High radio frequency closed type ammunition-belt-removing ammunition-supplying mechanism

An off-chain and ammunition feeding technology, applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of low structural strength requirements, low working frequency, incompetent conventional structures, etc., to reduce strength requirements and ensure reliable operation. the effect of diversifying structural risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

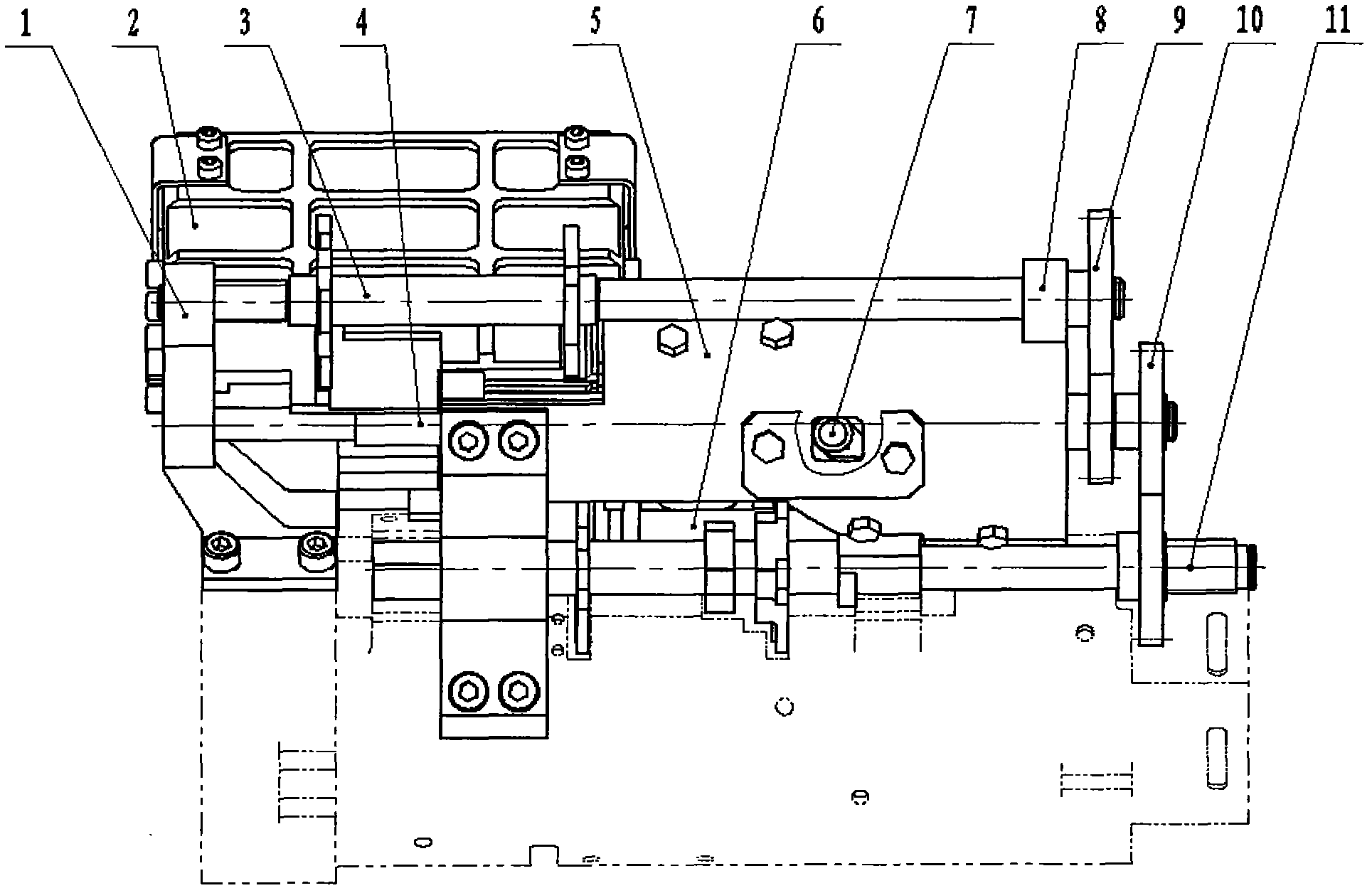

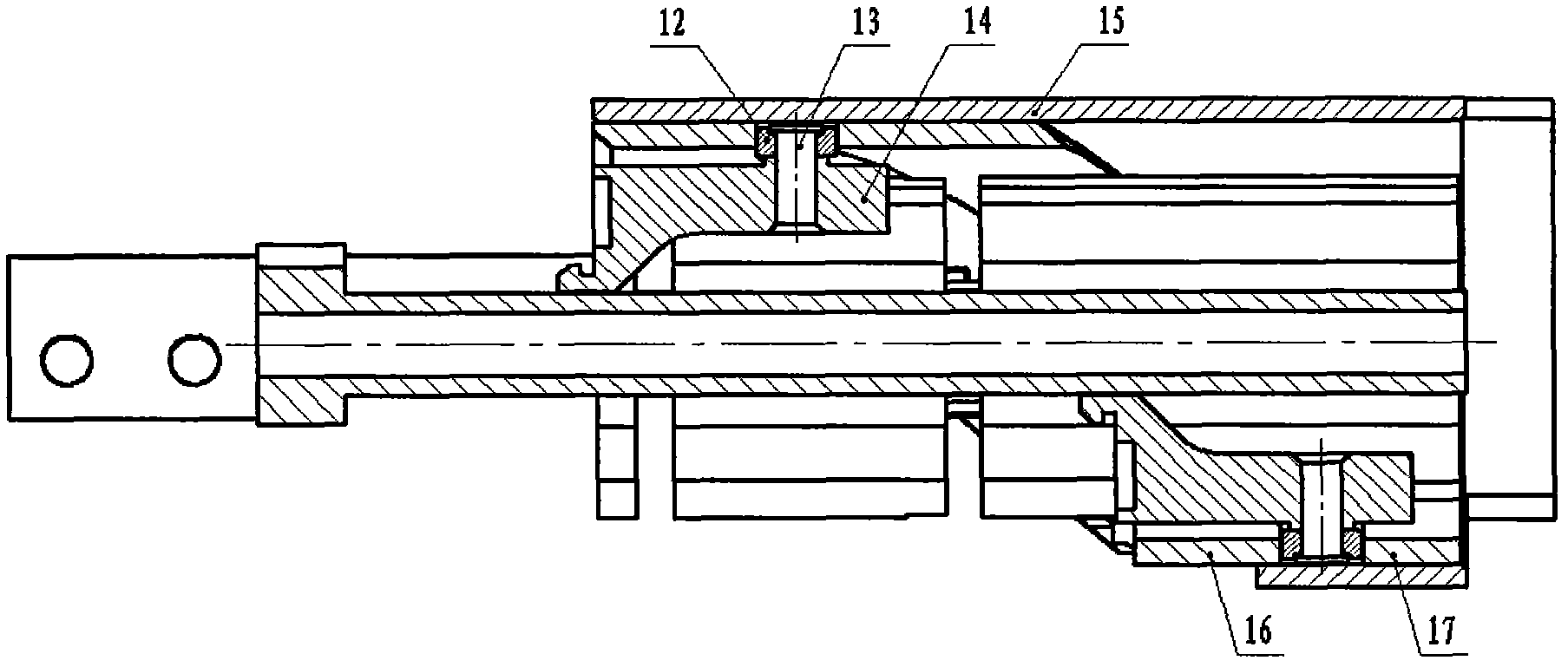

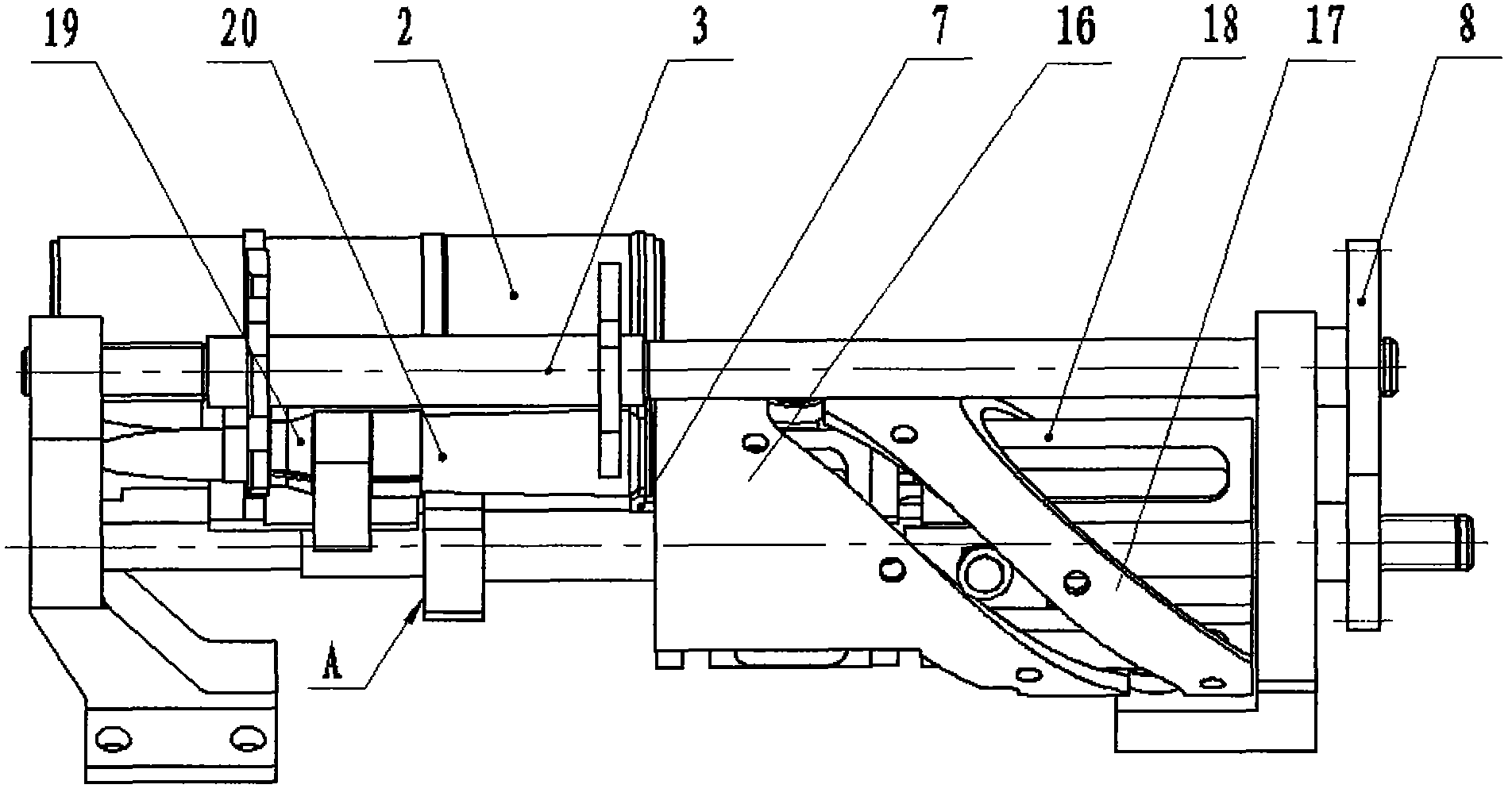

[0040] Below, combined with figure 1 and 2 , to describe in detail the high-frequency closed-type bullet chain-off-chain bomb feeding mechanism of the present invention.

[0041] figure 1 It is an overall schematic diagram of the high-frequency closed-type bullet chain-off-chain bomb feeding mechanism of the present invention. Such as figure 1 As shown, the high-frequency closed-type bullet chain-off-chain feeding mechanism of the present invention includes: front axle seat 1, ammunition delivery box part 2, front dial elastic wheel part 3, off-chain planetary body part 4, and off-chain curved groove part 5 , Missile plate 6, 4 off-chain cores 7, rear axle base 8, off-chain gear set 9, bullet feeding gear set 10 and dial wheel parts 11.

[0042] The ammunition feeding box part 2 is fixedly connected to the front shaft seat 1 and the off-chain curved groove part 5 by screws, and the four off-chain cores 7 are introduced into the off-chain planetary part 4 through T-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com