Patents

Literature

1185results about "Machine valve testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for modality conversion of multimedia contents

InactiveUS20060294546A1Clear expressionTelevision system detailsValve arrangementsContent ModelData mining

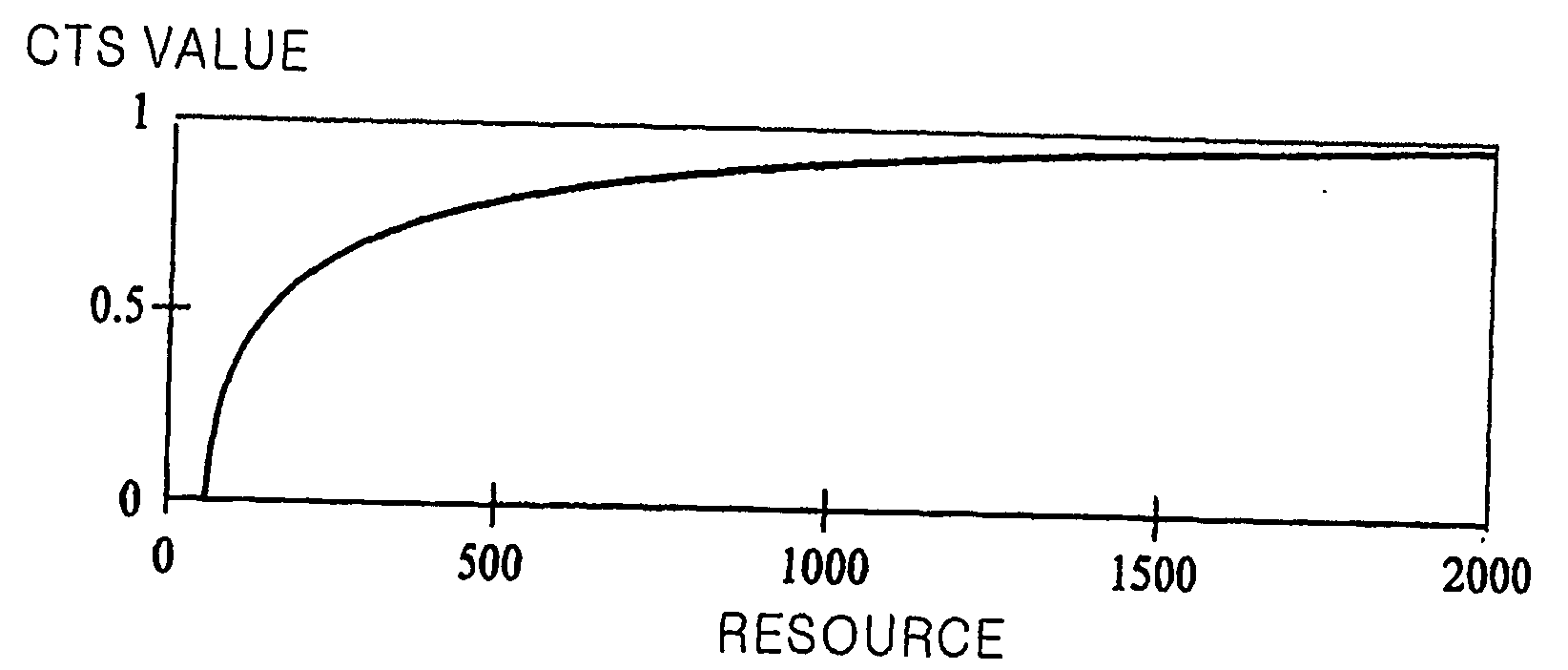

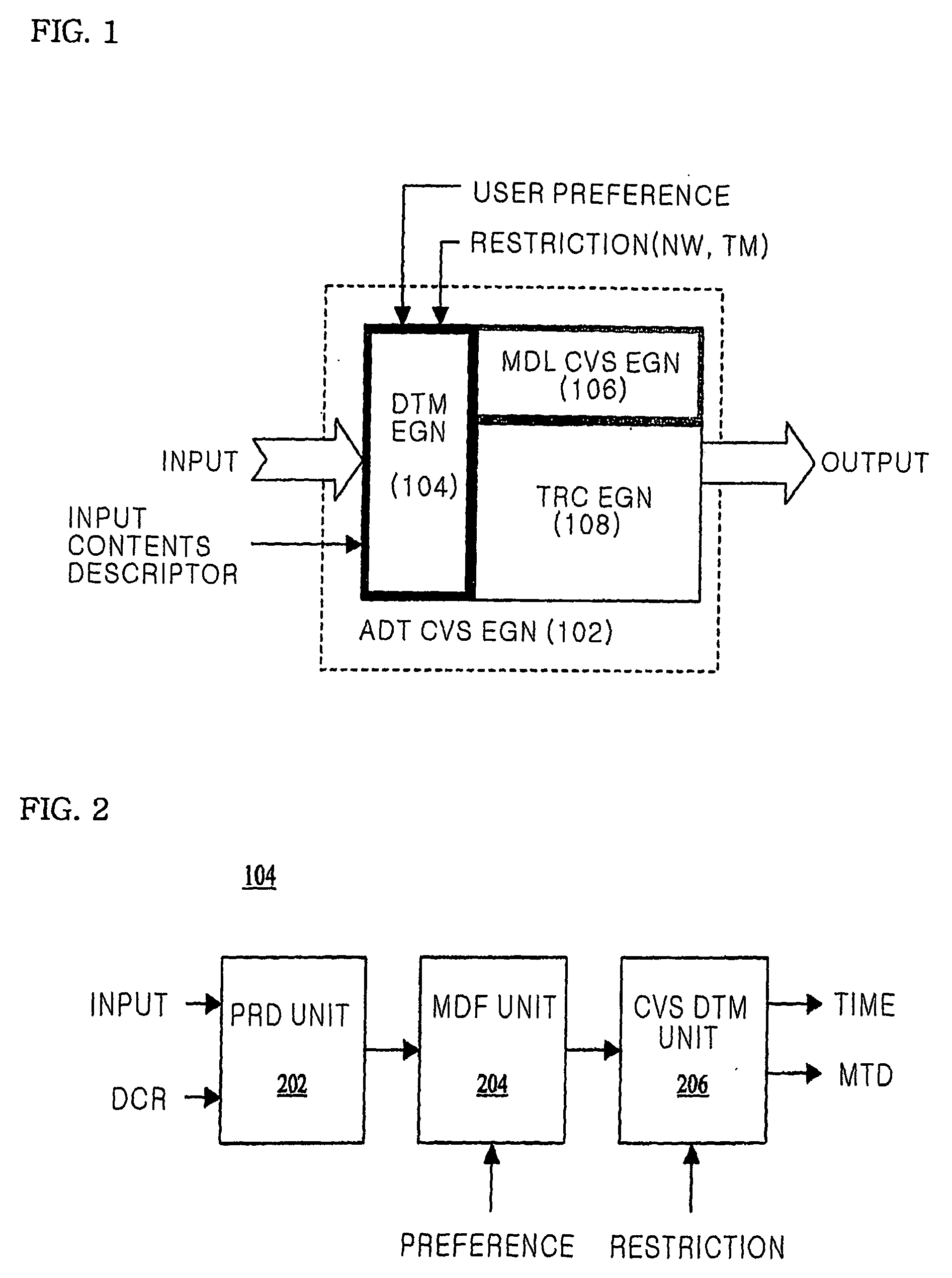

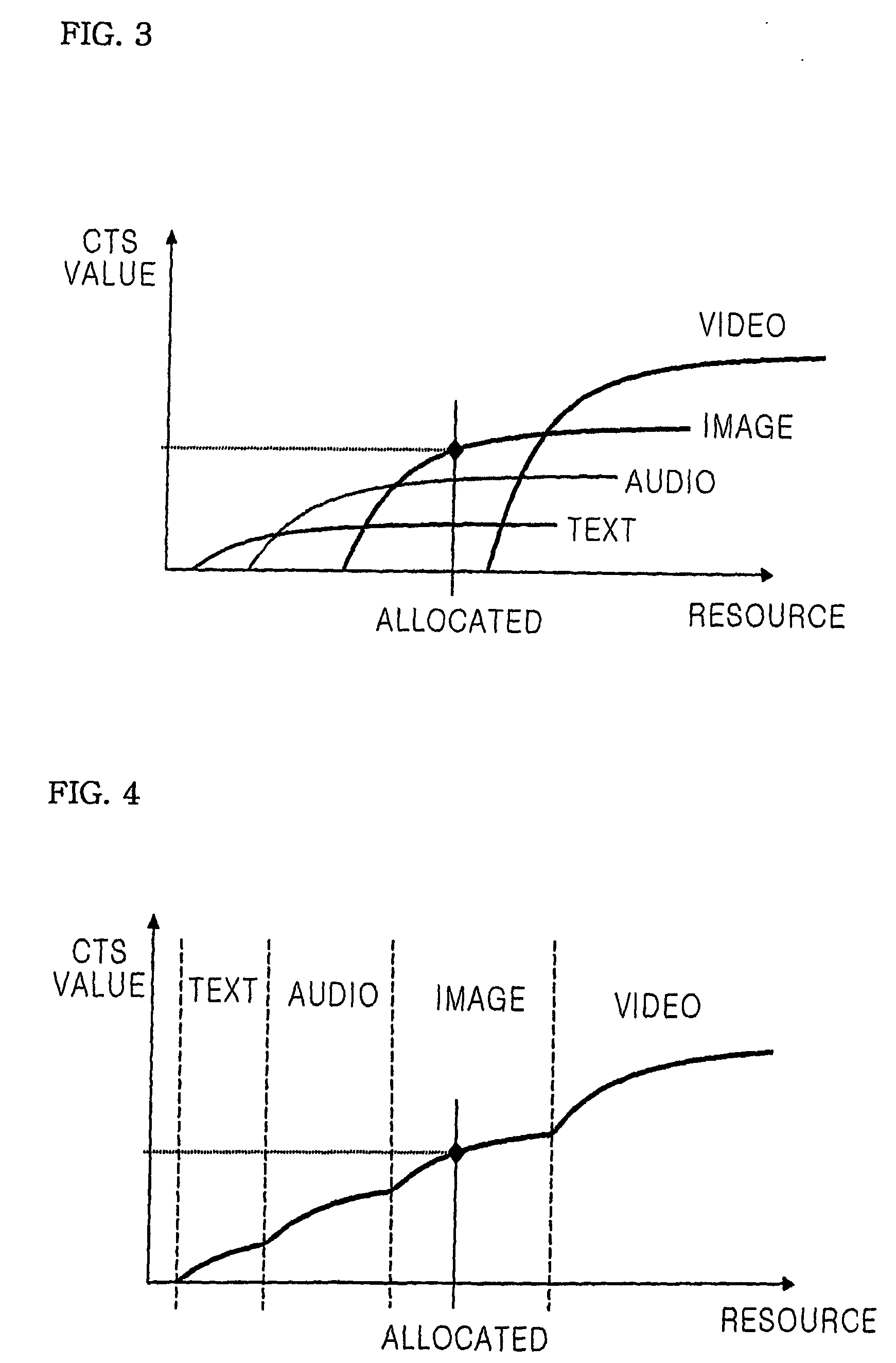

The present invention relates to a method of systematically and synthetically accessing modality conversion that is an important part in the contents adaptive conversion process of a universal multimedia access system. The present invention provides an effective method of solving a problem, which is incurred at the time of modality conversion and still remains as one of difficult problems incurred during adaptive contents conversion. For this purpose, the present invention includes overlapped contents modeling newly proposed to determine modality conversion, a method of flexibly and clearly expressing and applying user preference for the modality conversion, and a resource allocation method of distributing resources among complicated contents based on the user preference. As a result, the integration of the above three methods provides a synthetic solution, particularly, to a problem incurred in the modality conversion and, generally, to a problem incurred in the adaptive conversion of contents.

Owner:ELECTRONICS & TELECOMM RES INST +1

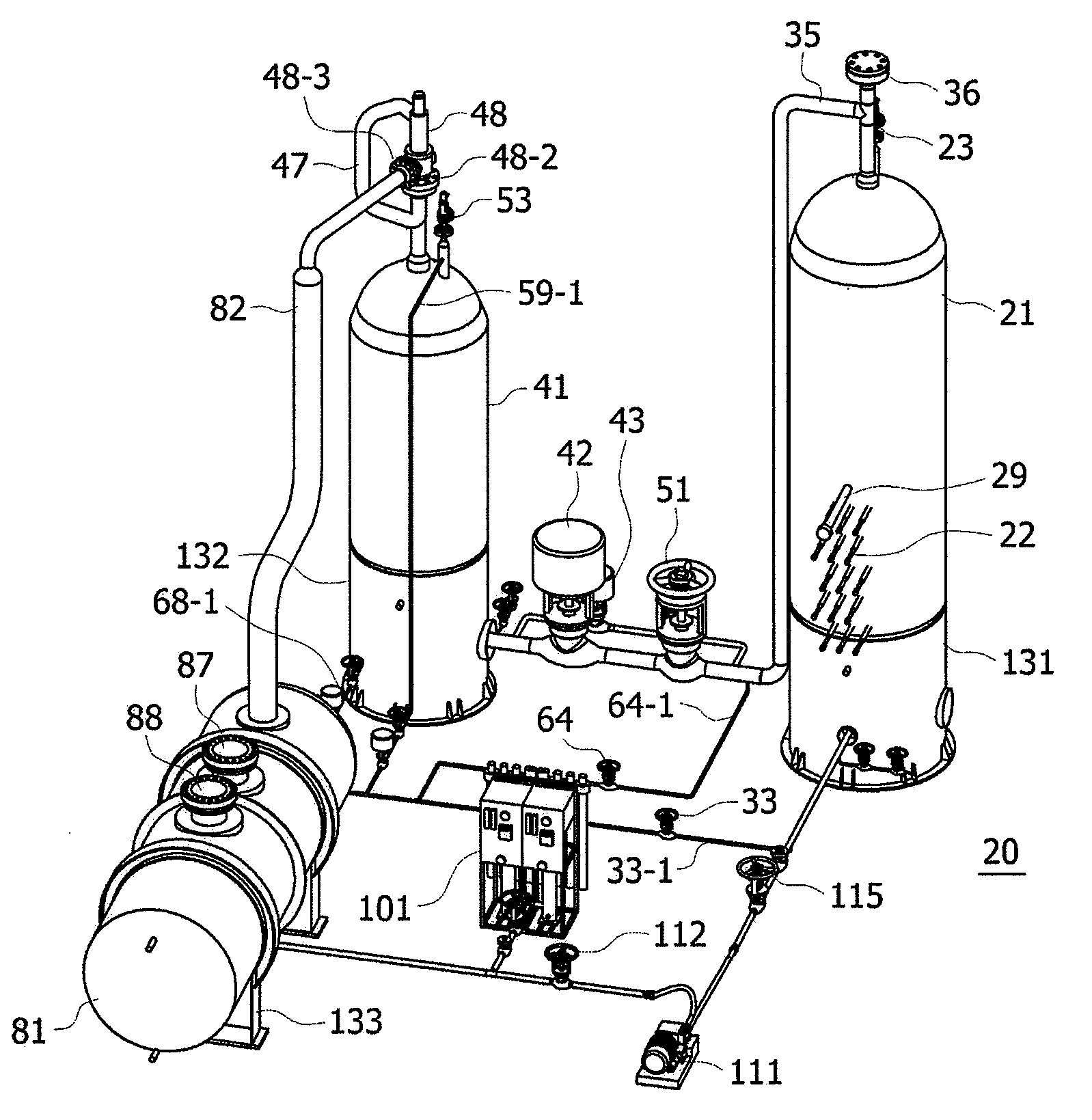

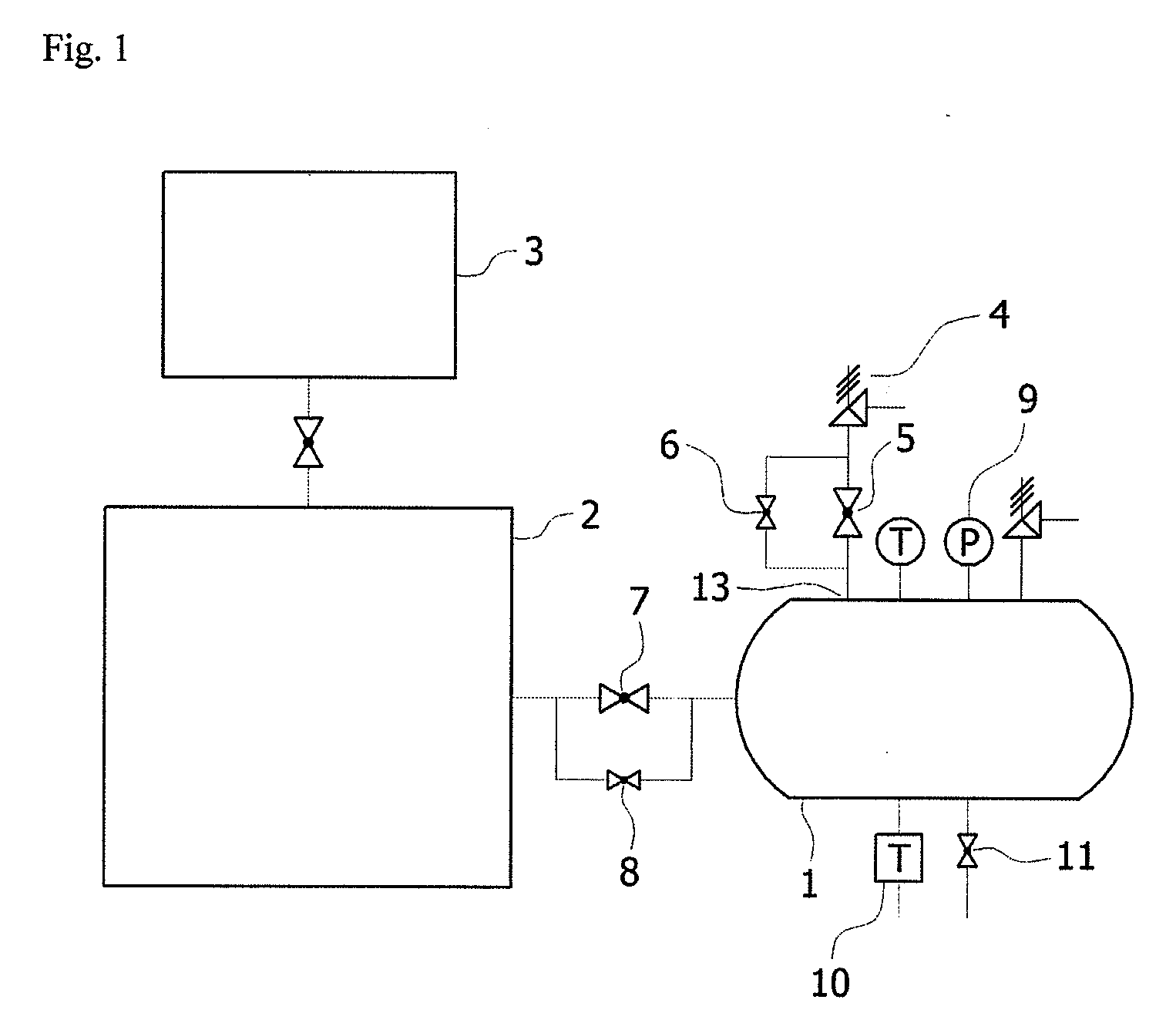

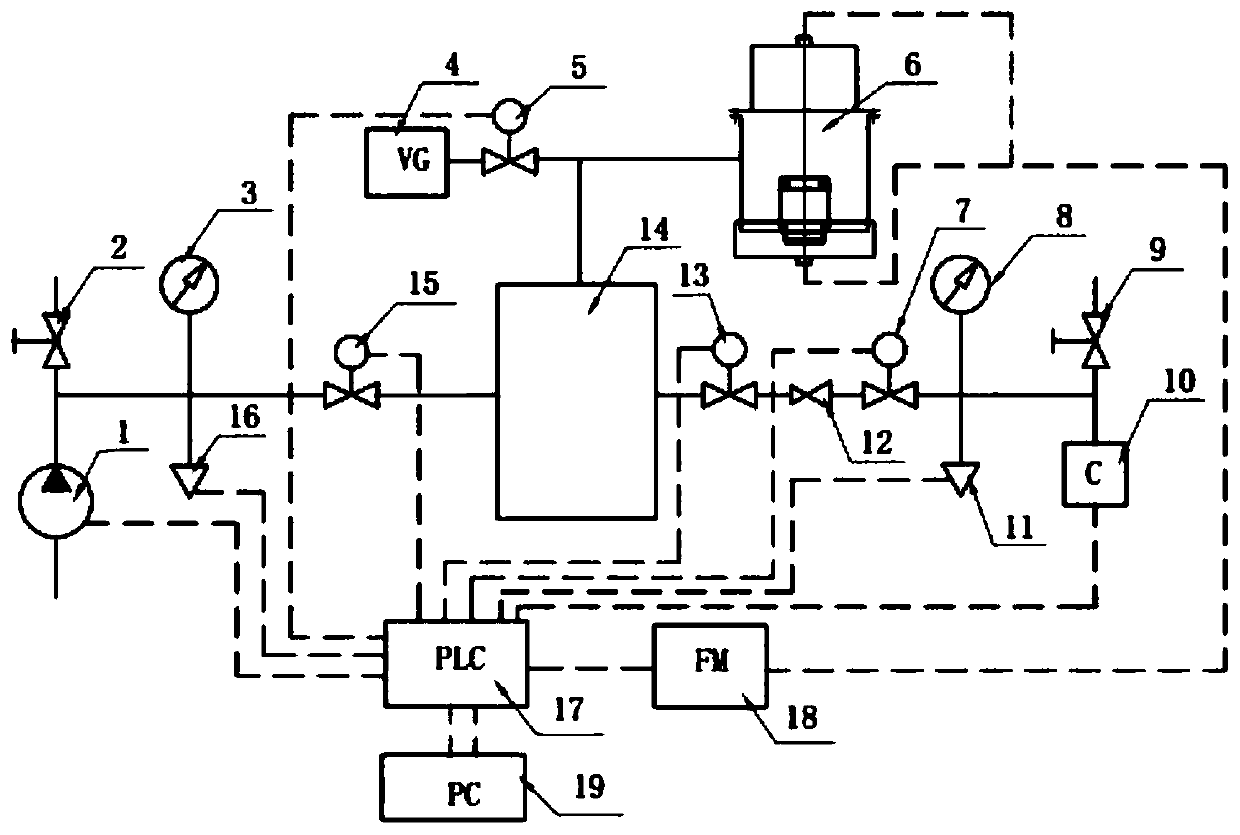

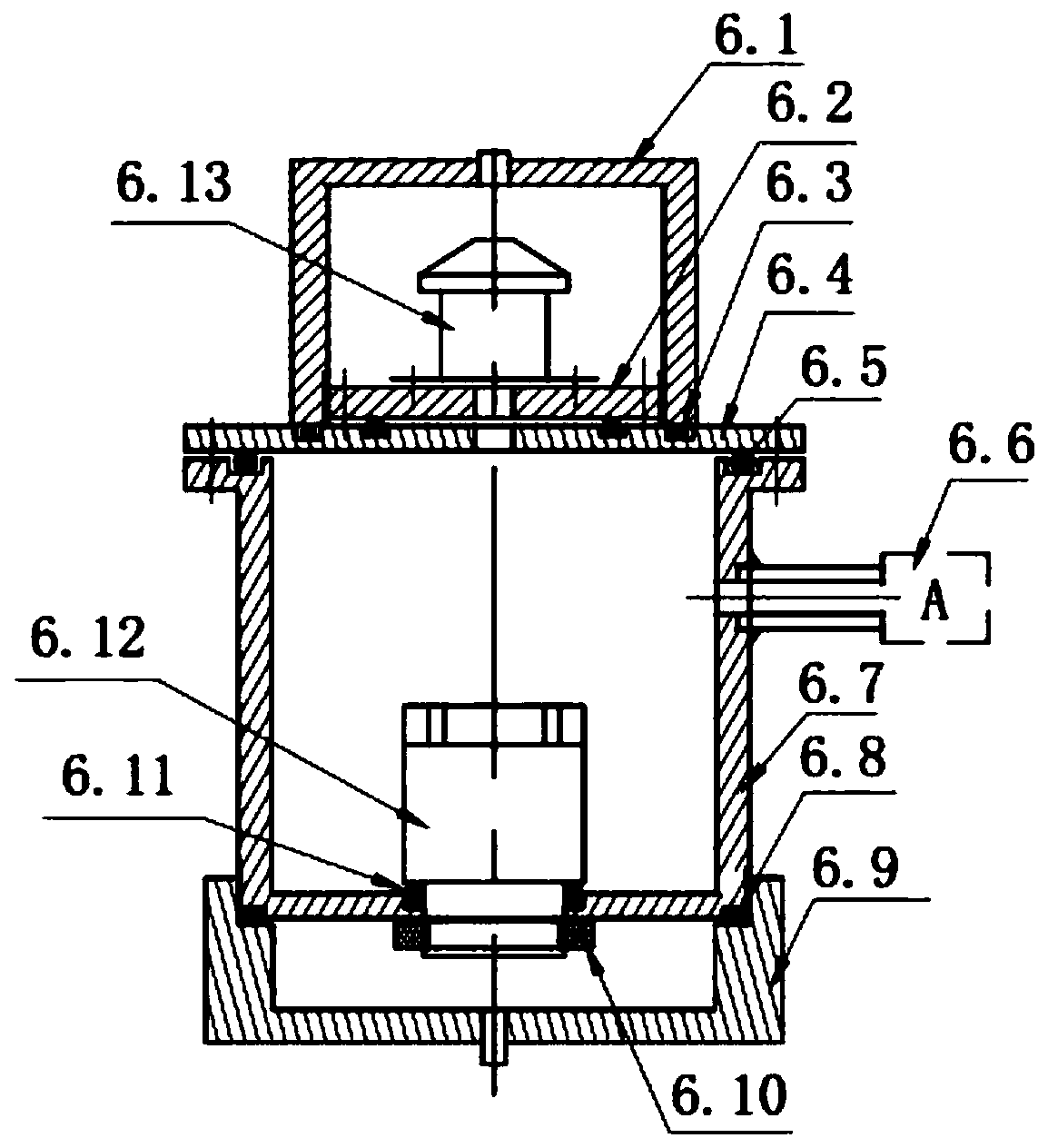

Test apparatus and method for safety valve

InactiveUS20100281954A1Ensure correct executionEasy to produceMeasurement of fluid loss/gain rateMachine valve testingControl flowEngineering

An apparatus and method for testing the performance of a safety valve. The apparatus includes an accumulator including at least one electric heater for heating a predetermined amount of water in the accumulator, and storing steam produced by the electric heater, a test vessel storing the steam supplied from the accumulator, and providing steam at a test pressure to a safety valve, the steam being supplied after controlling flow rate and pressure, a condensing tank storing demineralized water to be supplied to the accumulator, and condensing and collecting the steam discharged from the safety valve, and a water-supply pump supplying the water stored in the condensing tank to the accumulator.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

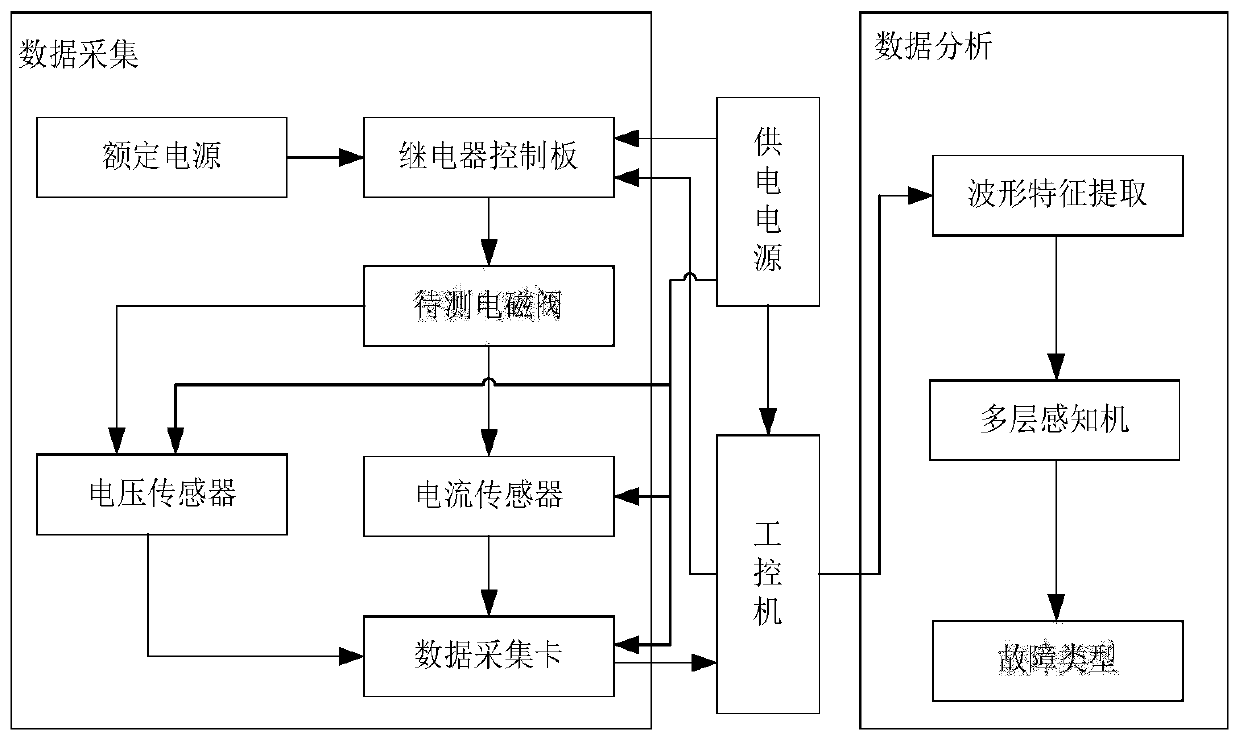

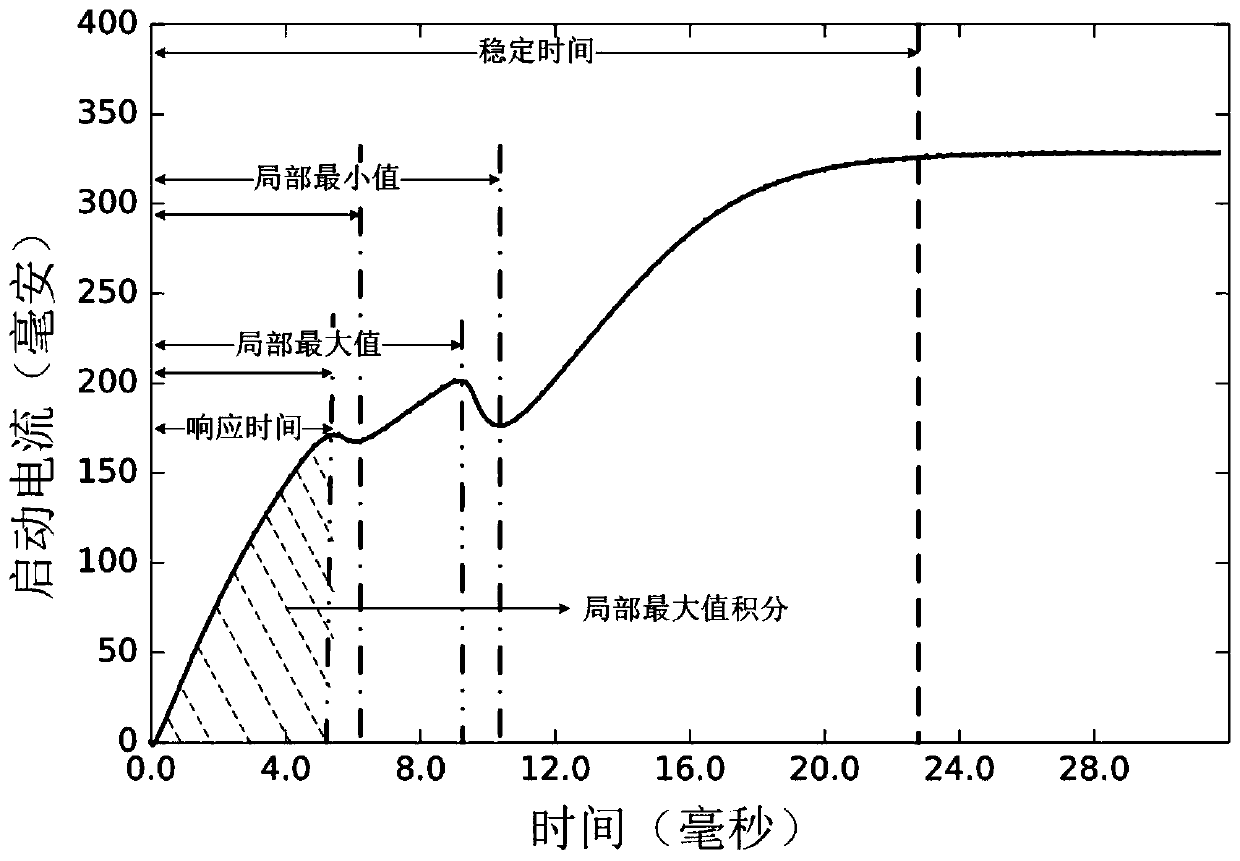

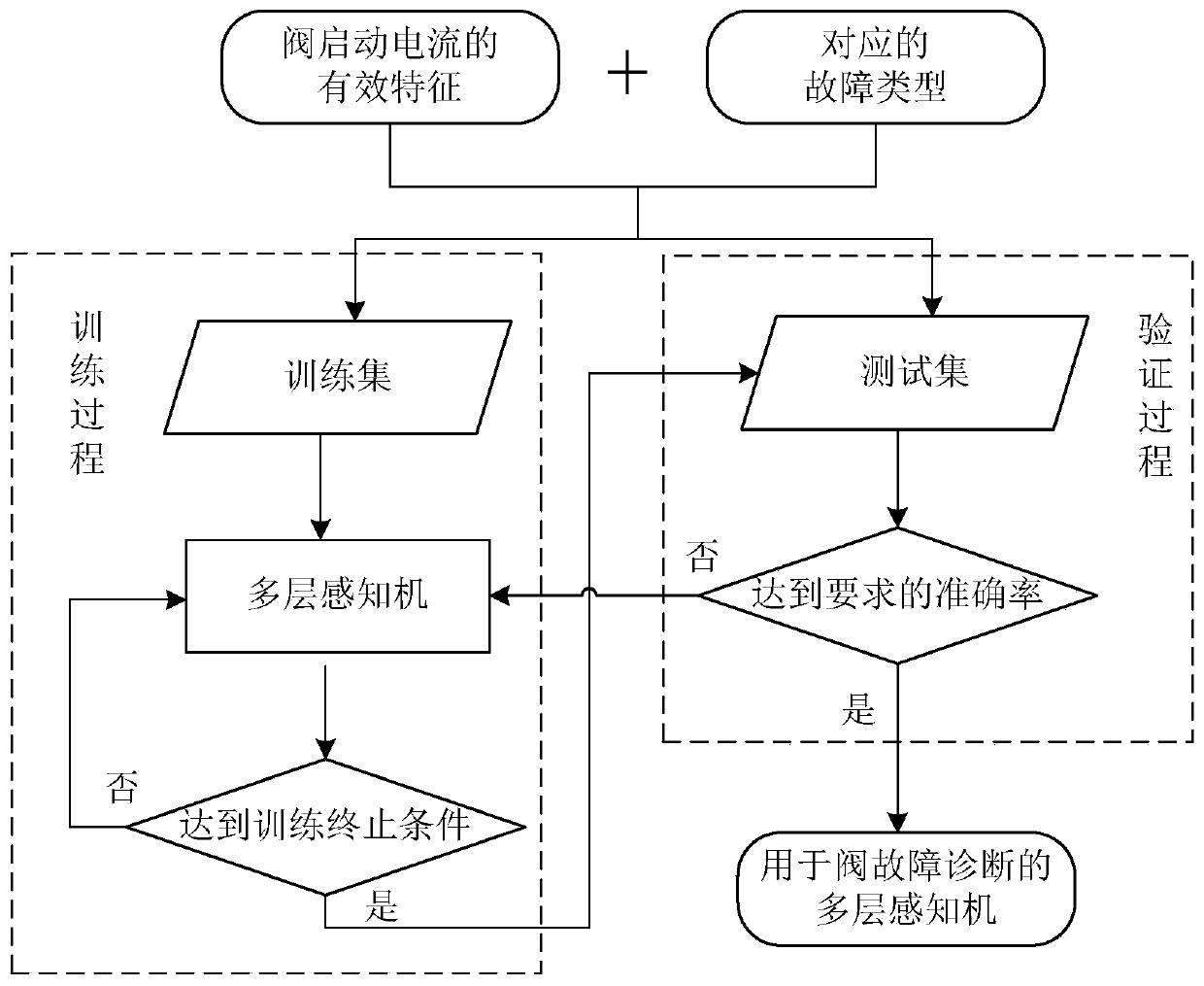

Solenoid valve fault diagnosis device based on feature extraction and multilayer perceptron and method

ActiveCN109917205AImprove accuracySimple fault diagnosis methodMachine valve testingElectrical testingFeature vectorFeature extraction

The invention discloses a solenoid valve fault diagnosis device based on feature extraction and a multilayer perceptron and method. The method comprises the following steps: starting current and working voltage are acquired in view of solenoid valve training samples, the response time of the starting current, the stabilization time, the local maximum, the local maximum integral, the local minimumand the local minimum integral are extracted, and together with the working voltage, eigenvectors are formed; with the eigenvectors of the solenoid valve training samples as input and with a fault type as output, the multilayer perceptron is trained, and a solenoid valve fault diagnosis model is obtained; and the eigenvector of a to-be-detected solenoid valve is acquired based on the same method of acquiring the eigenvector of the solenoid valve training sample, the eigenvector is inputted to the solenoid valve fault diagnosis model, and the solenoid valve fault diagnosis model performs faultdetection on the to-be-detected solenoid valve. The solenoid valve eigenvector can better explain the starting current waveform of the electromagnetic valve and enhance the accuracy of the diagnosis of the electromagnetic valve fault, and can be widely applied to the fault diagnosis of the electromagnetic valve.

Owner:CENT SOUTH UNIV

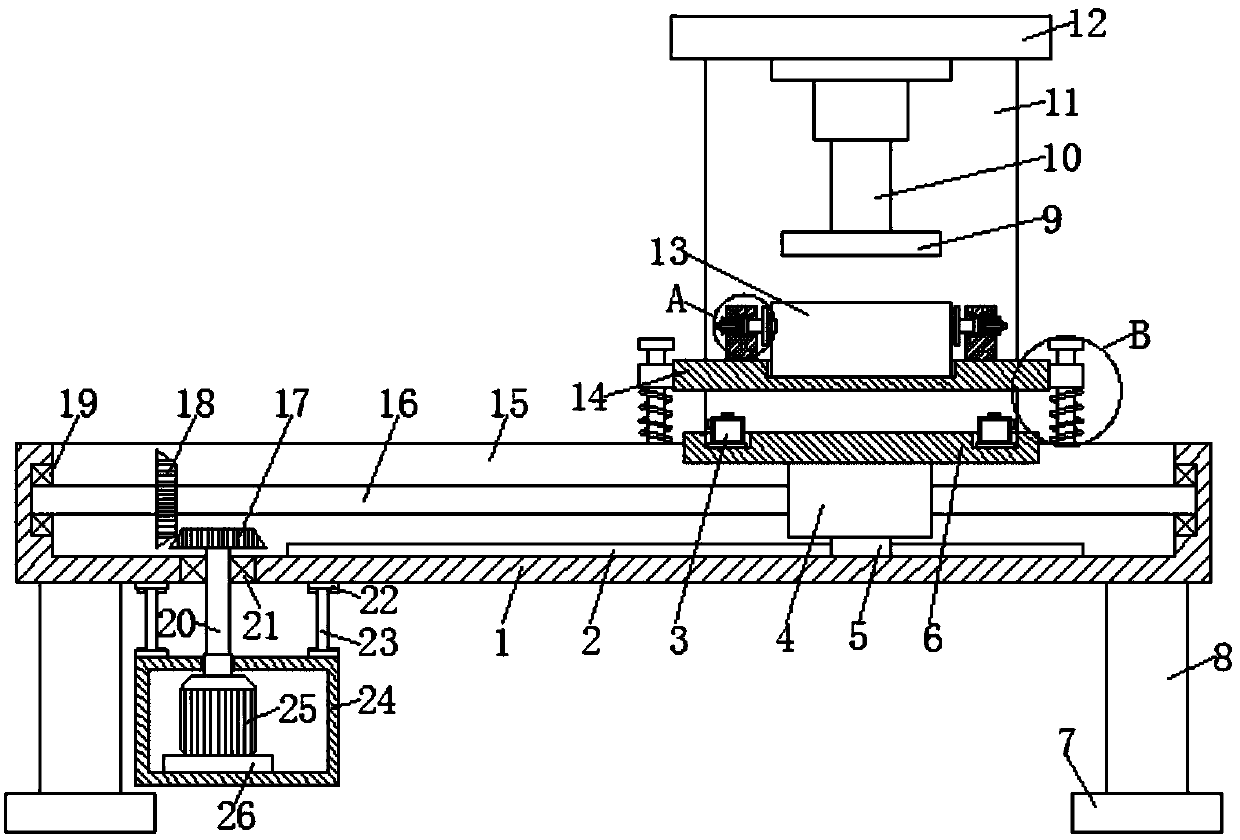

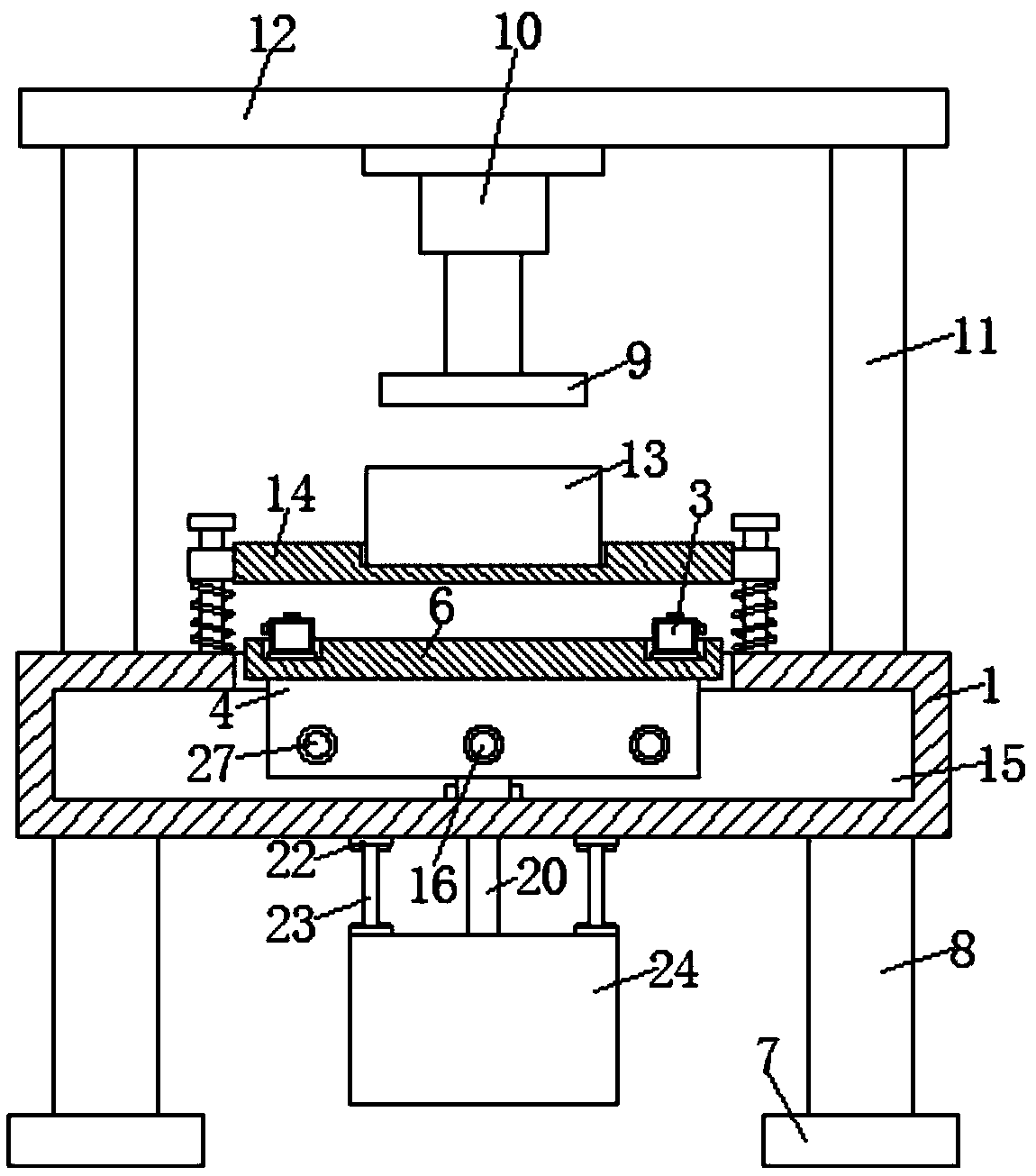

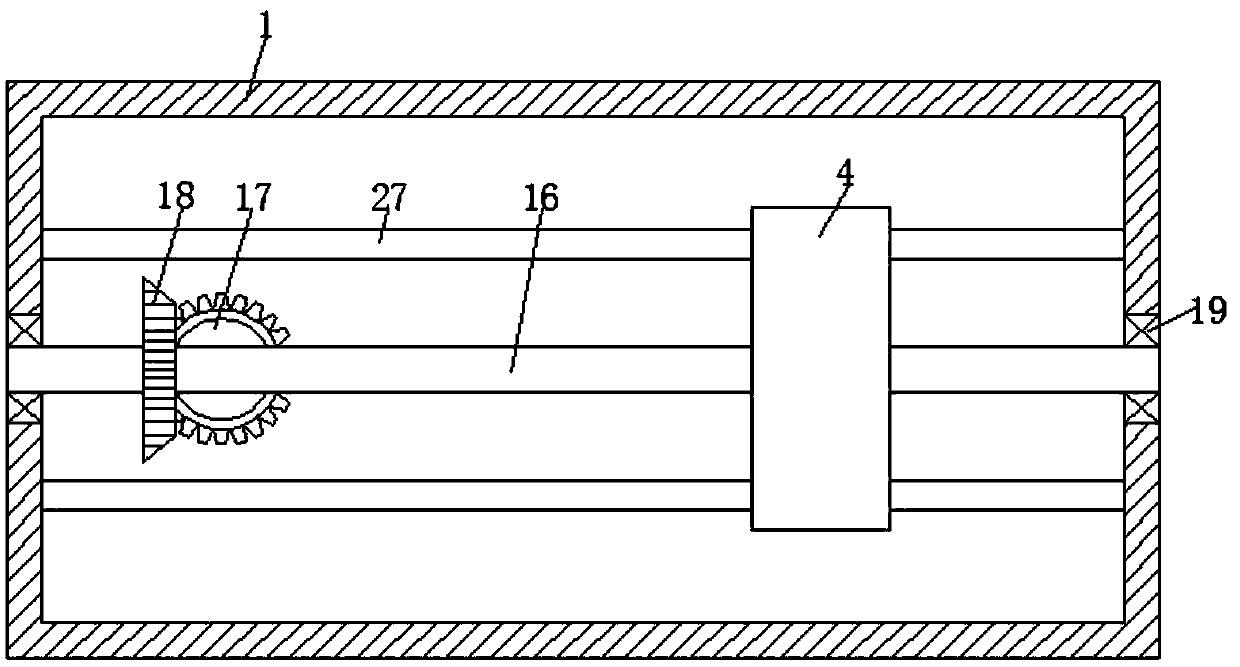

Multifunctional hydraulic comprehensive test bench

ActiveCN109612703AReduce the risk factorPlay a protective effectMachine valve testingMaterial strength using tensile/compressive forcesCombined testEngineering

The invention relates to the technical field of hydraulic test equipment, in particular to a multifunctional hydraulic comprehensive test bench, comprising a platen. A groove is formed on the upper surface of the platen. A first bearing is though provided on the middle of each of the two sides of the inner wall of the groove. An adjusting rod is rotationally provided between the two first bearings. A pressure sensor is fixedly mounted at each of the four corners of the upper surface of the movable plate. A supporting plate is fixedly mounted on each of the two ends of one side of the upper surface of the platen. A top cover is fixedly mounted on the upper end of each of the supporting plates. A hydraulic push rod is fixedly mounted at the middle of the lower surface of the top cover. A pressing plate is fixedly mounted at the lower end of the hydraulic push rod. Four positioning mechanisms are fixedly mounted on one side of the upper surface of the platen. A placing plate is fixedly mounted among the four positioning mechanisms. A mounting groove is formed on the upper portion of one side of the fixed block. A second sliding groove is fixedly mounted on each of the two sides of theinner wall of the mounting groove. According to the multifunctional hydraulic comprehensive test bench, a test piece can be fixed and adjusted, the operation is simple, the use is convenient and thepracticability is high.

Owner:湖北泰和电气有限公司

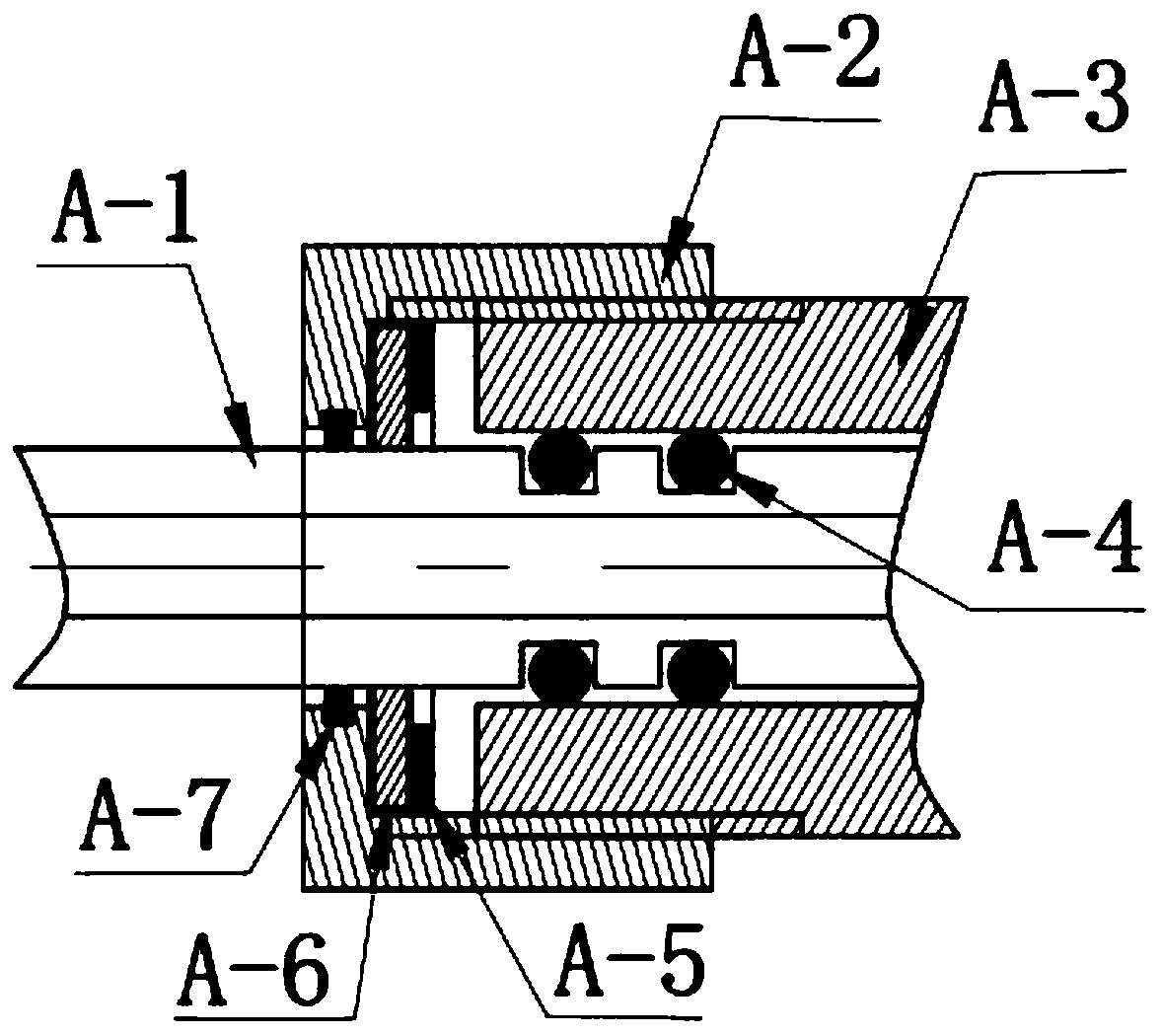

Test module, system and test method for testing damping valve of oil damper

The invention provides a test module, a system and a test method for testing the dynamic characteristic of the damping valve of an oil damper at high / low temperature. The test module includes an oil storage cylinder component, a guide component, a guide exhaust plate, a pressure cylinder, a piston-piston rod component, hydraulic oil, a bottom valve component, a pressure cylinder gasket, a bottom valve gasket, an oil guide plate component, a magnet, an oil return component, a framework oil seal, a screw cap, and a dustproof ring. The test module integrates the hydraulic oil, an oil supply mechanism, a tested damping valve and a sensor through the principle of integrated design. The entire test module can be placed in a high / low-temperature box. The problem on how to control the oil temperature of the tested damping valve can be conveniently, effectively and accurately solved. An automatic test system based on the test module and a related test method are further provided.

Owner:DONGGUAN UNIV OF TECH

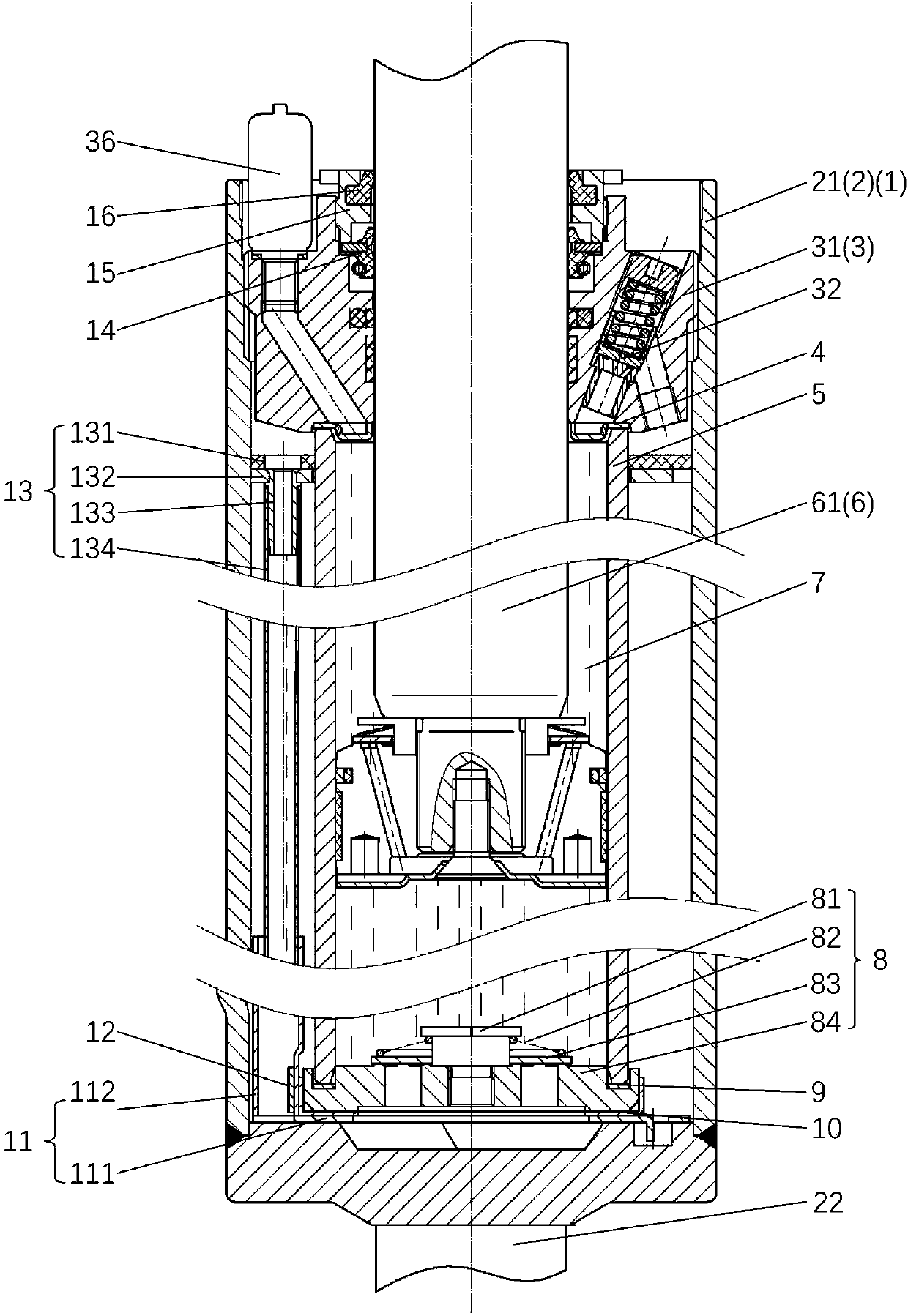

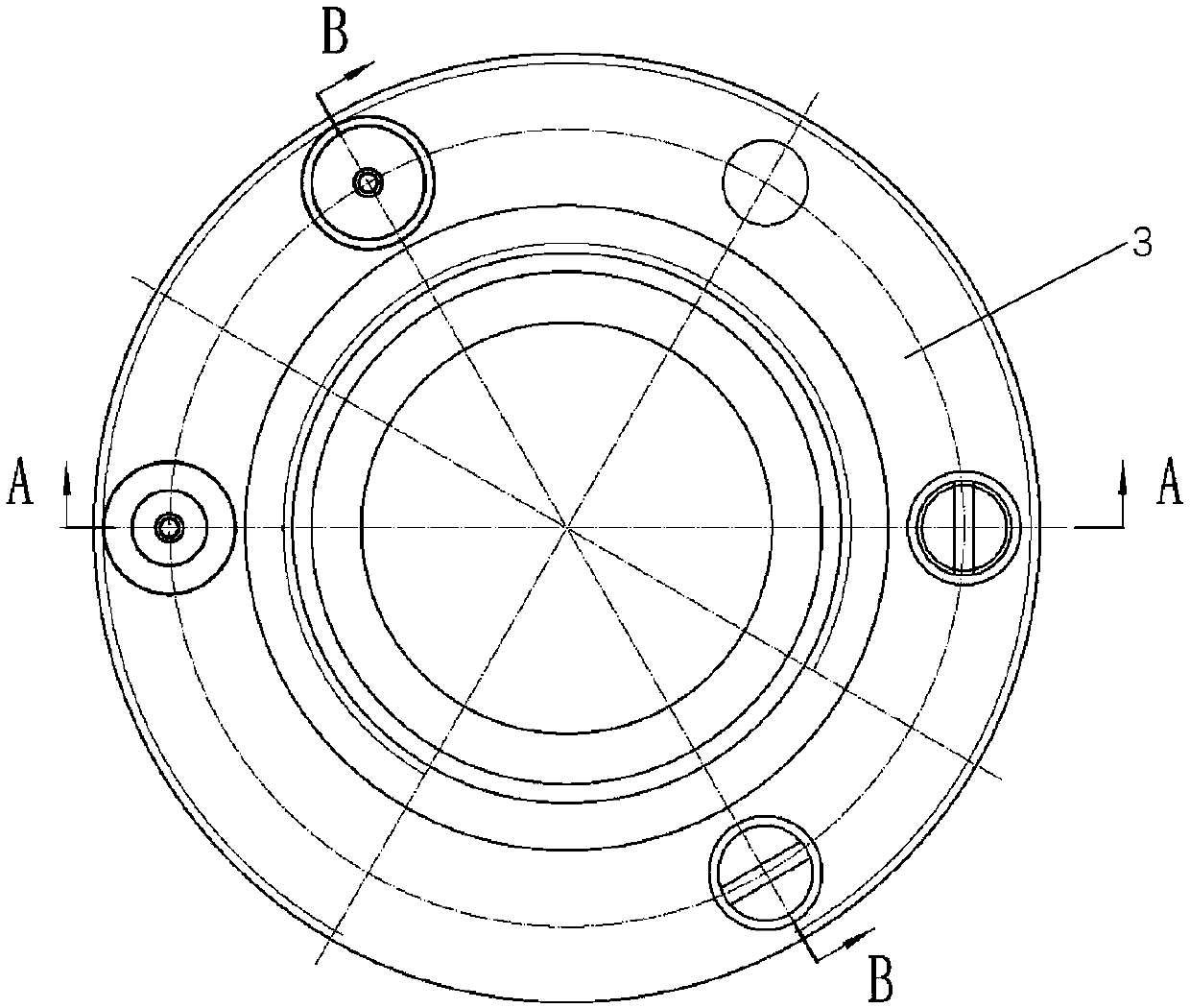

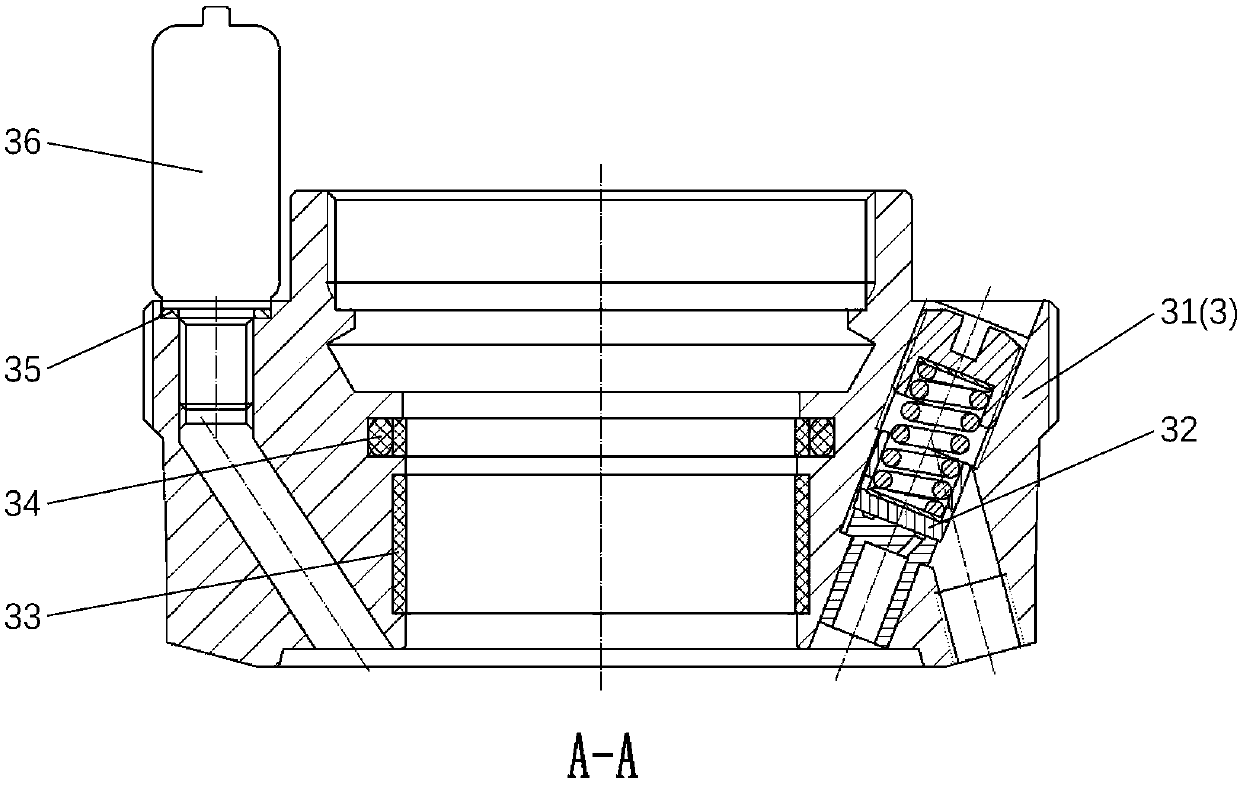

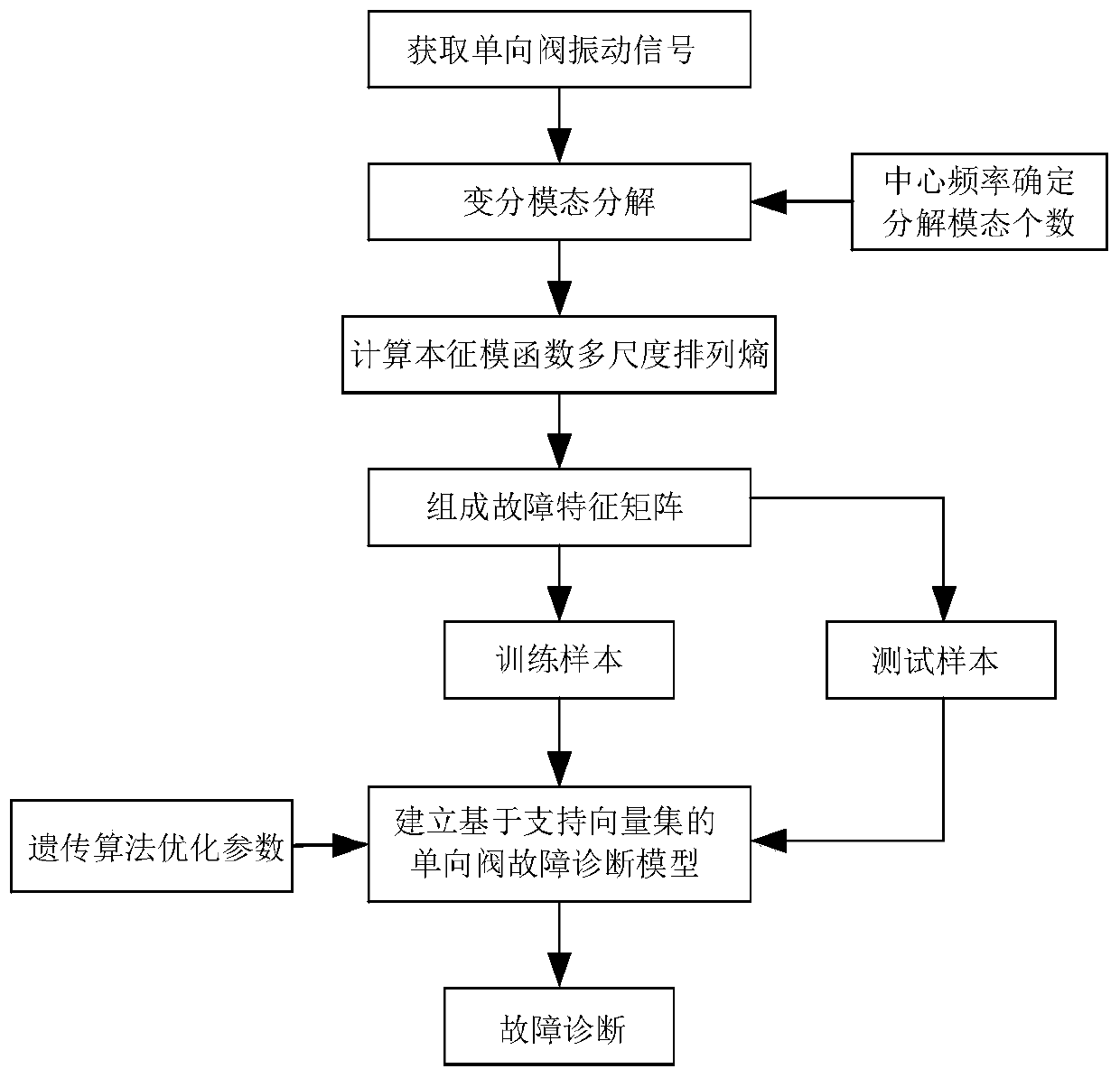

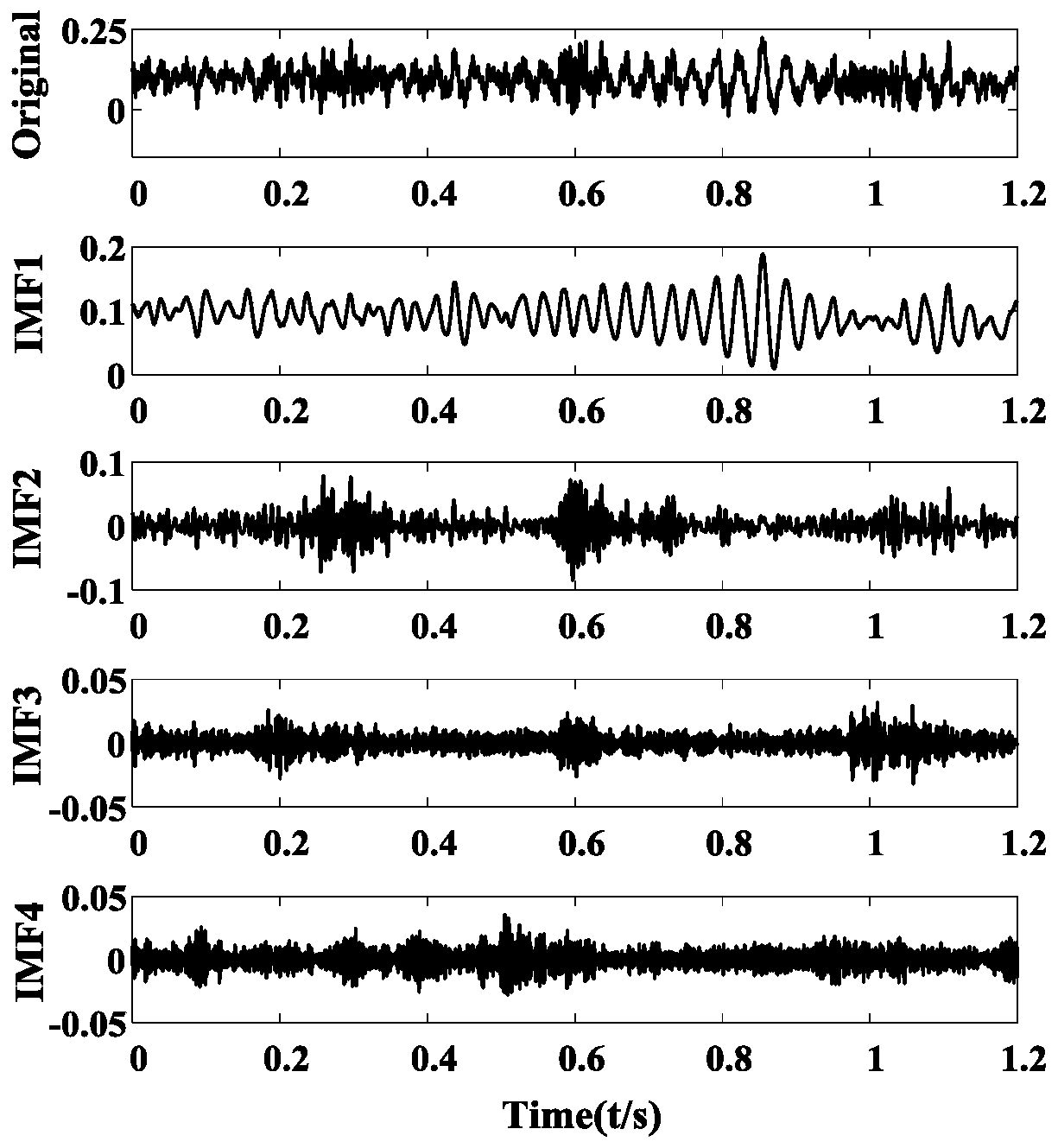

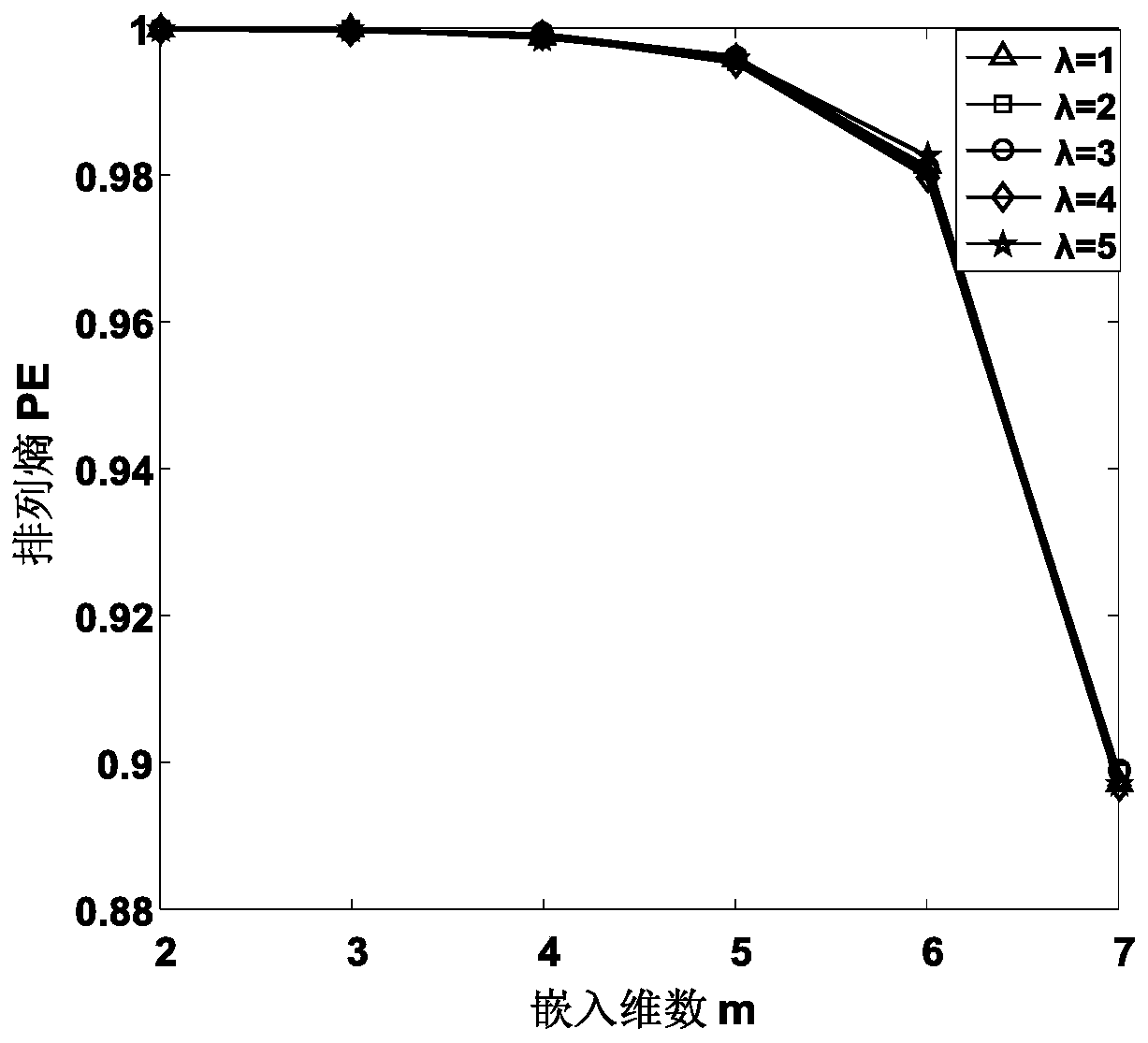

High-pressure diaphragm pump check valve fault diagnosis method based on vibration signal analysis

InactiveCN110044602AImprove the problem of poor vibration signal effectRich in detailsMachine valve testingVibration testingDecompositionEngineering

The invention relates to a high-pressure diaphragm pump check valve fault diagnosis method based on vibration signal analysis, and belongs to the field of mechanical fault diagnosis and signal processing. The high-pressure diaphragm pump check valve fault diagnosis method based on the vibration signal analysis comprises the following steps that firstly, VMD decomposition is carried out on a vibration signal of a check valve of a high-pressure diaphragm pump, and the number K of decomposition modes is determined through a center frequency to obtain K IMF components with physical significance; the MPE of the IMF components is then calculated to form a multi-scale complexity measure feature vector; and finally, a high-dimensional feature matrix is input into a classifier established by a support vector machine optimized based on a genetic algorithm to identify a working state of the check valve of the high-pressure diaphragm pump. According to the high-pressure diaphragm pump check valvefault diagnosis method based on the vibration signal analysis, the vibration signal of the check valve is denoised and decomposed into the IMF components without mode-mixing through a VMD algorithm, the multi-scale arrangement entropy of each IMF component is calculated to collect fault characteristic information distributed on multiple scales, the correct rate of fault identification of the checkvalve is improved, and higher practicability and engineering significance are achieved.

Owner:KUNMING UNIV OF SCI & TECH

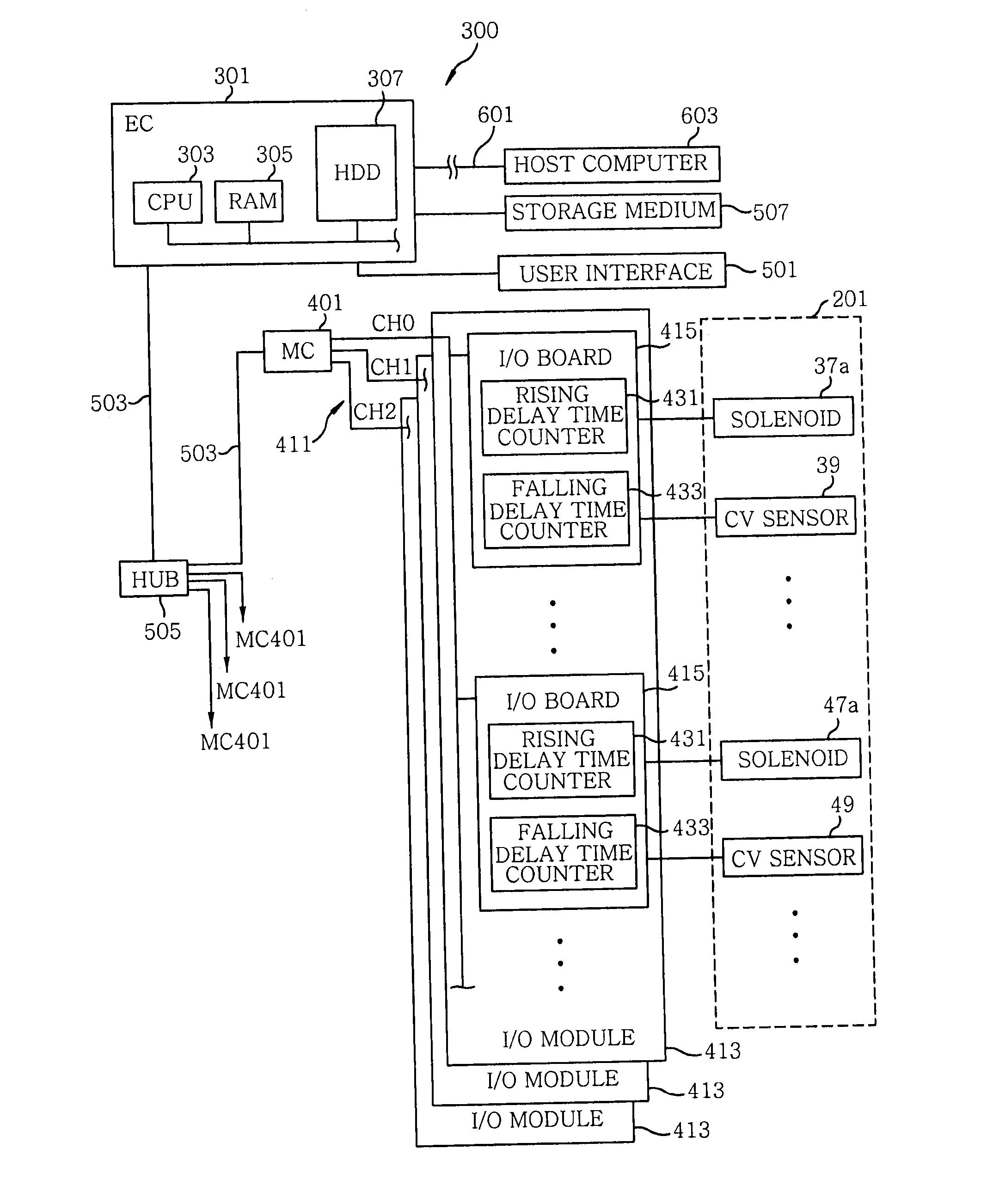

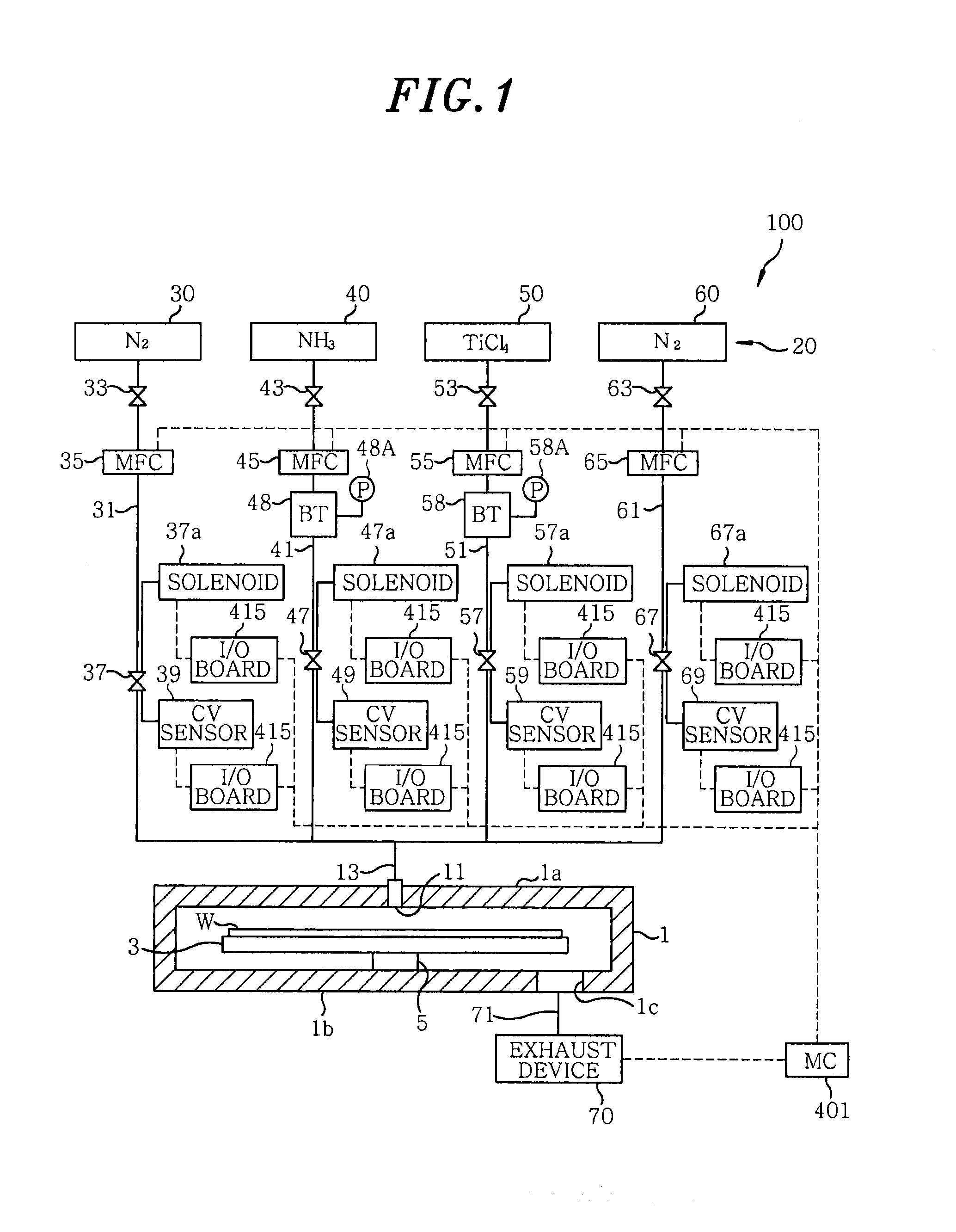

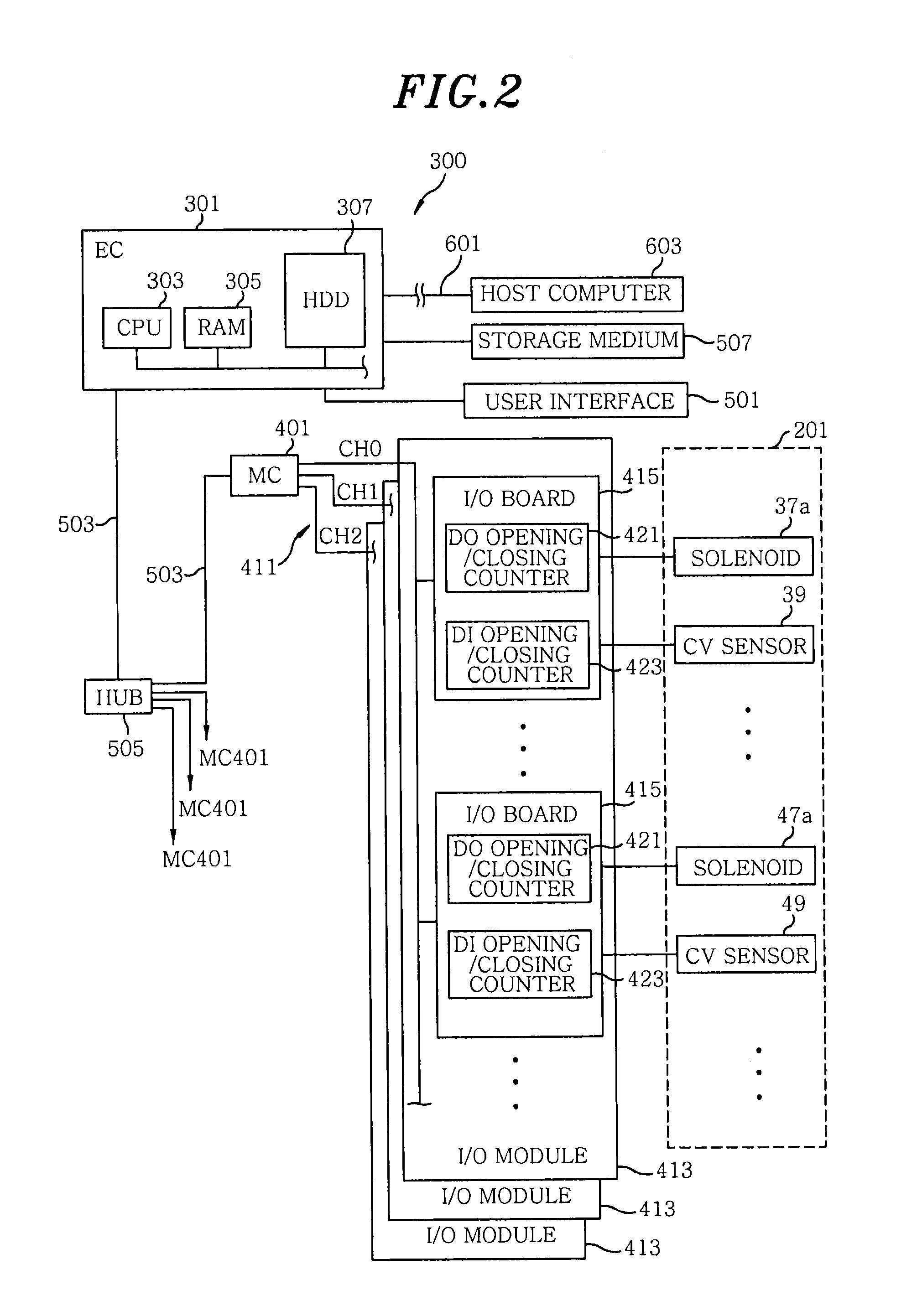

Processing apparatus and valve operation checking method

ActiveUS20130183443A1Avoid it happening againValve arrangementsLiquid surface applicatorsProcess engineeringGas supply

A processing apparatus includes a processing chamber configured to accommodate a target object to be processed, gas supply paths provided in a corresponding relationship with the kinds of process gases supplied into the processing chamber, and valves respectively arranged in the gas supply paths to open and close the gas supply paths. The processing apparatus further includes valve drive units configured to independently drive the valves, sensor units configured to independently monitor opening and closing operations of the valves, and a control unit configured to determine operation statuses of the valves based on valve opening and closing drive signals transmitted to the valve drive units and / or valve opening and closing detection signals transmitted from the sensor units.

Owner:TOKYO ELECTRON LTD

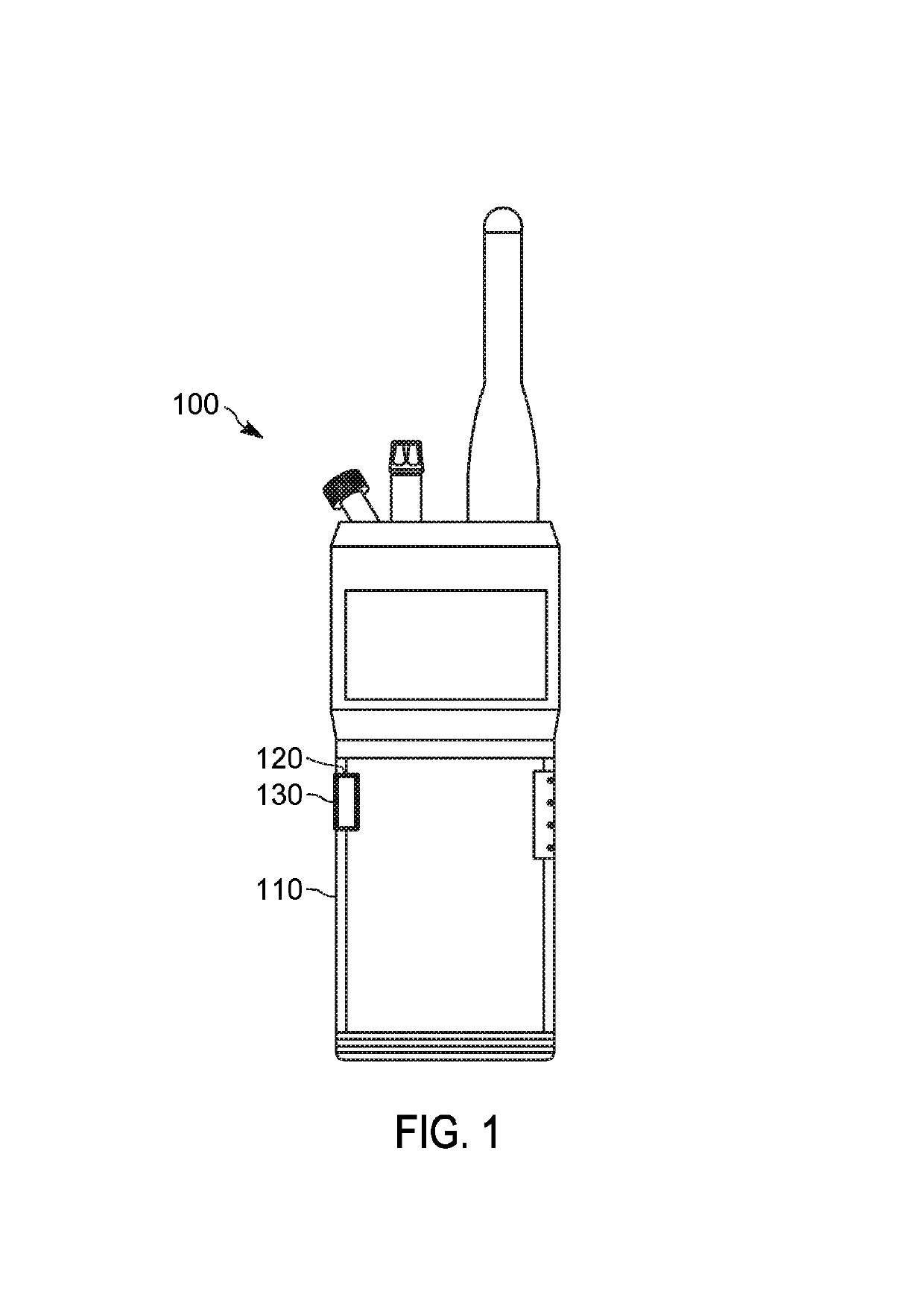

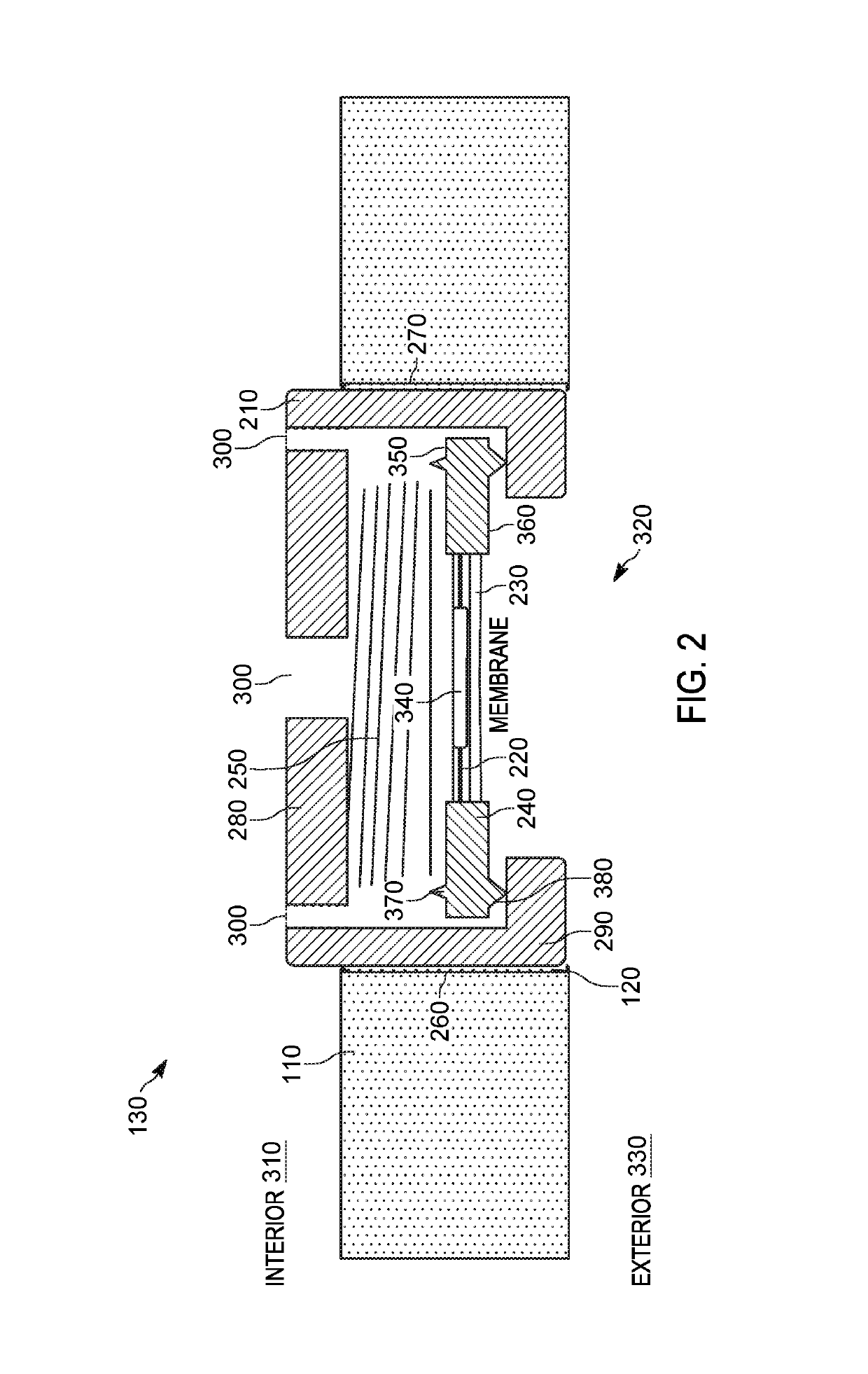

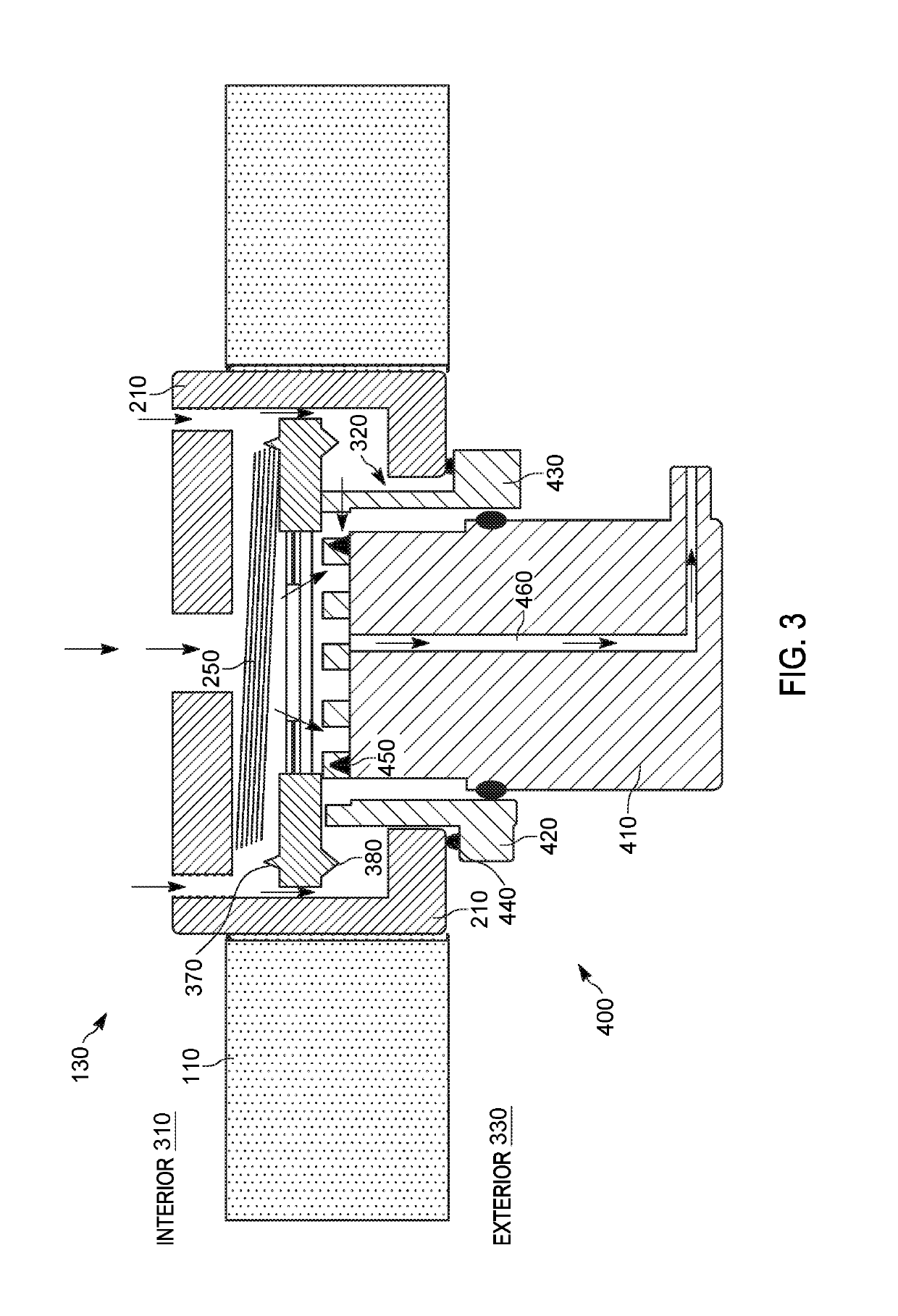

Automatic testable breather valve

ActiveUS10264693B1Measurement of fluid loss/gain rateMachine valve testingBreatherPortable communications device

A breather valve and a portable communication device including a breather valve are provided. The breather valve includes a housing having a bottom portion having an opening and side portions, a rigid substrate located within the housing and a breathable membrane mounted to the rigid substrate. The breather valve further includes a gasket having a top surface and a bottom surface, and a preloaded compression element across the gasket and the rigid substrate. The gasket has an upper energy director located at the top surface and a lower energy director located at the bottom surface. The preloaded compression element provides at least a first compressive position providing a contact between the lower energy director and the bottom portion of the housing and a second compressive position in which air passes around the lower energy director and the upper energy director.

Owner:MOTOROLA SOLUTIONS INC

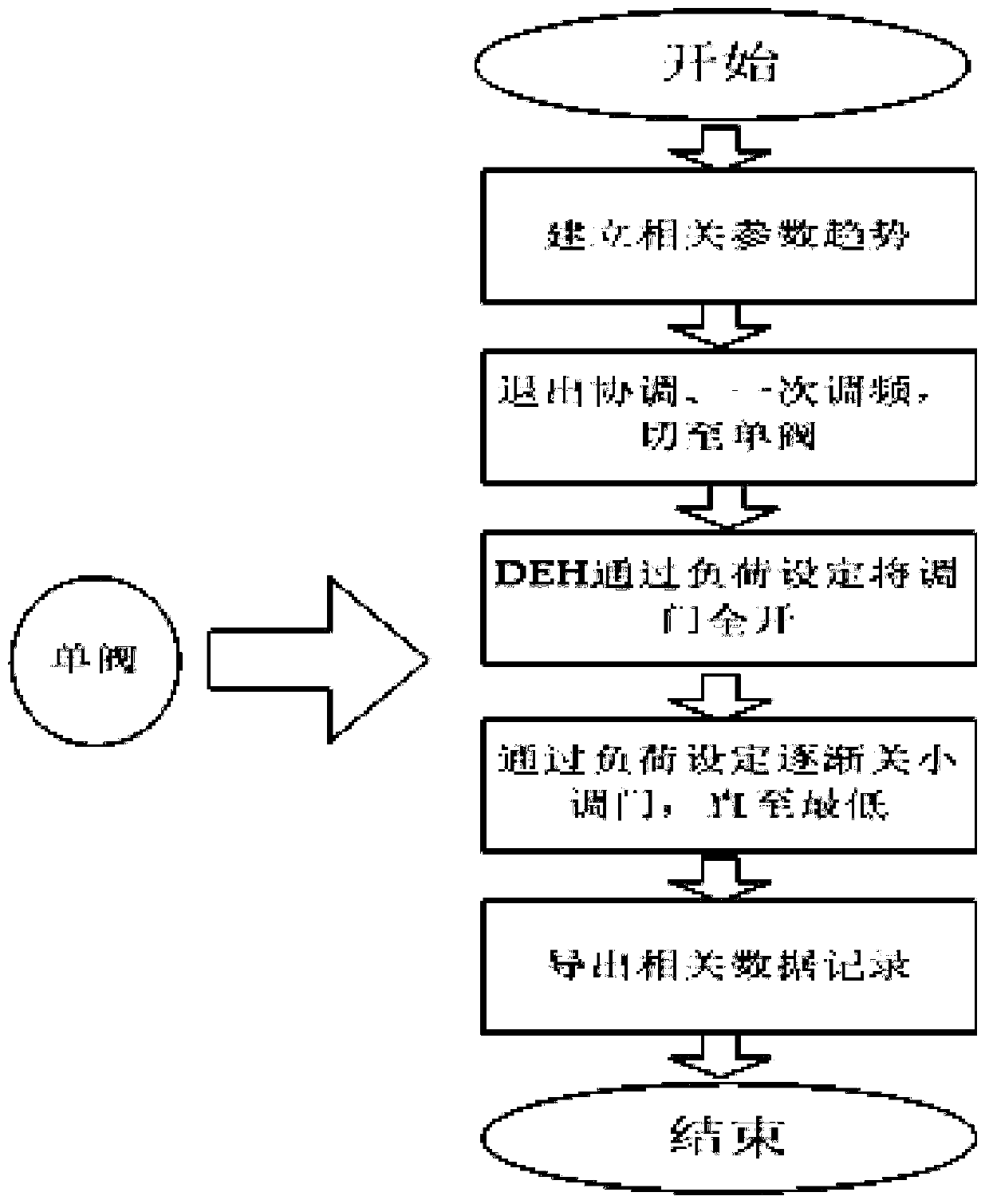

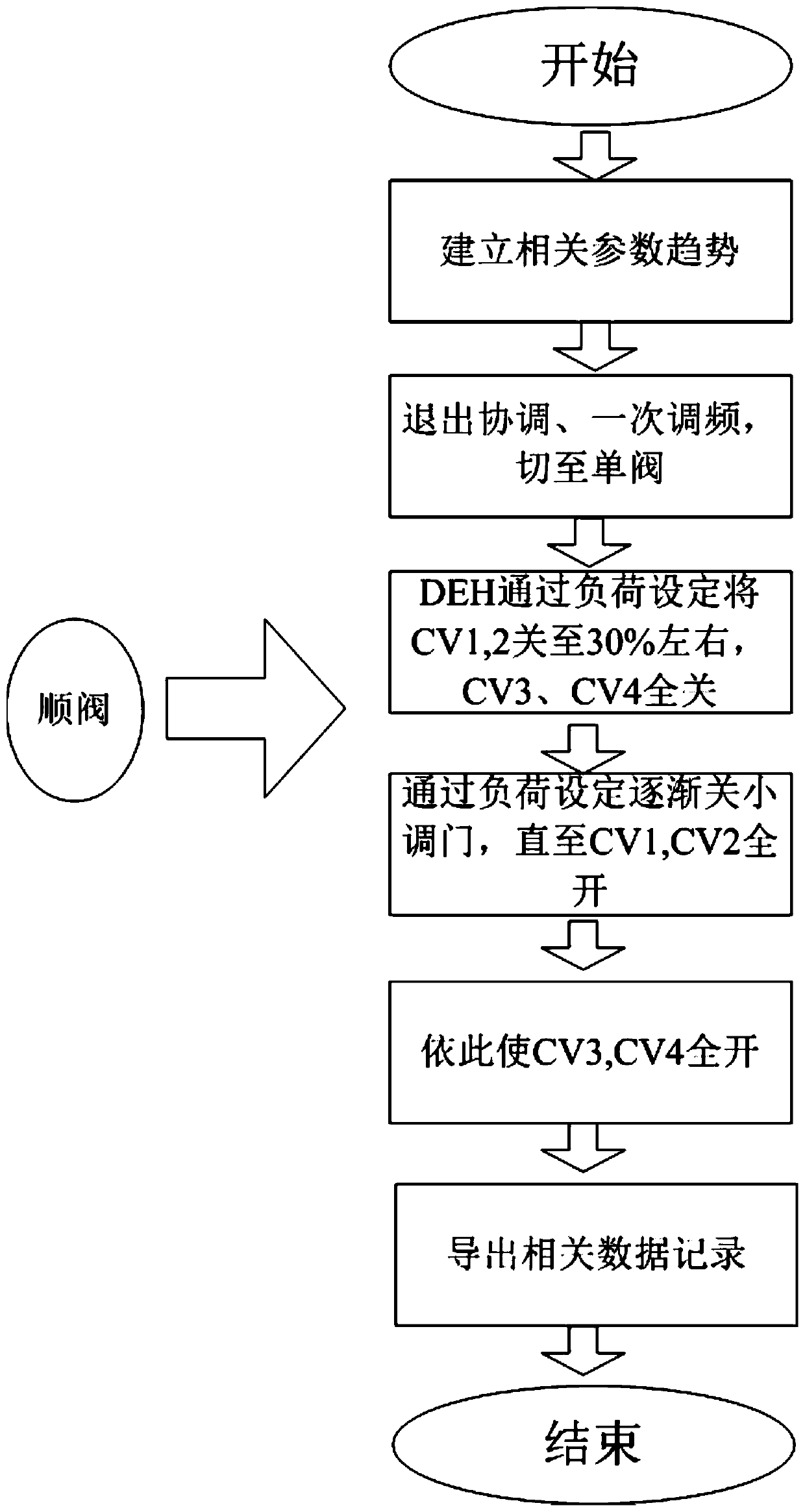

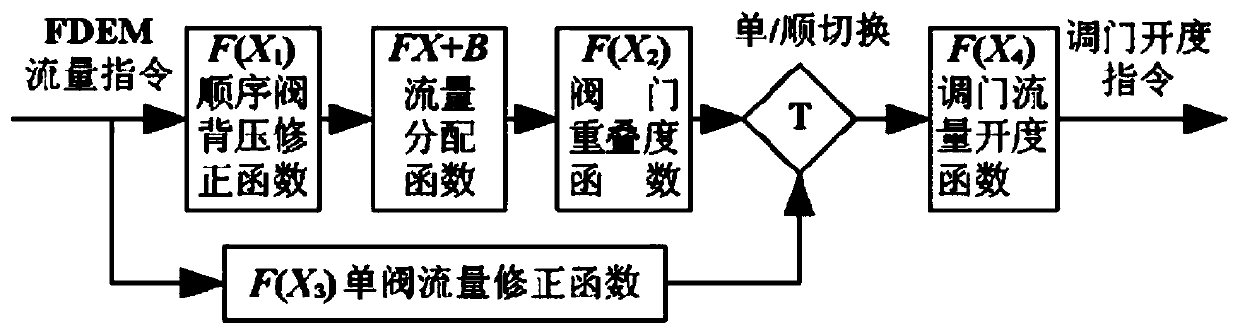

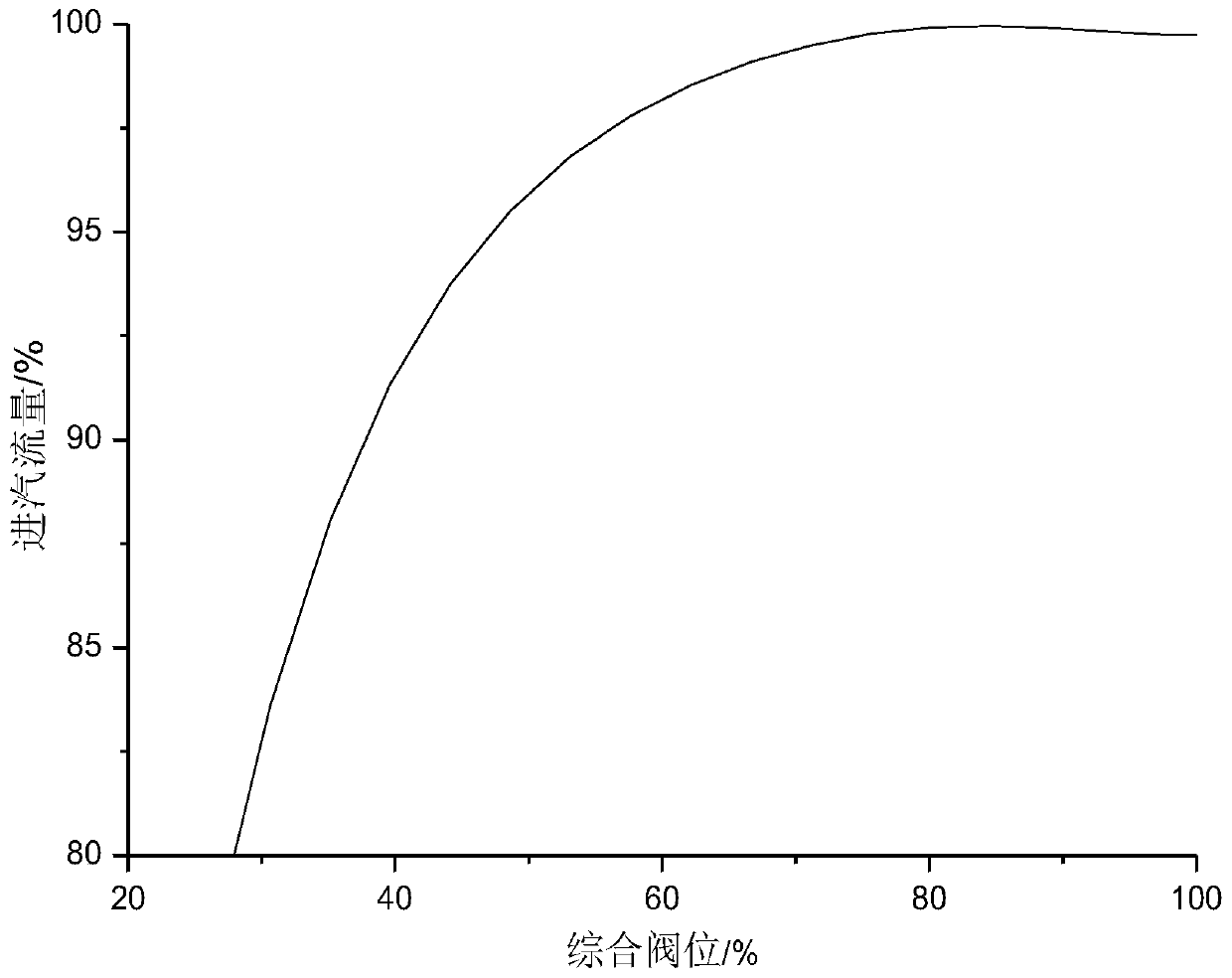

Method for setting valve flow characteristic curve of steam turbine

InactiveCN110346121AVerify reliabilityImprove accuracyMachine valve testingData validationFlow curve

The invention discloses a method for setting a valve flow characteristic curve of a steam turbine and belongs to the technical field of steam turbines. An overlap function is calculated by using datain single valve operation of a unit to obtain a new valve flow curve, and the reliability of a new characteristic curve is verified by using the data obtained in sequence valve operation of the unit.According to the method, valve flow characteristic parameters of the steam turbine can be completely and specifically set, so that switching between single valve and sequence valves is smooth, steam flow change is gentle during switching, load fluctuation is small, segment temperature and vibration do not greatly change and safe and stable operation of the unit is ensured; the response rate of AGCis optimized and the primary frequency modulation effect is improved; the overlap of regulating valves is reduced to improve the economy of the unit; and computation is simplified by using MATLAB programming.

Owner:JILIN ELECTRIC POWER RES INST +1

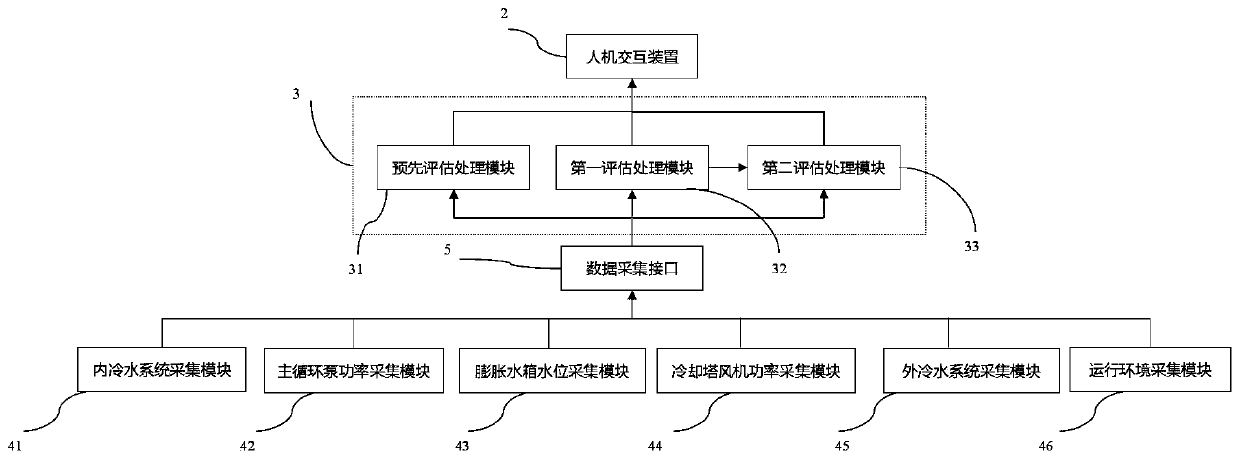

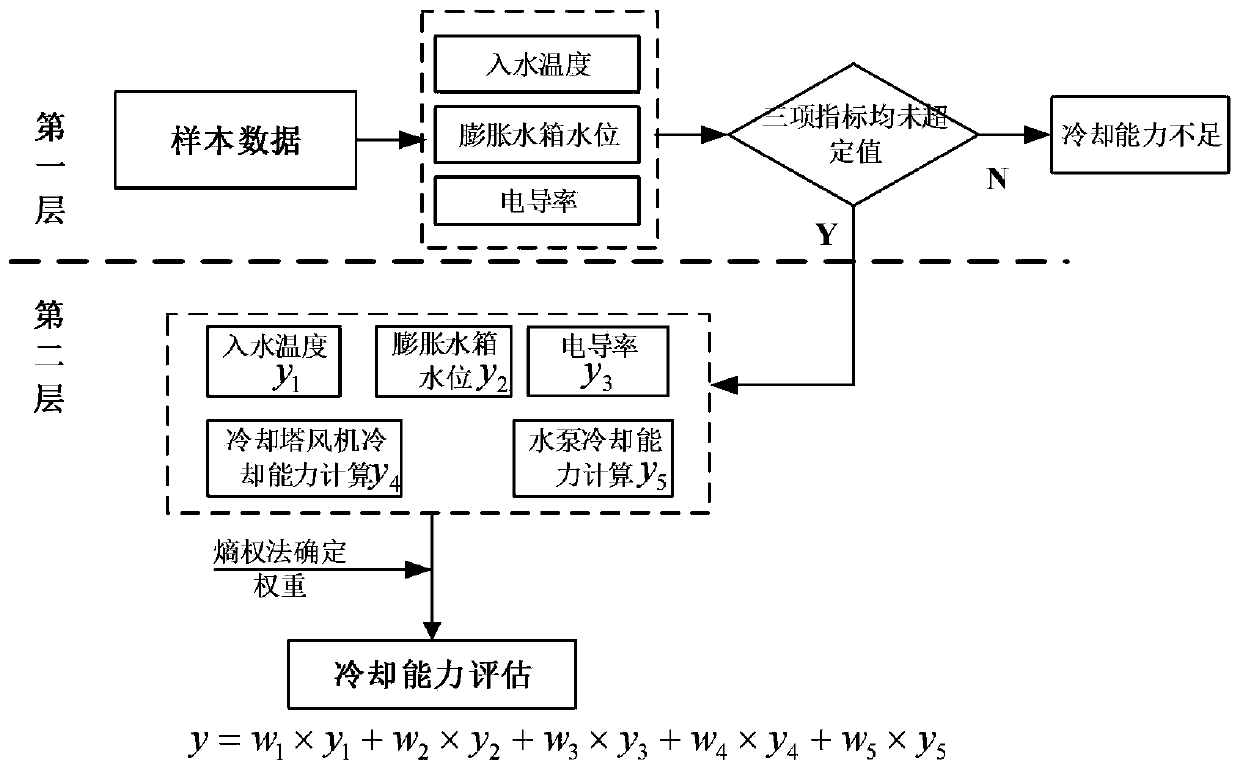

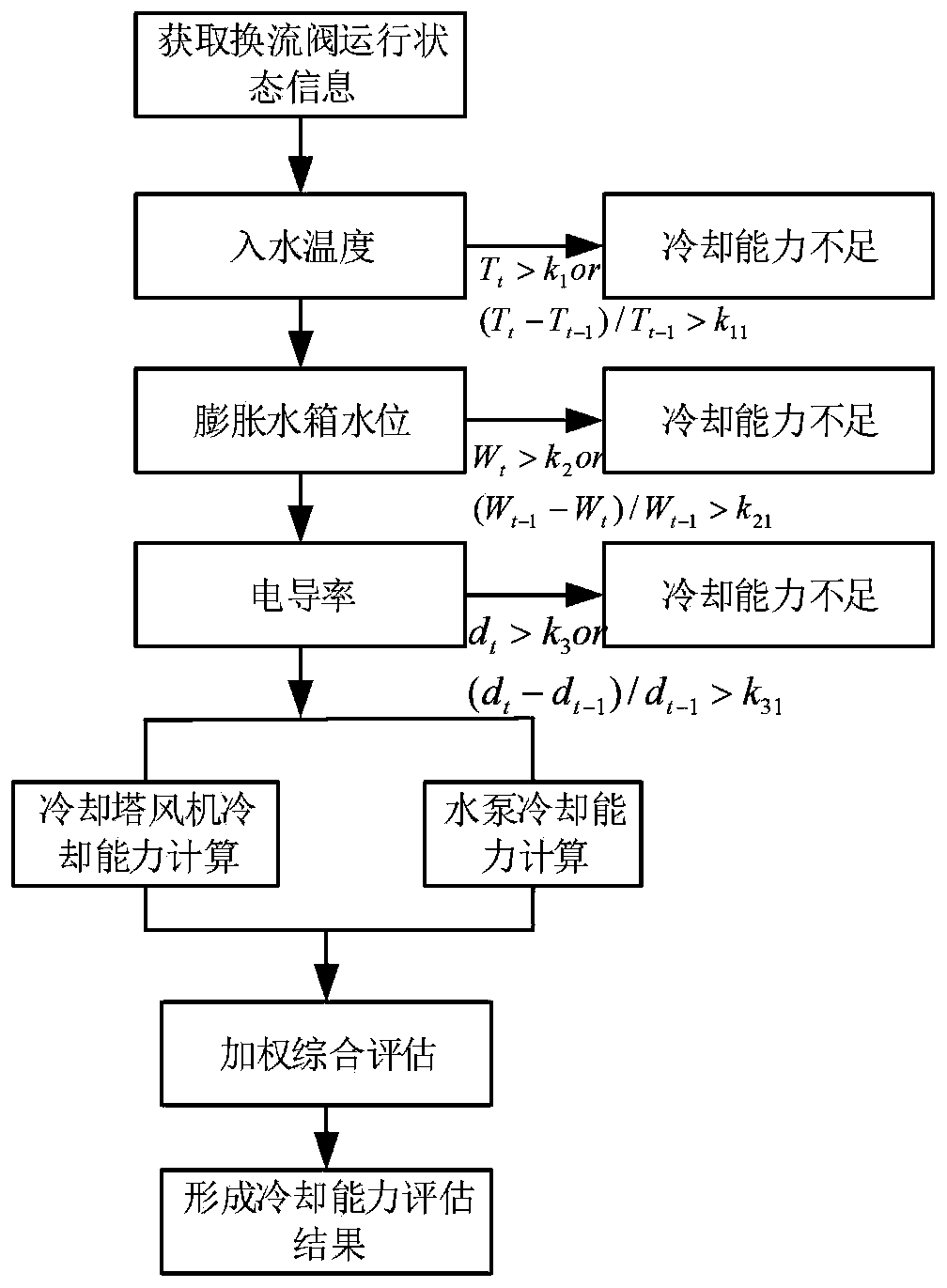

Converter valve cooling capacity multidimensional analysis early-warning method and system

The invention discloses a converter valve cooling capacity multidimensional analysis early-warning method and system and relates to the field of converter valve monitoring technologies. The system comprises early-warning units, a man-machine interaction device, a central processing unit and a data collection module, wherein the data collection module is used for collecting a state quantity of a converter valve cooling system and transmitting the state quantity to the central processing unit through a data collection interface; the central processing unit is used for assessing the cooling capacity of the state quantity and outputting an early-warning signal of the assessment result through an advanced early-warning unit, a first early-warning unit and a second early-warning unit respectively; and the man-machine interaction device is used for inputting a user instruction and displaying a monitored value of the state quantity. According to the method, a cooling capacity quantitative model is established from different dimensions, cooling capacity quantitative assessment indexes are formed, and a converter station valve cooling system defect early-warning model based on multidimensional analysis is established.

Owner:GUANGZHOU BUREAU CSG EHV POWER TRANSMISSION

Intelligent comprehensive test device for breather valve for oil tank truck

ActiveCN110207976AAccurate quantitative measurementReal-time acquisitionMachine valve testingPressure stabilizationBreather

The invention relates to an intelligent comprehensive test device for a breather valve for an oil tank truck. The intelligent comprehensive test device comprises a vacuum pump, an air compressor, a test container, a pressure stabilization tank, a human-computer interaction computer system and a high-accuracy gas flowmeter set; the pressure stabilization tank is connected with the test container; the pressure stabilization tank is also connected with the vacuum pump for vacuumizing the test container; the pressure stabilization tank is also connected with the air compressor for providing a positive pressure gas medium to the test container; the test container is provided with a leakage rate detection hole; the leakage rate detection hole is connected with the high-accuracy gas flowmeter set; and the human-computer interaction computer system for controlling the vacuum pump, the air compressor and the test container is connected with the vacuum pump, the air compressor and the test container. The intelligent comprehensive test device has the advantages of complete function, convenience and rapidness for mounting and low cost; and the designed test container can meet requirements of different specifications of internal and external breather valves for positive pressure and negative pressure opening tests, a valve seat sealing performance test and an overturn sealing performance test.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE

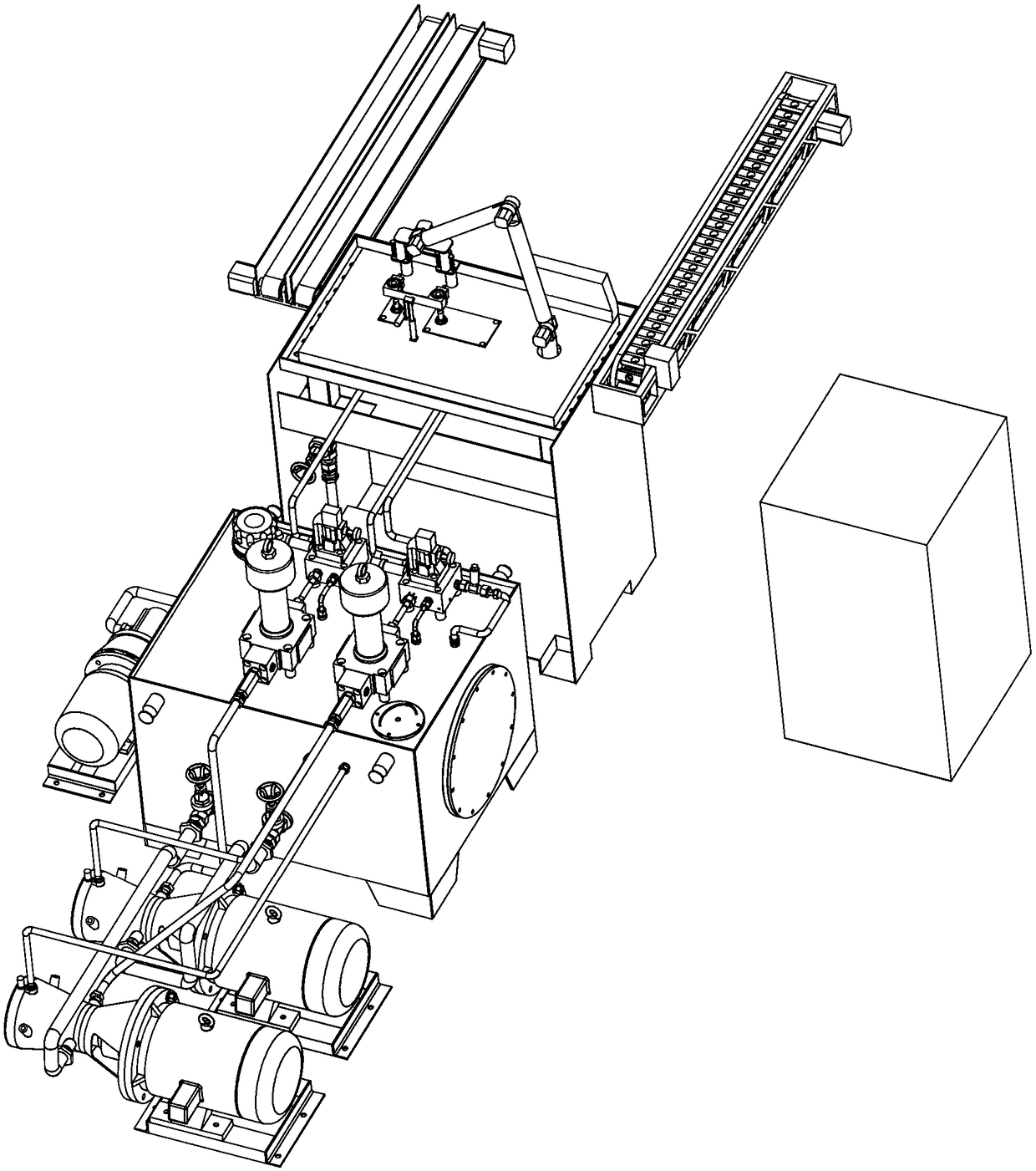

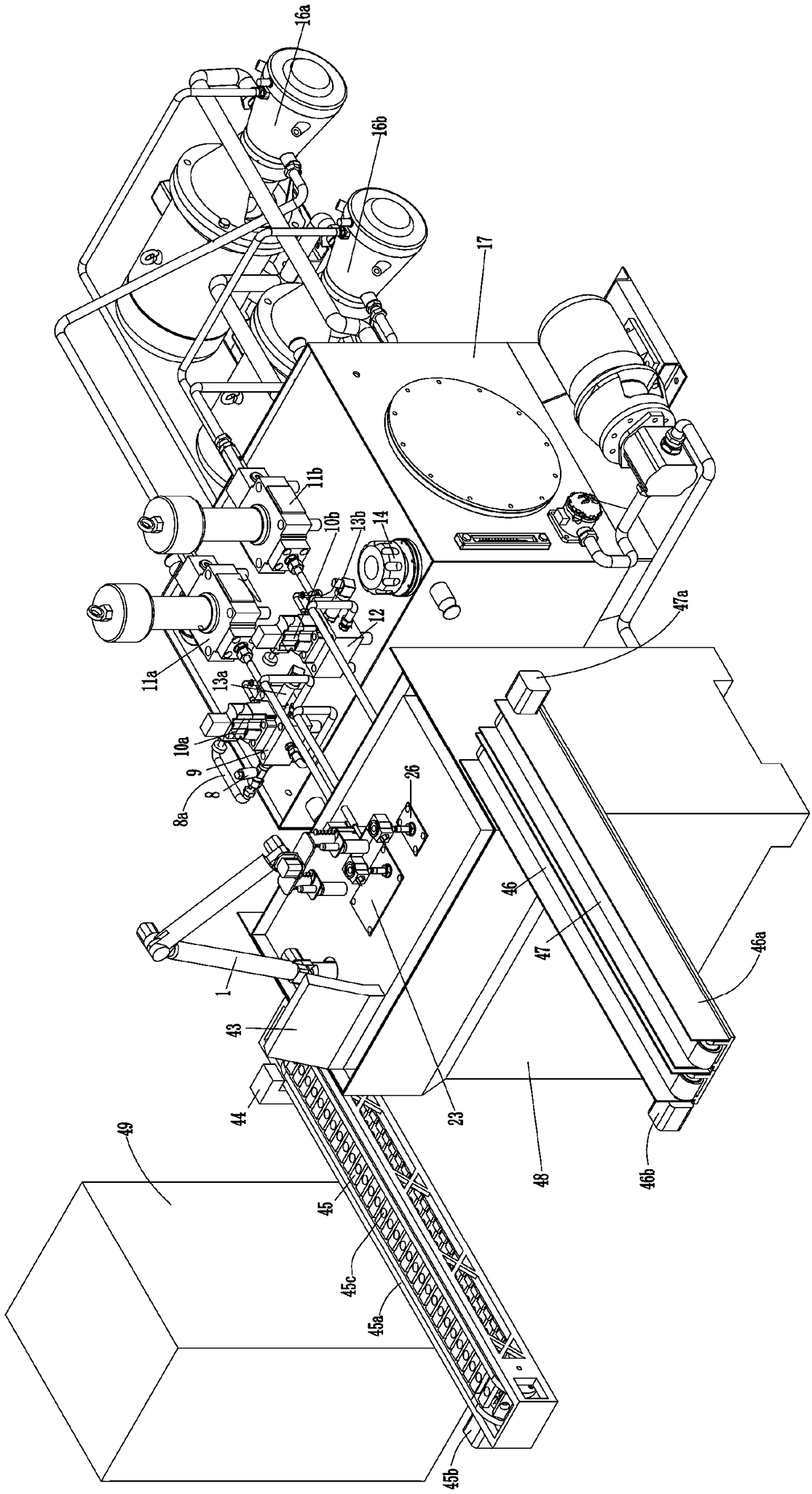

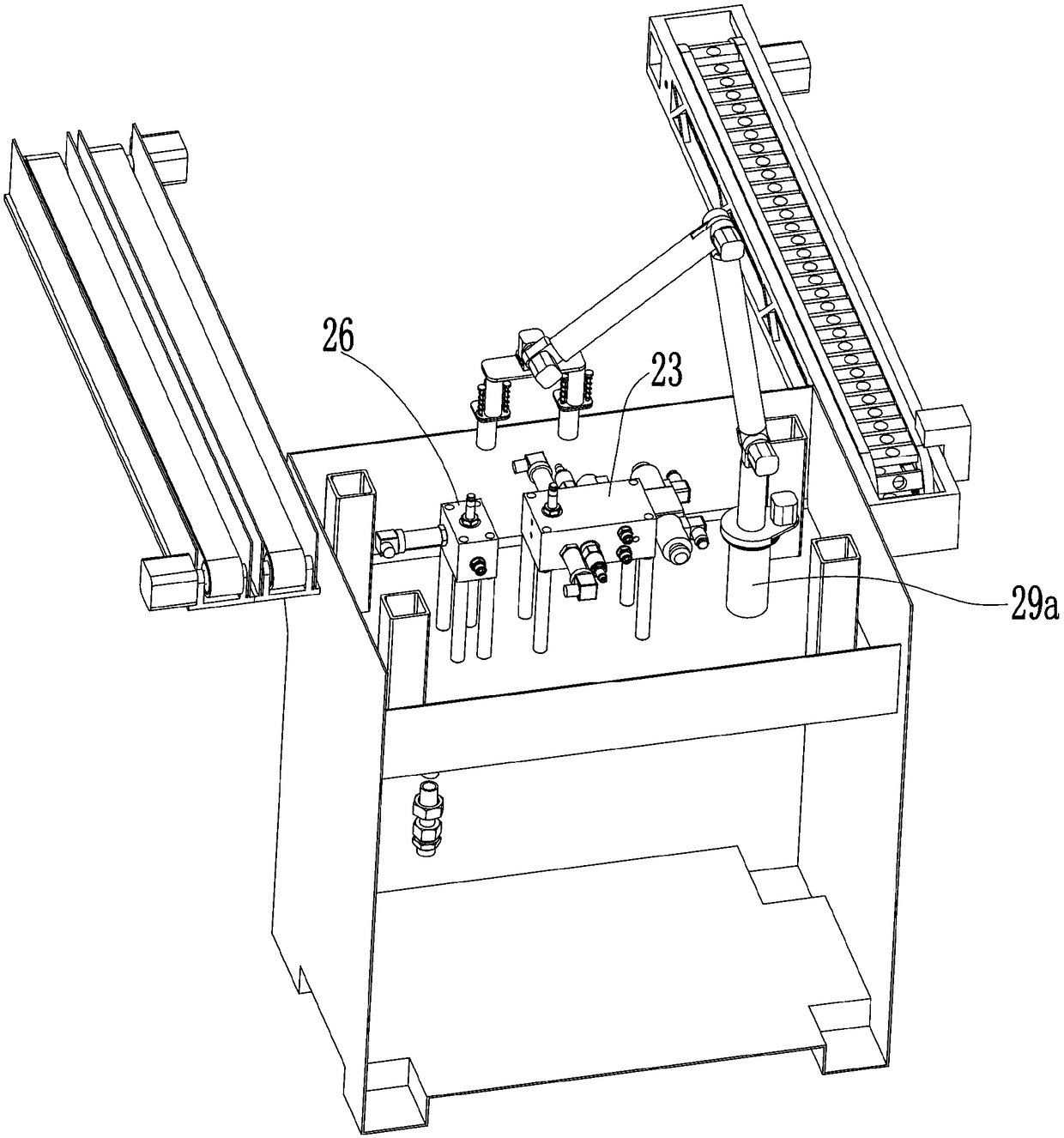

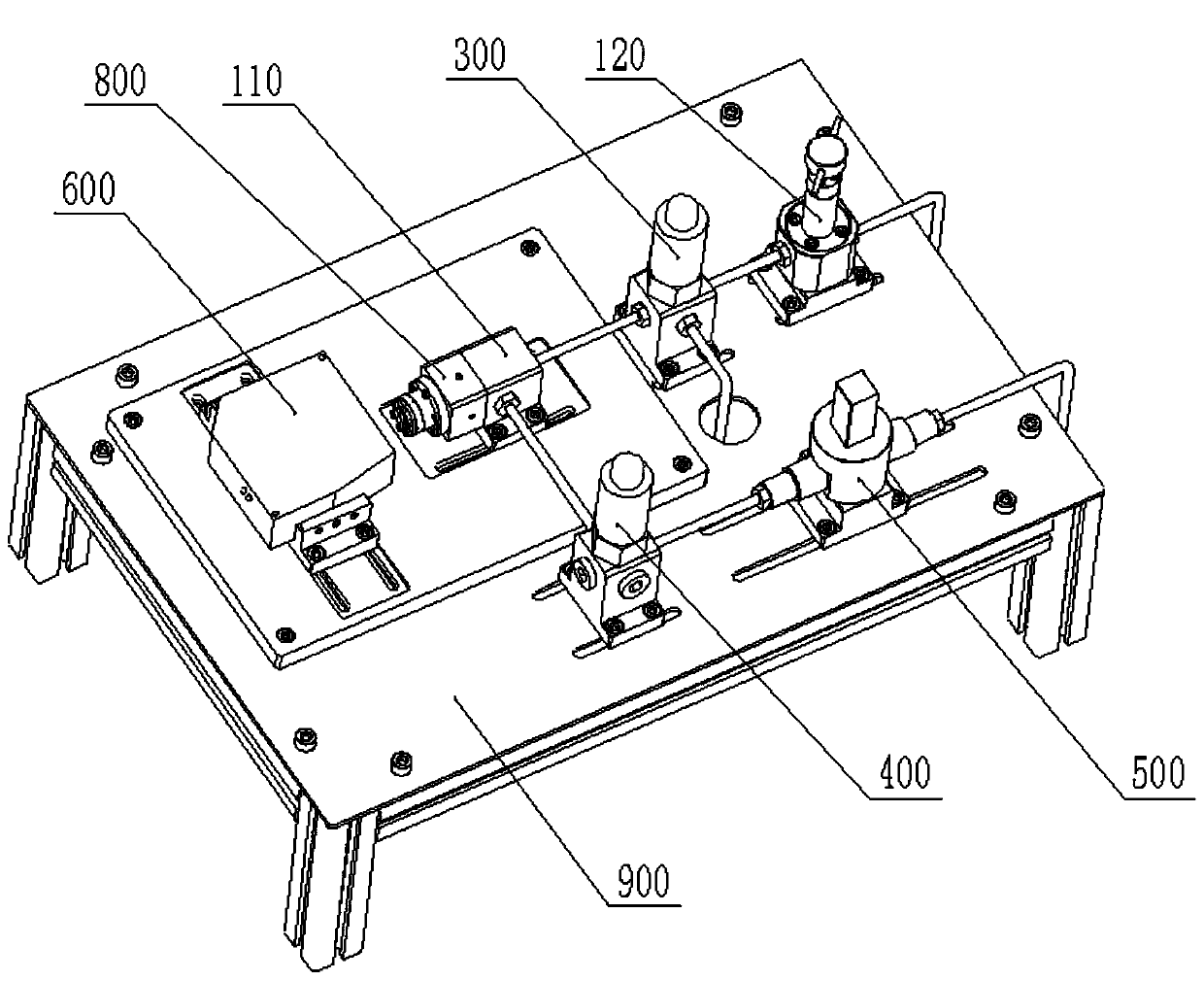

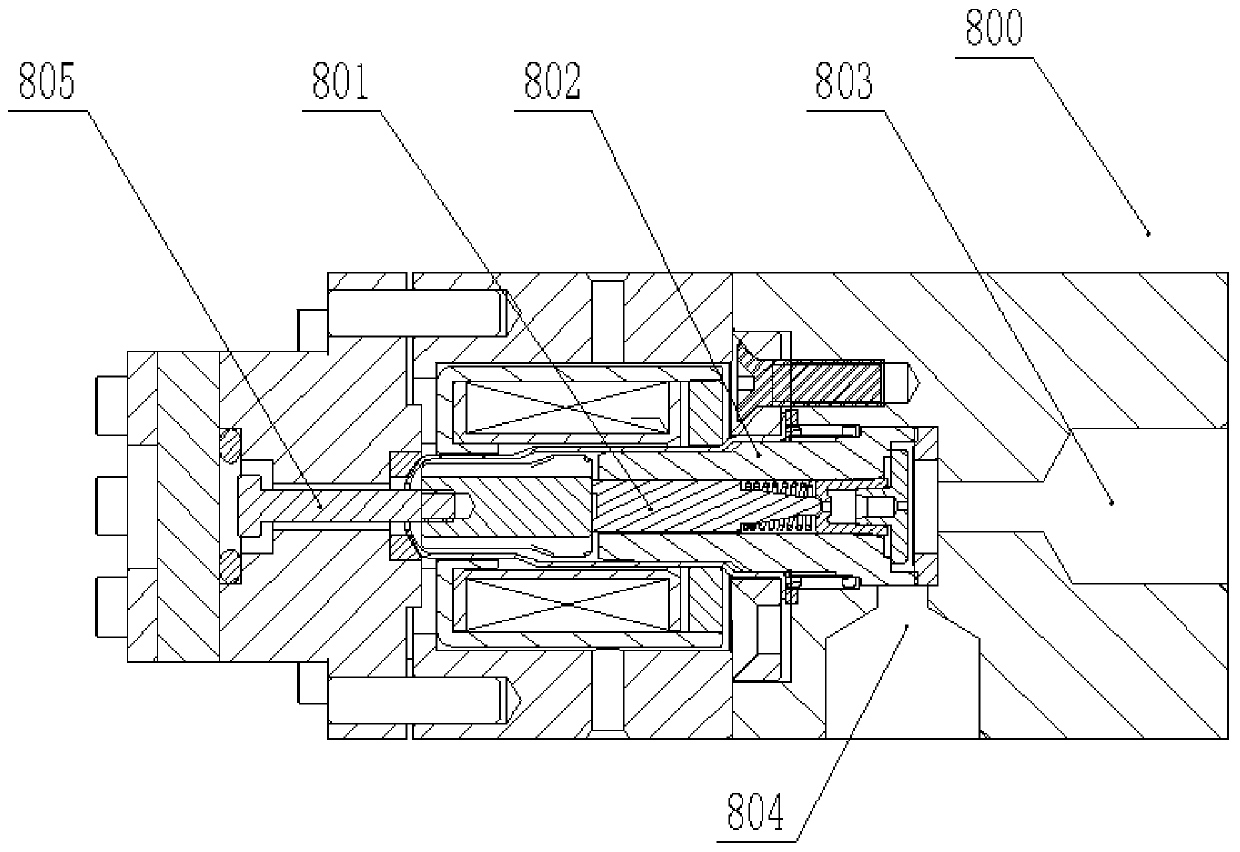

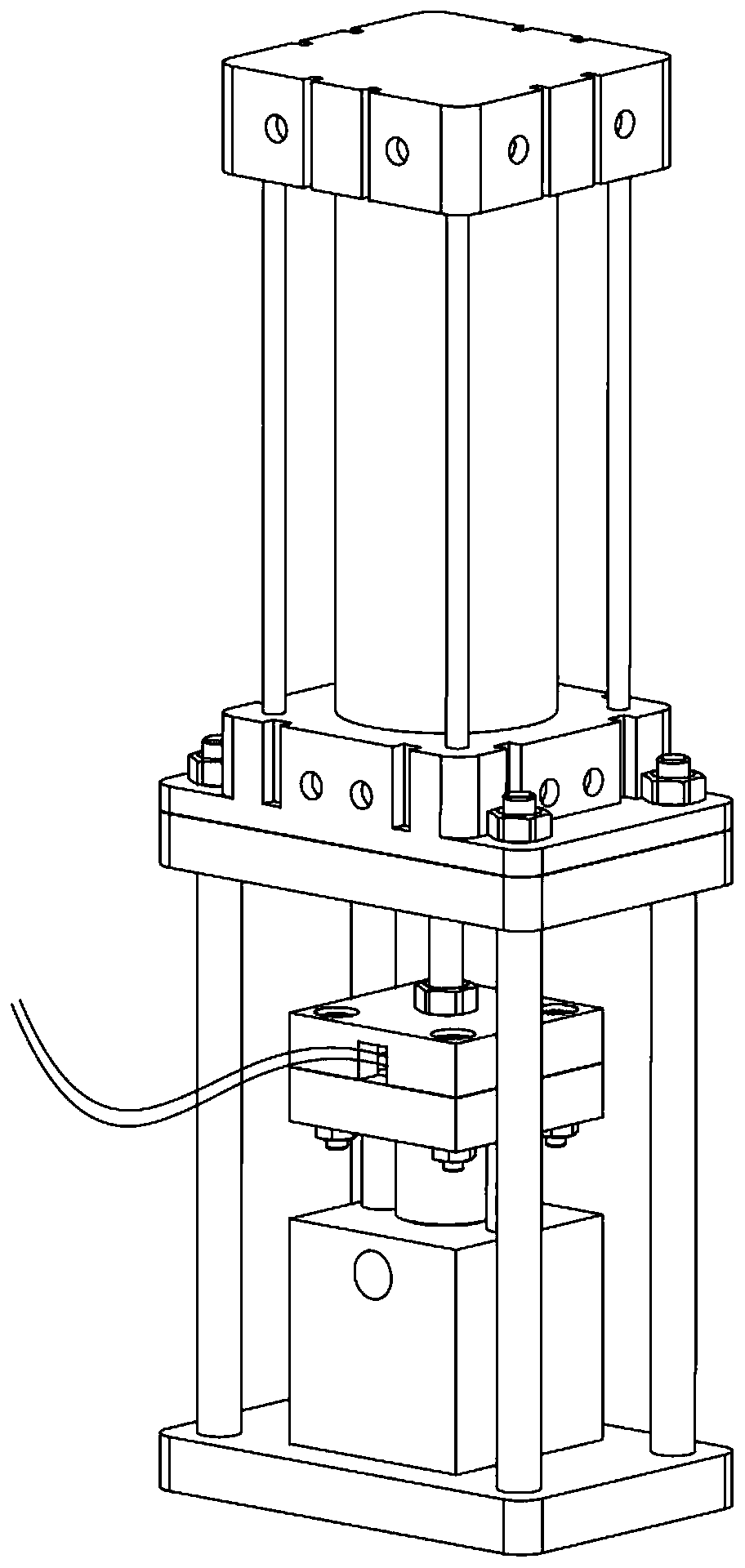

Automatic test device for two-position two-way threaded cartridge valve, and operating method thereof

InactiveCN109443747AImprove test efficiencyLabor savingMachine valve testingElectricityAutomatic test equipment

The invention discloses an automatic test device for a two-position two-way threaded cartridge valve, and an operating method thereof. The automatic test device for a two-position two-way threaded cartridge valve includes an electric control cabinet, a test stand and a hydraulic oil tank, wherein a flexibility testing mechanism and a pressure maintaining performance testing mechanism electricallyconnected to the electric control cabinet are arranged between the test stand and the hydraulic oil tank; the test stand is provided with a clamping mechanism and a coil mounting mechanism of the tested two-position two-way threaded cartridge valve; the test stand is further provided with a display screen; and the display screen, the clamping mechanism and the coil mounting mechanism are electrically connected to the electric control cabinet. The automatic test device for the two-position two-way threaded cartridge is not only simple in structure, but also can realize automatic clamping and mounting, automatic testing and automatic dismounting and placement.

Owner:邹城市劳思模具制造股份有限公司

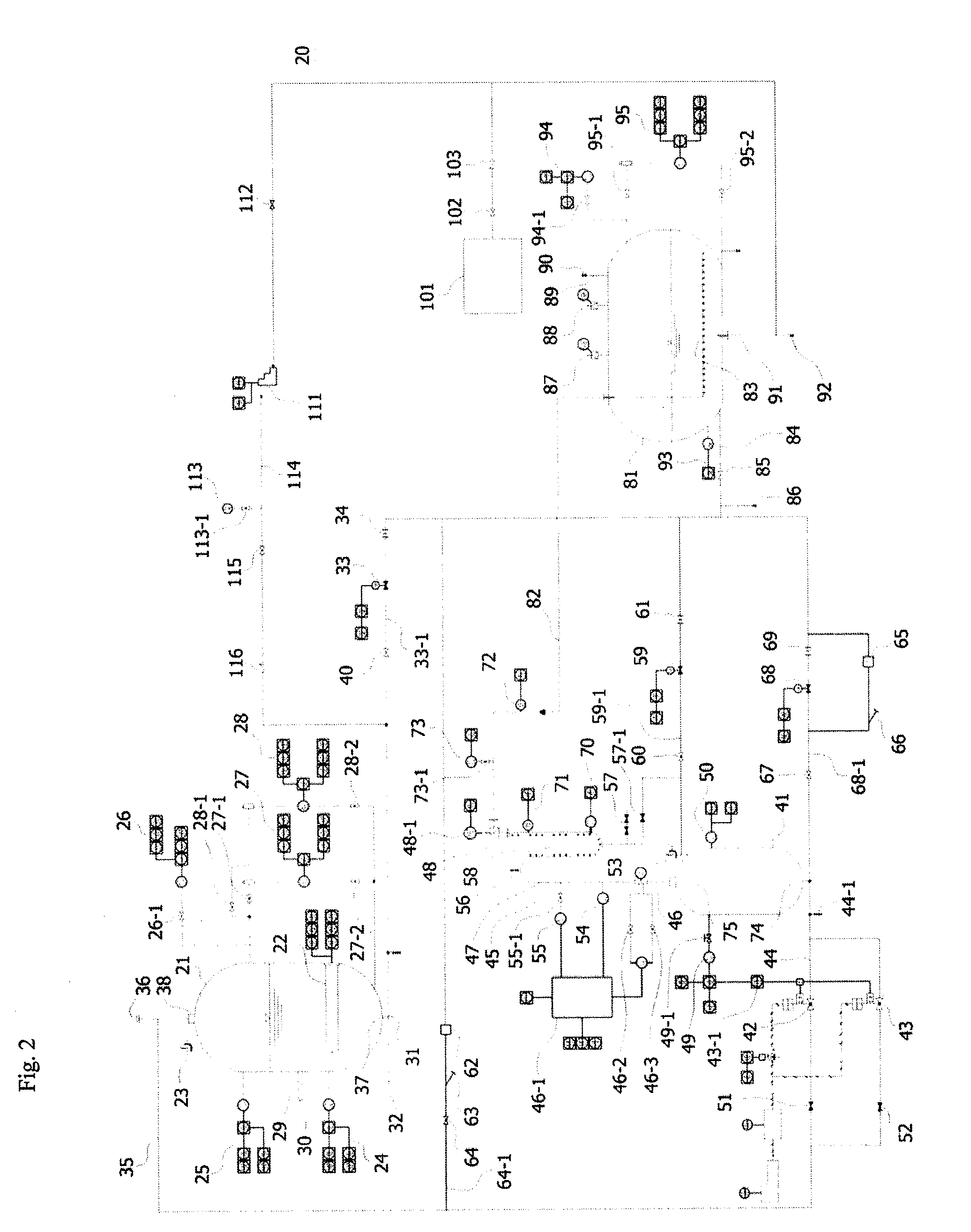

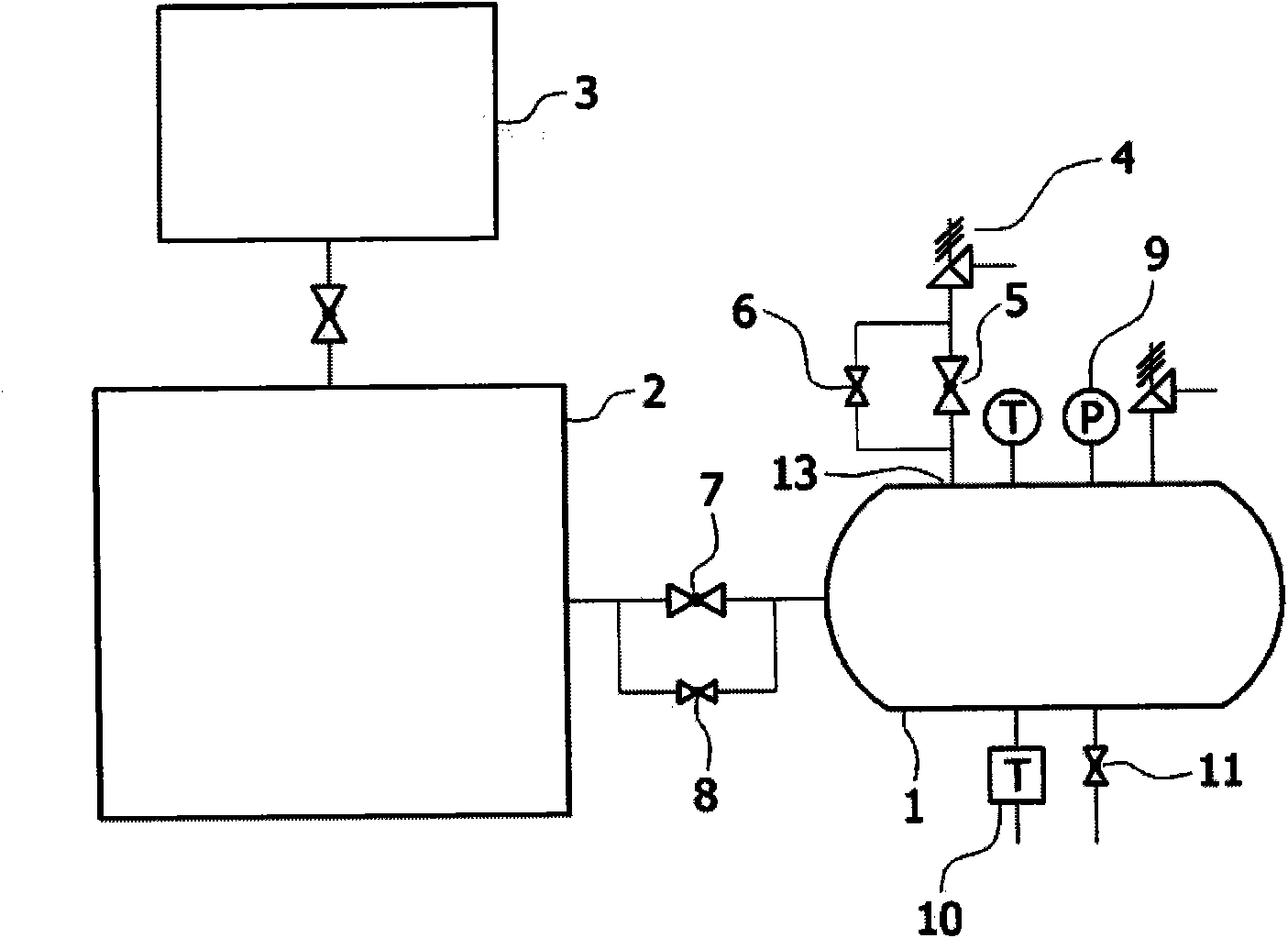

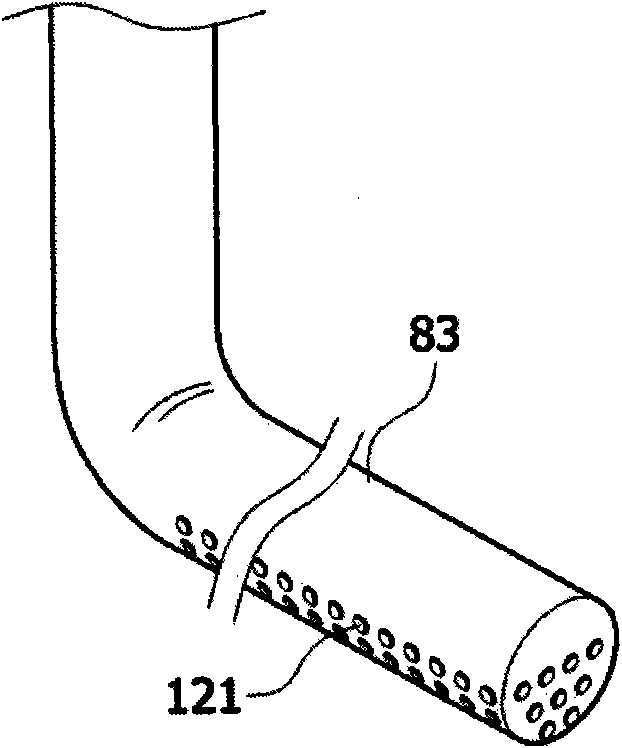

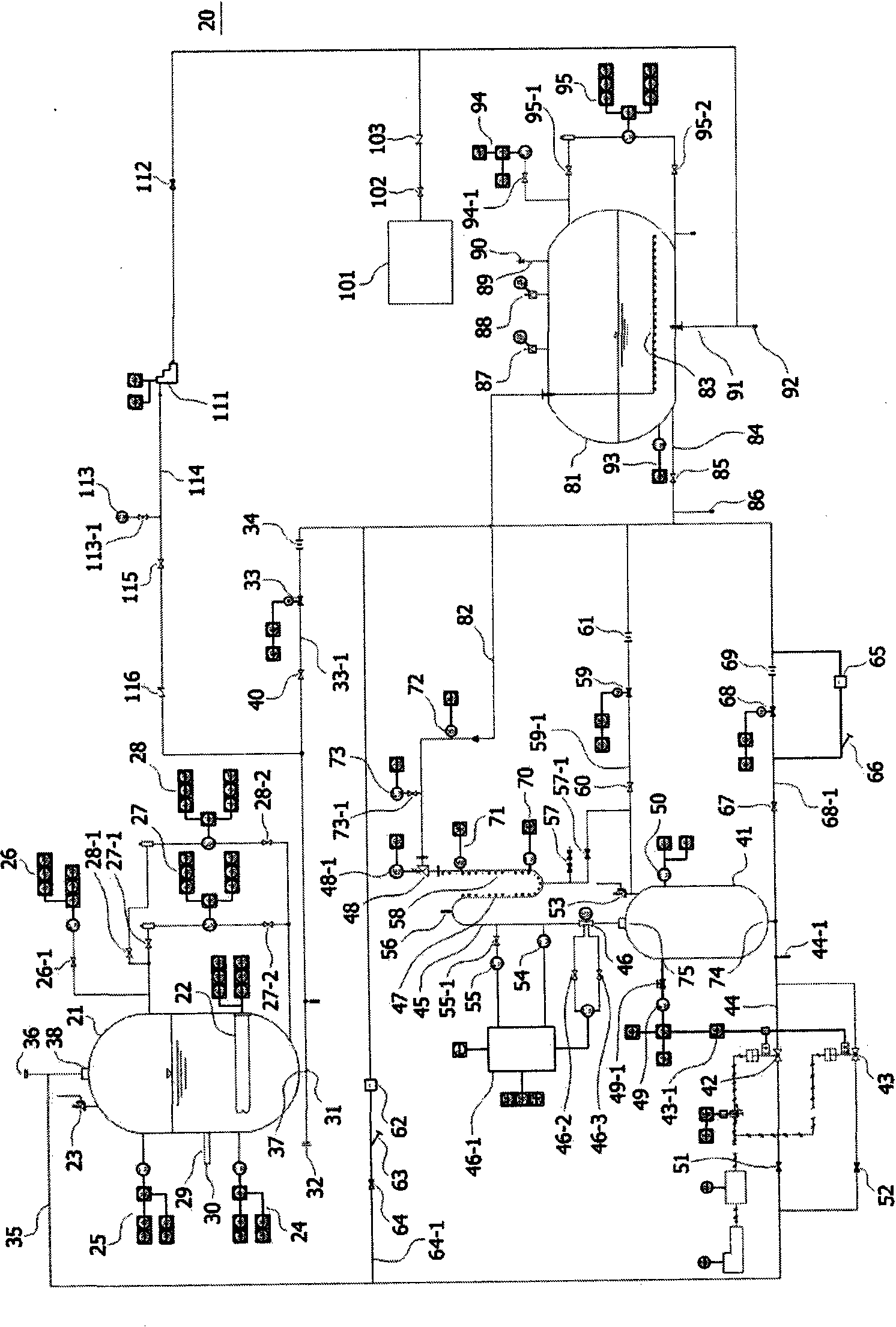

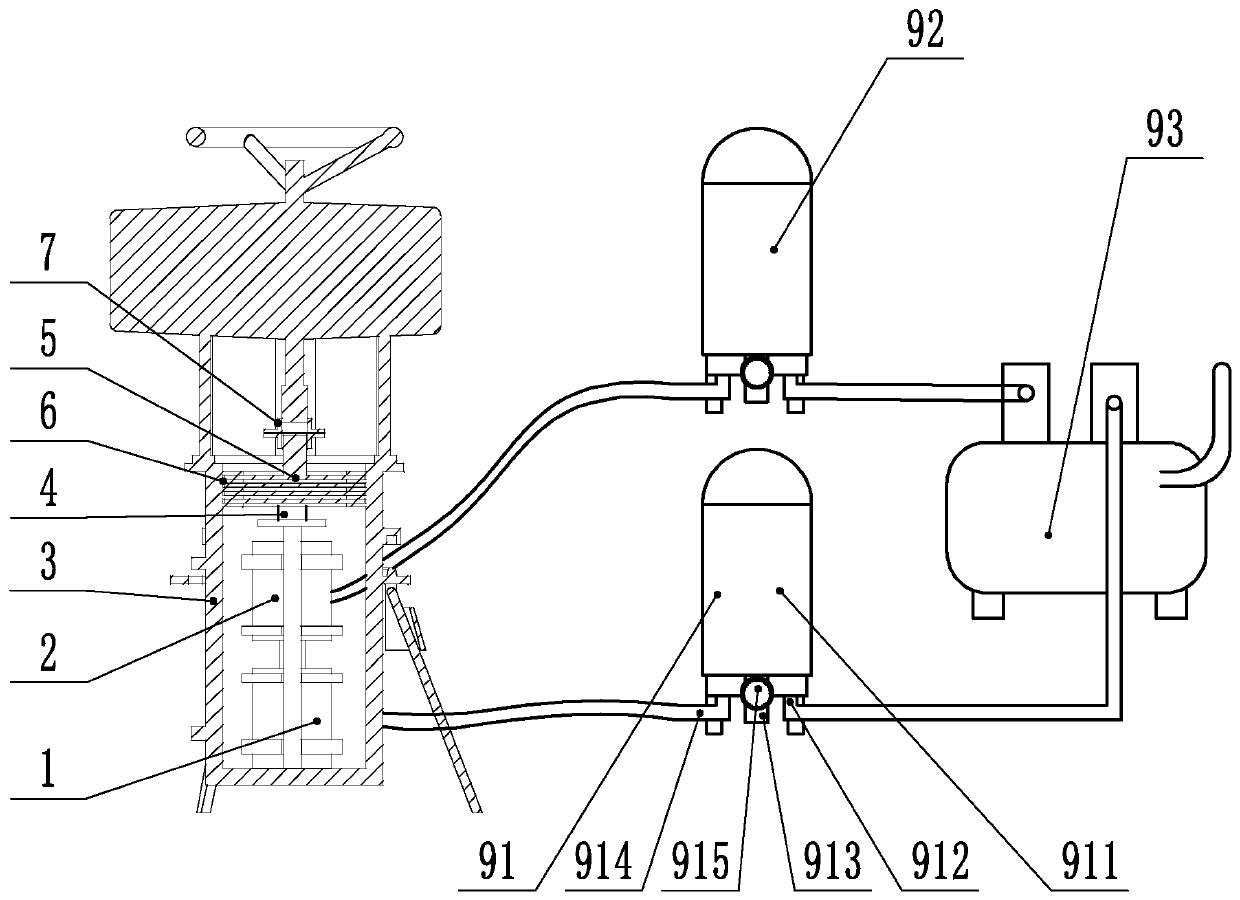

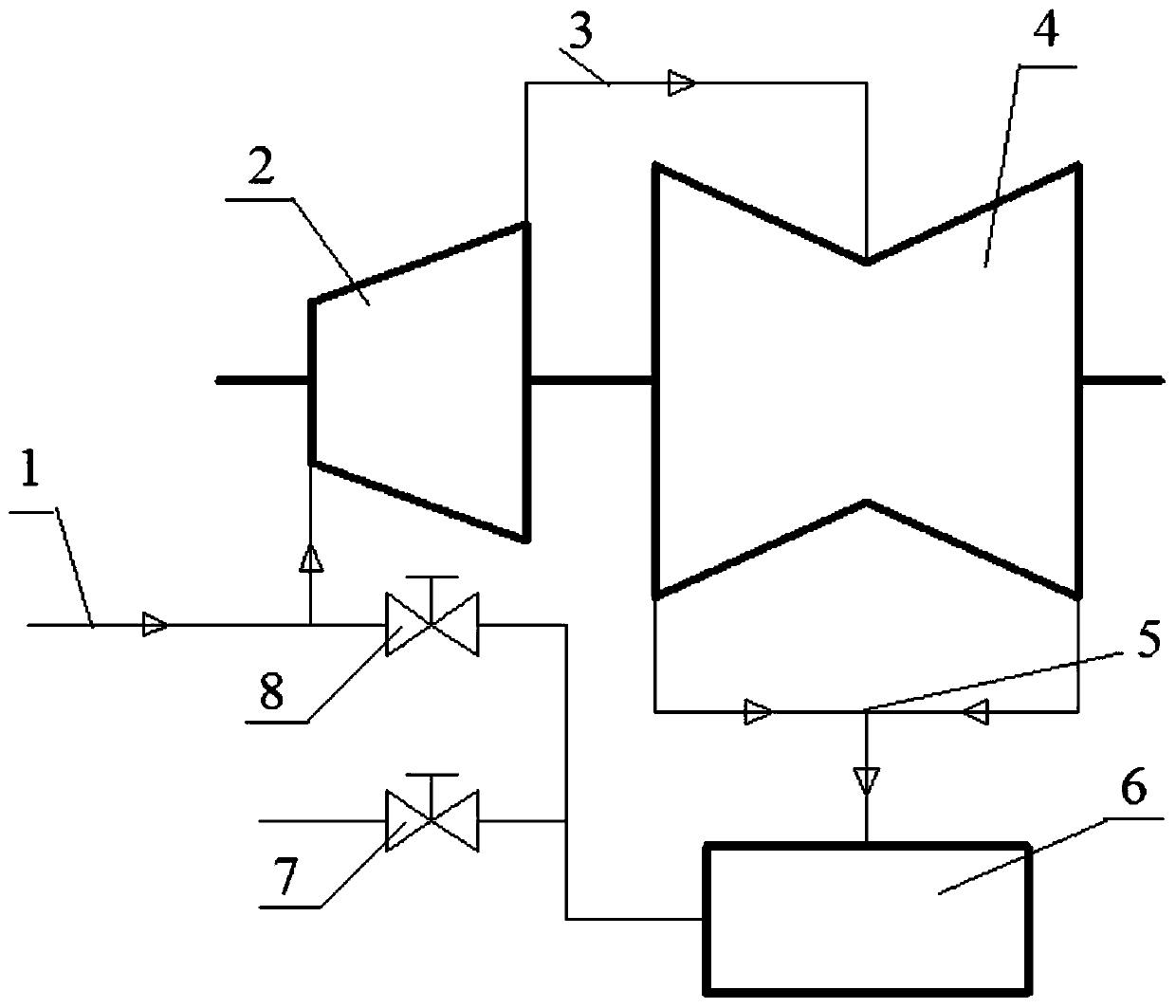

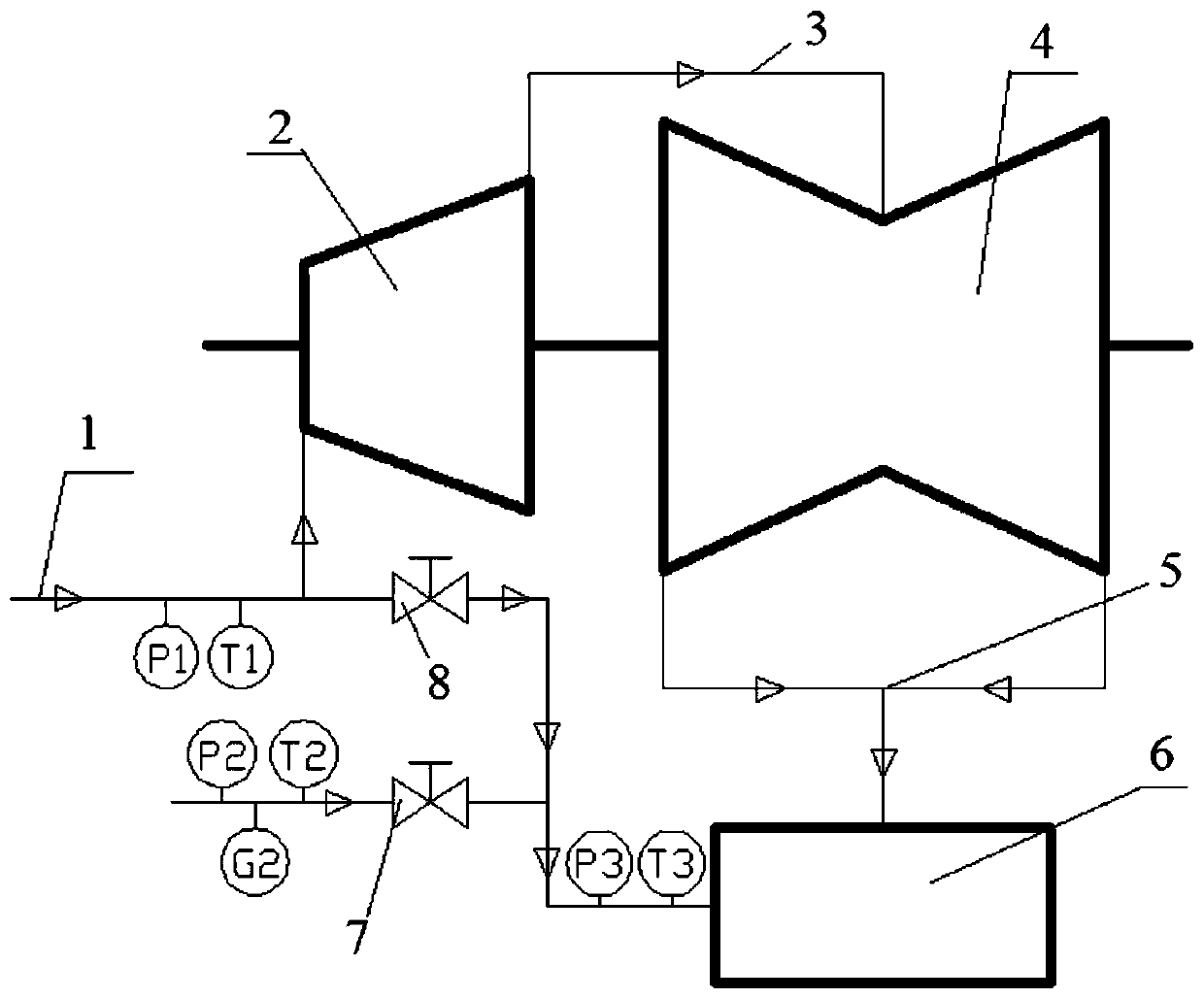

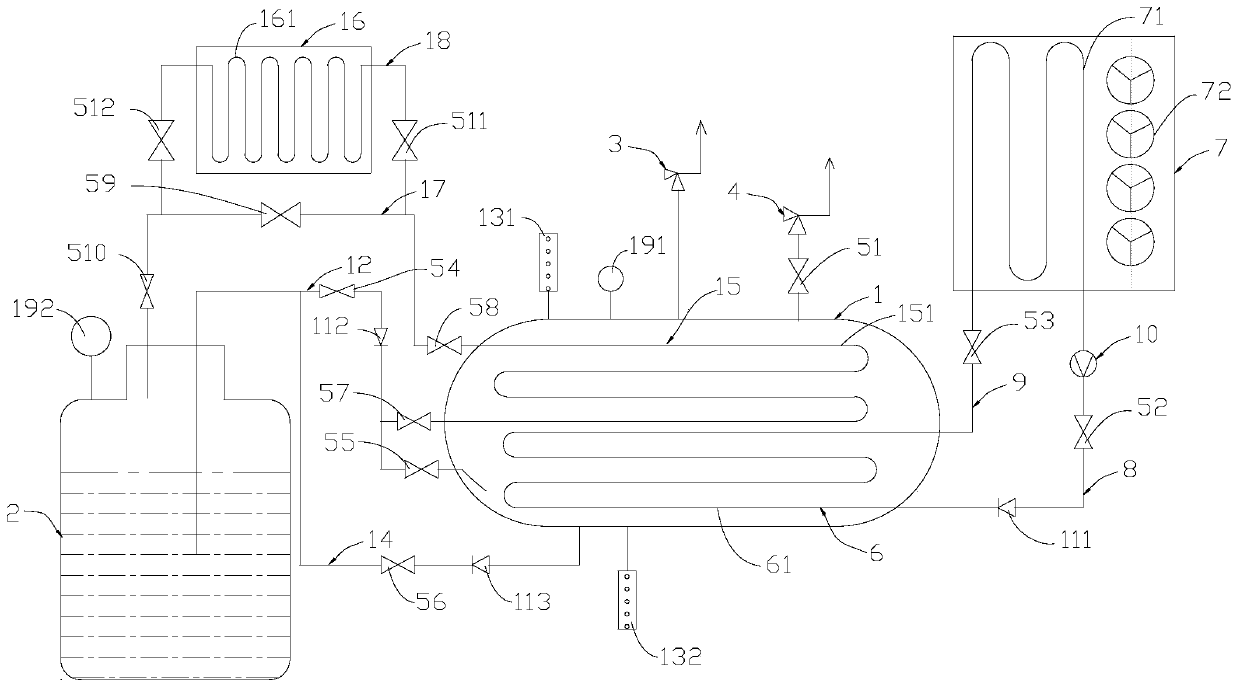

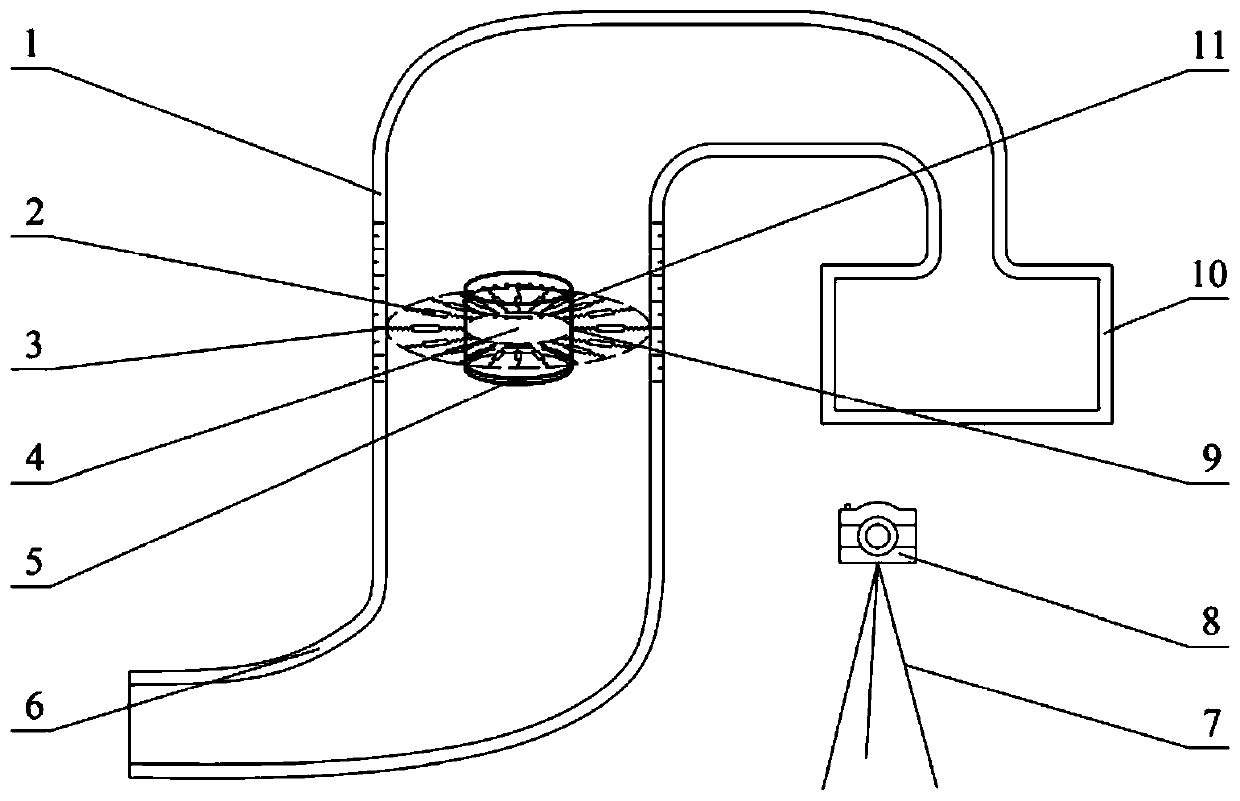

Test apparatus and method for safety valve

InactiveCN101960280ATest accurateIncrease capacityMachine valve testingMachine sealing rings testingWater dischargeEngineering

An apparatus and method for testing the performance of a safety valve perform tests under the same operation conditions as a pressurizer safety valve installed on a reactor coolant system of a nuclear power plant. The apparatus for testing the performance of a safety valve, i.e., a set pressure test, a seat tightness test, a flow rate test, a blow-down test, a water discharge test of a loop seal, a discharge load test, etc. on the safety valve, includes an accumulator 21 including at least one electric heater 22 for heating a predetermined amount of water filled therein, and storing steam produced by the electric heater 22 under high pressure, a test vessel 41 storing the steam supplied from the accumulator 21 under high pressure, and providing test pressure to a subject safety valve 48, the steam being supplied after flow rate and pressure thereof are controlled, a condensing tank 81 storing demineralized water to be supplied to the accumulator 21, and condensing and collecting the steam discharged from the subject safety valve 48, and a water-supply pump 111 supplying the water stored in the condensing tank 81 to the accumulator 21.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD

High-pressure valve service life testing device

PendingCN111272414AAchieving processing powerImplement storageMachine valve testingControl systemSystem pressure

The invention relates to a high-pressure valve service life test device. An electrically-driven valve to be tested is placed in a high-pressure simulation container, a torque sensor is installed between the valve to be tested and an electric drive head, a strain gauge is installed on a valve body, and the valve to be tested is connected with a valve internal pressure output system and used for simulating internal pressure loads borne by the inner wall of the valve body in the opening and closing process of the valve to be tested. The high-pressure simulation container is connected with a valveexternal pressure output system and used for simulating an external pressure load borne by the outer wall of the tested valve under the deep sea high-pressure environment condition; a collection, storage and control system is connected with a torque sensor, the strain gauge, an electrically-driven tested valve, a valve internal pressure output system and a pressure transmitter so as to be used for respectively controlling the automatic opening and closing of the electrically-driven tested valve, applying an internal pressure load, an external pressure load and internal and external simultaneous pressure loads to the electrically-driven tested valve, and realizing the fatigue life test of the electrically-driven tested valve under the action of the dynamic pressure load.

Owner:SHANGHAI MARINE EQUIP RES INST

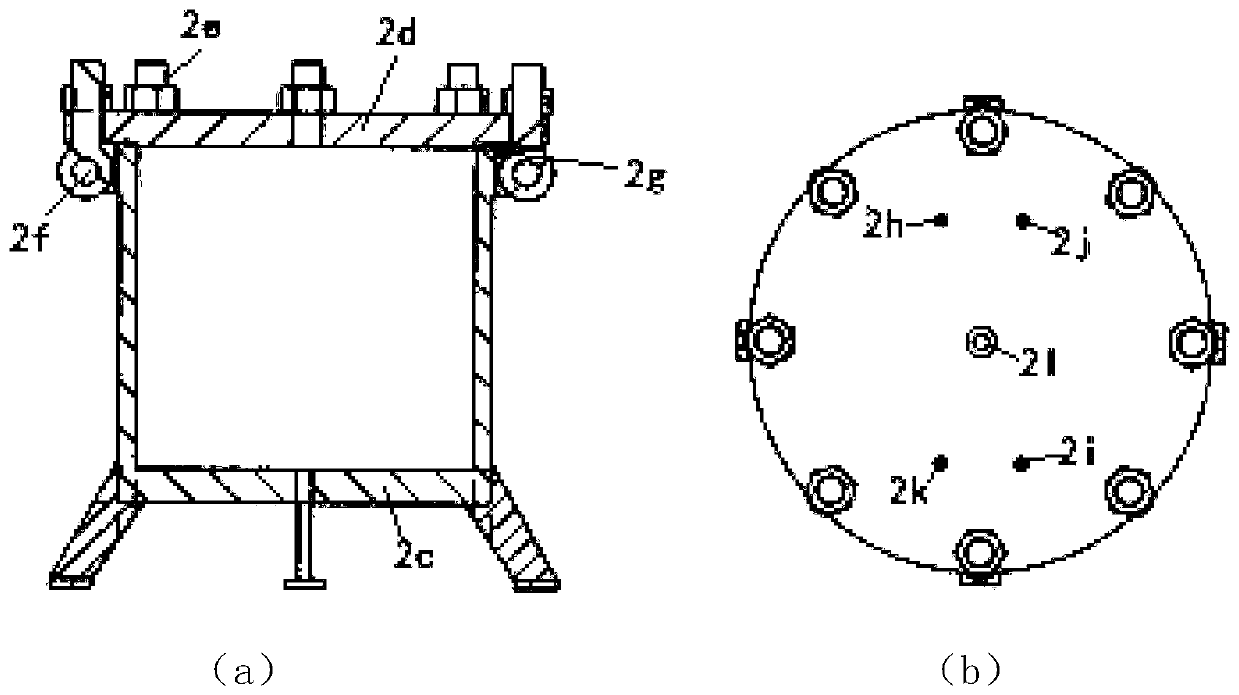

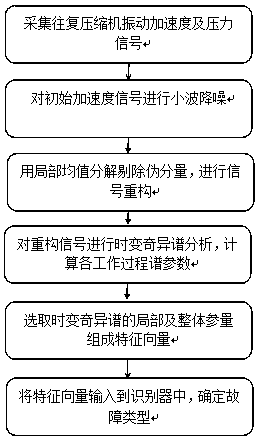

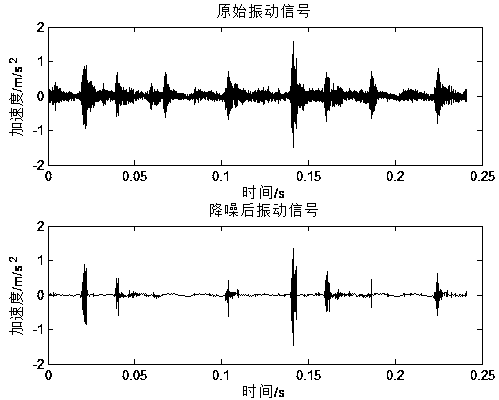

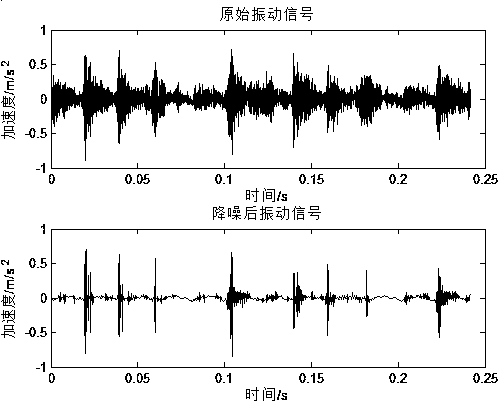

Reciprocating compressor air valve fault diagnosis method based on time-varying singular spectrum

InactiveCN111259992AEfficient extraction of feature vectorsVerify validityMachine valve testingCharacter and pattern recognitionWavelet noiseTime information

The invention relates to a reciprocating compressor air valve fault diagnosis method based on a time-varying singular spectrum, and the method specifically comprises the steps: collecting an air valvevibration acceleration signal and a pressure signal, carrying out the wavelet noise reduction and decomposition of an initial vibration acceleration signal, and removing a pseudo-component; selectinga proper time delay to construct a window function, and introducing time information into the multi-fractal analysis of the vibration signal, thereby obtaining a time-varying singular spectrum; and enabling the drawn time-varying singular spectrogram of each working process to describe the whole and detail information of the vibration signal more finely, so that parameters with large influence difference for a certain fault type are captured, fault feature vectors are convenient to construct, an SVM classifier is convenient to establish, parameters are optimized and set, and finally, the fault diagnosis of the air valve is successfully realized. The problem of fault diagnosis of the air valve of the reciprocating compressor is solved.

Owner:NORTHEAST GASOLINEEUM UNIV

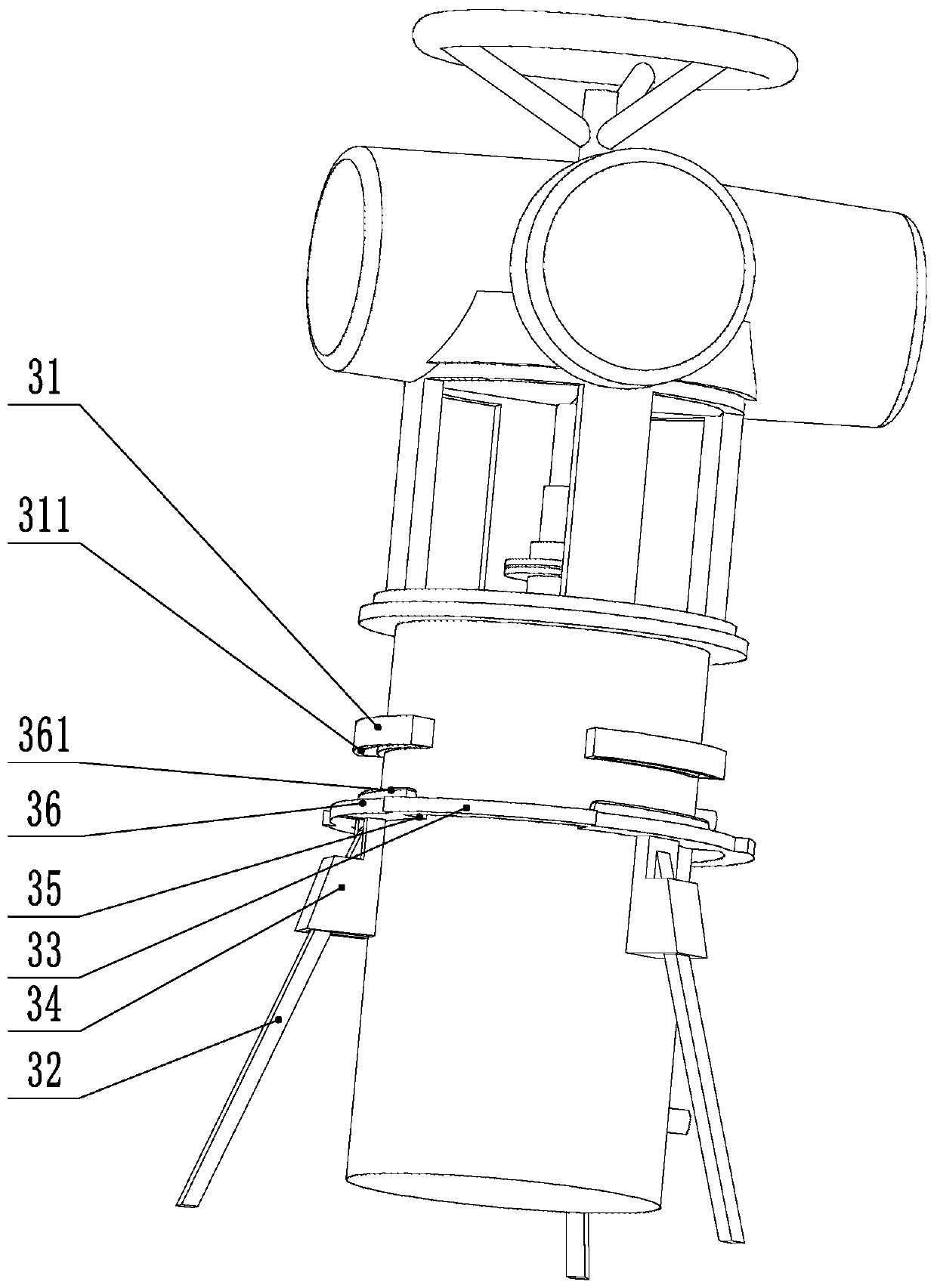

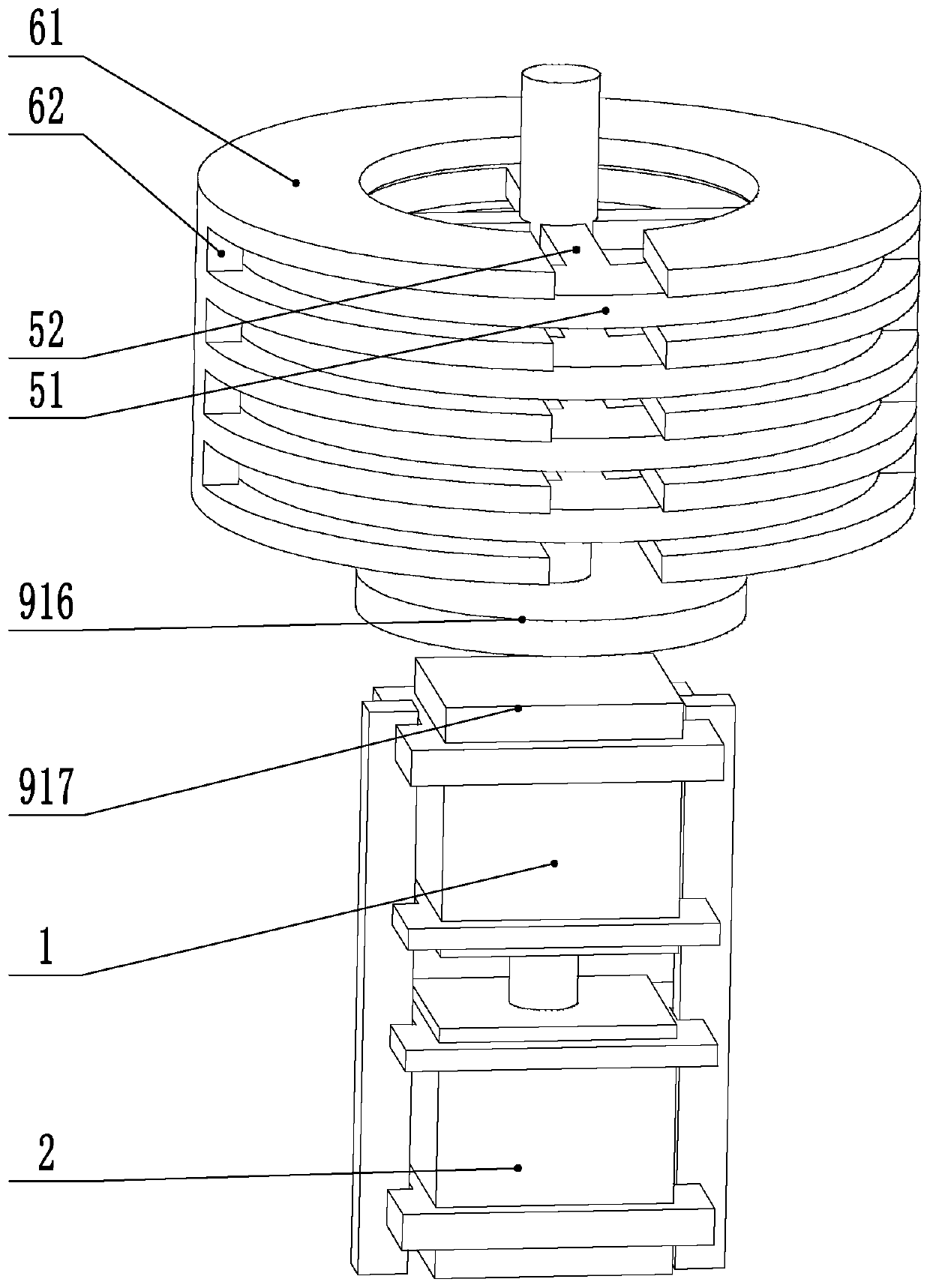

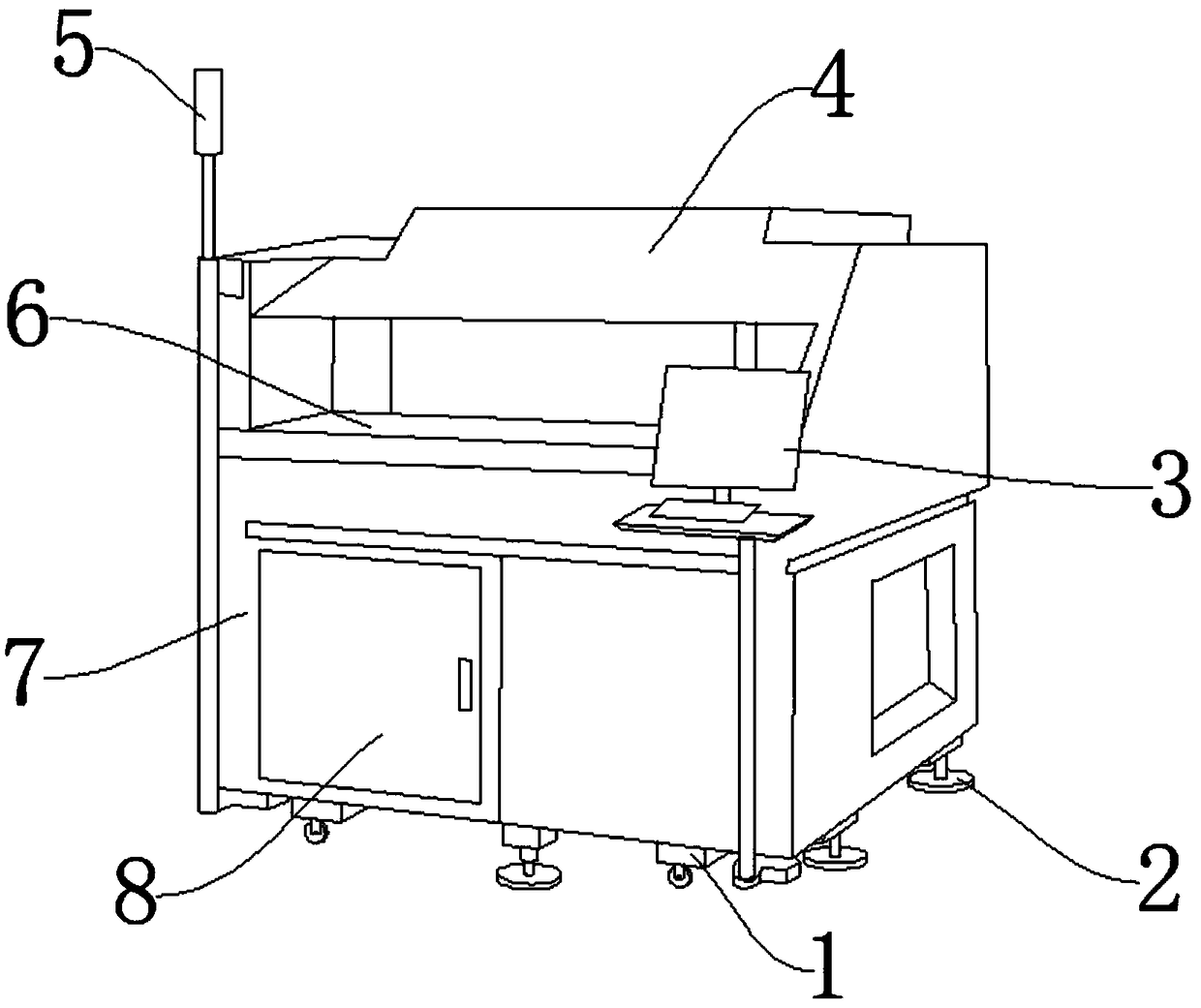

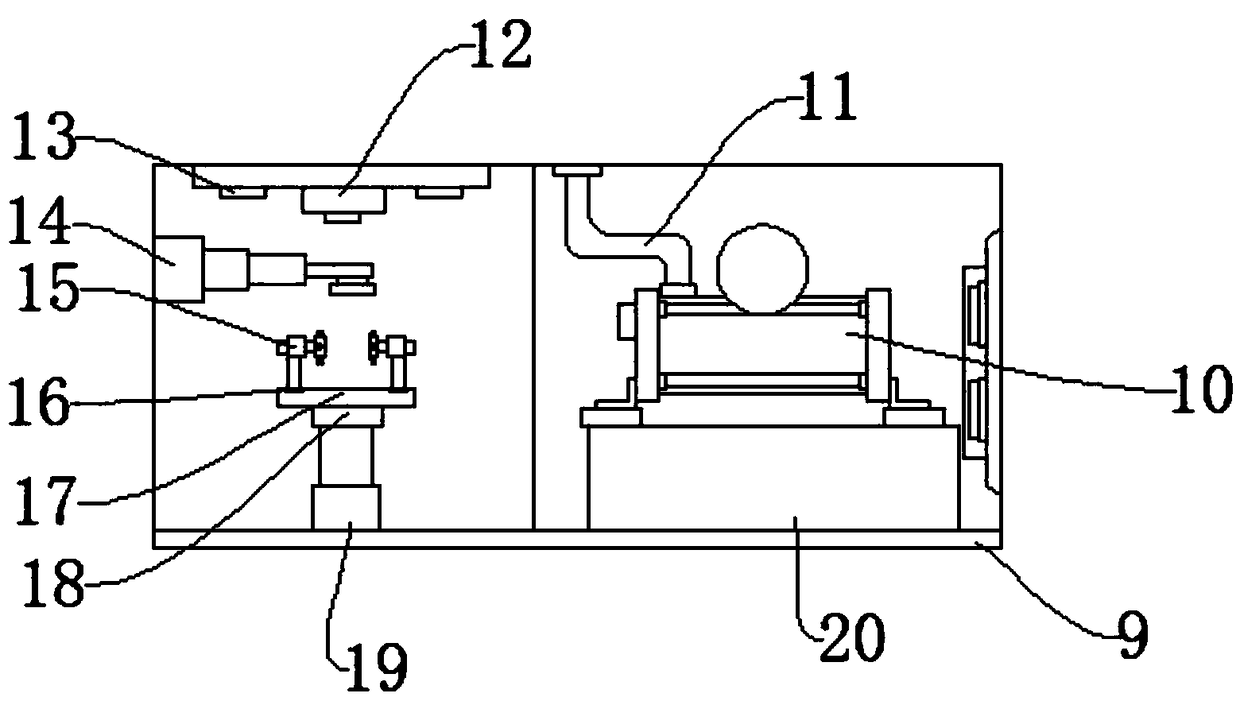

Comprehensive testing device for rotary valve electric actuator

The invention discloses a comprehensive testing device for a rotary valve electric actuator. The comprehensive testing device comprises a base, a first cylinder, a second cylinder, an encoder, a movable friction disc, a fixed friction disc, a torque sensor and a coupler, wherein a mounting cavity is formed in the base, a mounting station for mounting an actuator is arranged at the top end of the base, a main shaft is arranged on the movable friction disc, the torque sensor and the main shaft are connected with an external actuator by means of the coupler, and the encoder is mounted on the movable friction disc, and the first air cylinder and the second air cylinder output alternately to generate variable pressure, so that the fixed friction disc generates variable friction forces on the movable friction disc, and the actuator is subjected to different torque. In the test process, the torque sensor tests the torque changes of the actuator, the encoder tests the rotation angle changes ofthe actuator, and the test values are compared with standards, so as to test whether the actuator is qualified or not. Through the arrangement, three key values of a valve can be tested at one time,the operation is convenient, and the efficiency is high.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE

Regulation valve cavitation diagnosis system and method

ActiveCN109668723AMachine valve testingInvestigating abrasion/wear resistanceFrequency changerCavitation

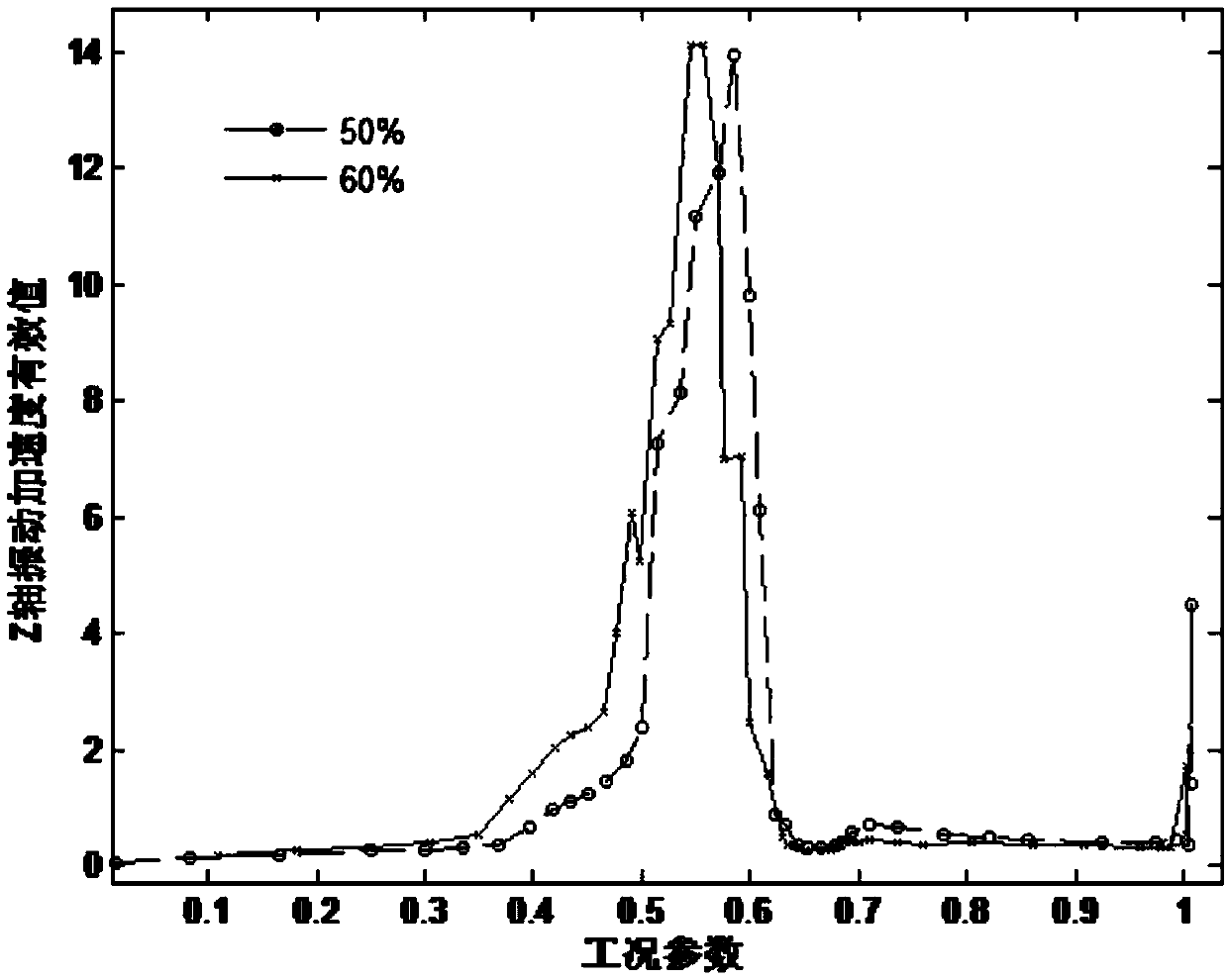

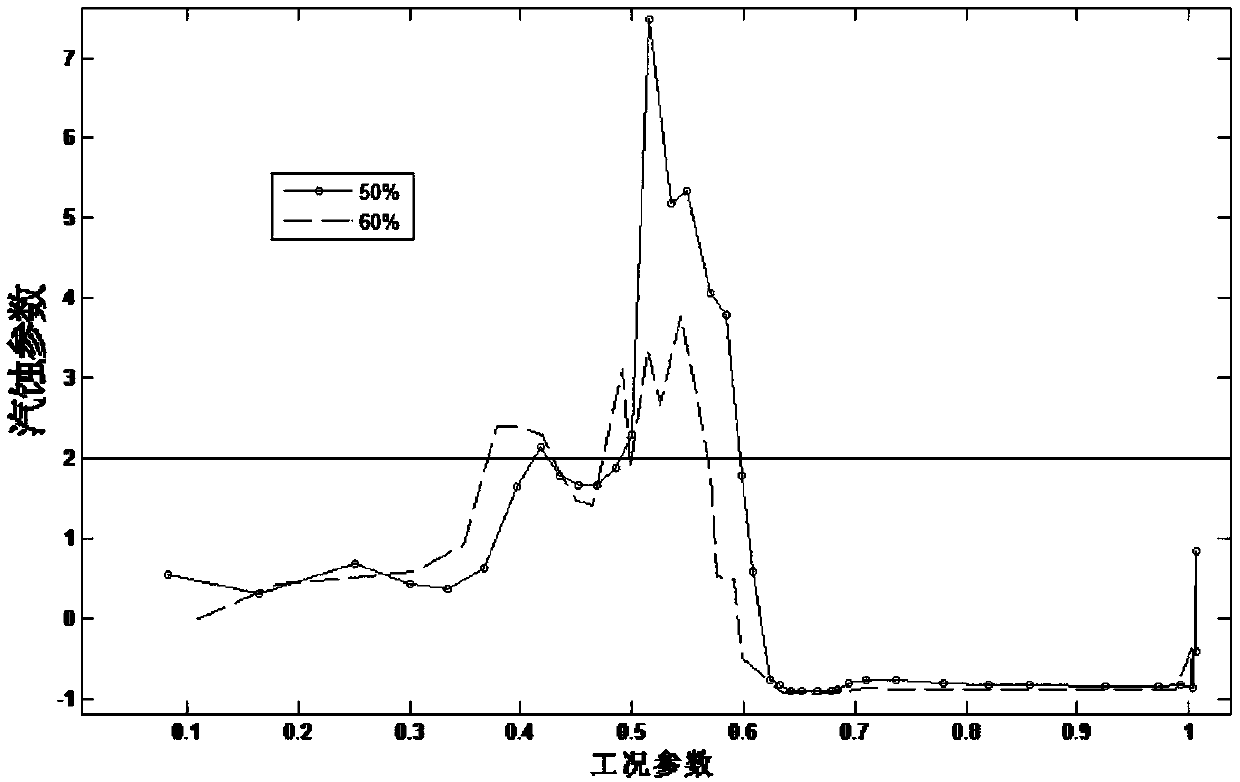

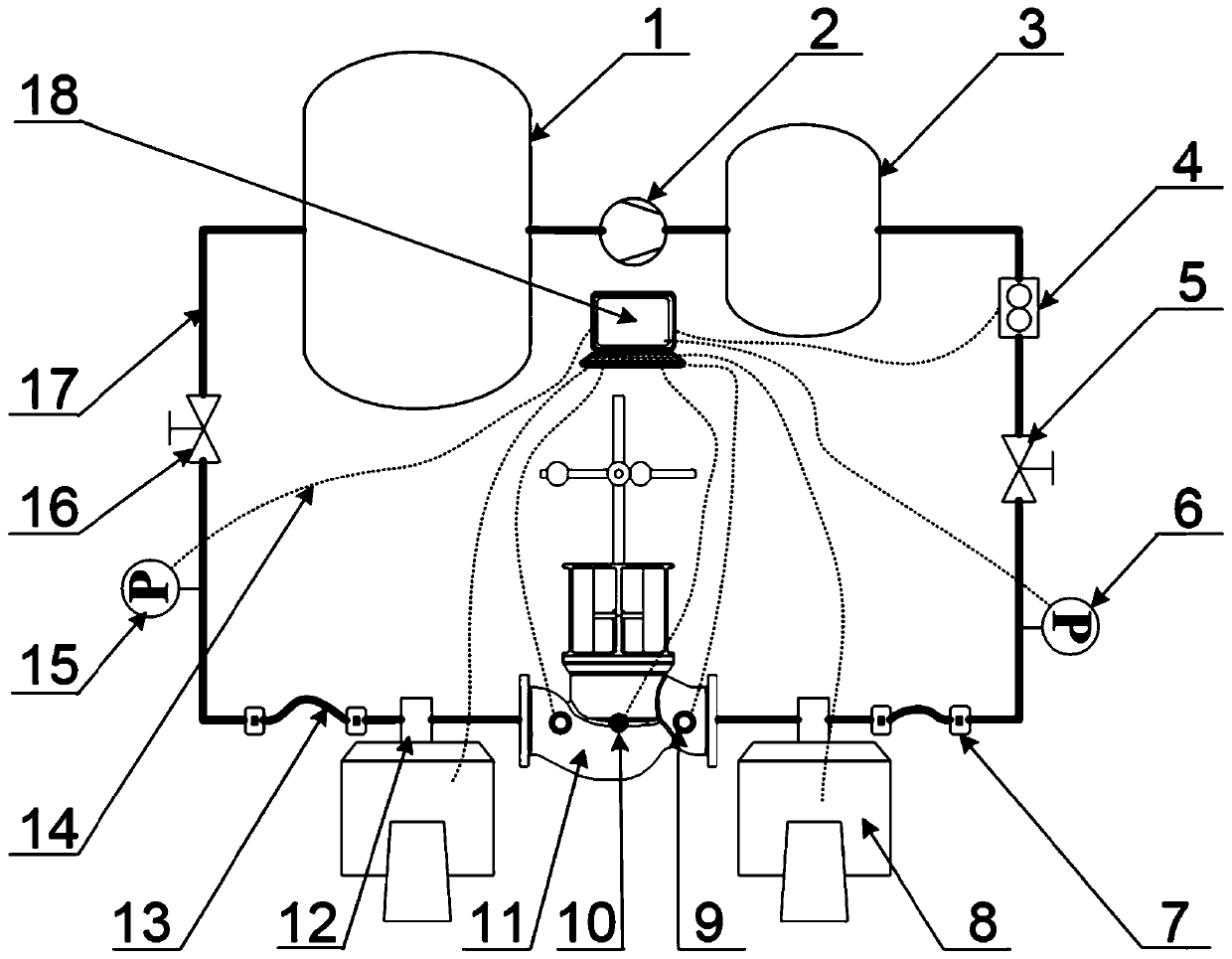

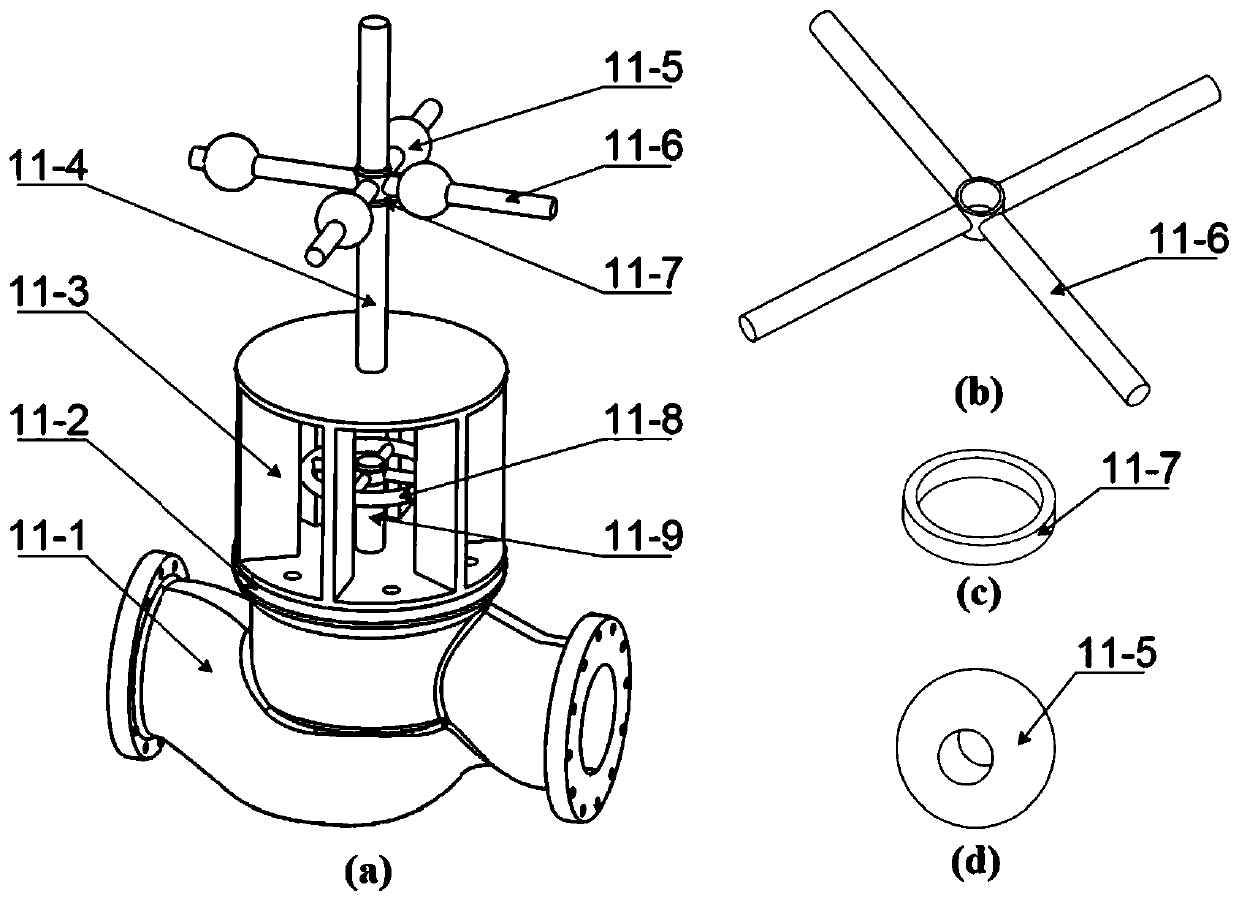

The invention relates to a regulation valve cavitation diagnosis system and method. A regulation valve testing pipeline system comprises a multistage centrifugal pump, a multistage centrifugal pump frequency changer, a to-be-tested regulation valve of a diagnosed object, an upstream stop valve, a downstream throttle valve and a system pipeline to be tested, wherein the multistage centrifugal pumpis used for providing relative pressure; the multistage centrifugal pump frequency changer is used for regulating the revolving speed of the multistage centrifugal pump; and the upstream stop valve and the downstream throttle valve are respectively arranged in front of and behind the to-be-tested regulation valve. According to the invention, through adopting the above technology, upstream pressurein front of the to-be-tested regulation valve, downstream pressure behind the to-be-tested regulation valve, Z-axis vibration acceleration behind the to-be-tested regulation valve and flow in front of the to-be-tested regulation valve are utilized for calculating and judging whether cavitation happens or not; through a cavitation diagnosis device, the cavitation parameters of the regulation valveunder a certain aperture are diagnosed, so that a condition for cavitation under a current regulation valve aperture can be accurately obtained, and the effectiveness value of the vibration acceleration, working condition parameters, cavitation parameters and cavitation severity coefficients can be solved, so that the cavitation diagnosis evaluation of the regulation valve is realized.

Owner:ZHEJIANG UNIV OF TECH

Valve coupling vibration testing device and testing method

ActiveCN110146278AReduce experiment costMachine valve testingVibration testingVibration accelerationBuffer tank

The invention discloses a valve coupling vibration testing device and a testing method. The test device comprises a storage tank, power machinery, a buffer tank, a flow meter, an upstream control valve, an upstream pressure gauge, a valve to be tested, a downstream pressure gauge and a downstream control valve which are sequentially connected to a pressure withstanding flexible pipe through a metal pipeline to form a fluid flow loop. External excited vibration excitation is provided by a vibration bench. A vibration acceleration sensor and a strain gauge are arranged on the valve to be testedand are used for measuring vibration acceleration and dynamic strain respectively, and a center of gravity adjustment mechanism is installed to replace an execution mechanism. In the invention, external excited vibration of valves, flow-excited vibration and coupling vibration when the two work together of different working media, different structural forms and different working conditions can beinvestigated, and the vibration caused by collision of components is distinguished through testing the valves of different assembling forms.

Owner:ZHEJIANG UNIV

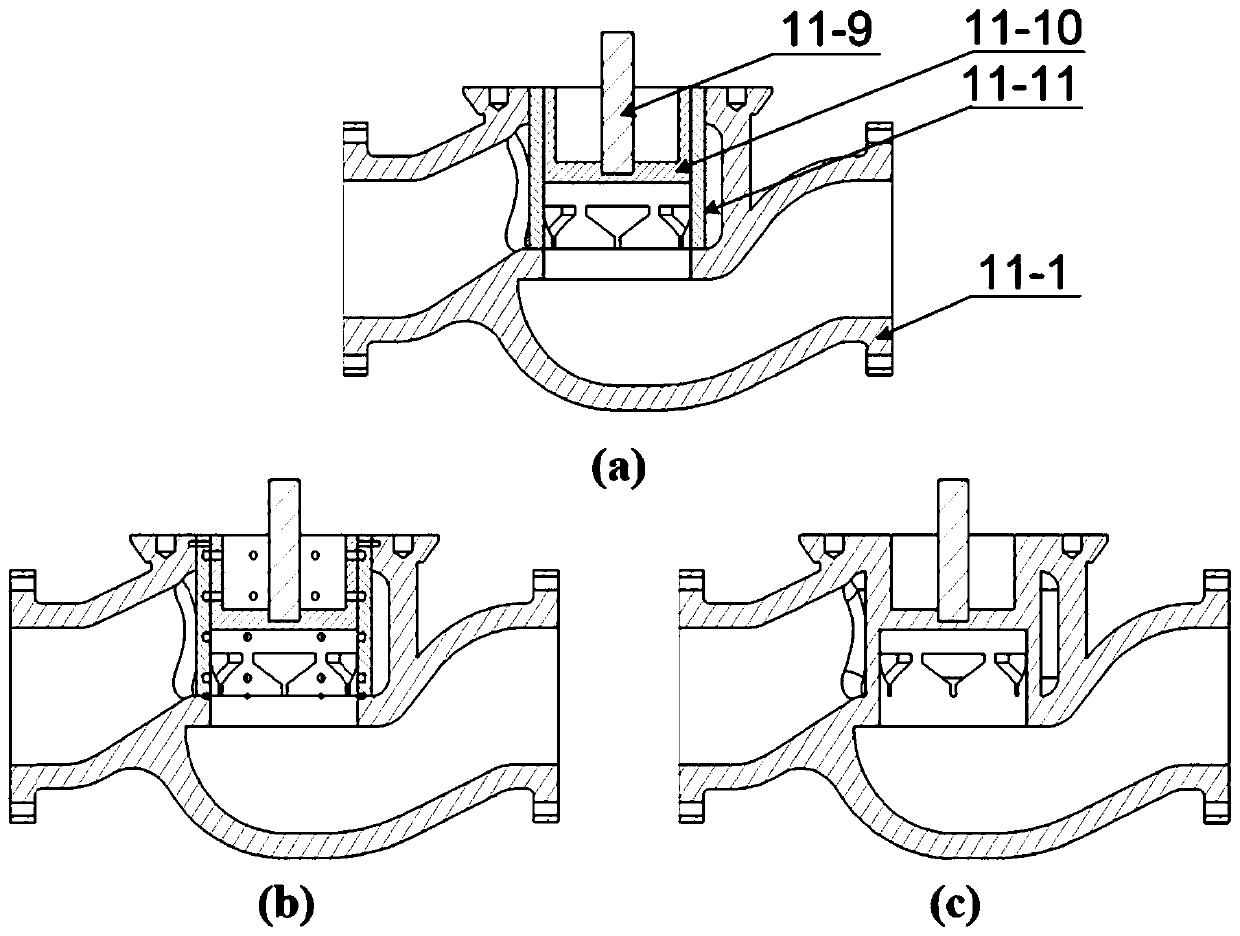

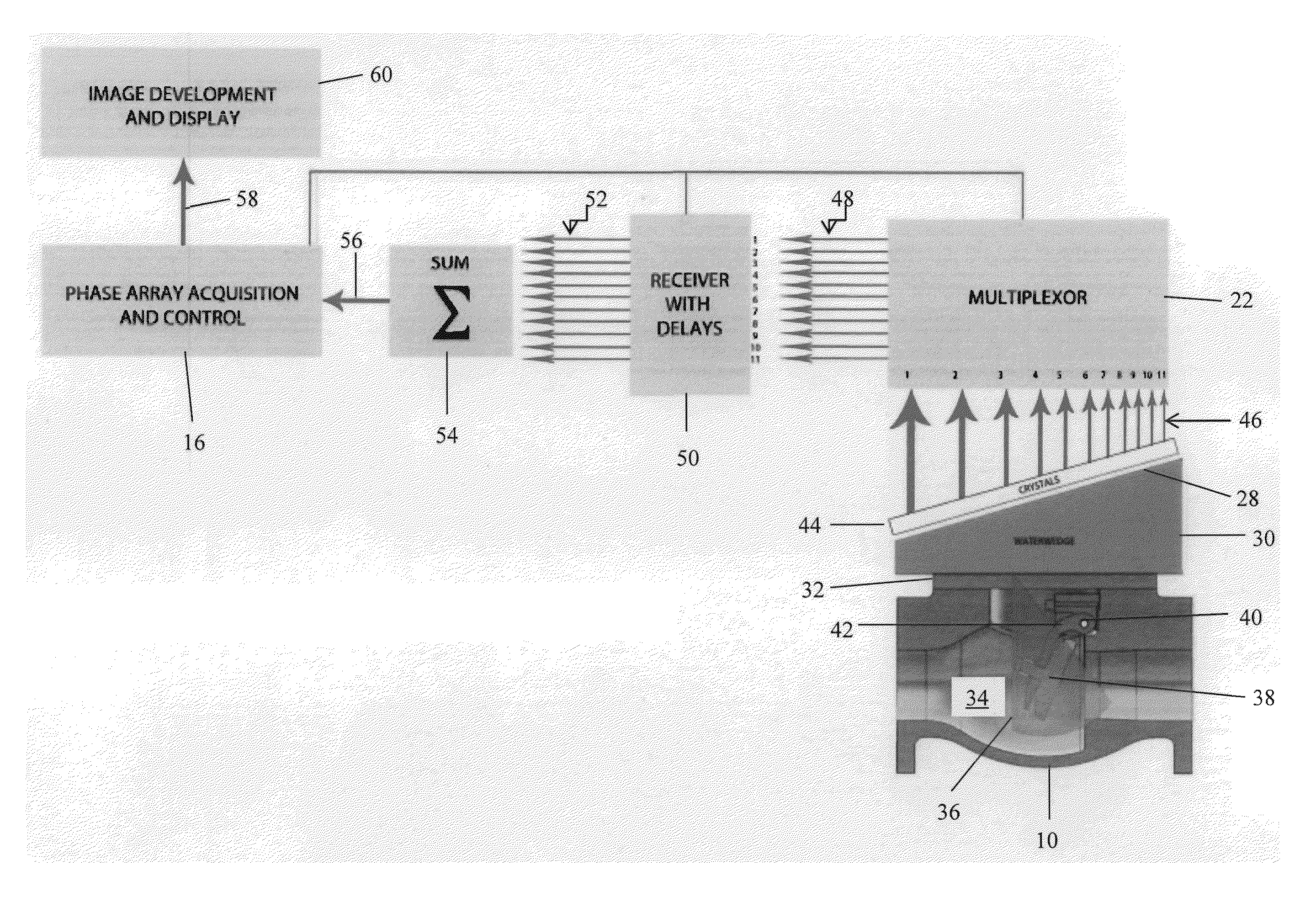

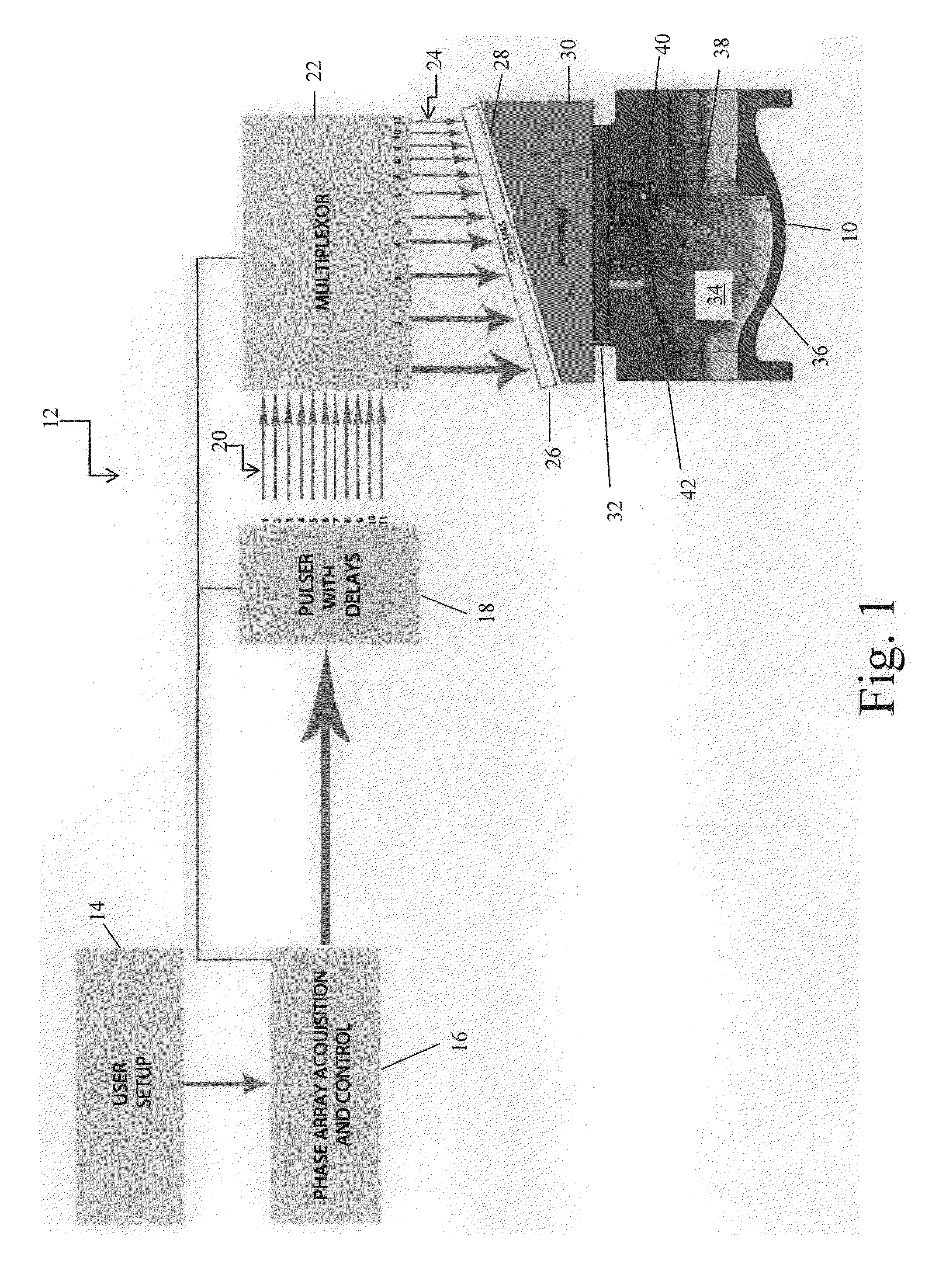

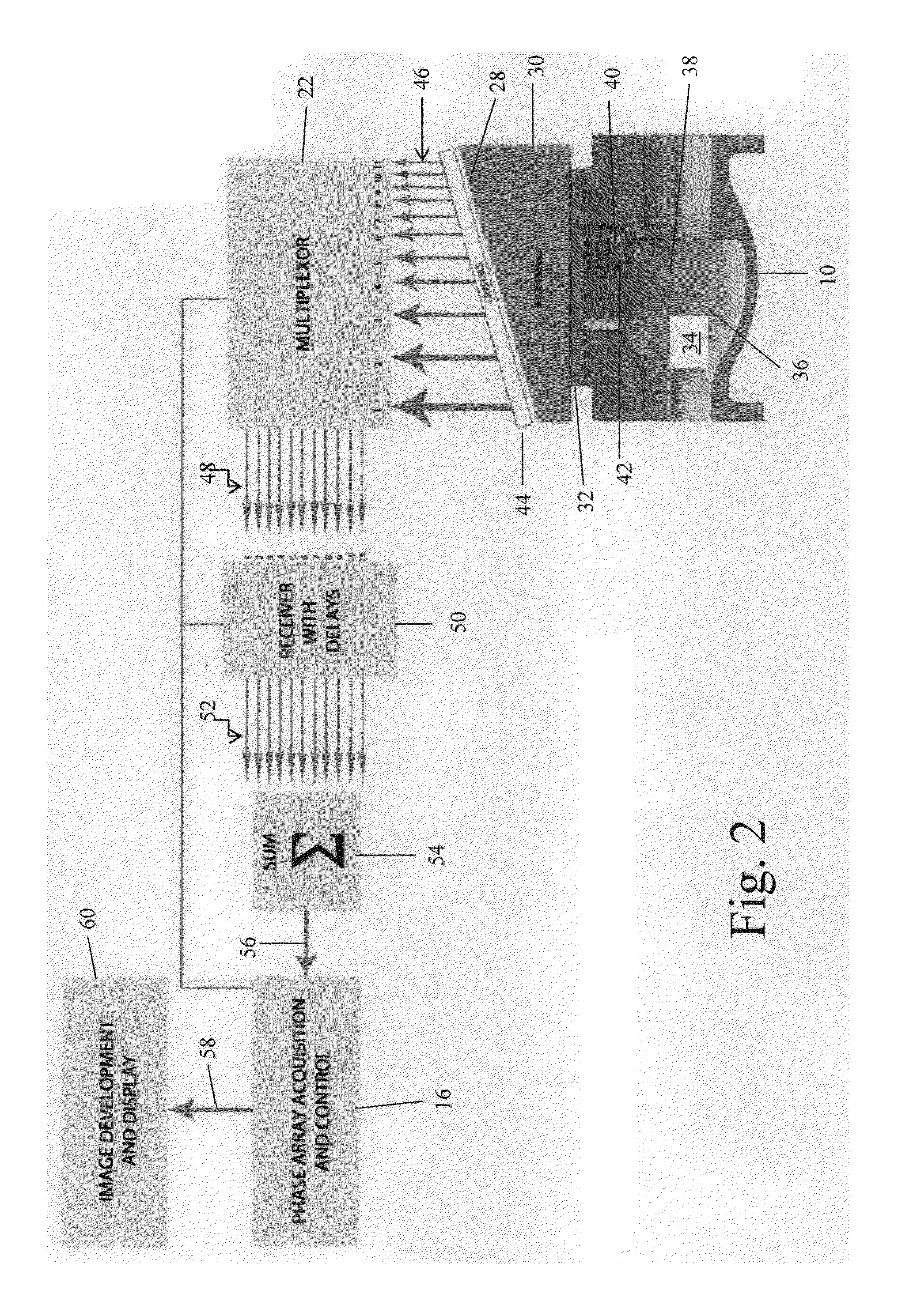

Testing of swing type check valves using phased array sequence scanning

ActiveUS8453508B2Analysing solids using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidElectricityPiezo electric

A computer with a proper program generates a phased array sequence of signals. In a pulser with delays, the signals are fed through a multiplexor into a water wedge that is attached to a valve being tested. For a sequential operation of the valves from the open to the closed position, ultrasonic signals are transmitted through the fluid contained in the valve and reflected back through piezo-electric crystals to the multiplexor. By summation and merger of the signals, an image can be developed of the operation of the valve to determine if the valve is operating properly. By use of the water wedge, the top plate of the valve appears to disappear because the water wedge has the same refractive angle as the fluid contained in the valve.

Owner:IIA NUCLEAR SERVICES INC

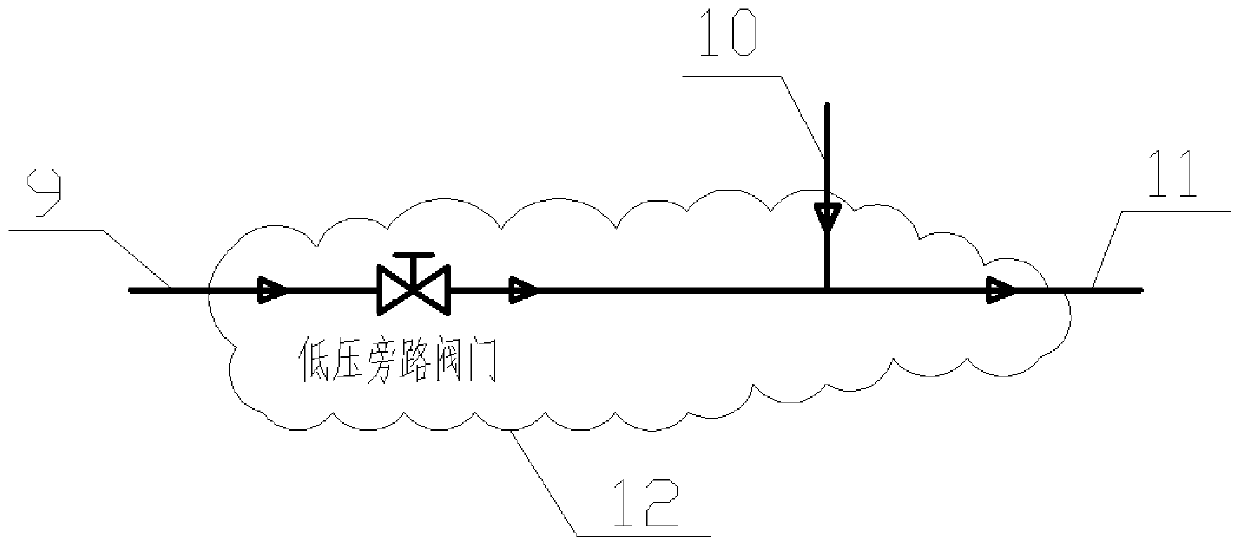

Test method for steam internal leakage quantity of low-pressure bypass valve of thermal generator set

ActiveCN110608858AEnables indirect measurementsMeasurement of fluid loss/gain rateMachine valve testingRunning economyEnergy balanced

A test method for steam internal leakage quantity of a low-pressure bypass valve of a thermal generator set comprises the following steps of (1) selecting a set load for performing internal leakage test on a bypass voltage of a low-pressure cylinder; (2) determining a boundary condition of experiment; (3) obtaining steam parameter change conditions of a low-pressure bypass system before and afterdesuperheating water flow change by changing bypass desuperheating water flow of the low-pressure cylinder; (4) recording an experiment parameter of each working condition point, and forming originalexperiment data; and obtaining internal leakage steam flow of the low-pressure bypass valve by calculation. An energy balance, mass balance and same boundary loss item offset method is employed, the internal leakage steam flow of the low-pressure bypass valve of the thermal generator set is obtained by accurate and quantitative calculation of experiment, quantitative analysis and calculation is performed for the low-pressure bypass valve of the thermal generator set when internal leakage occurs, and the most direct data support is provided for power plant running economy and maintenance operation of the low-pressure bypass valve of a power plant.

Owner:魏丽蓉

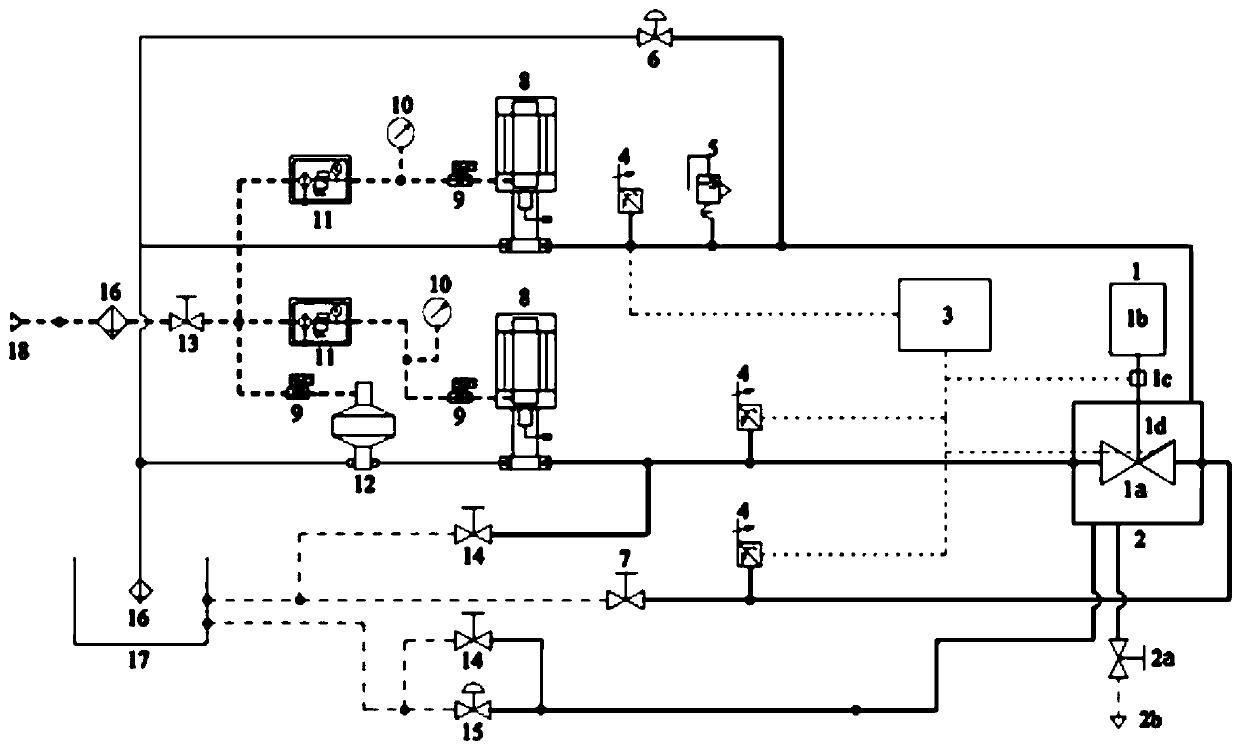

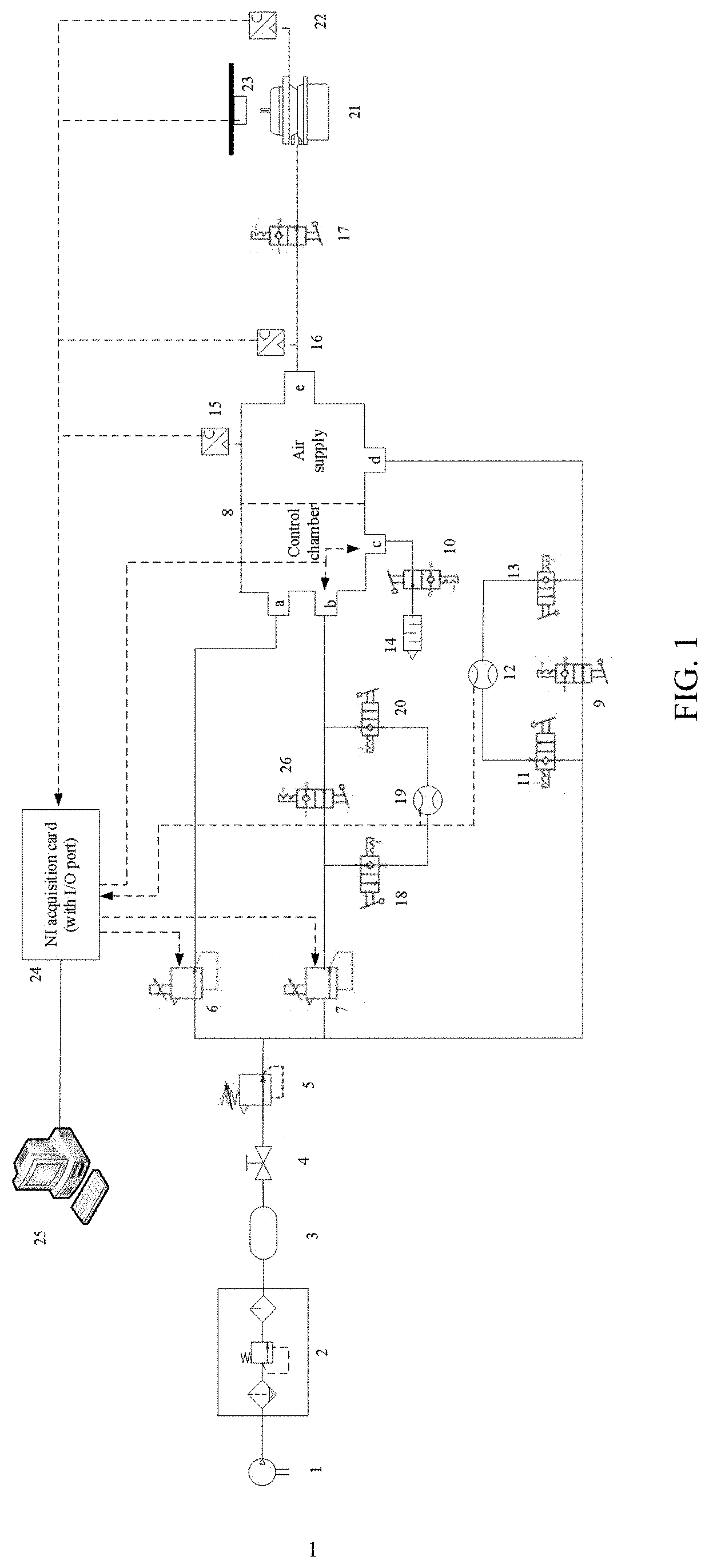

Test device and method for automatic pressure regulating valve of electronic braking system

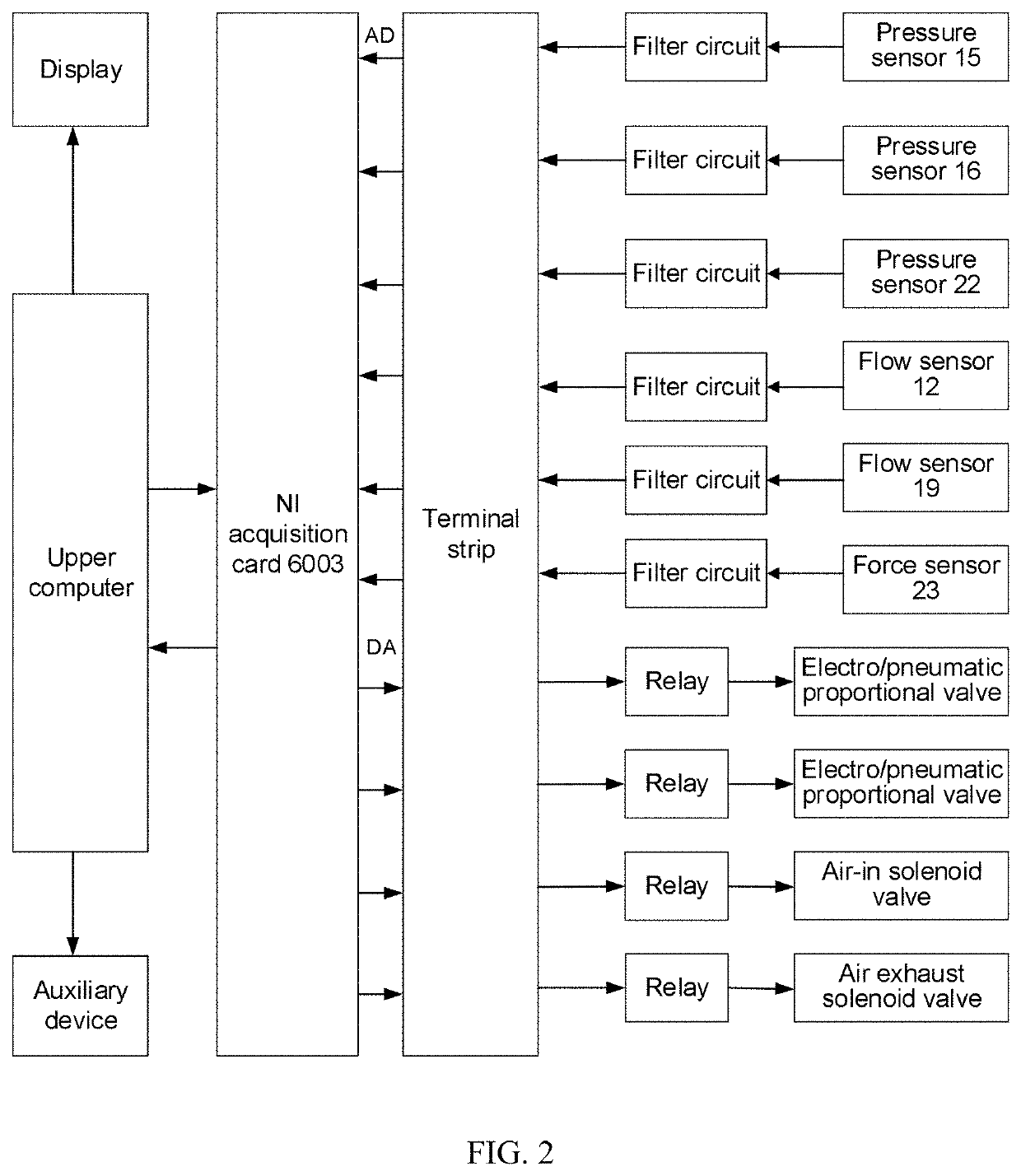

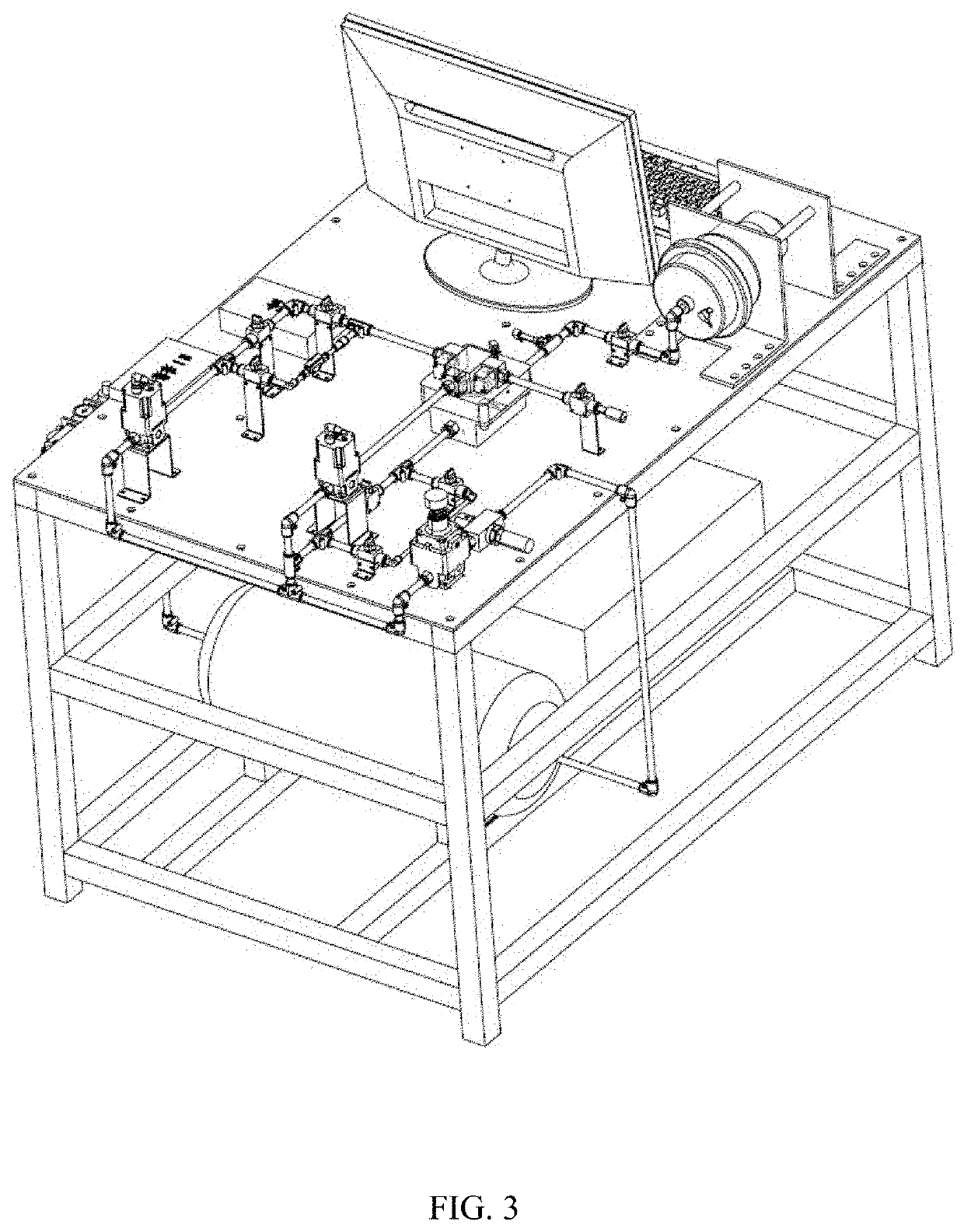

PendingUS20220196513A1Improve efficiencyReduce riskMeasurement of fluid loss/gain rateMachine valve testingBench testControl cell

A test device for an automatic pressure regulating valve of an electronic braking system includes a test device composed of an air supply, a pneumatic circuit, a valve, a sensor, a signal processing unit, and a control unit. By subjecting an automatic pressure regulating valve to a bench test including a functional test, a static performance test, a dynamic performance test, an air tightness test, a leakage test, and a brake chamber braking force test, the present disclosure avoids the high risk of a field test, improves the test efficiency, and ensures the test consistency. An automatic pressure regulating valve is tested before being loaded on a vehicle, and parameters of the automatic pressure regulating valve are continuously modified through tests to improve the performance, such that the automatic pressure regulating valve can meet the real-time, fast, independent, and accurate regulation requirements of EBS of commercial vehicles.

Owner:WUHAN UNIV OF TECH

Safety valve inspection device

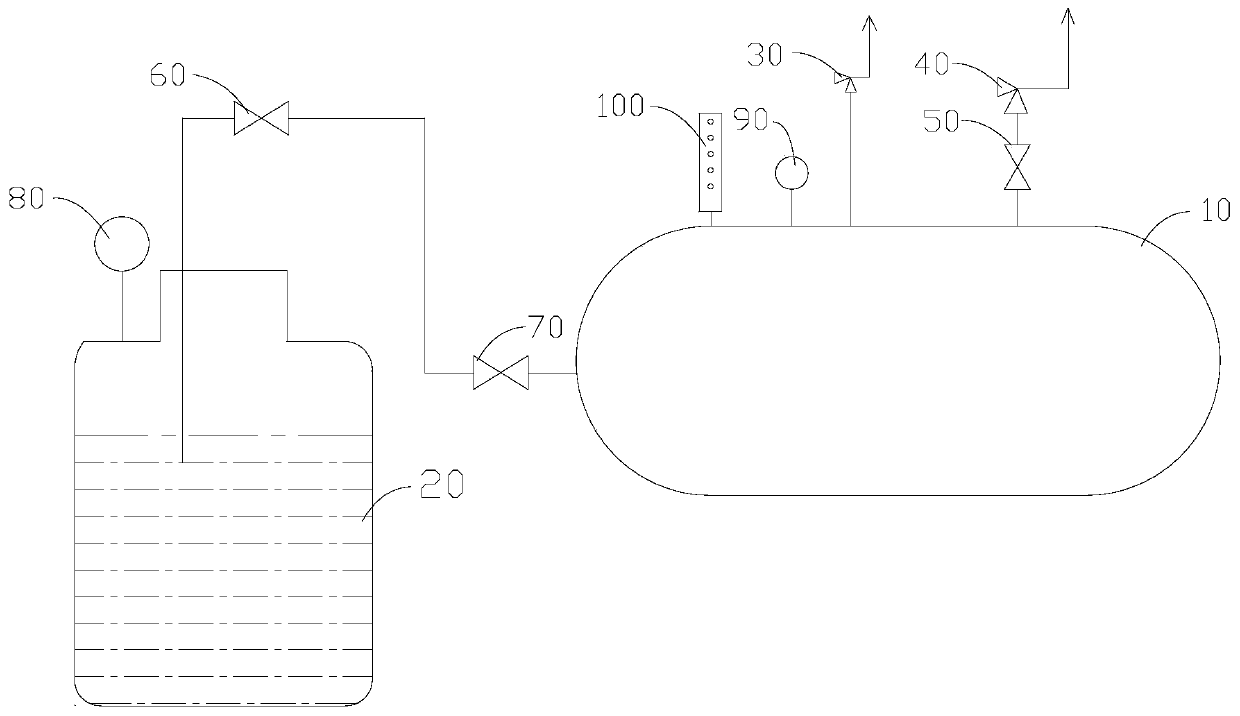

PendingCN110823461AIncreased self-evaporation capacityIncrease and expand the heat exchange areaMachine valve testingFluid-tightness measurement using fluid/vacuumLiquid storage tankProcess engineering

The invention relates to a safety valve inspection device. The safety valve inspection device comprises a test container and a liquid storage tank; the liquid storage tank communicates with the innercavity of the test container and can inject a low-temperature medium into the test container; the top of the test container is provided with a first control valve which communicates with the inner cavity of the test container and can be connected with a tested safety valve; a first booster is arranged in the inner cavity of the test container; the first booster comprises a first heat exchange tube; a second booster is arranged outside the test container; the second booster comprises a second heat exchange tube; the first heat exchange tube and the second heat exchange tube communicate with each other end to end, and a heat exchange circulation channel for circulating a heat exchange medium is formed; when the heat exchange medium flows through the interior of the first booster, the heat exchange medium exchanges heat with the low-temperature medium in the test container, so that the low-temperature medium absorbs the heat and expands, thus the pressure of the test container increases to verify the tested safety valve; and through the setting of the boosters, the self-evaporation capacity of the low-temperature medium is increased, the boosting rate of the test container is increased, the safety valve inspection time is shortened, the inspection efficiency is improved, and the labor cost is reduced.

Owner:深圳市质量安全检验检测研究院

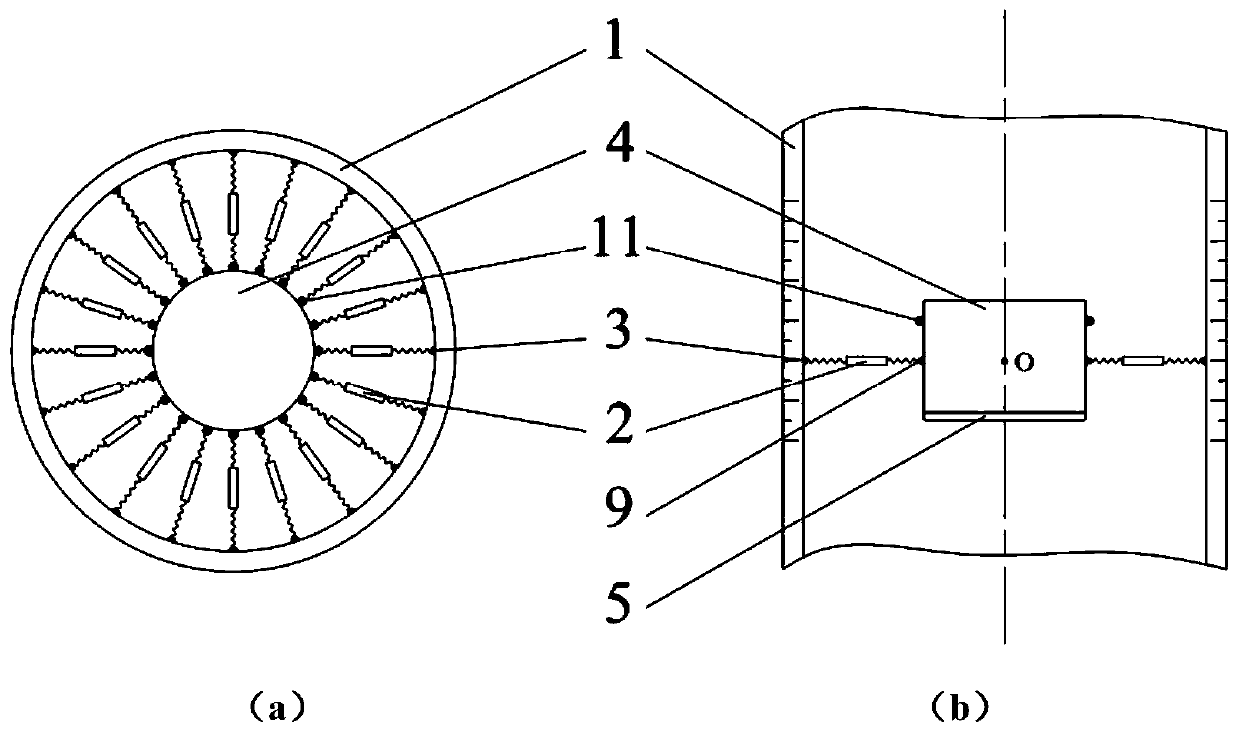

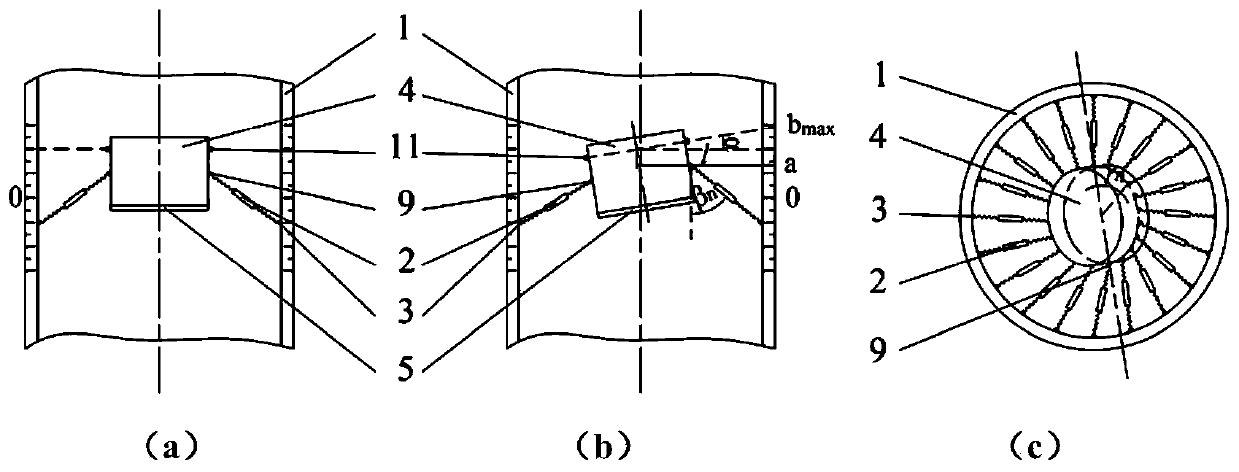

Device and method for measuring unbalanced moment of bottom surface of round valve element

ActiveCN110132455AStrong targetingCompact structureForce measurement using counterbalancing forcesMachine valve testingMeasurement devicePull force

The invention discloses a device and a method for measuring an unbalanced moment of the bottom surface of a round valve element. The device comprises a divergent type special-shaped pipe, a water tank, a transparent tube, a spring dynamometer, laser sources, the round valve element, a valve element bottom surface additional layer, a high-speed camera and a photographing support. Inner hook rings and the laser sources are uniformly distributed on the outer side of the circular valve element of the device; the spring dynamometer is connected with the inner hook rings and outer hook rings uniformly distributed on the inner wall of the transparent tube; and positioning scales are arranged on the outer wall of the transparent tube. According to the measuring method, the high-speed camera is erected on the photographing support to record an unbalanced state formed by the circular valve element under the impact of water flow in different directions; the scales, corresponding to the laser sources, on the outer wall and a pulling force of the spring dynamometer are read out; and a torque, corresponding to a certain specific symmetry axis, of the circular valve element is calculated. The device is simple in structure and easy to manufacture, and can be widely popularized and applied.

Owner:ZHEJIANG UNIV

Valve detection method and valve detection system

InactiveCN110261100AImprove detection accuracyReduce detection errorMachine valve testingEngineeringInlet pressure

The invention provides a valve detection method and a valve detection system, and relates to the technical field of valve detecting. The valve detection method provided by the invention comprises the steps that the position of the valve element of a detected valve is detected, and the sectional area of the orifice of the detected valve is calculated; from the valve cavity size and the valve element position of the detected valve, the sectional area of the orifice between the valve element and the inner wall of the valve cavity is calculated; the inlet pressure and the outlet pressure of the detected valve are measured, and the pressure difference between the inlet pressure and the outlet pressure is calculated; and the flow coefficient of the detected valve is calculated. According to the invention, the valve detection method alleviates the technical problem of large error of valve detection in the prior art; the flow coefficient of the detected valve under different opening degrees can be calculated; and the detection accuracy of the flow coefficient is improved.

Owner:TIANJIN TRINOVA AUTOMOTIVE TECH CO LTD

Valve detection device and use method thereof

InactiveCN109186999AReasonable structural designSmall footprintMachine valve testingUsing optical meansHydraulic cylinderFailure rate

The invention discloses a valve detection device and a use method thereof. The valve detection device comprises a base platform, a detection table and a sealing cover, wherein an alarm indicator lampis arranged on the outer side wall of the base platform; a controller is arranged on one side of the alarm indicator lamp, and moving pulleys are arranged below the base platform; stabilizing bases are arranged on one sides of the moving pulleys; a size detection chamber is arranged at the bottom of the base platform, and a height adjustment hydraulic cylinder is arranged in the size detection chamber; a rotating motor is arranged above the height adjustment hydraulic cylinder, and a rotating disk is arranged above the rotating motor; a weight detector is arranged at the top of the rotating disk; and a fixing device is arranged above the weight detector. The valve detection device and the use method thereof have the beneficial effects that 1, the device has reasonable structural design, small occupied area, low installation difficulty and simple operation; 2, the device has diversified detection functions and high detection precision, thereby remarkably reducing the labor intensity ofworkers; and 3, the device has a long service life, low failure rate, high intelligence degree and high practicability.

Owner:天津百诚阀门制造股份有限公司

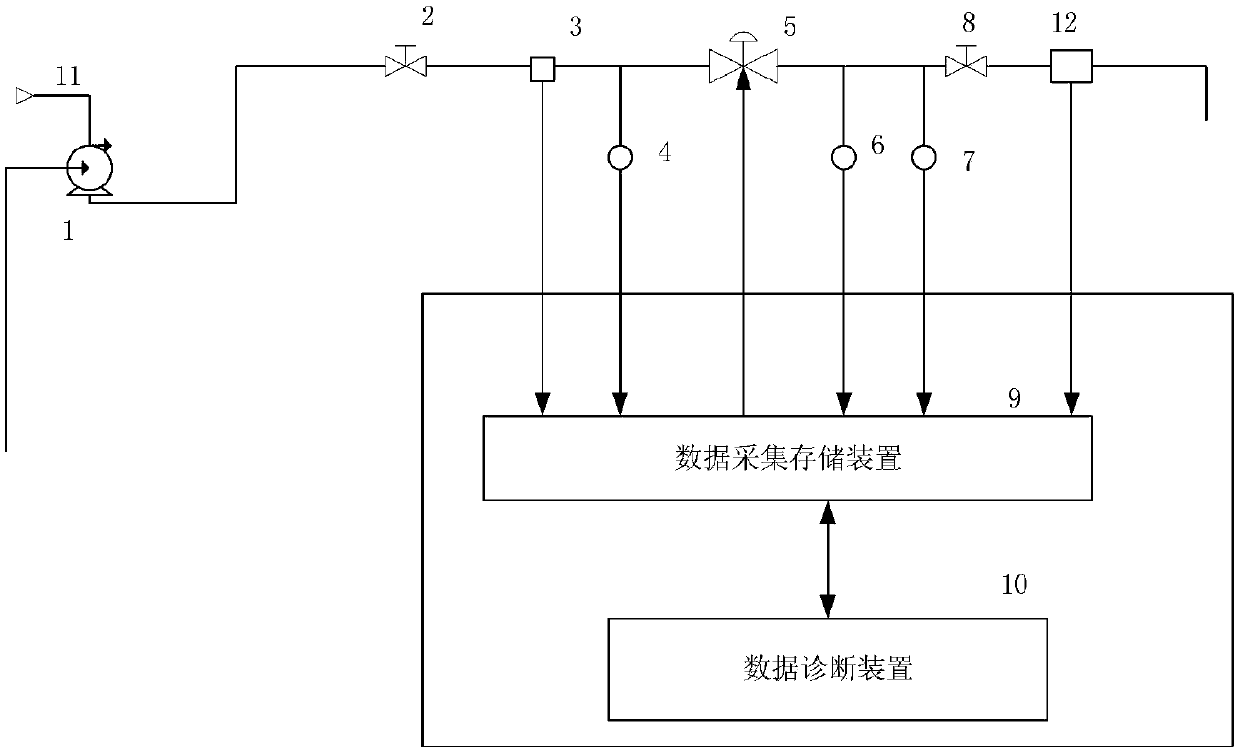

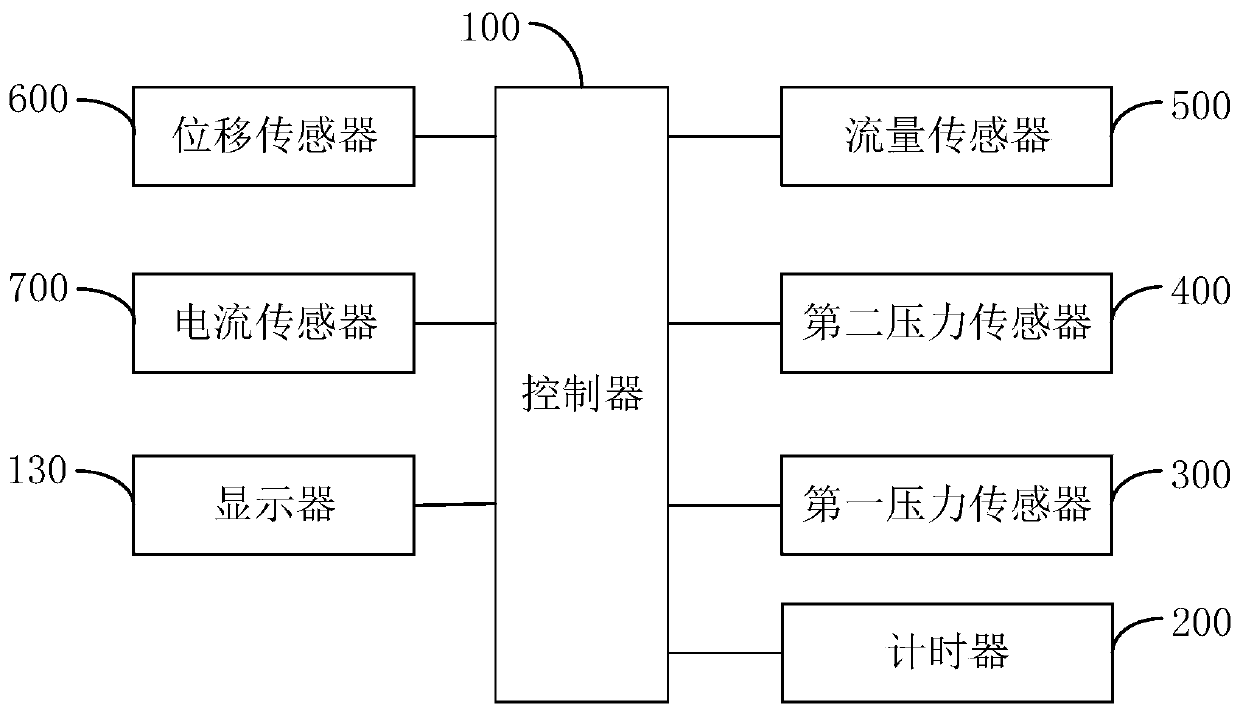

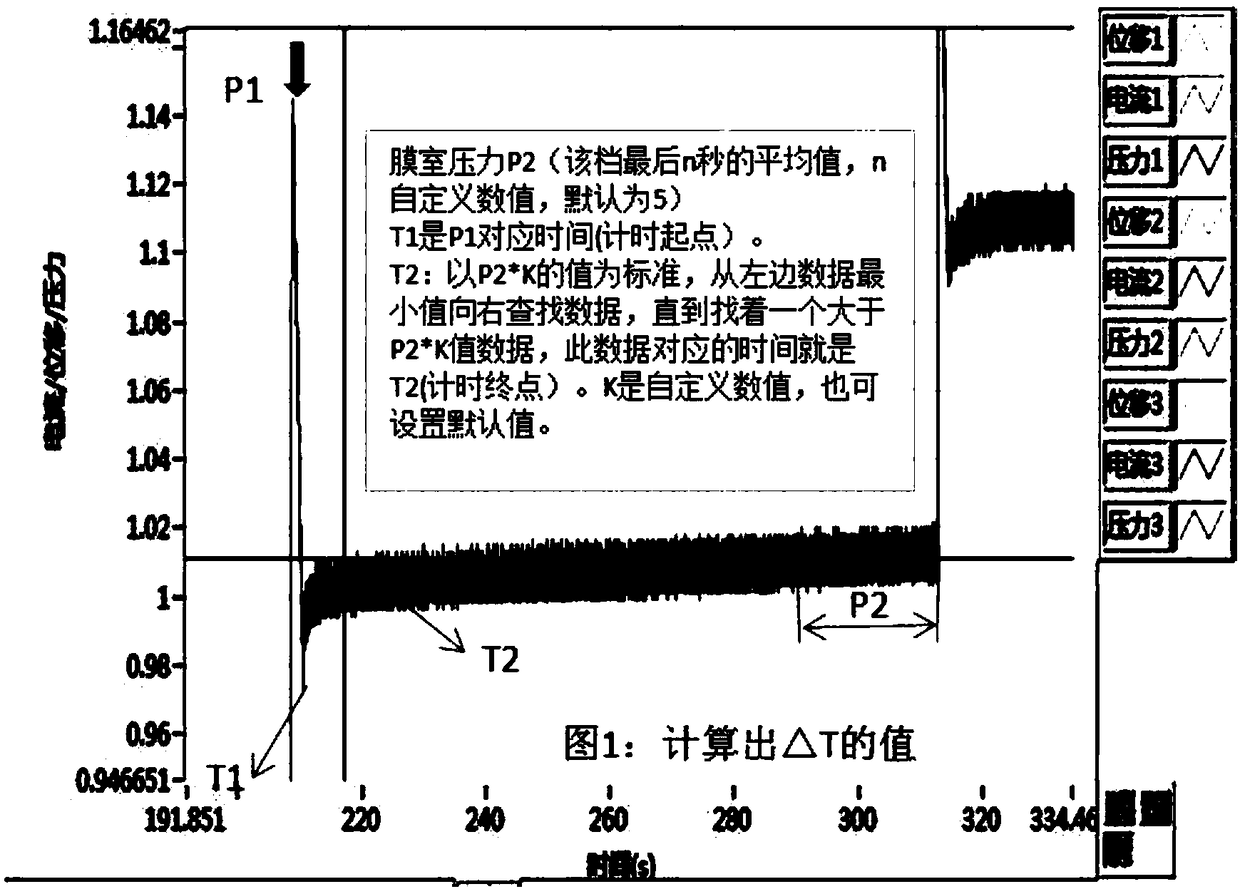

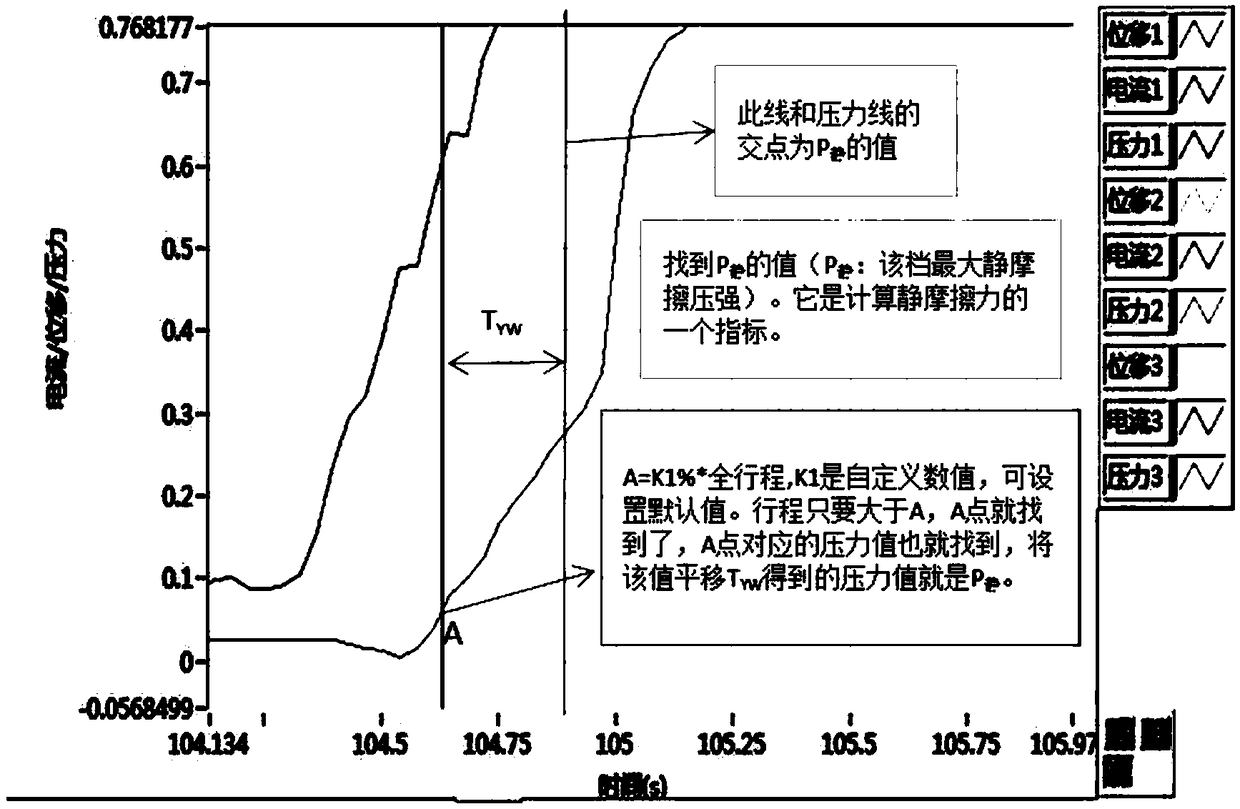

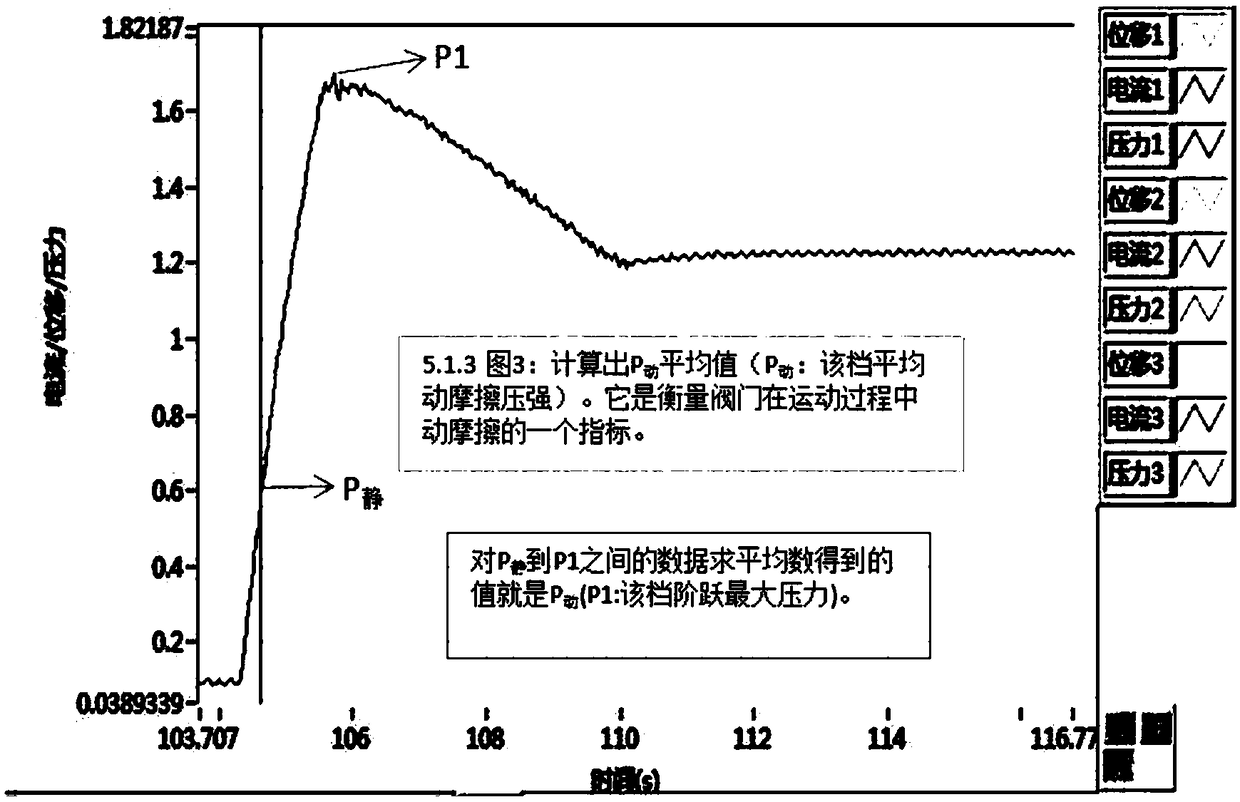

Online performance and fault detection analysis system for regulating valve

InactiveCN109187002AKnow the real operating conditionsEnable predictive maintenanceMachine valve testingOriginal dataEngineering

The invention discloses an online performance and fault detection analysis system for a regulating valve. A displacement sensor is used for feeding back a displacement signal of the regulating valve;a membrane chamber pressure sensor is used for recording a pressure signal in a membrane chamber of an executive mechanism; an input signal collector is used for monitoring an input signal of a positioner; a time recorder is used for recording a time constant; a fault diagnosis device simply processes the input signal, membrane chamber pressure, displacement and time data, and compares the data with original data of the regulating valve to judge a running condition and a fault type of the regulating valve; and for the condition of exceeding a performance index original data limit value, the system transmits the operation data and the fault type to a detection data storage device, and sends the operation data and the fault type to a detection data receiving device in a manufactory control part through a detection data transmitter and a network cable. According to the system, online performance and fault detection analysis and diagnosis of the valve are realized.

Owner:XUZHOU AKA CONTROL VALVE CO LTD

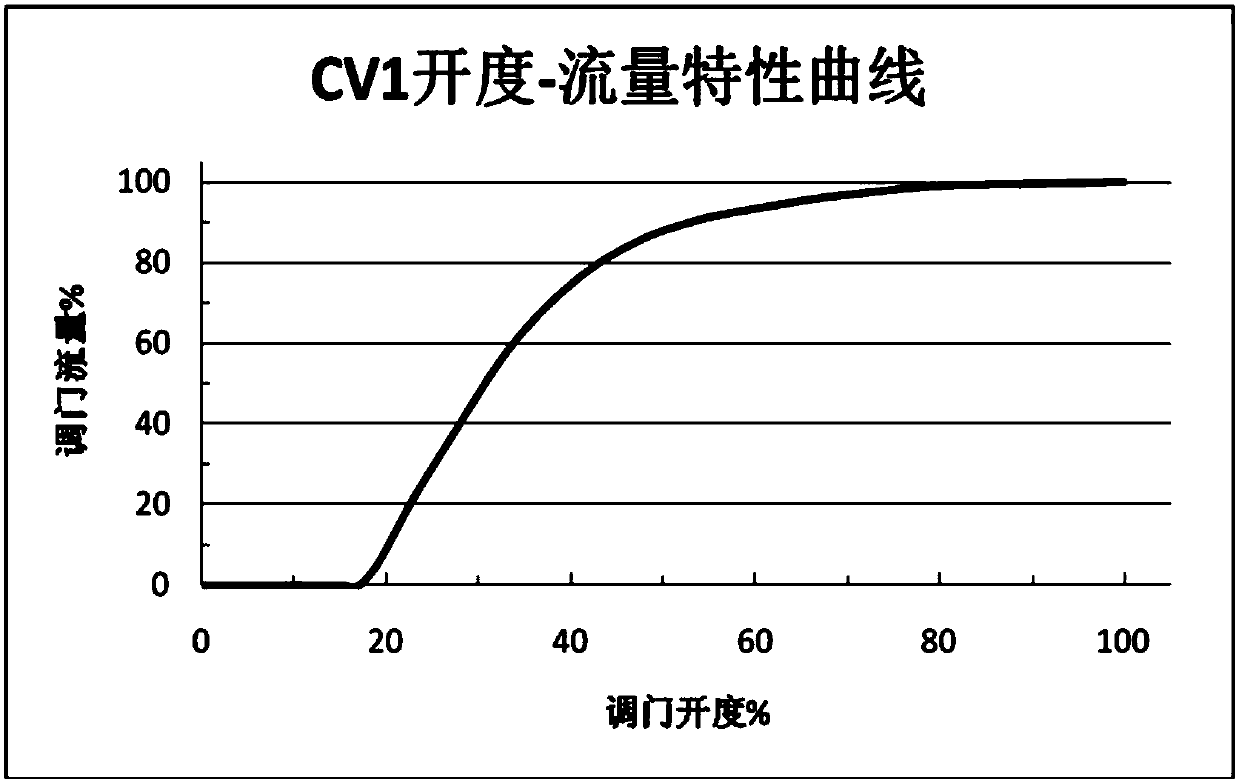

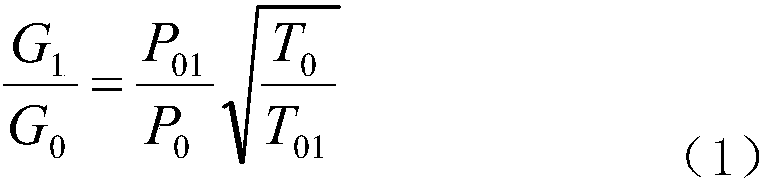

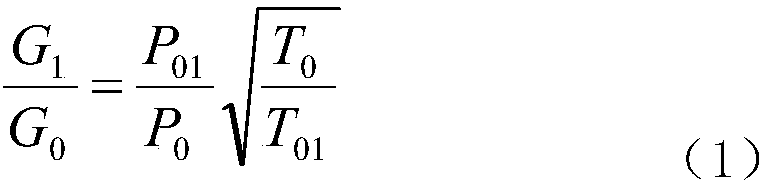

Test method for obtaining flow characteristics of high pressure regulating valve of steam turbine

ActiveCN110646193AGuaranteed accuracyImprove representationMachine valve testingProcess engineeringSteam turbine

The invention relates to a test method for obtaining flow characteristics of a high pressure regulating valve of a steam turbine. According to the method, a first-level steam extraction parameter of ahigh pressure cylinder is used as a calculation basis of main steam flow, and the flow characteristics of the high pressure regulating valve of the steam turbine are obtained by calculating the variable quantity of the main steam flow. Compared with the prior art, the test method provided by the invention has the advantages of better representative measuring points, installation at the outside the cylinder, convenient for inspection and processing, capability of ensuring the accuracy of the measuring points, and so on.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

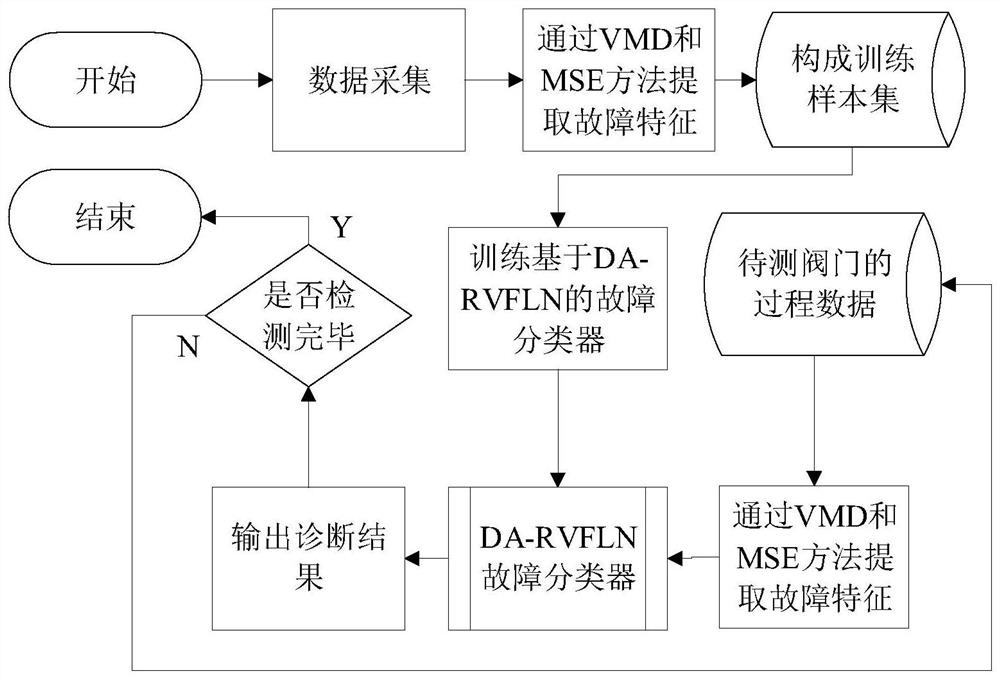

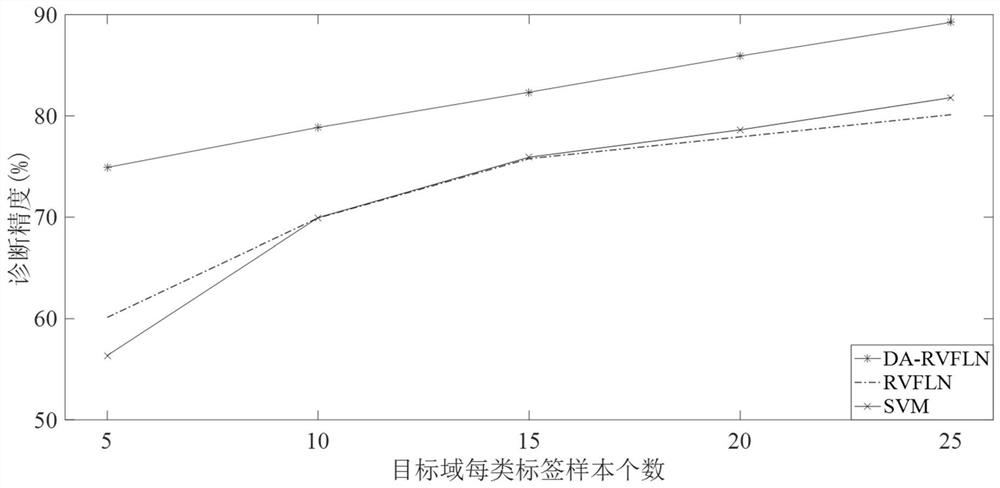

DA-RVFLN-based pneumatic control valve domain adaptive fault diagnosis method

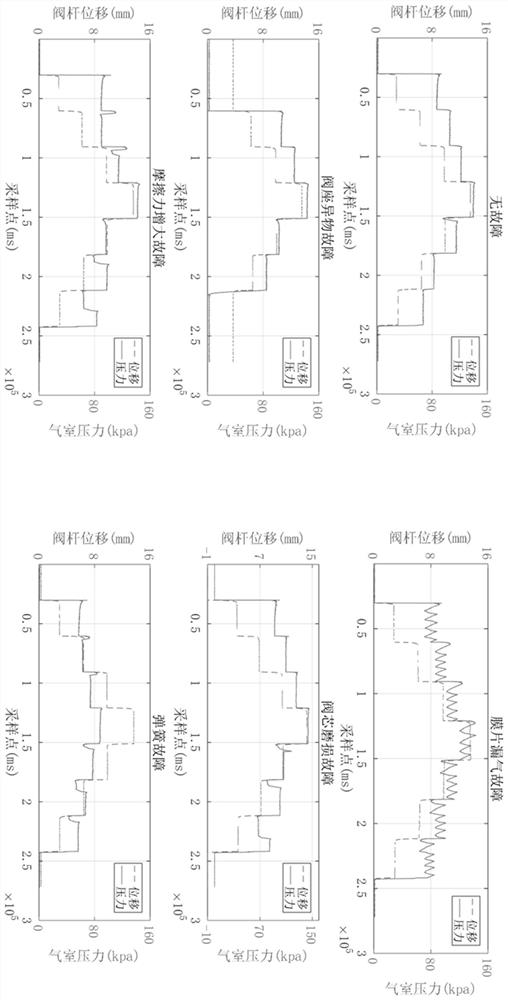

ActiveCN111929053AImprove diagnostic accuracyImprove adaptabilityValve arrangementsMachine valve testingData acquisitionVariational mode decomposition

The invention discloses a DA-RVFLN-based pneumatic control valve domain adaptive fault diagnosis method, which comprises the steps of firstly, collecting air chamber pressure and valve rod displacement signals in the operation process of a pneumatic control valve through a data collection device; secondly, analyzing the process signal by adopting variational mode decomposition (VMD) and a multi-scale entropy (MSE) method, and extracting fault features; and finally, taking the extracted fault features as input, adopting a domain adaptive random vector function link network (DA-RVFLN) as a classifier, and utilizing the trained classifier to realize domain adaptive fault diagnosis of the pneumatic control valve. The method is advantaged in that relatively high diagnosis precision is acquired,and domain adaptability and generalization of fault diagnosis are improved.

Owner:CHINA UNIV OF MINING & TECH

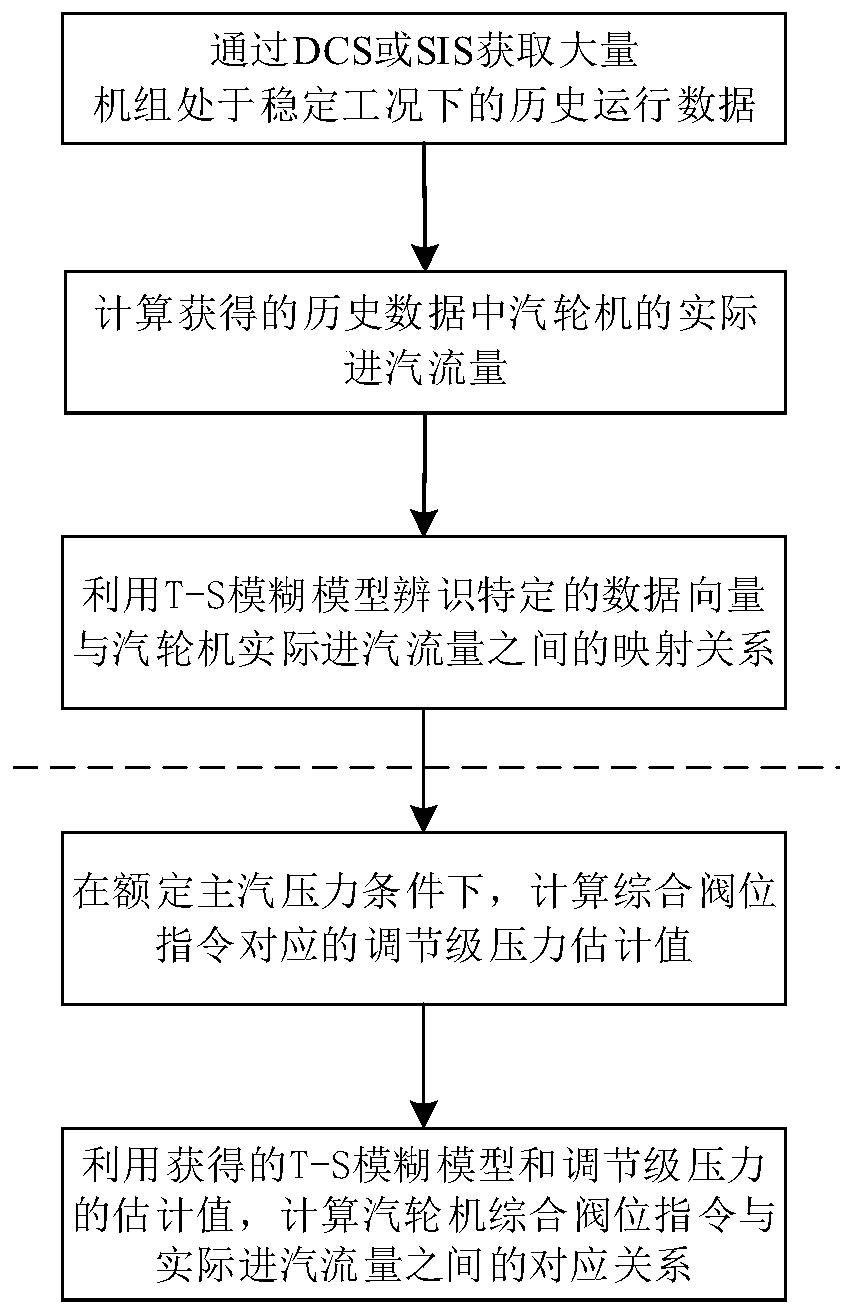

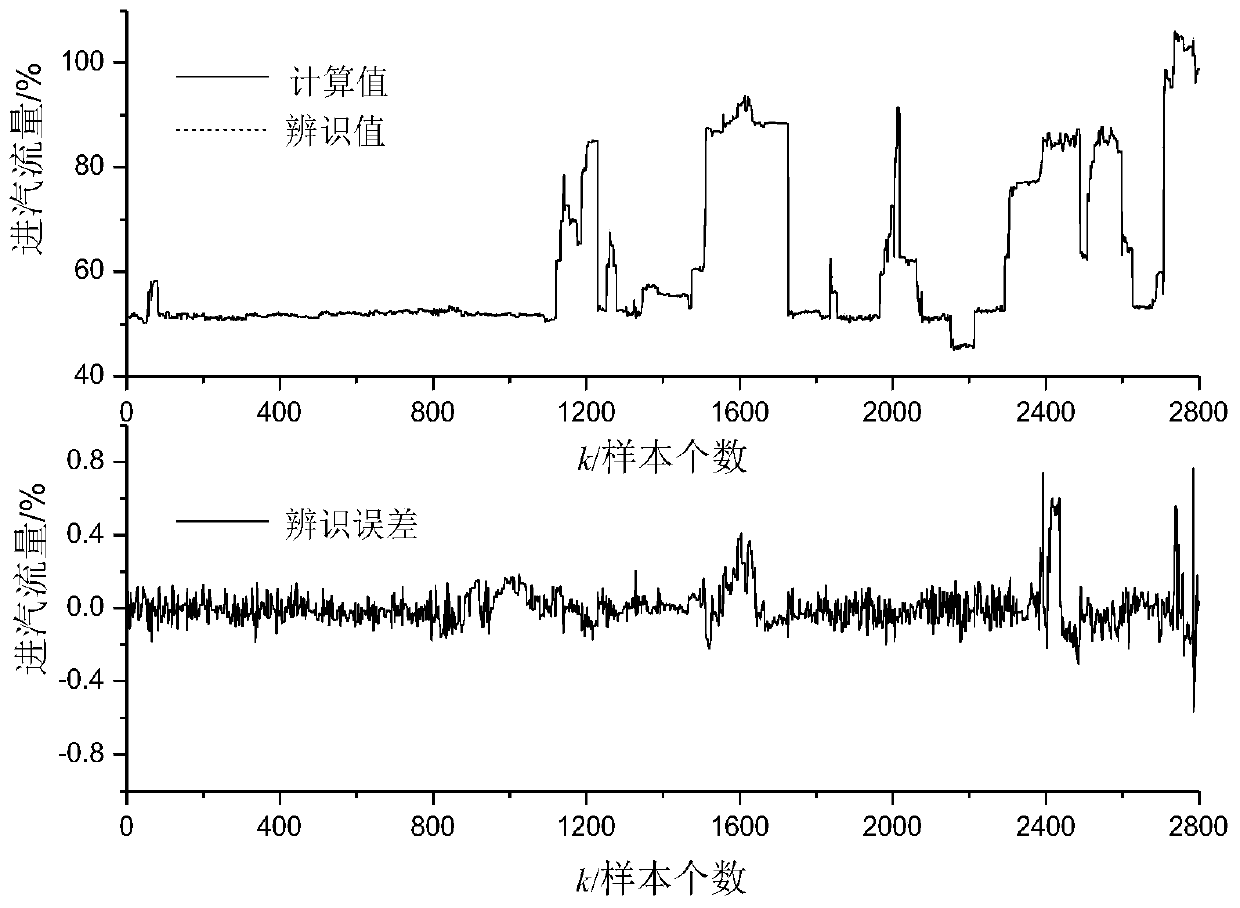

Steam turbine valve flow characteristic identification method and system based on T-S fuzzy model and medium

PendingCN110705042AEliminate adverse effects on safe and stable operationSave manpower and material resourcesMachine valve testingMachines/enginesSteam pressureProcess engineering

The invention discloses a steam turbine valve flow characteristic identification method and system based on a T-S fuzzy model and a medium. The steam turbine valve flow characteristic identification method based on the T-S fuzzy model comprises the steps: calculating and obtaining a regulating stage pressure estimation value corresponding to a steam turbine comprehensive valve position instructionwhen main steam pressure maintains a rated value; and inputting an input vector composed of the turbine comprehensive valve position instruction, the main steam pressure rated value and the regulating stage pressure estimated value into a preset T-S fuzzy model to obtain the actual steam inlet flow of the turbine, thereby obtaining the corresponding relation between the turbine comprehensive valve position instruction and the actual steam inlet flow under the working condition. According to the steam turbine valve flow characteristic identification method, the valve flow characteristics of the steam turbine are identified by adopting the T-S fuzzy model, and a steam turbine valve flow characteristic test is not needed, and manpower and material resources are saved, and the workload is greatly reduced, and adverse effects of a conventional test method on safe and stable operation of a unit are avoided.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

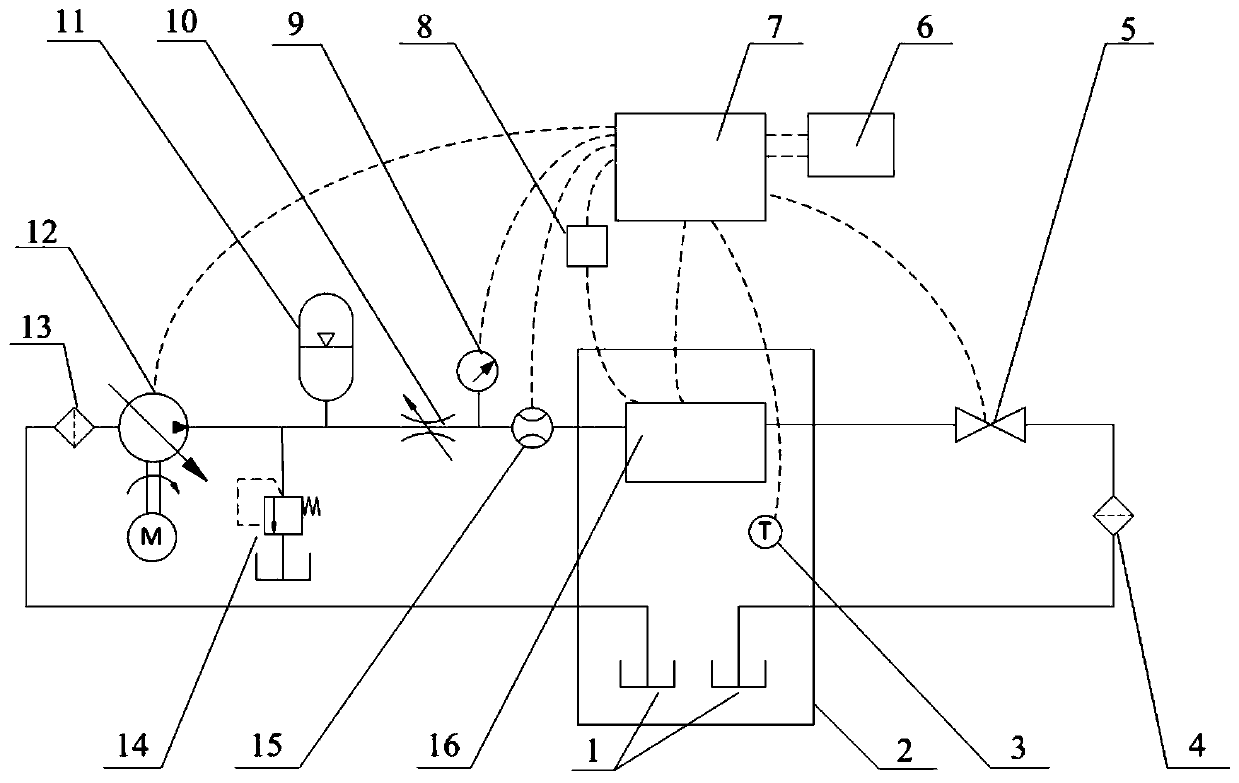

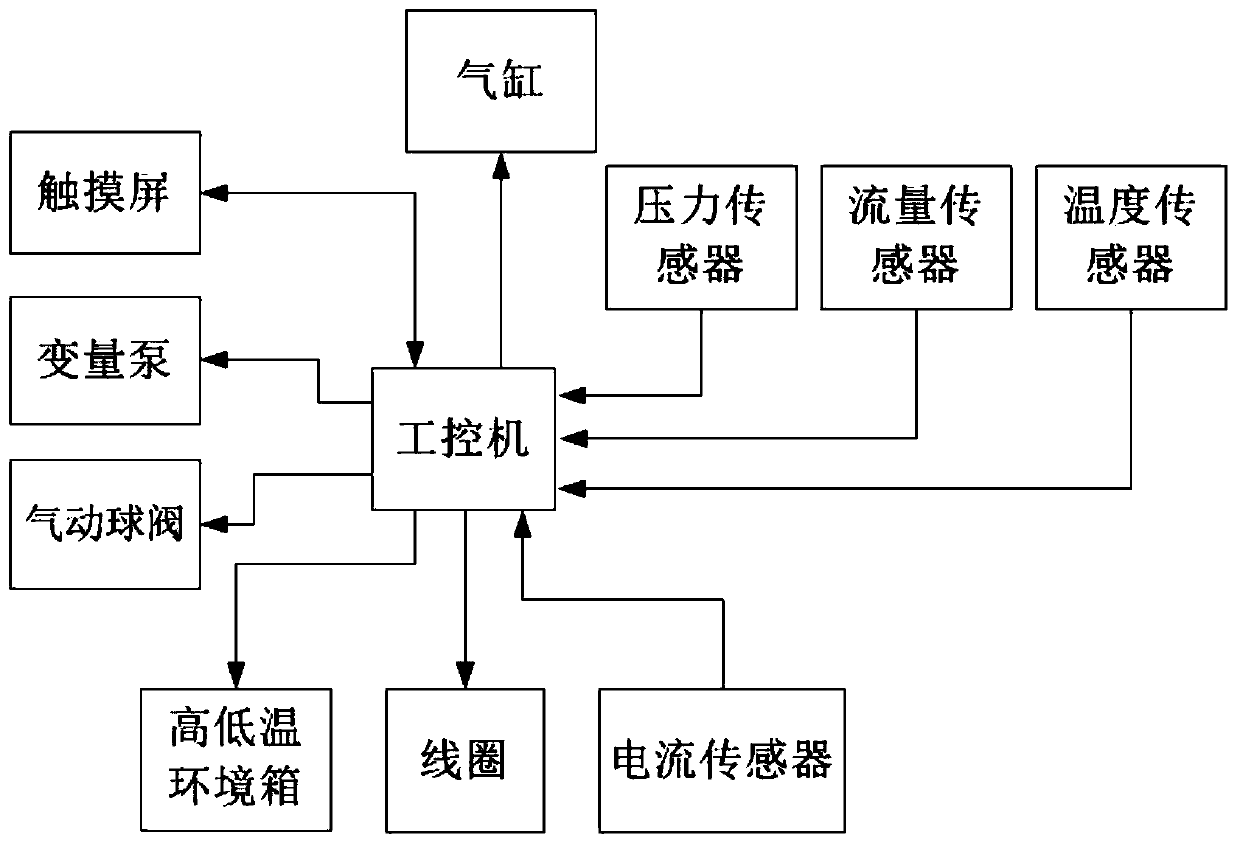

Automobile brake system high-speed switch valve development test method

PendingCN110940510ATroubleshoot development test system issuesTrue Test Scale PropertiesMeasurement of fluid loss/gain rateMachine valve testingControl systemControl theory

The invention discloses an automobile brake system high-speed switch valve development test method. A test tool of a high-speed switch valve, an oil tank and a temperature sensor are fixedly installedin a high-low temperature environment box. The oil tank is connected with an inlet of the variable pump through the inlet filter; an outlet of the variable pump is connected with an inlet of the testtool through a throttle valve; an overflow valve and an energy accumulator are connected and installed on a pipeline between the throttle valve and the outlet of the variable pump, a pressure sensorand a flow sensor are connected and installed on a pipeline between inlets of the throttle valve testing tools, and an outlet of each testing tool is connected back to the oil tank after sequentiallypassing through a pneumatic ball valve and an outlet filter. The flexibility of development and test of the high-speed switch valve is improved, the test range is widened, and the test cost is reduced; the testing method is simple, feasible, small in debugging workload and high in testing efficiency, provides data reference for algorithm development of an electro-hydraulic control system, and hasimportant significance in improving pressure control precision and reducing product noise.

Owner:ZHEJIANG ASIA PACIFIC MECHANICAL & ELECTRONICS

Popular searches

Color television details Two-way working systems Electrical cable transmission adaptation Selective content distribution Special data processing applications Digital non-picture data transmission Digital data information retrieval Natural language data processing Transmission Input/output processes for data processing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com