Automatic testing system and automatic testing method for operation of hydraulic wrench

A hydraulic wrench, automatic inspection technology, applied in the direction of instruments, measuring devices, force/torque/work measurement instrument calibration/testing, etc., can solve problems such as the impact of wind turbine quality, and achieve the effect of preventing potential hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

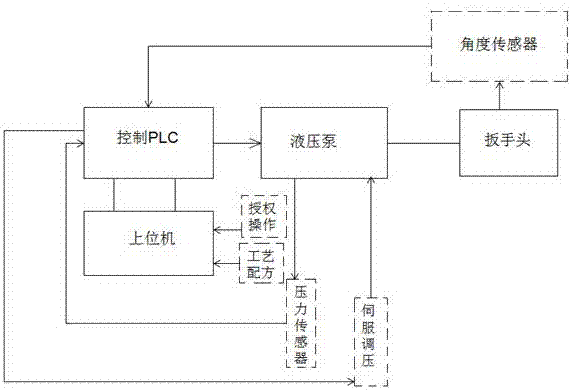

[0012] Such as figure 1 The schematic block diagram of the structure of the hydraulic wrench operation automatic inspection system of the present invention is shown. The upper computer is equipped with a process formula table. According to the type of fan, the process formula table provides the torque value required for bolt tightening, and the calibration of the wrench head is also provided. The report formula converts the torque value into a pressure value and sends it to the PLC controller. The PLC converts the pressure value into a servo motor drive electrical signal and sends it out. The servo motor drives the hydraulic pump to work. A pressure sensor is added to the outlet of the hydraulic pump, and the pressure sensor collects the pressure signal and feeds it back to the PLC. The PLC compares the pressure value corresponding to the output torque value, adjusts the output to the servo motor, and automatically adjusts the pressure of the hydraulic pump to ensure that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com