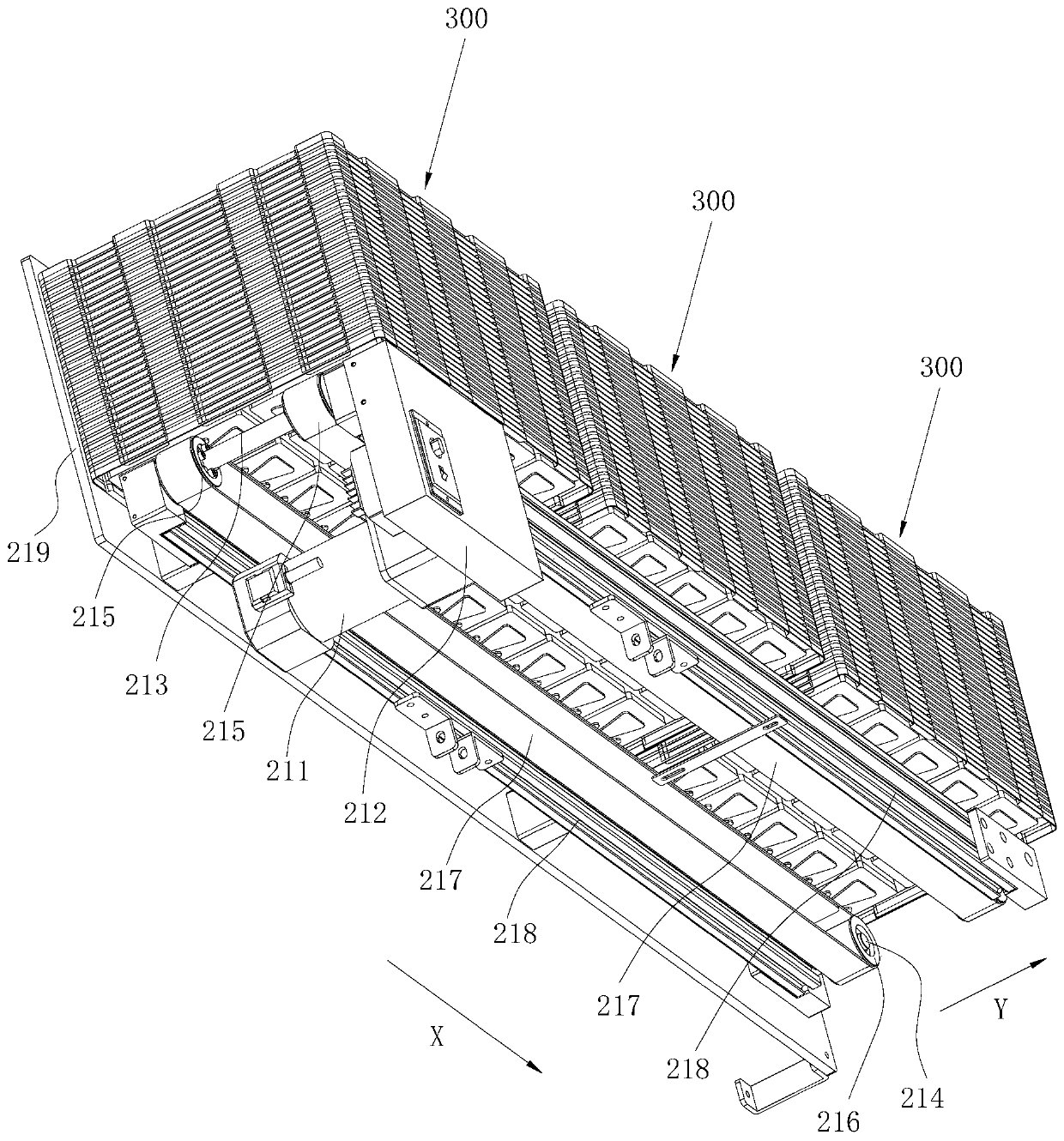

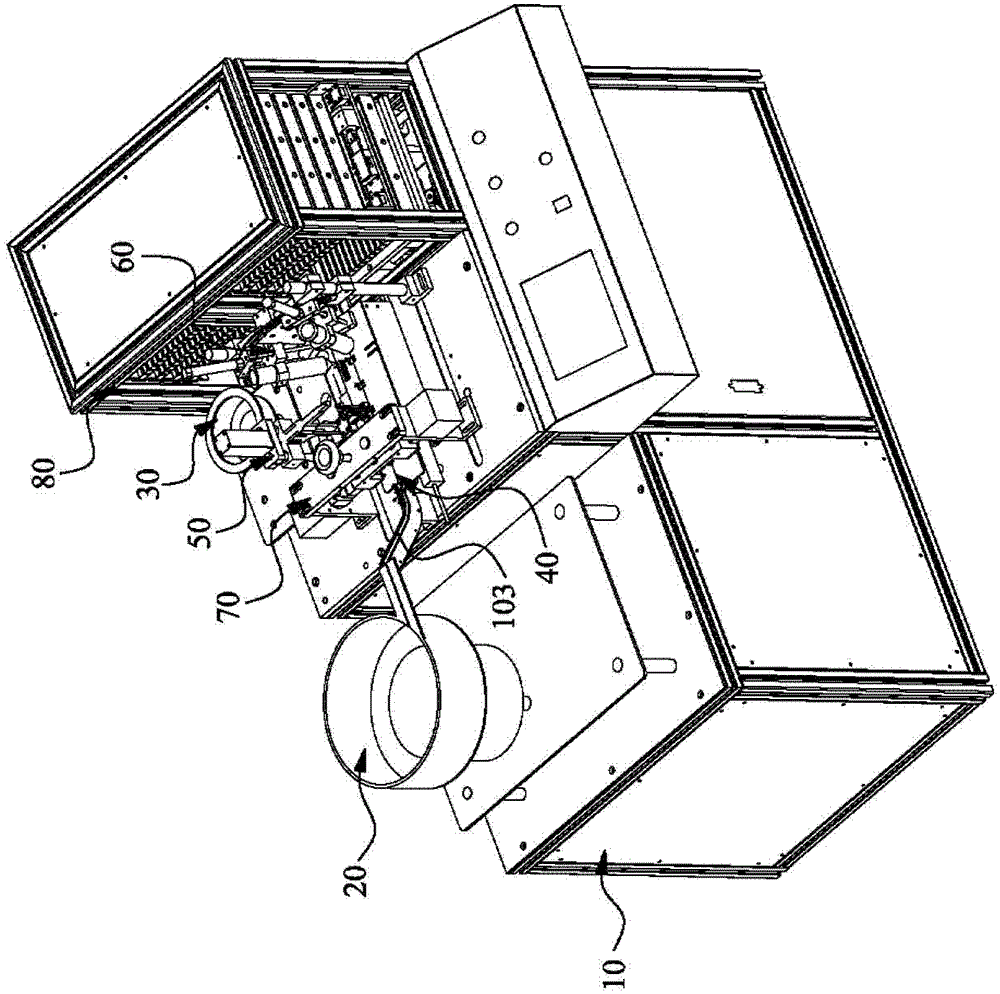

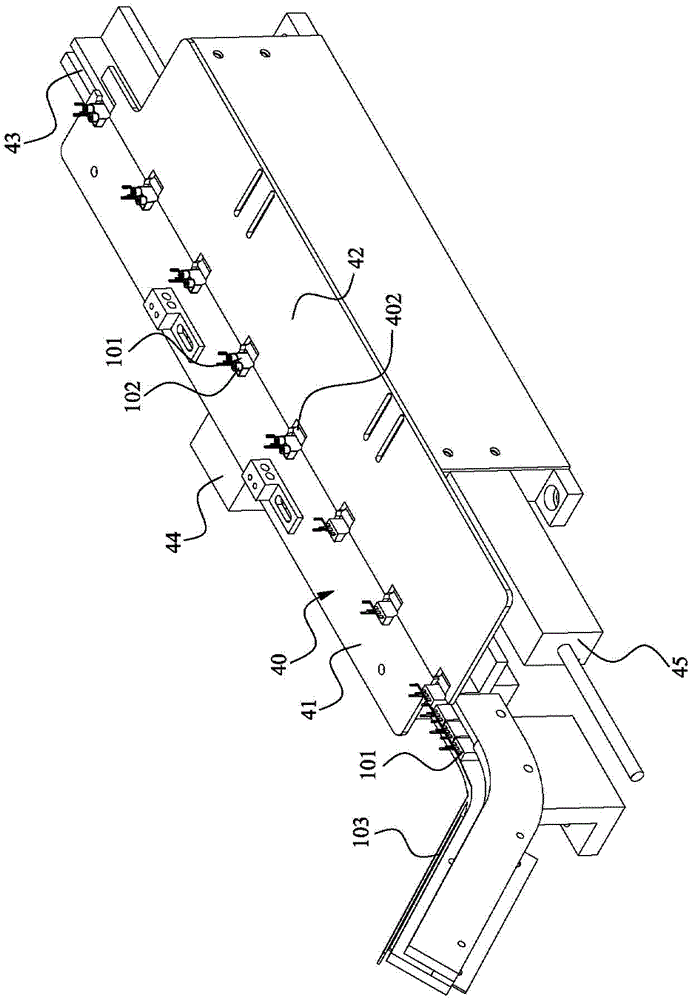

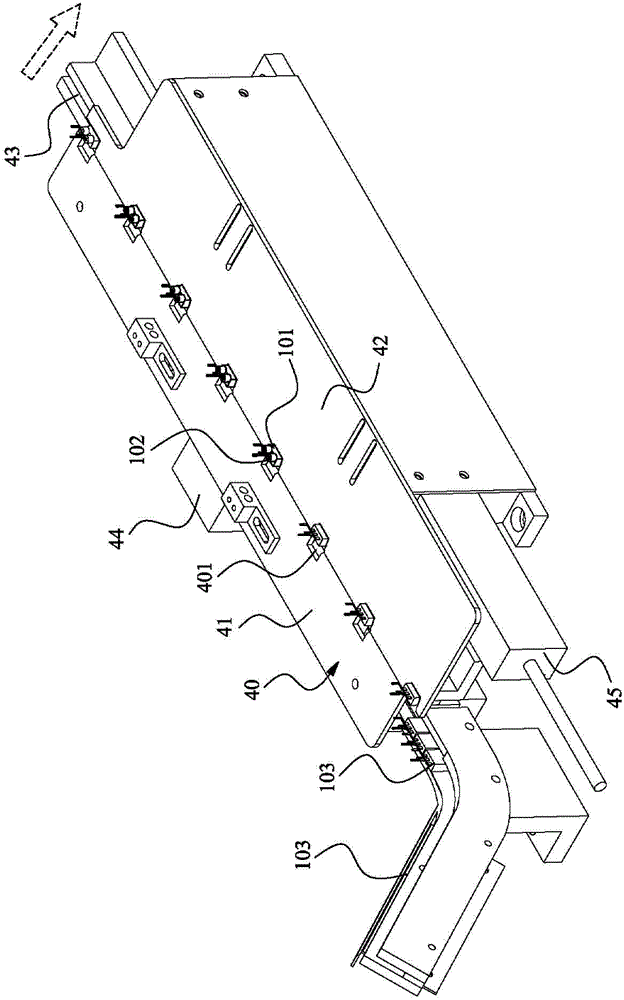

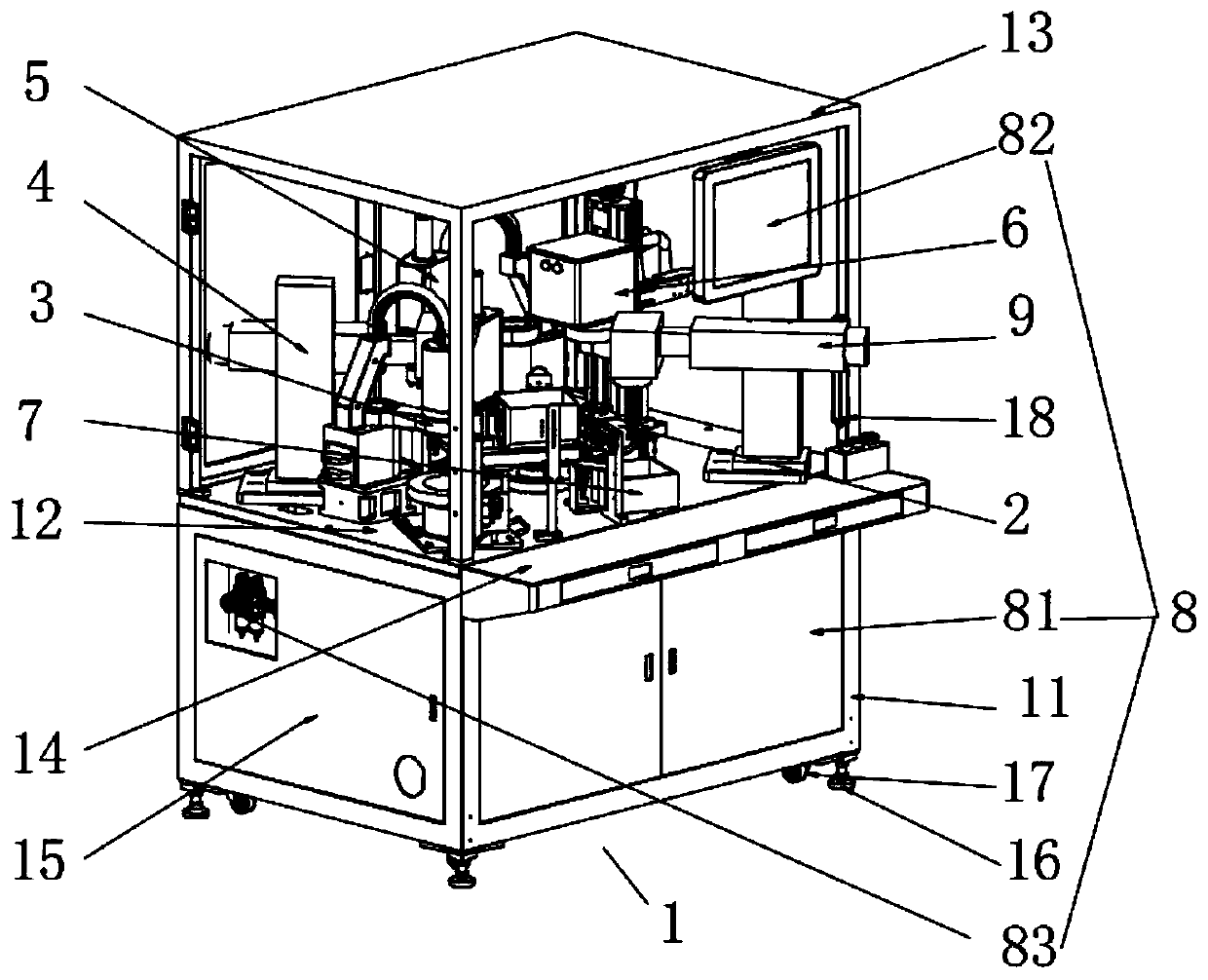

Gantry single-arm mounting and inserting machine

InactiveCN107333464AReasonable structural designMovement precisionElectrical componentsInteraction systemsControl system

The invention relates to a gantry single-arm mounting and inserting machine, comprising a main frame, a housing, XYZ axis motion devices, a mounting and inserting execution device, a PCB transfer device, a PCB positioning device, a feeding device, a detection deviation correction device, a control system and a human-computer interaction system. The feeding device is configured to convey the material to the designated positions on both sides of the main frame, XYZ axis motion devices drive the mounting and inserting execution device to absorb or grasp the material to reach the detection deviation correction device for deviation correction, the PCB in the mounting and inserting machine reaches the middle position of a general frame under the driving of the PCB transfer device, the PCB positioning device jacks up, limits and fixes the PCB, and the material after deviation correction is moved to the PCB for mounting and inserting. The devices cooperatively move under the control of the control system, the motion is smooth, the assembly position is accurate, the production speed is fast, the pass rate is increased, and mounting process and inserting process can be performed at the same time. The gantry single-arm mounting and inserting machine is strong in versatility, wide in application range, and capable of meeting diverse demands of customers.

Owner:东舜机电有限公司

Core for turbomachine blades

ActiveUS7562691B2The assembly position is accurateFoundry mouldsFoundry coresMechanical engineeringLost-wax casting

The present invention relates to a ceramic core used in the manufacture, by lost wax casting, of a turbomachine blade with cooling cavities and a squealer, comprising at least one main core, wherein the main core (10) comprises an element (10B) shaped so as to constitute the squealer and an element (10SB) shaped so as to constitute at least one cavity beneath the squealer, the two elements leaving between them a space (13) shaped so as to constitute, at least in part, the bottom wall of the squealer. In particular, the elements (10B and 10SB) are joined together by ceramic rods (TG).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

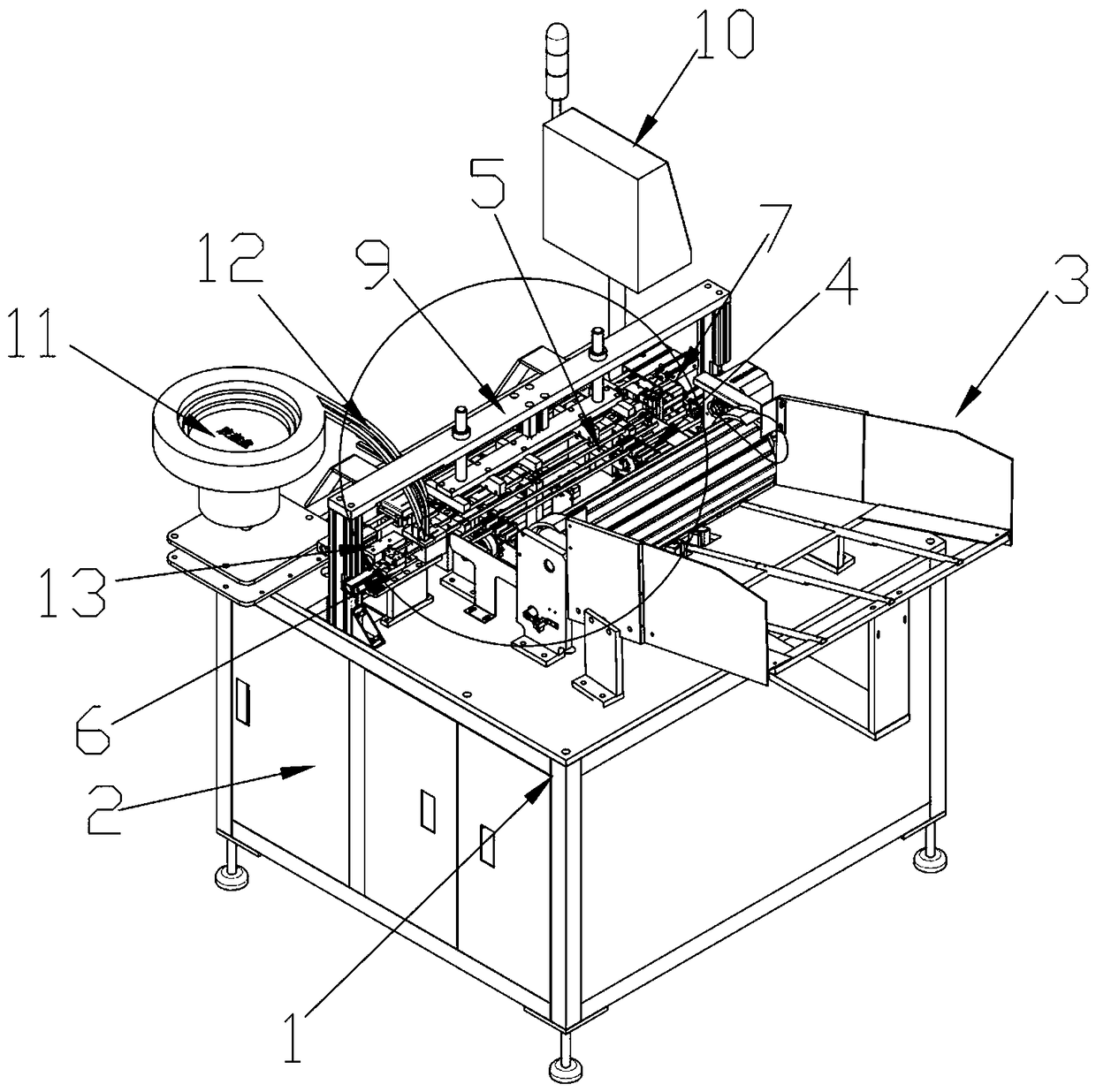

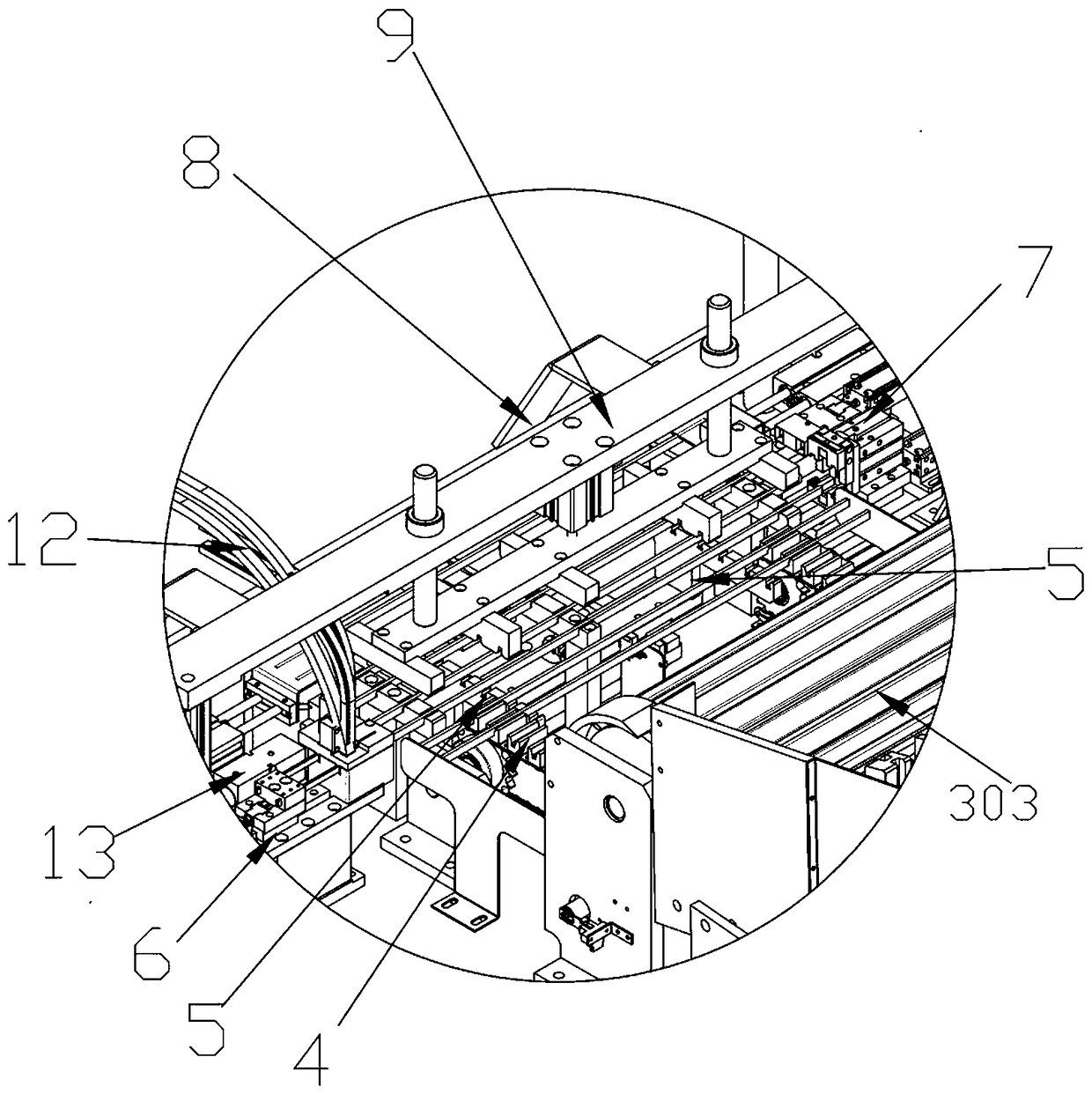

Electronic element rubber pipe and rubber plug assembly machine

The invention relates to an electronic element rubber pipe and rubber plug assembly machine in the field of automatic equipment. The machine comprises a frame, and an automatic assembly platform arranged at the top of the frame; the automatic assembly platform comprises a rubber pipe unloading mechanism, a rubber pipe conveying mechanism, a rubber plug unloading mechanism, a rubber pipe back end positioning mechanism, a shifting mechanism and a discharge mechanism; the shifting mechanism can be directly adopted to synchronously realize receiving, shifting and discharge actions, so that more shifting structures can be saved, and the overall structure is simple; compared with traditional manual assembly, an automatic production line is used for operating to realize automatic feeding, automatic assembly and automatic discharge, so that the working efficiency is high, the rejection rate is lower, and a lot of labor costs can be saved; the whole assembly process is precise in positioning; packing pipes are positioned from all directions; real-time detection can be realized after assembly; and precise assembly and precise detection can be realized through automatic machinery.

Owner:广州市速波光电科技有限公司

Device for assembling stainless steel vehicle body of railway vehicle

Provided is a device for assembling a stainless steel vehicle body of a railway vehicle. The device comprises a side wall external positioning and internal propping device, a special chassis centering, positioning and clamping mechanical device and a specific track rocker arm type tension device, wherein through the side wall external positioning and internal propping device, a side wall is tightly attached to side wall positioning devices on walking boards on two sides in an external positioning mode by matching a horizontal oil cylinder, a first connecting block, a sliding seat, a linear guide track, a side wall external positioning piece and a side wall inner propping piece; a chassis of the vehicle body is symmetrically tensioned along a longitudinal center line of the vehicle body by the special chassis centering, positioning and clamping mechanical device through a drag hook, a tensioning lead screw and a gear transmission mechanism, so that the chassis can be automatically centered, positioned and tensioned when mounted; the chassis is placed on a supporting seat with a height and width adjustable function; and meanwhile, by the specific track rocker arm type automatic tension device, the chassis is tightly attached to the supporting seat. By the device, the vehicle body can be assembled quickly and accurately, and production efficiency and automation degree are high.

Owner:CRRC QINGDAO SIFANG CO LTD

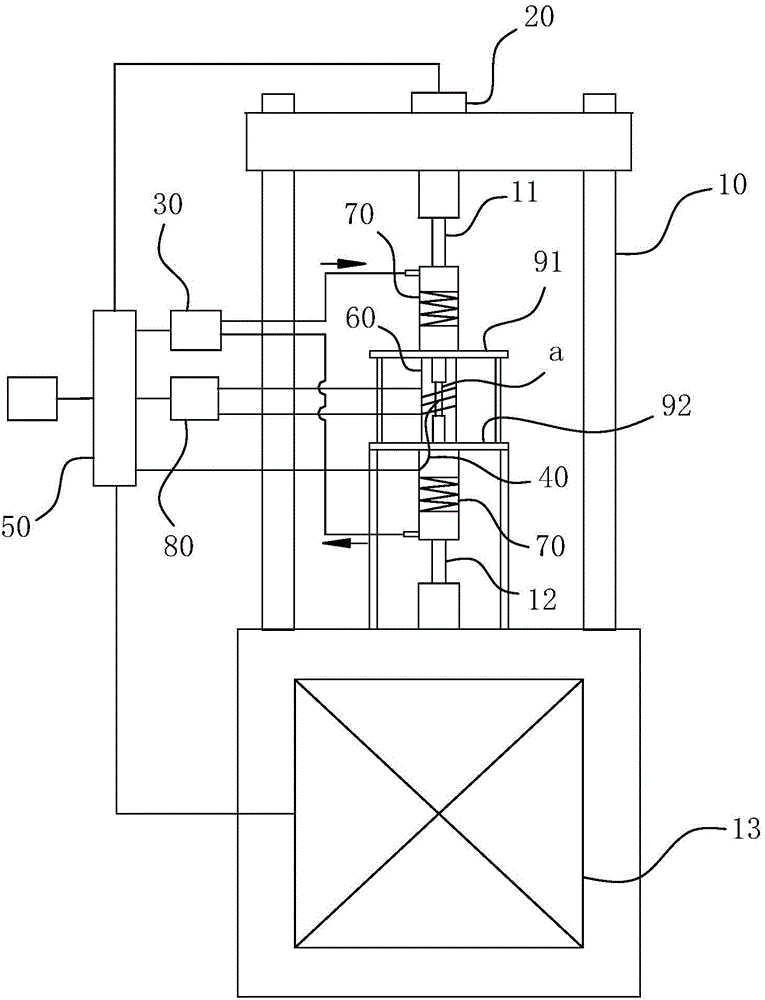

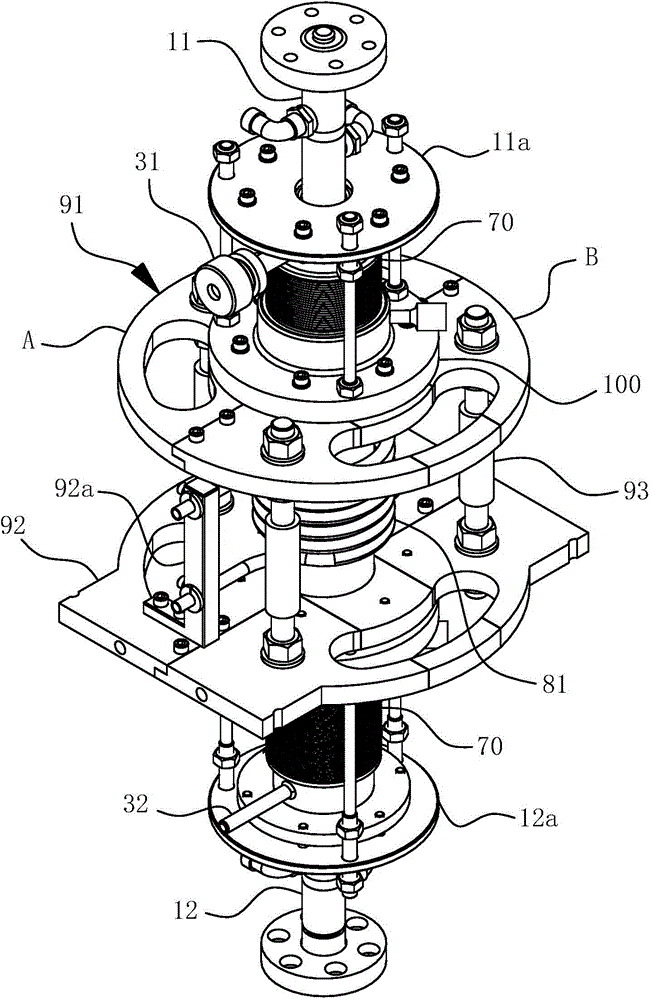

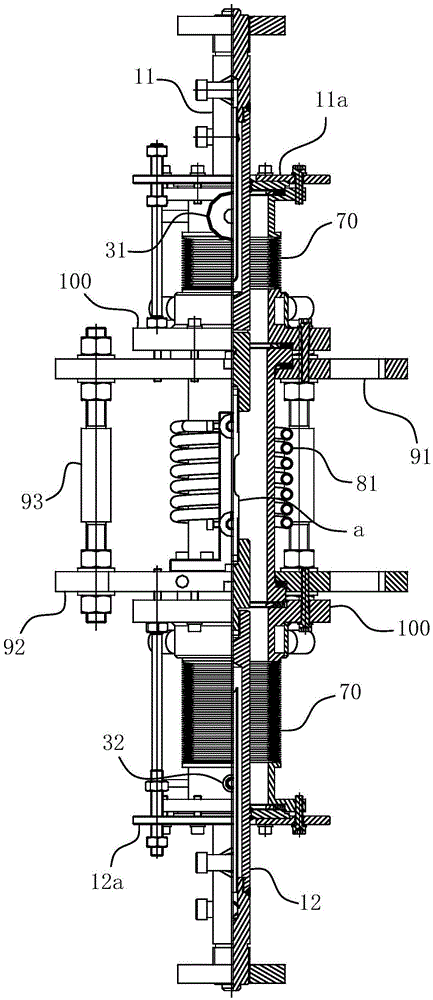

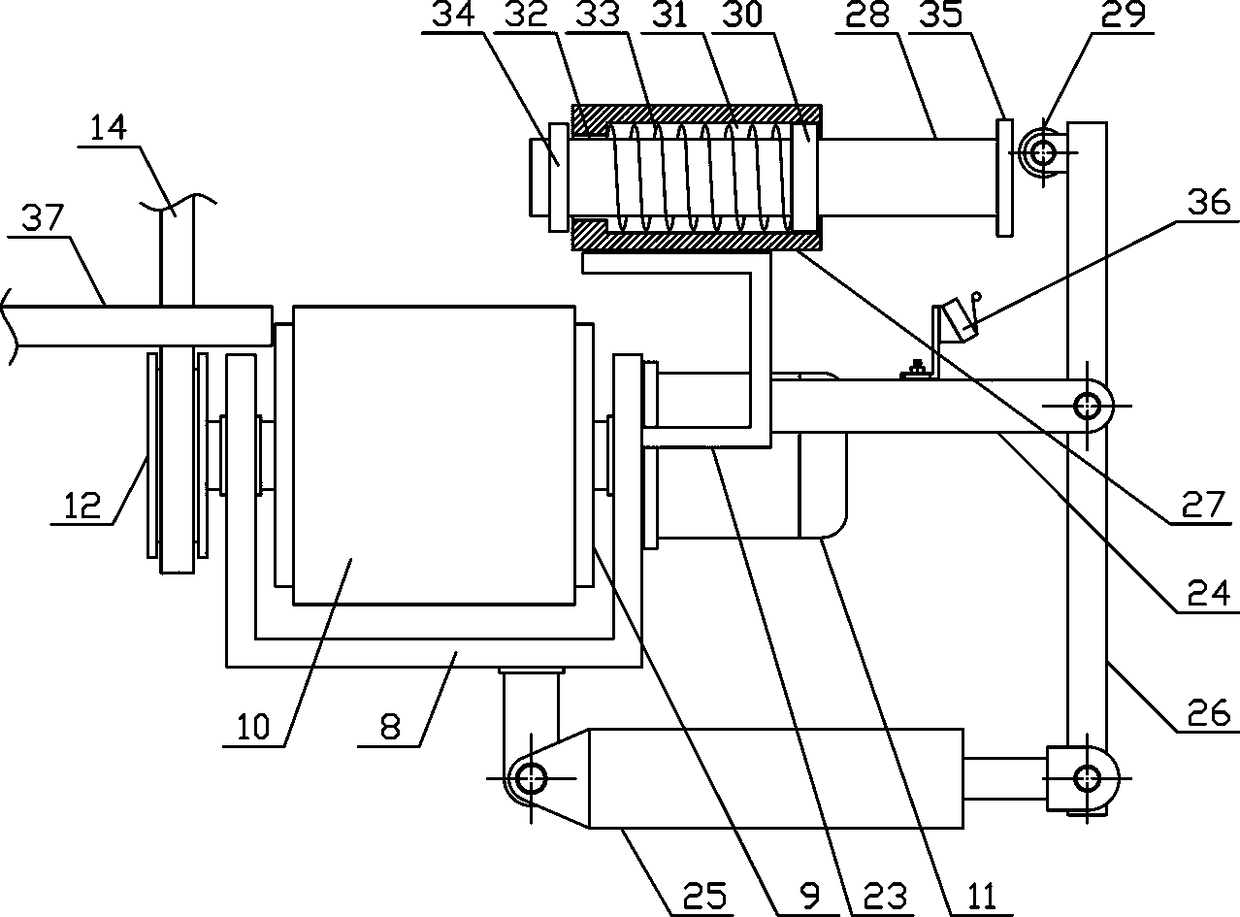

High temperature superheated steam environment creep fatigue test device

ActiveCN104964887ARealize all-round packageGood reproducibilityMaterial strength using repeated/pulsating forcesEngineeringHeat resistant

The invention relates to the field of material tension loading creep fatigue test, in particular to a high temperature superheated steam environment creep fatigue test device. The device at least comprises a creep fatigue test machine loading frame, which is provided with an upper pull rod and a lower pull rod. The device also includes a heat-resistant transparent pipe, an upper ring cap and a lower ring cap are coaxially fixed on the upper pull rod body and the lower pull rod body, corrugated pipes are coaxially disposed in seal joint with the upper ring cap, the lower ring cap and the corresponding end pipe orifices of the heat-resistant transparent pipe, and the upper ring cap, the corrugated pipe walls, the heat-resistant transparent pipe wall and the lower ring cap together enclose a sealed cladding type sample test environment. The air inlet end and air outlet end of a steam generation assembly run through the upper ring cap and the lower ring cap to communicate with the seal cavity. The device also includes an induction heating assembly. The device provided by the invention can accurately detect various material performance of a to-be-tested sample in a service environment, and provides the necessary equipment for the material failure mechanism research.

Owner:HEFEI GENERAL MACHINERY RES INST +1

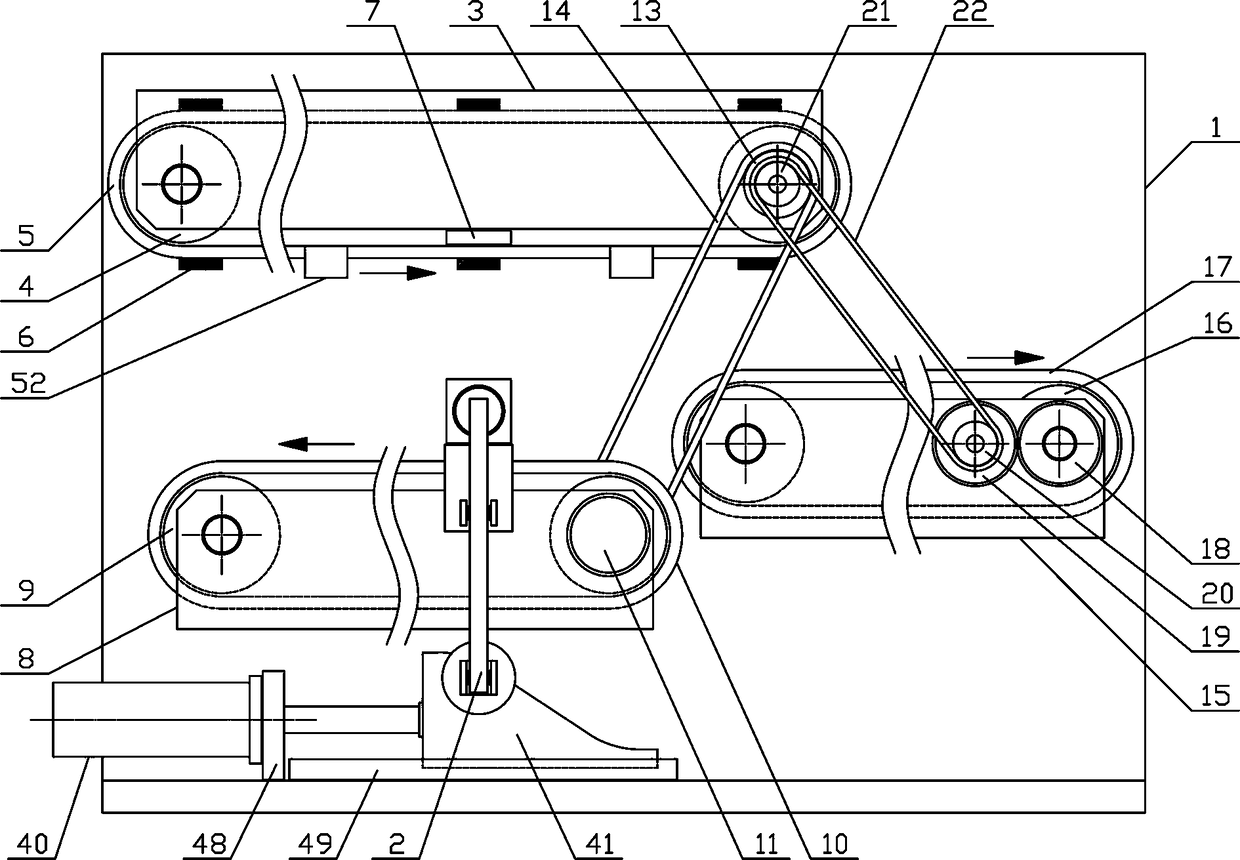

Automatic feeding device for steel disc assembling

ActiveCN106425391APrevent movementSimple structureMetal working apparatusMechanical engineeringEngineering

The invention discloses an automatic feeding device for steel disc assembling. The automatic feeding device for steel disc assembling comprises a rack. A conveying device is arranged on the rack. A groove is formed in the middle of the conveying device. Conveying belts are arranged on the portions, located on the two sides of the groove, of the conveying device correspondingly. A jacking device is arranged on the portion, located at one end of the conveying device, inside the groove, and fixed to a chain in the groove. A jacking positioning device and an ejecting device are arranged on the portion, located at the other end of the conveying device, inside the groove. The jacking positioning device is arranged on the portion, located between the ejecting device and the jacking device, inside the groove. A first infrared induction device is arranged on the portion, located at one side of the ejecting device, of the conveying device. A second infrared induction device is arranged between the jacking positioning device and the ejecting device. Material blocking plates are arranged on the portions, located at the two sides of the jacking positioning device, of the conveying device. A movable clamp is arranged on the rack through movable rails. The automatic feeding device for steel disc assembling is simple in structure, reasonable in design and capable of automatically assembling steel discs onto a to-be-assembled component, shortening the assembling time and guaranteeing that the assembling position is accurate.

Owner:苏州阿西机器人有限公司

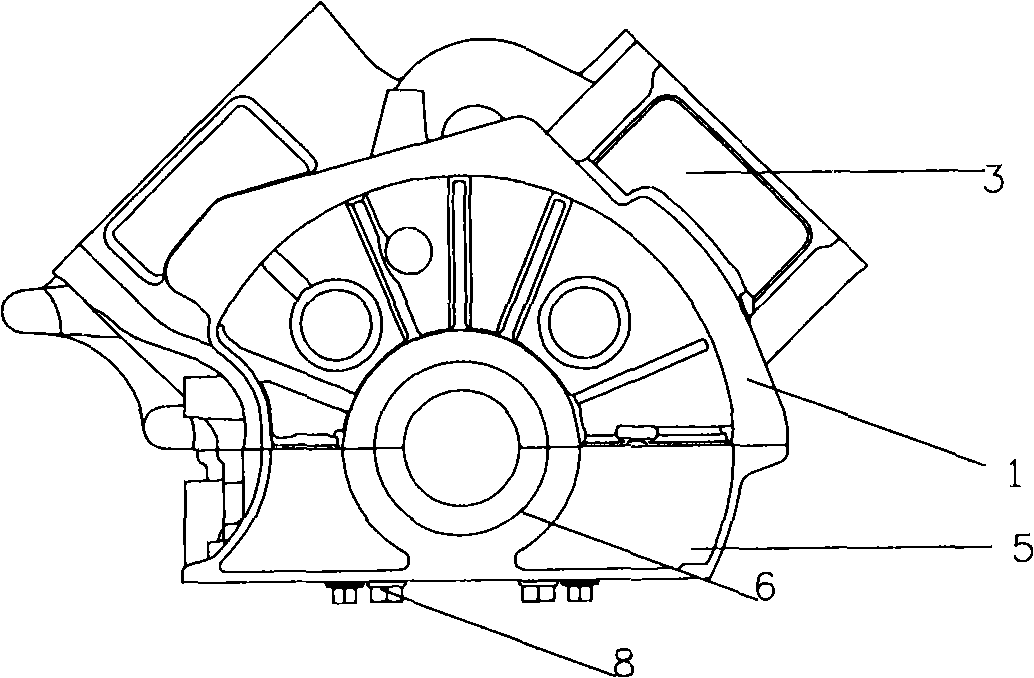

V-type engines cylinder

The invention discloses a V-shaped engine cylinder body, which consists of an upper cylinder body with a V angle, a sleeve, a lower framework and a main bearing cover, wherein a positioning pin and a main bearing cover bolt are arranged on the main bearing cover. The V-shaped engine cylinder body has the advantages that a V angle structure of 90 degree is adopted for the cylinder body. The distortion or deformation of the sleeve and the oil consumption can be reduced because the structure of an upper cylinder body provided with a lower framework is adopted for the cylinder body, wherein the upper cylinder body is molded by aluminum alloy; the cylinder body is directly cast in the sleeve in the process of casting; gray iron is adopted as the material for the sleeve. The lower framework body is cast by aluminum alloy; ductile cast iron main bearing cover is adopted to be cast in the aluminum alloy. In the assemblies of the upper cylinder body and the lower framework, five positioning pins are arranged on four main bearing covers for positioning, so that the assembling positions among the main bearing cover, the framework and the cylinder body can be precise in the assembling process. The cylinder body is tightly connected with the left and the right rows of fastening bolts, so that the intensity of the main bearing cover is greatly improved, thus avoiding loosening and distortion or deformation of the main bearing cover in the process of high-speed operation of the engine.

Owner:CHERY AUTOMOBILE CO LTD

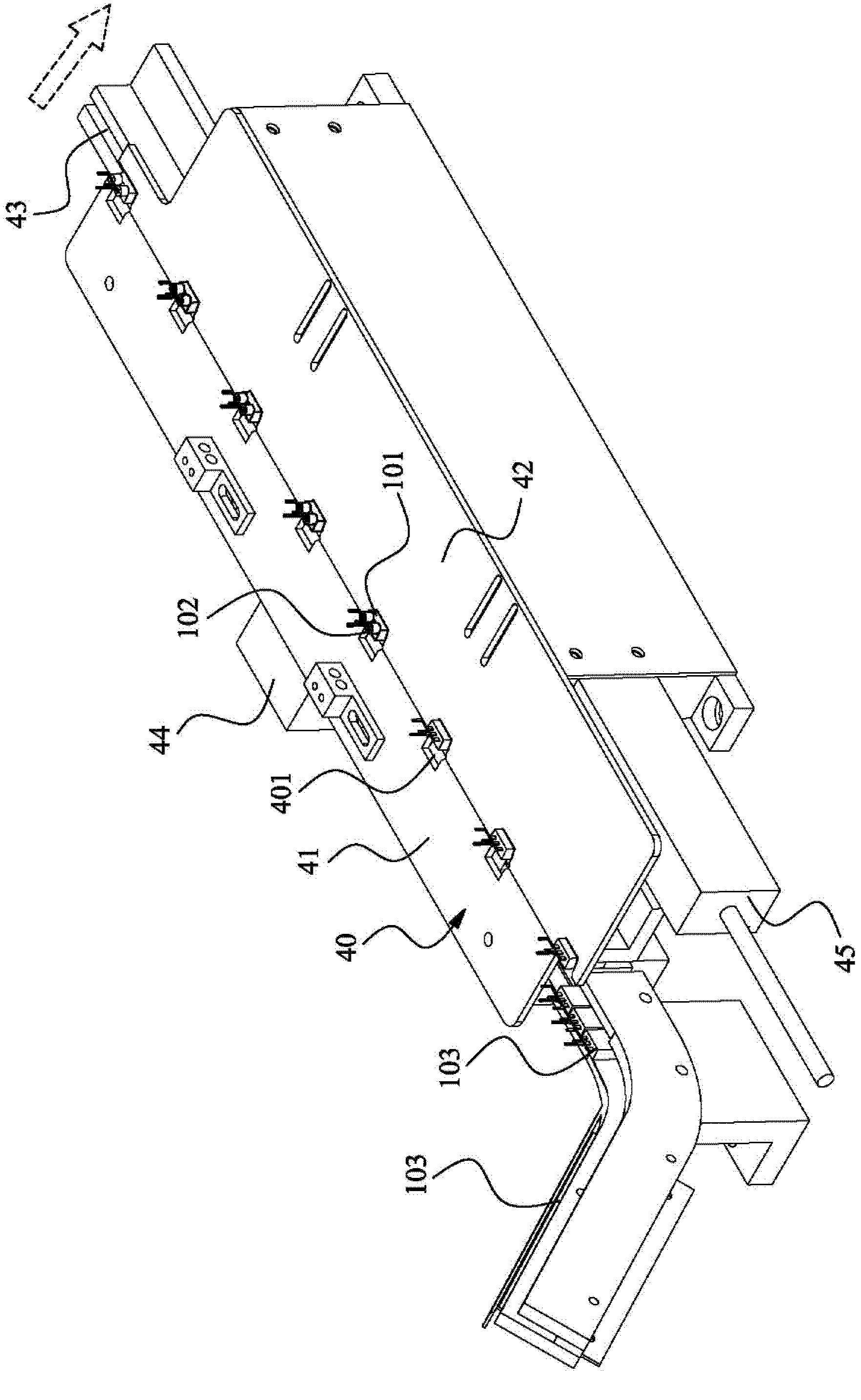

Workpiece loading mechanism and workpiece assembling equipment

ActiveCN113352069ARealize automatic feeding processImprove efficiencyLiquid surface applicatorsCoatingsProcess equipmentStructural engineering

The invention relates to the field of machining equipment, in particular to a workpiece loading mechanism and workpiece assembling equipment. The workpiece loading mechanism comprises a feeding assembly, a pretreatment assembly and a second loading assembly. To-be-loaded workpieces are field-effect tubes; the feeding assembly is used for separating the multiple field-effect tubes loaded in containing tubes one by one, the second loading assembly is used for conveying the separated field-effect tubes to the pretreatment assembly, and the pretreatment assembly is used for pretreating pins of the field-effect tubes; the second loading assembly is further used for conveying the pretreated field-effect tubes to next process equipment; and the second loading assembly comprises a loading adsorption part and a driving assembly for driving the loading adsorption part to move in the three perpendicular directions, and the loading adsorption part is used for adsorbing or releasing the field-effect tubes. According to the workpiece loading mechanism, the to-be-loaded workpieces can be automatically loaded, the efficiency is higher, the subsequent assembling position is more accurate, and the stability of assembled products can be improved.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

Quick assembly tool for valve seat support

The invention provides a valve seat support rapid assembling tool which comprises a wrench assembly and a driving assembly, the driving assembly is used for installing a valve seat support on a valve body, the wrench assembly enables the driving assembly to rotate through a vertical rod part, the rod part of the wrench assembly is further sleeved with a positioning disc, and the positioning disc makes contact with a valve body channel in the valve body. A driving head at the front end of the wrench assembly acts on the driving assembly, and the driving assembly drives the valve seat support to rotate, so that the valve seat support is connected into the valve body in a threaded mode. According to the quick assembling tool for the valve seat support, the magnetic steel block on the inner wrench is attracted to the sliding clamping block arranged in the bottom plate made of the ceramic material, it is ensured that the wrench assembly is connected with the driving assembly, and the valve seat support is driven by the driving key to be tightly connected to the valve body in a threaded mode.

Owner:CHENGDU CHENGGAO VALVE +1

Device for sticking magnetic steel in casing

PendingCN110649772AAvoid offsetThe assembly position is accurateManufacturing stator/rotor bodiesClassical mechanicsStructural engineering

The invention aims to provide a device for sticking a magnetic steel in a casing, which can prevent the magnetic steel from deviating so as to enable the assembly position of the magnetic steel to bemore accurate. In order to achieve the purpose, the invention adopts the following technical scheme: the auxiliary device for sticking a magnetic steel in a casing comprises a plurality of movable blocks; the plurality of movable blocks are annularly arranged at intervals; the movable block is fixed at the output end of a driving mechanism; the casing is arranged on the circumferential outer sideof the movable block in a sleeving mode and supported on a first supporting table; the movable blocks move towards the inner wall side of the casing under the action of the driving mechanism; the lower ends of the movable blocks extend outwards in the circumferential direction to form second supporting tables used for supporting the magnetic steel; the distance between the circumferential outer edge of the second supporting table and the circumferential outer walls of the movable block is smaller than the thickness of the magnetic steel; two check blocks are arranged on the circumferential outer wall of each movable block; the movable blocks are located on the upper side of the second supporting table, and the shape of the outer wall, located between the two check blocks, of each movable block is the same as that of the inner wall of the magnetic steel.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

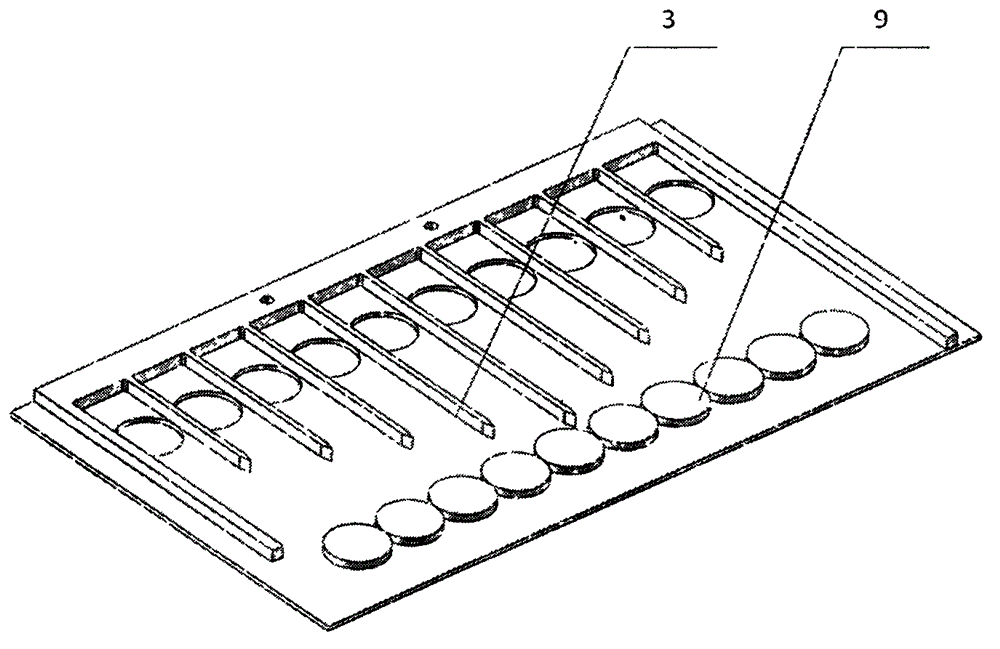

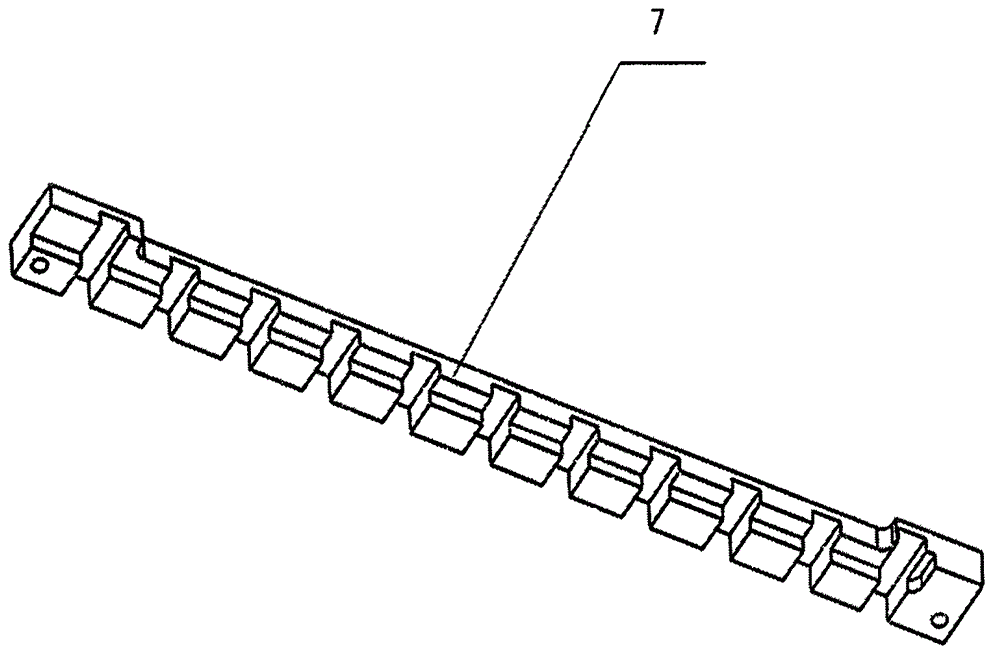

Device for separating button cells at equal intervals and loading button cells in plate

InactiveCN104393314AThe assembly position is accurateReduce labor intensityPrimary cell manufactureFinal product manufactureButton batteryEngineering

The invention discloses a device for separating button cells at equal intervals and loading the button cells in a plate. The device is characterized by comprising a rack assembly, a cell limiting mechanism and a separating mechanism, wherein the rack assembly comprises a vertical plate and an air cylinder mounting plate, and the air cylinder mounting plate is fixed on the vertical plate; the cell limiting mechanism comprises a button cell left limiting plate and a button cell right limiting plate, and the button cell left limiting plate and the button cell right limiting plate are fixed on the vertical plate by screws at the two ends, so that the button cells are ensured to enter the limiting plates through a left inlet; the separating mechanism comprises a separating plate, a connection plate and an air cylinder, the separating plate is embedded in a slot of the vertical plate, the slot of the vertical plate supports the limiting and guiding functions, the connection plate is fixedly connected with the upper surface of the separating plate through threads, and the air cylinder is fixed on the air cylinder mounting plate and is connected with the separating plate through the connection plate.

Owner:TIANJIN POLYTECHNIC UNIV

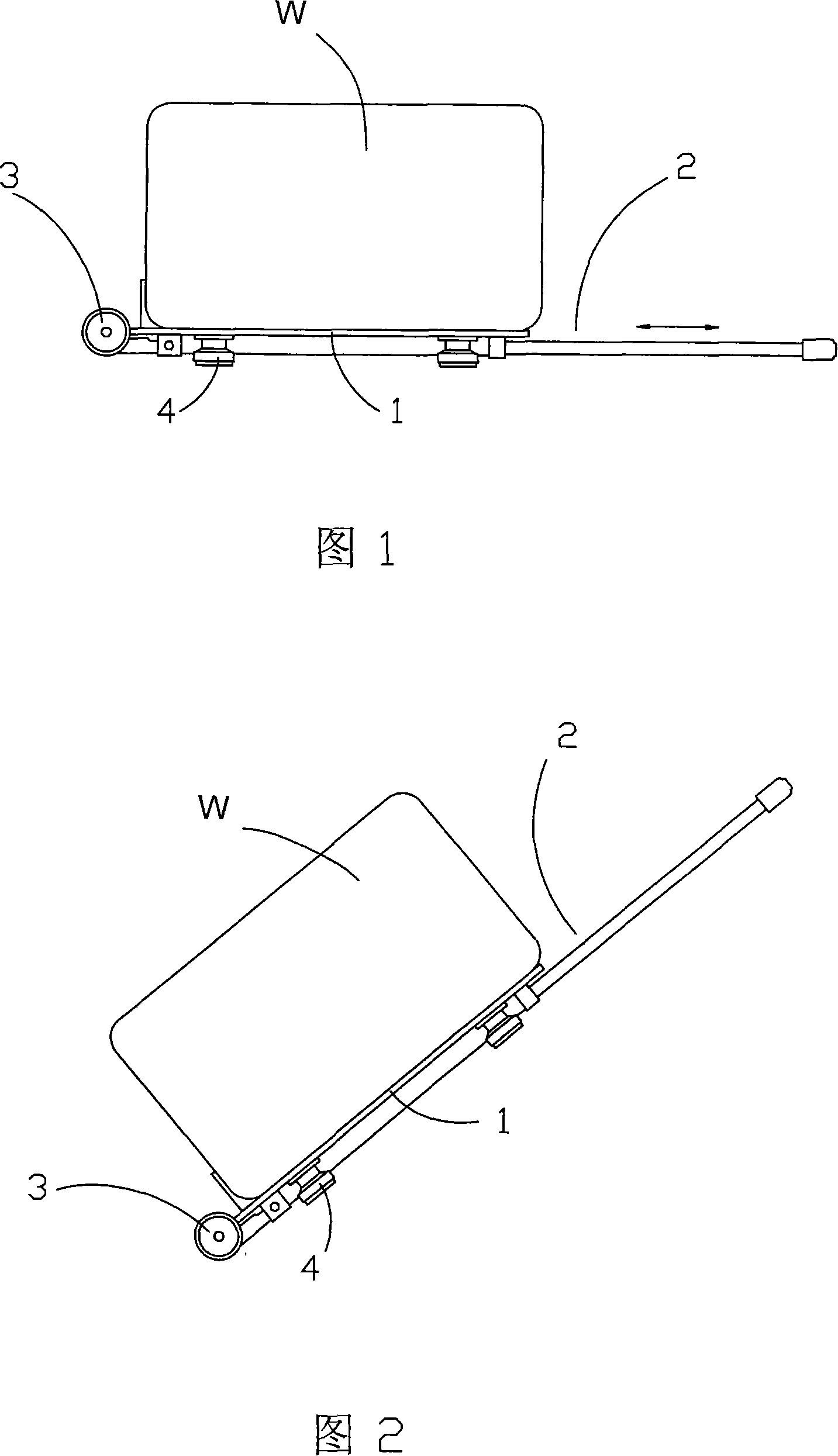

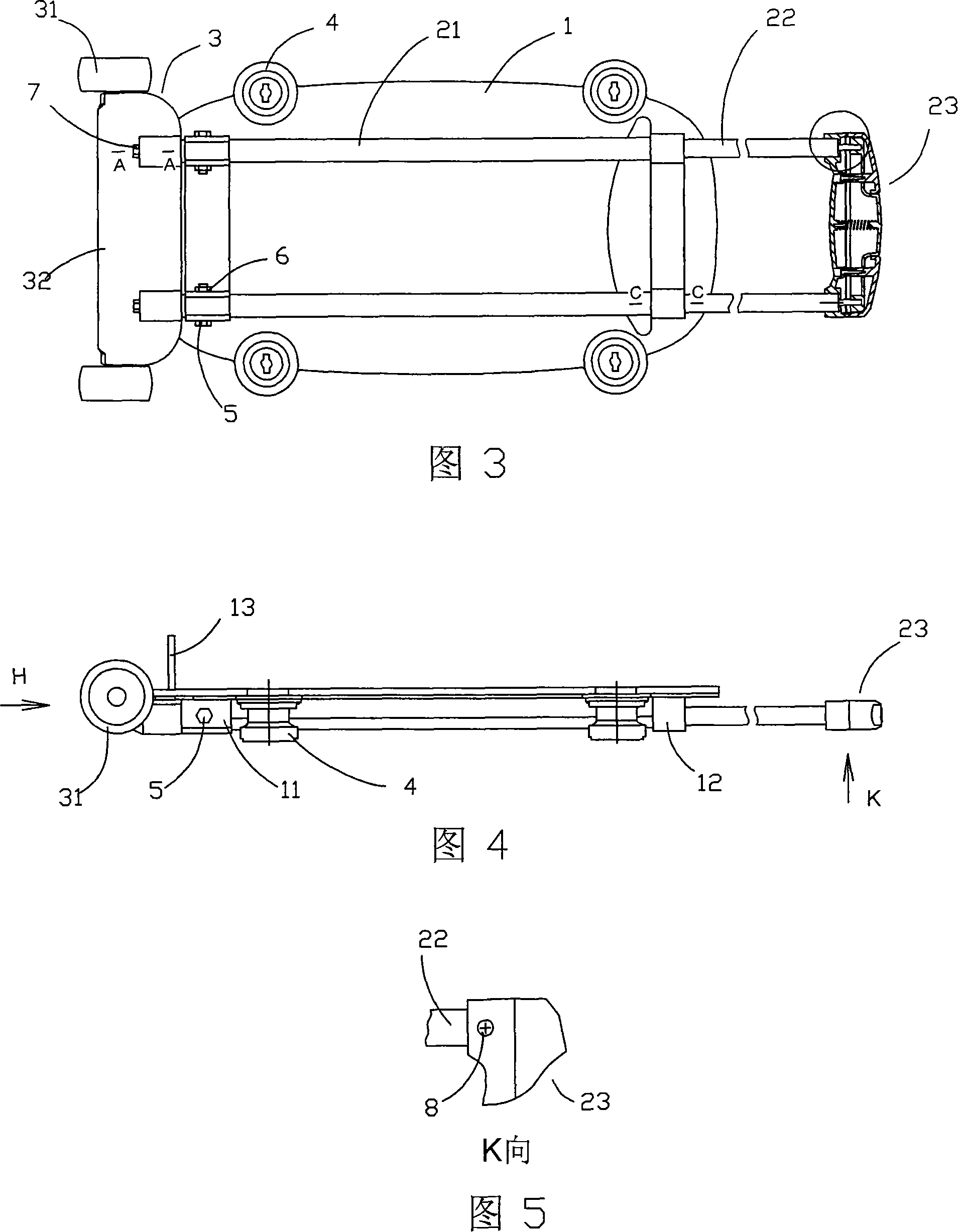

Portable carry goods moving device

ActiveCN101103855ACompact structureEasy to carryOther accessoriesHand carts with one axisCarrying capacityEngineering

The invention relates to a portable object carrying shifter which belongs to the technical field of handcars. The invention is characterized in that a drag link mechanism is arranged under an object stage; a roller mechanism is arranged at the non-drawable end of the drag link mechanism; support legs are fixed under the object stage. When laid flat the carried object is supported completely by the support legs fixed under the object stage and wheels are in a suspension state without any load; in need of shifting, the drag link of the drag link mechanism is drawn out and is lifted upward to make the object stage be supported by the wheels in a slant state which facilitates shifting. The invention has simple and compact structure and high carrying capacity; the drawable drag link mechanism and the roller system are arranged reasonably to ensure the invention to shift conveniently and effortlessly.

Owner:WUXI KIPOR POWER CO LTD

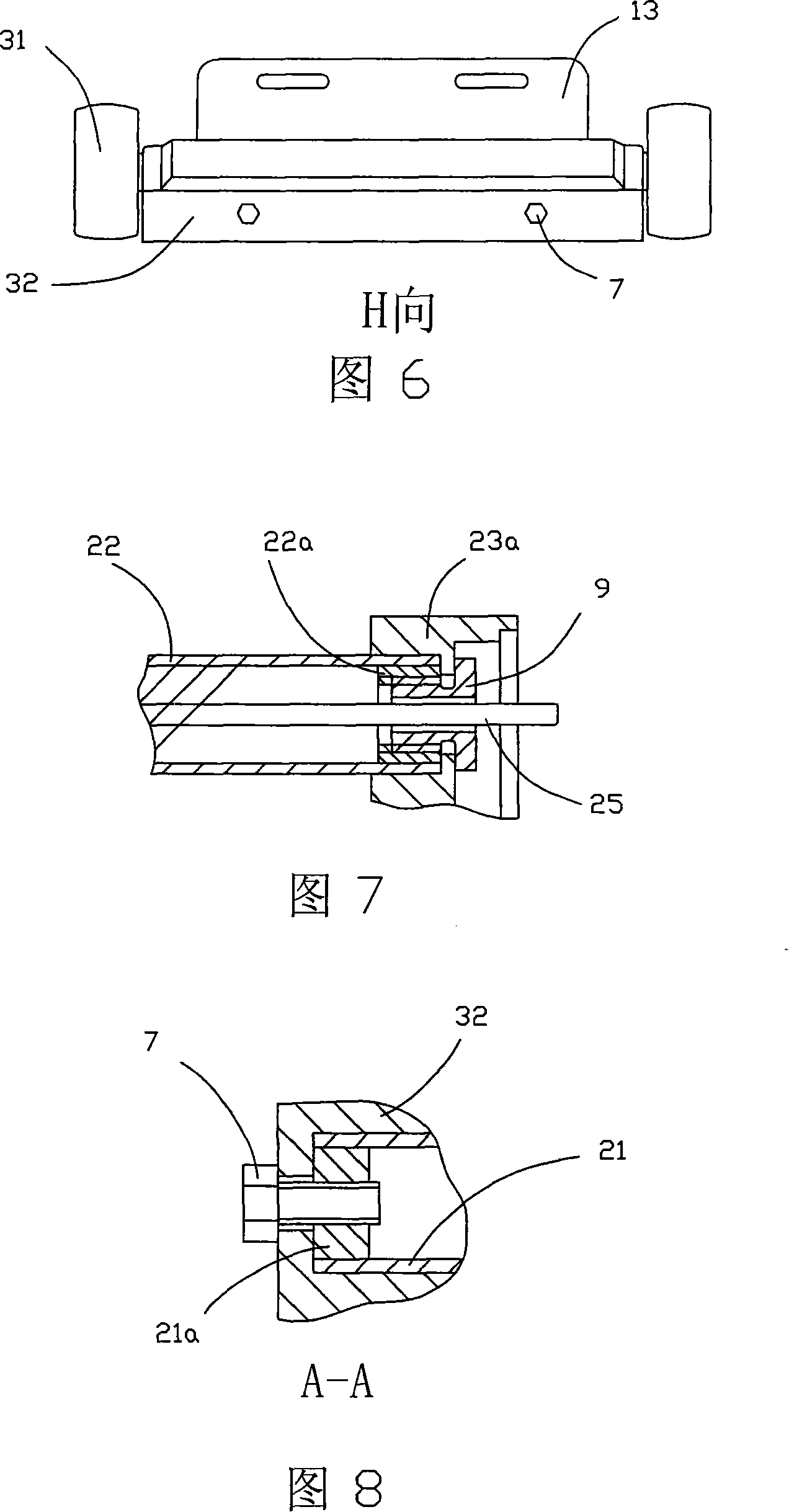

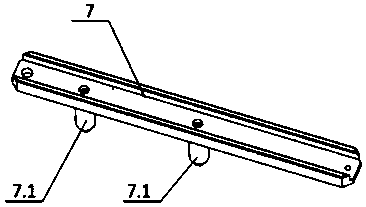

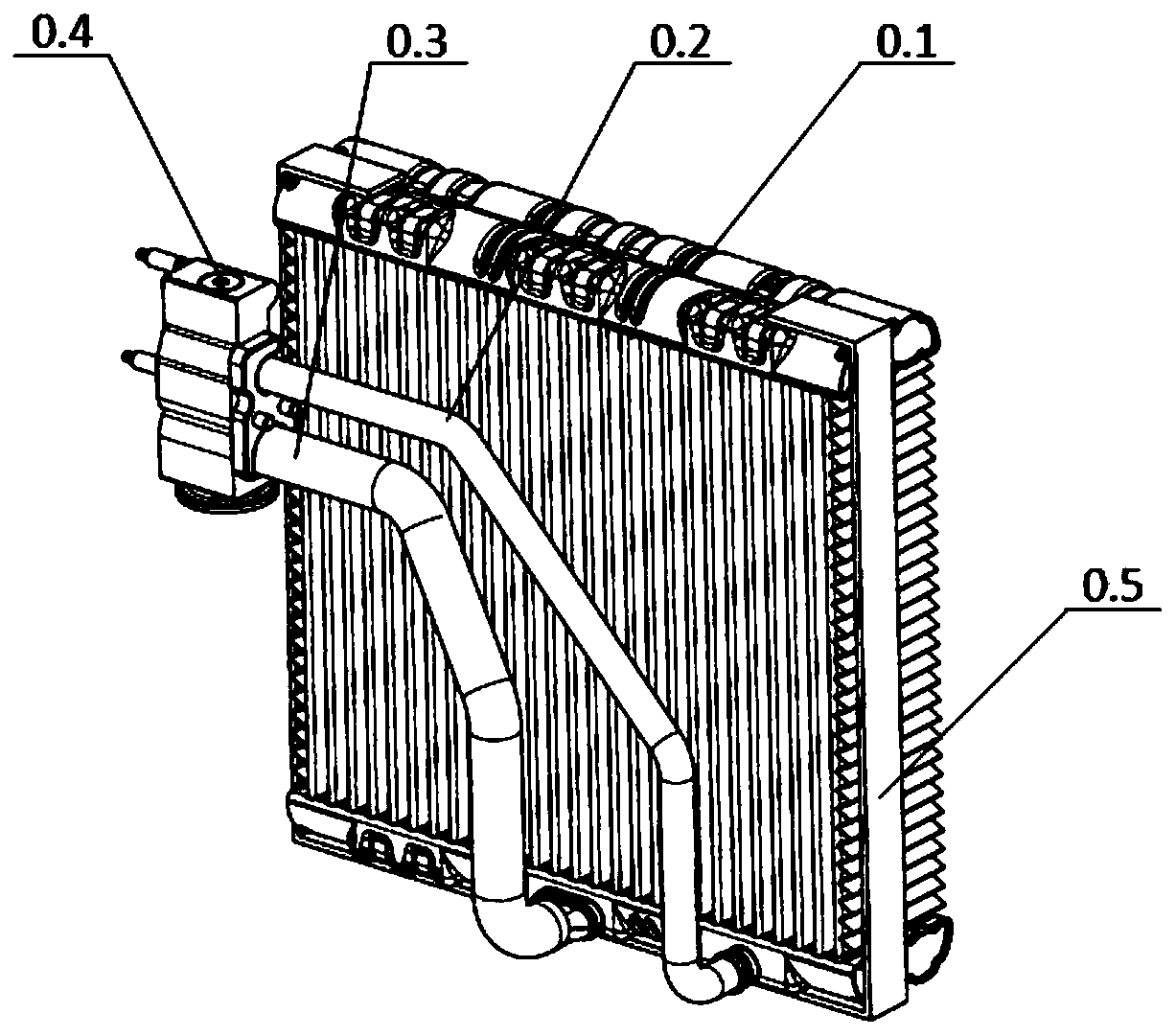

Assembling device for core sponge of evaporator assembly

PendingCN110842846AImprove assembly efficiencyCorrect locationMachine valve testingWork holdersStructural engineeringMechanical engineering

The invention relates to an assembling device for a core sponge of an evaporator assembly. The assembling device for the core sponge comprises a bottom plate and a limiting and supporting mechanism. The limiting and supporting mechanism comprises a front supporting plate, a rear supporting plate, a left supporting plate, a right supporting plate and a lower supporting plate; a gap for installationof the core sponge is formed between the front supporting plate and the right supporting plate, and the gap is provided with a first sponge bed plate where the core sponge is placed; the left supporting plate is provided with a gap for installation of the core sponge; and the rear supporting plate is provided with a locking mechanism for locking an evaporator core. The bottom plate is provided with the limiting and supporting mechanism to limit and support the evaporator core, the rear supporting plate is provided with the locking mechanism to lock the evaporator core, the gaps for installation of the core sponge are formed between the front supporting plate and the rear supporting plate and on the left supporting plate respectively, and sponge bed plates limit and support the core sponge. The above structure guarantees that the core sponge can be accurately and efficiently assembled on the evaporator core.

Owner:DONGFENG BEHR THERMAL SYST

Beach chair pipe base foot riveting assembly line

The invention relates to a beach chair pipe base foot riveting assembly line. The beach chair pipe base foot riveting assembly line comprises a supply device and a production line which are arranged in sequence, and a riveting machine which is arranged on at least one side edge of the production line. The beach chair pipe base foot riveting assembly line is characterized in that the supply device comprises a pipe frame provided with a loading manipulator, and a vibrating disc correspondingly arranged at one side of the riveting machine; and multiple tools are arranged on the production line in sequence. The beach chair pipe base foot riveting assembly line uses the vibrating disc and the loading manipulator for synchronously transferring a base foot and a pipe to a riveting position; fixed grooves and fixed columns arranged on the tools fix the pipe in an exactly structure matching manner, and a radial angle in fixation is determined; and before riveting, actions of a transplantation manipulator can be timely adjusted through CCD image information feedback to satisfy a pose relation between the base foot and one end of the pipe, so that the assembly angle and position are both precise.

Owner:JIANGSU BVM INTELLIGENT TECH

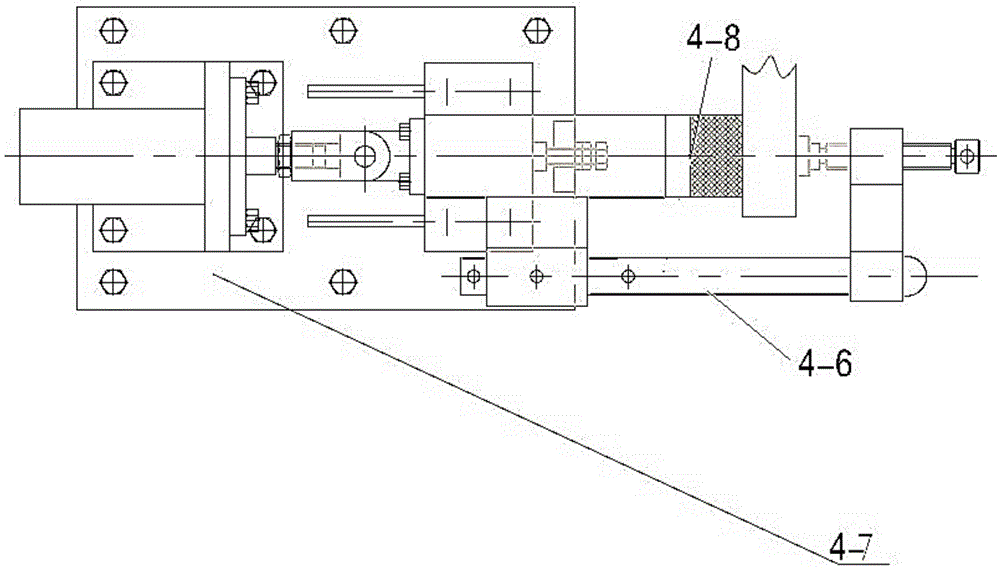

Press mounting machine for workpiece

ActiveCN103350338AThe assembly position is accurateThe processing position is accurateMetal working apparatusDevice formEngineering

The invention discloses a press mounting machine for a workpiece, which comprises a fixing plate, and as well as a clamping device for clamping the workpiece, a sliding part sliding in an accommodating groove and providing a slide rail for the clamping device, a push device for pushing the workpiece to an assigned position, and a driving device for providing power for the clamping device and the push device, wherein the accommodating groove is fixed on the fixing plate; the driving device is composed of a first motive power piece placed at the upper part of the sliding part and providing power for the clamping device, and a second motive power piece providing power for the push device; the clamping device forms a compressing piece with one end slidably connected with the slide rail and the other end used for compressing the workpiece, and a guiding piece used for limiting the sliding range of the workpiece; the push device forms a connecting rod fixedly connected with the second motive power piece, a compression rod for pushing the workpiece to move, and a slide rod fixed with the lower part of the connecting rod. Aiming at the L-shaped workpiece, the invention provides the press mounting machine with simple structure, low cost and excellent press mounting effect.

Owner:江苏烽禾升智能科技有限公司

Assembling device for rectangular frame and assembling method of assembling device

PendingCN109227086AAchieve clamping positioningSimple structureMetal working apparatusHigh volume manufacturingEngineering

The invention discloses an assembling device for a rectangular frame and an assembling method of the assembling device. The assembling device comprises a rack, a rotary frame driven by a first power device is rotationally mounted on the rack, and short frame clamping and locating mechanisms driven by a driving device are slidingly mounted at the two ends of the rotary frame. Long frame clamping and locating mechanisms are fixedly mounted on the two sides of the rotary frame. By means of the assembling device for the rectangular frame, mechanical and automatic assembling of the rectangular frame is achieved, the effect of mass production of the rectangular frame is achieved, the assembling efficiency and production efficiency of the rectangular frame are greatly improved, the assembling effect is good, and the forming quality of the rectangular frame is high. Meanwhile, the labor intensity of workers is reduced, the number of the needed workers is reduced, and then the labor cost is reduced.

Owner:JIANGSU HAGONG PHARMA MACHINE TECH CO LTD

Assembling machining line and assembling process for right gear lever handle for automobile steering wheel

ActiveCN112264783AAccurate clamping and positioningEasy to pressMetal working apparatusSteering wheelMachine parts

The invention relates to the technical field of automobile steering wheel assembling, in particular to an assembling machining line and an assembling process for a right gear lever handle for an automobile steering wheel. The assembling machining line for assembling the right gear lever handle comprises an electrostatic dust collection assembly, a first press-fitting assembly, a detection assembly, a locking assembly and a second press-fitting assembly which are sequentially arranged according to the assembling sequence of the right gear lever handle. Through combined use of a positioning clamp, a locking clamp and a press-fitting clamp, in all assembling steps, a machined part can be accurately clamped and positioned, press-fitting and locking work can be conveniently carried out, the assembling precision and the assembling quality are improved, the technical problem that in the assembling process, the assembling precision is low due to manual factors is solved, and the defective rateis effectively reduced.

Owner:浙江金麦特自动化系统有限公司

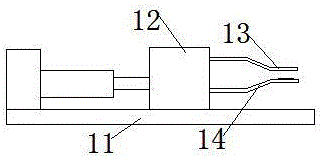

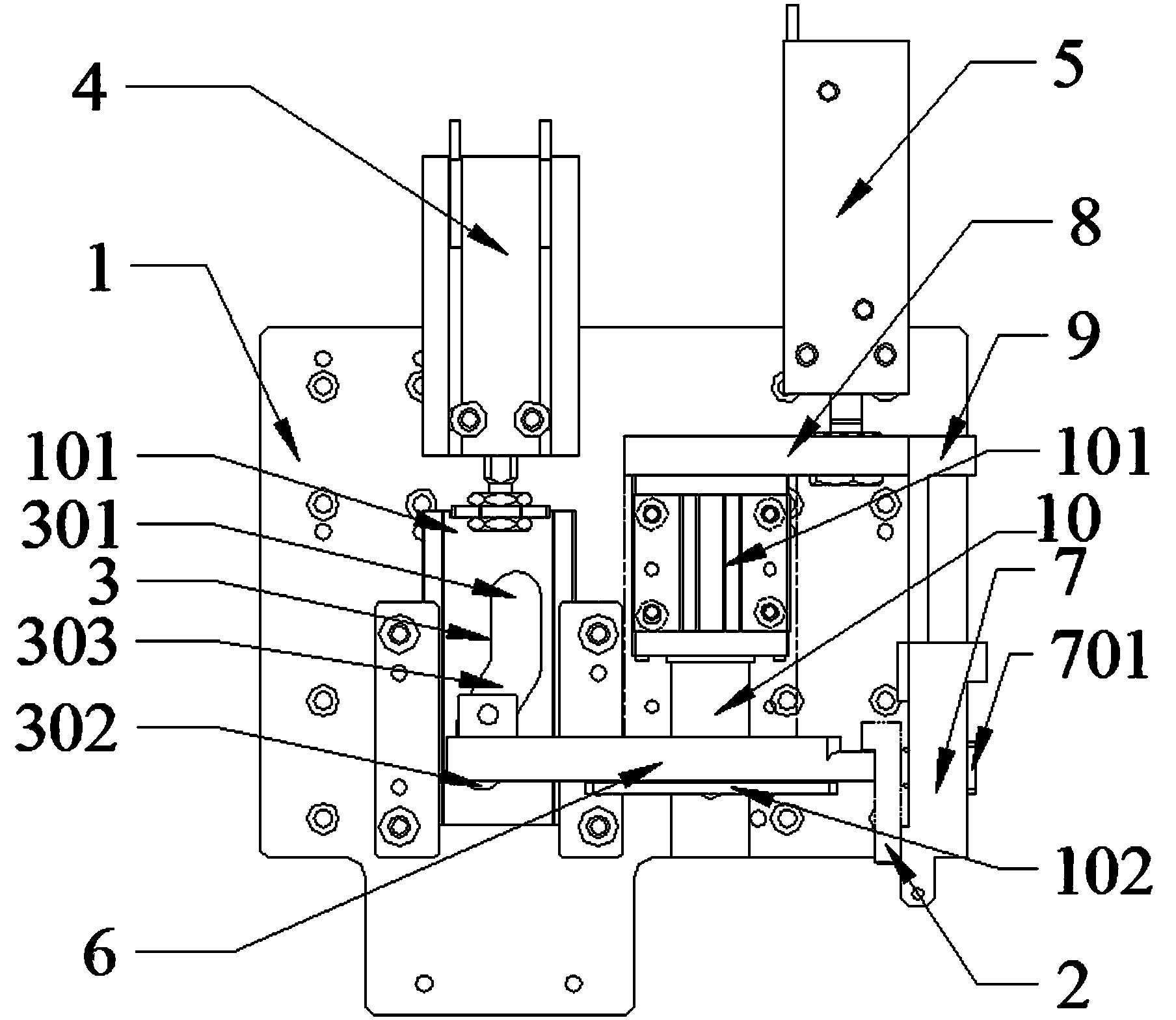

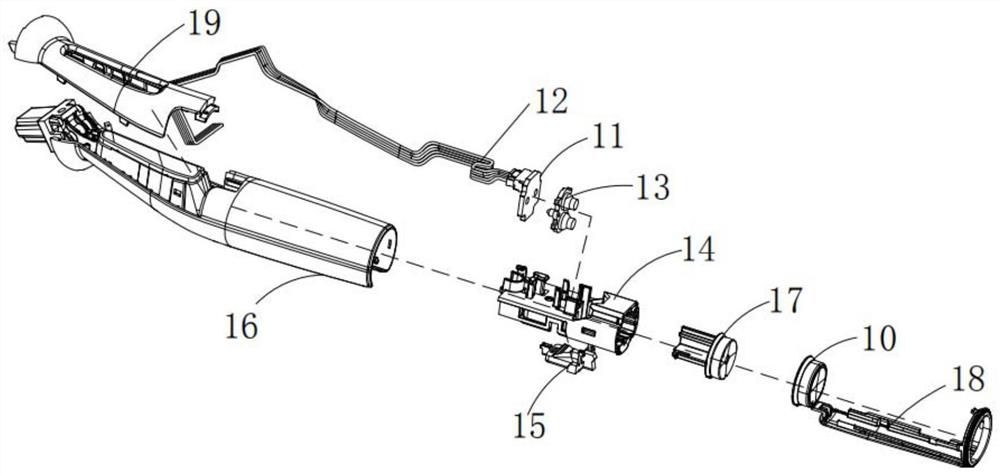

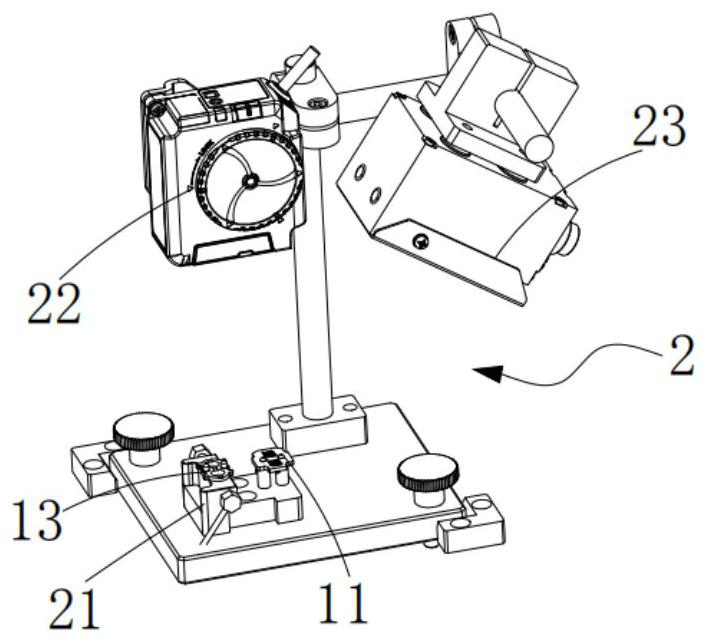

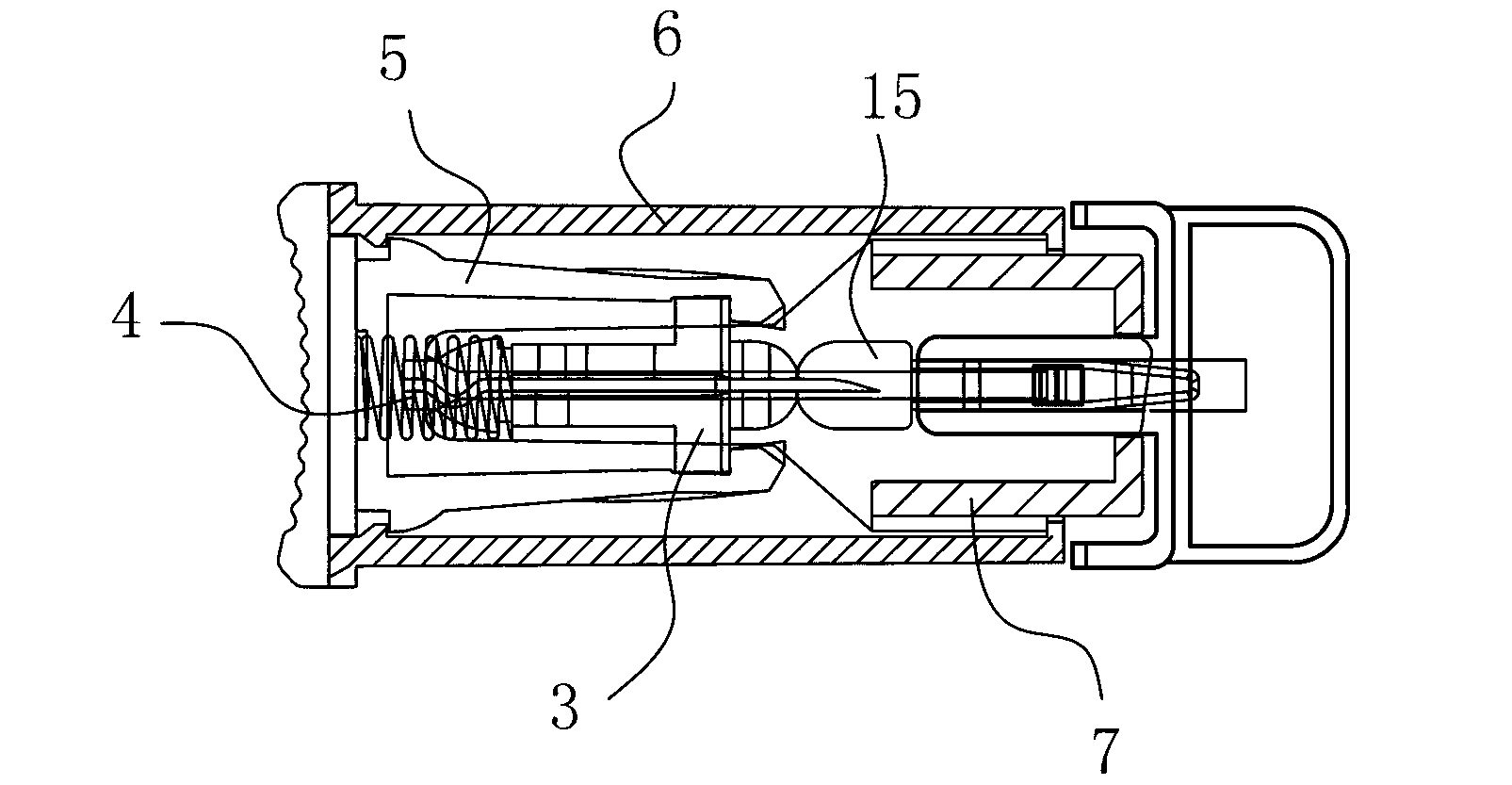

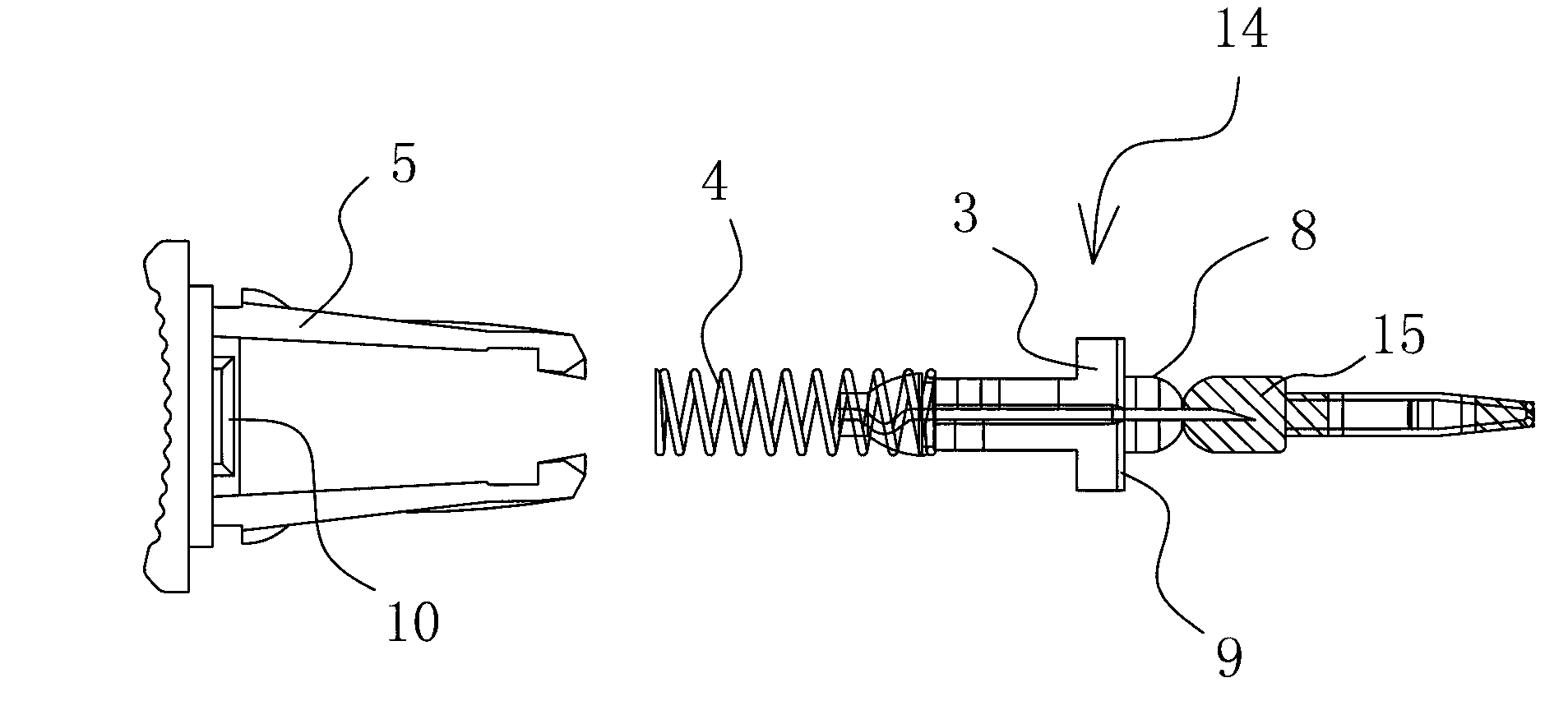

Assembling and positioning jig in blood sampling needle automatic assembling equipment

ActiveCN102699848APrecise assembly positionSimple structureWork holdersBlood samplingBiomedical engineering

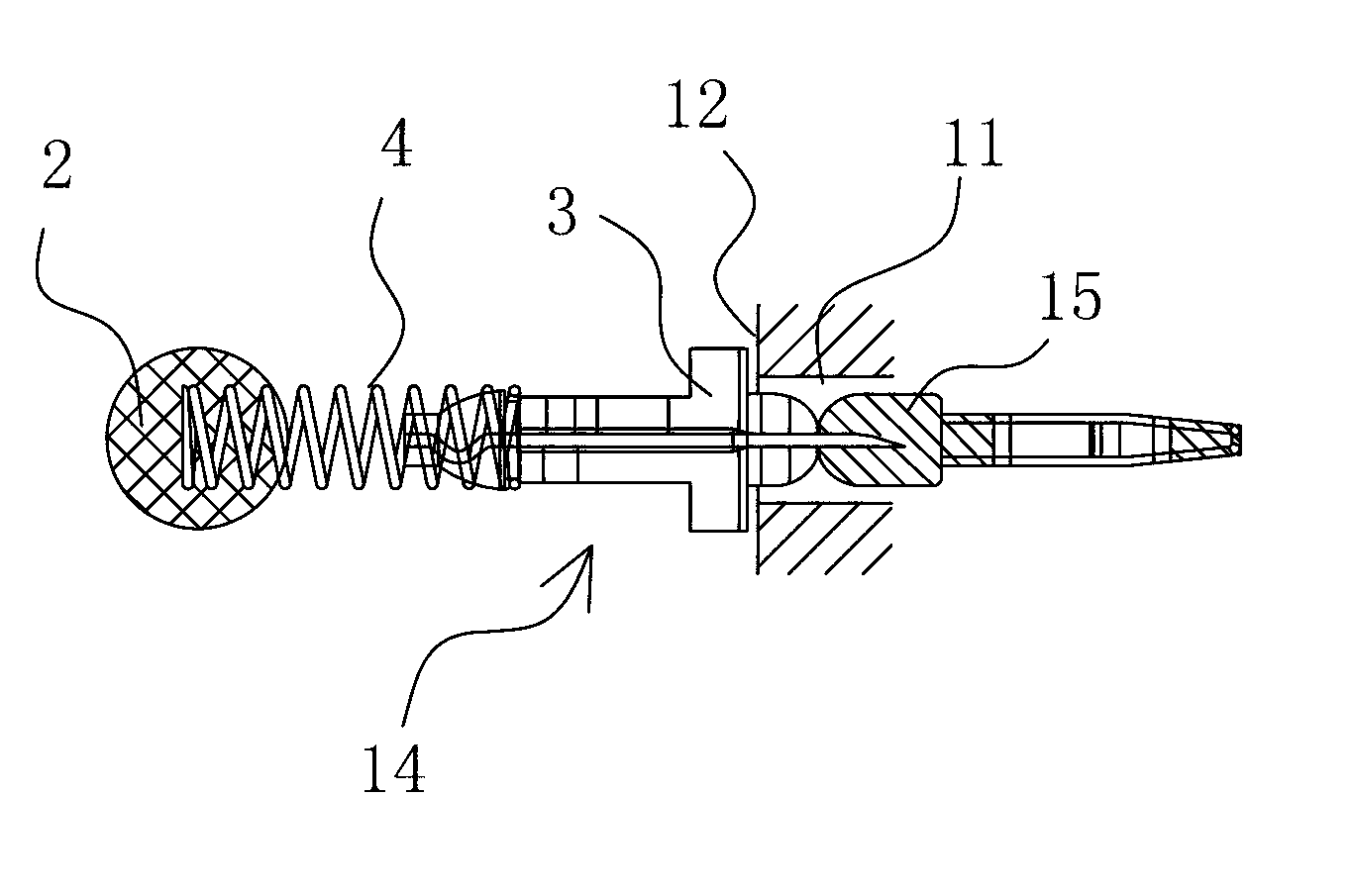

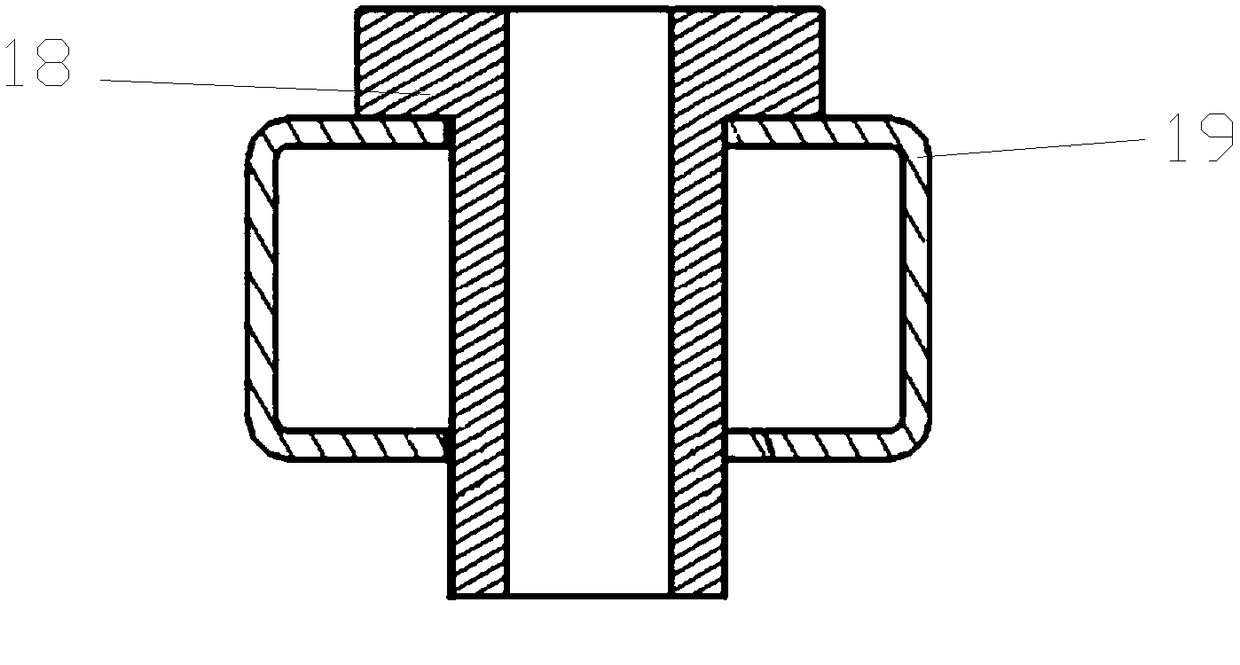

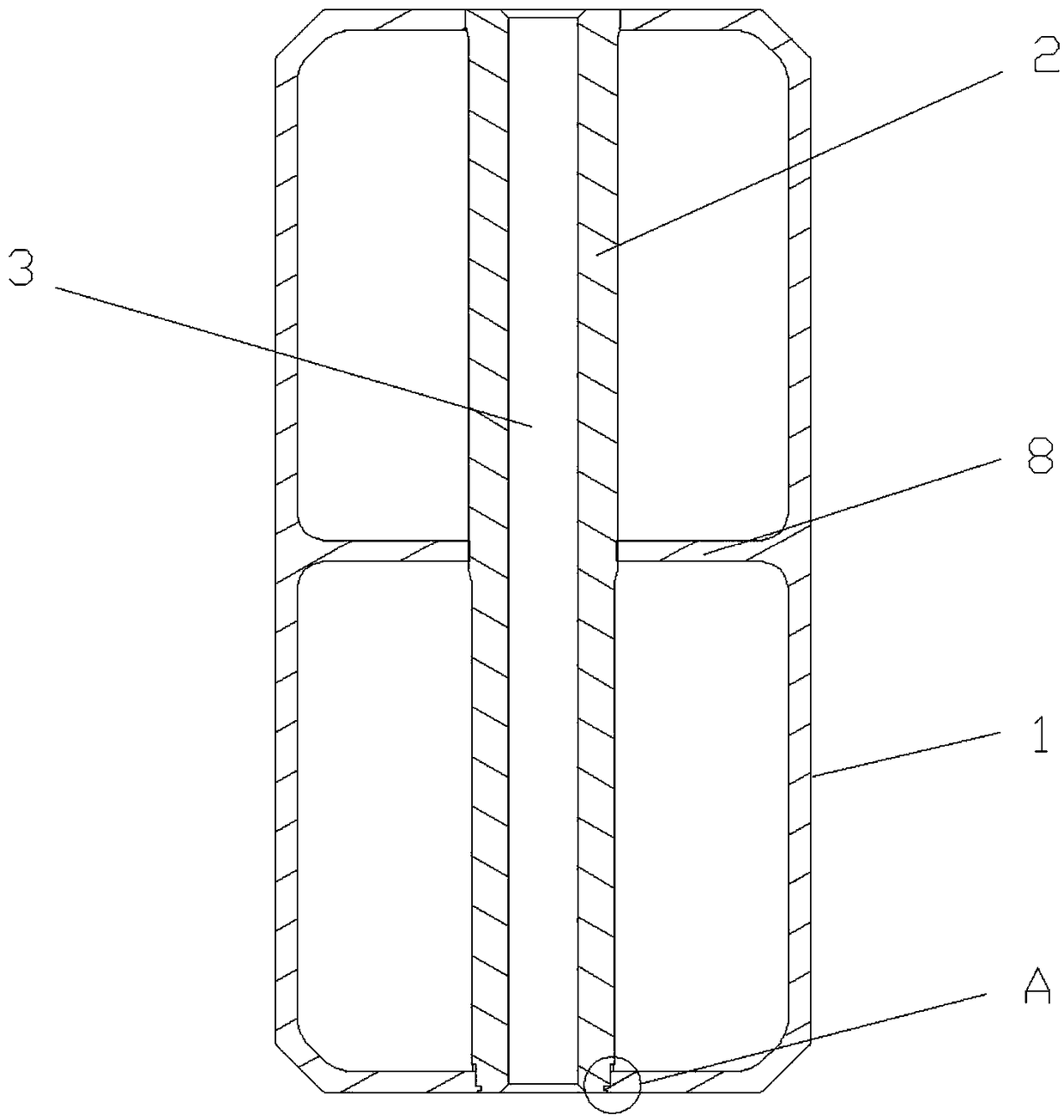

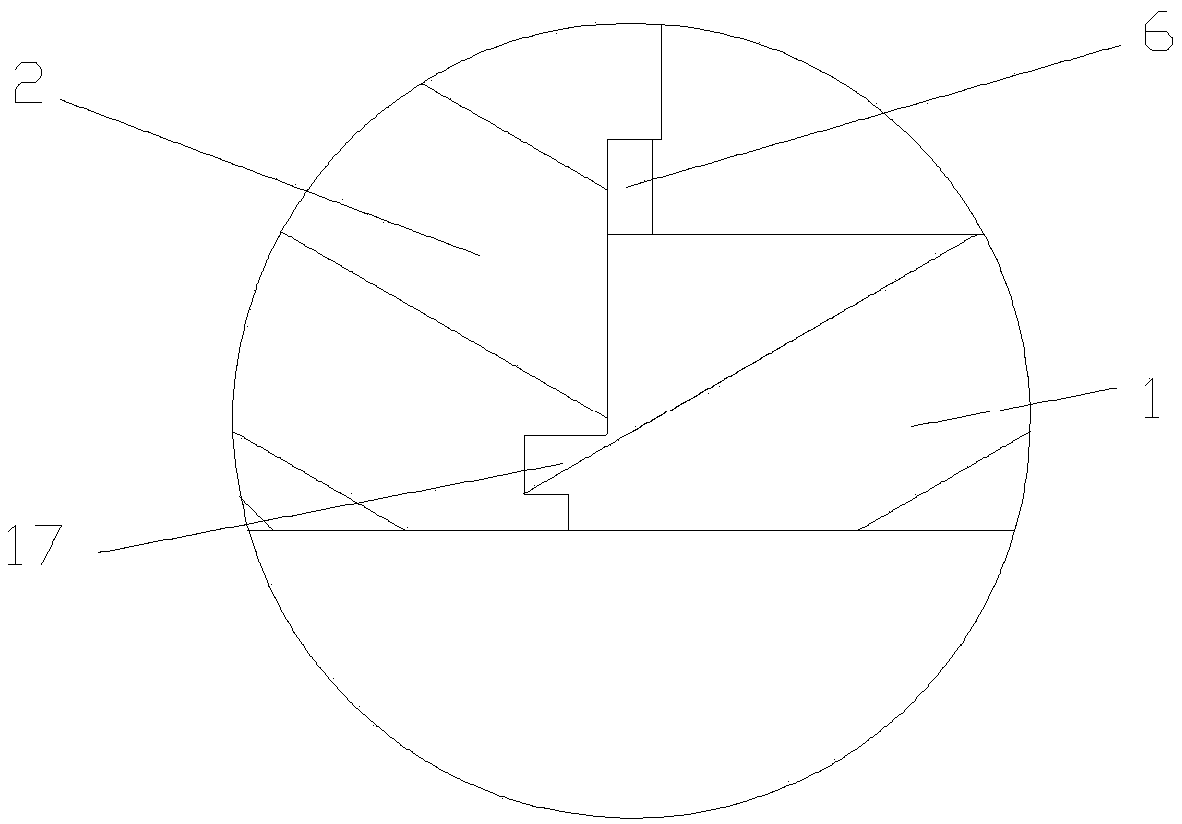

The invention relates to an assembling and positioning jig in blood sampling needle automatic assembling equipment, which is characterized in that aiming at a needle core spring assembly (14) in a blood sampling needle, the assembling and positioning jig is provided with a base (1); at least one station (13) for positioning the needle core spring assembly (14) is arranged on the base (1); a U-shaped positioning groove (11) is arranged at the position on the station (13), which corresponds to a shaft neck (8) of a needle core (3) in the needle core spring assembly (14); a positioning end face (12) is arranged at the end of the U-shaped positioning groove (11), which corresponds to a first end face (9) of the needle core (3); a magnetic positioning block (2) is arranged at the position on the station (13), which corresponds to the tail part of a spring (4) in the needle core spring assembly (14), so as to form a positioning structure of the needle core spring assembly (14). The assembling and positioning jig in the scheme can be used for positioning the needle core spring assembly when the blood sampling needle is automatically assembled, the yield of a product is greatly improved and the blood is ensured to be successfully sampled by the blood sampling needle.

Owner:STERILANCE MEDICAL SUZHOU

Body longitudinal beam and auxiliary frame mounting structure

ActiveCN108820054AImprove torsion resistanceImprove fatigue toleranceUnderstructuresSuperstructure connectionsVehicle frameEngineering

The invention relates to a body longitudinal beam which comprises a body longitudinal beam body and a fixed part arranged in the body longitudinal beam body. The fixed part is integrally in the shapeof a rod, a threaded hole is formed in the bottom of the fixed part, a first through hole is formed in a bottom plate of the body longitudinal beam body, the fixed part comprises a first rod section matched with the first through hole, an outward projecting extrusion portion is arranged on the outer wall of the first rod section, a recess is arranged on the outer wall of the first rod section, andthe bottom plate of the body longitudinal beam body is provided with a groove formed by extruding the bottom plate of the body longitudinal beam body by the extrusion portion along the axis directionof the first rod section, the wall of the first through hole is provided with a squeezing-out portion which is formed by extruding the bottom plate of the body longitudinal beam body by the extrusionportion along the axis direction of the first rod section and expands into the recess, the extrusion portion and the groove are jogged, and the squeezing-out portion is embedded into the recess, so that the fixed part is fixed into the body longitudinal beam body. The fatigue resistance of a mounting port of an existing body for mounting an auxiliary frame can be improved. The invention further provides an auxiliary frame mounting structure.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

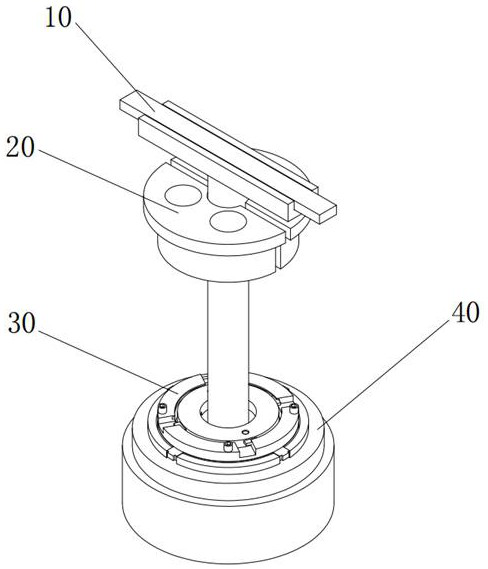

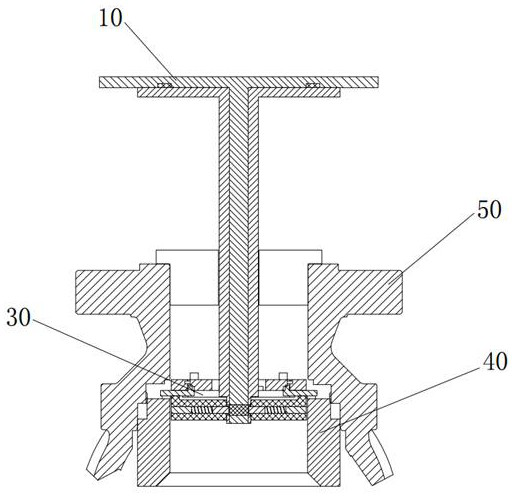

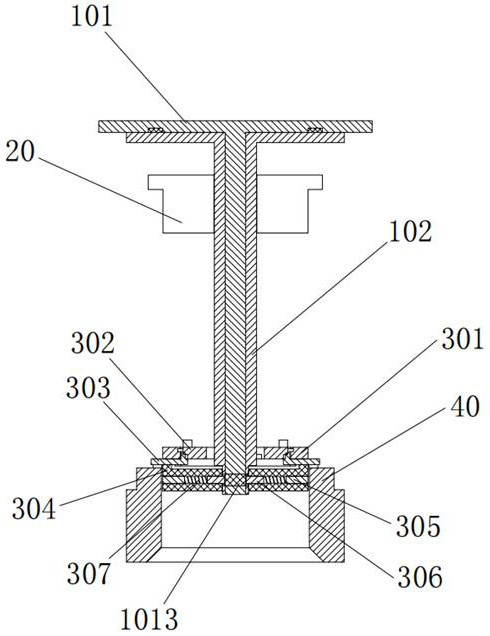

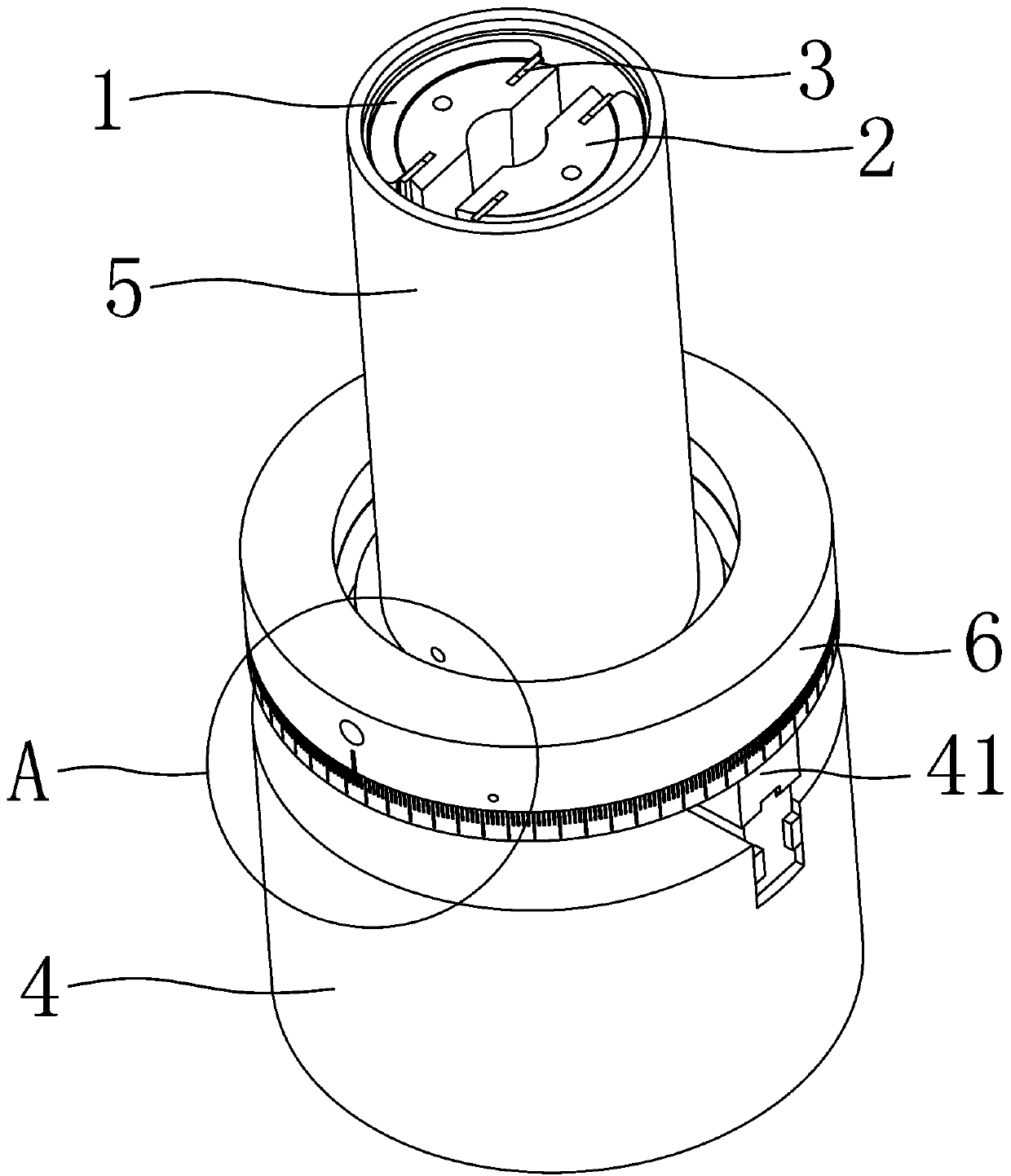

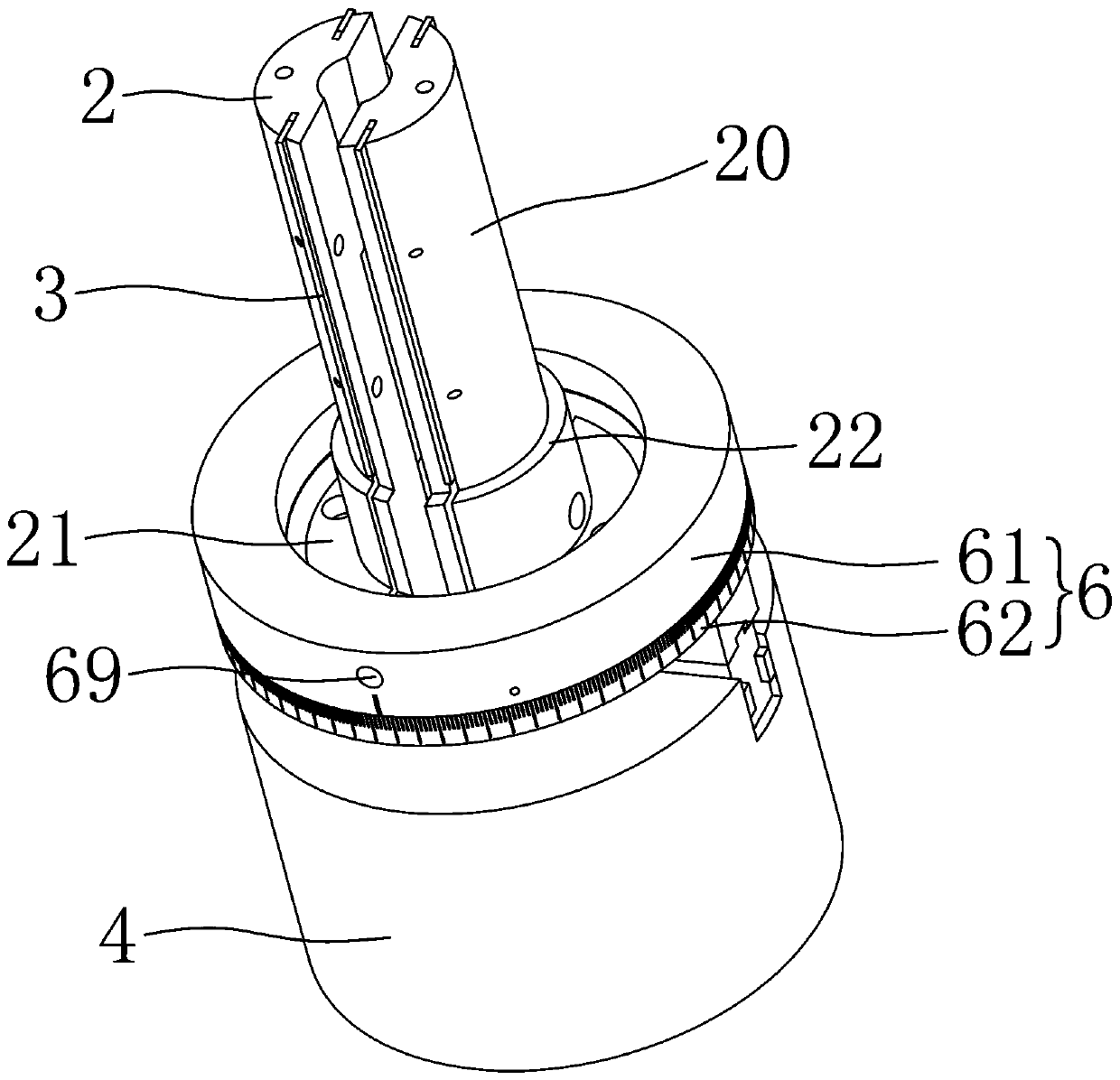

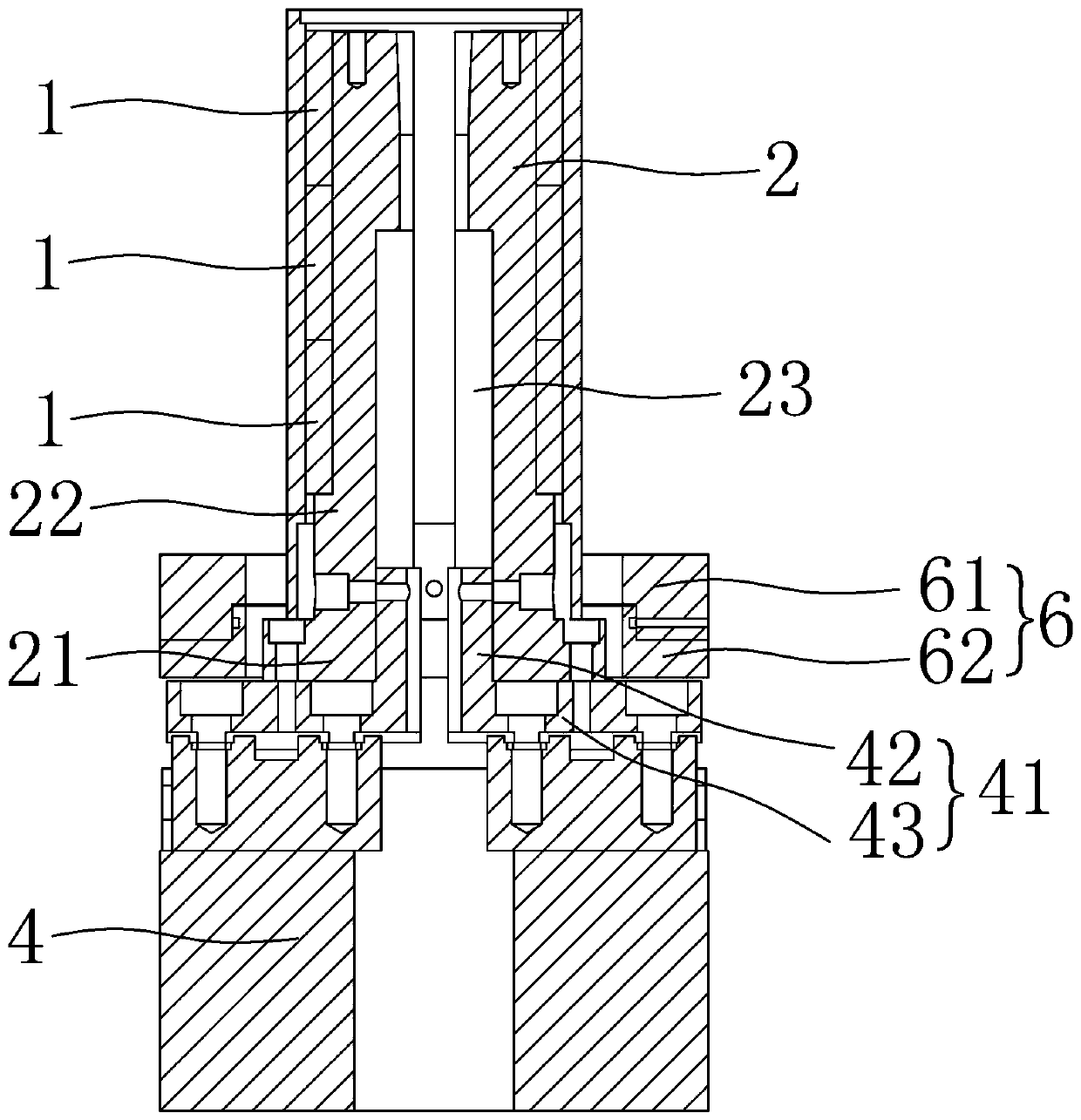

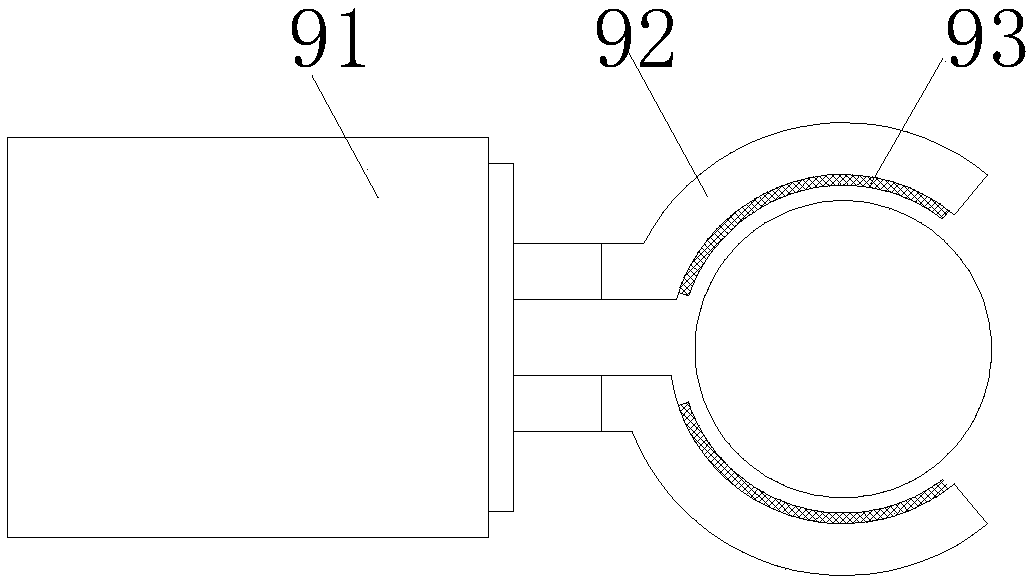

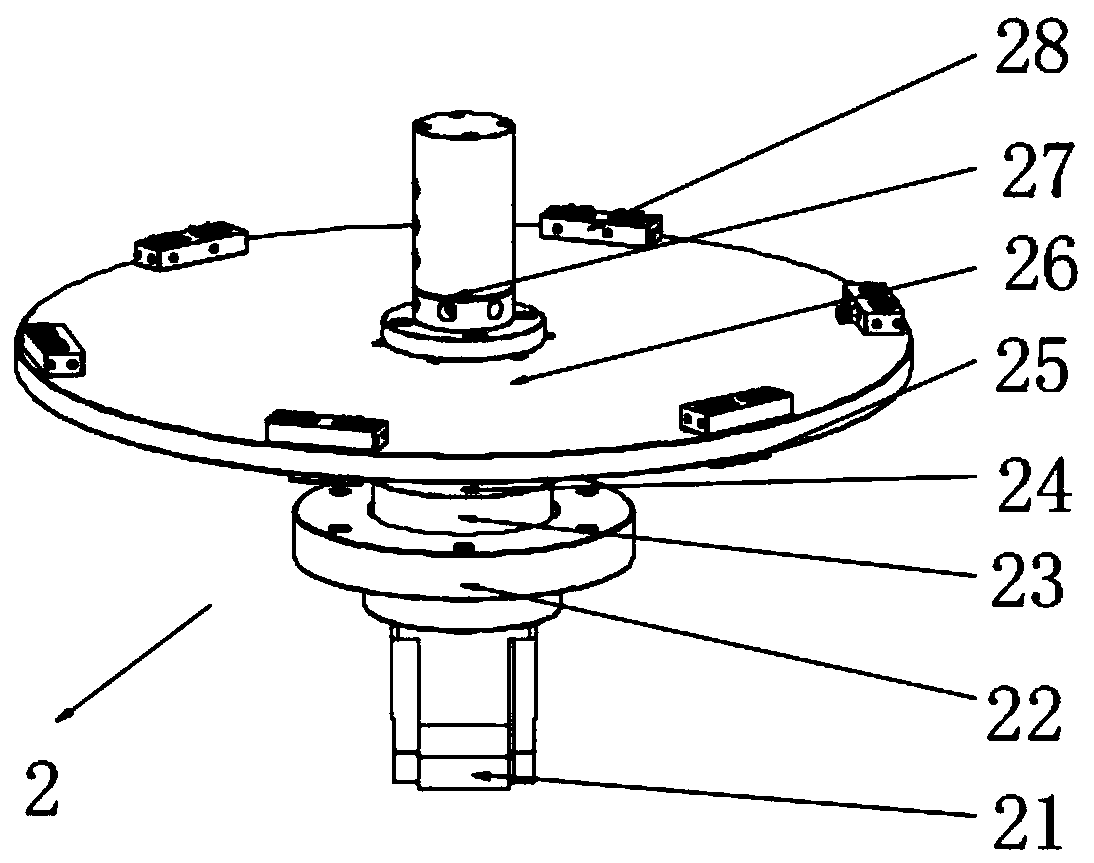

Multi-station permanent magnetic motor assembling device

ActiveCN108712027AReasonable structural designThe assembly position is accurateCentering/balancing rotorsStatorEngineering

The invention relates to a multi-station permanent magnetic motor assembling device. The device comprises a base plate and a rotary bench. A stator installation bench, a lead screw penetrating throughthe stator installation bench and a guidance rod are arranged on the rotary bench. The lead screw is connected with a motor. A rotor installation bench is connected to the lead screw and the guidancerod. Multiple hydraulic cylinders are arranged on the rotor installation bench in a cycle manner. A clamping jaw mechanism is connected to each hydraulic cylinder. A limiting seat is correspondinglyarranged on the lower side of each hydraulic cylinder. A moving plate is slidably connected to the right side of the base plate. An air cylinder connected with the moving plate is fixed on the base plate. Screws and sliding columns are arranged on the moving plate. Rotor loading plates are connected to the screws and the sliding columns. Rotor installation seats are fixed to the left ends of the rotor loading plates. A power mechanism for driving the rotation bench and the screws to rotate is arranged on the base plate. According to the invention, it can be ensured that the assembling positions of the rotor and the stator of the permanent magnetic motor are precise; the rotor is prevented from deflecting; motor rejection rate is reduced; multiple stators and rotors can be assembled; rotorscan be loaded; labor intensity is reduced; and working efficiency is improved.

Owner:芜湖翡叶动力科技有限公司

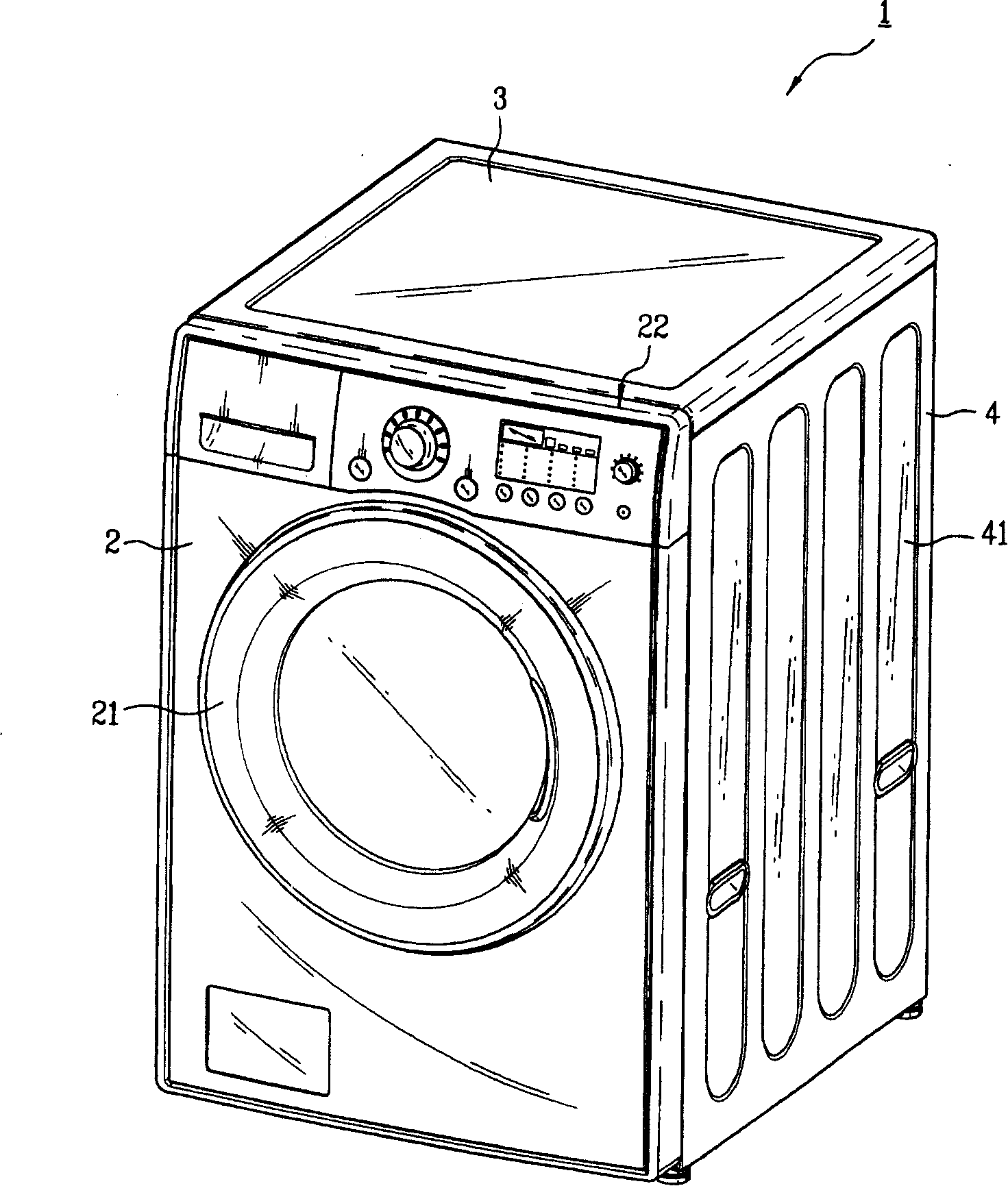

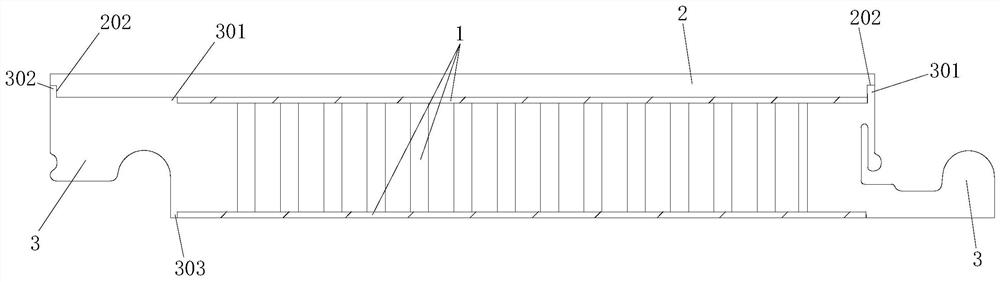

Coating and guiding element for drying machine

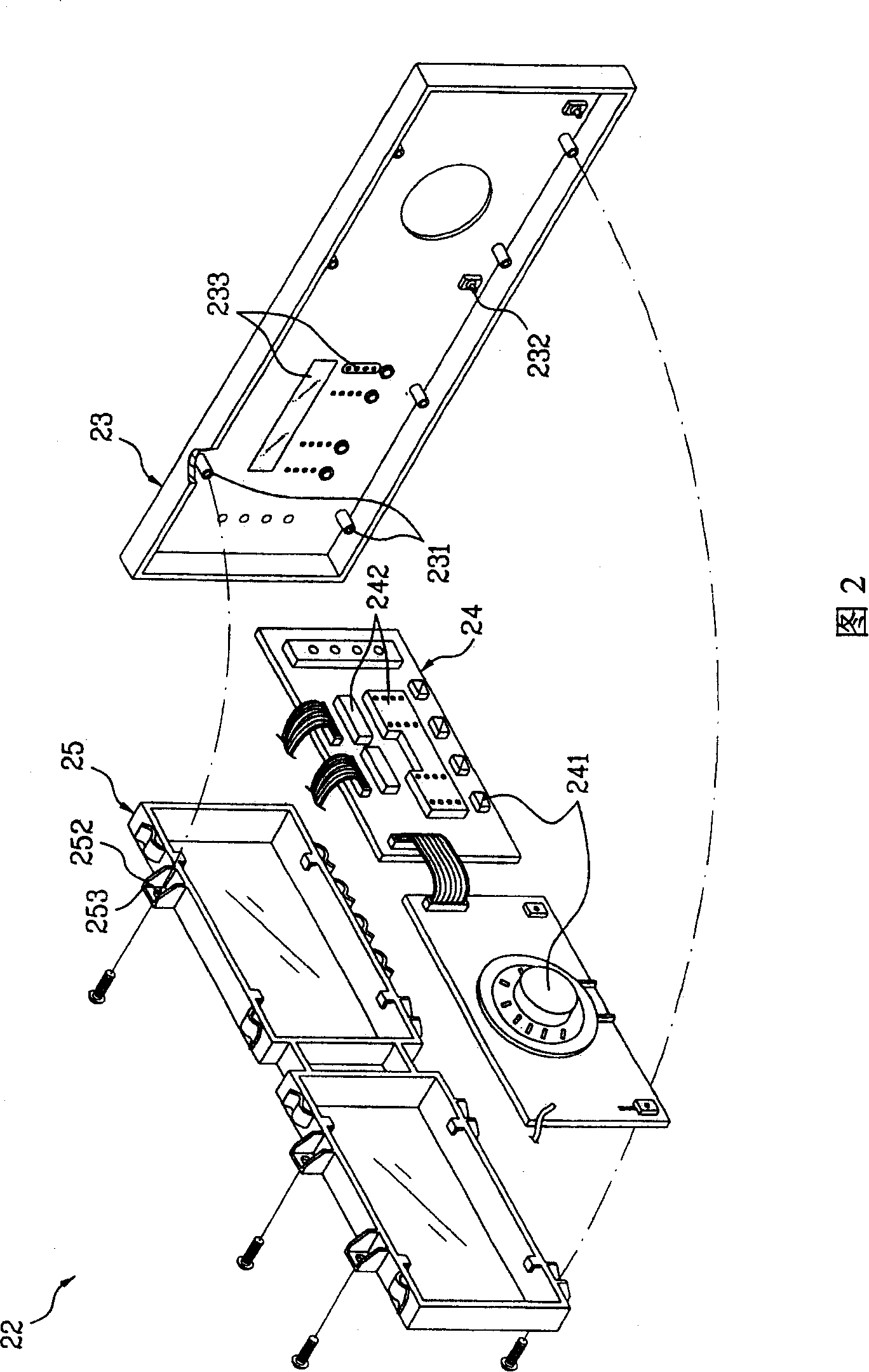

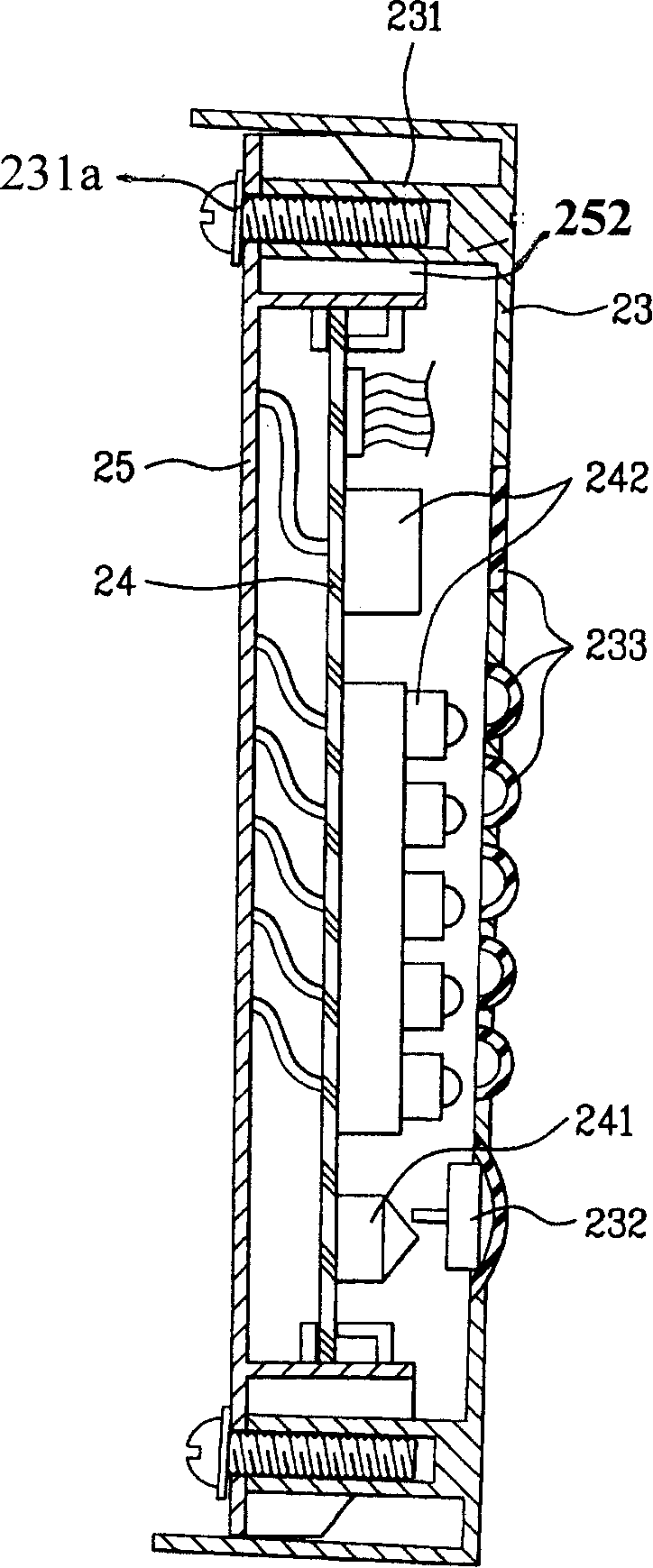

InactiveCN101168922AAssembled preciselyEasy to understandTextiles and paperLaundry driersEngineeringElectronic component

The invention relates to a clothes dryer, in particular to an assembling structure of a coating guide piece in each component of a controlling part. The coating guide piece of the clothes dryer of the invention comprises a controlling panel forming the appearance of the controlling part of the clothes dryer and provided with a plurality of assembling heads in an inner side; the coating guide piece of the combining part of an assembling hole positioned corresponding to the assembling heads of the controlling panel and provided with an assembling screw; a printed circuit board arranged on the inner side of the coating guide piece and provided with each electronic element controlling the drying procedure and each input device driving each electronic element; and also comprises more than one shaking preventing rib arranged on the inner side of the combining part of the coating guide piece, and provided with the assembling heads guiding the controlling panel to enter the inner part of the combining part to prevent the shake. Through improving the structure of the combining part of the coating guide piece, the operator can easily and accurately align the assembling position of the combining part and the assembling heads of the controlling panel. Therefore the coating guide piece can be accurately assembled on the controlling panel.

Owner:NANJING LG PANDA APPLIANCES

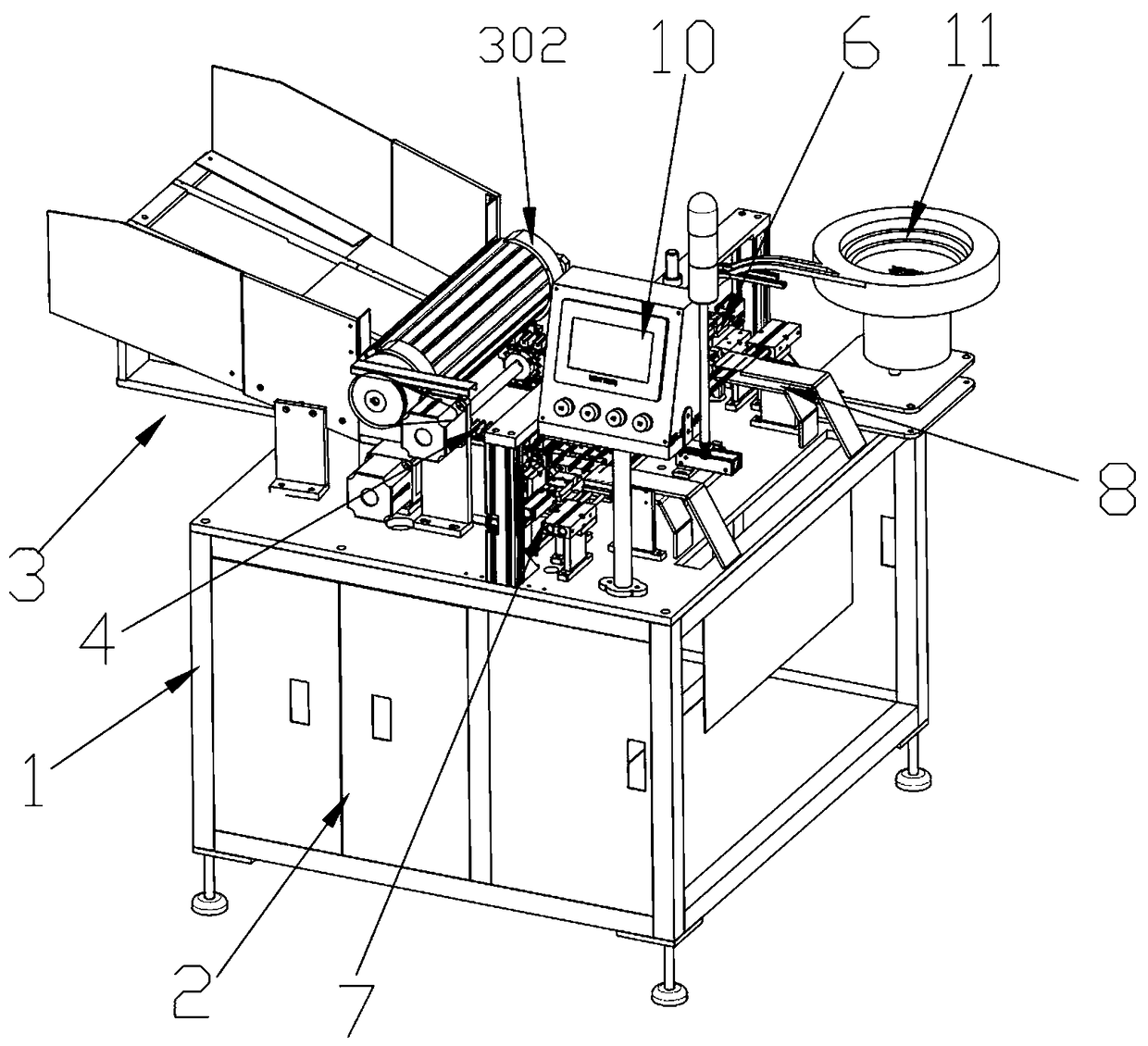

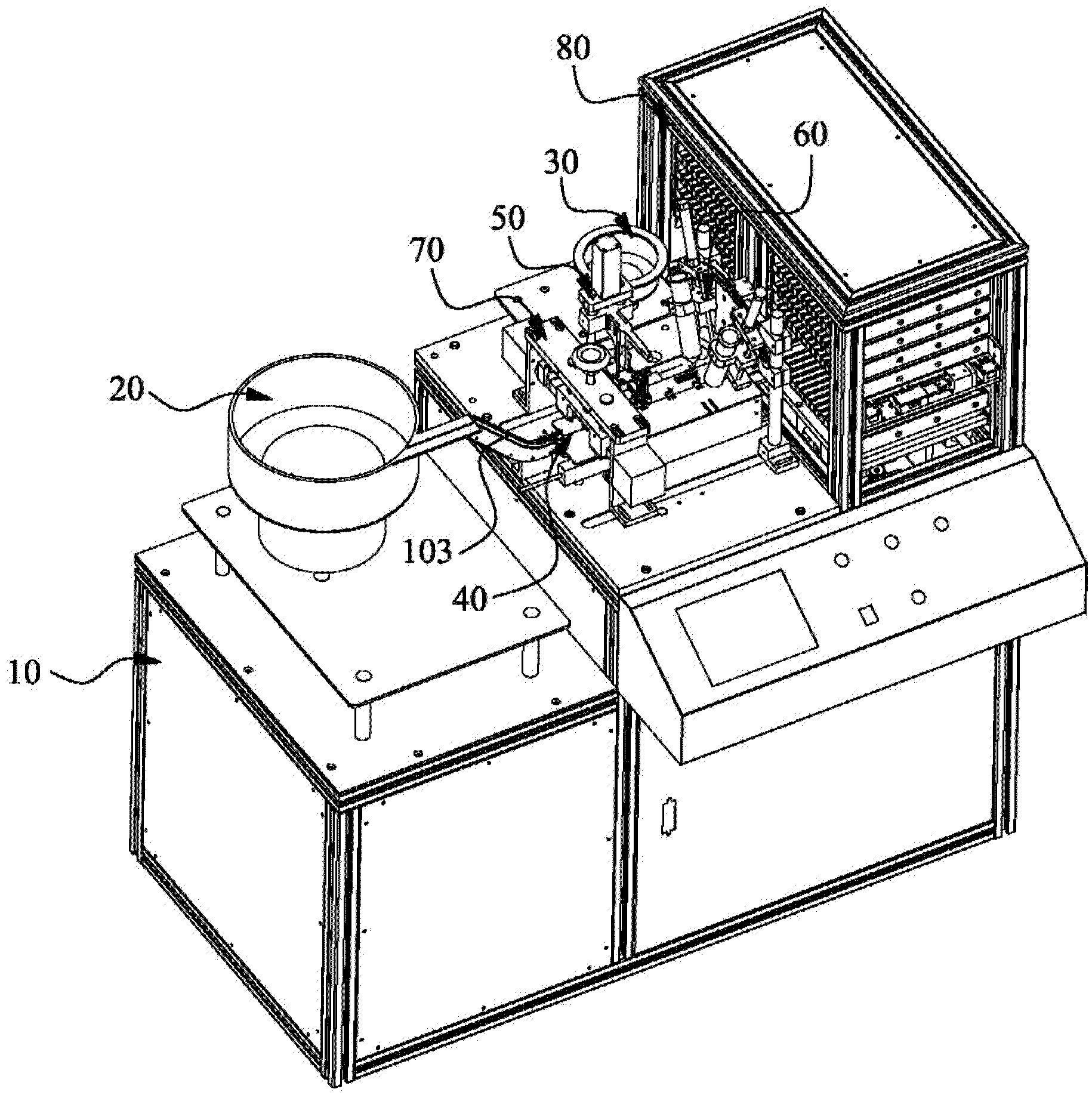

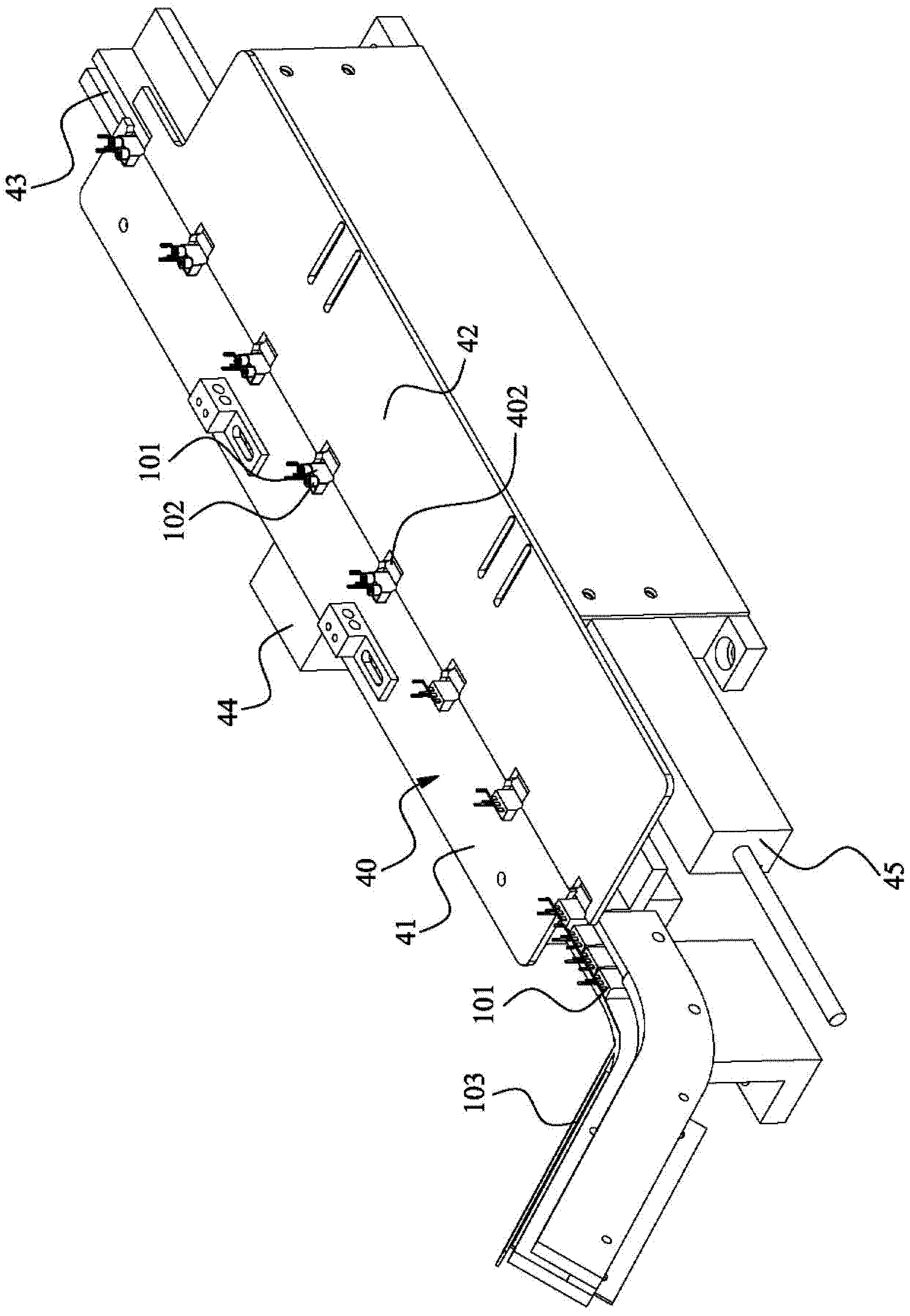

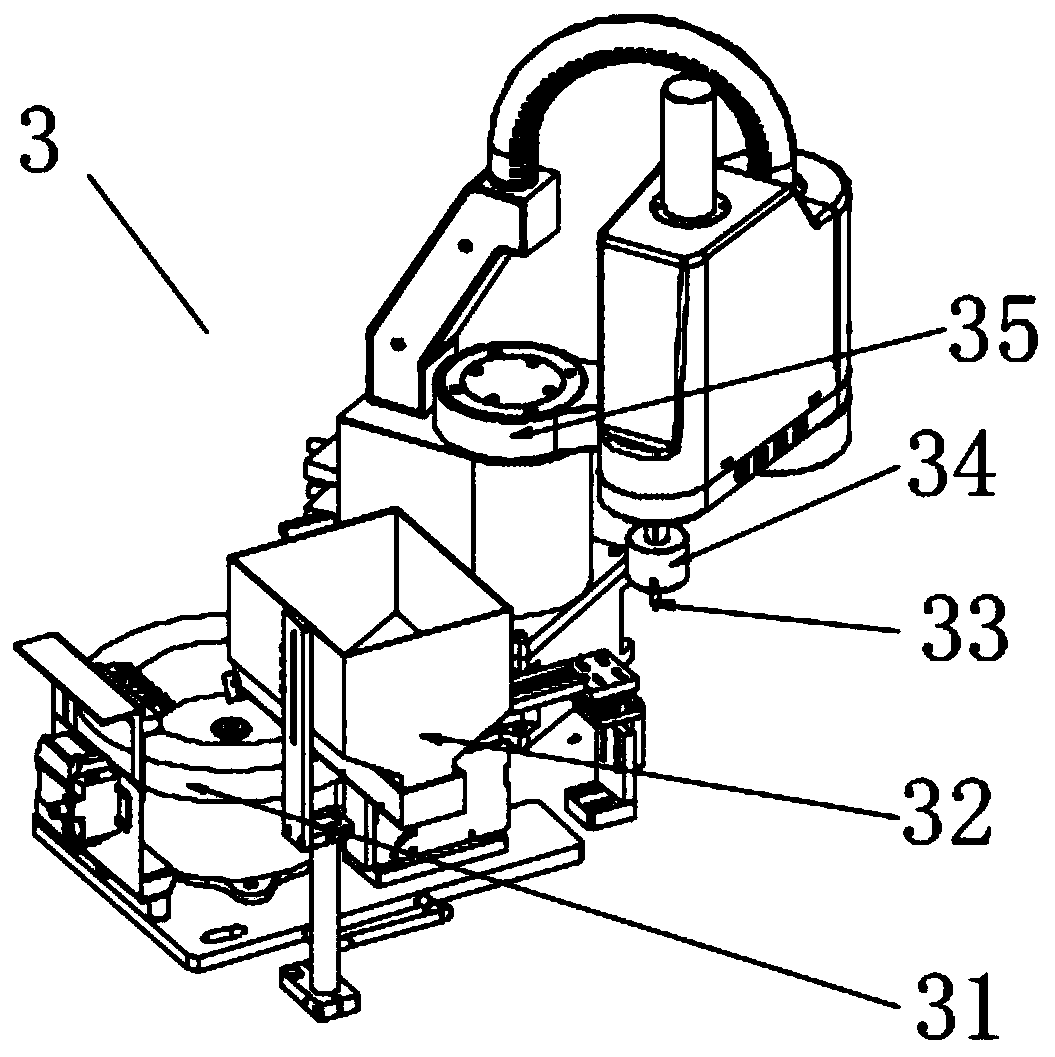

Assembling machine with transistor automatically sleeved with magnet ring

ActiveCN103260391APrecise positioningNo offsetPrinted circuit assemblingElectrical componentsPosition errorMagnetic loop

The invention discloses an assembling machine with a transistor automatically sleeved with a magnet ring. The assembling machine comprises a machine frame, a transistor vibrating disc feeding device, a magnet ring vibrating disc feeding device, a linear moving mechanism, a magnet ring sleeve device and a gluing device. The linear moving mechanism comprises a fixed board, a movable board and a movable material duct, wherein a first driving mechanism is arranged and corresponds to the movable material duct, a first locating groove is formed in the fixed board, a second locating groove is formed in the movable board, and a second driving mechanism is arranged and corresponds to the movable board. Therefore, the function of being automatically sleeved with the magnet ring is achieved by utilizing the linear moving mechanism to convey the transistor and utilizing the magnet ring sleeve device and the gluing device to install and fix the magnet ring on a pin of the transistor in a sleeved mode, operation efficiency can be effectively improved, due to the matched arrangement of the first locating groove and the second locating groove, the transistor can be well located in the process of being sleeved with the magnet ring and glued, excursion will not occur, errors of assembling positions are avoided, the accurate assembling positions are ensured, and accordingly the assembling quality of products can be improved.

Owner:东莞市展荣电子设备有限公司

Loading machine and loading method

PendingCN110844577APrecise feeding positionThe assembly position is accurateConveyor partsDust controlEngineering

The invention provides a loading machine. The loading machine comprises a loading device, a dust removal device, a material transfer device, a positioning device and a control device, wherein the control device is electrically connected to the loading device, the dust removal device, the material transfer device and the positioning device separately; the loading device is used for conveying materials to the dust removal device; the dust removal device is used for cleaning dust on the materials; the material transfer device is used for transferring the materials cleaned by the dust removal device to a follow-up assembly process; the positioning device is used for positioning and calibrating materials on the transfer device; and the control device is used for controlling a working sequence of the loading device, the dust removal device, the material transfer device and the positioning device. The invention further provides a loading method which is used for loading. The loading machine provided by the invention loads a back plate, so that the back plate can be automatically loaded, and therefore, a backlight source assembly effect is good, dust-removal and positioning can be performed simultaneously, and the backlight source yield is guaranteed to be high.

Owner:SHENZHEN WEIHONGKE TECH

Transistor automatic magnetic ring assembly machine

ActiveCN103260391BPrecise positioningNo offsetPrinted circuit assemblingElectrical componentsMagnetic loopTransistor

The invention discloses an assembling machine with a transistor automatically sleeved with a magnet ring. The assembling machine comprises a machine frame, a transistor vibrating disc feeding device, a magnet ring vibrating disc feeding device, a linear moving mechanism, a magnet ring sleeve device and a gluing device. The linear moving mechanism comprises a fixed board, a movable board and a movable material duct, wherein a first driving mechanism is arranged and corresponds to the movable material duct, a first locating groove is formed in the fixed board, a second locating groove is formed in the movable board, and a second driving mechanism is arranged and corresponds to the movable board. Therefore, the function of being automatically sleeved with the magnet ring is achieved by utilizing the linear moving mechanism to convey the transistor and utilizing the magnet ring sleeve device and the gluing device to install and fix the magnet ring on a pin of the transistor in a sleeved mode, operation efficiency can be effectively improved, due to the matched arrangement of the first locating groove and the second locating groove, the transistor can be well located in the process of being sleeved with the magnet ring and glued, excursion will not occur, errors of assembling positions are avoided, the accurate assembling positions are ensured, and accordingly the assembling quality of products can be improved.

Owner:东莞市展荣电子设备有限公司

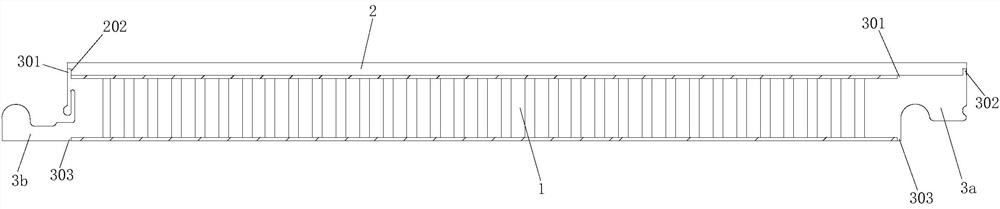

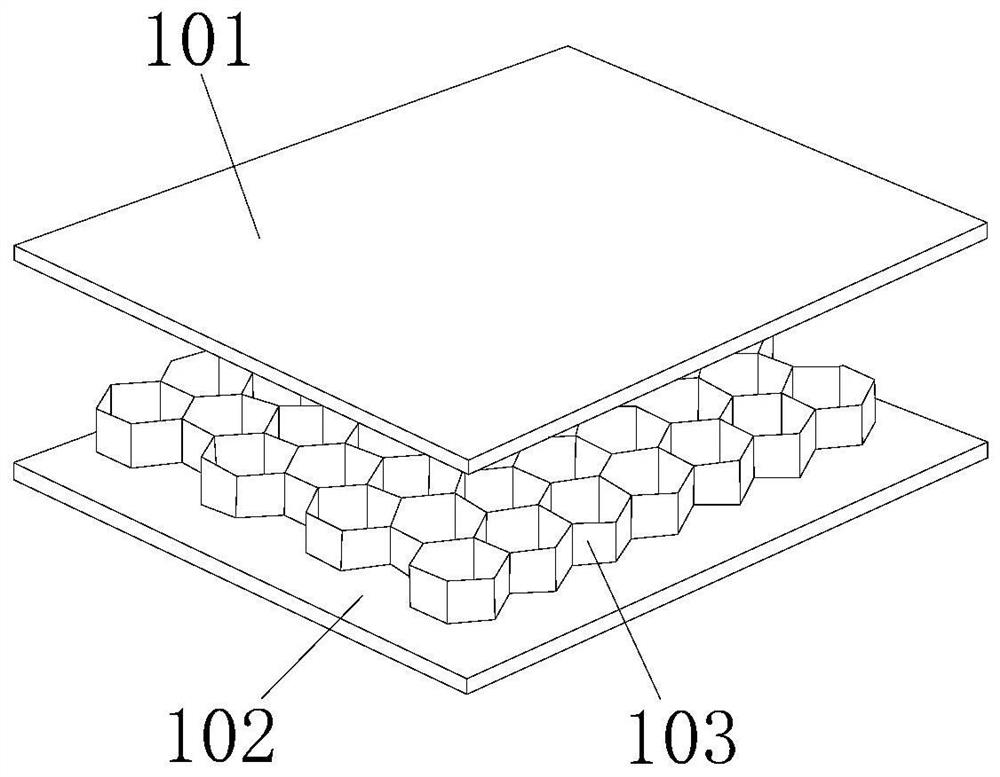

Floor block, wall panel and assembling method of floor block and wall panel

PendingCN111997296AQuick stitchingMake up for the shortcomings of low structural strength and easy damageCovering/liningsFlooringHoneycombStructural engineering

The invention relates to a floor block, a wall panel and an assembling method of the floor block and the wall panel. The floor block and the wall panel each comprise a honeycomb substrate, a finish coating fixed to the upper side plate face of the honeycomb substrate and a buckle fixedly arranged on the side edge of the honeycomb substrate; the honeycomb substrate comprises an upper plate body, alower plate body and a honeycomb core layer fixedly connected between the upper plate body and the lower plate body; and a buckle embedding gap is formed between the upper plate body and the lower plate body, the buckle comprises a positioning protrusion protruding upwards, the buckle is embedded into the buckle embedding gap and welded or bonded and fixed to the upper plate body or / and the lowerplate body, and the side edge of the upper plate body abuts against the positioning protrusion in the horizontal direction. The buckle structure with the accurate position can be ingeniously and additionally arranged on the side edge of the floor block or the wall panel, and therefore, the floor blocks or the wall panels made of various materials can be tidily laid and connected through full-dry construction.

Owner:SHANGHAI XINGYE MATERIALS TECH CO LTD

Continuous assembly mechanism for workpieces

InactiveCN108436428AImprove synchronicityReasonable structural designMetal working apparatusEngineeringMachining

The invention discloses a continuous assembly mechanism for workpieces, and belongs to the field of mechanical workpiece machining equipment. According to the continuous assembly mechanism for the workpieces, a push mechanism is vertically arranged at one side of a lower conveying mechanism; a plurality of attraction electromagnets are uniformly and fixedly arranged at the outer side of an upper conveying guide belt in sequence in the horizontal direction; a lower conveying belt wheel is in transmission connection with an upper main conveying belt wheel through a main connection belt; an upperauxiliary conveying belt wheel is in transmission connection with a rear conveying belt wheel through an auxiliary connection belt; the output end of a push cylinder is hinged to the lower side of apush rotary plate; a horizontal push guide column is slidably arranged in a push sleeve in the horizontal direction; a lifting guide column is slidably arranged in a limit sleeve in the vertical direction; an assembly push plate is slidably arranged on a translation support in the horizontal direction; and a push column inclined surface is arranged at the upper side of the assembly push plate. Thecontinuous assembly mechanism for the workpieces is reasonable in structural design, capable of efficiently and accurately assembling the workpieces one by one, and capable of rapidly and stably conveying the workpieces in the horizontal direction, thereby meeting the needs of machining and use.

Owner:屠明州

Rotation disc type marking welding machine

PendingCN110449747ARealize the retrieving functionAccurate outputLaser beam welding apparatusEngineeringDISC assembly

The invention discloses a rotation disc type marking welding machine. The rotation disc type marking welding machine comprises a machine base assembly and further comprises a rotating rotation disc assembly, a product A feeding assembly, a first laser marking machine, a product B feeding assembly, a laser welding machine, a discharging assembly, an industrial control assembly and a second laser marking machine which are arranged on the machine base assembly. The rotating rotation disc assembly is provided with a special product jig. The product A feeding assembly can feed products A to a special product jig, the first laser marking machine is used for marking, then, the product B feeding assembly feeds products B to a special product jig, the laser welding machine welds the products A andthe products B, and the second laser marking machine is used for marking the welded products again. The rotation disc type marking welding machine has the effects that the functions of assembling, marking and welding of the products A and the products B are achieved, the automation degree is high, material collecting and releasing can be conducted only according to the material situation, one person guards multiple machines, cost is saved, and efficiency is improved.

Owner:SHENZHEN LLMACHINECO LTD

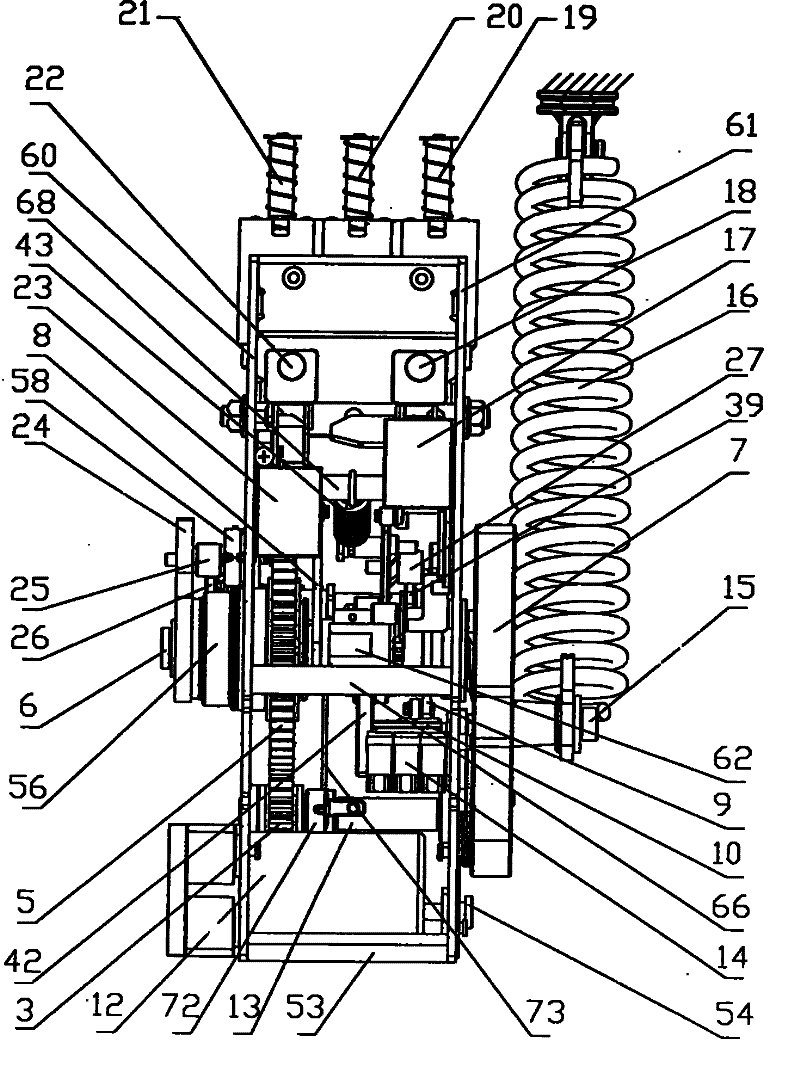

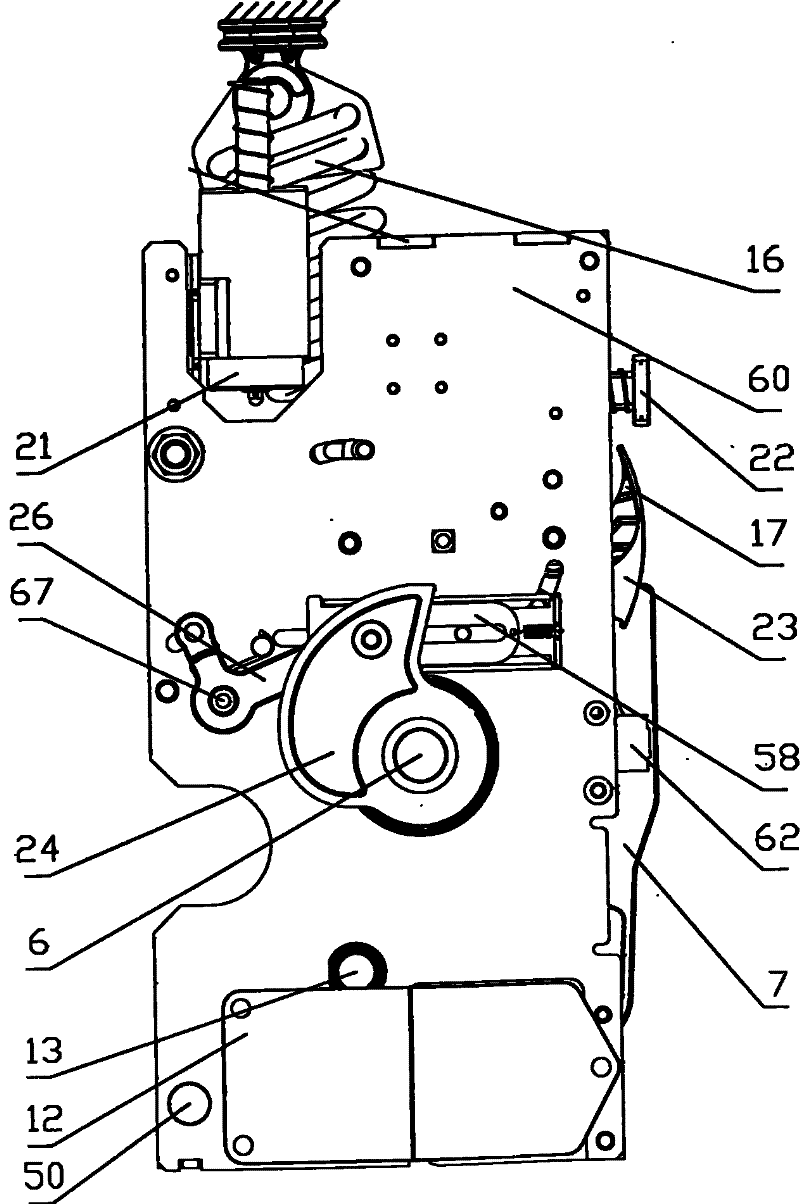

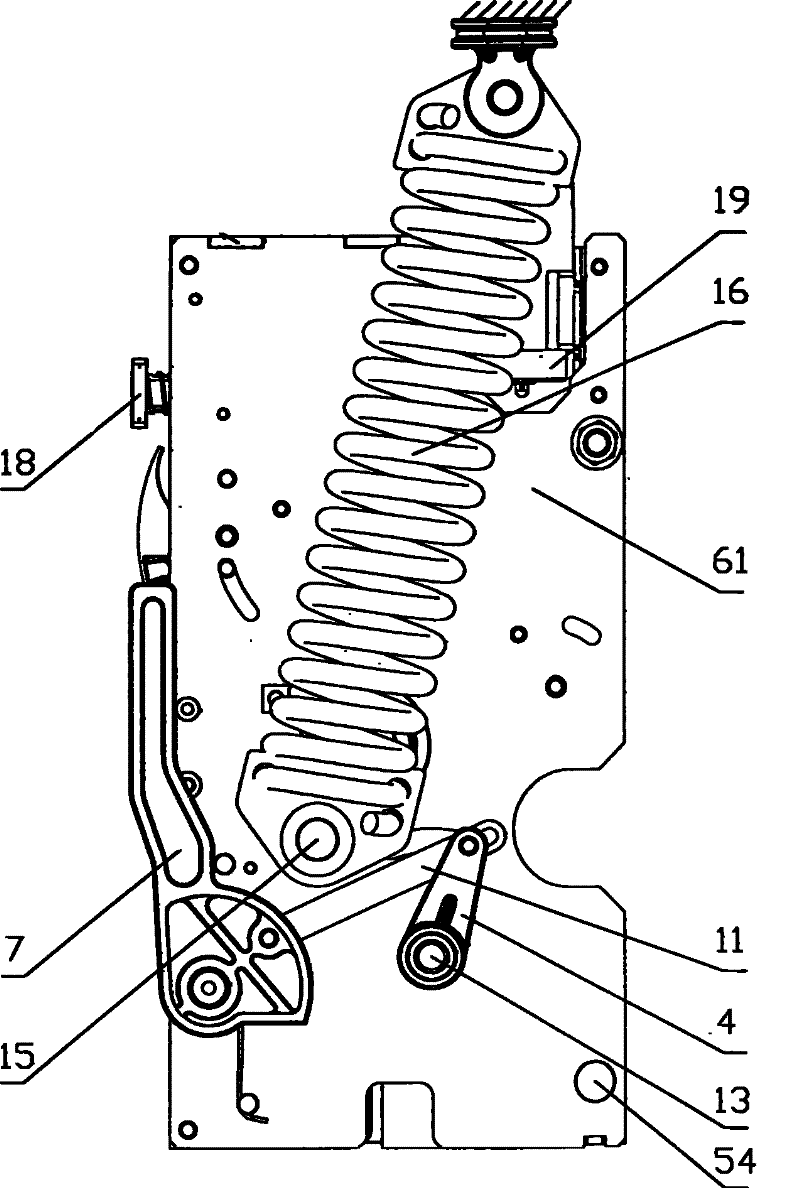

Spring actuating mechanism of vacuum circuit-breaker

InactiveCN101656167BAchieve integrationThe assembly position is accurateHigh-tension/heavy-dress switchesAir-break switchesInterior spaceEngineering

The invention relates to a spring actuating mechanism of a vacuum circuit-breaker, which comprises a frame, and is characterized in that an energy storage component is arranged on the middle part of the frame; a handle closing connecting rod component is arranged on the left side of the middle upper part of the frame; a hand opening connecting rod component is arranged on the right side of the middle upper part of the frame; a hand energy storage component is arranged on the middle lower part of the frame; an electric energy component is arranged on the lower part of the frame; and an electromagnet component is arranged on the upper part of the frame. The spring actuating mechanism has the advantages that the inner space of the actuating mechanism is fully utilized; the assembled positions of parts are accurate; the integration of the actuating mechanism is realized; driving parts are reduced; the driving process is simplified; the reliability and the stability of the mechanism are greatly increased; the visible adjustment of the lock joint amount can be easily realized; the closing and opening resistance failures of the circuit-breaker in the working process can be avoided; a reliable and safe interlocking device is provided; and the standard is only.

Owner:CHONGQING YIKE ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com