Patents

Literature

103results about How to "Precise feeding position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

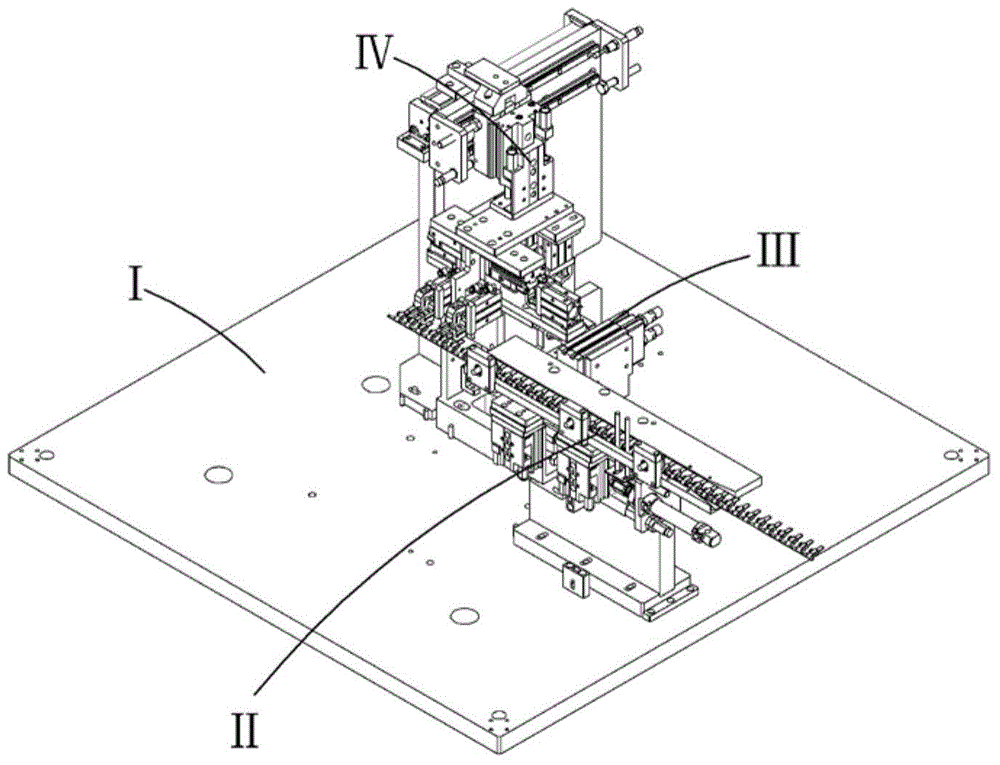

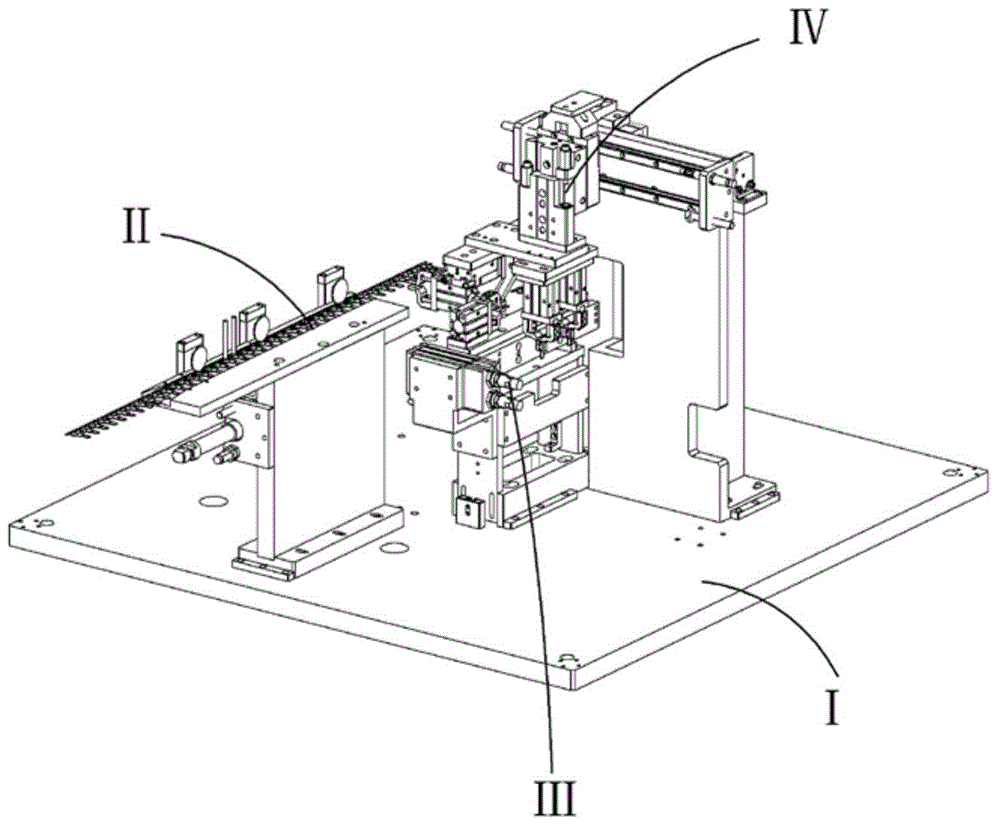

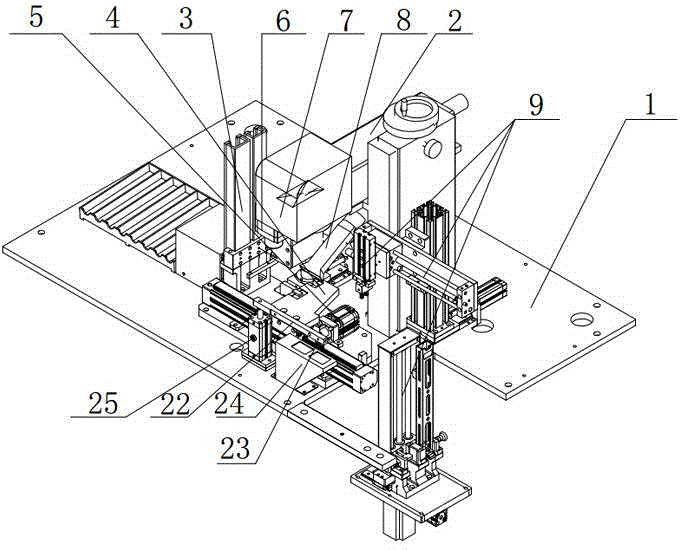

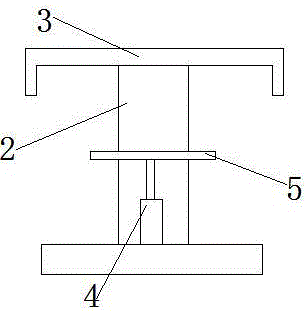

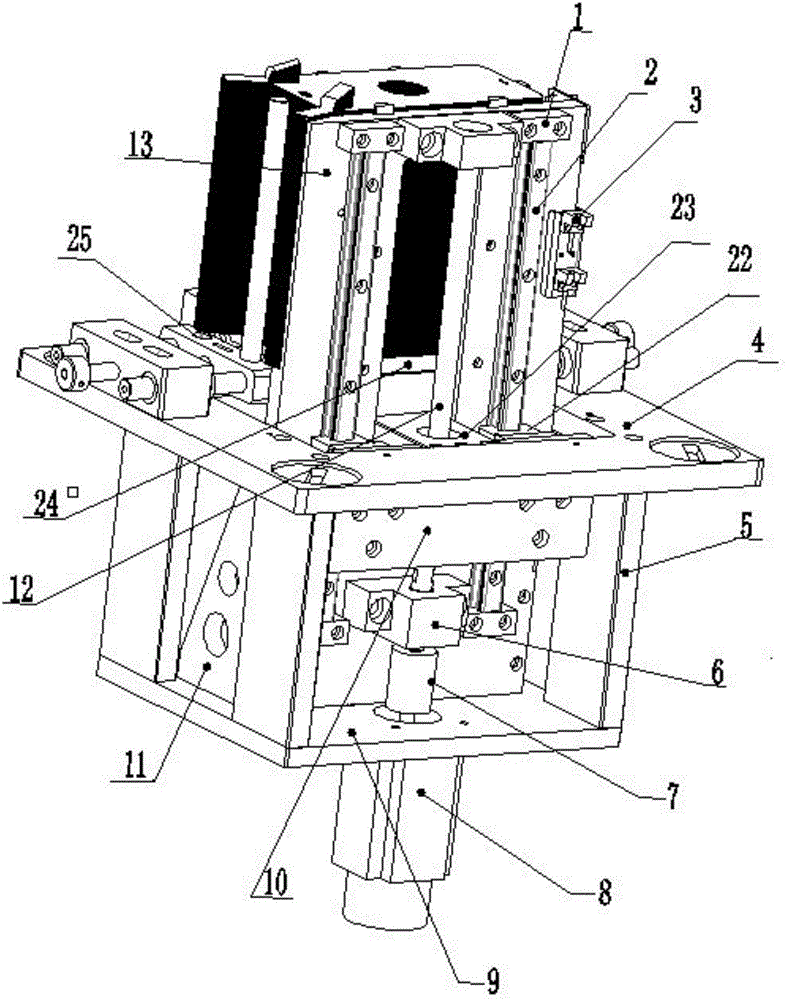

Automatic feeding mechanism

ActiveCN104444289ANo overtravelReduce labor intensityControl devices for conveyorsEngineeringUltimate tensile strength

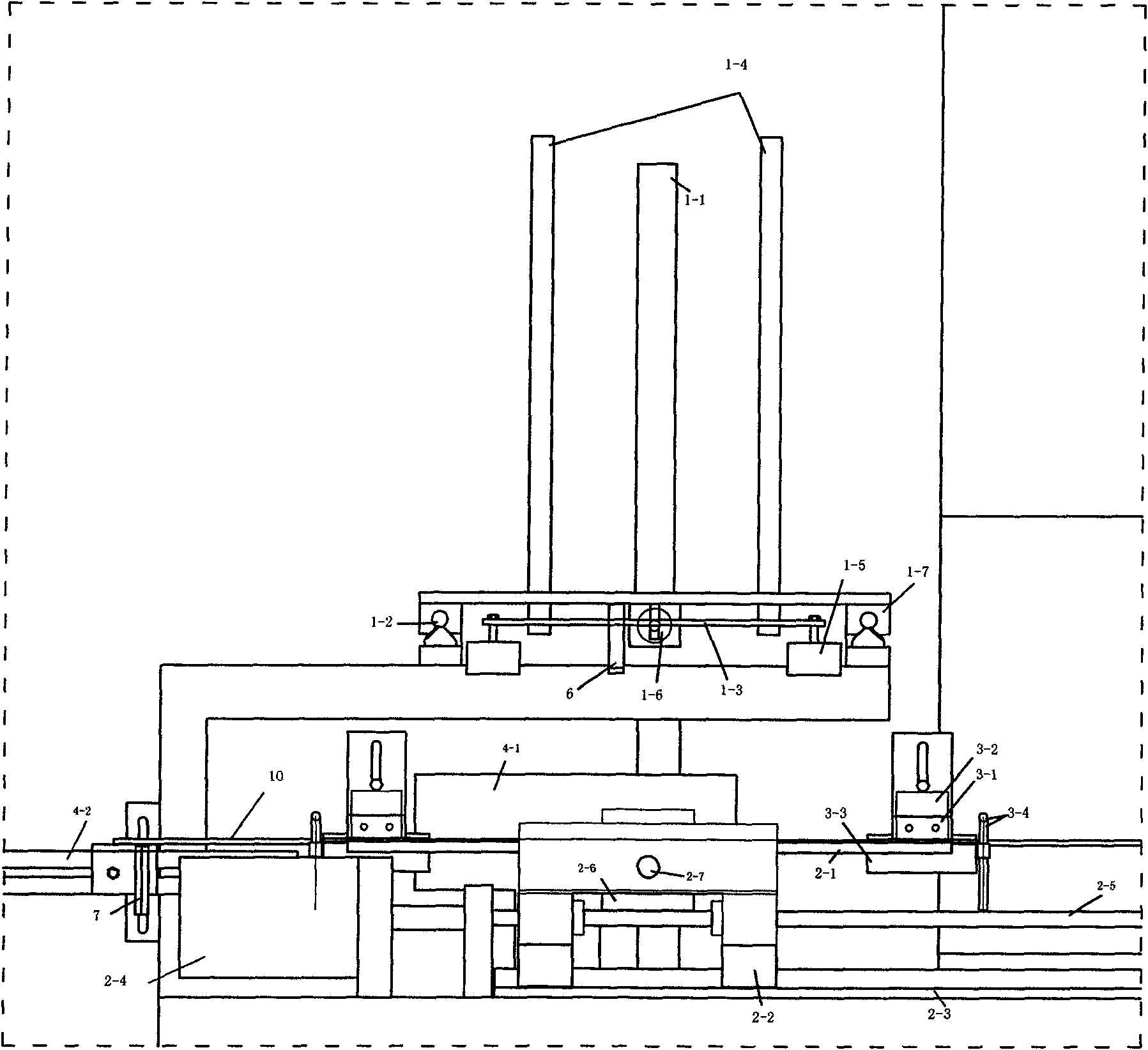

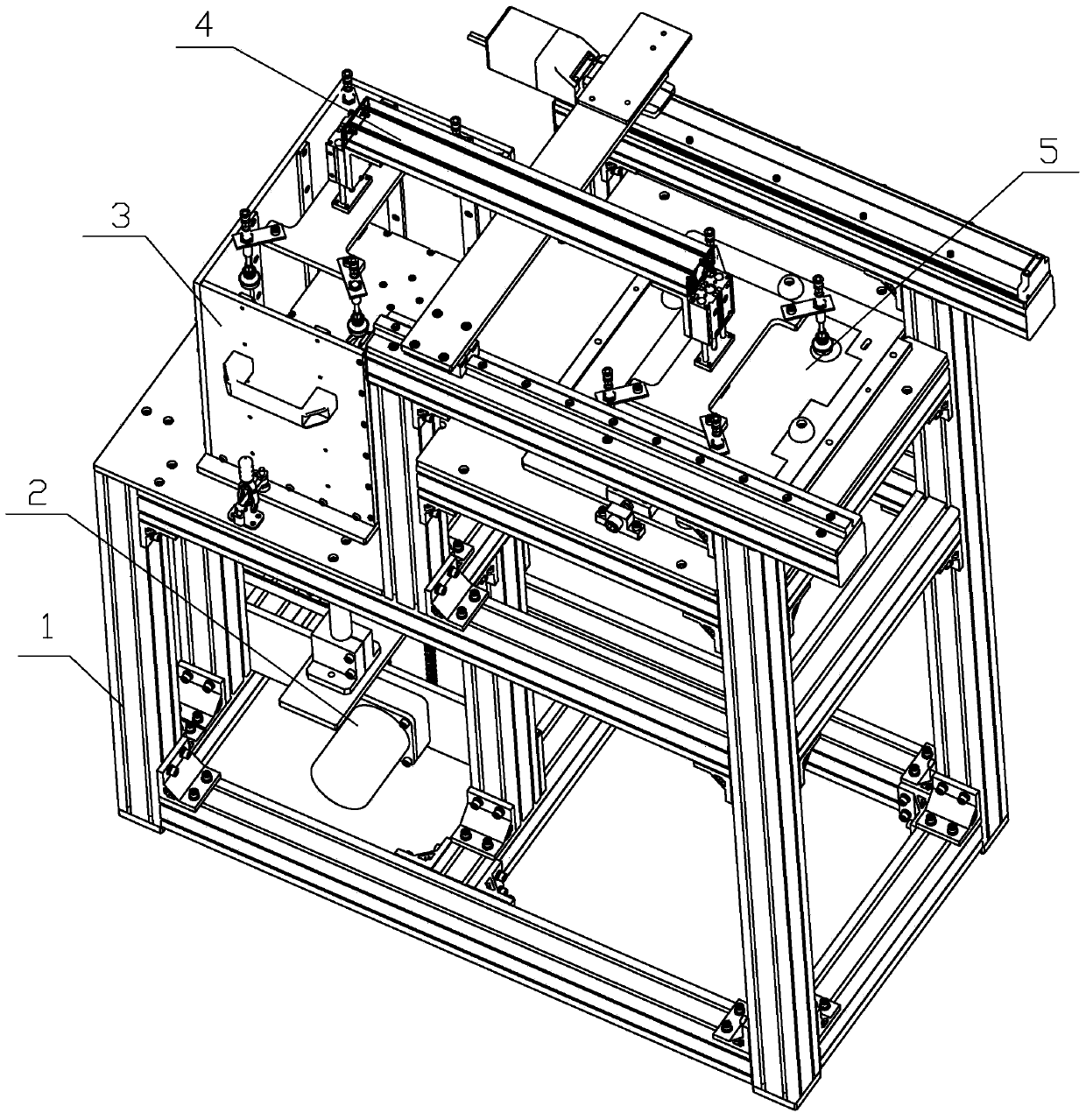

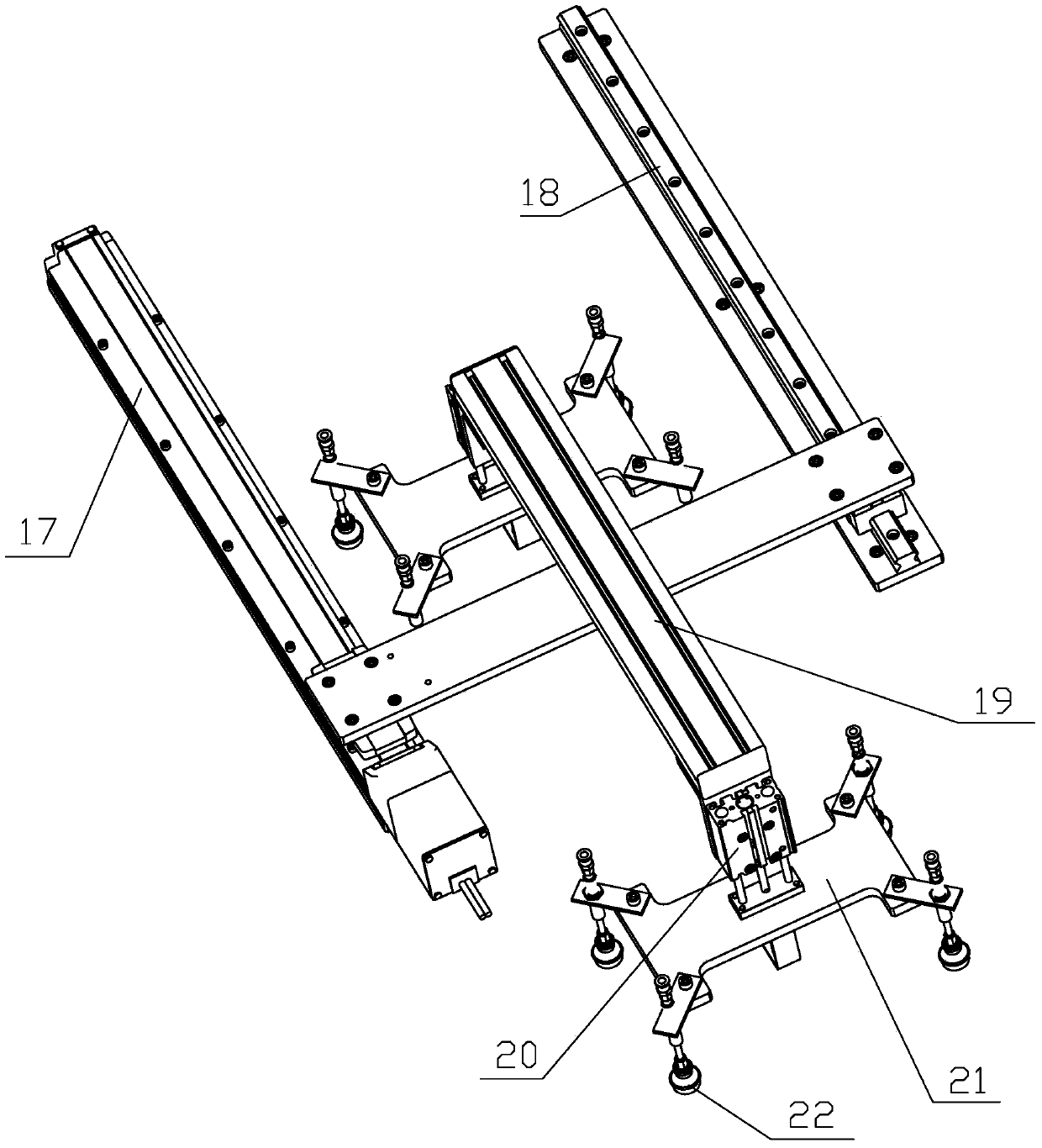

The invention relates to an automatic feeding mechanism. A feeding mechanism, a material overturning mechanism and a material transferring mechanism are mounted on a large base plate; the feeding mechanism can realize reciprocating feeding and material supply; the material overturning mechanism can be used for clamping a product, and the product rotates by 90 degrees under the driving of a rotating cylinder; the material transferring mechanism can be used for fetching a material from a material belt of the feeding mechanism and transferring the product onto the material overturning mechanism, and after the product is overturned by 90 degrees, the material transferring mechanism can be used for receiving the material and transferring the product to other mechanisms for making preparations for the next step. Under cooperation with the feeding mechanism, the material overturning mechanism and the material transferring mechanism, the product is conveyed to a standard position, so that the work efficiency is high, the feeding position is accurate and the labor intensity of workers is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

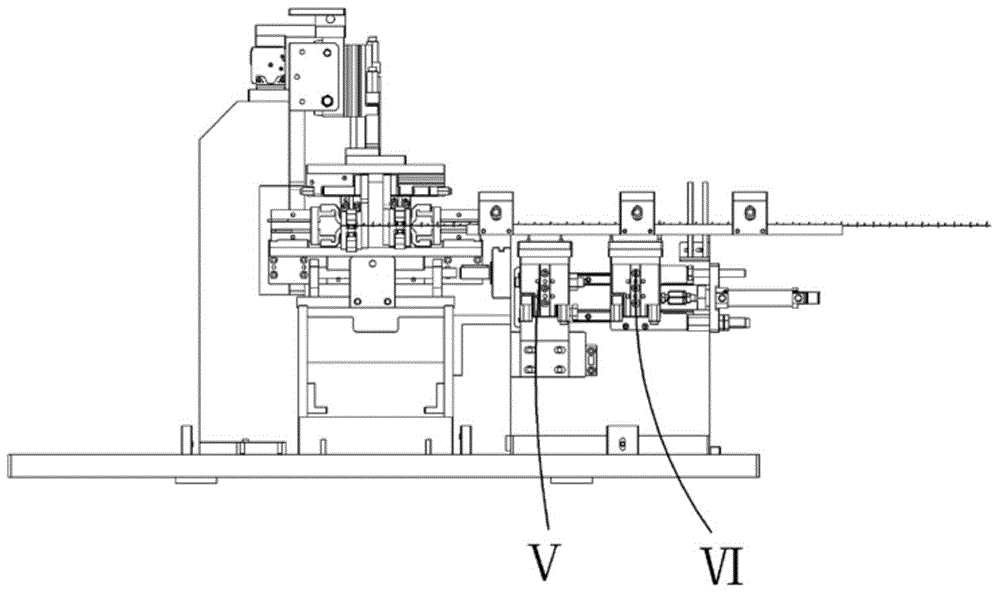

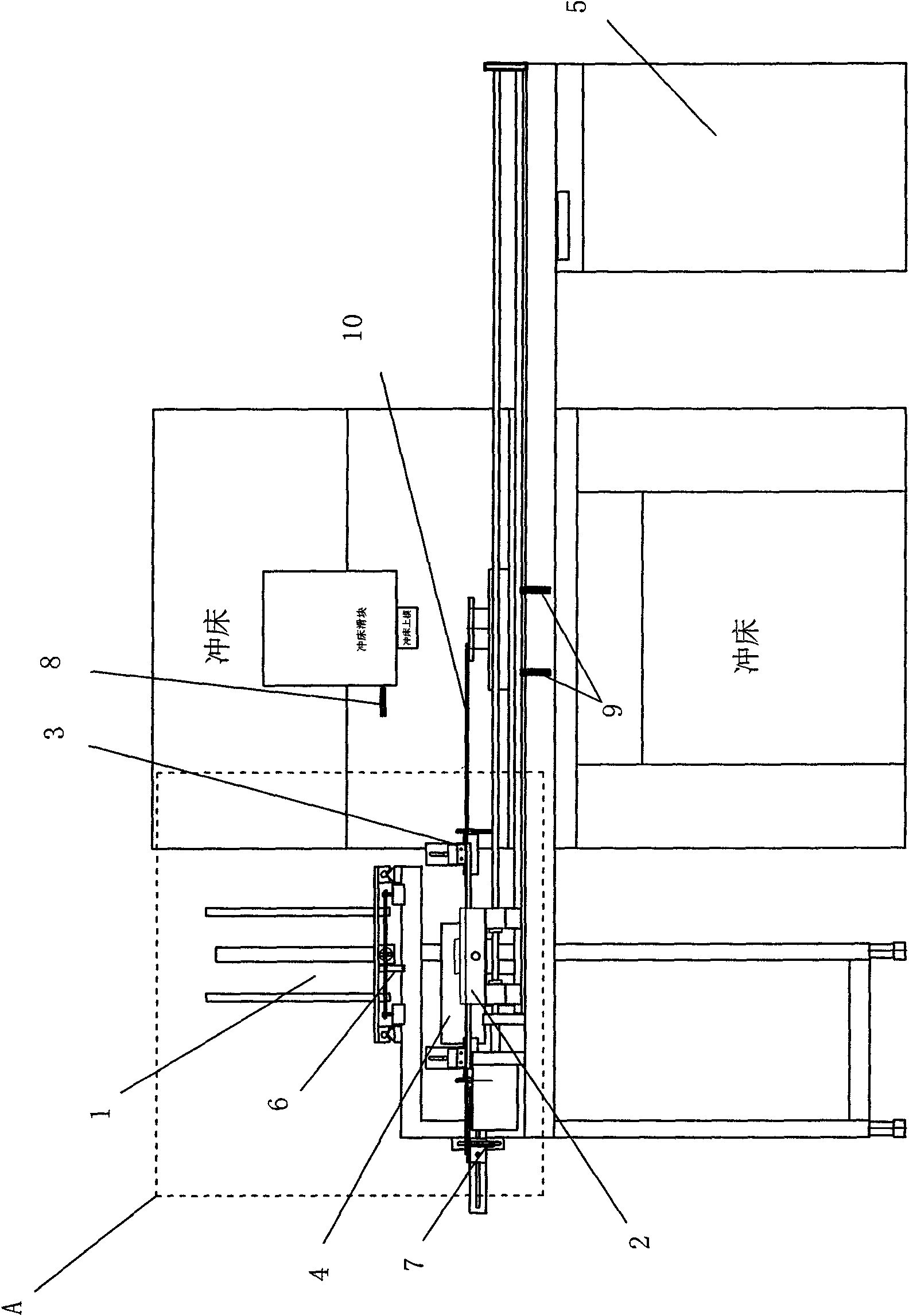

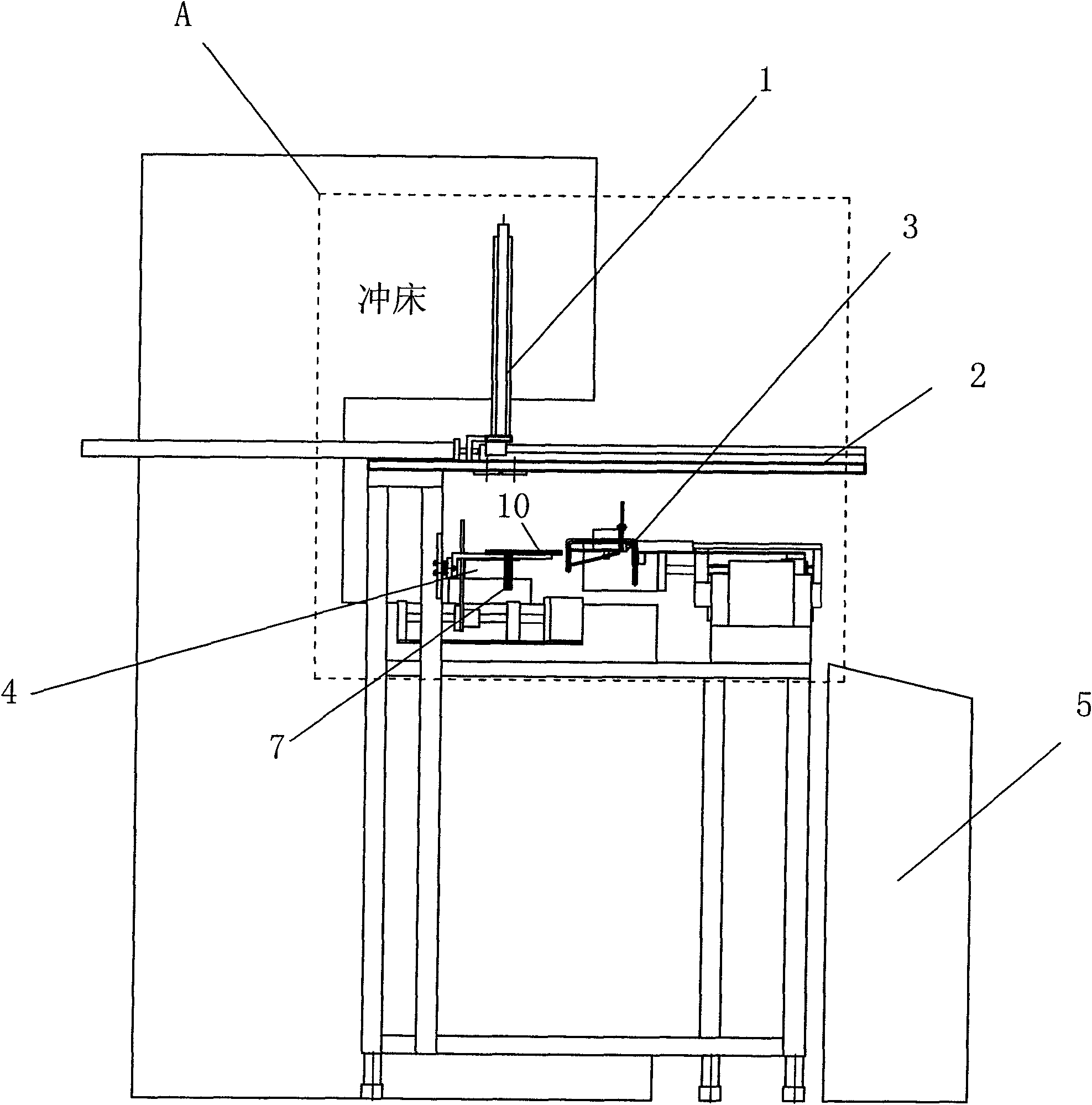

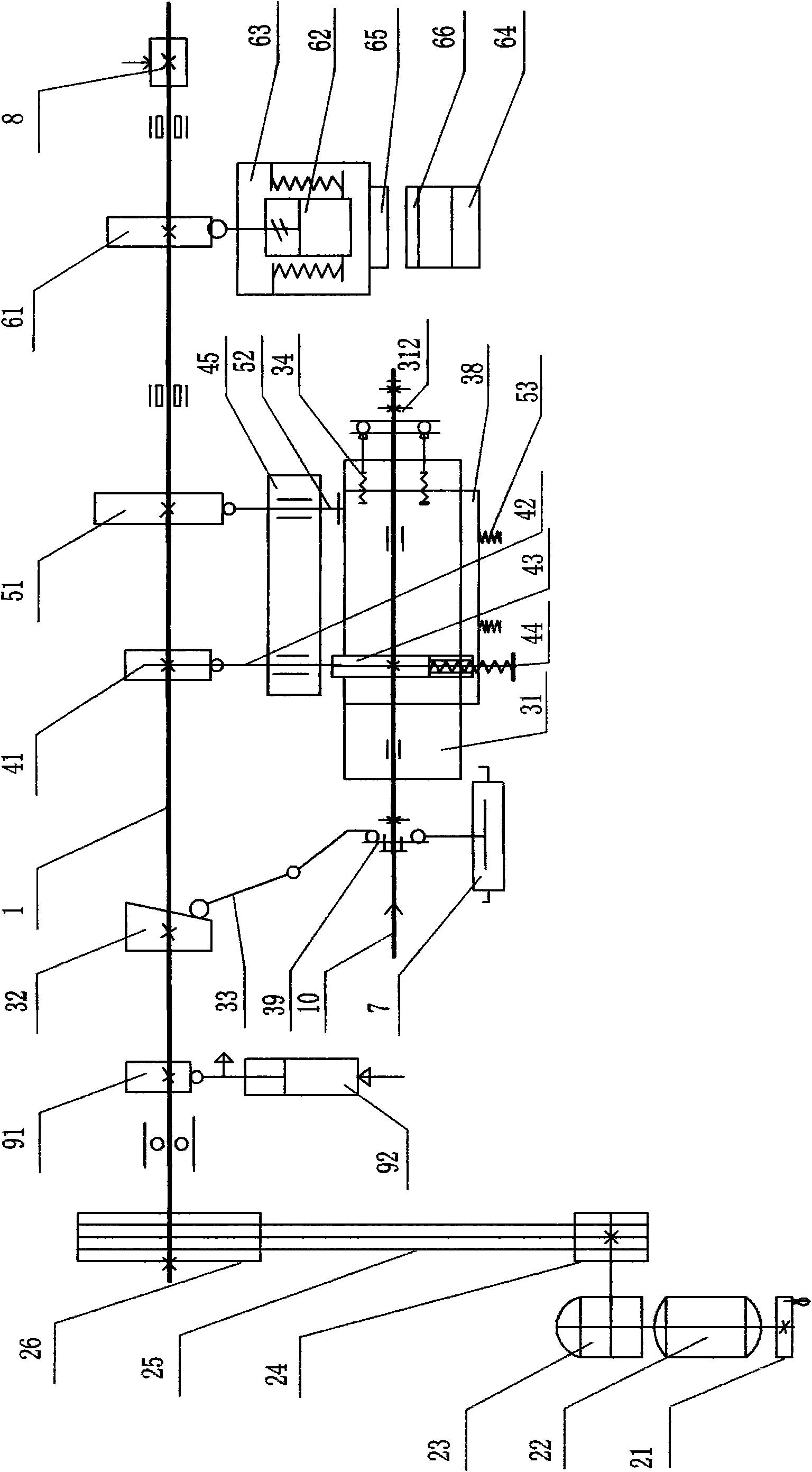

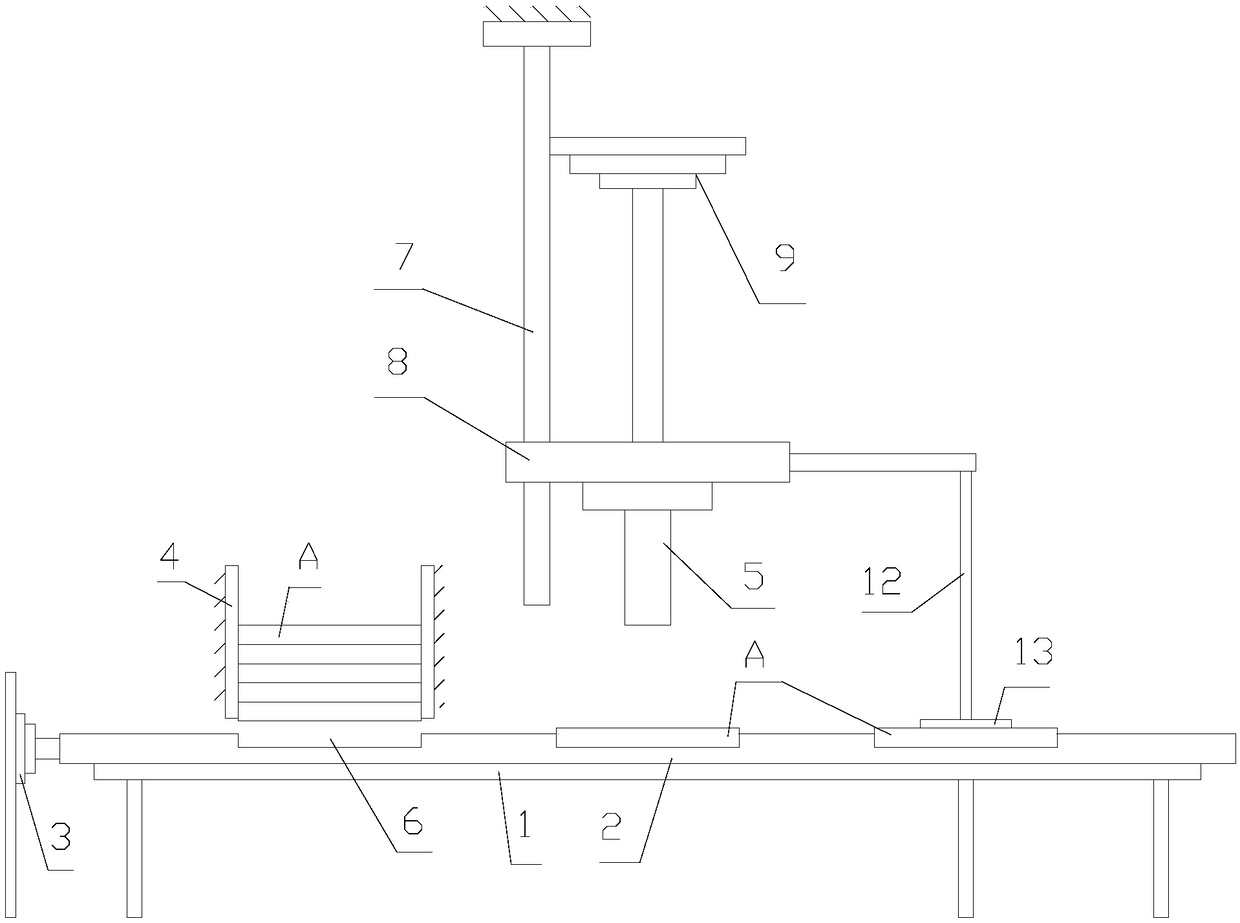

Automatic material loading, feeding and unloading equipment for bar stock blanking and method thereof

InactiveCN102180366AIncrease profitEasy to switchArticle feedersArticle separationPunch pressMulti machine

The invention discloses automatic material loading, feeding and unloading equipment for bar stock blanking and a method thereof. The equipment comprises a material loading mechanism, a feeding mechanism and an electric cabinet, wherein the feeding mechanism is provided with a mechanical arm, and the mechanical arm is connected with a manipulator. The equipment has the following beneficial effects: 1, the equipment can replace workers in the whole process to realize full-automatic operation of material loading, feeding and unloading, thus the purpose that one worker operates multiple machines can be realized; 2, varieties are convenient to switch; 3, in the feeding process, the manipulator has a function of automatically avoiding a punch die so as to realize multi-row reciprocating operation, especially automatic punching operation of narrow bar stock relatively to the die width; 4, although the structure is installed in front of the punch die, the structure barely affects workers to assemble, disassemble and adjust a die in front of a punch; 5, the shutdown rate of the punch is improved; 6, the equipment has the advantages of simple mechanical structure and low cost and is convenient to maintain; and 7, after material is automatically fed, the bar stock can be subjected to multiple-particle blanking because feeding position is accurate.

Owner:吴丽威

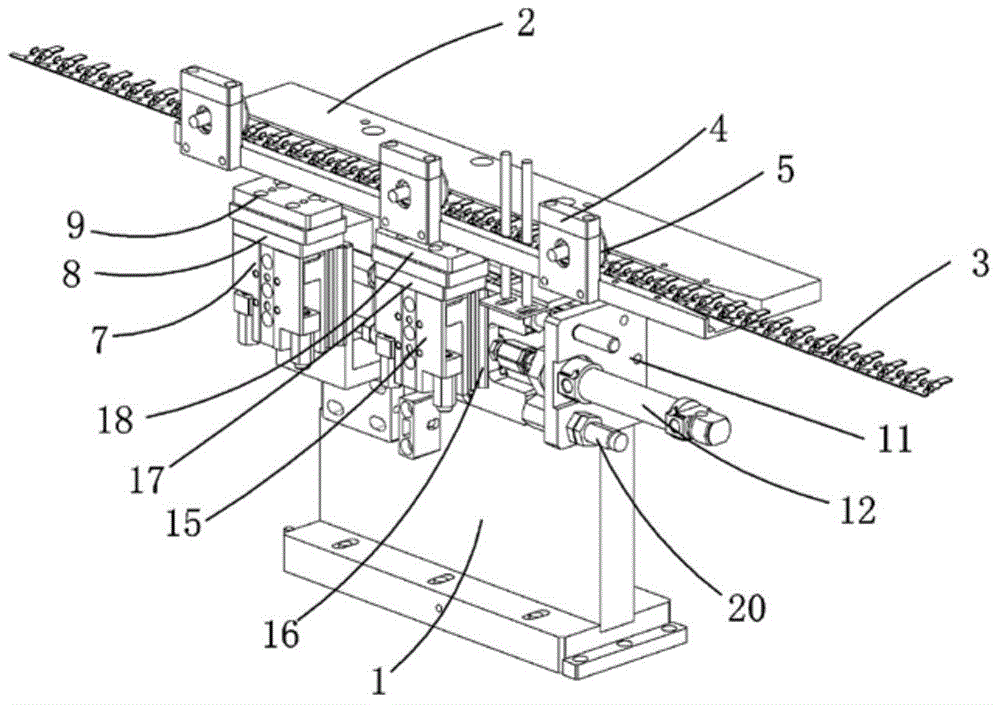

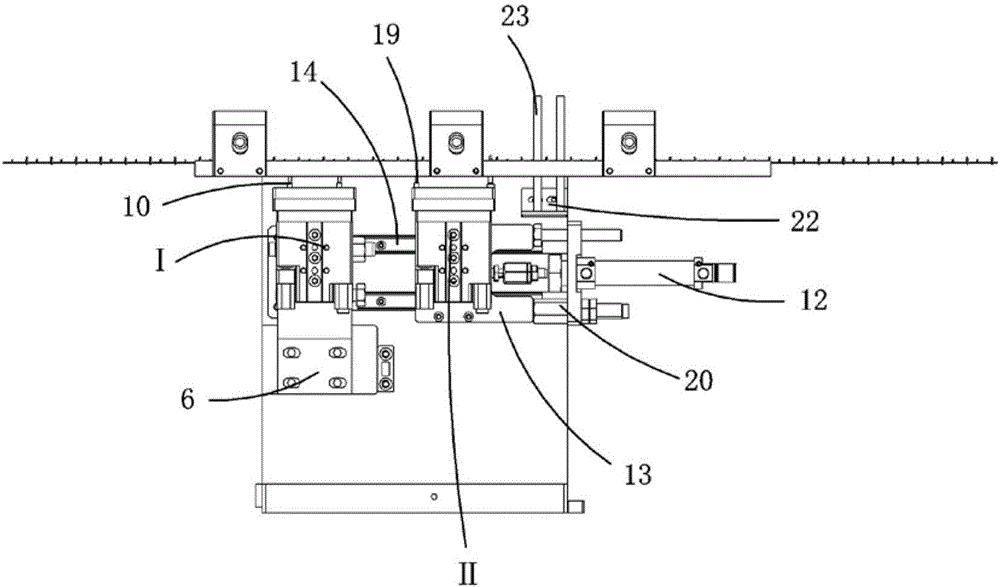

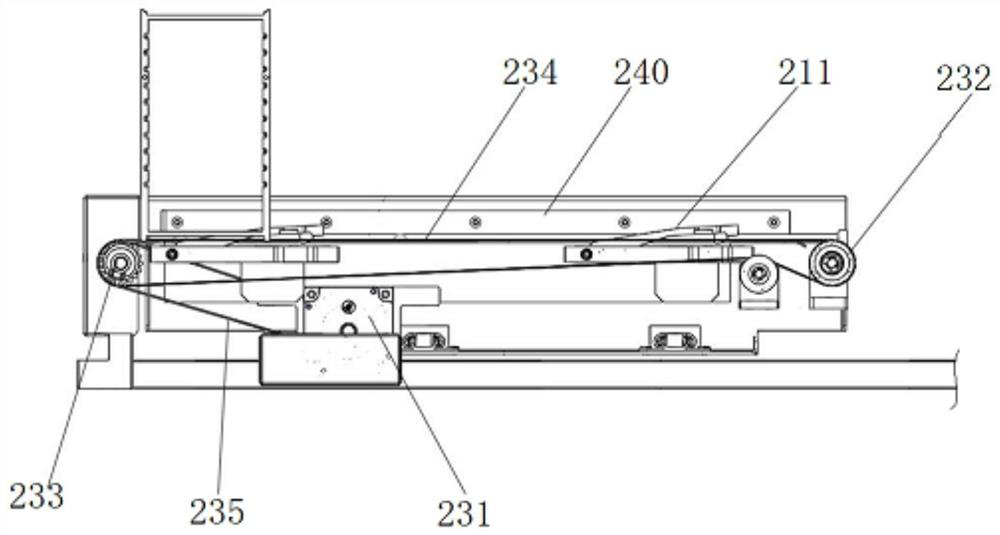

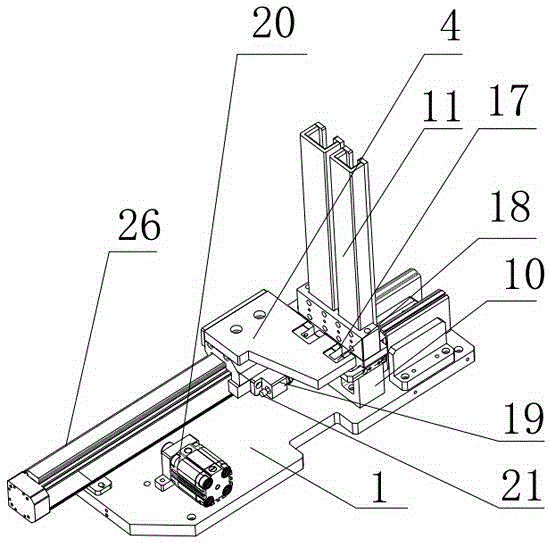

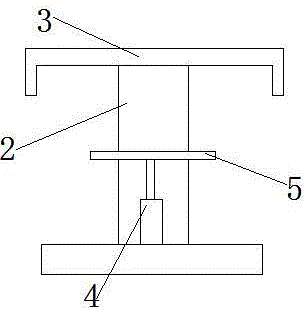

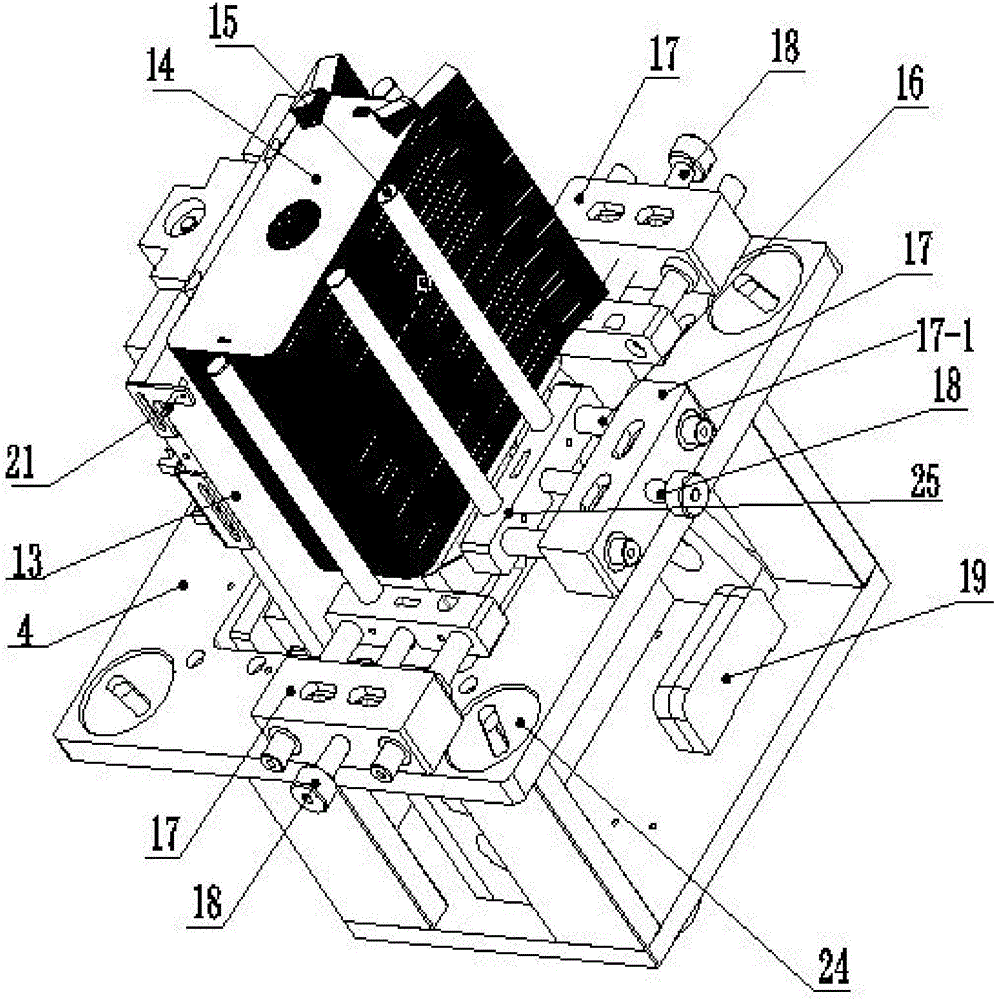

Feeding mechanism

ActiveCN104444336AReduce labor intensityReduce deliveryControl devices for conveyorsEngineeringMechanical engineering

Owner:BOZHON PRECISION IND TECH CO LTD

Semi-automatic punching machine for packaging tube

ActiveCN102862183AReasonable structureSimple and fast operationMetal working apparatusPunchingEngineering

The invention relates to a semi-automatic punching machine for a packaging tube, comprising a base, wherein steps are formed on the upper surface of the base, a workbench is arranged at the middle of the first step surface, a main guide rail is arranged on the lower part of the workbench, and punching mechanisms are symmetrically installed on the main guide rail and at the both ends of the workbench respectively; a bottom plate is installed on the second step surface of the base, a groove opening is formed at the middle of the bottom plate, an arranging frame is arranged at the groove opening, packaging tube limit mechanisms are arranged at the outer ends of the bottom of the arranging frame respectively, and a feeding mechanism is arranged on the lower part of the bottom plate; and a pressing mechanism is further arranged above the workbench. The semi-automatic punching machine reduces labour intensity, is high in production efficiency and reliable in working, and guarantees the product quality.

Owner:WUXI JIAXIN ELECTRONICS PRODS

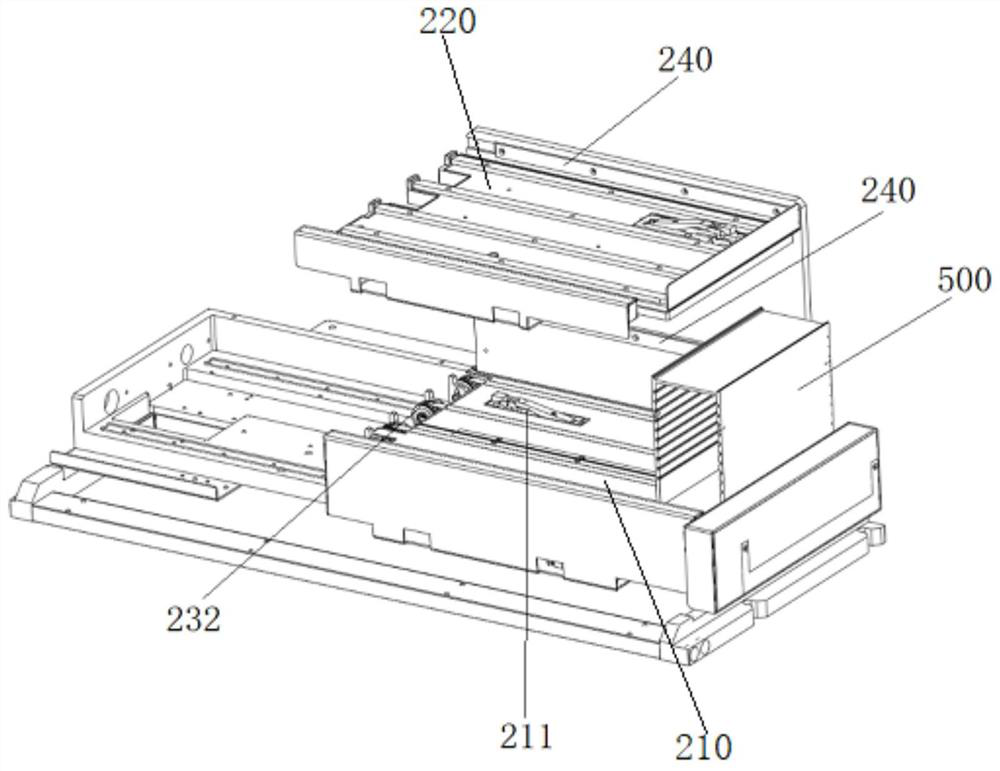

Automatic feeding device of power lithium battery pole pieces

InactiveCN103803300APrecise feeding positionImprove automation production efficiencyConveyor partsPole pieceEngineering

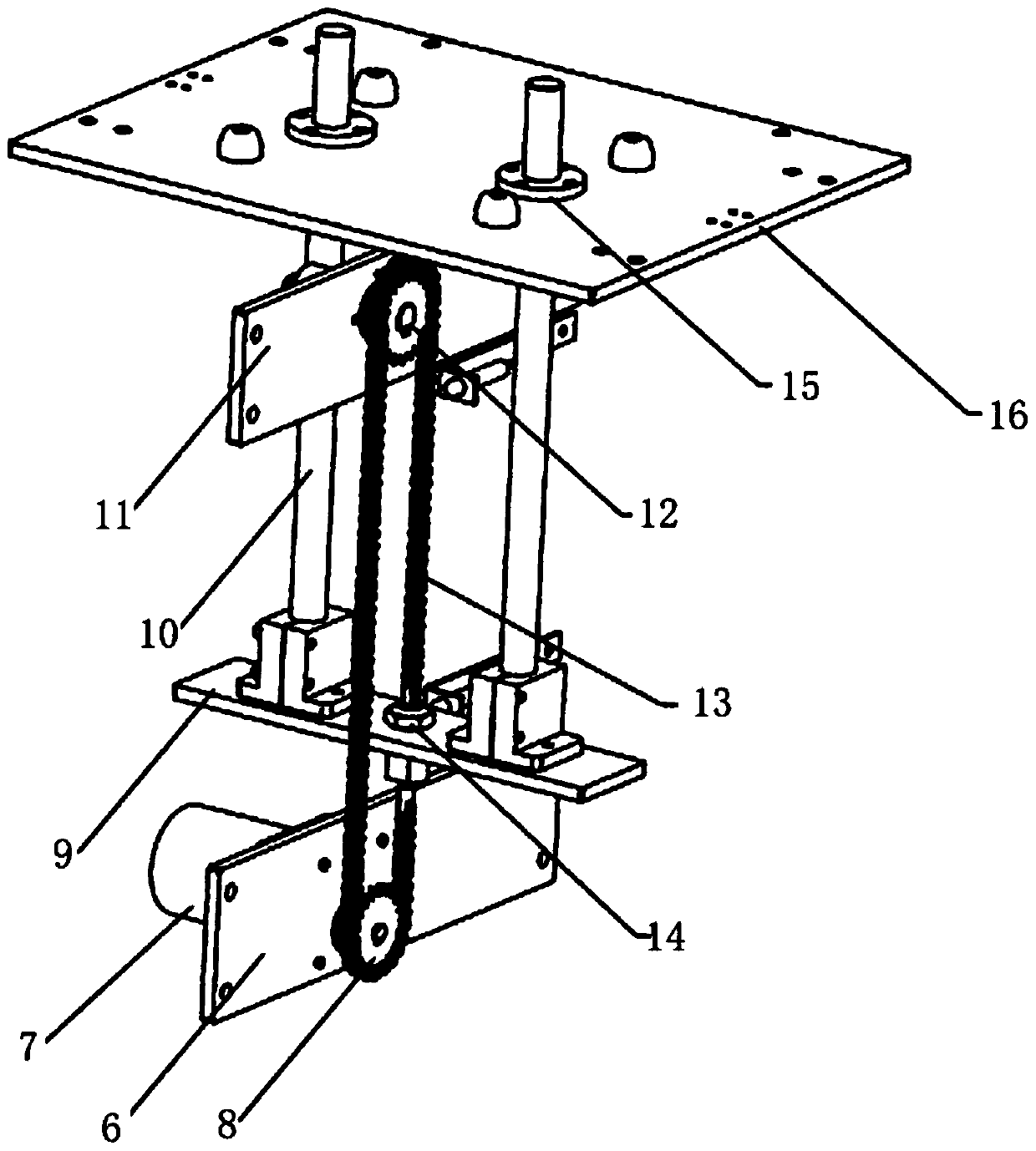

The invention discloses an automatic feeding device of power lithium battery pole pieces, and belongs to feeding devices. The automatic feeding device structurally comprises a section bar support, a jacking mechanism, a pole piece work bin, a carrying mechanical hand and a secondary positioning system, wherein the jacking mechanism, the pole piece work bin, the carrying mechanical hand and the secondary positioning system are respectively arranged on the section bar support, the jacking mechanism is arranged on the lower portion of the pole piece work bin, the secondary positioning system is arranged at the rear of the pole piece work bin, and the carrying mechanical hand is arranged at the position, between the pole piece work bin and the secondary positioning system, of the section bar support. Compared with the prior art, the automatic feeding device of the power lithium battery pole pieces has advantages, thereby having excellent popularization and application value.

Owner:SHANDONG ATAW IND ROBOT TECH

Automatic feeding device of high-speed precision punching machine and method of using same

InactiveCN102407266ANot easy to damageImprove securityMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention discloses an automatic feeding device of a high-speed precision punching machine and a method of using same. The automatic feeding device of the high-speed precision punching machine comprises a pushing mechanism, a storing mechanism, a feeding mechanism, a bar stock limiting block, a bottom frame platform, bar stocks to be conveyed, conveyed bar stocks, a magnetic base plate and aninfrared probe. Two ends of each bar stock to be conveyed are clamped in a storing groove; a pushing cylinder rod drives a pushing block to quickly push a bar stock on the bottommost layer to the place where the bar stocks are conveyed; a finger cylinder drives an upper clamping block and a lower clamping block to clamp the bar stocks; a feeding cylinder drives the upper clamping block and the lower clamping block to move to a punching machine, and the upper clamping block and the lower clamping block are released and reset; and the infrared probe senses a conveyed bar stock until the delivery is finished, then next bar stock is conveyed. The automatic feeding device of the high-speed precision punching machine is simple to operate and high in stability and can be used for accurately conveying materials with different specifications. The whole feeding process is continuous, the automation level is high, the punch die is difficultly damaged, the working efficiency and safety in operation of workers are improved, the production demand is satisfied and the large scale production can be realized conveniently.

Owner:NINGBO VANDA PUNCH TECH

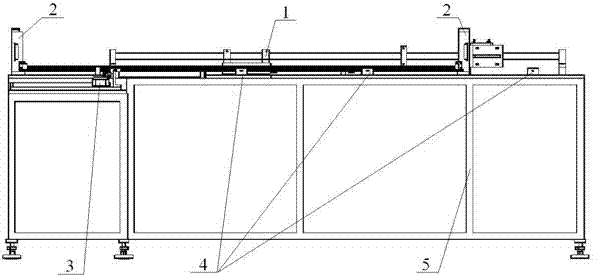

Full-automatic feeding device

InactiveCN111731829ARealize the function of automatic feedingSave time for manual loadingConveyor partsStructural engineeringMechanical engineering

The invention provides a full-automatic feeding device. The full-automatic feeding device comprises a rack, a material conveying mechanism, a material lifting mechanism and a material pushing mechanism are arranged on the rack, wherein the material conveying mechanism comprises a material conveying layer used for conveying a material bin, a recovering layer used for recovering the material bin andmaterial conveying driving assemblies arranged on the material conveying layer and the recovering layer correspondingly, the material lifting mechanism is arranged on one side of the material conveying mechanism, the material lifting mechanism comprises a clamping assembly and a lifting driving assembly used for driving the clamping assembly to move, the clamping assembly is used for clamping thestock bin conveyed through the material conveying layer, the material bin is driven by the driving assembly to be aligned with a material feeding position, and the material pushing mechanism is arranged opposite to the material lifting mechanism and is used for pushing materials in the material bin to the material feeding position. According to the full-automatic feeding device, the function of full-automatic feeding of the materials can be achieved, the manual feeding time is shortened, the feeding position is accurate, and the production efficiency is improved.

Owner:TZTEK TECH

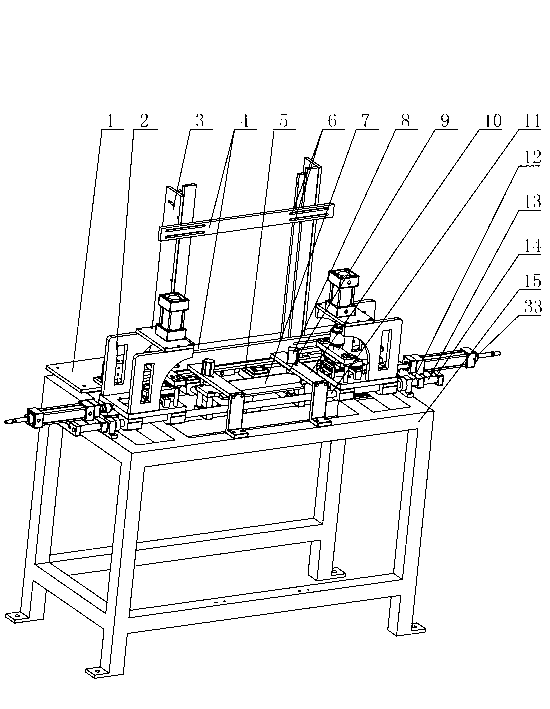

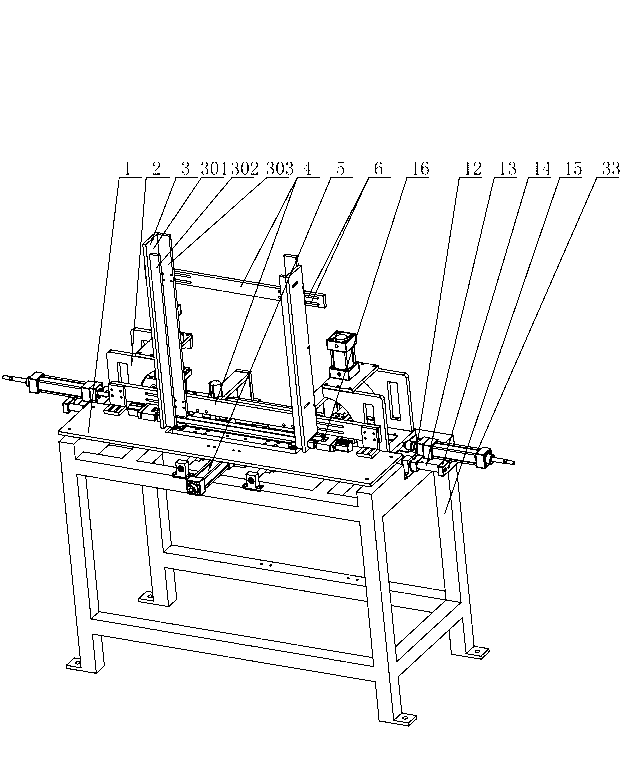

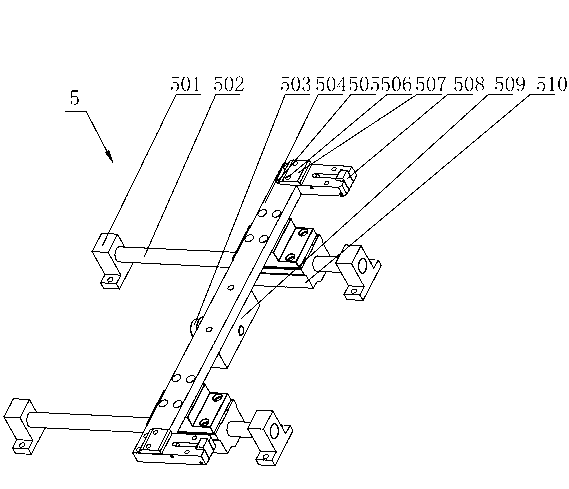

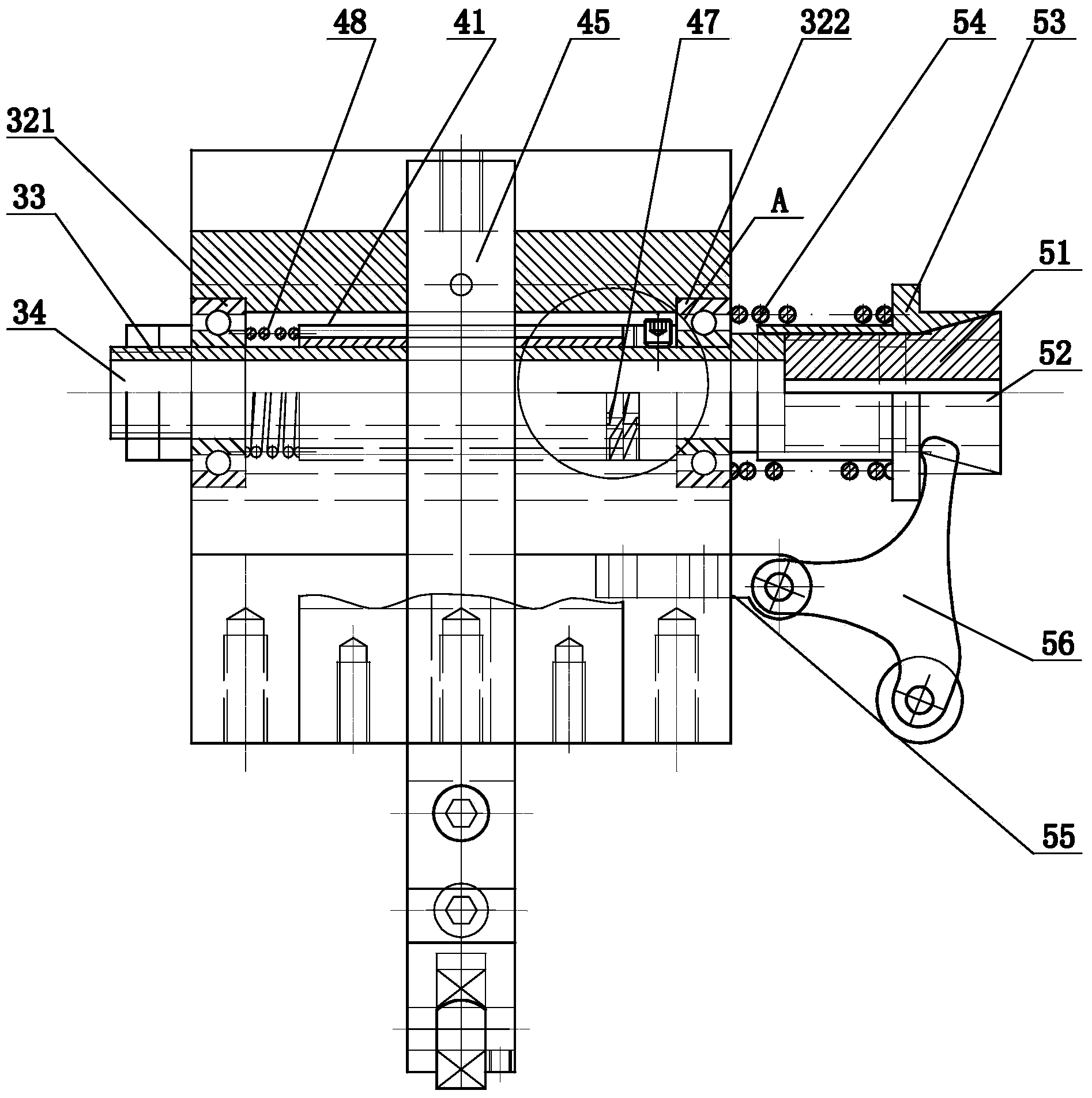

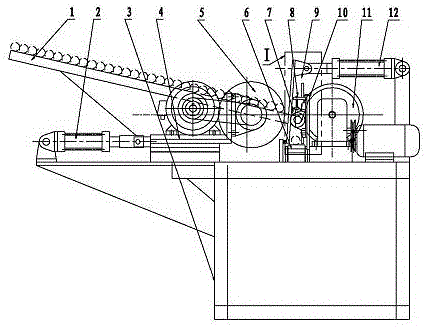

Automatic thin wall gold tube necking machine

ActiveCN103861963AQuality improvementPrecise feeding positionShaping toolsMetal-working feeding devicesEngineeringMachining process

The invention discloses an automatic thin wall gold tube necking machine, belonging to the technical field of jewelry processing equipment. The automatic thin wall gold tube necking machine comprises a rack, wherein the rack is provided with a feed system; the downstream of the feed system is provided with a mould system used for stamping a tube billet of a thin wall gold tube into bead strings; the feed system comprises an axial feeding device used for conveying the tube billet of the thin wall gold tube, a rotation feeding device used for rotating the tube billet of the thin wall gold tube in an intermittent way and a clamp device used for clamping or loosening the tube billet of the thin wall gold tube. According to the automatic thin wall gold tube necking machine, feeding, rotating clamping and stamping of the tube billet of the thin wall gold tube are automatic, so automatic feeding and stamping of the processing of the tube billet of the thin wall gold tube are realized. When the stamping is performed, the tube billet of the thin wall gold tube is clamped, so the quality of the produced bead strings is stable. In the machining process, stock lifting for the tube billet of the thin wall gold tube is not needed, so the working efficiency is significantly improved.

Owner:SHANDONG MOKINGRAN JEWELRY

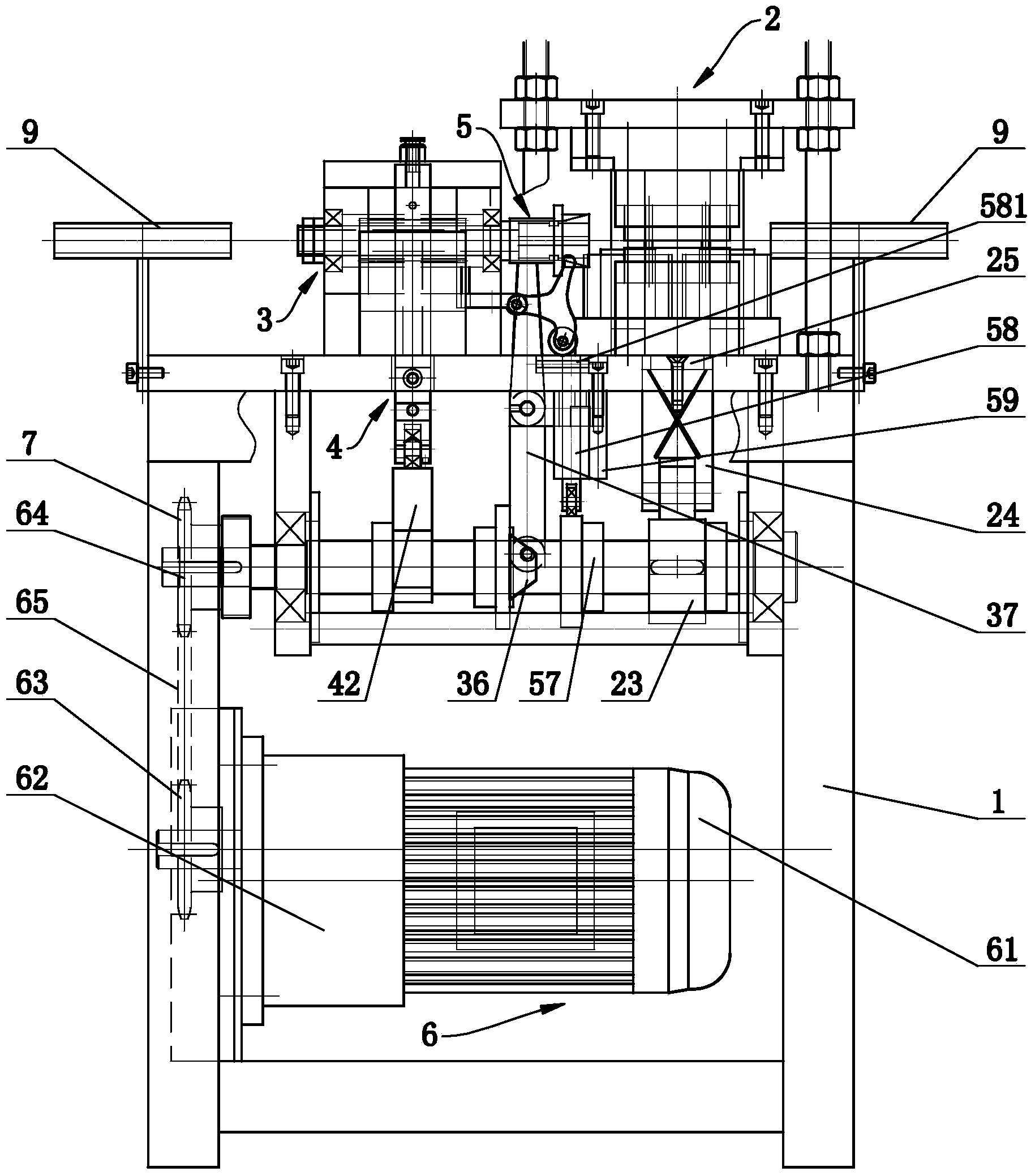

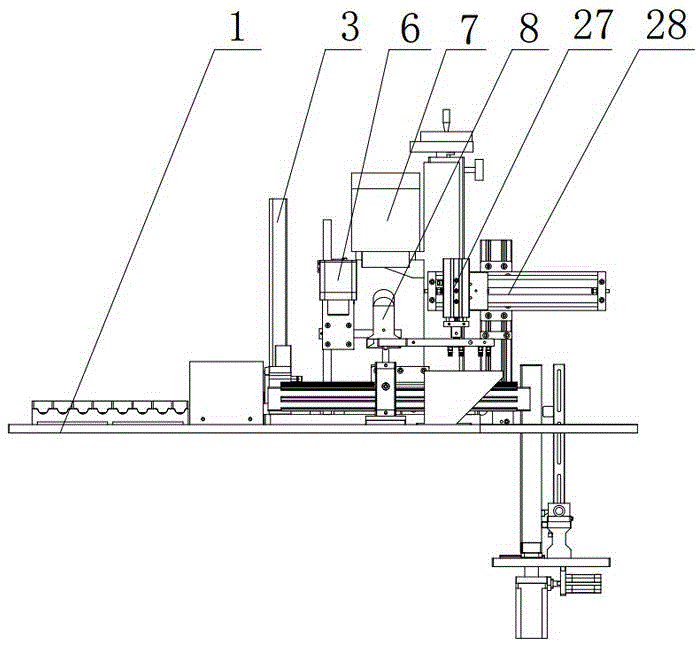

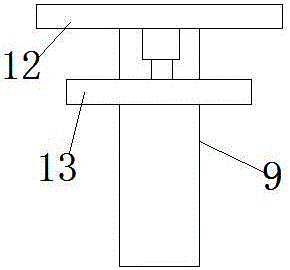

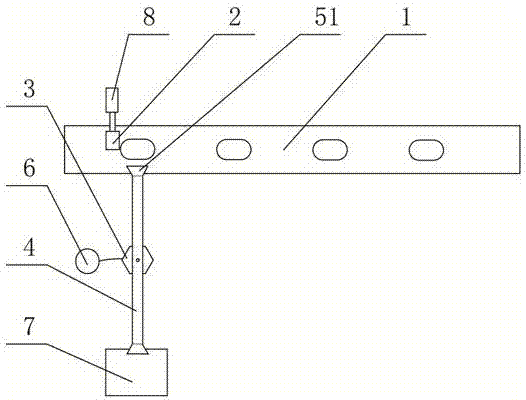

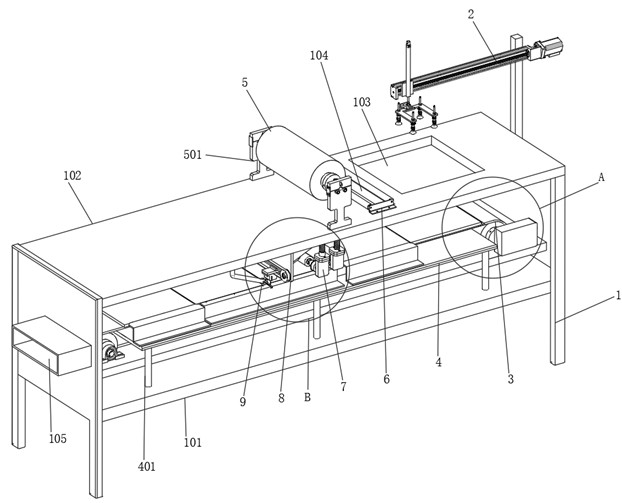

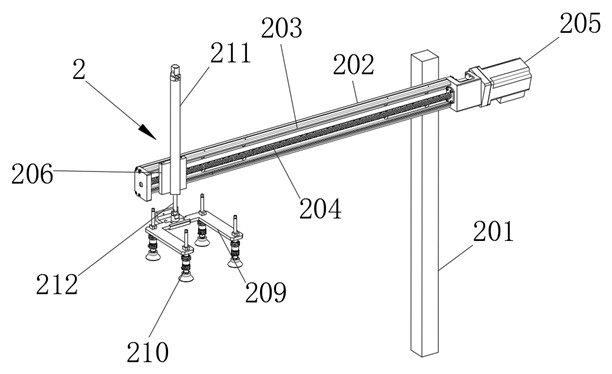

Name board marking machine

InactiveCN104085710AReduce labor intensityImprove work efficiencyPile receiversArticle feedersEngineeringRejection rate

The invention relates to the technical field of marking machines, in particular to a name board marking machine. The name board marking machine comprises a control device, a working table (1), a support (2), a material storage and sending device (3), a containing table (4) used for receiving name boards conveyed from the material storage and sending device, a positioning device (5) used for positioning the containing table (4), a detection device (6) used for detecting whether name boards are placed on the containing table or not, whether the size of name boards is accurate or not and whether name board marking is accurate or not, a laser marking device (7) used for marking name boards, a dust removal device (8) used for absorbing sweeps generated in the marking process, and a material collection and storage device (9) used for collecting marked name boards. The name board marking machine is high in production efficiency and low in rejection rate.

Owner:宁波亿控自动化科技有限公司

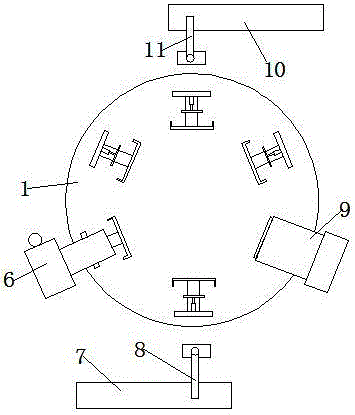

Vehicle lamp gluing and lamination device

InactiveCN106513261AReduce labor intensitySimple structureLiquid surface applicatorsCoatingsUltimate tensile strengthManipulator

The invention discloses a vehicle lamp gluing and lamination device. The vehicle lamp gluing and lamination device comprises a rotating worktable; multiple fixing devices are arranged on the rotating worktable; the fixing devices include fixed bases; front side baffle plates are arranged on the front sides of the upper ends of the fixed bases; back side fixed plates are arranged on the back sides of the upper ends of the fixed bases; automatic push rods are arranged on the back side fixed plates; movable baffle plates are arranged at the front ends of the automatic push rods; a gluing device is arranged on the right side of a selection fitting worktable; a loading conveying belt is arranged on the back side of the rotating worktable; a loading manipulator is arranged between the loading conveying belt and the rotating worktable; a lamination device is arranged on the side edge of the rotating worktable on the back side of the loading manipulator; an unloading conveying belt is arranged on the side edge of the rotating worktable on the back side of the pressing device; and an unloading manipulator is arranged between the unloading conveying belt and the rotating worktable. The vehicle lamp gluing and lamination device is simple in structure and reasonable in design, can guarantee uniform gluing and precise lamination position, is high in automation degree, effectively relieves the labor intensity of workers, and improves the production efficiency.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

Gluing and pressing device for automobile lamps

InactiveCN106493541AReduce labor intensitySimple structureLiquid surface applicatorsMaterial gluingEngineeringConveyor belt

The invention discloses a gluing and pressing device for automobile lamps. The gluing and pressing device comprises a rotating workbench. A plurality of fixing devices are arranged on the rotating workbench. Each fixing device comprises a fixing base. A front side baffle is arranged on the front side of the upper end of each fixing base, and a rear side fixing plate is arranged on the rear side of the upper end of each fixing base. Each rear side fixing plate is provided with an automatic push rod. The front end of each automatic push rod is provided with a movable baffle. A gluing device is arranged at the right side of the rotating workbench. A feeding conveyor belt is arranged on the rear side of the rotating workbench, and a feeding mechanical arm is arranged between the feeding conveyor belt and the rotating workbench. A pressing device is arranged on the side edge of the rotating workbench and located on the rear side of the feeding mechanical arm. A discharging conveyor belt is arranged on the side edge of the rotating workbench and located on the rear side of the pressing device, and a discharging mechanical arm is arranged between the discharging conveyor belt and the rotating workbench. The gluing and pressing device is simple in structure and reasonable in design, gluing evenness can be guaranteed, the pressing position is accurate, the degree of automation is high, labor intensity of workers is effectively relieved, and production efficiency is improved.

Owner:DANYANG ZHENGLIAN INTPROP OPERATIONS MANAGEMENT CO LTD

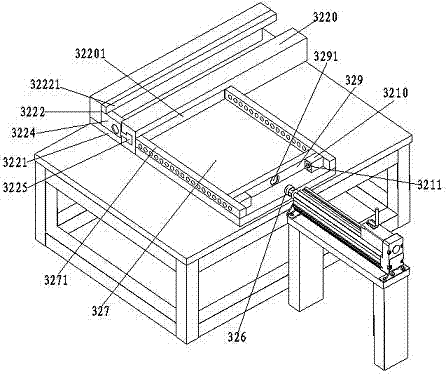

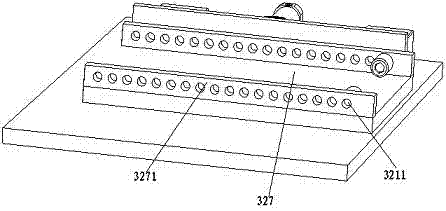

Automatic fabric feeding device used for air cushion bed production

The invention provides an automatic fabric feeding device used for the air cushion bed production, comprising a supporting frame and a bearing platform arranged on the supporting frame and used for stacking fabric. The automatic fabric feeding device is characterized in that two parallel first guide rails are also arranged on the part, above the bearing platform, of the supporting frame; the plane where the first guide rails are located is parallel to the plane where the bearing platform is located; slide bars capable of sliding along the corresponding guide rails are arranged on the two first guide rails; one end of each slide bar is provided with a fabric grabbing mechanism used for grabbing and clamping the fabric. The automatic fabric feeding device, disclosed by the invention, has a simple structure, and is reasonable in design, the fabric grabbing mechanism grabs the fabric on the bearing platform and then clamps the fabric, and conveys to a workbench along the first guide rails, high efficiency feeding movements are completed under fully automated operation, the whole feeding process does not need human participation, the feeding position is accurate, and the function of automatic alarm for prompting reloading is also realized.

Owner:SUZHOU UNIV OF SCI & TECH

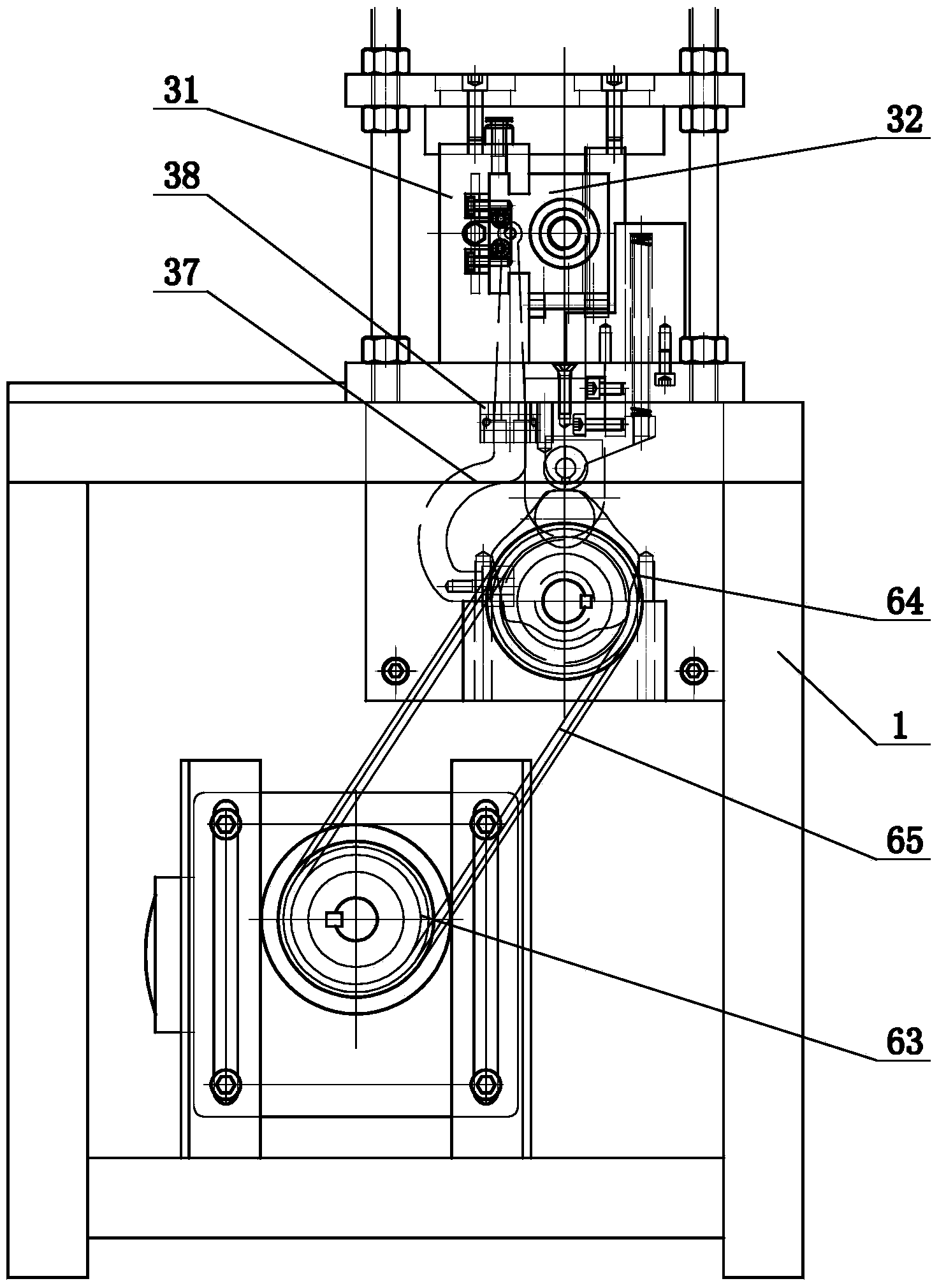

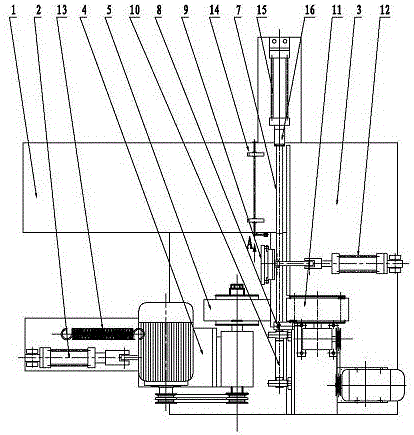

Jewellery bead making machine

ActiveCN101602083AQuality assuranceIncrease productivityHandling devicesEngineeringMechanical engineering

The invention discloses a jewellery bead making machine, comprising a rack, a stamp forging shaping device and a feeding device arranged on the rack, wherein, the stamp forging shaping device is arranged on the rack, and is provided with a plurality of striking and forged stations arranged along the proceeding direction of a metal tube blank in sequence, and the stations are used for striking and forging the metal tube blank into a bead string or a single bead; the feeding device comprises an auxiliary material lifting device for lifting the metal tube blank, the lifted metal tube blank is transmitted by a step downwards to the next striking and forged station through an axial feeding device, so that the metal tube blank intermittently rotates in a striking and forged station and forms an overturn feeding device with a plurality of striking and forged phase positions. The feeding, overturning, striking and forging, and lifting of the metal tube blank are automatic machine work, so the specification of the thin-wall spherical gold beads and silver beads which are produced by the jewellery bead making machine of the invention can be kept uniform, the quality thereof can be ensured, and the production efficiency can be obviously improved; meanwhile, the jewellery bead making machine of the invention eliminates potential safety hazard.

Owner:SHANDONG MOKINGRAN JEWELRY

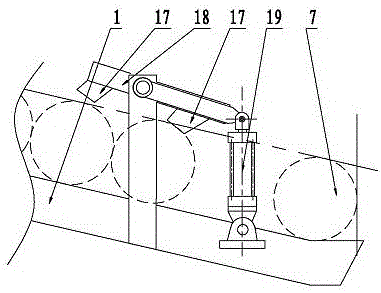

High-reliability pneumatic feeding mechanism

InactiveCN107486503ARealize pneumatic handling functionImprove work efficiencyMetal-working feeding devicesPositioning devicesPulp and paper industryConveyor belt

The invention discloses a pneumatic feeding mechanism with high reliability, which comprises a conveyor belt, a limit block, a rotary cylinder, a connecting rod, a vacuum suction cup and a vacuum generator, the limit block is located above the conveyor belt, and the upper end of the rotary cylinder Connected to the middle of the connecting rod, the two ends of the connecting rod are respectively provided with the vacuum suction cups, the vacuum suction cups are connected to the vacuum generator, and the two ends of the connecting rod are respectively located above the conveyor belt and the stamping station superior. The beneficial effects of the present invention are: use the limit block to block the material to be processed on the conveyor belt, and play a positioning role for the vacuum suction cup to absorb the material; the role of the rotating cylinder and the vacuum suction cup is equivalent to the role of the manipulator, realizing the pneumatic conveying function of the material, The vacuum suction cup sucks the material, and the rotary cylinder achieves a 180° rotation, and sends the material to the stamping station.

Owner:天津市斯佳琦机械有限责任公司

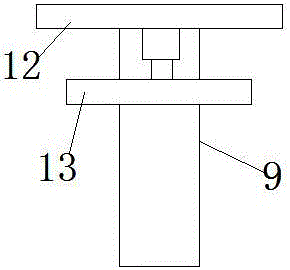

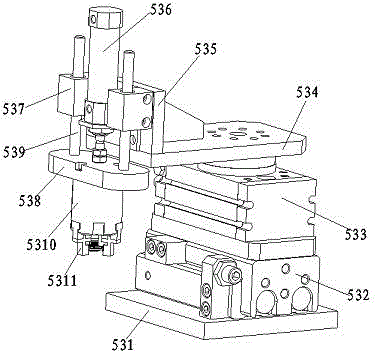

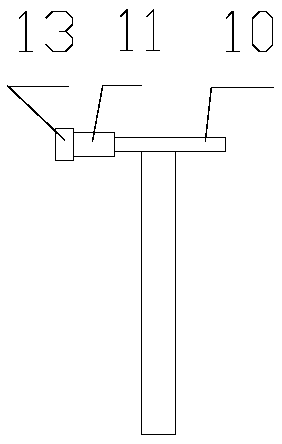

The Spring washer feeding manipulator of electromagnetic valve part assembling machine

The invention discloses a spring washer feeding manipulator of electromagnetic valve part assembling machine, which comprises a fixing bottom plate, a horizontal movement clamping and a taking-out sliding table cylinder installed on the upper plane of the fixed bottom plate, a rotating cylinder mounted on a sliding table of cylinder through an feeding material rotating cylinder connecting plate. A rotating mounting plate is mounted on a rotating table of the feeding rotary cylinder. One end of the upper plane of the rotating mounting plate is installed with a vertical feeding guide cylinder mounting plate through a reinforcing rib. A side surface of the upper material guiding cylinder mounting plate is fixed with a longitudinal feeding guide cylinder through a cylinder fixing device, and a guide block is arranged on both sides of the loading guide cylinder mounting plate on both sides of the feeding guide cylinder. According to the above-described method, the invention is convenient to take materials, high in the working efficiency and low in the production cost.

Owner:SUZHOU GUANHAOSI PRECISION MACHINERY CO LTD

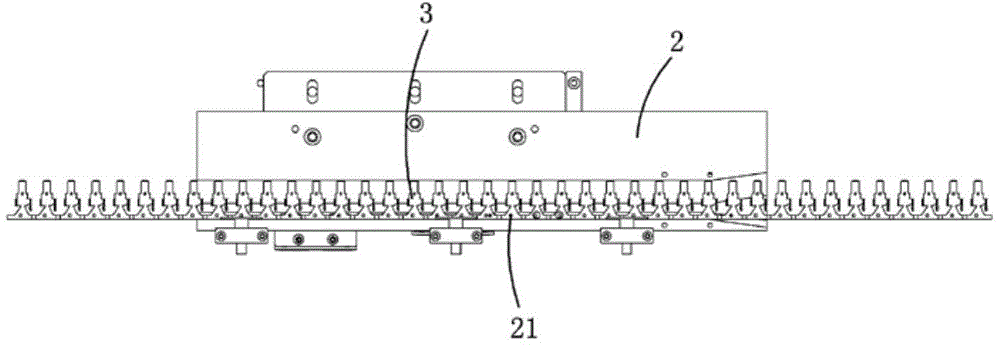

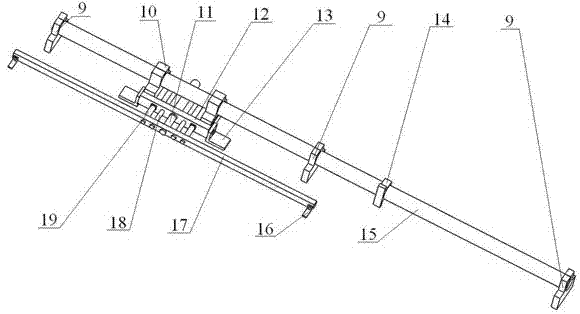

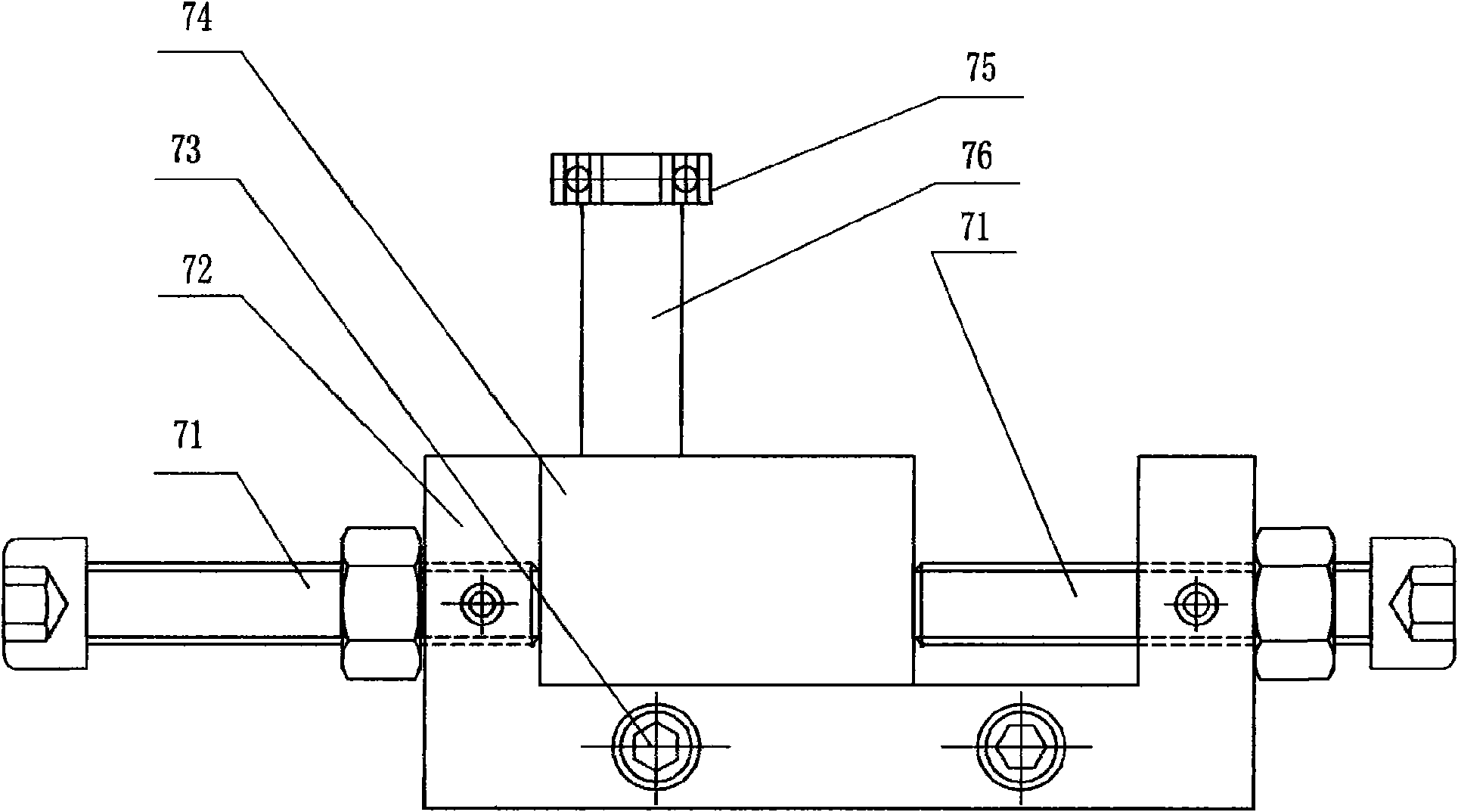

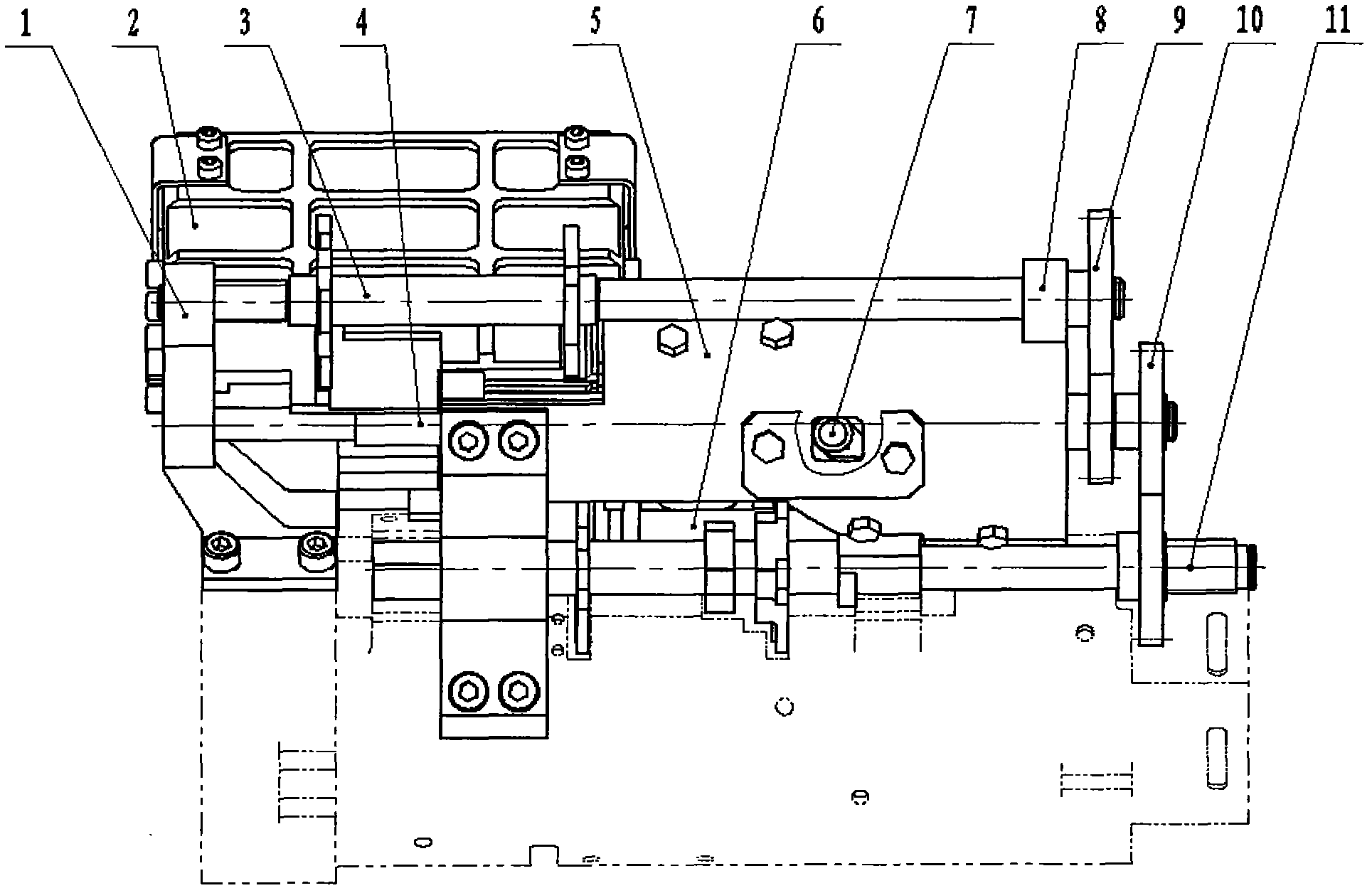

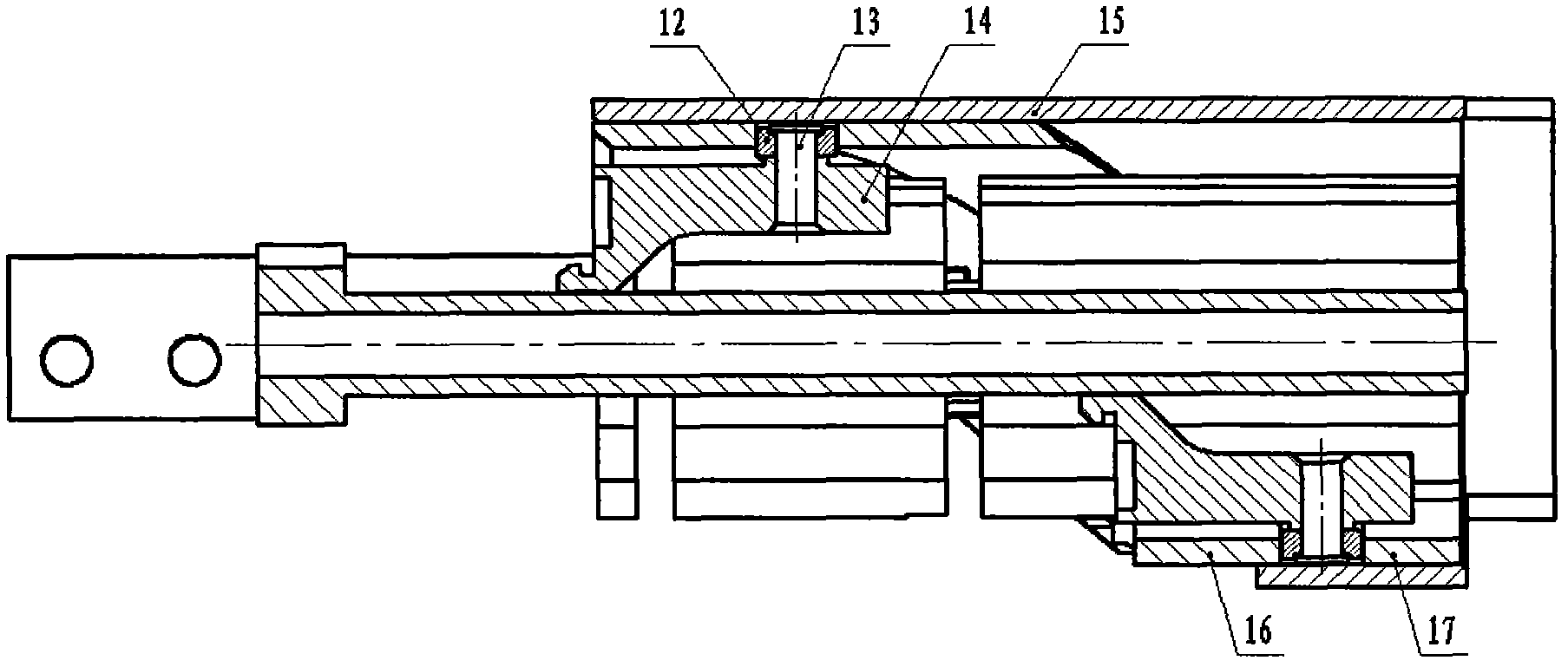

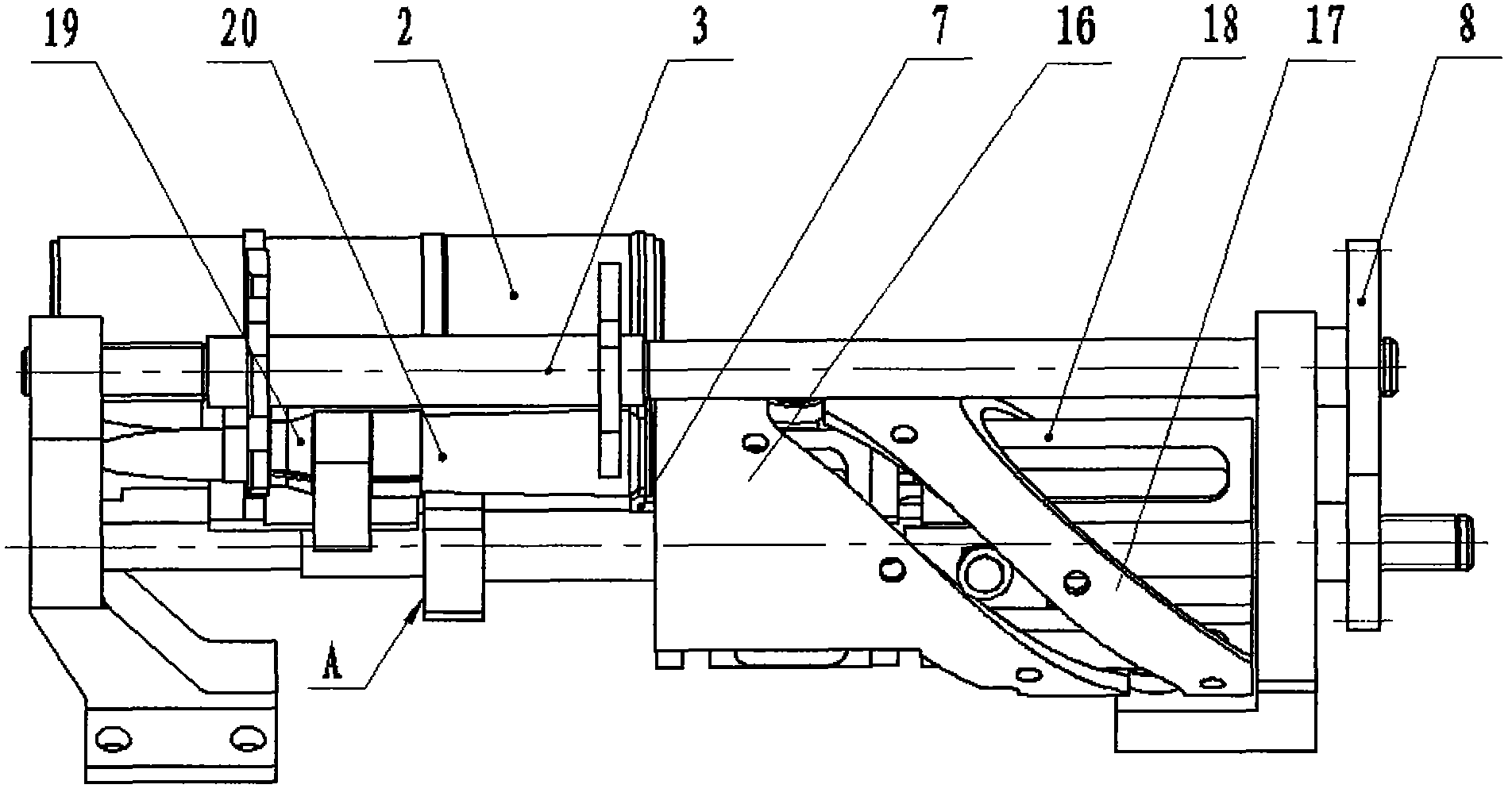

High radio frequency closed type ammunition-belt-removing ammunition-supplying mechanism

InactiveCN103453798AOff-chain guaranteeGuaranteed operational reliabilityAmmunition loadingEngineeringUltimate tensile strength

The invention provides a high radio frequency closed type ammunition-belt-removing ammunition-supplying mechanism which is used for ammunition belt removing and ammunition supplying of high radio frequency multi-barrel turning guns using closed type belt ammunitions. The mechanism is characterized by comprising a plurality of belt removing movements. By means of the structure, one belt removing mechanism can be provided with a plurality of belt removing movements, the requirement for strength of a single belt removing movement is greatly reduced on the premise that the high shooting frequency of the guns is ensured, and structure risk is dispersed. In addition, by means of accurate restraining of a belt removing curve groove, the mechanism is accurate in belt removing and ammunition supplying positions and timely in belt moving and ammunition supplying, and high operation reliability of the mechanism is guaranteed.

Owner:SICHUAN HUAQING MACHINERY +1

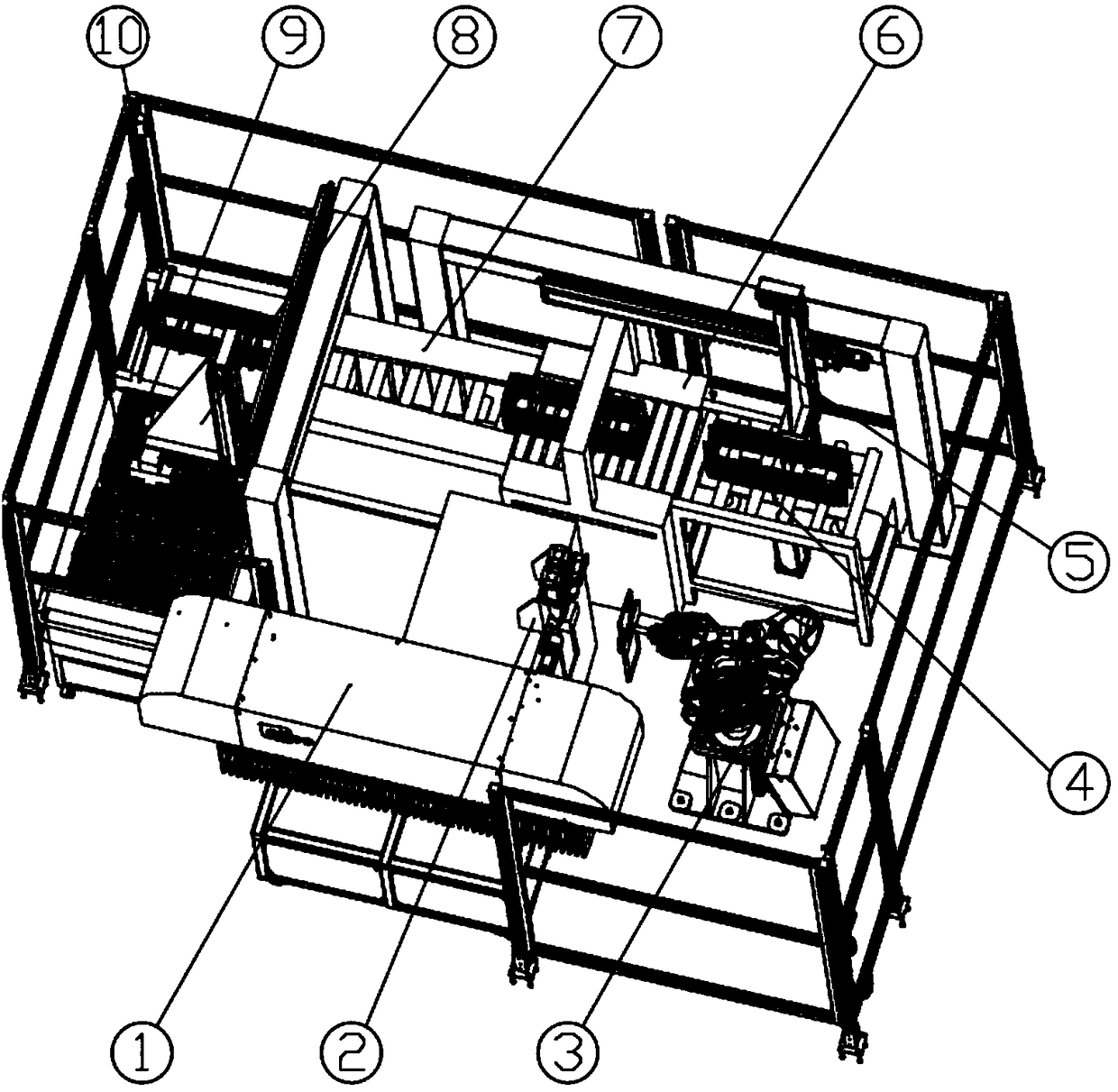

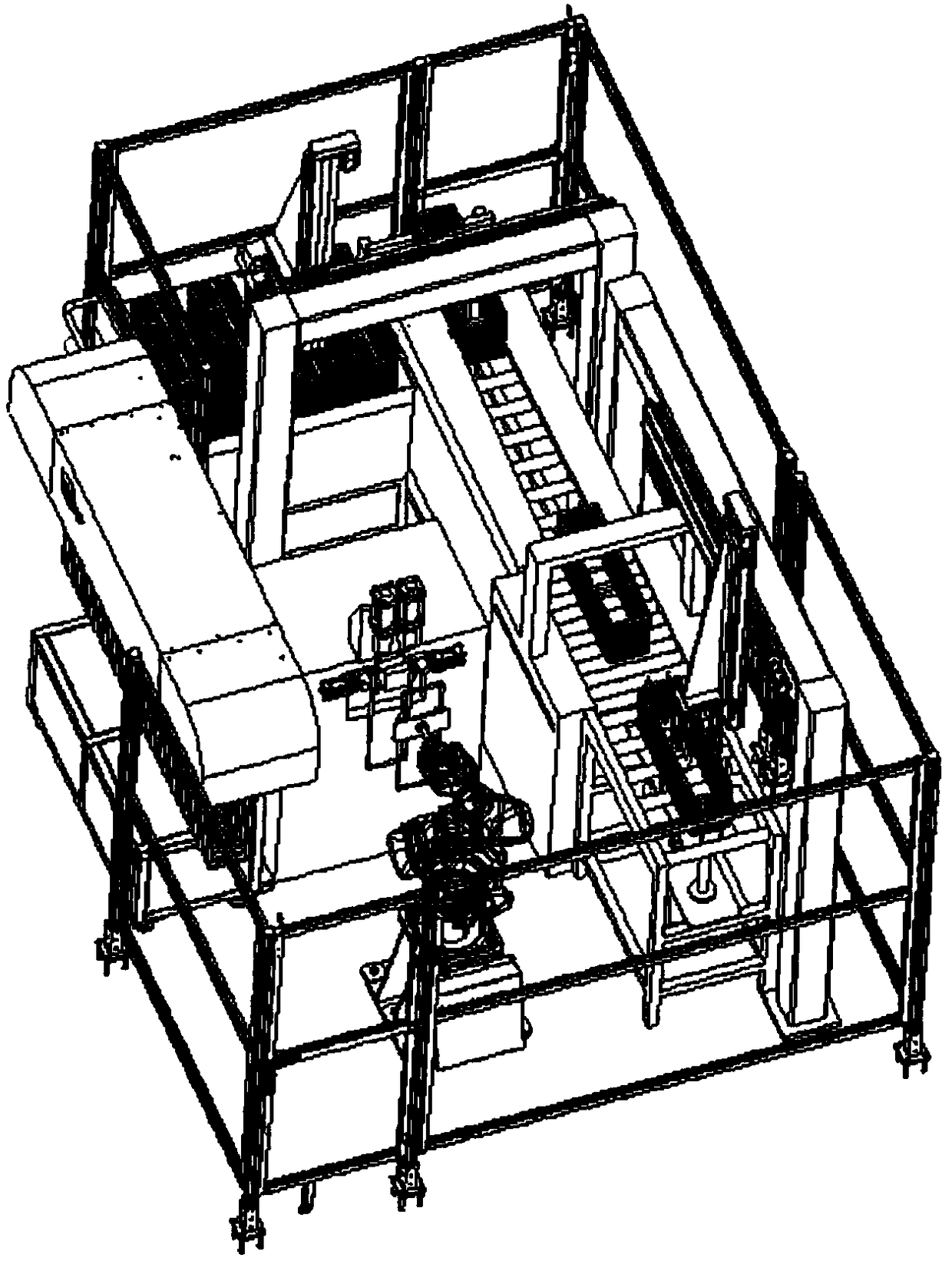

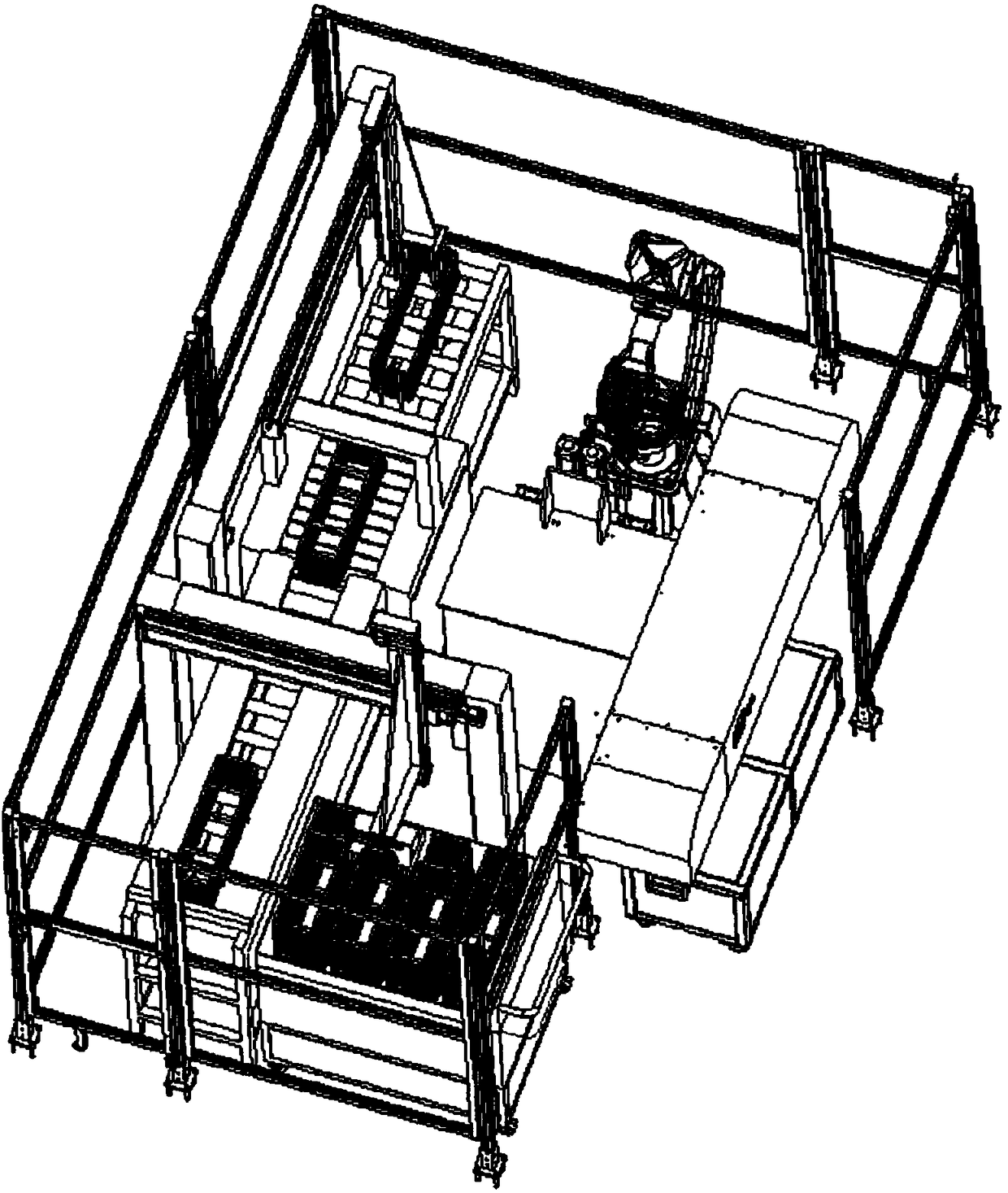

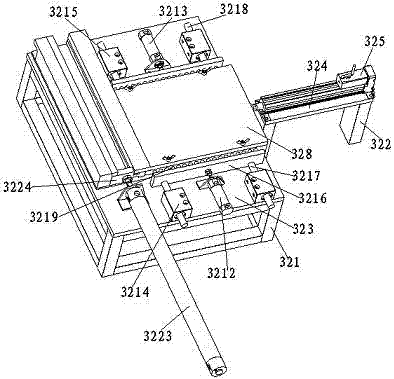

Stirrup welding and packing integration machine

PendingCN108838595APrecise feeding positionReplace high-load laborWelding/cutting auxillary devicesAuxillary welding devicesButt weldingStirrup

The invention discloses a stirrup welding and packing integration machine, and relates to the technical field of stirrup welding and packing. The stirrup welding and packing integration machine comprises an automatic feeding module, a mechanical taking and placing mechanism, a butt welding machine, an unloading jaw and a packing machine; the mechanical taking and placing mechanism is arranged neara taking port of the automatic feeding module; the butt welding machine is positioned on one side of the automatic feeding module; an unloading position is arranged on the back side of the mechanicaltaking and placing mechanism; the unloading jaw is arranged in the unloading position; and the packing machine is arranged on the back side of the unloading position. The stirrup welding and packingintegration machine realizes full-automatic loading, taking, welding, unloading and packing, replaces high-load manual work, and improves the working efficiency.

Owner:BEIJING YANTONG BUILDING COMPONENTS PROD +1

Limiting arm feeding device of assembly machine for main body parts of automobile door limiters

InactiveCN107052744ACompact structureEasy to operateMetal working apparatusEngineeringAssembly machine

The invention discloses a limit arm feeding device of an assembly machine for the main part of an automobile door limiter. The limit arm feeding device of the assembly machine for the main part of an automobile door limiter includes assembly frames sequentially installed on the ground And the electric cylinder bracket, the assembly mounting plate is installed on the assembly frame, the electric cylinder mounting plate is fixed on the electric cylinder bracket, the electric cylinder is installed on the upper surface of the electric cylinder mounting plate, and the output end of the electric cylinder is fixed with a pusher, assembled and installed The upper end surface of the plate is fixed by the spacer, and the side wall opposite to the limit arm placement plate extends vertically upwards to form ribs, and the upper end surfaces of the two ribs are equipped with detachable baffles through butterfly bolts. The positioning arm placement plate, the two ribs and the baffle form the shifting channel of the limiting arm, and the opposite outer surfaces of the two ribs are sequentially provided with equidistant positioning holes, and the positioning holes on the two ribs correspond one by one . Through the above method, the present invention has the advantages of convenient feeding, high working efficiency and low production cost.

Owner:苏州鑫夷斯精密机械有限公司

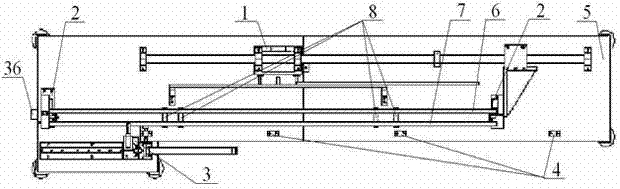

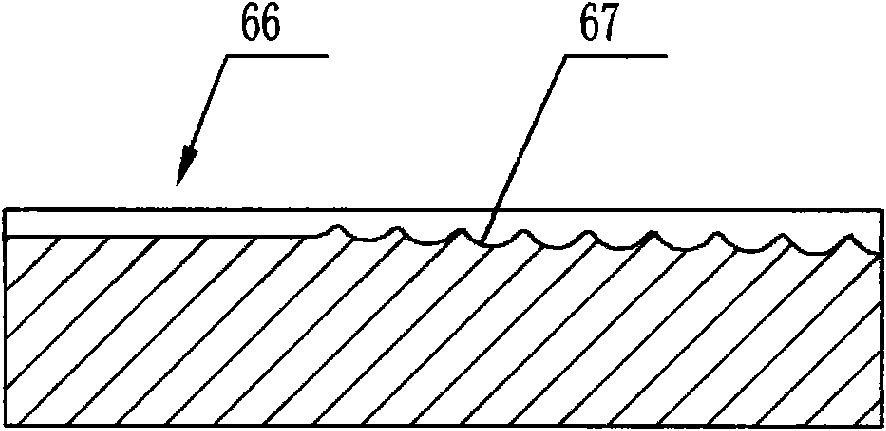

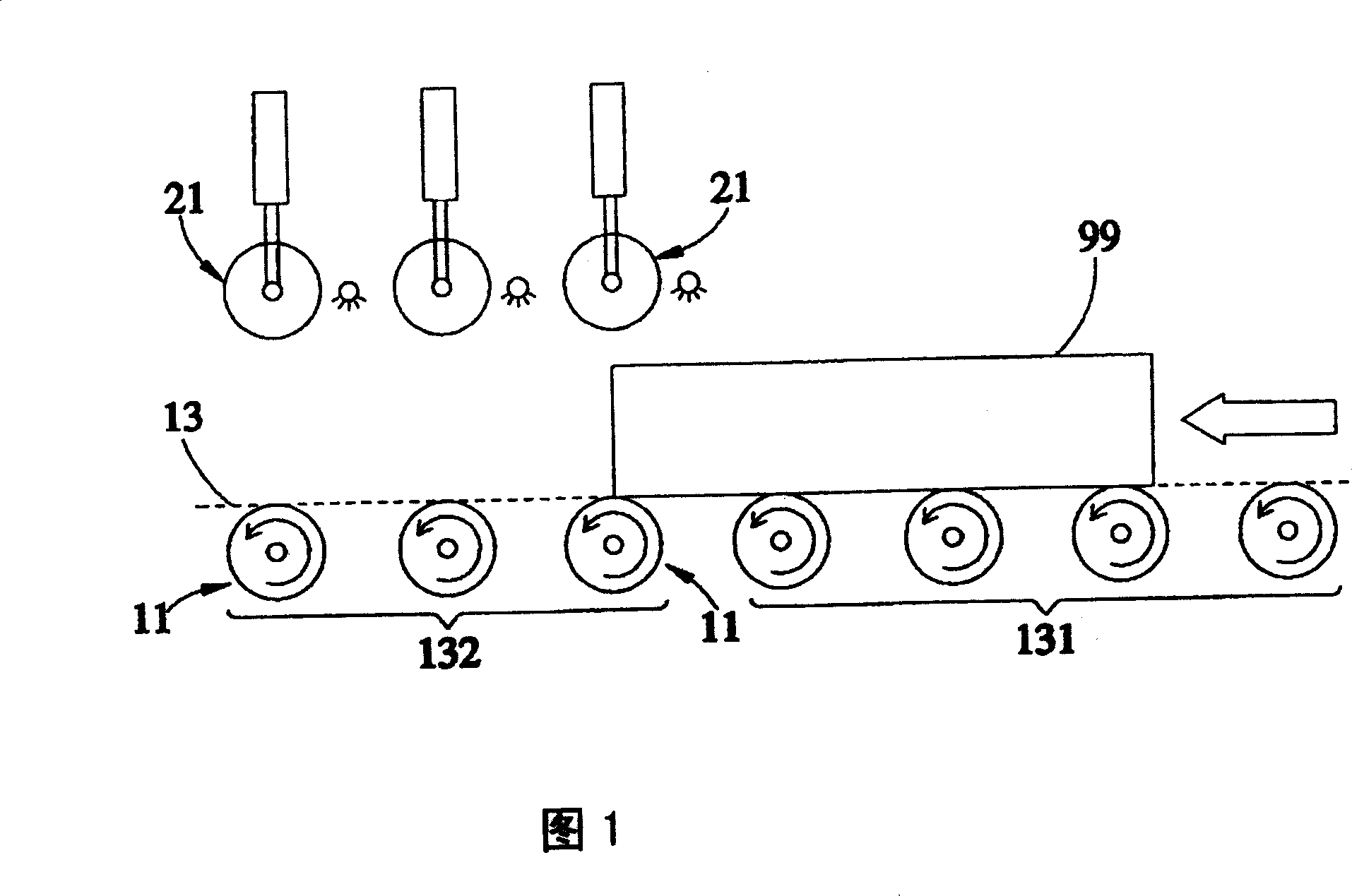

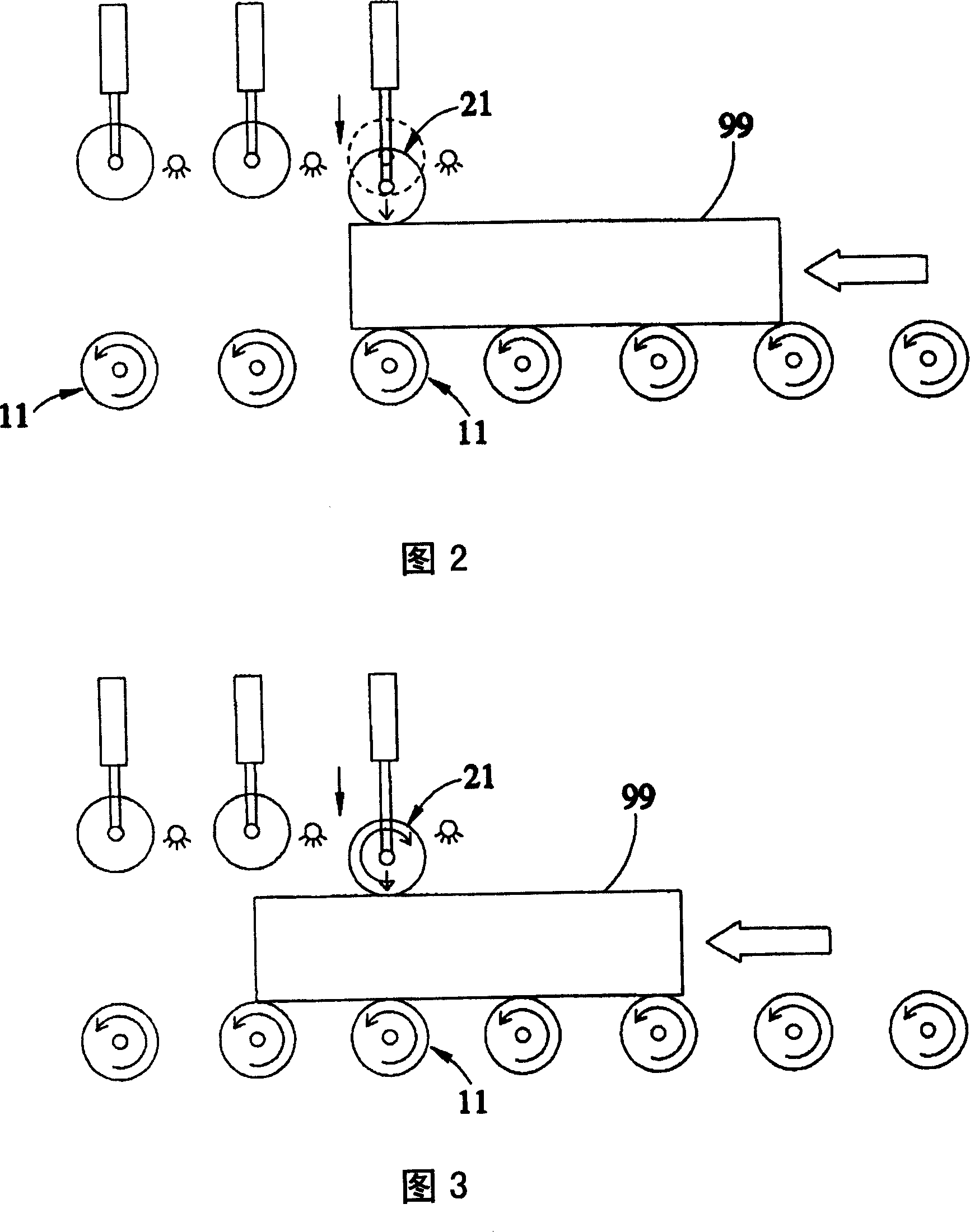

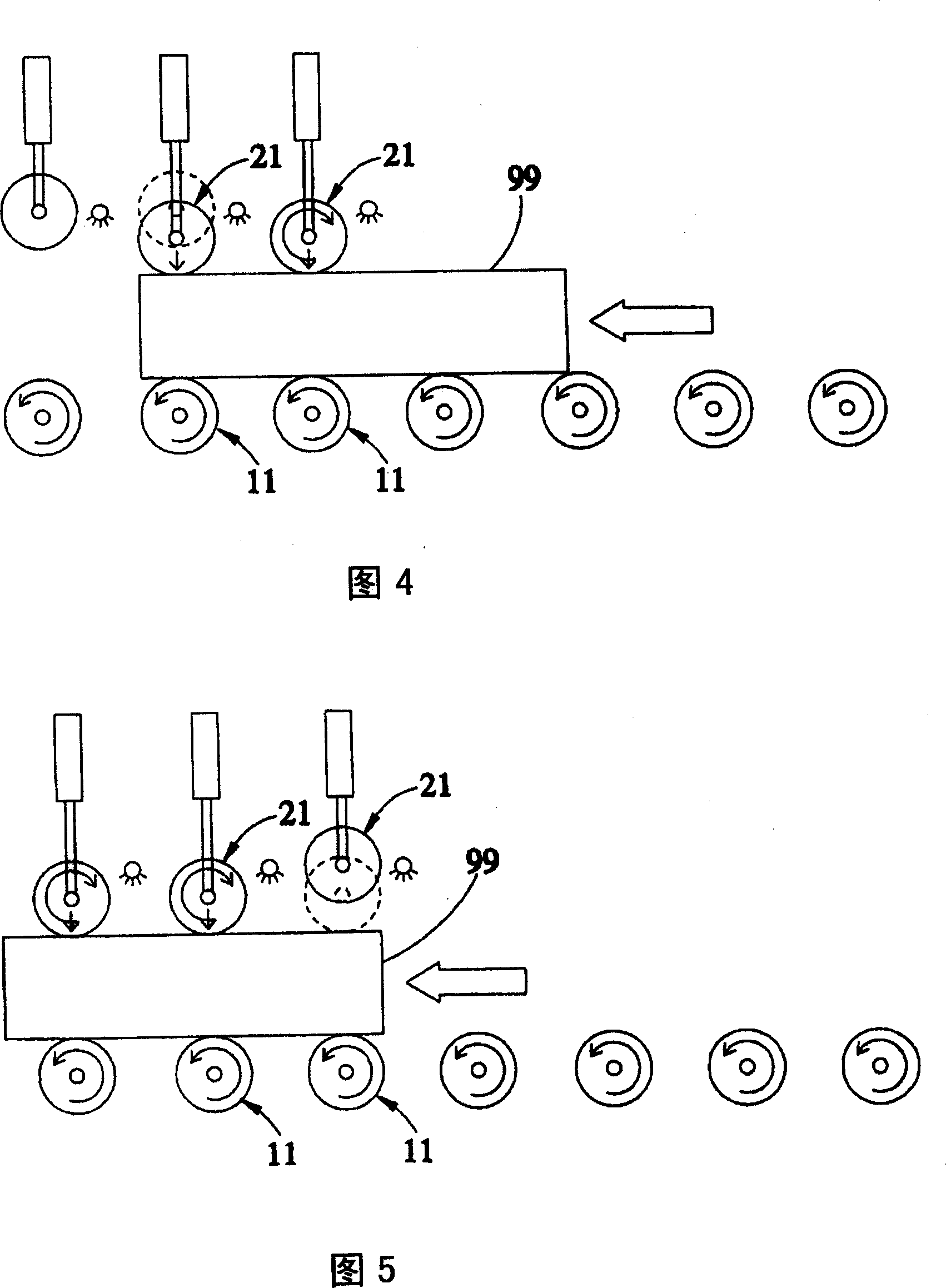

Low-error-feeding method for plate material and apparatus using said method

InactiveCN101069969APrecise feeding positionWood feeding arangementsFeeding devicesDrive wheelControl engineering

The invention is a low error feeding method of platy materials and its device. It contains the following steps: A. Prepare several promoting wheels and driven wheels. B. Feeding. C. Gradually pressing. D. Gradually relieve pressing. According to the above steps, pressing and clamping are not completed until the platy materials arrive at between the promoting wheels and driven wheels to avoid it has impacting or extra component forces with the driven wheels and the position errors. The device of the method is composed of a frame body, several promoting wheels, a drive assembly, several driven wheels, several sensors and a control circuit. The low error of feeding position can be realized by using the above method and device.

Owner:CARPENTER MACHINERY

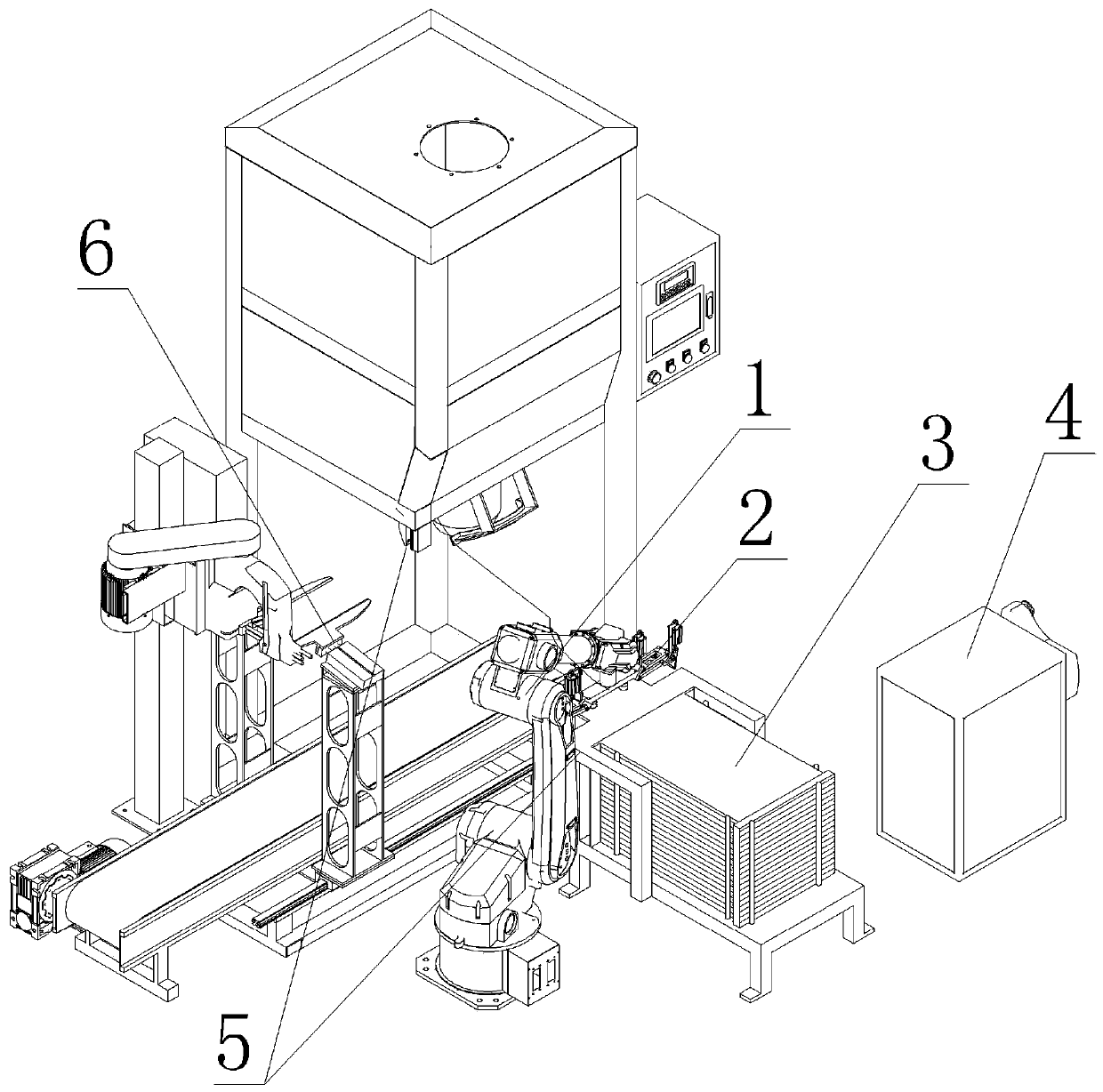

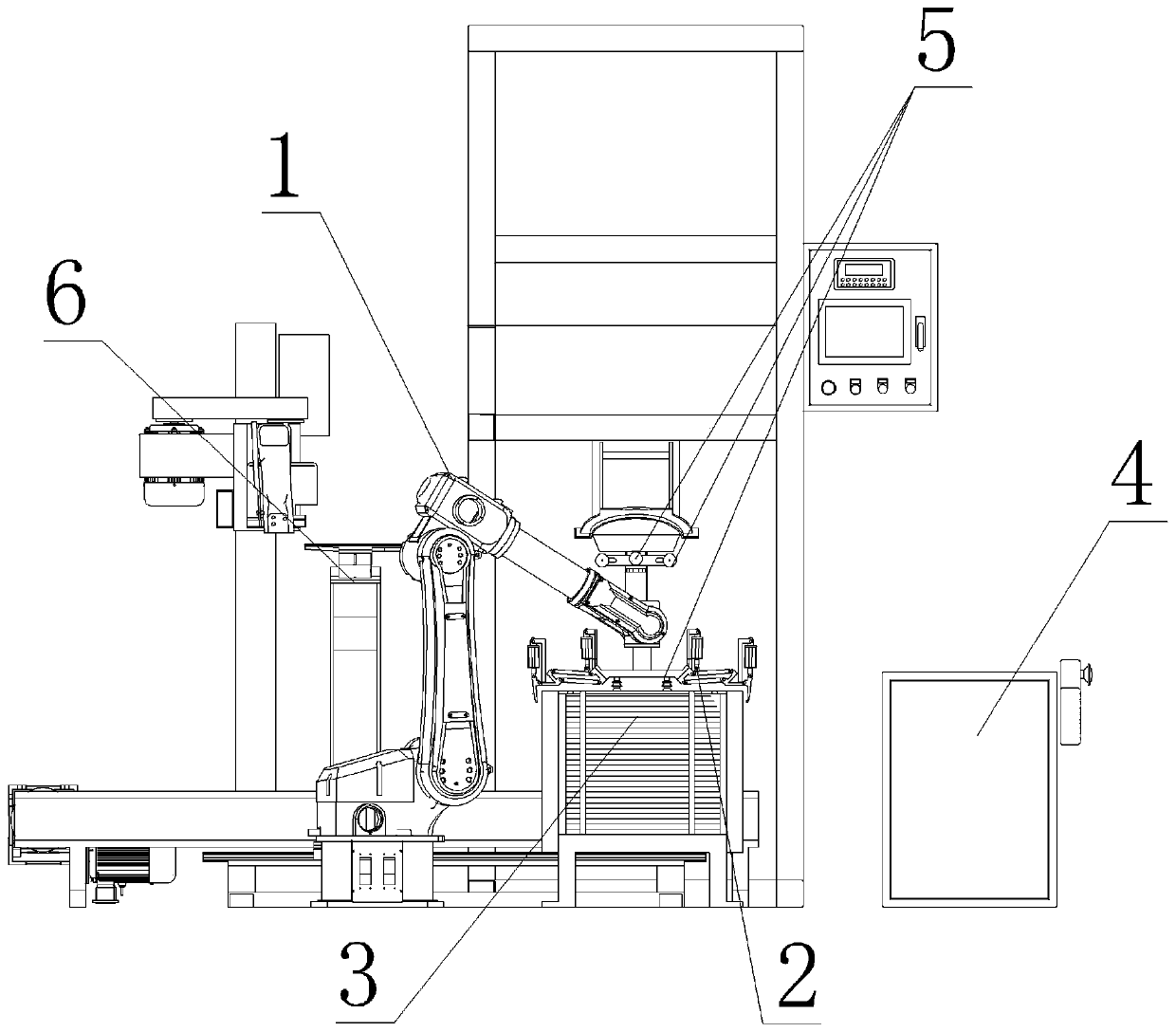

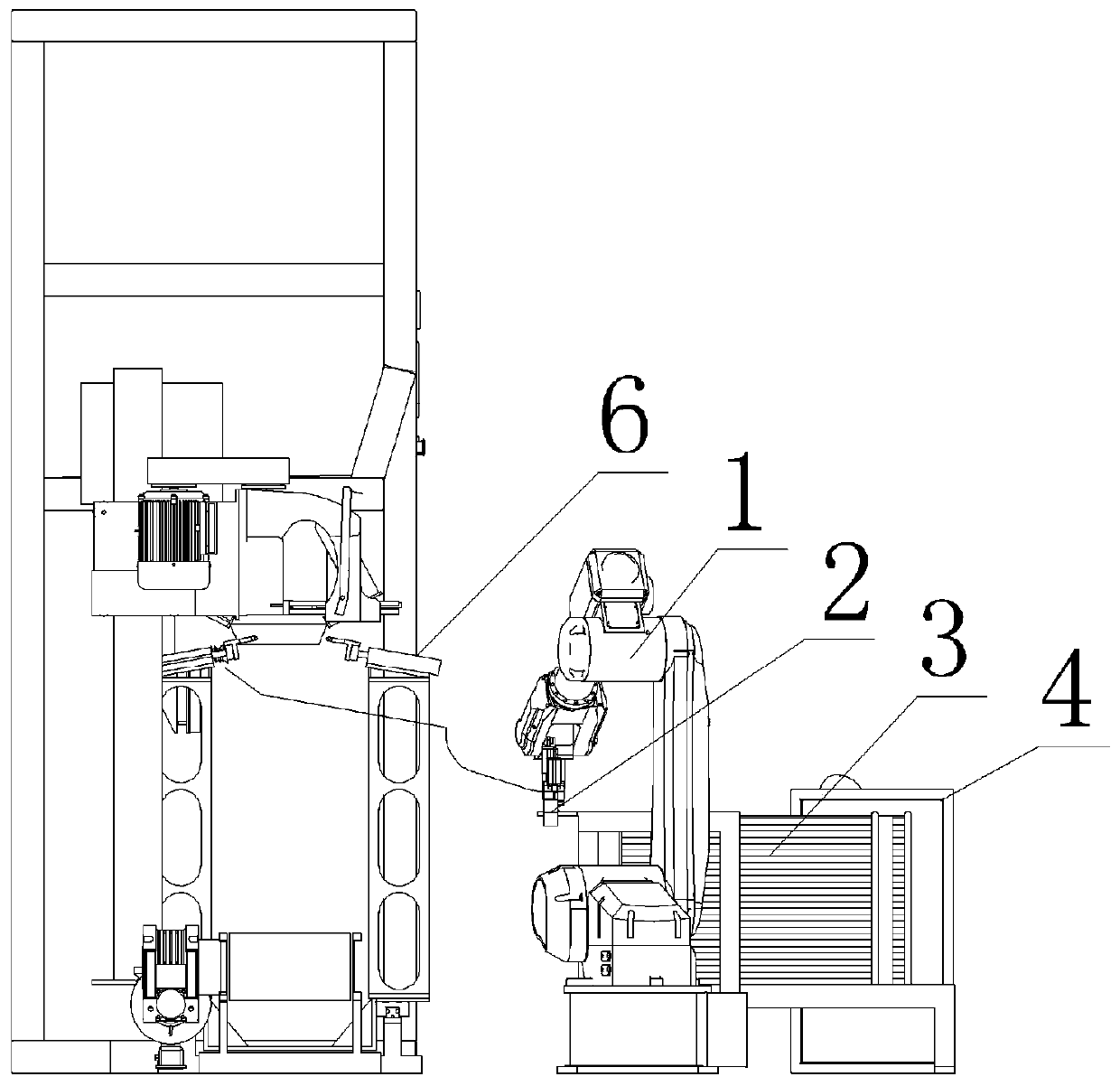

Powder packaging robot intelligent bagging system

InactiveCN109835531AHarm reductionImprove work efficiencyWrapper twisting/gatheringManipulatorIndustrial robot

The invention discloses a powder packaging robot intelligent bagging system. The system consists of six parts, namely a six-axis industrial robot body, a grabbing mechanical arm mechanism, an empty bag library, a feeding trolley, a special coordinate point detection mechanism and a control cabinet, the controller controls the six-axis industrial robot to rotate, ascend, descend and move in the working coordinates, the controller controls the grabbing mechanical arm mechanism to sleeve the bag opening of the packaging empty bag onto a discharging port of a packaging machine, the empty bag library can be controlled to realize intelligent bag supplying, the feeding trolley is controlled to convey the bag filled with materials to the inlet of the sewing machine along the track. The system canautomatically sleeve the seam opening of the packaging equipment of the round discharging opening of the universal powder packaging machine with the size of 10-50 kg, manual operation is replaced, andfull-automatic packaging is realized.

Owner:孙志宇

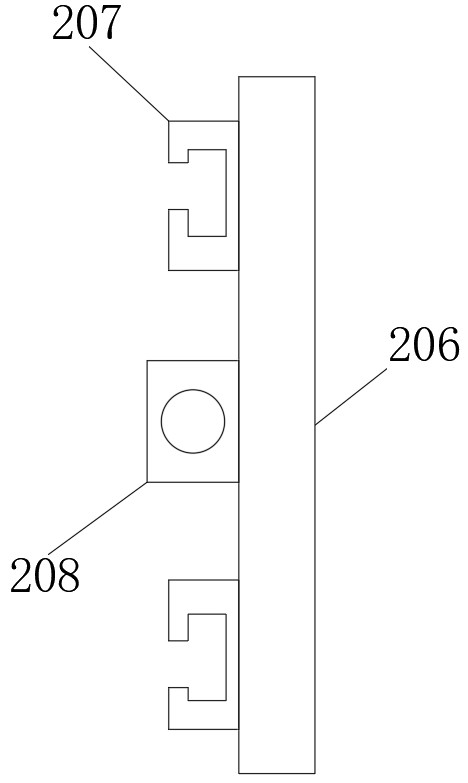

Material charging and collecting structure

PendingCN106736804ALow costPrecise feeding positionMetal working apparatusCouplingElectric machinery

The invention relates to the technical field of automatic material feeding equipment, in particular to a material charging and collecting structure. The material charging and collecting structure is characterized in that a vertical plate is arranged in an adjusting installation base frame; a linear guide rail is arranged on the vertical plate, and extends along the height direction of the vertical plate; a slide block is fixedly arranged at the inside wall of the adjusting installation base frame and is matched with the linear guide rail; the slide block is inserted into the linear guide rail; a screw nut is fixedly arranged at the inside wall of the adjusting installation base frame; a screw fixing block is fixedly arranged at one end of a screw; the other end of the screw is connected with the screw nut by threads; a screw fixing block is fixedly connected with an output point of a servo motor through a coupling; a material supporting plate is arranged on the adjusting installation base frame; a product material arrangement mechanism is arranged on the adjusting installation base frame; a light ray sensor is arranged at the top part of the vertical plate. The material charging and collecting structure has the advantages that a material feeding position is accurate, material feeding is quick, the product quality is improved, the production efficiency is furthest improved under the automatic environment, and the enterprise cost is reduced.

Owner:SHENZHEN FUHEDA AUTOMATION CO LTD

Workpiece stamping machining production line

InactiveCN108817251ARealize automatic feedingAvoid manual workMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention discloses a workpiece stamping machining production line. The production line comprises a machining table, a machining plate, a power unit, a limiting plate, a punch and a driving mechanism, wherein a plurality of containing grooves are formed in the machining plate, the plurality of containing grooves are sequentially distributed in the length direction of the machining plate, the depth of each containing groove is smaller than H, wherein H is the height of a workpiece, the machining plate is arranged on the machining table, the power unit is used for driving the machining plateto move in the length direction of the machining plate, the limiting plate is located above the machining plate, the plane where the limiting plate is located is perpendicular to or obliquely intersected with the length direction of the machining plate, the distance between the limiting plate and the bottom walls of the containing grooves is larger than H and is smaller than 2H, the punch is located on the downstream side of the limiting plate and located above the machining plate, and the driving mechanism is used for driving the punch to move close to or away from the containing grooves.

Owner:芜湖华铸汽车部件有限公司

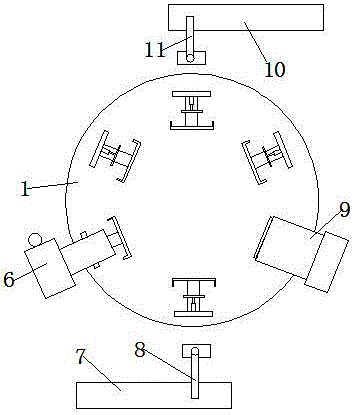

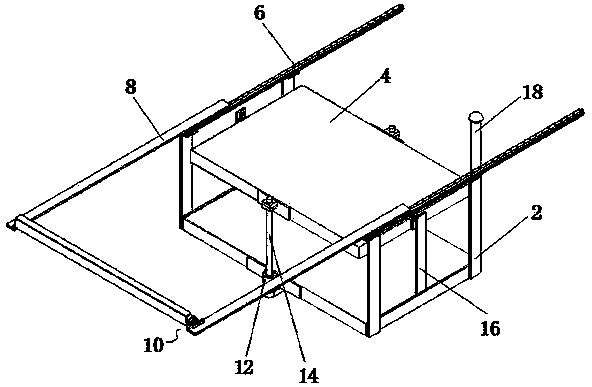

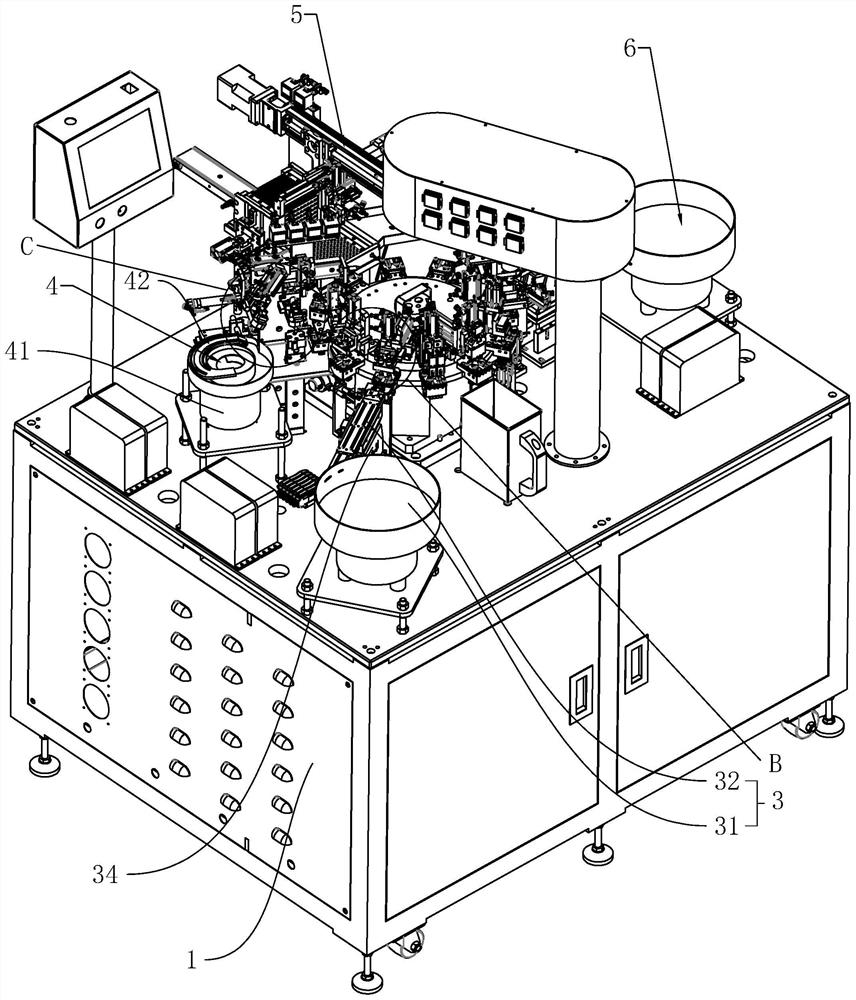

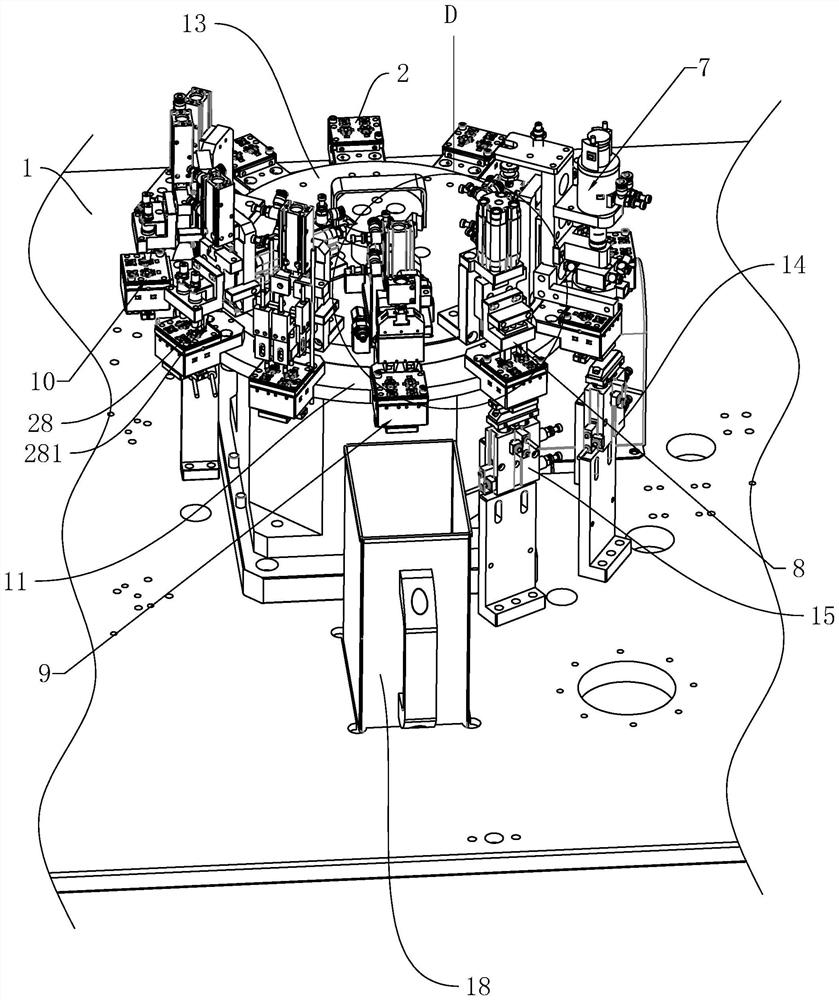

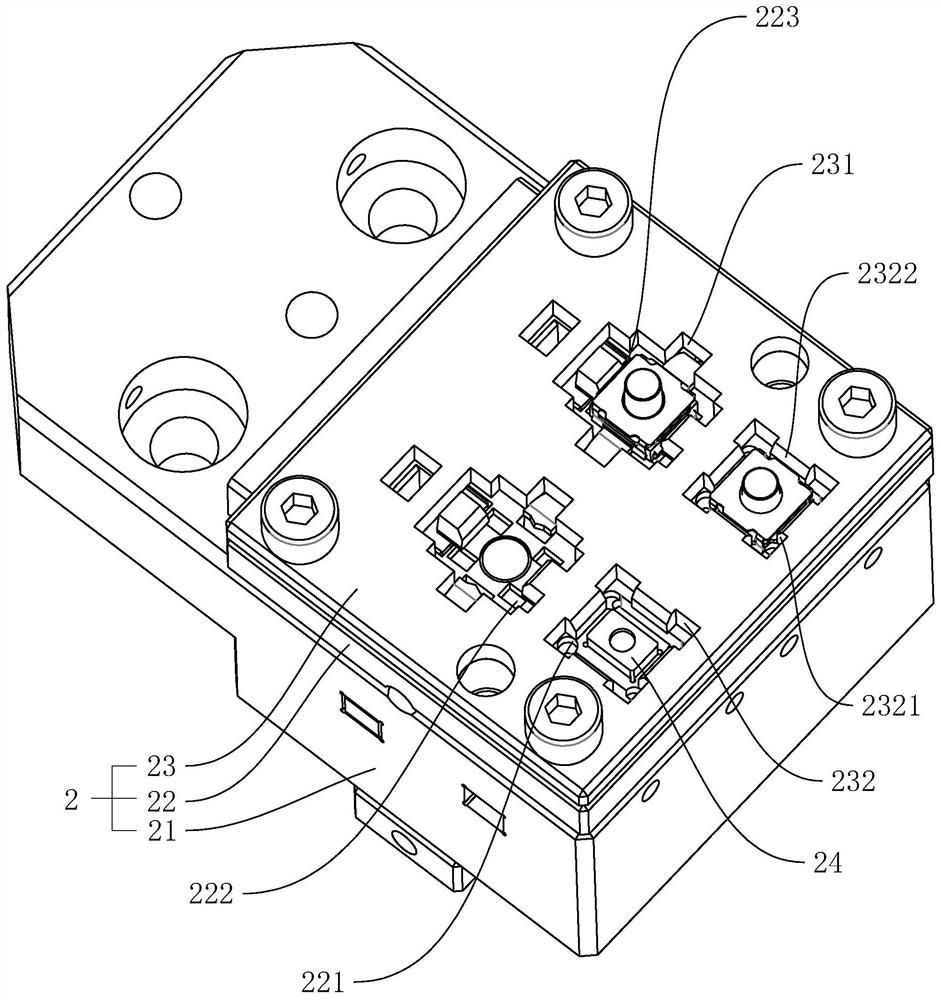

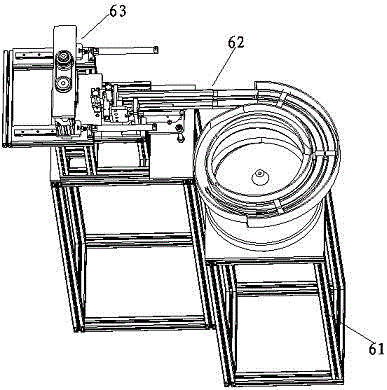

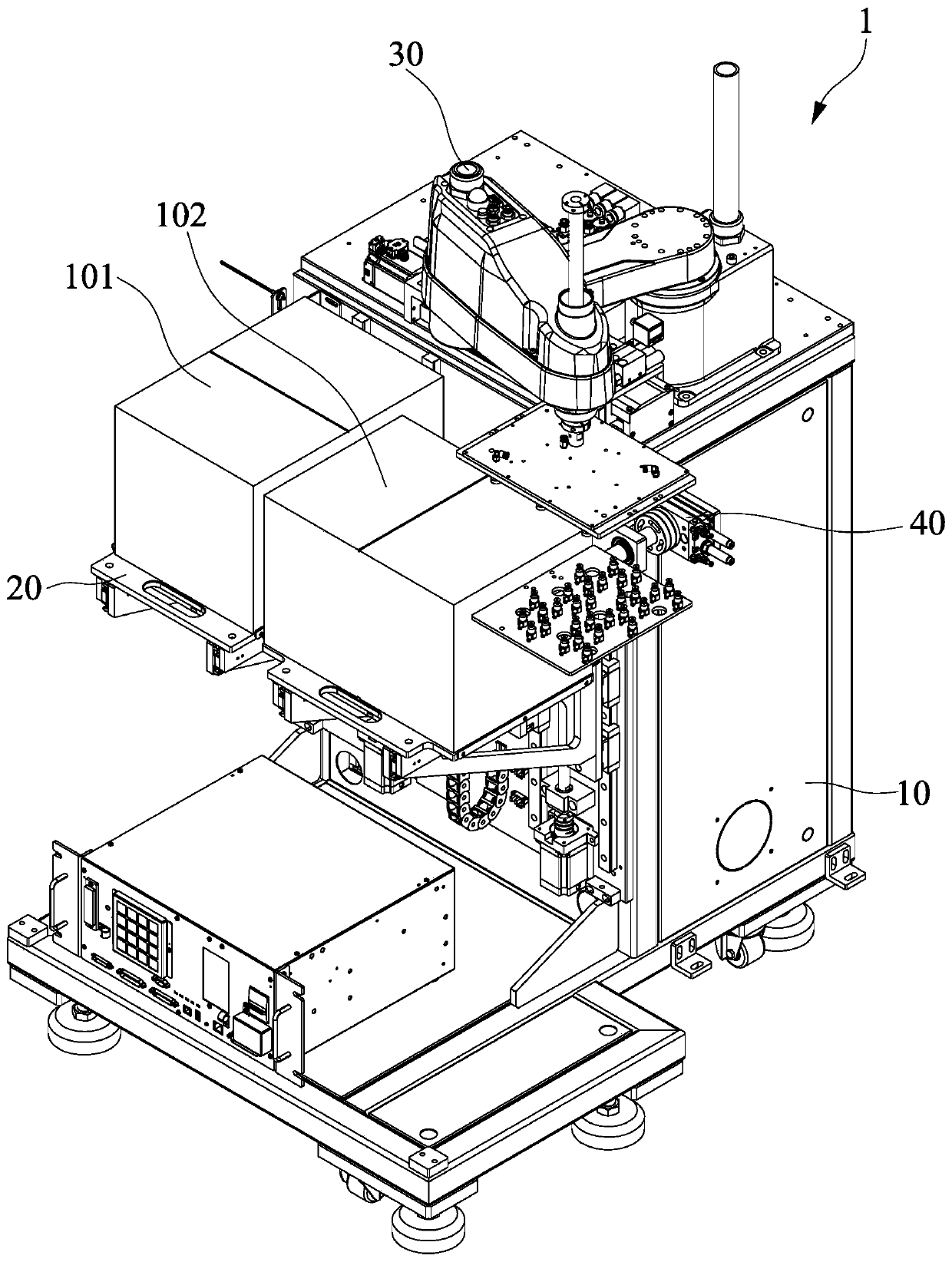

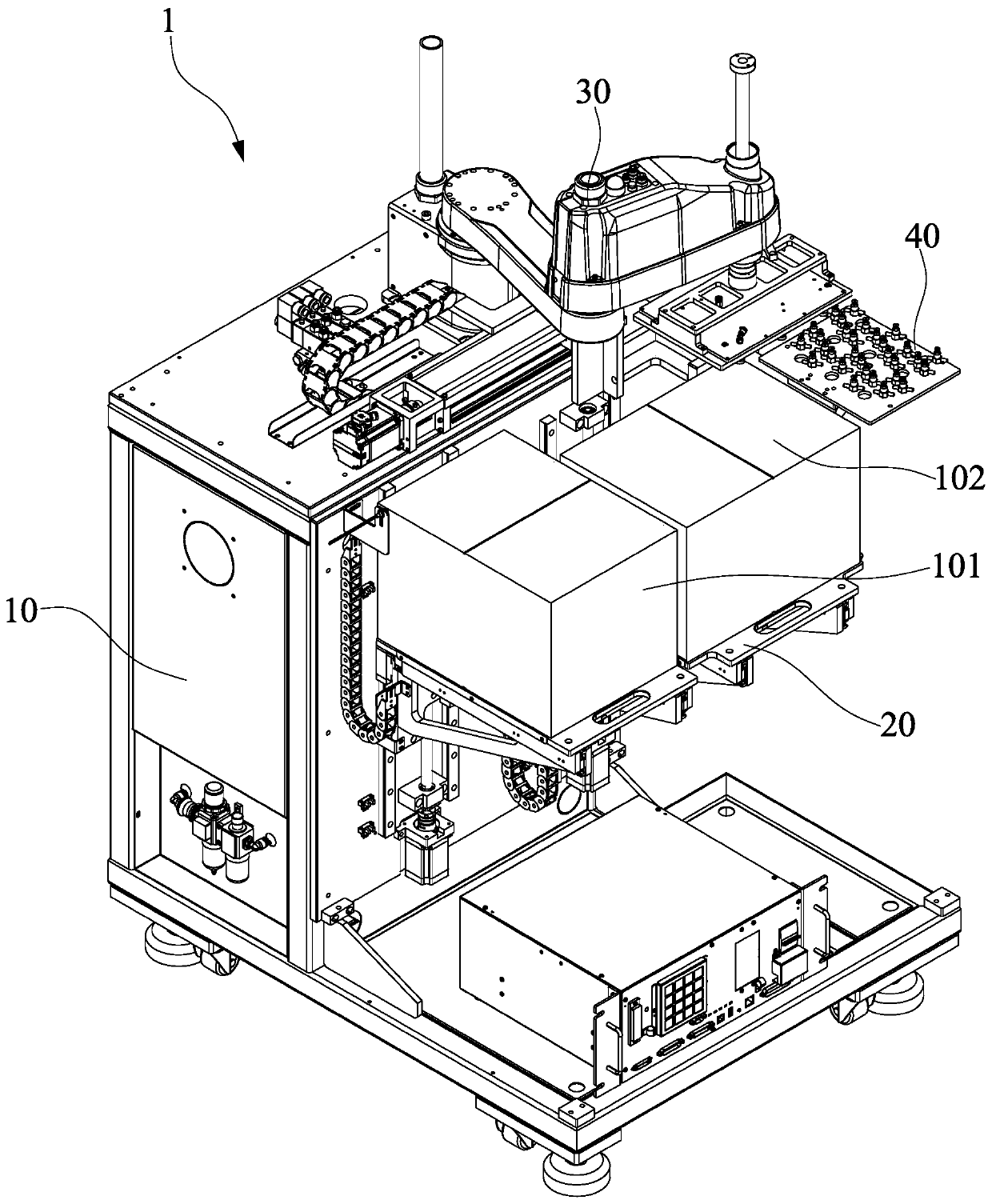

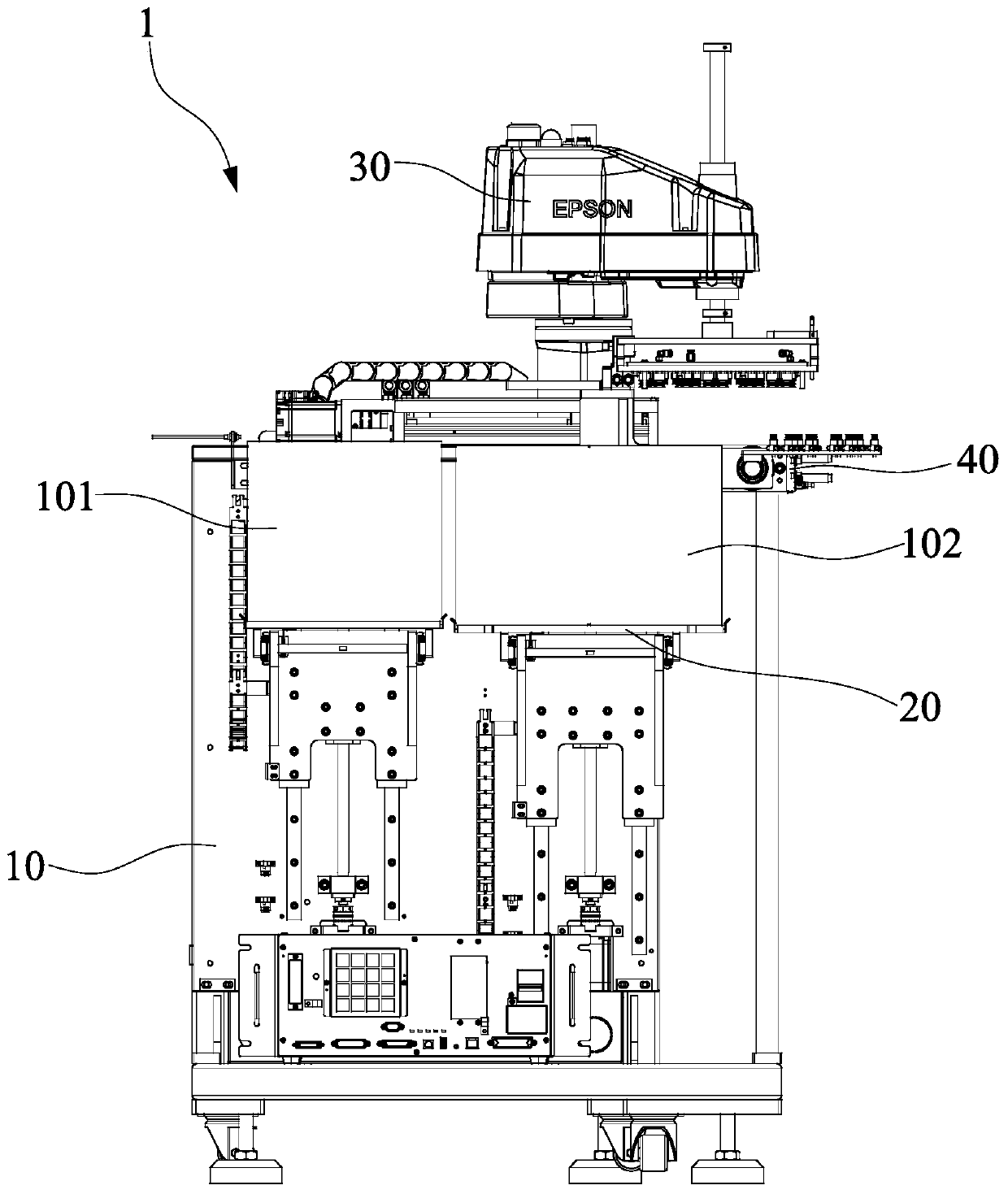

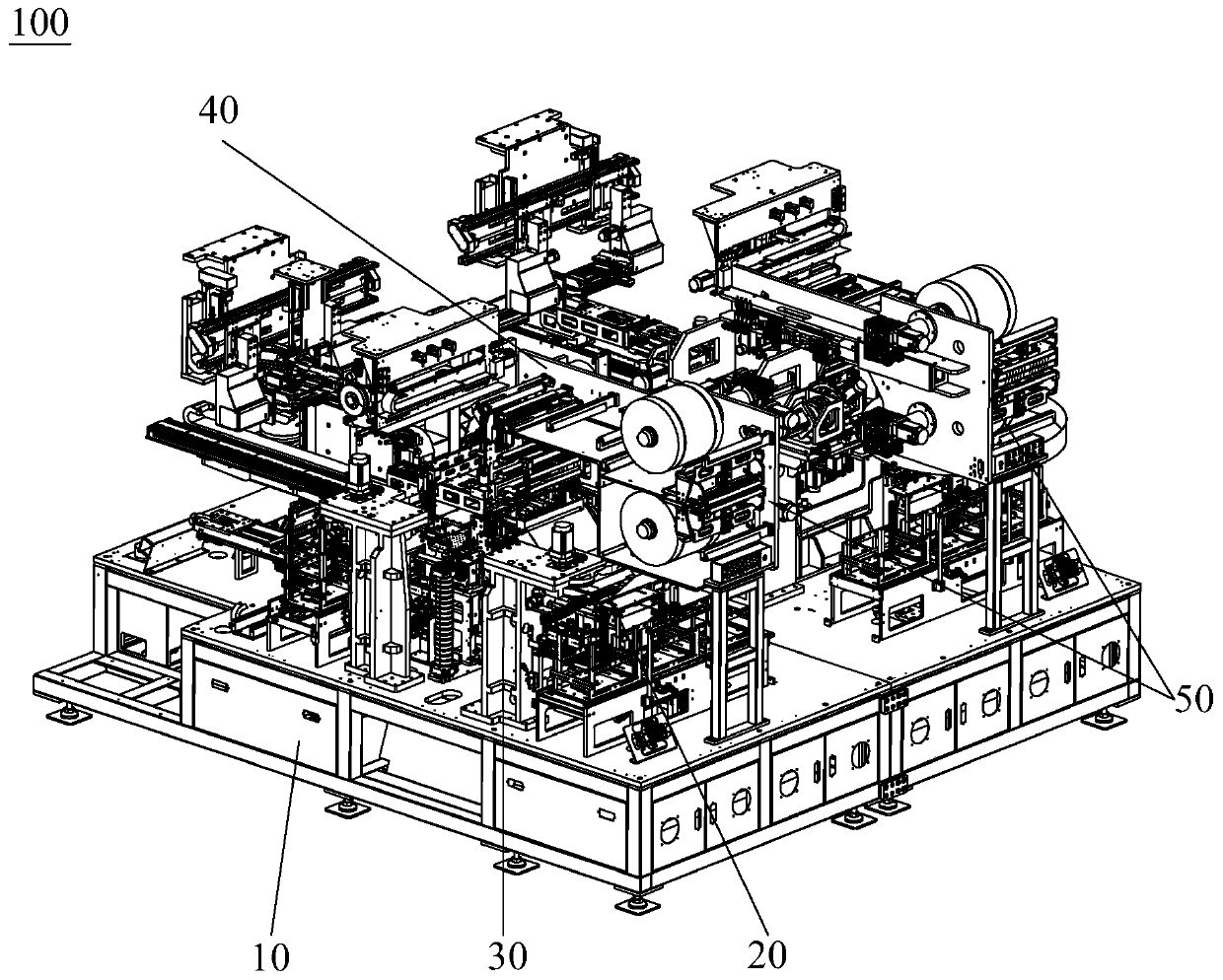

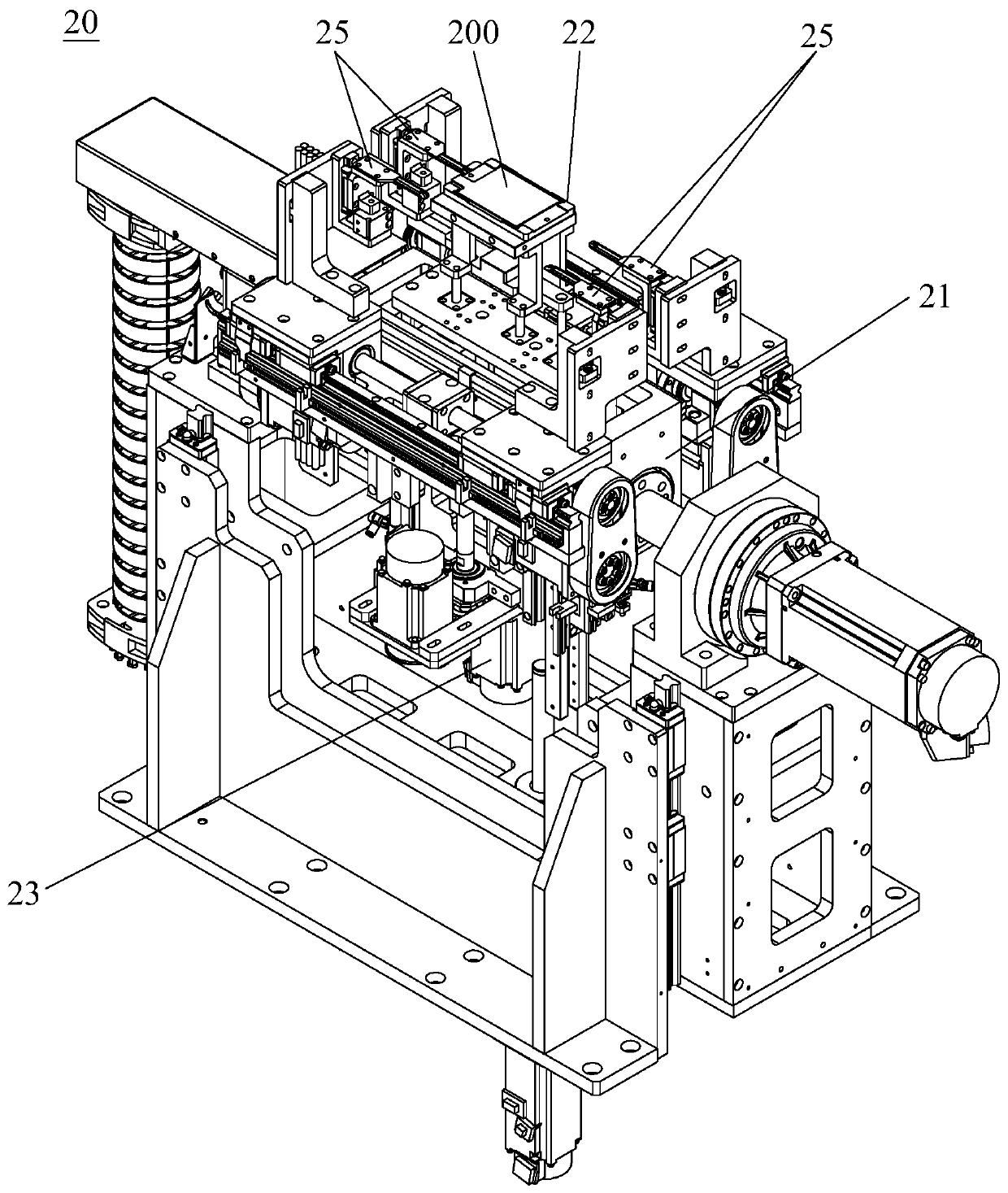

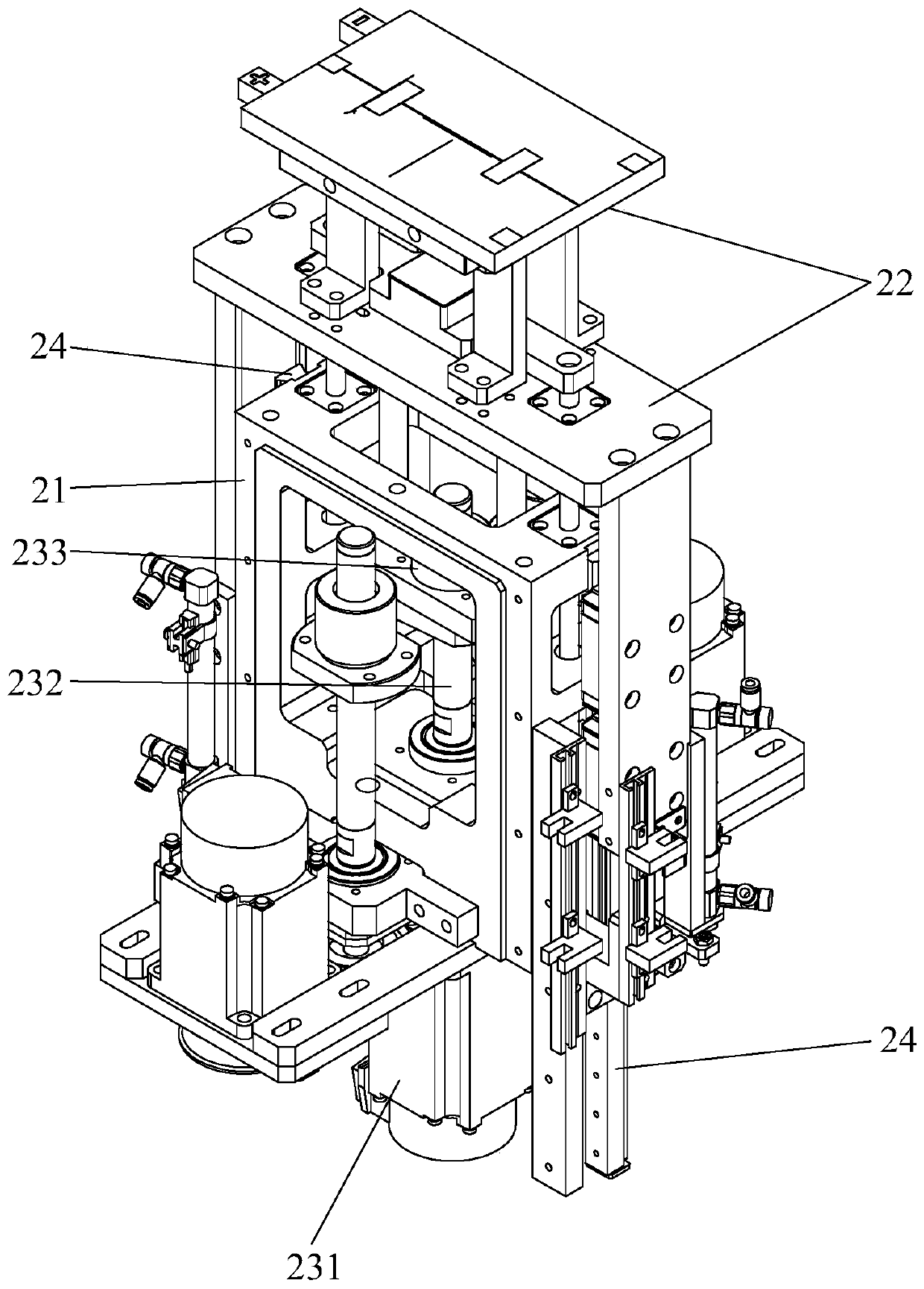

Full-automatic assembling equipment for micro touch switch

ActiveCN112518312AImprove assembly efficiencyImprove assembly accuracyAssembly machinesElectric switchesStructural engineeringIndustrial engineering

The invention discloses full-automatic assembling equipment for a micro touch switch. According to the technical scheme, the full-automatic assembling equipment is characterized in that the full-automatic assembling equipment comprises a stand, the upper end of the stand is connected with a rotary disc, the rotary disc is rotationally connected with the stand, a plurality of jigs are arranged on the side wall of the rotary disc, and first assembling grooves and second assembling grooves are formed in the upper ends of the jigs respectively; a base feeding mechanism, an elastic sheet feeding mechanism, a button feeding mechanism, an upper cover feeding mechanism, an assembling mechanism, a clamping mechanism used for clamping an upper cover and a base, and a discharging mechanism are also included; and the base feeding mechanism, the elastic piece feeding mechanism, the button feeding mechanism, the upper cover feeding mechanism, the assembling mechanism, the clamping mechanism and thedischarging mechanism are sequentially arranged around the rotary disc and each correspond to one jig. The full-automatic assembling equipment is reasonable in structure; the base, an elastic piece, abutton and the upper cover are sequentially fed through the plurality of mechanisms, and then the base, the elastic piece, the button and the upper cover are assembled and discharged; and at the moment, switch assembling does not need to be conducted manually any more, and the switch production efficiency is improved.

Owner:SHENZHEN GANGYUAN MICRO KEY TECH CO LTD

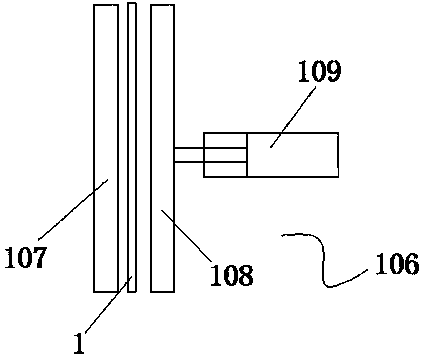

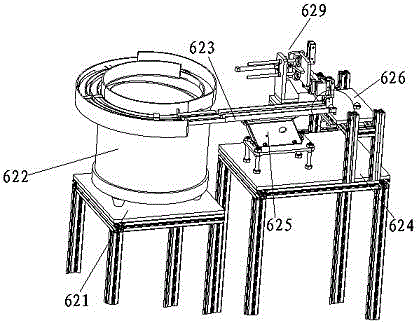

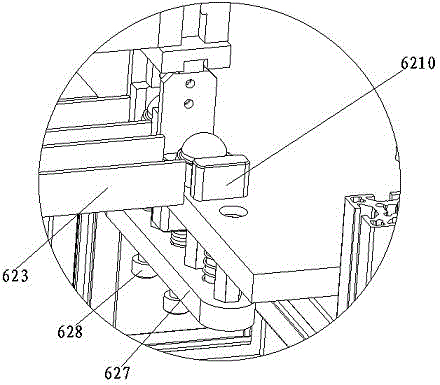

Nut feeding device of solenoid valve part assembly machine

ActiveCN106363386ASimple structureEasy to operateMetal working apparatusSolenoid valveAssembly machine

The invention discloses a nut feeding device of a solenoid valve part assembly machine. The nut feeding device of the solenoid valve part assembly machine comprises a nut feeding rack, wherein the nut feeding rack is installed on the ground, a nut discharging device is installed on the nut feeding rack, the nut discharging device comprises a nut vibration disk mounting plate which is installed on the nut feeding rack, a nut vibration disk is installed on the upper plane of the nut vibration disk mounting plate, nut conveying tanks are respectively installed at two discharge ports of the nut vibration disk, a discharge installation bottom plate is further installed on the nut feeding rack, a nut vibrator is installed on the upper plane of the discharge installation bottom plate by virtue of a nut vibrator bracket, the nut vibrator is fixed to the lower end surfaces of the two nut conveying tanks, a nut placing plate is installed on the nut feeding rack, and a lifting bolt mounting plate is fixed to one end of the lower end surface of the nut placing plate by virtue of a support pillar. In the mode, the nut feeding device has the advantages of convenience in feeding and operation and high working efficiency.

Owner:HEXIAN KEJIA VALVE CASTING

Film coating equipment for photovoltaic solar module production and working method thereof

ActiveCN114311644AHigh degree of automationAvoid injuryFinal product manufacturePhotovoltaic energy generationPhotovoltaic solar energyEngineering physics

The invention relates to the technical field of photovoltaic solar module film covering, in particular to film covering equipment for photovoltaic solar module production and a working method thereof.The film covering equipment comprises a supporting frame, a feeding assembly, a conveying assembly, a film covering roller, a film covering assembly, a film cutting assembly and a film pressing wheel; according to the film laminating equipment, the film laminating roller and the film laminating assembly are used for laminating in the conveying process, and the connected film is cut by the film cutting assembly, so that the film laminating equipment can be used for automatically laminating the photovoltaic solar panel in a streamlined manner, and all links of the film laminating equipment do not need to be manually operated by automatically laminating the film, so that the labor intensity of workers is reduced, and the production efficiency is improved. Compared with the prior art, labor is saved, meanwhile, the situation that personnel are hurt by the equipment or the photovoltaic solar panel in the manual operation process is avoided, and meanwhile, through film laminating streamline of the equipment, all links of film laminating of the equipment are matched more tightly, and the film laminating speed is higher.

Owner:ANHUI GUOCHENG PHOTOELECTRIC TECH CO LTD

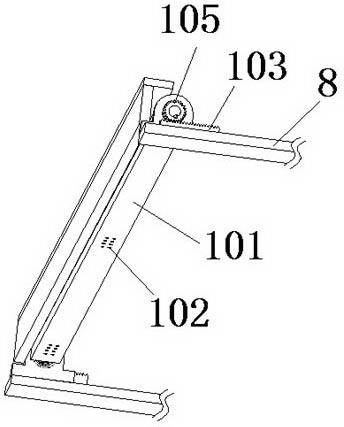

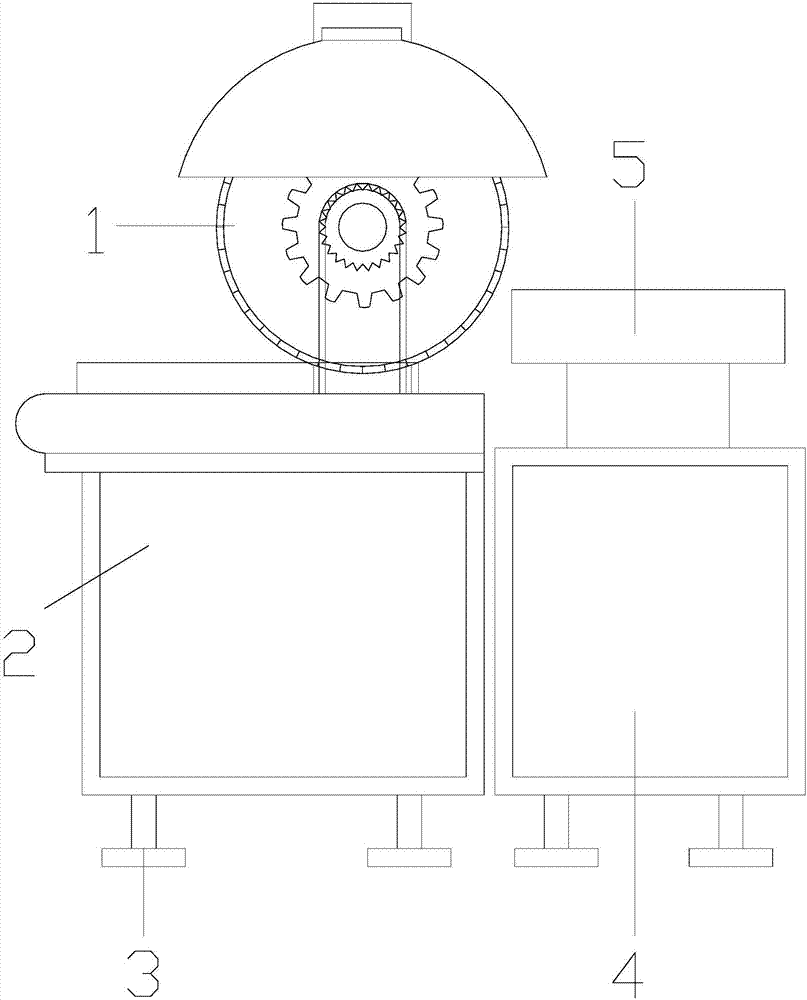

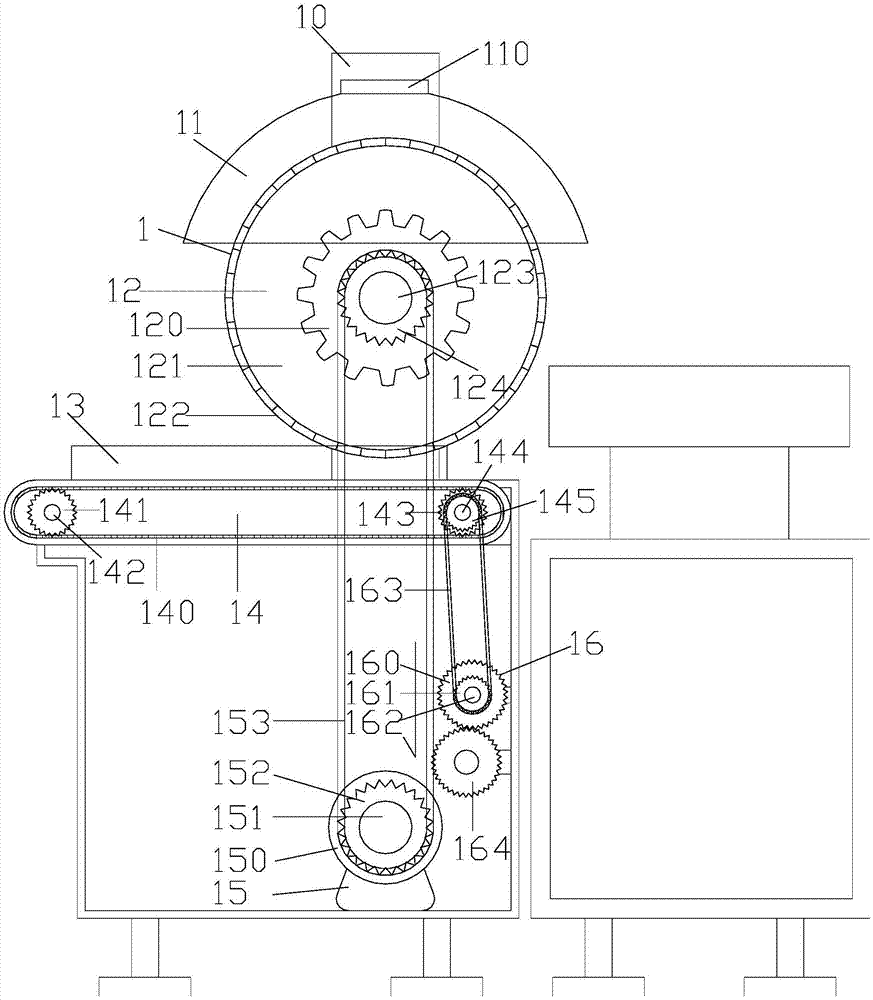

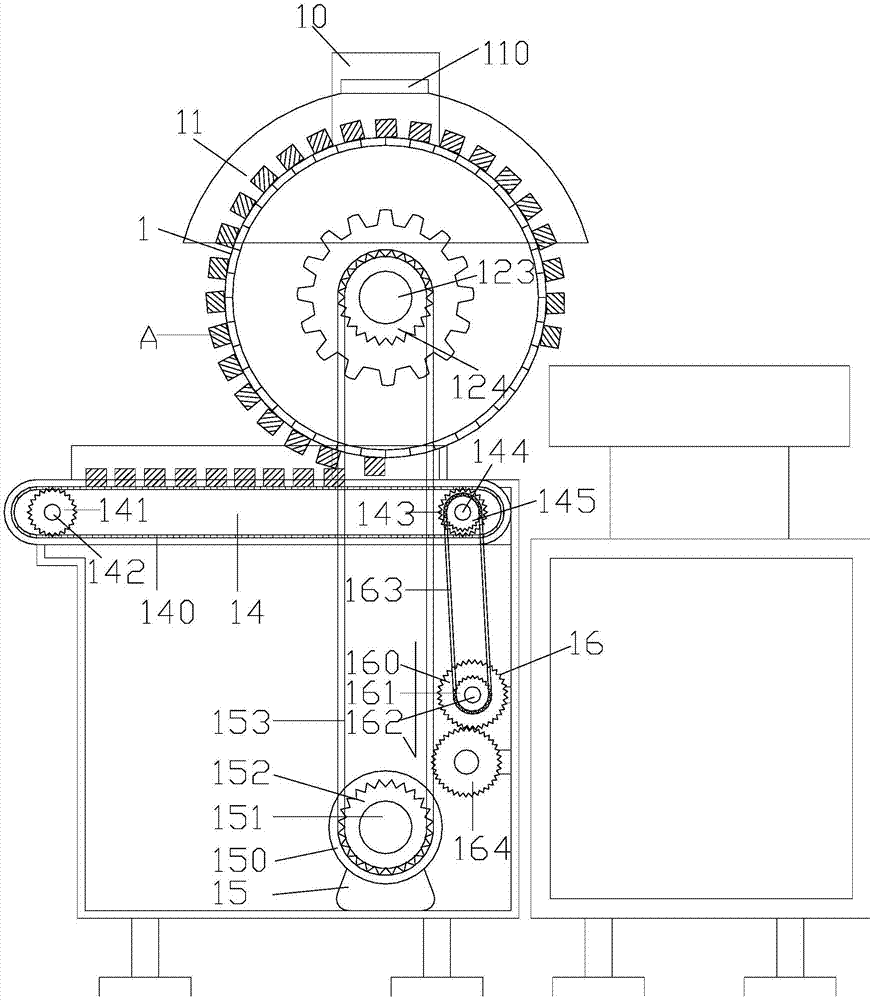

Full-automatic plate strip feeding machine for thin-film capacitor production

ActiveCN107963417ARealize automatic feeding processReduce labor requirementsThin/thick film capacitorStacked capacitorsEngineeringMechanical engineering

The invention discloses a full-automatic plate strip feeding machine for thin-film capacitor production. The structure of the full-automatic plate strip feeding machine for thin-film capacitor production comprises an automatic conveying mechanism, an operation box, eight supporting legs, an operation round disk and a round disk operation box. The automatic conveying mechanism is arranged on the operation box. The eight supporting legs are evenly divided into two groups, the two groups of supporting legs are arranged on the lower side of the operation box and the lower side of the round disk operation box correspondingly, and connection is reinforced through bolts. The round disk operation box and the operation box are located on the same plane. The operation round disk is movably connectedto the round disk operation box through a shaft. The automatic conveying mechanism is composed of a supporting vertical rod, an upper protective cover, a rotating disk conveying mechanism, a protective baffle, a conveying platform, a motor start mechanism and a conveying mechanism. The supporting vertical rod is perpendicularly welded to the upper side of the conveying platform and is reinforcedthrough a bolt. When the full-automatic plate strip feeding machine for thin-film capacitor production conducts feeding, the demand for manual labor can be lowered, automatic feeding can be achieved,the feeding position is more accurate, and the work efficiency is greatly improved.

Owner:东台市高科技术创业园有限公司

Automatic feeding and discharging machine for punching

PendingCN110328711AReliable grabbingPrecise feeding positionMetal working apparatusPrinted circuit boardEngineering

The invention discloses an automatic feeding and discharging machine for punching. The machine comprises a rack, a feeding and discharging mechanism and a mechanical arm mechanism. The feeding and discharging mechanism comprises a feeding assembly and a discharging assembly, the feeding assembly and the discharging assembly are arranged on the front end of the rack side by side in an up and down sliding manner, the mechanical arm mechanism is arranged above the rack, and comprises mechanical arms and a suction cup jig, the mechanical arms are arranged on the rack and can move above the feedingand discharging mechanism, the suction cup jig can be rotatably arranged below the mechanical arms, the suction cup jig is provided with multiple air channels which are independently arranged, duringfeeding, the mechanical arm drives the suction cup jig to suck a product or tray from the position above the feeding assembly, during discharging, the mechanical arms drive the suction cup jig to place the product or tray to the position above the discharging assembly, automation of the punching process of a printed circuit board can be achieved, intelligent manufacturing is achieved, labor forceis saved, production efficiency is improved, the product machining quality is stabilized, and the economic benefits are improved.

Owner:XIAMEN HONGXIN ELECTRON TECH +1

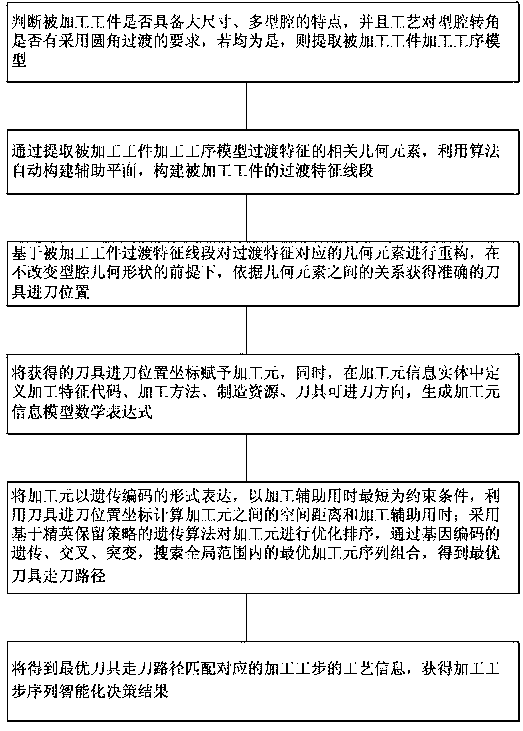

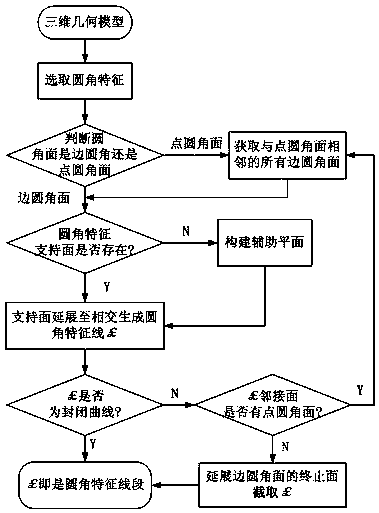

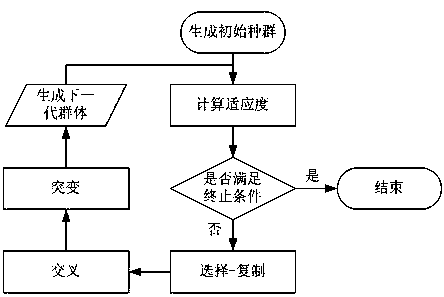

Multi-cavity structural part processing step sequence decision method based on transition characteristic simplification

ActiveCN110412938APrecise feeding positionTo achieve an organic combinationTotal factory controlNumerical controlAlgorithmGenetic algorithm

The invention discloses a multi-cavity structural part processing step sequence decision method based on transition characteristic simplification. The method sequentially comprises the steps that thecharacteristics and cavity corner requirements of a processed workpiece are judged, and a processing procedure model of the processed workpiece is extracted from a three-dimensional processing technology design system; an algorithm is utilized to automatically construct an auxiliary plane by extracting relevant geometric elements of transition characteristics, and transition characteristic segments are constructed; the geometric elements corresponding to the transition characteristics are reconstructed based on the transition characteristic segments, and an accurate tool advancing position isobtained according to the relation among the geometric elements; processing elements are given to coordinates of the obtained tool advancing position, technological information is defined in a processing element information entity, and a mathematical expression of a processing element information model is generated; a genetic algorithm of an elitism strategy is adopted to perform optimal orderingon the processing elements, and an optimal tool feeding path is obtained; and finally the obtained optimal tool feeding path is matched with the technological information of corresponding processing steps, and an intelligent decision result of a processing step sequence is obtained.

Owner:TAIYUAN UNIV OF TECH

Full-automatic polishing machine

InactiveCN106002581ASimple structureEasy to automateGrinding carriagesPolishing machinesEngineeringMechanical engineering

The invention discloses a full-automatic polishing machine. The full-automatic polishing machine comprises a machine frame. A material clamping wheel is rotationally borne on the machine frame. A polishing wheel base is further movably borne on the machine frame relative to the radial direction of the material clamping wheel. A polishing wheel is rotationally borne on the polishing wheel base. The axis of the material clamping wheel and the axis of the polishing wheel are arranged in parallel. A material frame is further arranged on the machine frame. A feed device is arranged outside a feed position at the tail end of the material frame. The feed route of the feed device is located between the material clamping wheel and the polishing wheel. An opening and closing material guide device is arranged between the inner side of the material frame and the polishing wheel. An axial limiting device is arranged on the side opposite to the feed device. A supporting and holding rotating shaft is arranged below the feed route of the feed device and rotationally borne on the machine frame. A conveying device is arranged below the supporting and holding rotating shaft. By means of the full-automatic polishing machine, the automatic operation of shaft type parts can be achieved in the process from feeding, clamping and polishing to discharging, and the production efficiency is high.

Owner:YANCHENG SIKEDA MACHINERY TECH

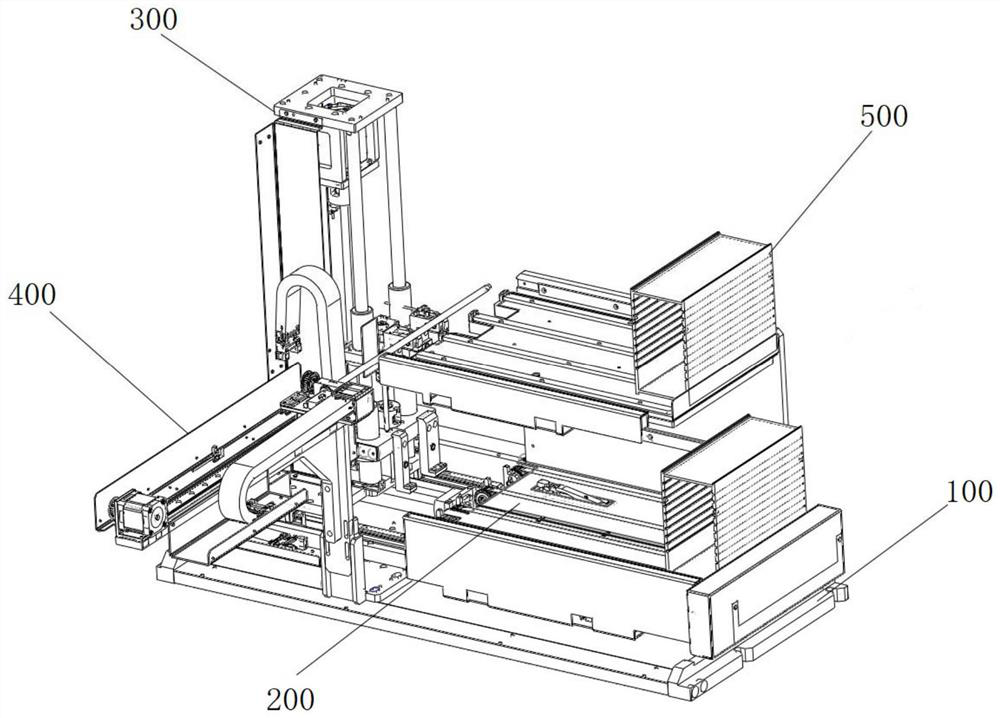

High-precision stacking machine

PendingCN110010974APrecise feeding positionStacking AccurateFinal product manufactureElectrolyte accumulators manufactureStack machineMechanical engineering

The invention discloses a high-precision stacking machine, comprising a frame, a stacking table for stacking battery pole pieces, and a pick-and-place mechanism for clamping the battery pole pieces and placing the same on the stacking table. The pick-and-place mechanism and the stacking table are all disposed on the frame. The stacking table comprises a rack fixed to the frame, a worktable for stacking the battery pole pieces, and a driving device connected to the worktable. The worktable, after receiving the battery pole pieces placed by the pick-and-place mechanism every time, is driven by the driving device to move a preset distance downwards in the height direction of the frame. The worktable downwards moves the preset distance so that the pick-and-place mechanism discharges the battery pole pieces at the same height relative to the frame every time. Thus, the pick-and-place mechanism can achieve an accurate discharging position and ensures accurate stacking between the battery pole pieces. In addition, the stacking efficiency of the high-precision stacking machine is also increased due to the reduced path of the pick-and-place mechanism.

Owner:DONGGUAN CHAOHONG AUTOMATION EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com