Transistor automatic magnetic ring assembly machine

A technology of transistors and assembly machines, which is applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components. It can solve the problems of poor quality and low efficiency of semi-automatic machines to cover magnetic rings, so as to achieve convenient operation and realize unmanned automation. The effect of production and guaranteed assembly position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

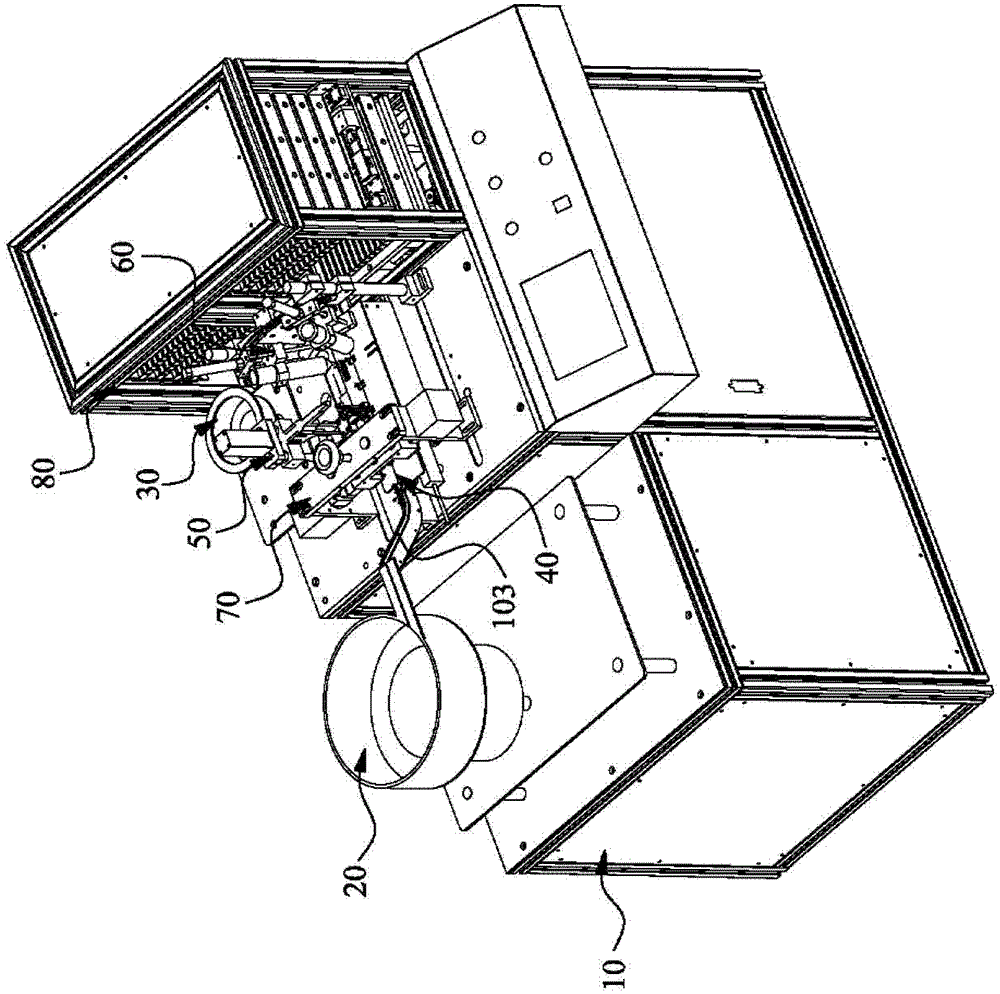

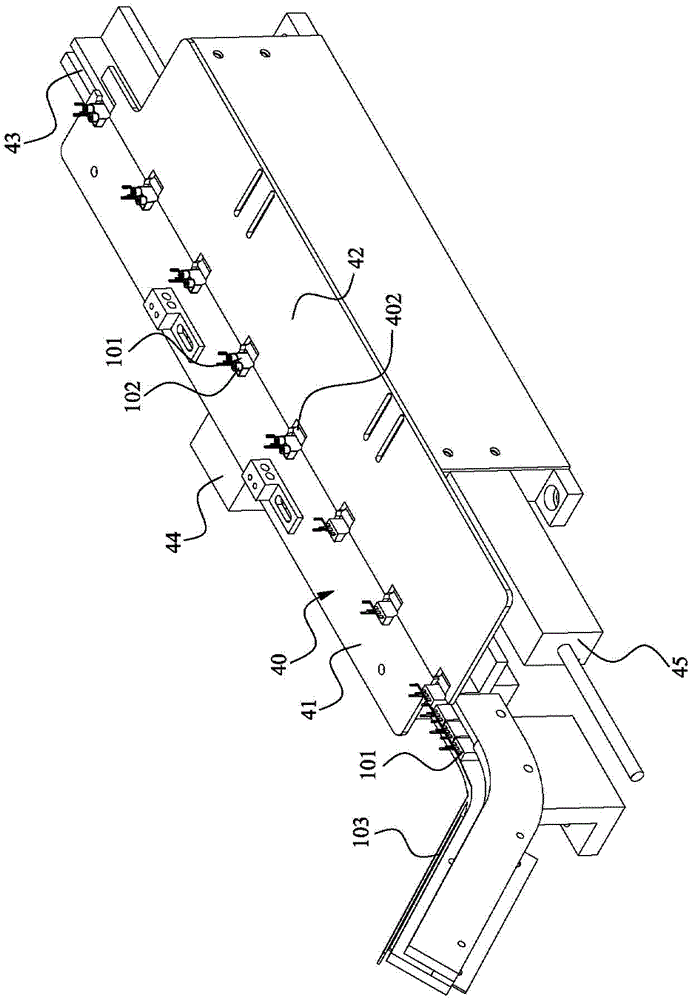

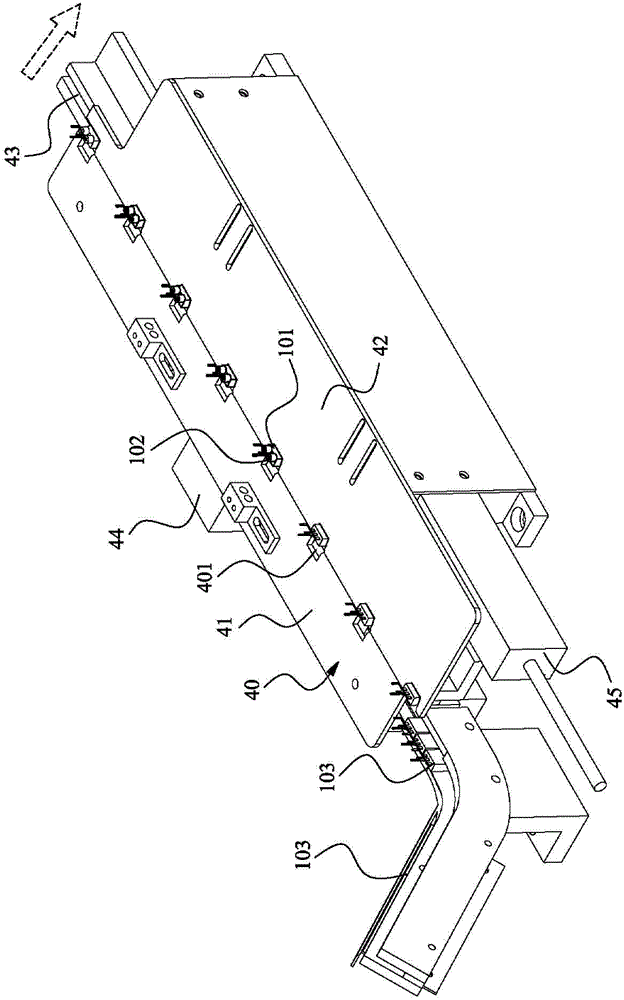

[0065] Please refer to Figure 1 to Figure 11 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a frame 10 and a transistor vibrating disk feeding device 20, a magnetic ring vibrating disk feeding device 30, and a linear movement mechanism 40 arranged on the frame 10. , Set magnetic ring device 50 and dispensing device 60.

[0066] Wherein, the transistor vibrating disk feeding device 20 is used to automatically output and load the transistor 101 in sequence, and the magnetic ring vibrating disk feeding device 30 is used to automatically output and load the magnetic ring 102 in sequence. The transistor vibrating disk feeding device 20 and The working principles of the magnetic ring vibrating disk feeding device 30 are existing mature technologies, and the working principles of the transistor vibrating disk feeding device 20 and the magnetic ring vibrating disk feeding device 30 will not be described in detail here.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com