Small-sized energy-saving air-cooled thermal insulation absorption gas air-conditioning plant

An air-conditioning device and air-cooling technology, which is applied in energy-saving heating/cooling, refrigerators, adsorption machines, etc., can solve the problems of large water vapor pressure loss, endangering human health, and lower mass transfer coefficient, so as to alleviate the load difference. Large status, avoiding potential harm to the environment, and enhancing the effect of heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

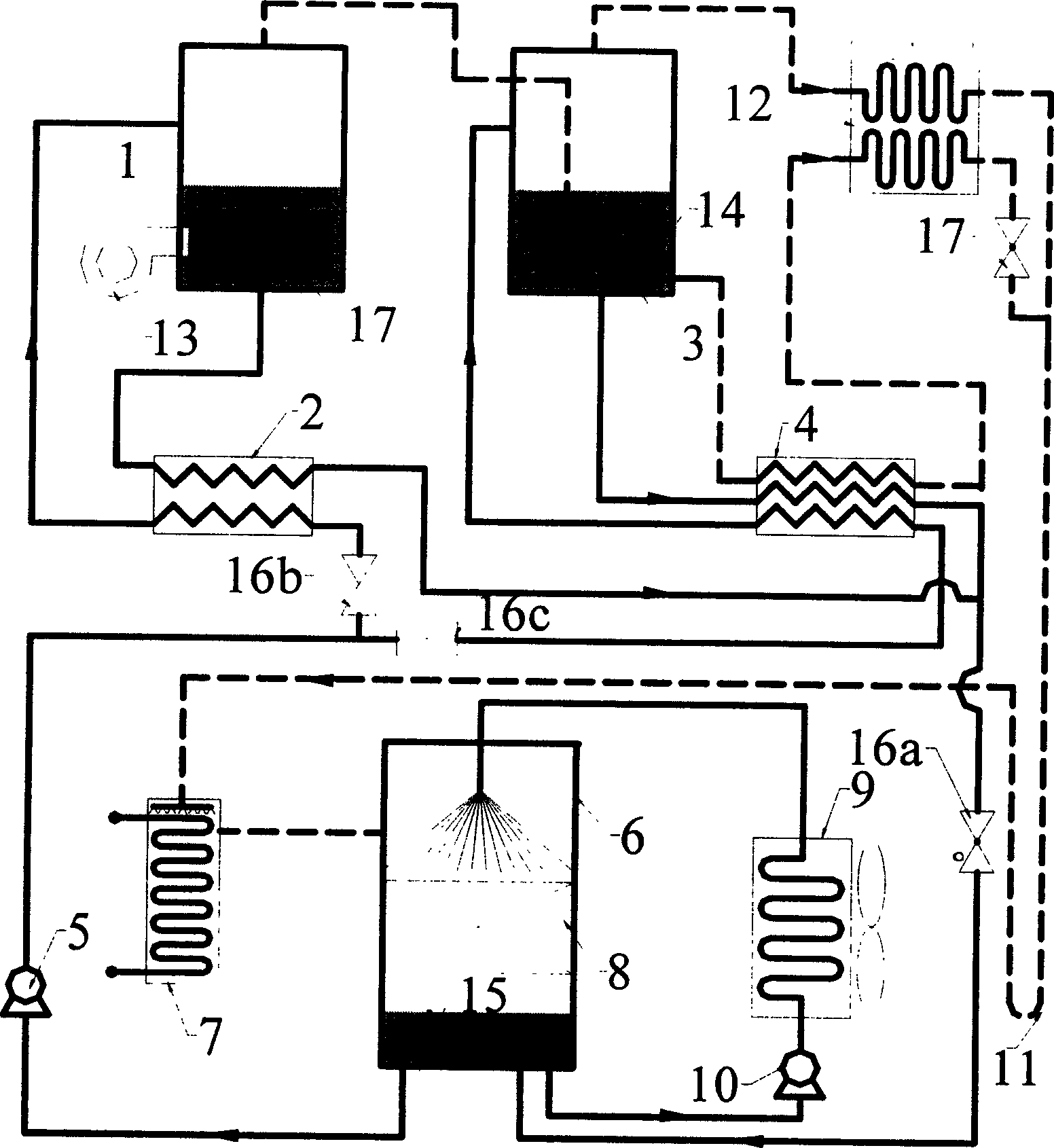

[0007] The small energy-saving air-cooled adiabatic absorption gas-fired air conditioner is a double-effect absorption refrigeration system that recovers the waste heat of saturated refrigerant water, air-cooled adiabatic absorption, and is connected in parallel. It has a high-pressure generator 1, and the high-pressure generator 1 is equipped with a burner 13 and a heat exchanger 17. The high-pressure generator 1 has three interfaces, among which the high-pressure generator 1 dilute solution interface is connected with the high-temperature heat exchanger 2 dilute solution channel outlet Connection, the high-pressure generator 1 concentrated solution interface is connected to the inlet of the high-temperature heat exchanger 2 concentrated solution channel, the high-pressure generator 1 superheated steam interface is connected to the low-pressure generator 3 internal heat exchanger 14, and the other end of the low-pressure generator 3 internal heat exchanger 14 The interface is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com