Patents

Literature

79results about How to "Clear expression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

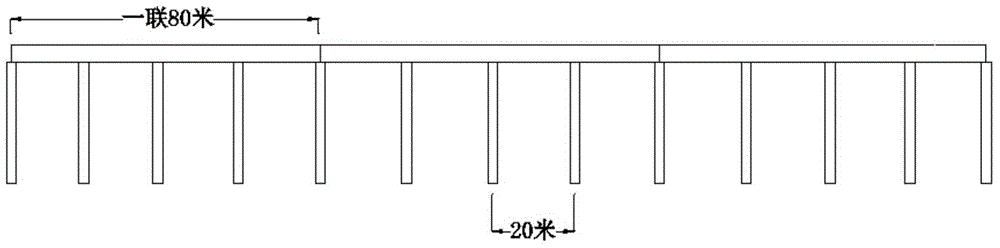

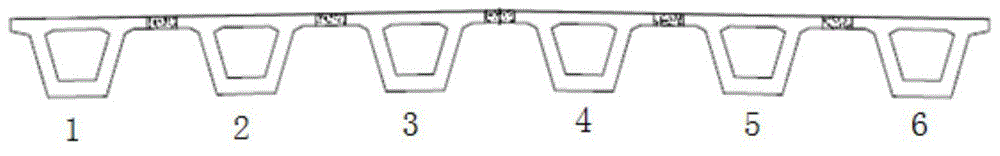

Bridge finite element model modifying method

InactiveCN104133959AImprove correction efficiencyAvoid the drawbacks of repeated iterative calculations that take too longSpecial data processing applicationsTest designUniform design

The invention discloses a bridge finite element model modifying method, which comprises the following steps that: 1, an entity finite element model of a whole bridge is built by universal finite element calculation software ANSYS; and 2, the entity finite element model of the whole bridge is subjected to primary modification by a uniform design method. The bridge finite element model modifying method has the following advantages that the uniform design method is used as a test optimization design method with obvious superiority, and the application of the uniform design method to the bridge structure finite element model modification is feasible; on the basis of the uniform design method, a more correct result can be found in a very short time by the uniform design method in the efficiency aspect, and the bridge large-scale finite element model modification efficiency is improved; a response surface method is used as a test design and mathematical statistics combined mathematical analysis method, and the application of the response surface method to the finite element model modification of a large-scale complicated bridge structure is feasible; and higher modification efficiency and higher modification precision can be ensured at the same time.

Owner:NORTHEASTERN UNIV LIAONING

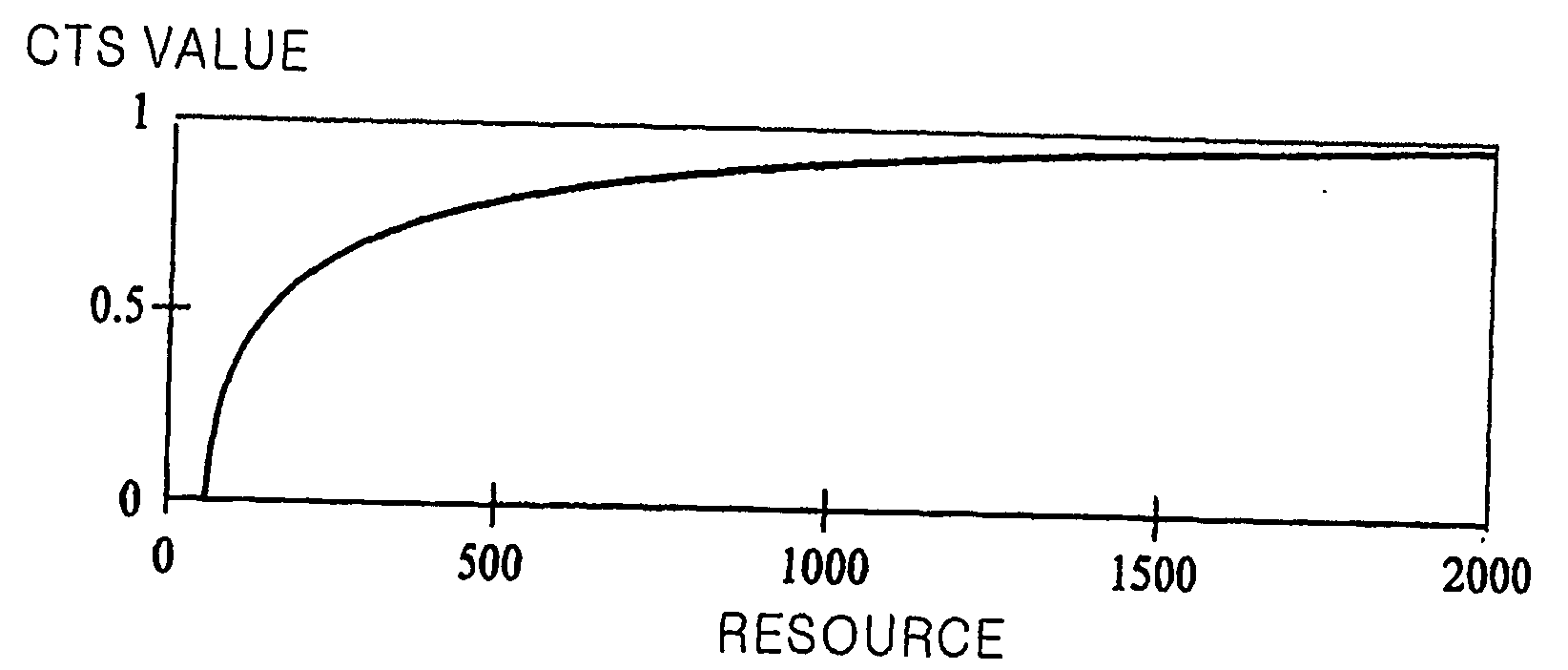

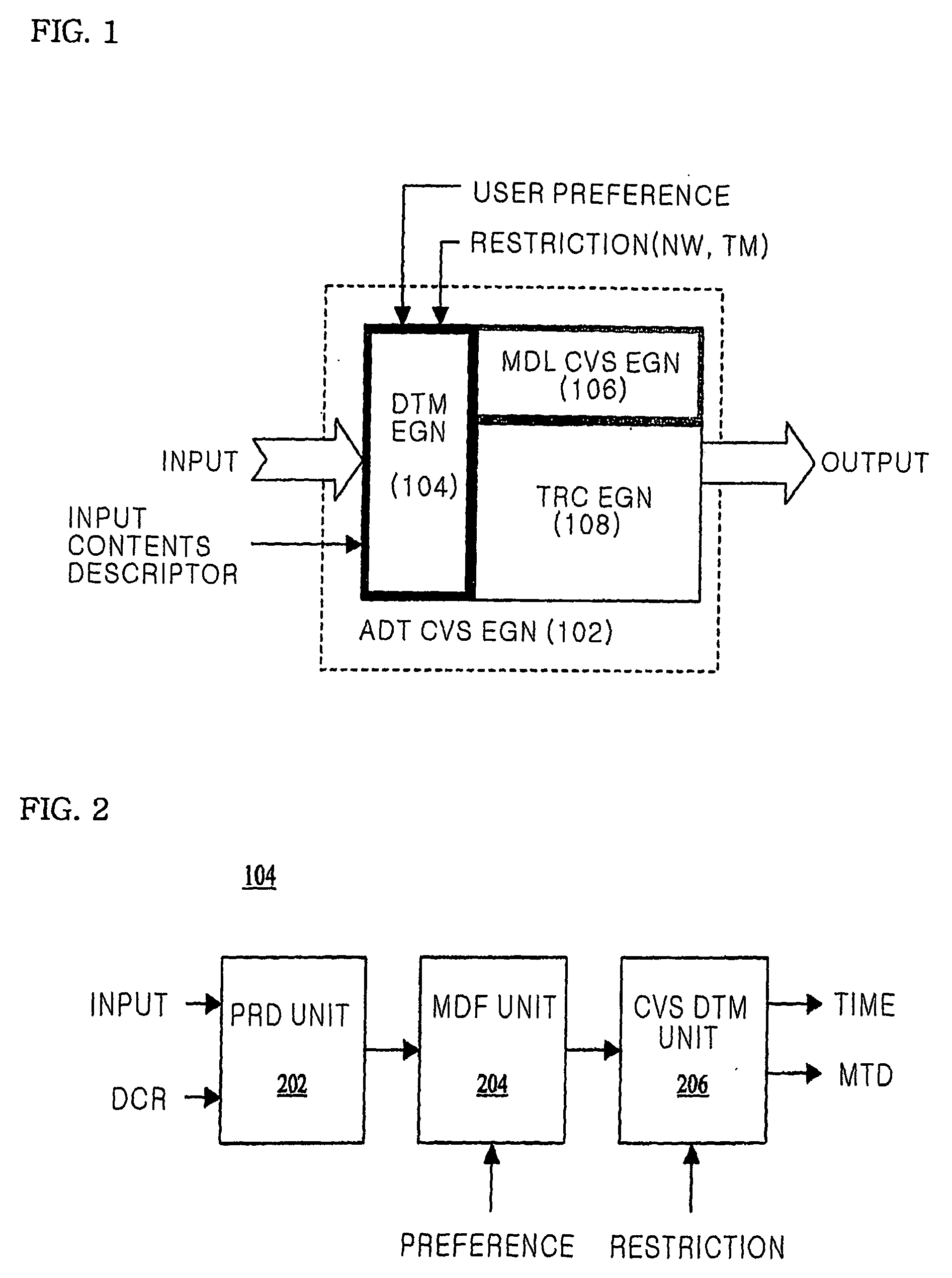

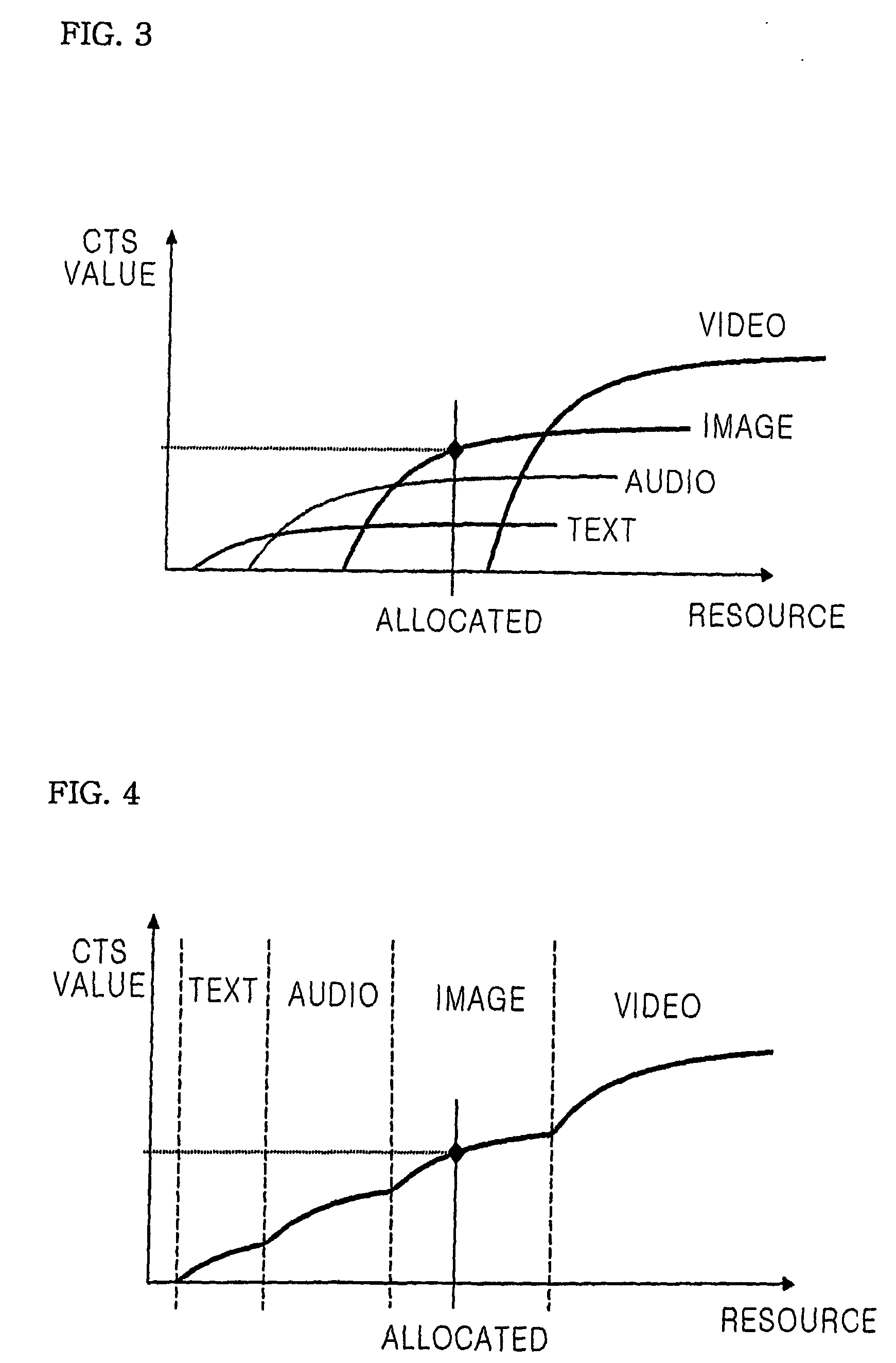

Device and method for modality conversion of multimedia contents

InactiveUS20060294546A1Clear expressionTelevision system detailsValve arrangementsContent ModelData mining

The present invention relates to a method of systematically and synthetically accessing modality conversion that is an important part in the contents adaptive conversion process of a universal multimedia access system. The present invention provides an effective method of solving a problem, which is incurred at the time of modality conversion and still remains as one of difficult problems incurred during adaptive contents conversion. For this purpose, the present invention includes overlapped contents modeling newly proposed to determine modality conversion, a method of flexibly and clearly expressing and applying user preference for the modality conversion, and a resource allocation method of distributing resources among complicated contents based on the user preference. As a result, the integration of the above three methods provides a synthetic solution, particularly, to a problem incurred in the modality conversion and, generally, to a problem incurred in the adaptive conversion of contents.

Owner:ELECTRONICS & TELECOMM RES INST +1

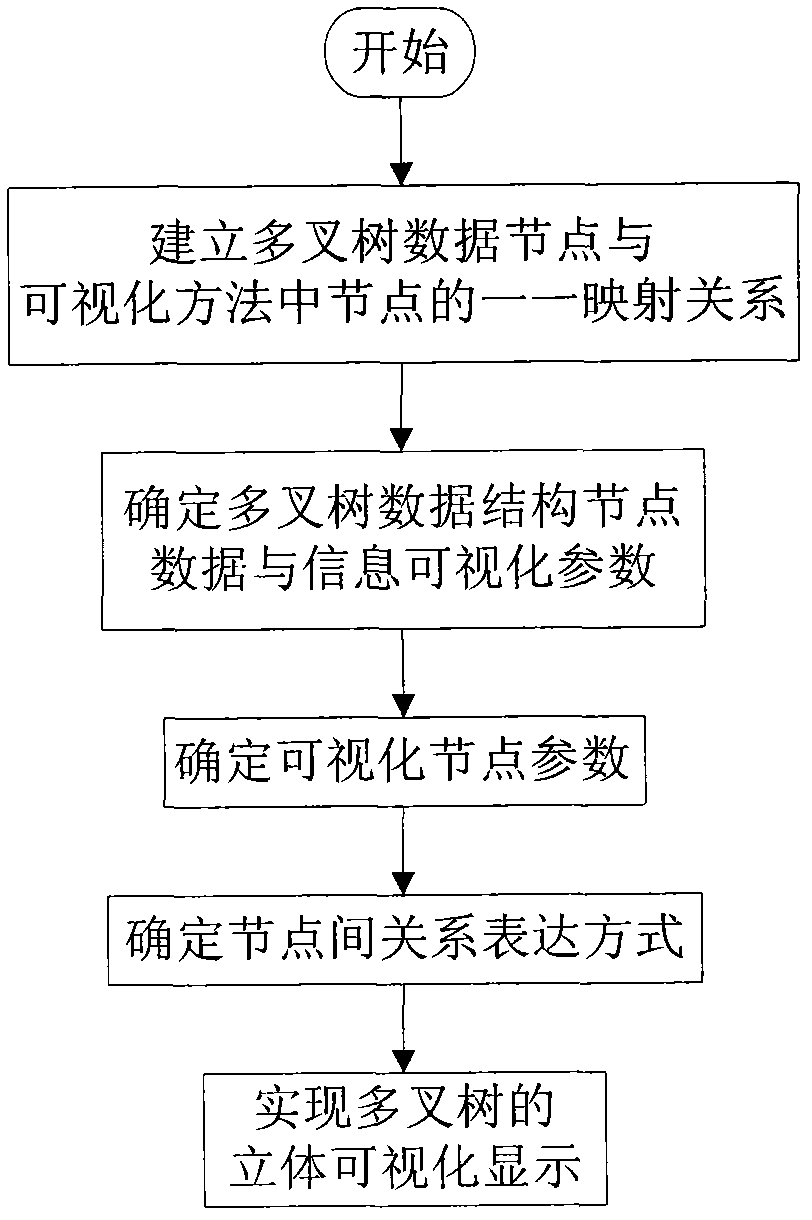

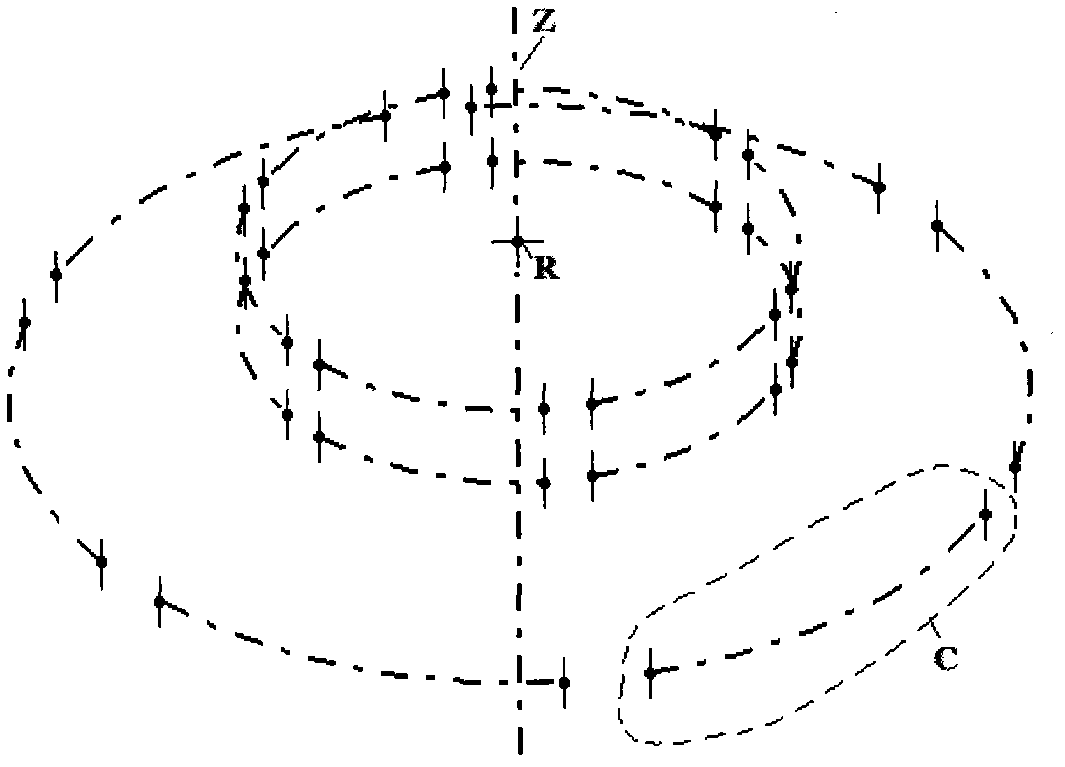

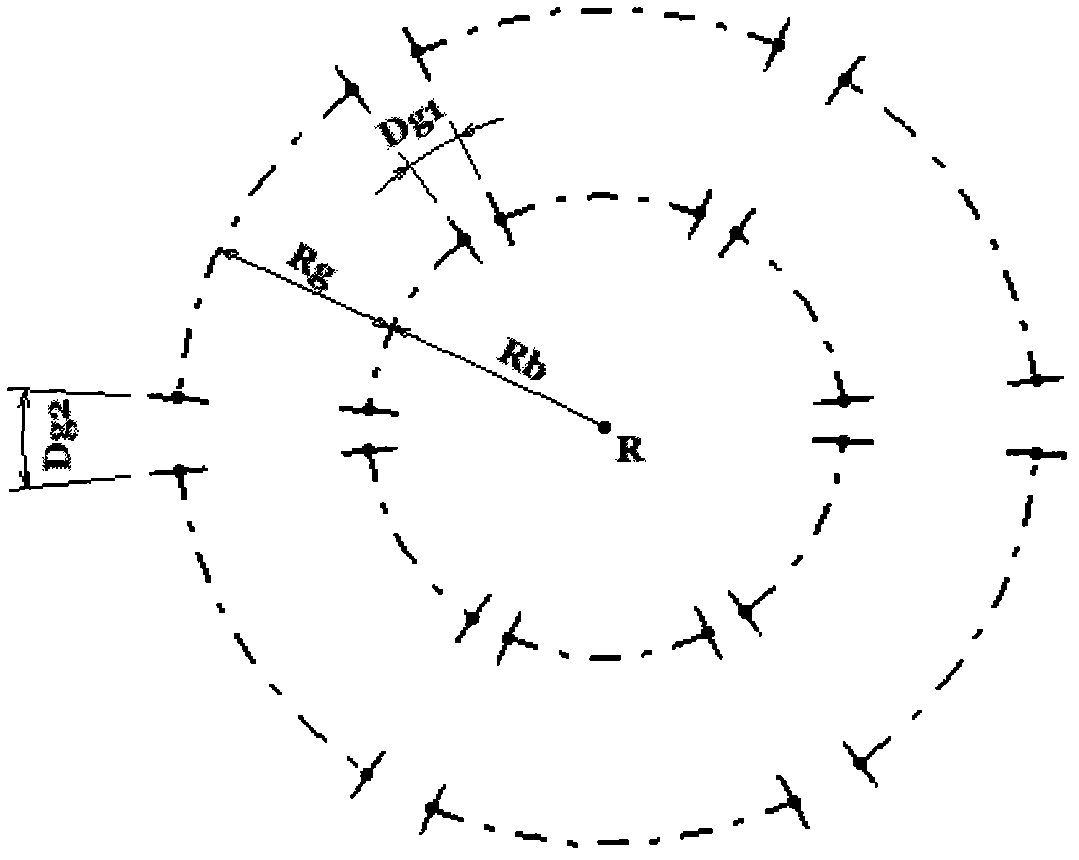

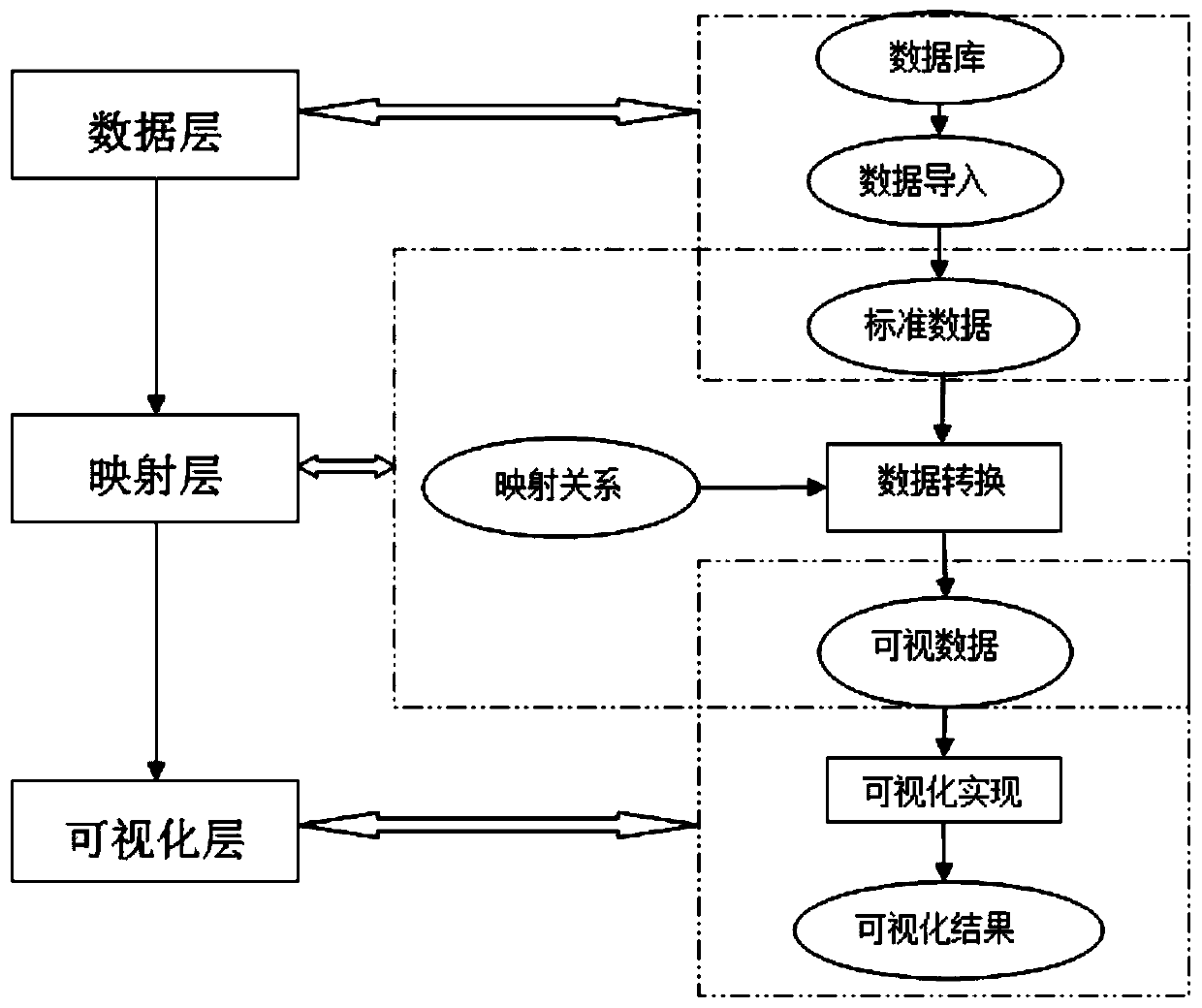

Three-dimensional ring visualization method of multi-branch tree data structure

ActiveCN101989178AIncrease profitClear expression2D-image generationSpecial data processing applicationsStereoscopic visualizationNODAL

The invention relates to a three-dimensional ring visualization method of a multi-branch tree data structure. The method comprises the following steps: 1) establishing the mapping relationship between the multi-branch tree data nodes and the nodes in the visualization methods to realize that the node information expressed by the visual nodes in each visualization method correspond to that of the corresponding multi-branch tree data nodes; 2) determining the node data of the multi-branch tree data structure and the information visual parameter; 3) determining the parameters of the visual nodes; 4) determining the expression way of the relationships of nodes (the relationship of brother nodes and the relationship of father and son nodes), modifying or adding the related parameters of the visual nodes with the expression demand; and 5) according to the parameters set by the step 2), 3) and 4), combining the information visualization of the multi-branch tree data nodes with the visual curved nodes to realize the three-dimensional visualization display of the multi-branch tree; and ensuring that the overall visual shape of the combined nodes still corresponds the characteristics of thearc body, and maintaining the characteristics of layers, clusters and other structures. The method is simple and has good application effect.

Owner:BEIHANG UNIV

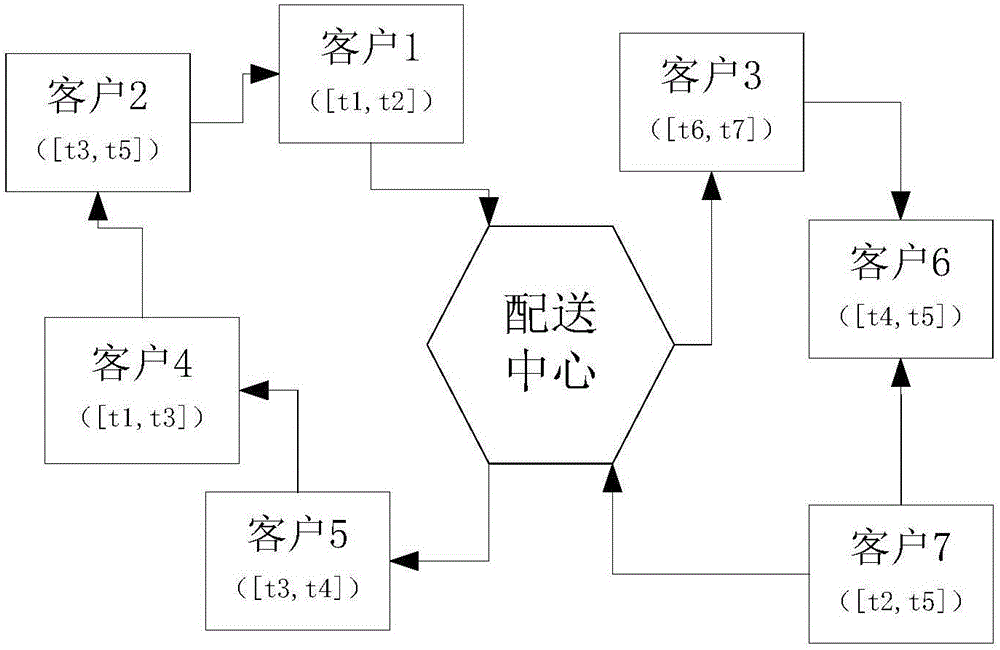

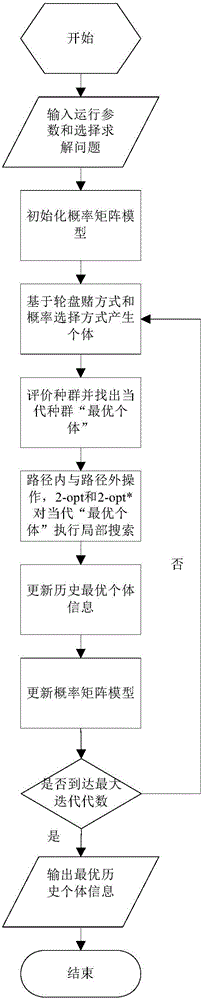

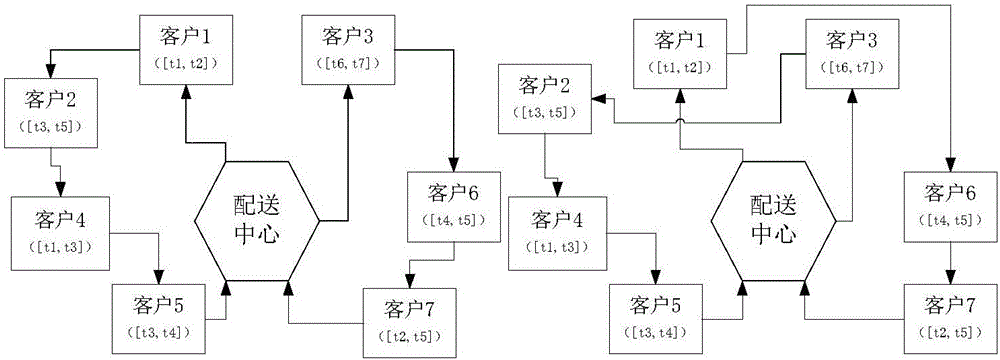

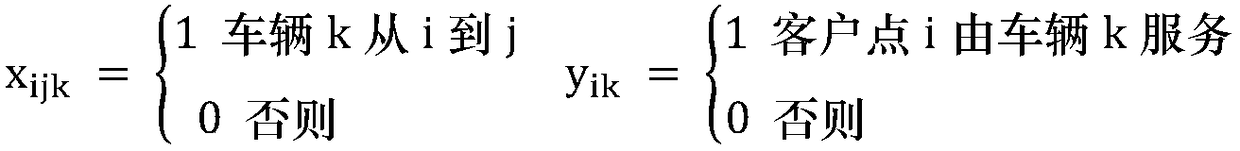

Delivery vehicle scheduling method with time limitation

InactiveCN105069523APrevent falling intoEffective global searchForecastingLogisticsIncremental learning algorithmDelivery vehicle

The invention relates to a delivery vehicle scheduling method with time limitation, and belongs to the technical field of vehicle routing in intelligent optimized scheduling. A scheduling model and an optimization object in the delivery process with time limitation are determined, the optimization object is obtained by solving the scheduling model on the basis of an improved population incremental learning algorithm, the optimization object of the scheduling model is the minimal total transport cost, and the limitation condition is established according to time limitation of the delivery vehicle, load-carrying restriction, position coordinates of a client point and the like. Global searching is guided by a possibility matrix observation model, individual information in a historical group is optimized in the improved population incremental learning algorithm, global searching is effectively guided, and the efficiency of global searching is higher; global searching aimed at problem property is constructed based on limitation of the problem, a high-quality solution area obtained via global searching is rapidly and effectively searched, the performance of the algorithm is improved, and the optimal solution is obtained.

Owner:KUNMING UNIV OF SCI & TECH

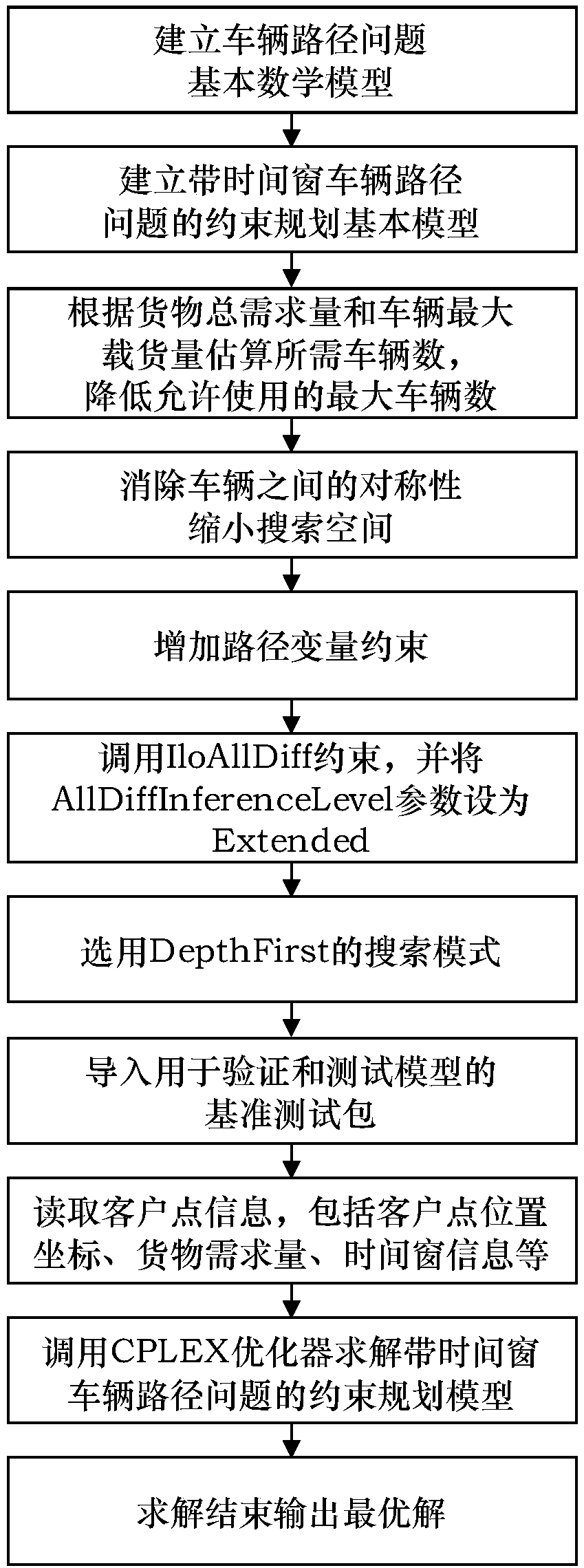

Modeling and optimization method for vehicle routing problem with time windows based on constrained programming

ActiveCN109034481AThe model expresses clearlyEasy to adjust and expandInternal combustion piston enginesForecastingTime windowsMathematical model

The invention discloses a vehicle routing problem modeling and optimization method with time window based on constraint programming, belonging to the field of intelligent transportation. The method comprises: 1. establishing the basic mathematical model according to the description of the routing problem of a vehicle; 2. based on the mathematical model of vehicle routing problem, establishing thebasic constrained programming model of vehicle routing problem with time windows. 3, adding other constraint conditions reasonably to optimize the model and speed up the solution of the model; 4, importing a benchmark test package of the verification and test model, and reading the customer point information; 5, a CPLEX optimizer being used to solve the constrained programming model of vehicle routing problem with time windows. The modeling and optimization method provided by the invention is convenient to describe and express the complex constraint conditions of the problem, and the model iseasy to be expanded. Heuristic constraints are reasonably added, which greatly reduce the search space and accelerate the solution. The exact global optimal solution can be obtained.

Owner:BEIHANG UNIV

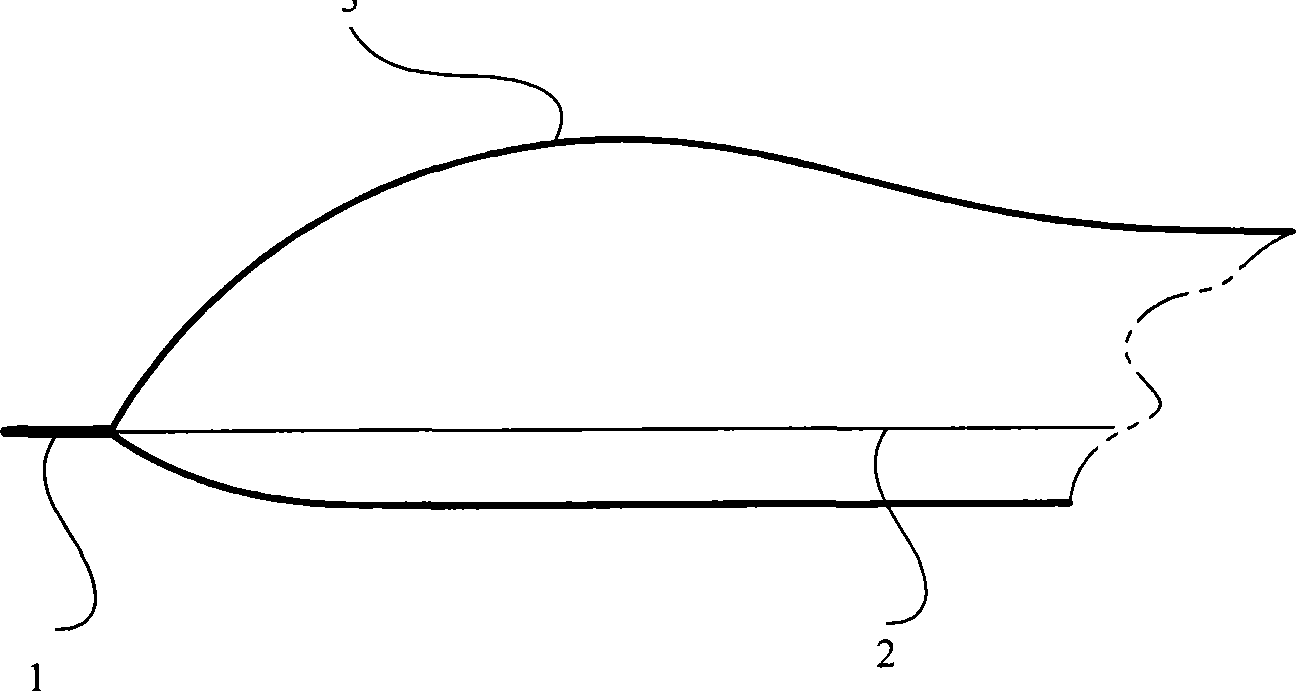

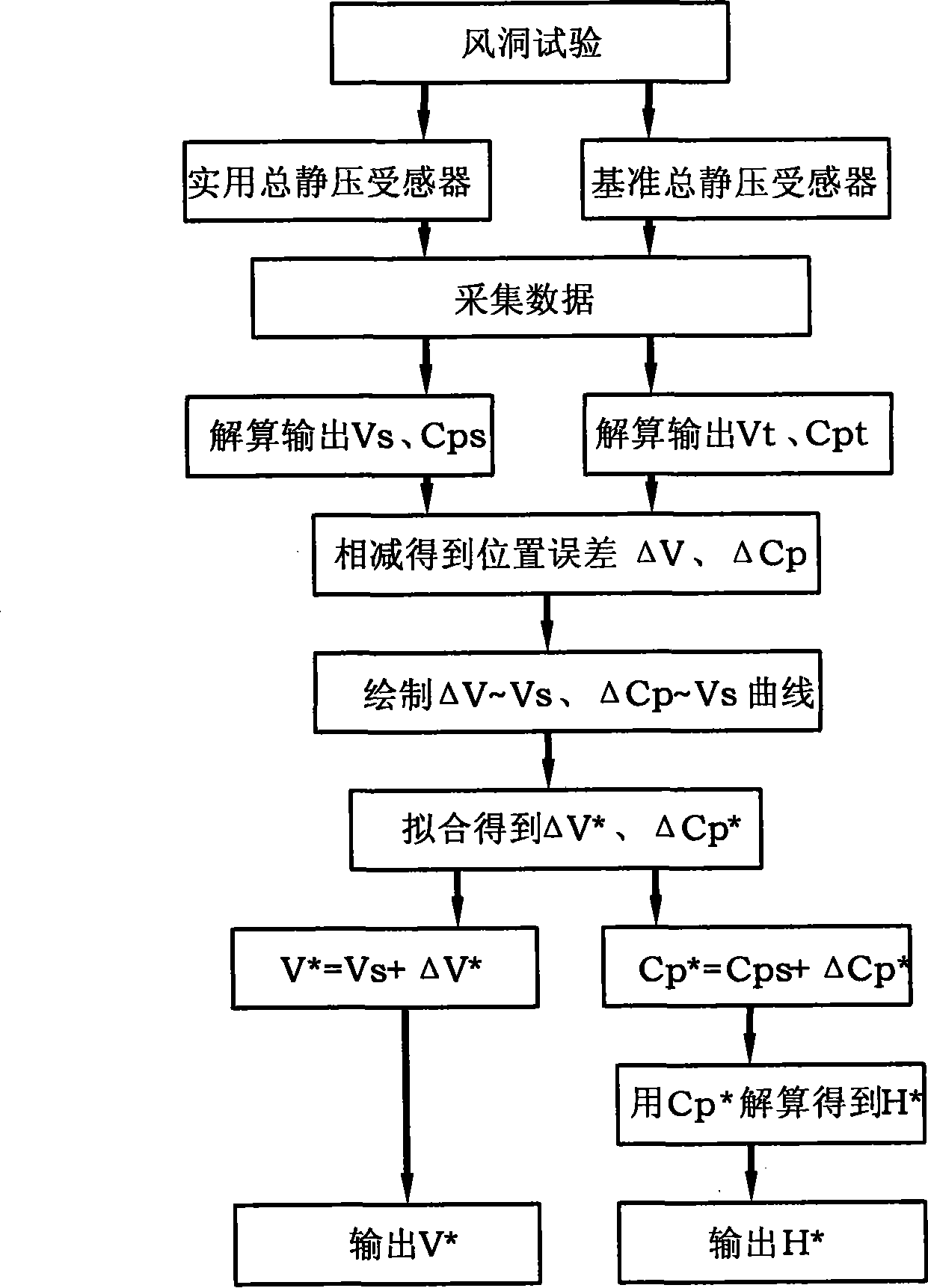

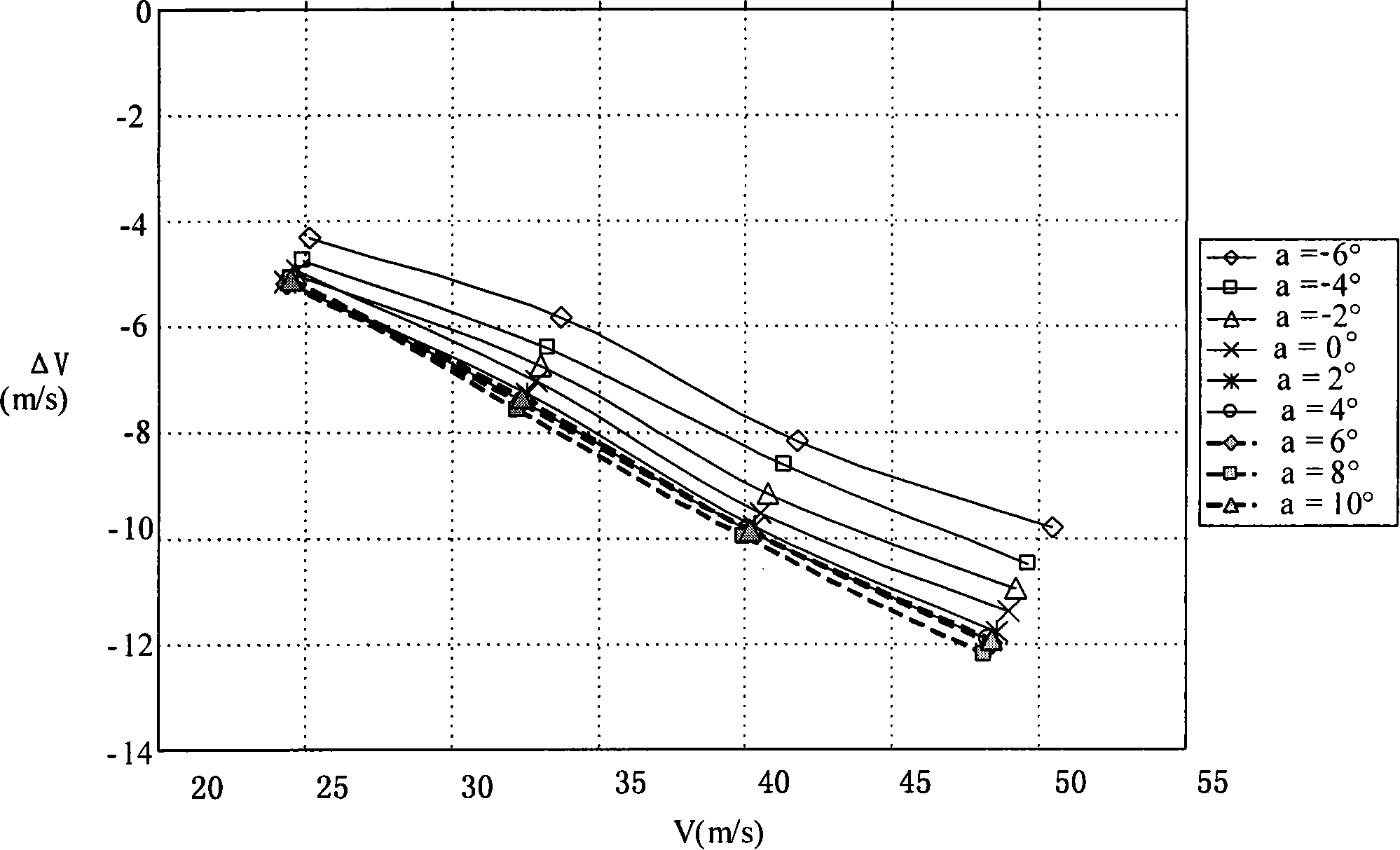

Amending method for positional error of total static pressure sensor on low-speed unmanned aerial vehicle

InactiveCN101246078ANo design changes requiredNo need to change the general arrangementAerodynamic testingFluid pressure measurementLow speedUncrewed vehicle

The present invention discloses a method for modifying the position error of the total static pressure pick-up. The method uses a wind tunnel experiment to obtain a simple modifying method for modifying the flight speed of the unmanned plane and the atmosphere static pressure data. When the modifying method provided by the invention is applied, the designing of the total static pressure pick-up and the general arrangement of the plane do not need modifying; besides the provided modifying formula is simple and definite formulated, the inner algorithm of the air data computer does not need modifying and the data can be automatically modified in the flight control software; and a higher modifying precision is provided to the typical flight condition.

Owner:BEIHANG UNIV

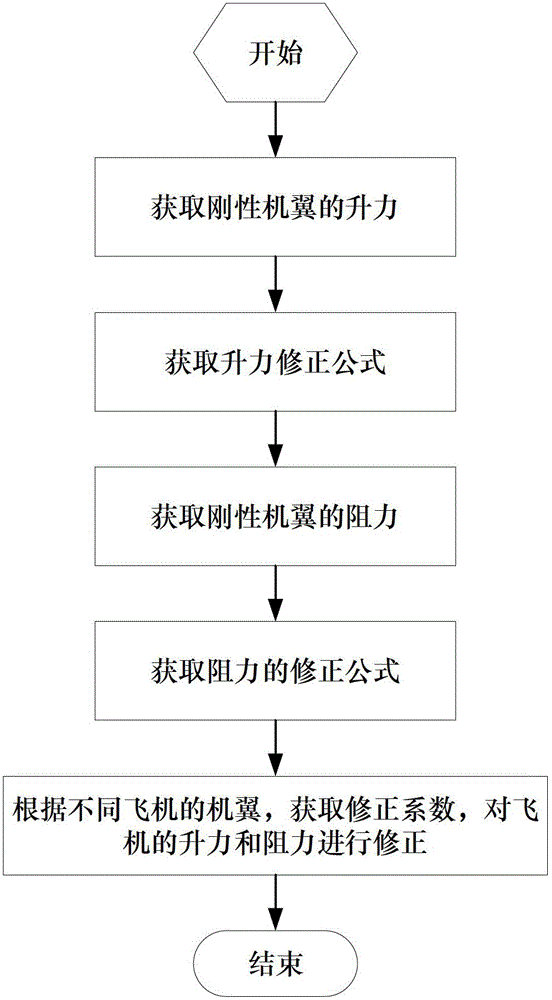

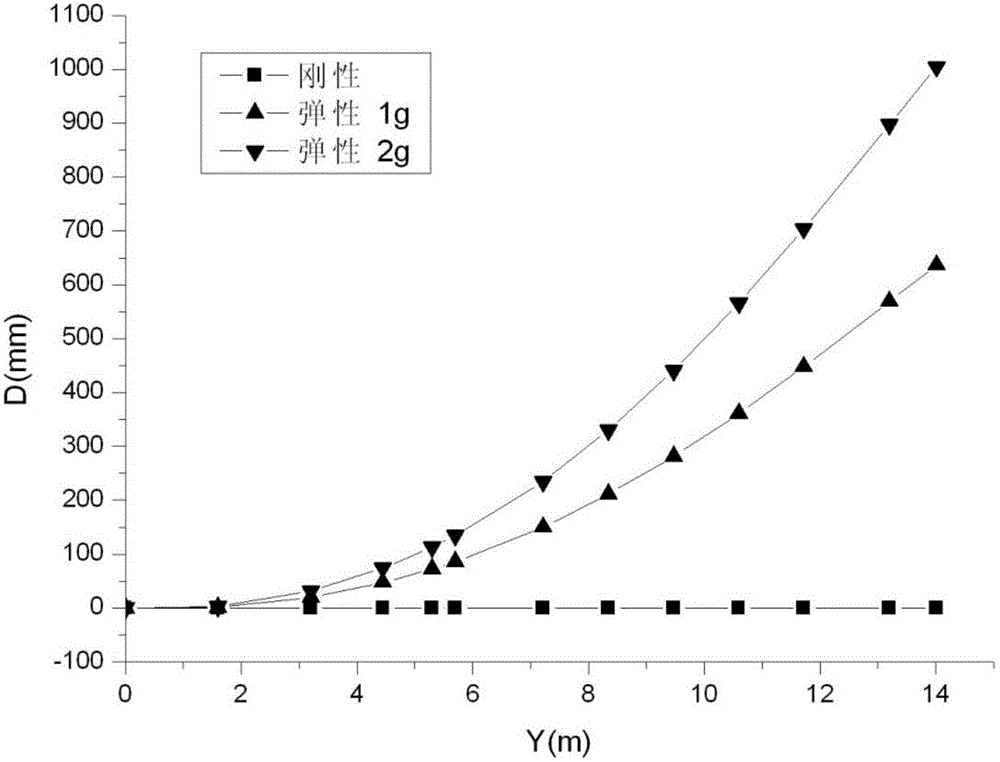

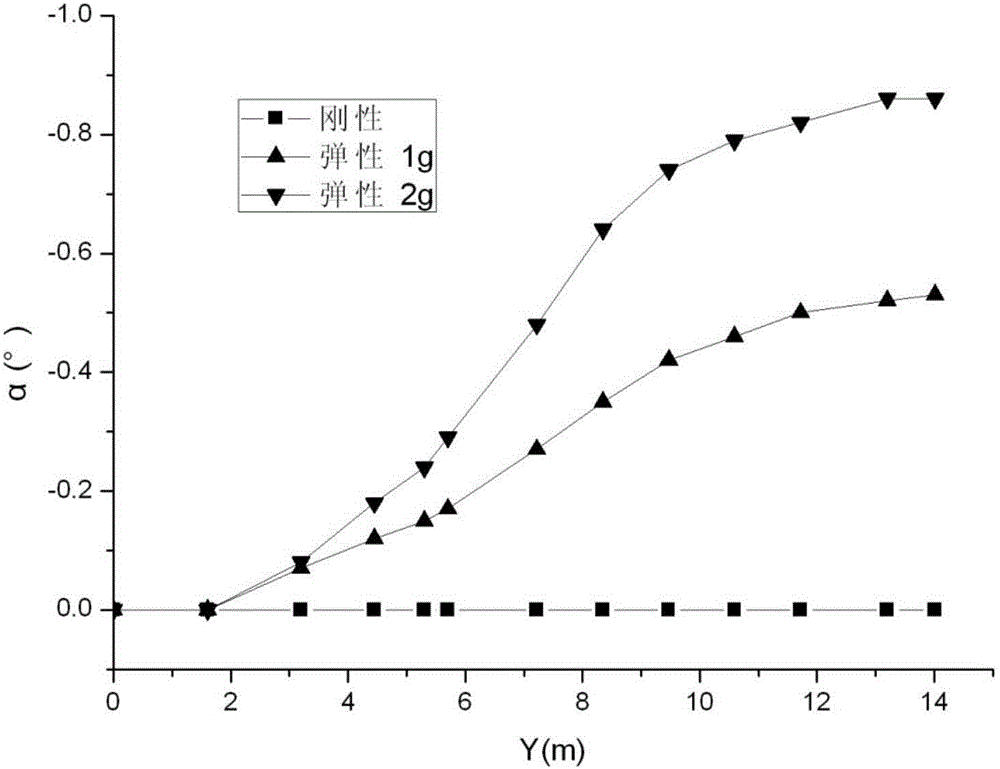

Elastic correction method of airplane lifting resistance aerodynamic characteristics

The invention discloses an elastic correction method of an airplane lifting resistance aerodynamic characteristics, which is characterized by comprising the following steps of: step 1, obtaining lifting force of a rigid wing; step 2, obtaining a lifting force correction formula; step 3, obtaining the resistance of the rigid wing; step 4, obtaining a resistance correction formula; and step 5, obtaining a correction parameter according to wings of different airplanes, and correcting the lifting force and the resistance of an airplane. According to the elastic correction method, the provided correction formulas are simple and clear to express by taking that the lifting force correction formula and the resistance correction formula of the airplane are finally provided as an aim, so that the elastic correction method is suitable for the airplane with a large span-chord ratio wing to carry out numerical value pneumatic calculation on a rigid model and elastic correction on lifting force and resistance properties characteristics after a wind tunnel test, and has higher correction precision on the airplane with the large span-chord ratio wing.

Owner:北京北航天宇长鹰无人机科技有限公司

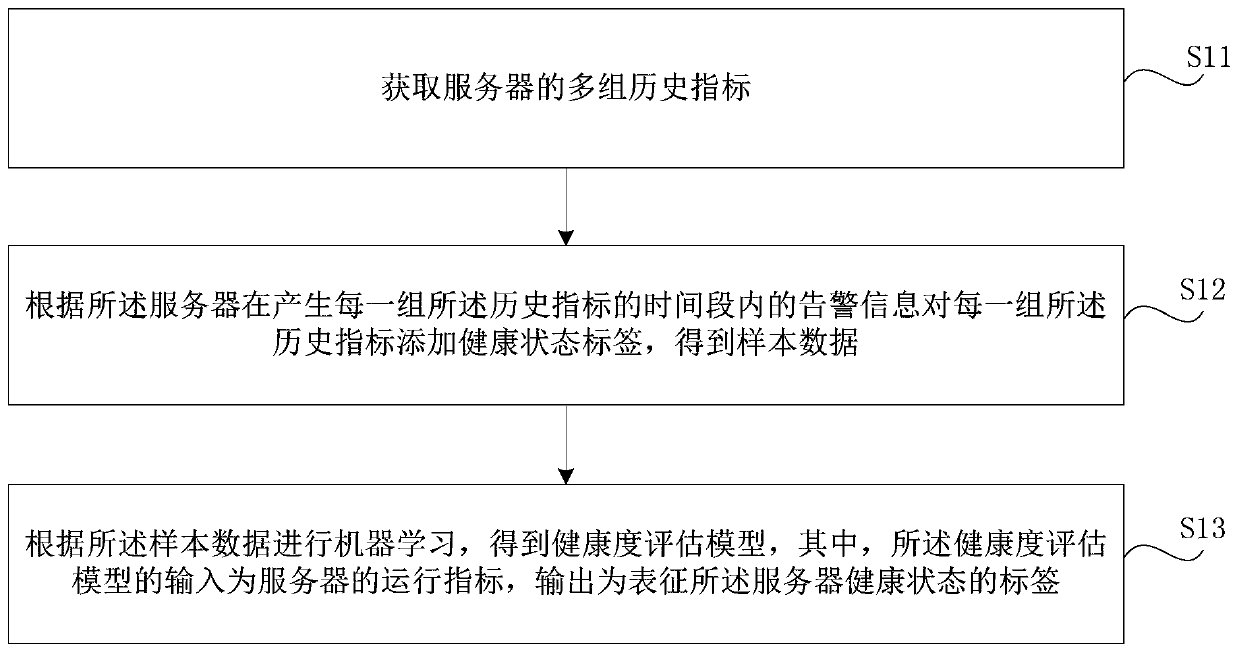

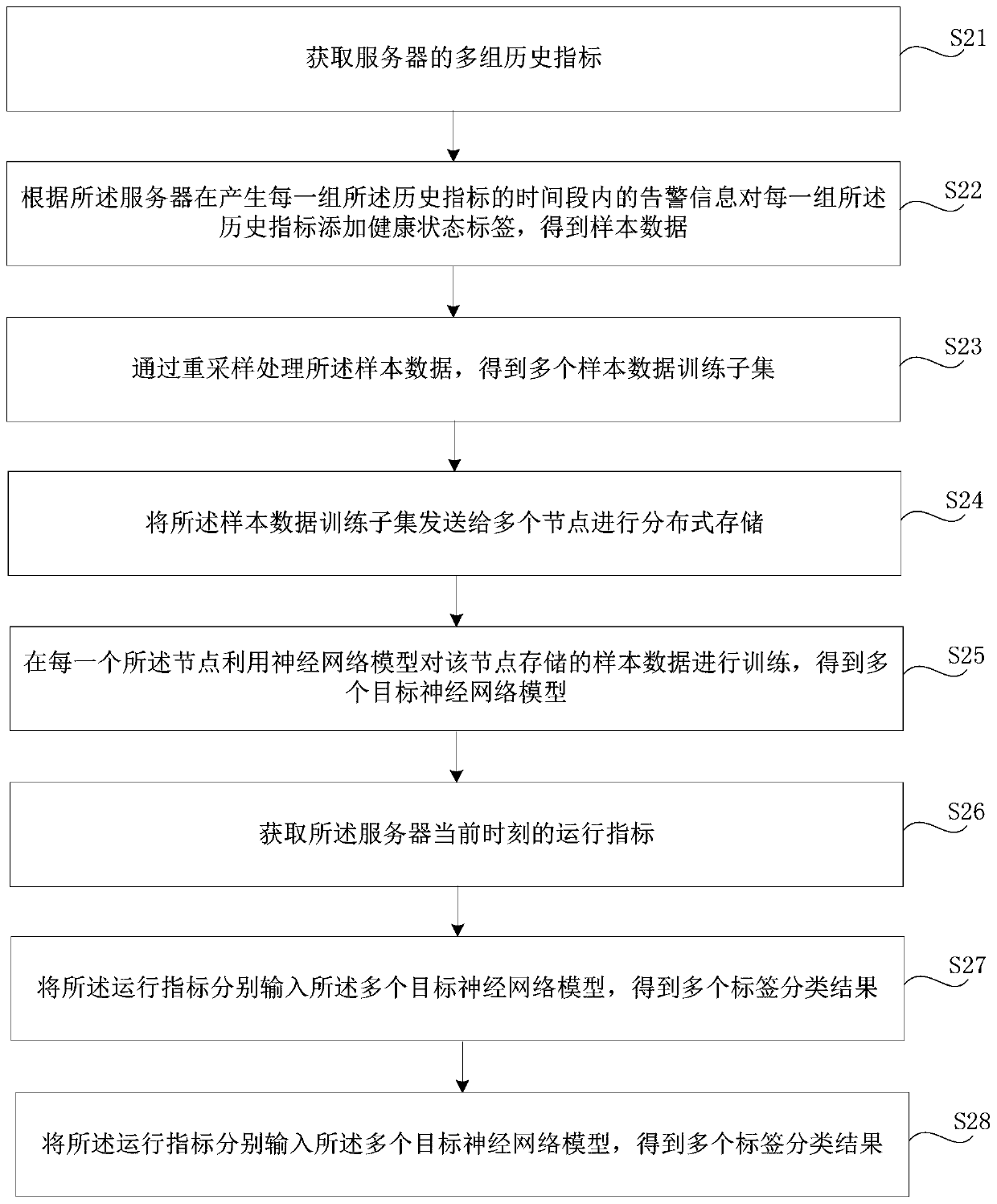

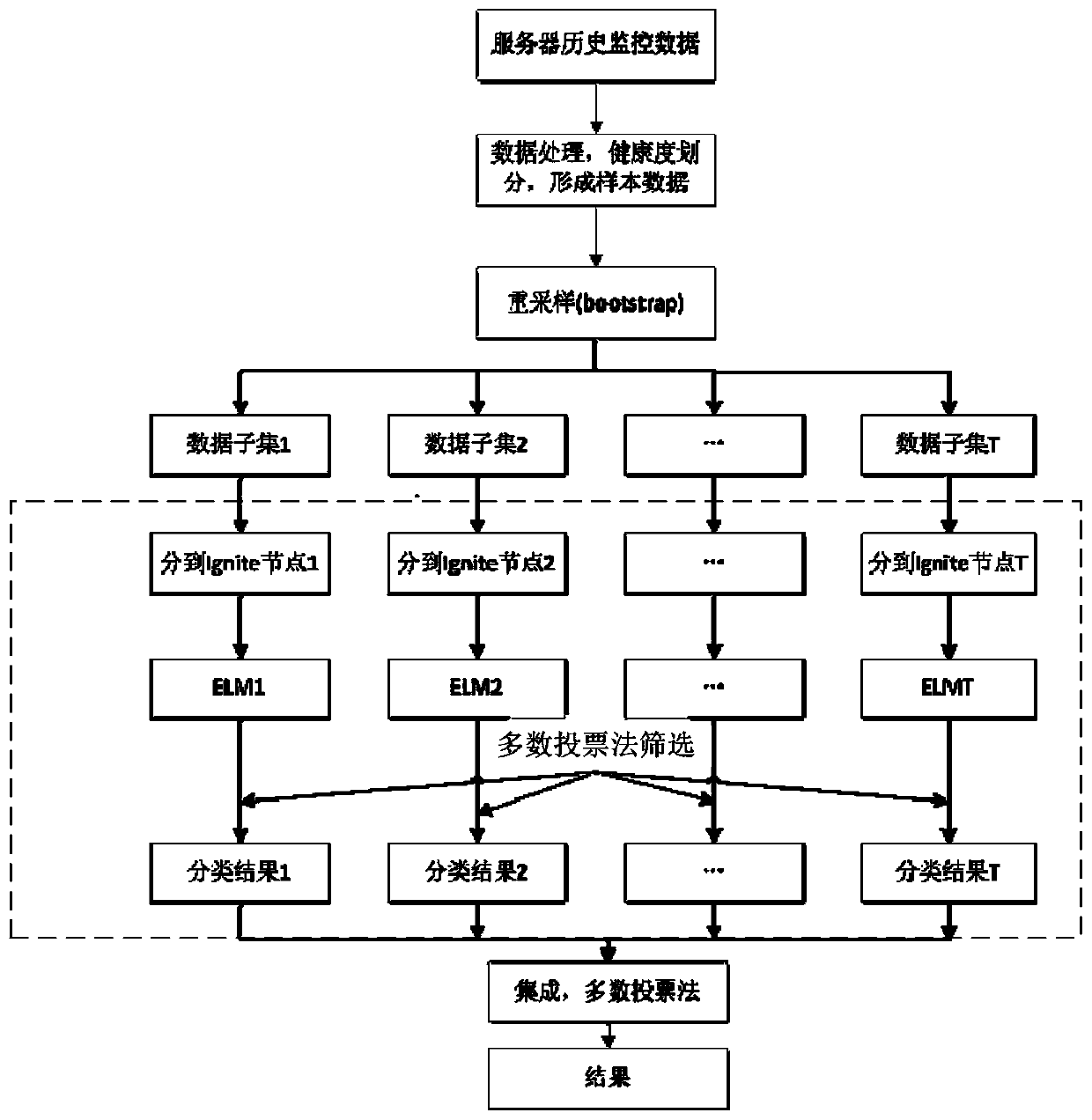

Server health degree analysis method and device, storage medium and electronic equipment

The invention aims to provide a server health degree analysis method and device, a storage medium and electronic equipment so as to solve the problem that in the prior art, server health analysis is not comprehensive enough. The method comprises the steps of obtaining multiple groups of historical indexes of a server; adding a health state label to each group of historical indexes according to thealarm information of the server in the time period of generating each group of historical indexes to obtain sample data; and machine learning is carried out according to the sample data to obtain a health degree assessment model, the input of the health degree assessment model is an operation index of a server, and the output of the health degree assessment model is a label representing the health state of the server.

Owner:NEUSOFT CORP

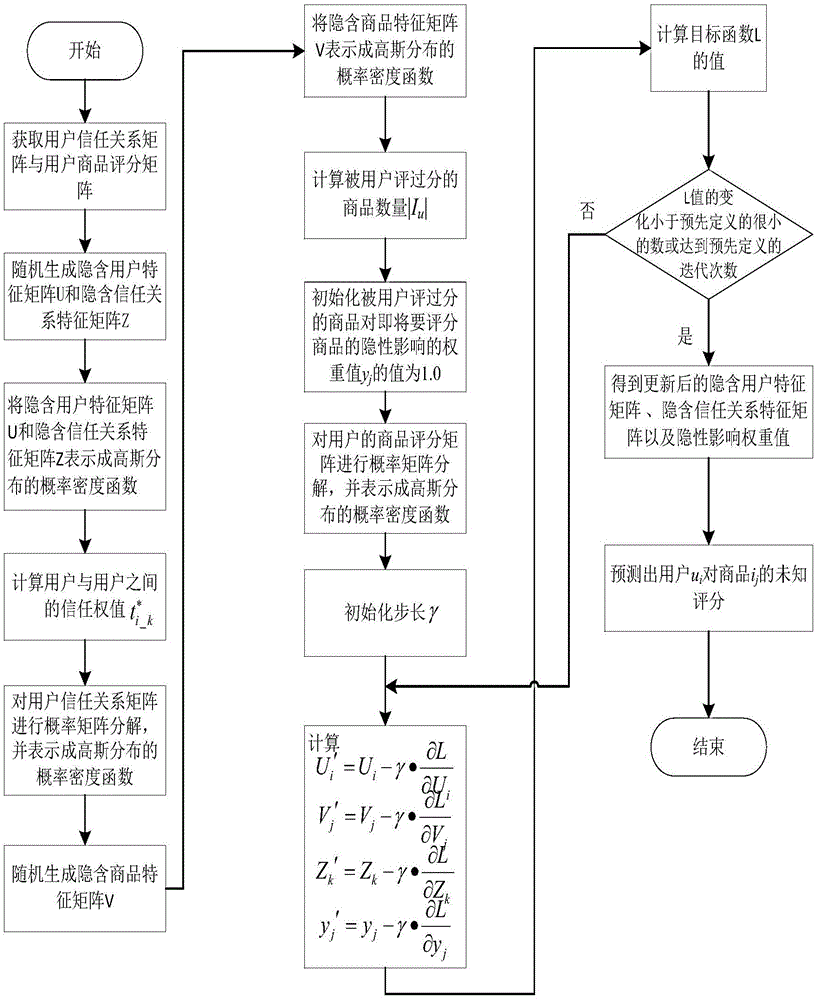

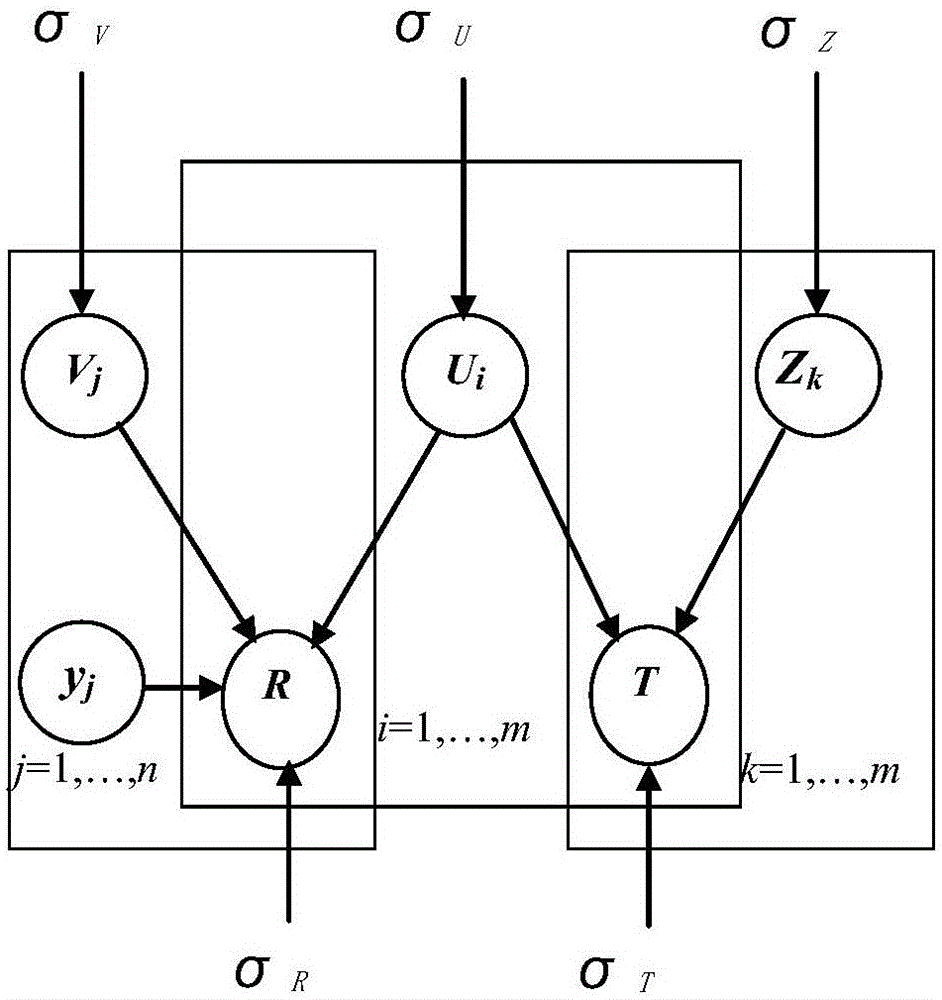

Probability matrix decomposition recommendation method

The invention provides a probability matrix decomposition recommendation method. The method provided by the invention is based on explicit and implicit feedback information and combined with a probability matrix decomposition technology at the same time so as to help a user to score the commodity. The method comprises the steps of firstly carrying out probability matrix decomposition on a user trust relationship matrix, then carrying out probability matrix decomposition on a commodity score matrix of the user and the implicit feedback information, solving an implicit user characteristic matrix, an implicit commodity characteristic matrix and an implicit feedback information characteristic vector by integrating results of the two times of decomposition, and finally calculating a recommendation score of the user. The method provided by the invention can help the user to recommend a score of the commodity by well utilizing an online social network, relieves a data sparse problem and a cold start problem in the social network, and has an excellent recommendation effect. Meanwhile, the probability matrix decomposition recommendation method can be applied to a recommendation system with a large-scale data set.

Owner:NANJING UNIV OF POSTS & TELECOMM

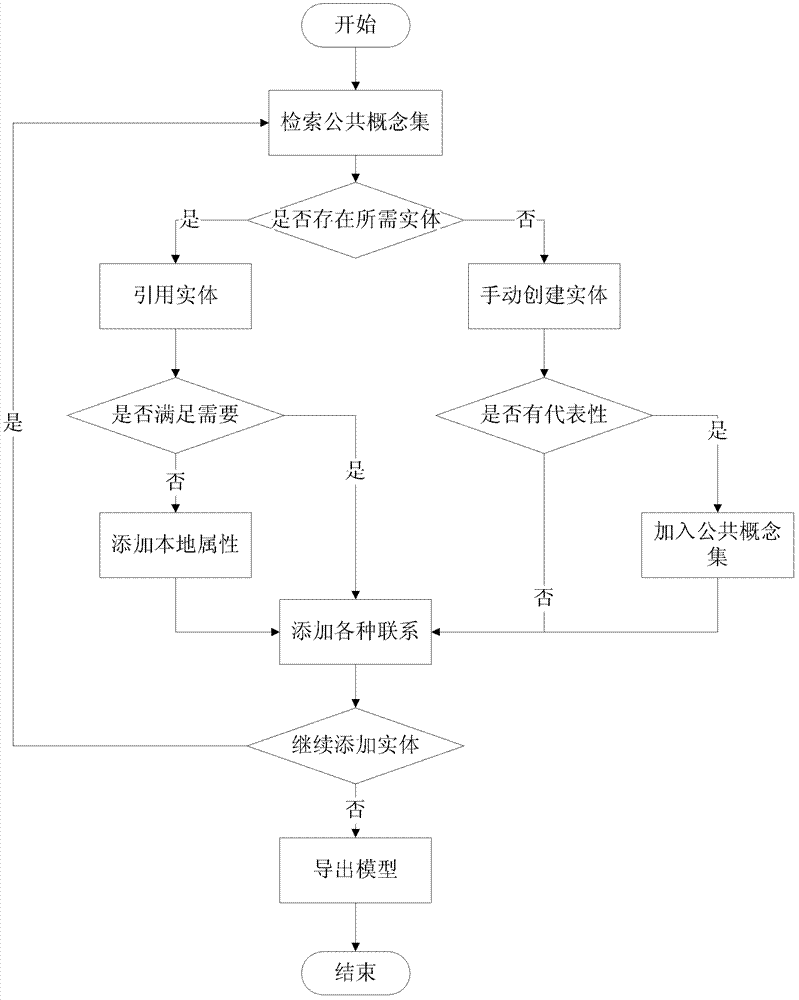

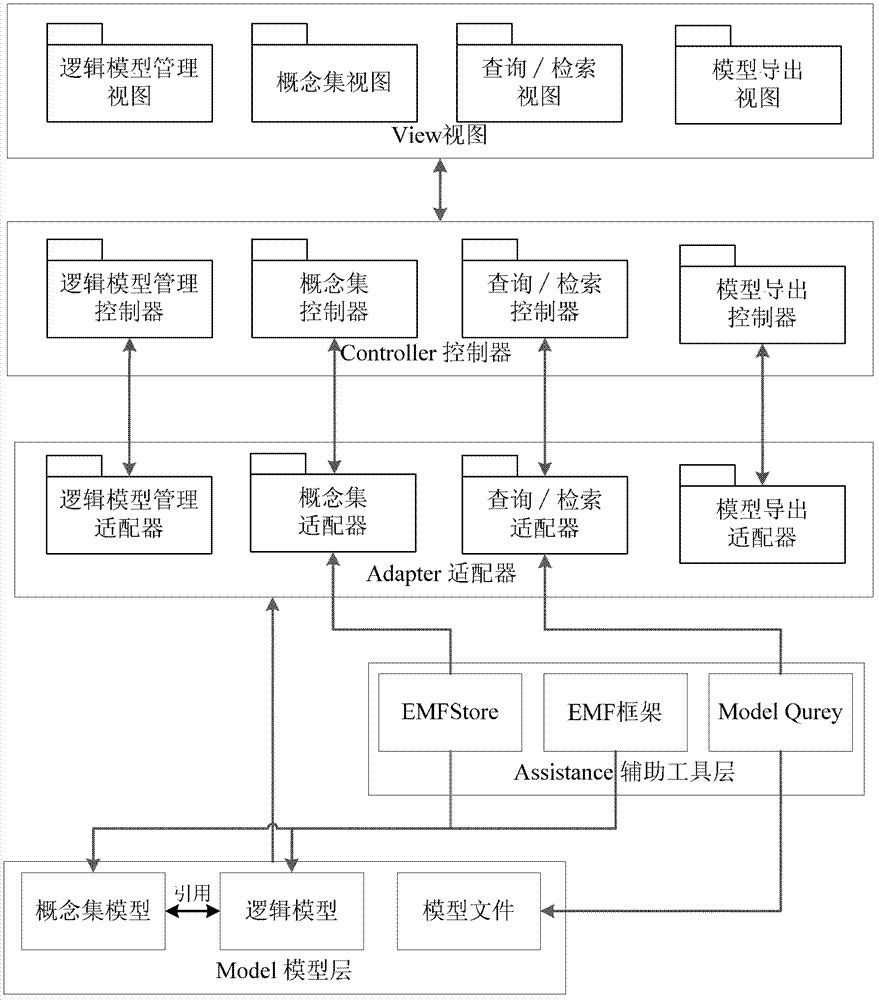

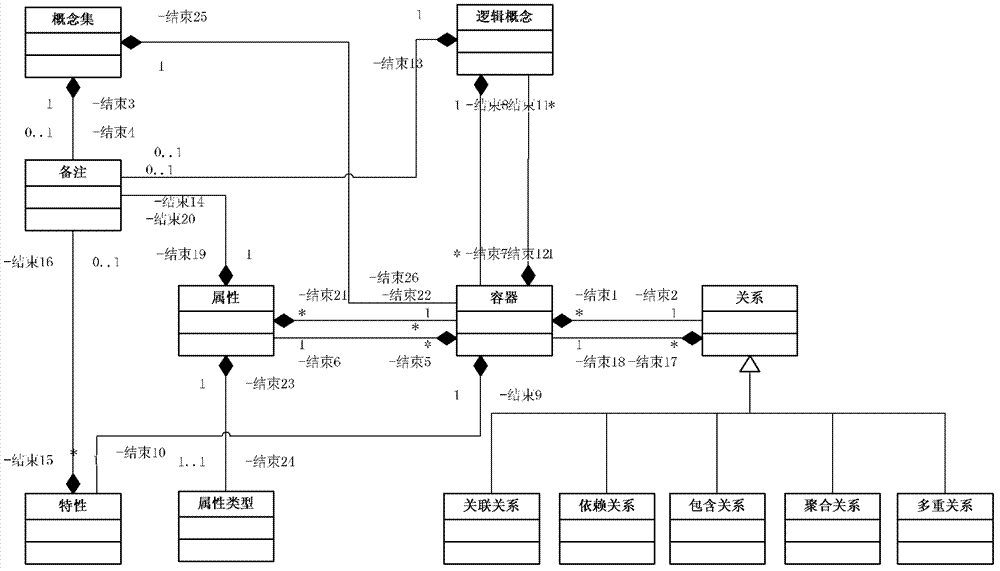

Modeling method of data logic model utilizing public conceptual sets

ActiveCN102708161AAccurate expressionClear expressionSpecial data processing applicationsMetadataModelling methods

The invention relates to a modeling method of a data logic model utilizing public conceptual sets. A set of symbolic languages supporting fast building of the data logic model is built. The modeling method comprises modeling elements such as relationship set and entity, basic attributes, conceptual attributes, and composite attributes, provides stronger semantic expression ability than traditional E-R (entity-relation) diagram, and can supports building of data models of various complex information systems. By using the public conceptual sets, building speed of the data models is increased, iterative development is avoided, data standardization is facilitated, visualized support systems are provided to building of logic models, the data models designed by a graphical interface can be exported into international XMI (XML metadata interexchange) format so as to be compatible with other model designing tools, building of the data models of the information systems is more convenient and faster, designing and implementation of a database mode are simplified greatly, and visualized fast building of the data models by developers during engineering is facilitated.

Owner:TSINGHUA UNIV

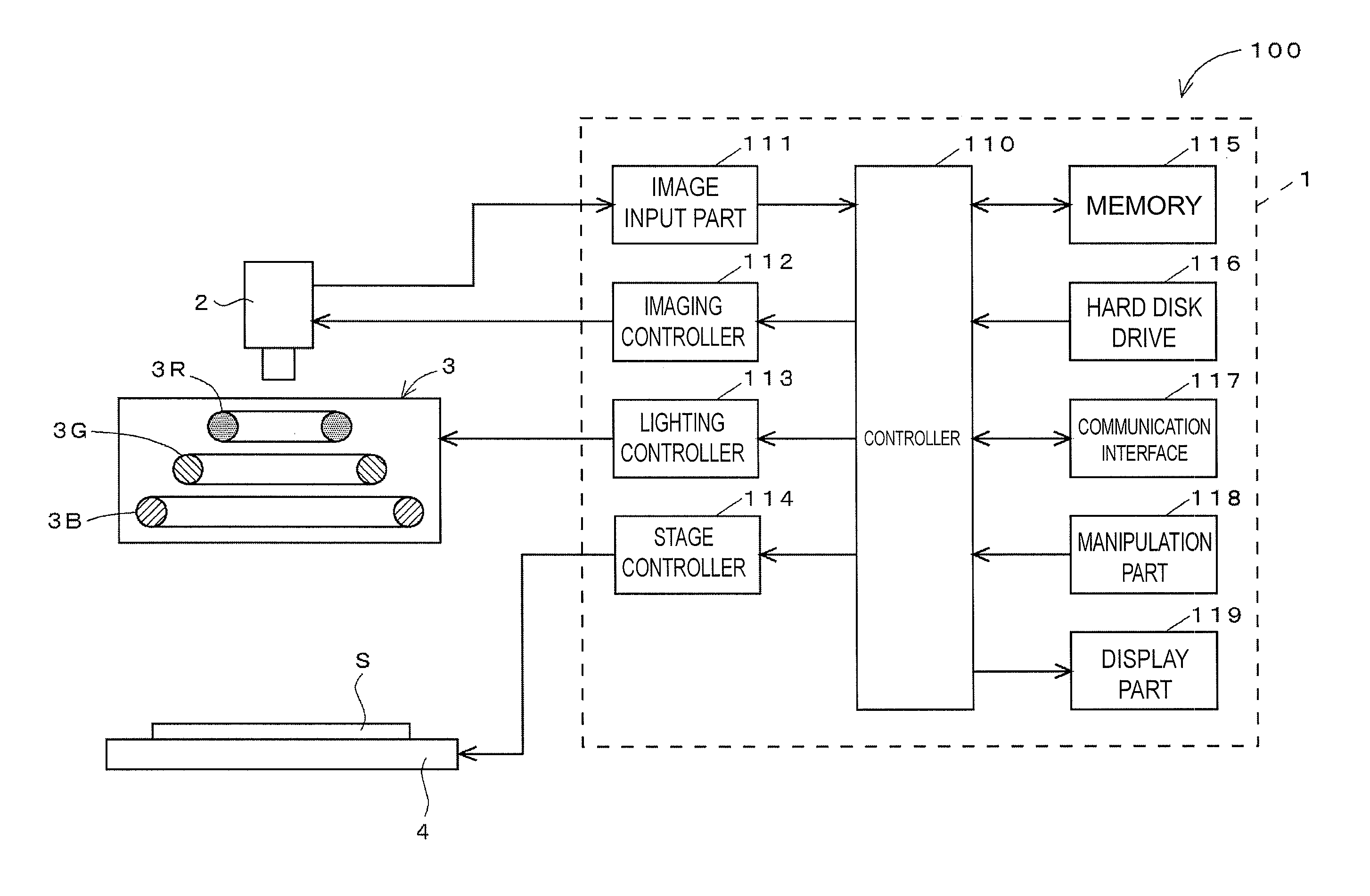

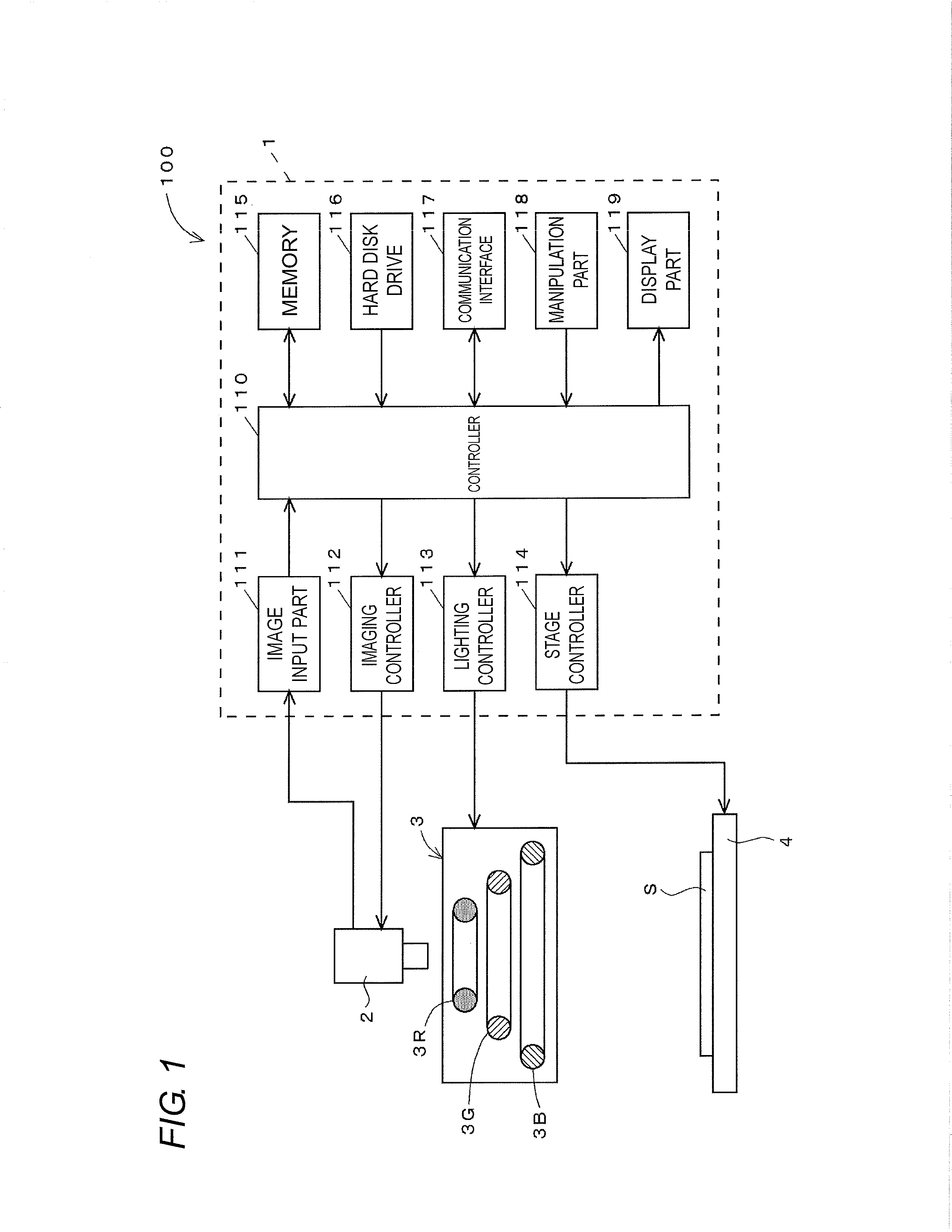

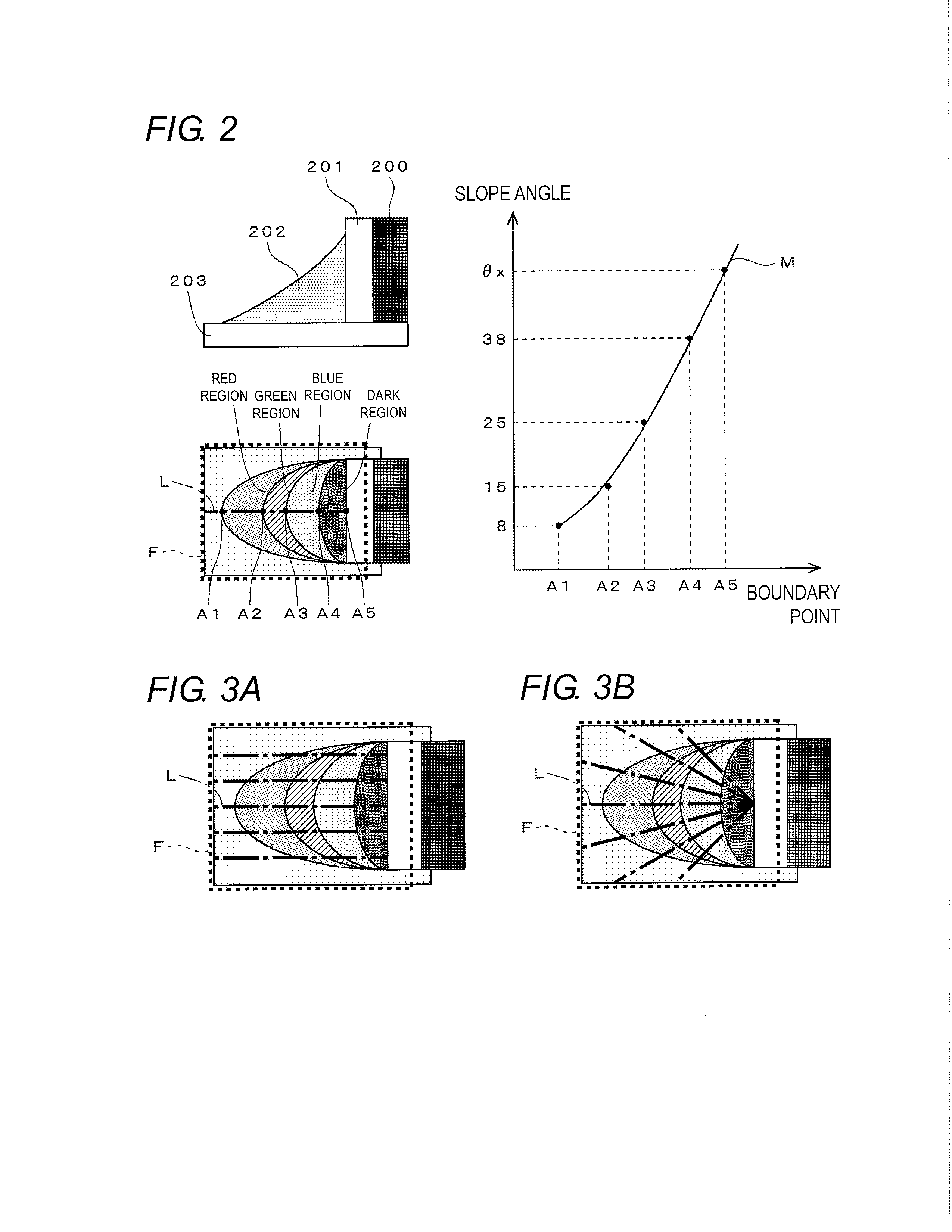

Method for registering inspection standard for soldering inspection and board inspection apparatus thereby

InactiveUS20130182942A1Easy to operateClear expressionImage analysisData processing applicationsThree dimensional shapeSoldering

Performing an inspection based on a shape of a solder fillet and setting a standard of the inspection. In order to set the standard of the inspection by a method for determining whether the solder fillet of a component mounted on a board is proper by obtaining a calculation of a numerical parameter indicating a three-dimensional shape of the solder fillet, a setting screen including an image display region indicating an image of a component of a setting target and an inspection standard list is displayed to receive a user manipulation. A list in which an item name of each of plural inspection items is correlated with an input field of a standard value of a numerical parameter measured by the inspection item is displayed in the inspection standard list.

Owner:ORMON CORP

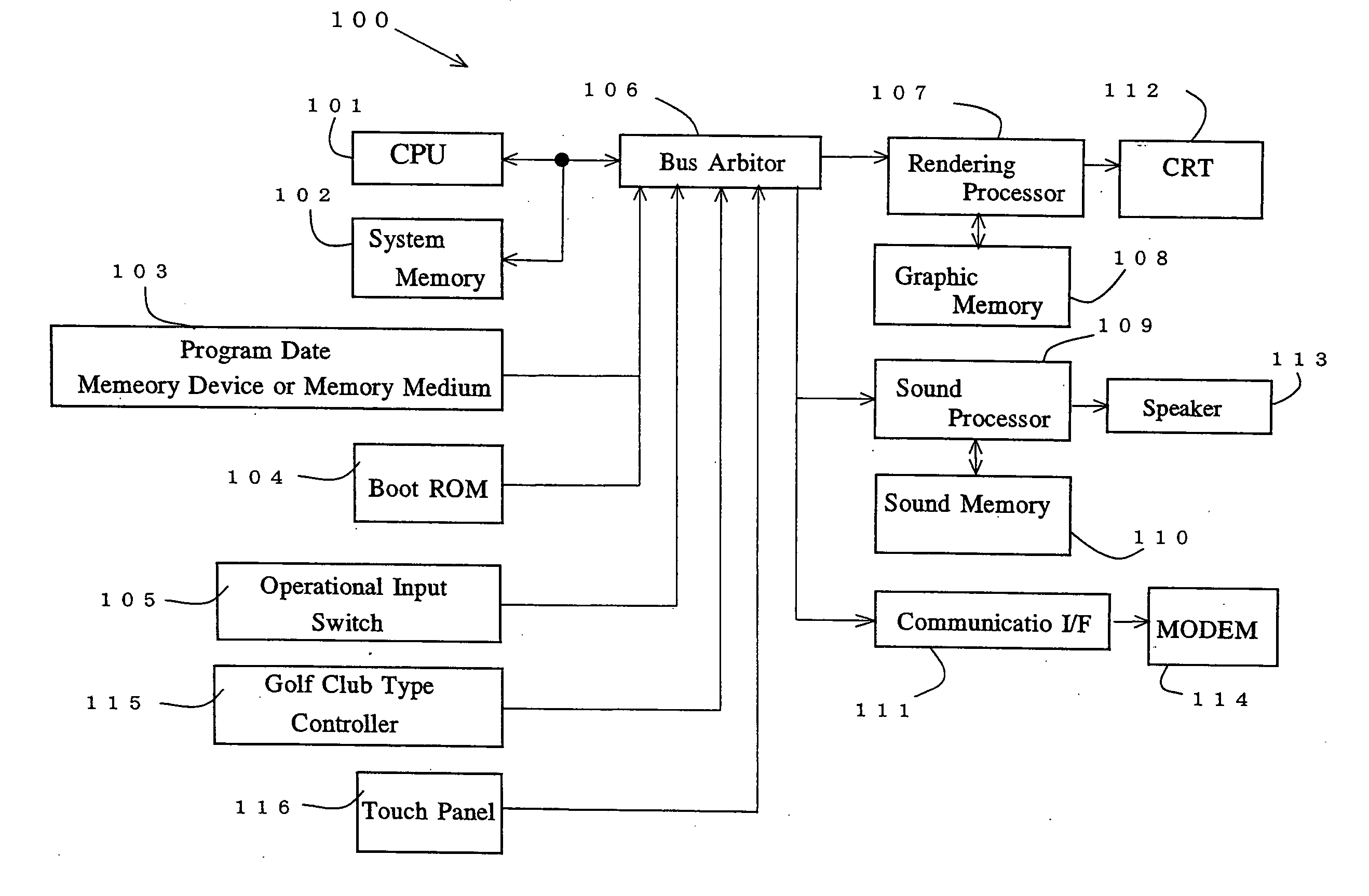

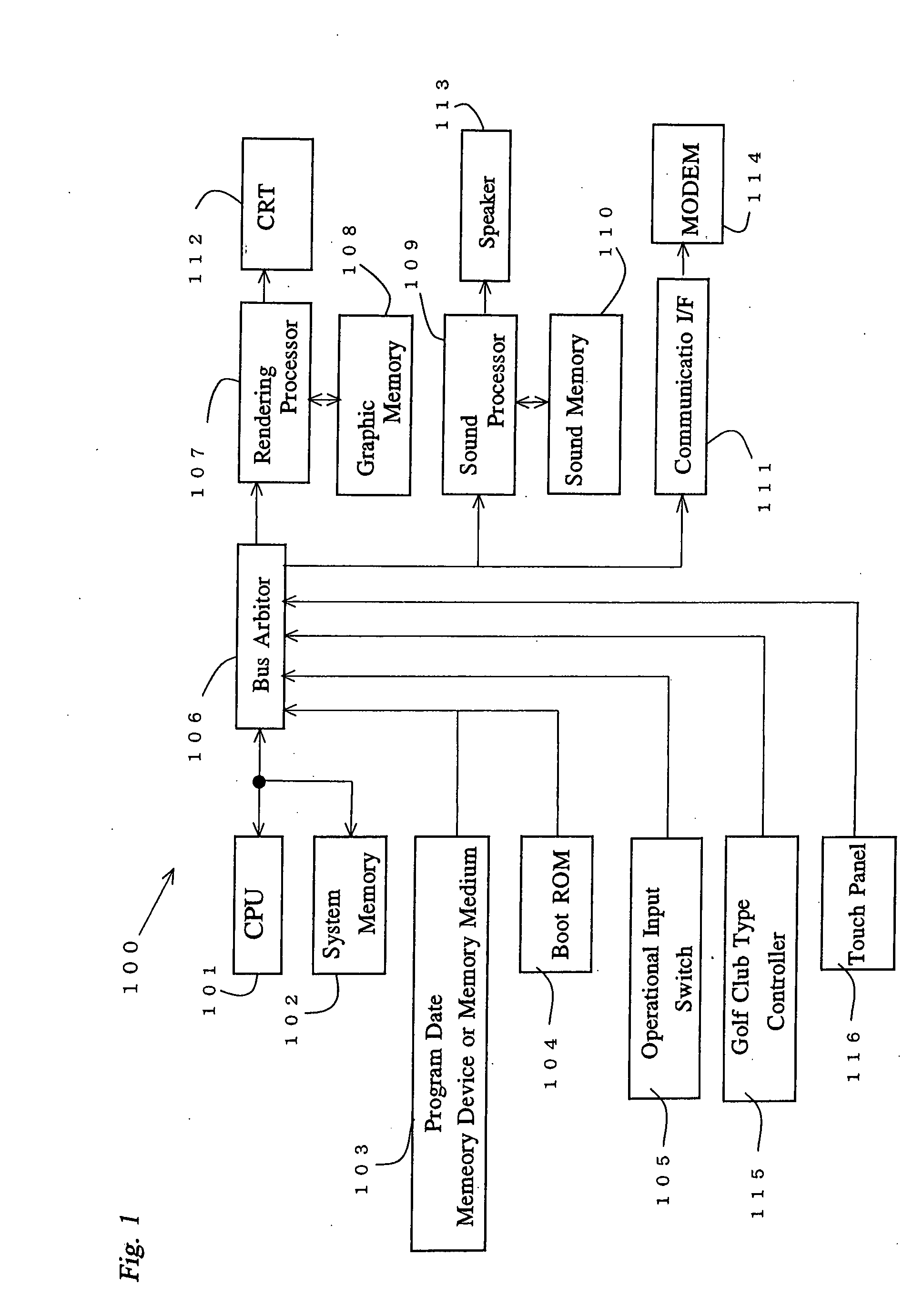

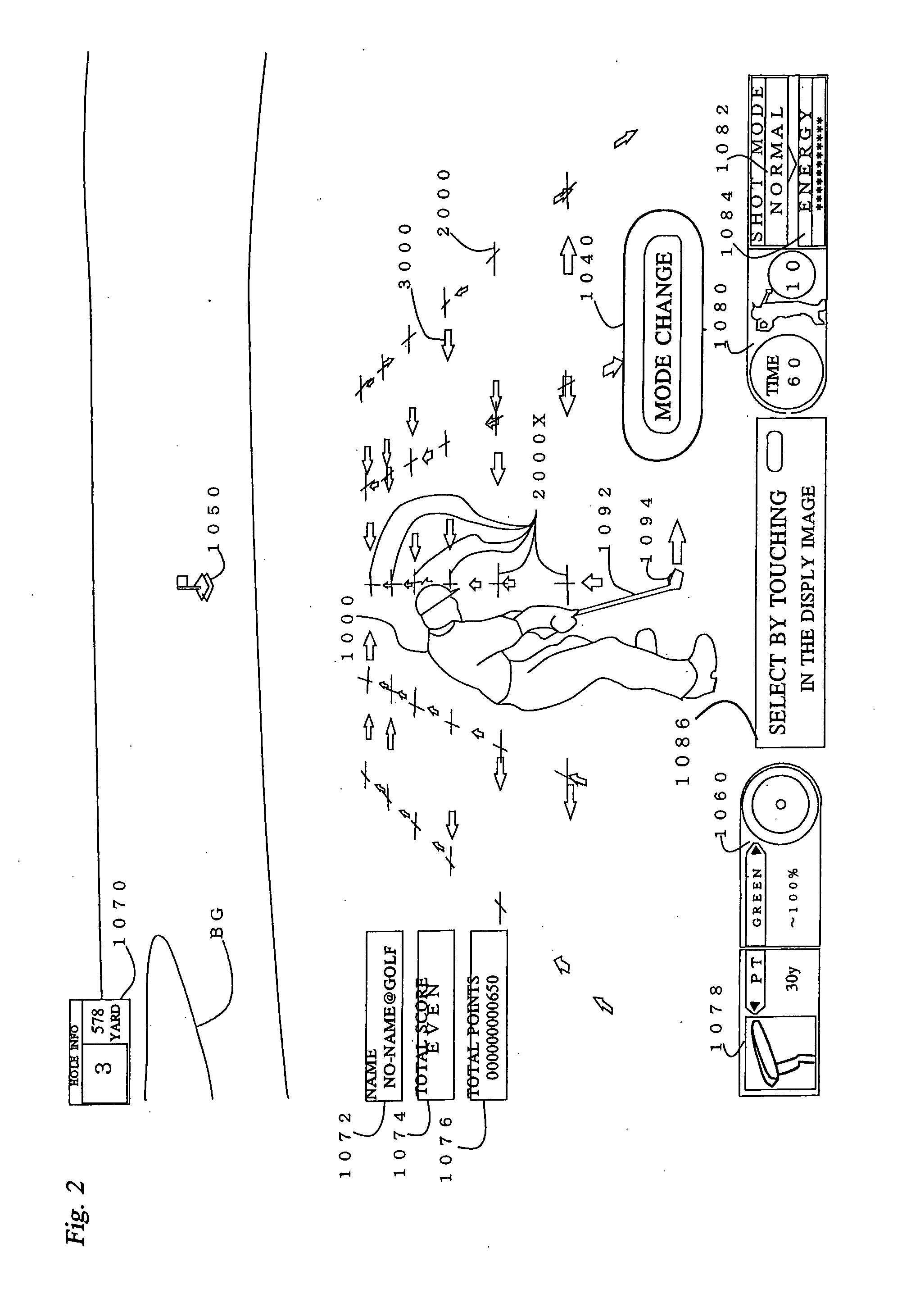

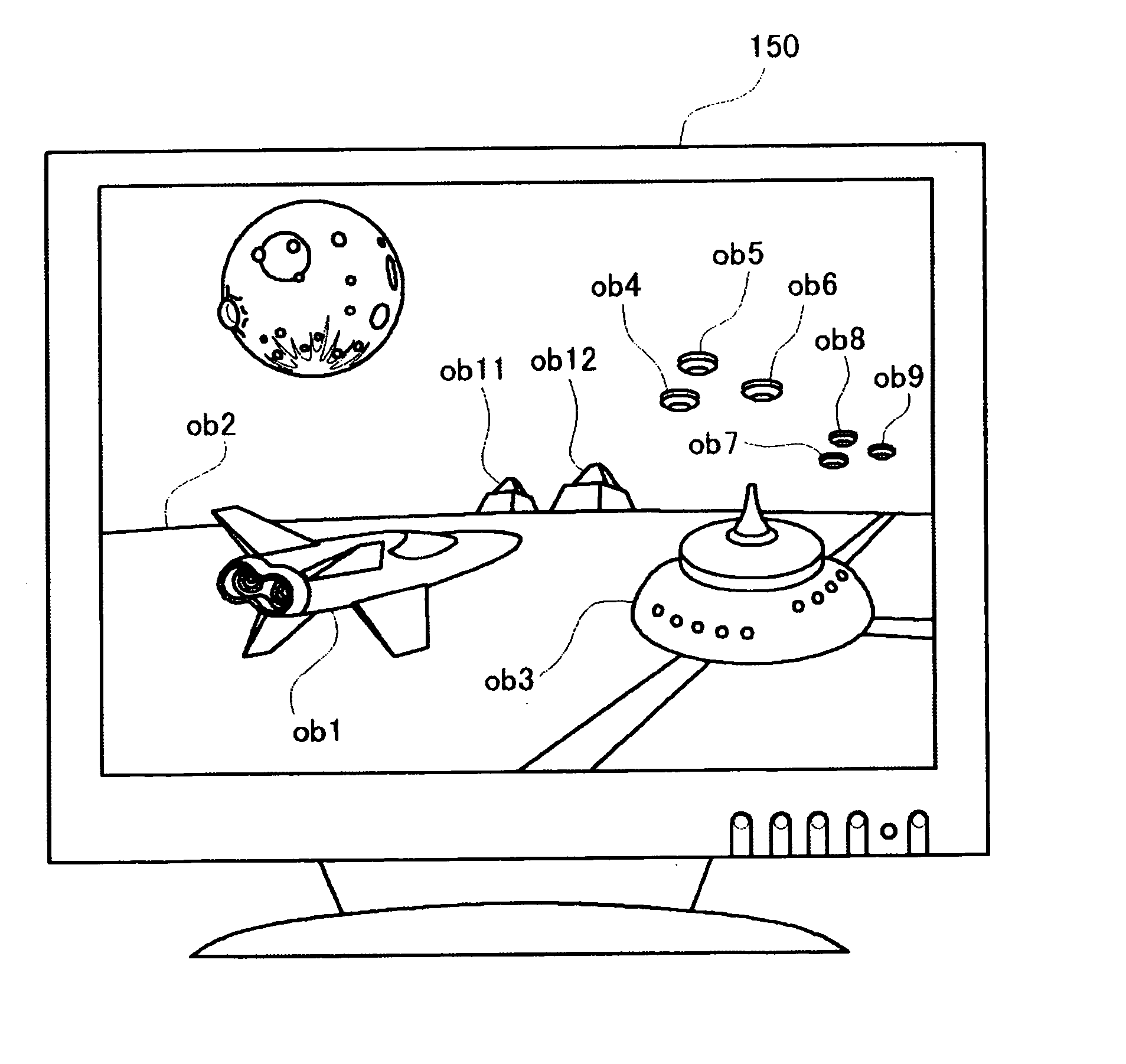

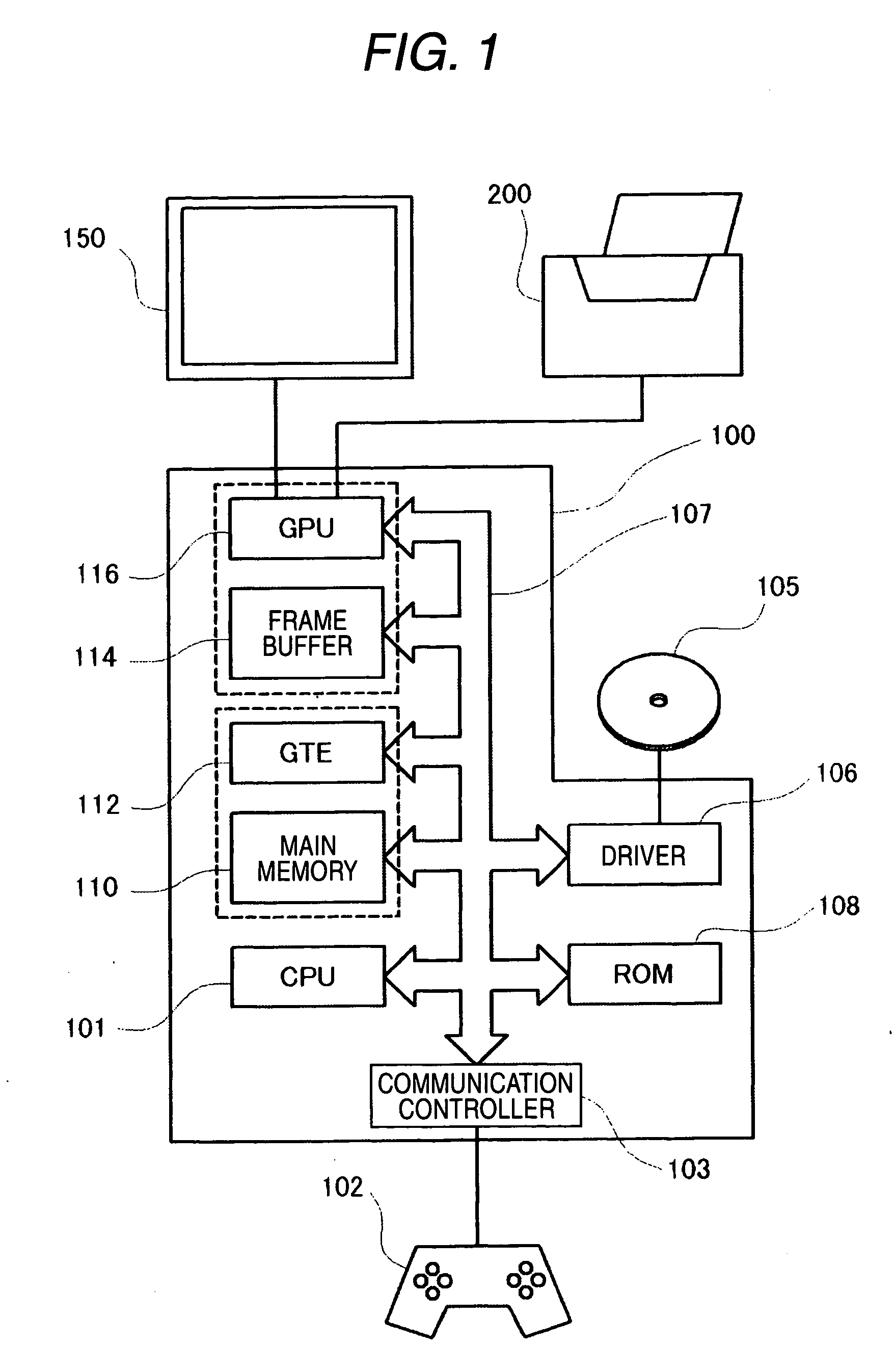

Image display system and information processing apparatus

InactiveUS20050193349A1Without deteriorationWithout deteriorating natural atmosphere of a virtual spaceVideo gamesSpecial data processing applicationsInformation processingDescent direction

The coordinate indicating objects are cross-shaped and aligned between the ball and cup. The virtual space has X axis from left to right, upward Y axis and Z axis toward depth direction. The coordinate indicating objects are arranged in a manner of check pattern on the X-Z coordinate. The Y-coordinate are set on the ground of course. The inclination indicating objects moves in descent direction between a pair of the coordinate indicating objects in a speed determined by the inclination value of the coordinate indicating objects adjacent in X or Z direction, that is, a difference of the Y-coordinate of the coordinate indicating objects. Therefore, clear expression is possible of inclination of inclined planes etc. without deteriorating natural atmosphere of a virtual space.

Owner:SEGA CORP

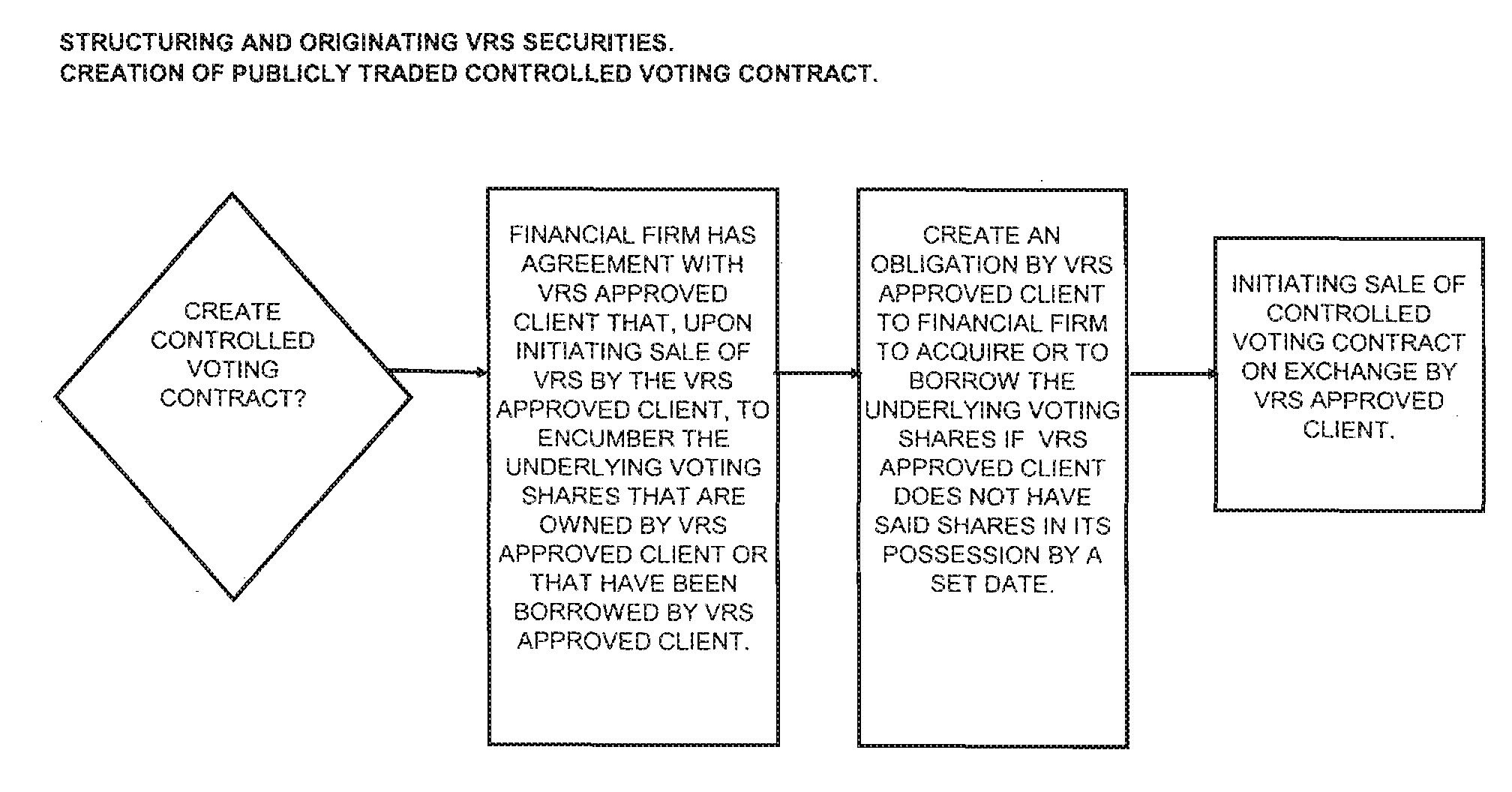

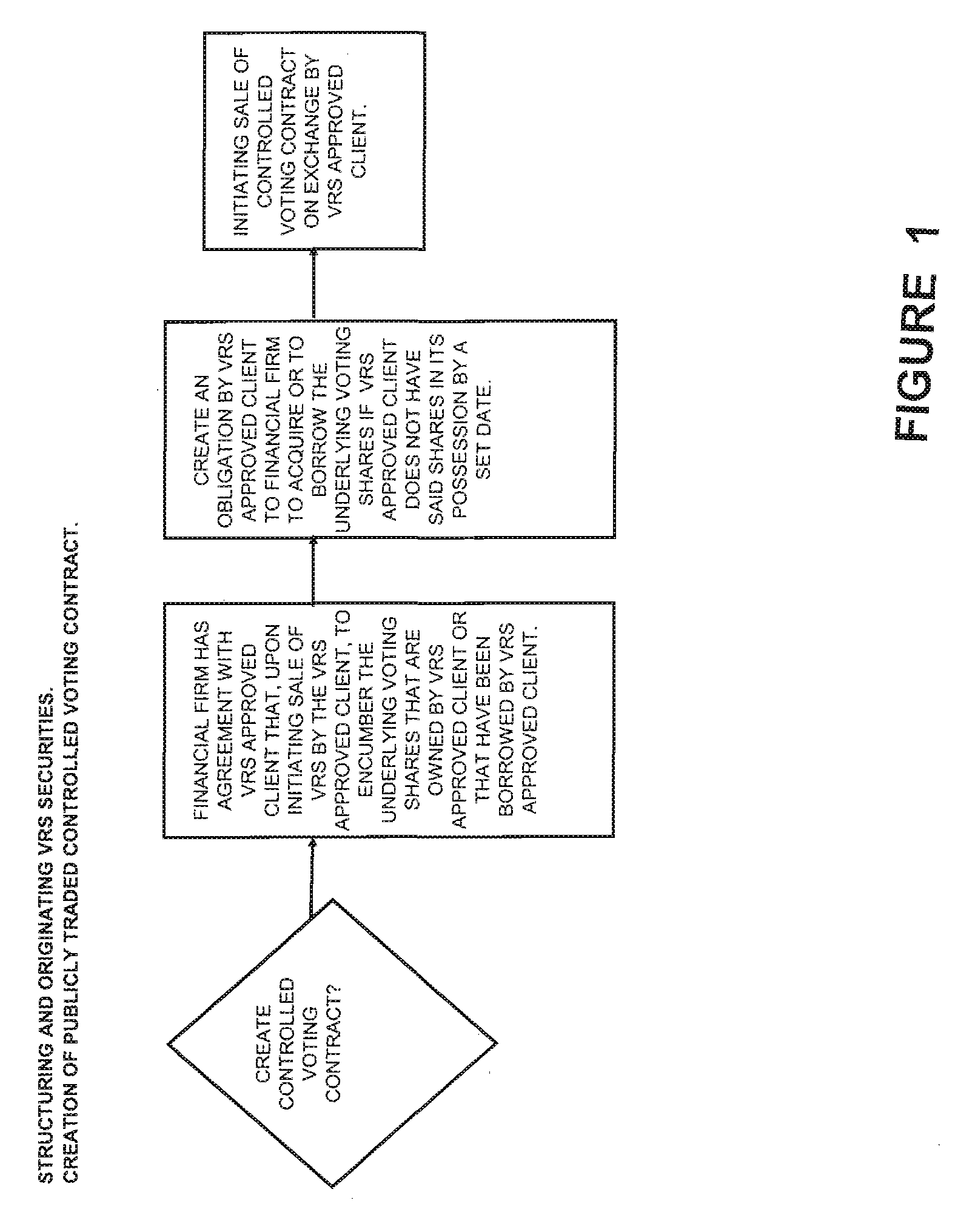

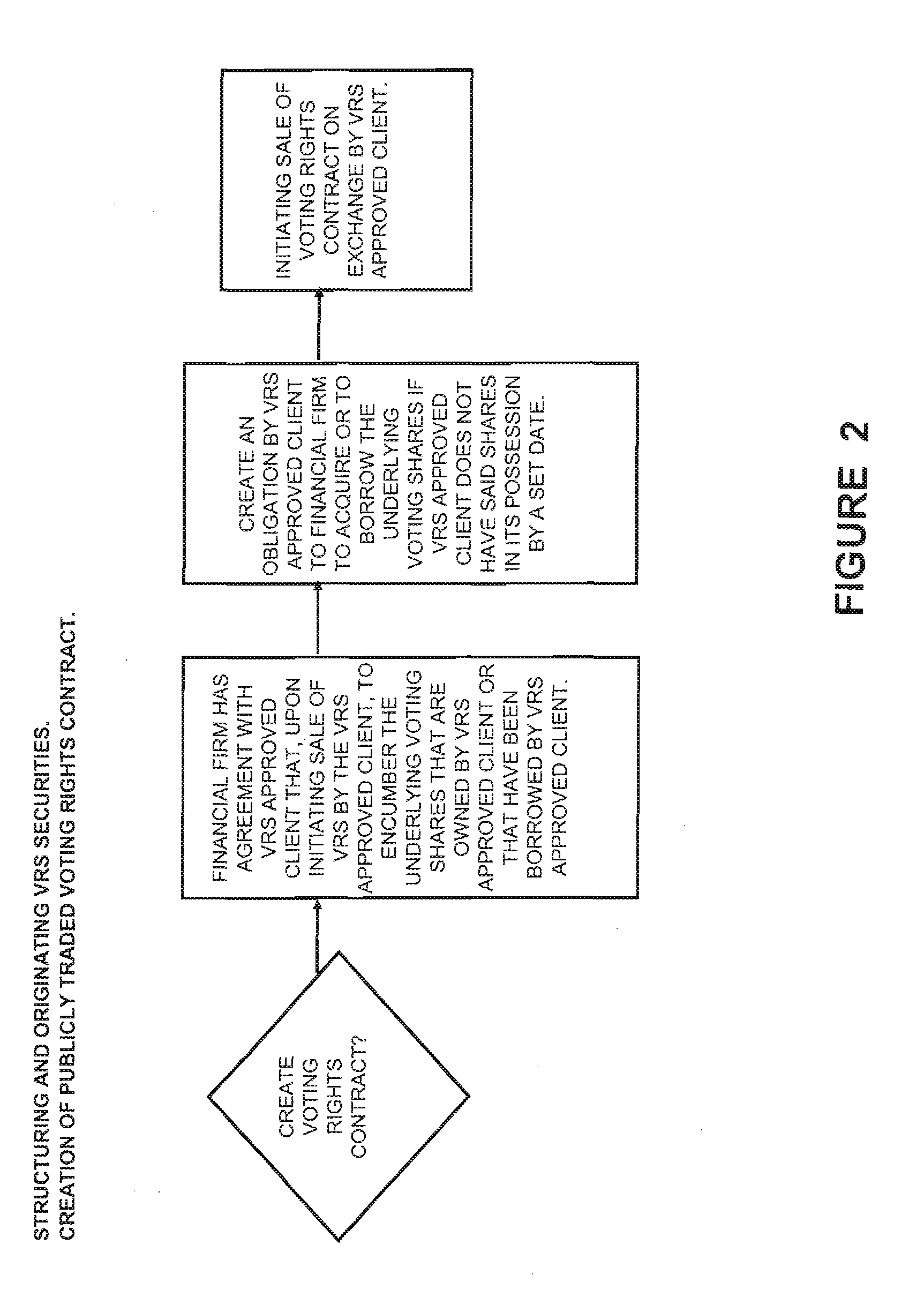

Financial security and a transaction method, system and index relating to the same

InactiveUS20100049647A1Efficient and cost-effectiveClear expressionFinanceFinancial securityComputer security

A tradable security comprising a voting right associated with an underlying financial security and an instrument for permitting at least said voting right to be separated from at least some residual rights in the underlying financial security to create a voting right security wherein the ownership and control of the voting right security is tradable separate from the residual rights in the underlying security to permit a value of said voting right security to be established in an open market. In another aspect the invention is directed to a method of creating such a voting right security. In another aspect the invention is directed to a method of clearing and setting trades of the voting right security. In another aspect the invention is directed to a method of creating an index from the voting right security.

Owner:DE CHABRIS ANDREW MARKS

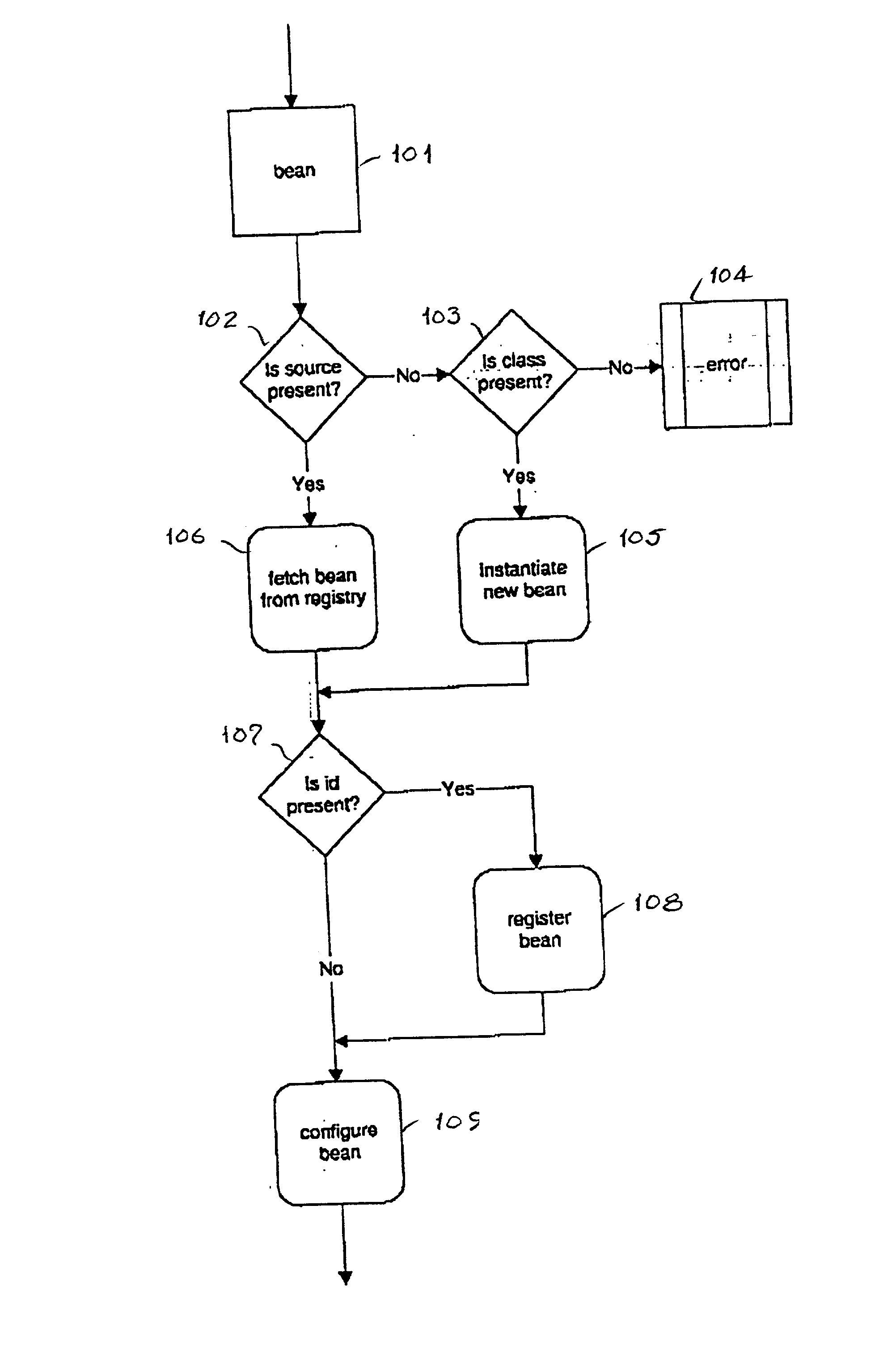

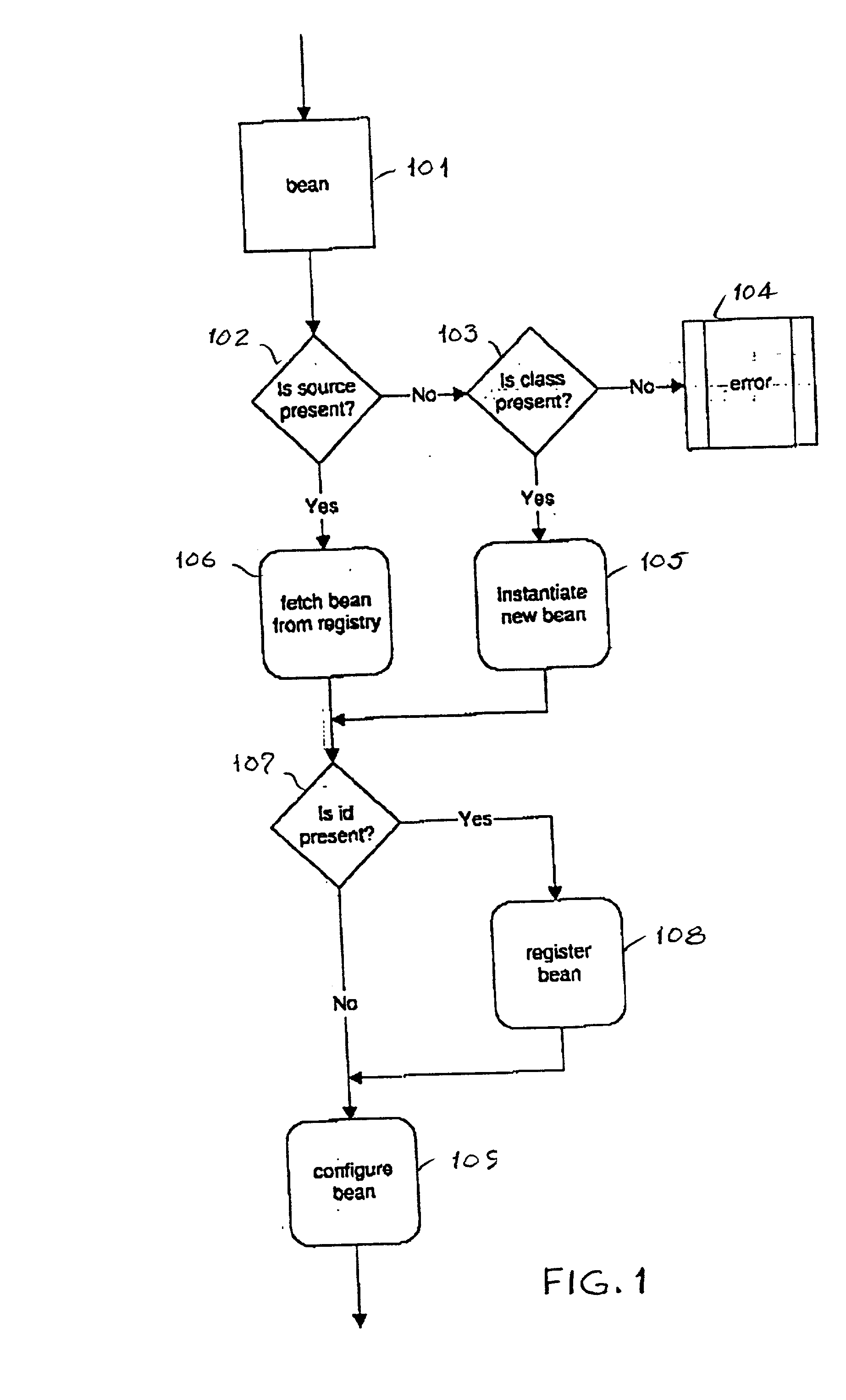

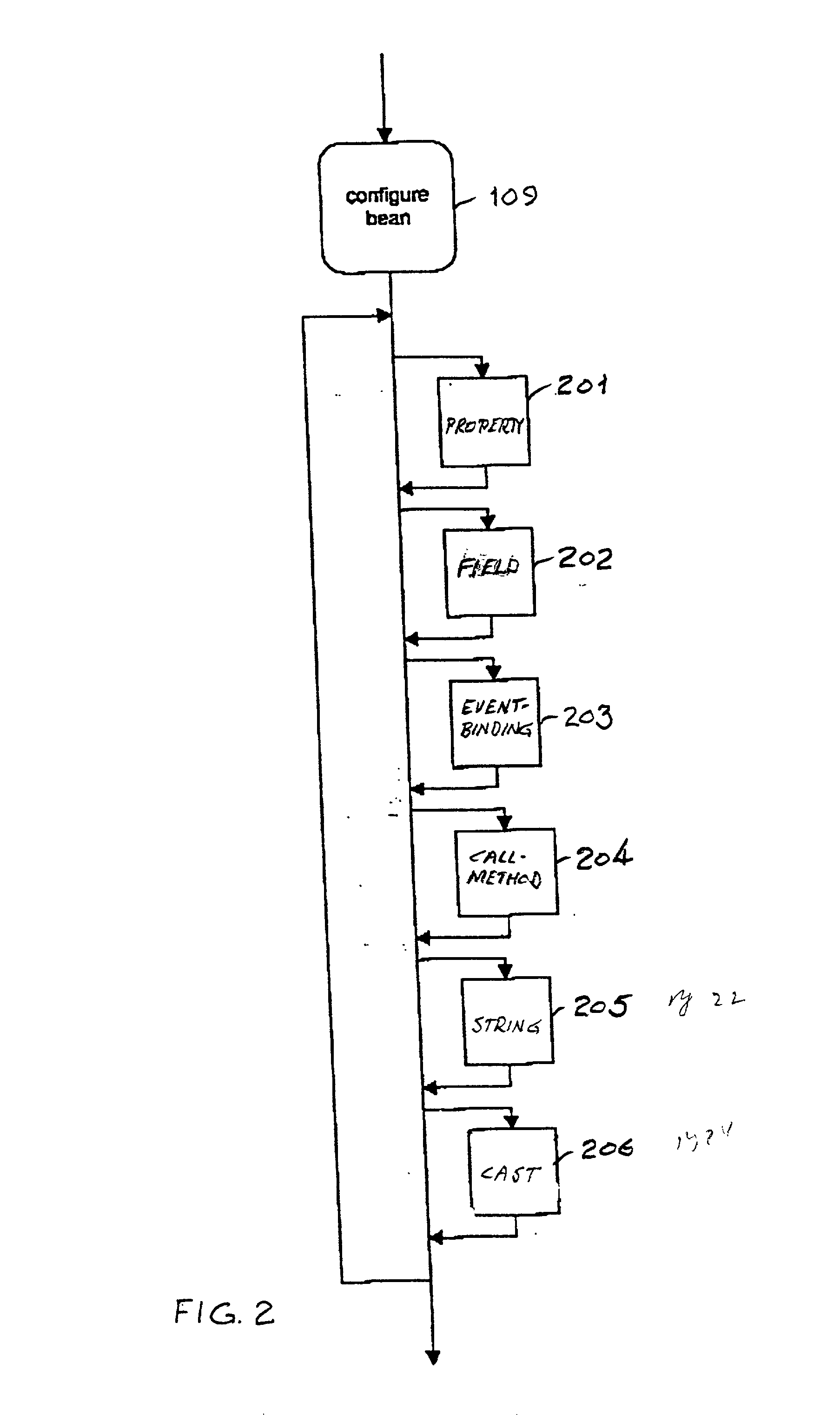

Component oriented programming (COP) language

InactiveUS20020104073A1Clear expressionSpecific program execution arrangementsMemory systemsOrthogonal basisExtensible markup

A new Component oriented programming (COP) language enables the explicit definition of the multi-component structure of a system. The syntax of the language is based on a structured markup language, such as XML (eXtensible Markup Lanugage). The language elements are designed to support the important intra- and inter-component relationships of creating and locating components, setting components' properties, associating events between components and arbitrarily configuring components via method calls. These operations form an orthogonal basis for the space of multi-component structures. The COP language abstracts the concept of a component so that there is no difference in specifying any type of component, whether visual or non-visual.

Owner:IBM CORP

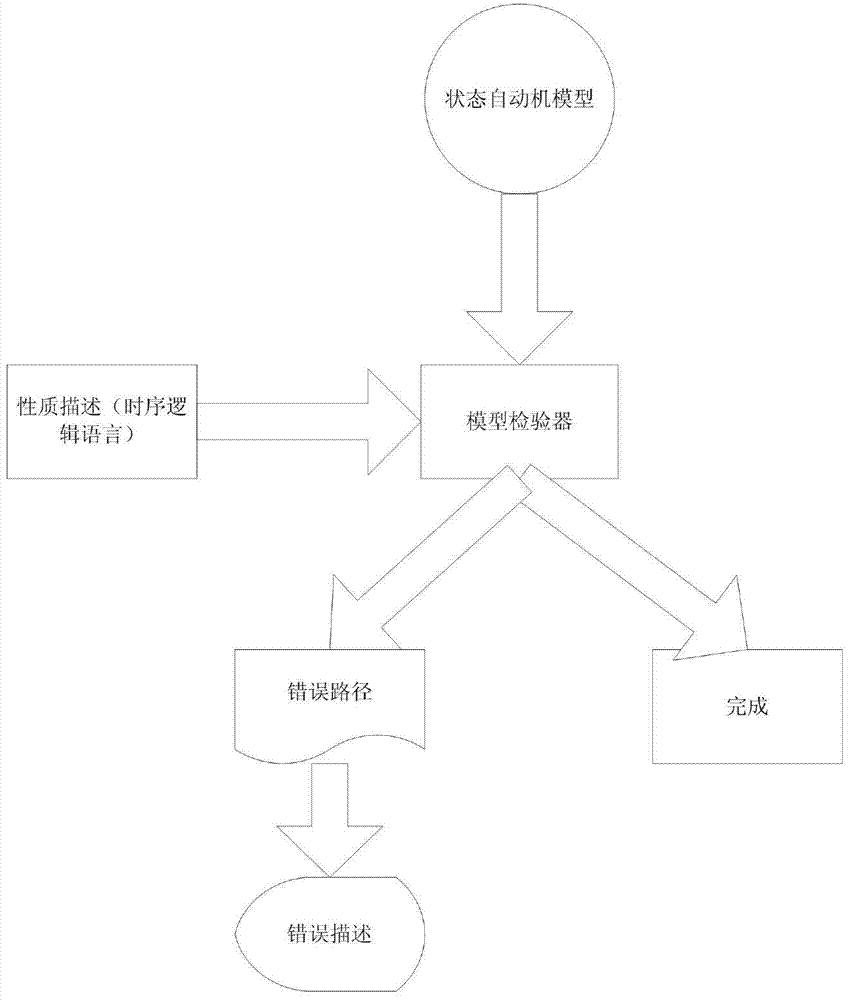

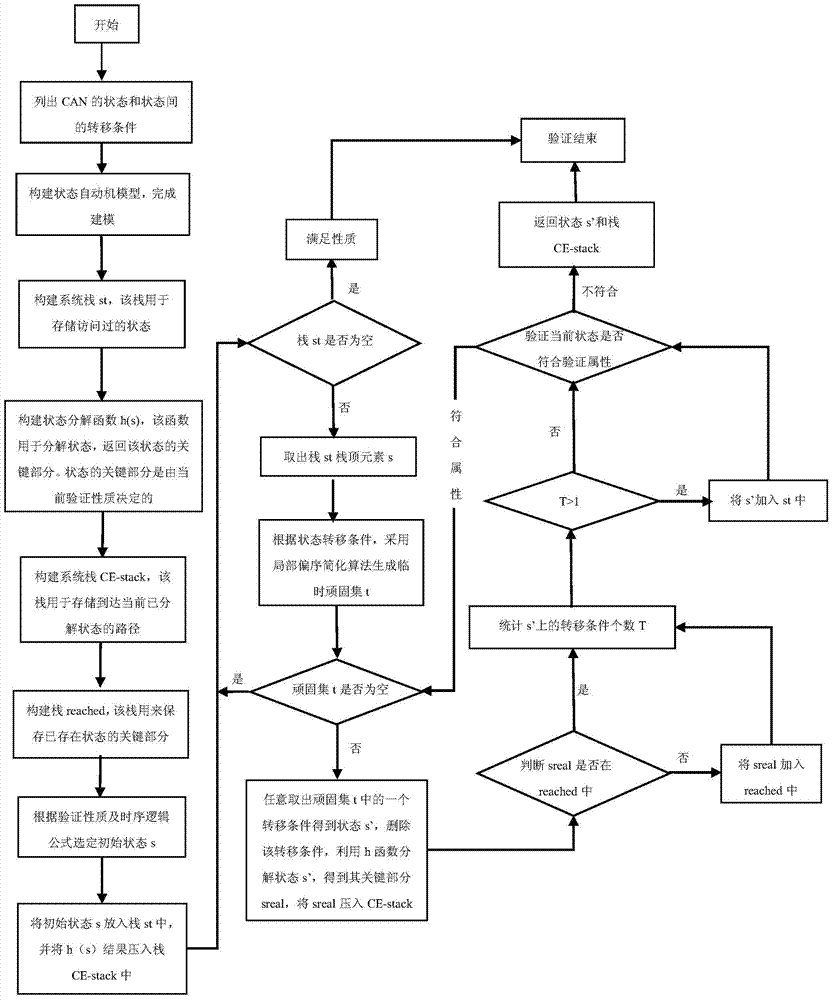

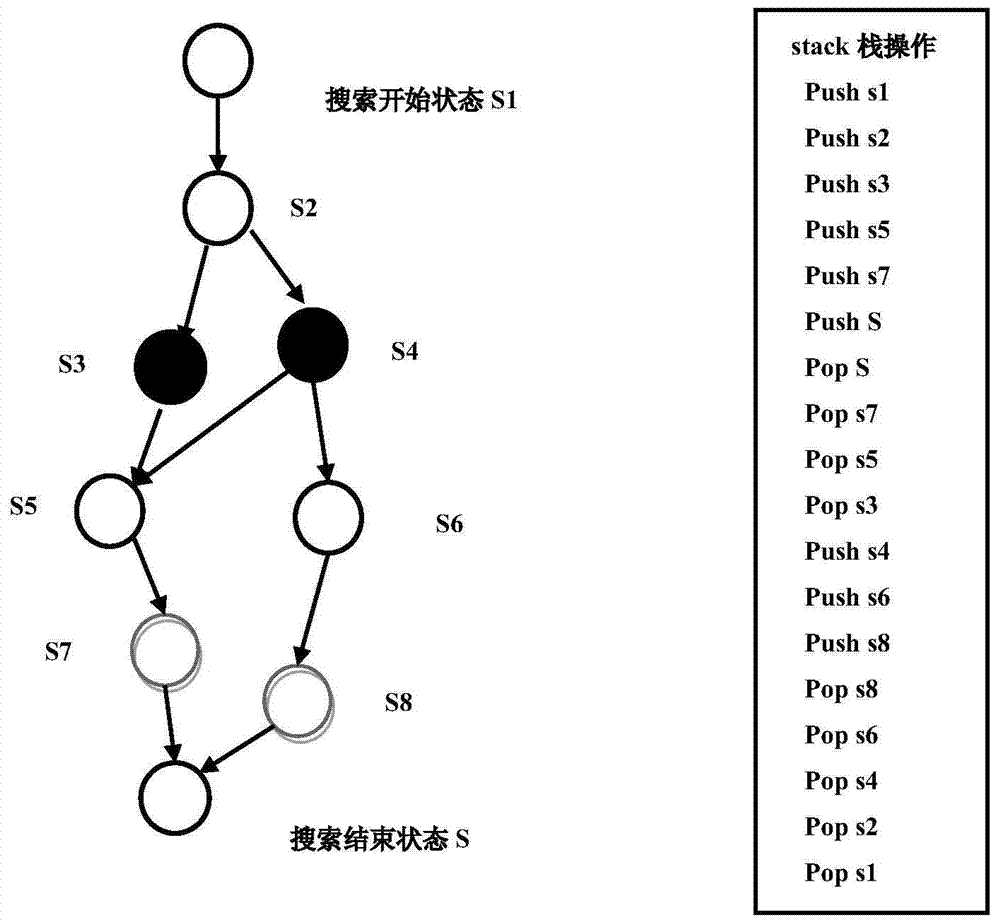

Controller local area network protocol verification method based on state space search

ActiveCN103888460ATime and Space Complexity OptimizationClear expressionTransmissionArea networkDynamic planning

The invention discloses a controller local area network protocol verification method based on state space search. The method comprises the steps of system modeling, model pre-processing and model verification. In the modeling process, an abstract time state automat model is constructed, a state transition diagram prevents, through the utilization of the idea of dynamic planning, a state spatial graph from being generated in a redundant state. In the verification of a controller load area network software model, the state search algorithm based on decomposition is used for further optimizing the state search space of the model, the verification process of the whole system is made to be further optimized in time and space complexity, and data processed through the algorithm are output and converted into a language form which can be understood by inspection personnel easily. The controller local area network protocol verification method can be used for effectively verifying whether relevant network protocols meet requirements, and relieves the problem of state space explosion in the verification process. The space-time complexity of the system in the verification process is low.

Owner:NANJING UNIV OF POSTS & TELECOMM

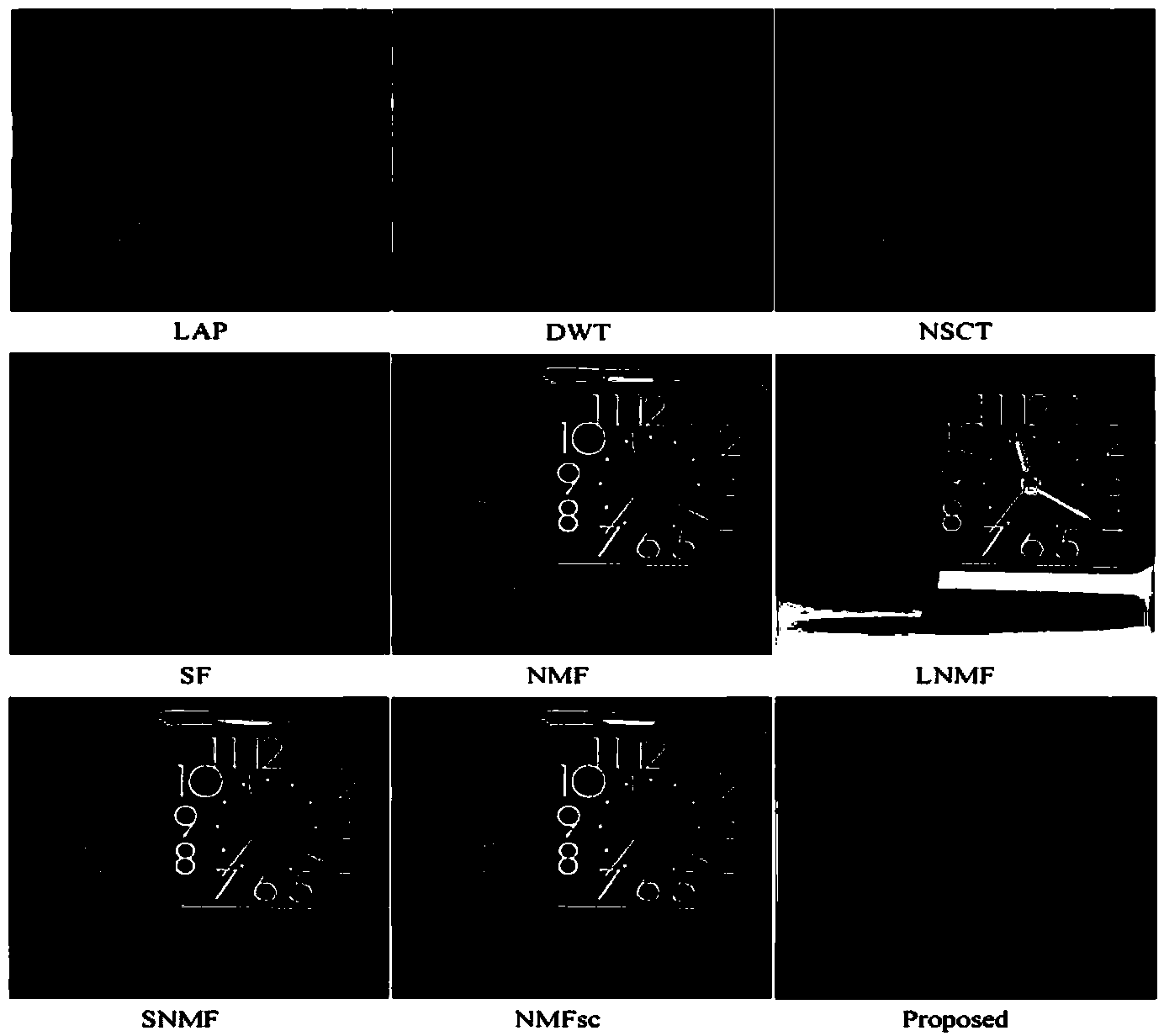

Multi-focus image fusion method based on non-negative matrix factorization

The invention discloses a multi-focus image fusion method based on non-negative matrix factorization. The method comprises the steps of: firstly fusing source images by a fusion algorithm based on NMF to obtain a temporary fused image; getting difference between the temporary fused image and each source image to obtain difference images of the temporary fused image and the source images; respectively commutating gradient energy of neighboring windows of the pixels in each difference image, building a decision matrix according to the size of gradient energy of neighboring windows of the pixels in the difference images, fusing corresponding pixels in the source images according to a certain fusion rule, and thereby obtaining a fused image. According to the method, the source images are fused for twice, the temporary fused image is built by extracting the global features of the source images, difference images of the temporary fused image and the source images are obtained, and accurate detection and judgment is performed to characteristics of the focusing areas of the source images by using the gradient energy of the difference images, and thereby quality of the fused image is improved.

Owner:NORTHWEST UNIV

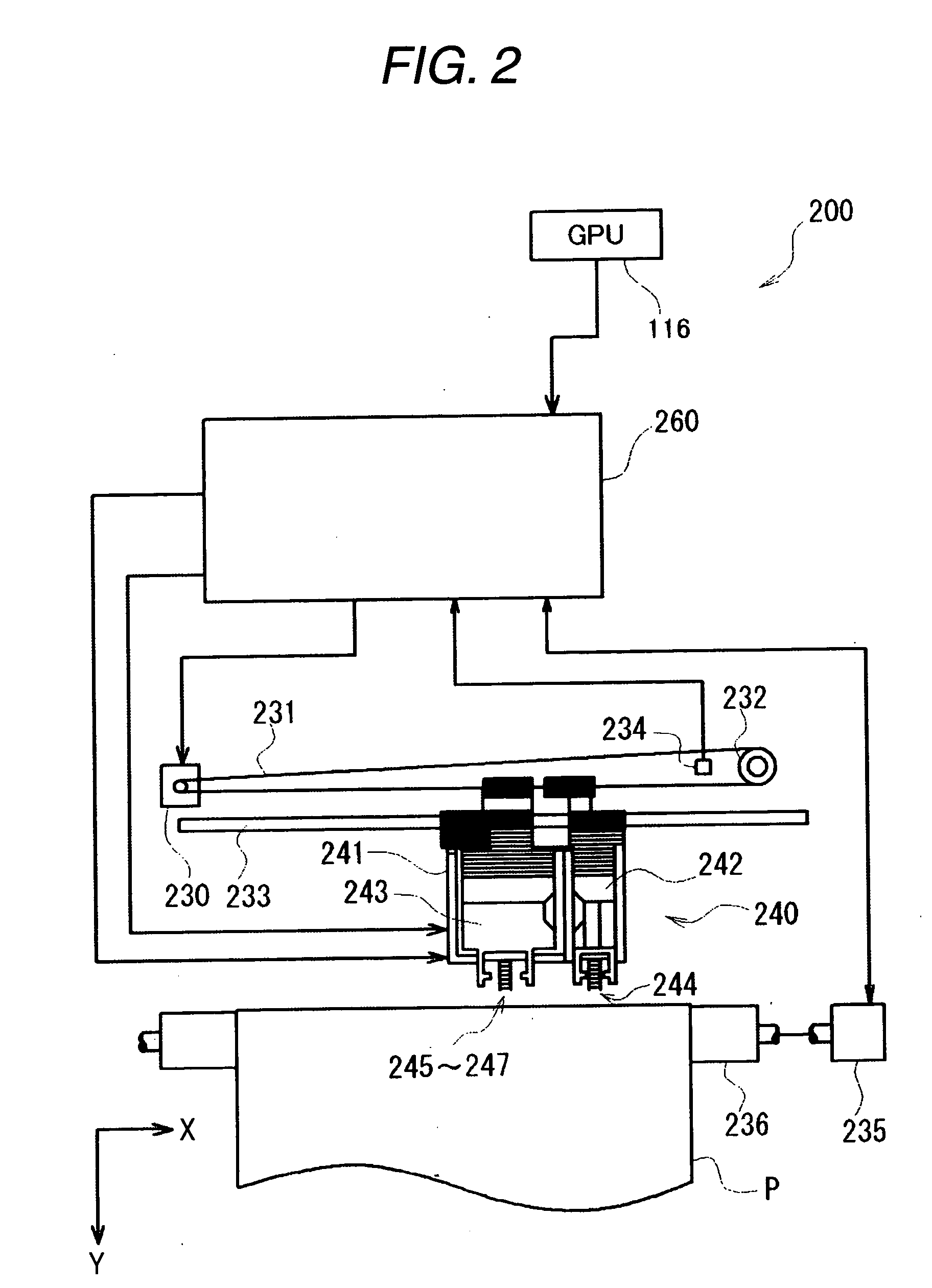

Apparatus and method for outputting print data

InactiveUS20060192778A1Clear expressionPictoral communication3D-image renderingComputer graphics (images)Computer printing

Owner:SEIKO EPSON CORP

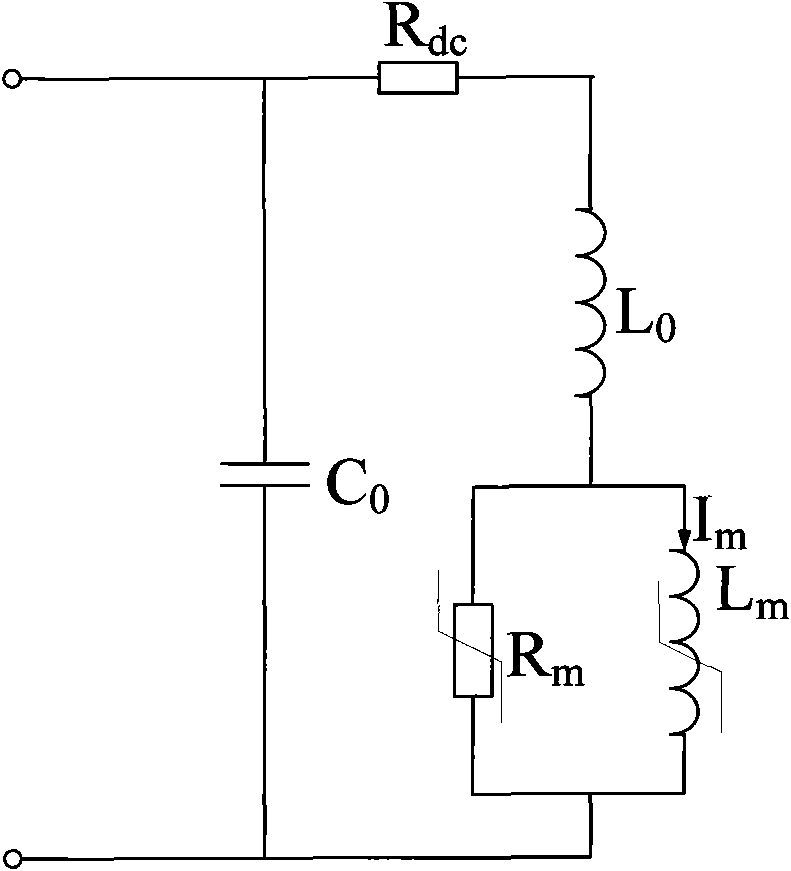

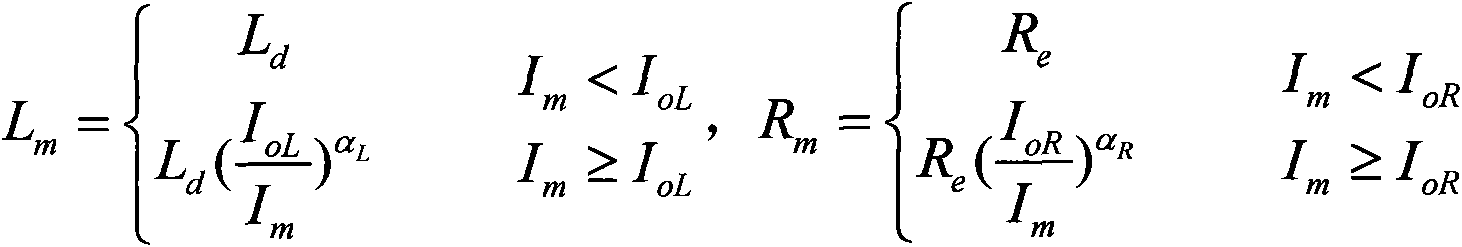

Analytical model for saturable reactor for converter valve

ActiveCN101930492APhysical concepts are clearClear expressionSpecial data processing applicationsElectrical resistance and conductanceCapacitance

The invention provides an analytical model for a saturable reactor for a converter valve. The saturable reactor for the converter valve consists of a coil and an iron core; and the working state of the iron core has a linear stage and a nonlinear stage under rated operation. In order to better perform electrical design and electrical analysis on the saturable reactor, the invention provides an analytical model for the saturable reactor for the converter valve. The analytical model comprises a coil resistance, a coil inductance, a core inductance, a core resistance, a terminal capacitance and other parameters. Corresponding electrical parameters of saturable reactors with different shapes and dimensions can be calculated. The analytical model has the advantages of clear physical conception, and capacities of easily acquiring each parameter needed in the model through a real object and providing a foundation for deep analysis of the saturable reactor.

Owner:CHINA ELECTRIC POWER RES INST +1

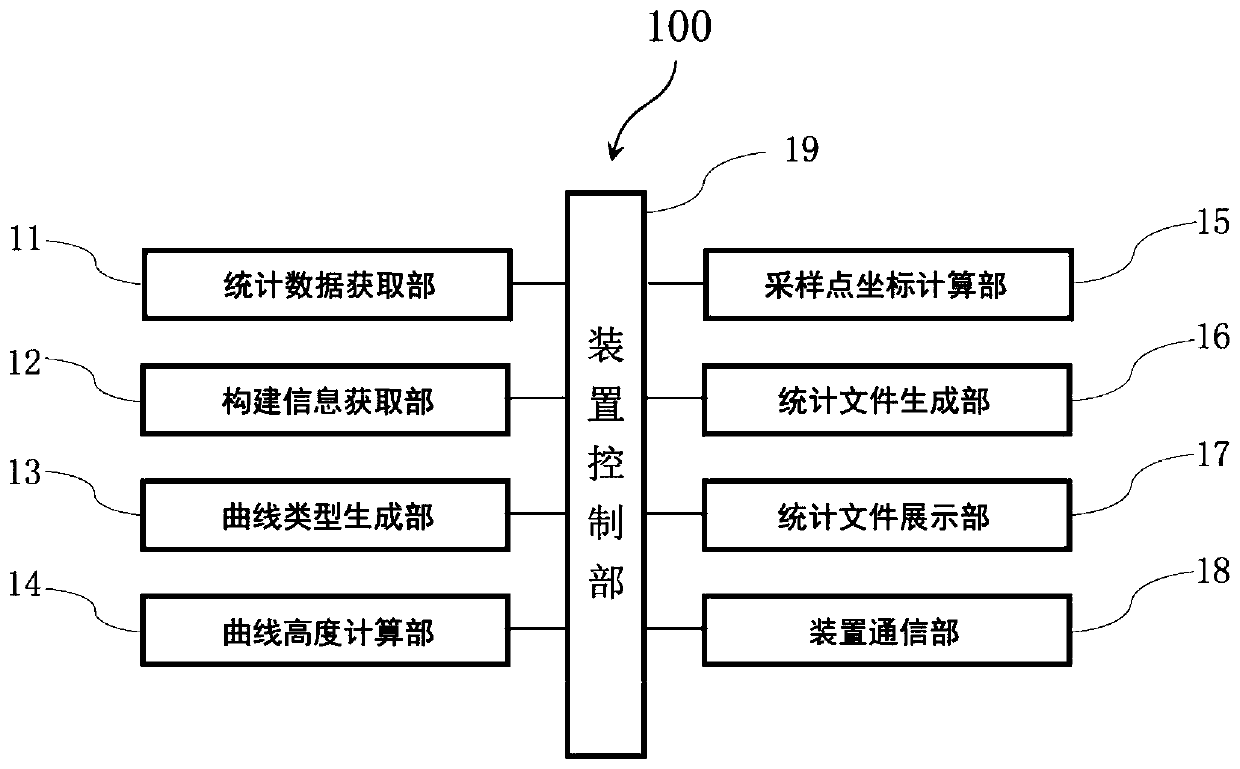

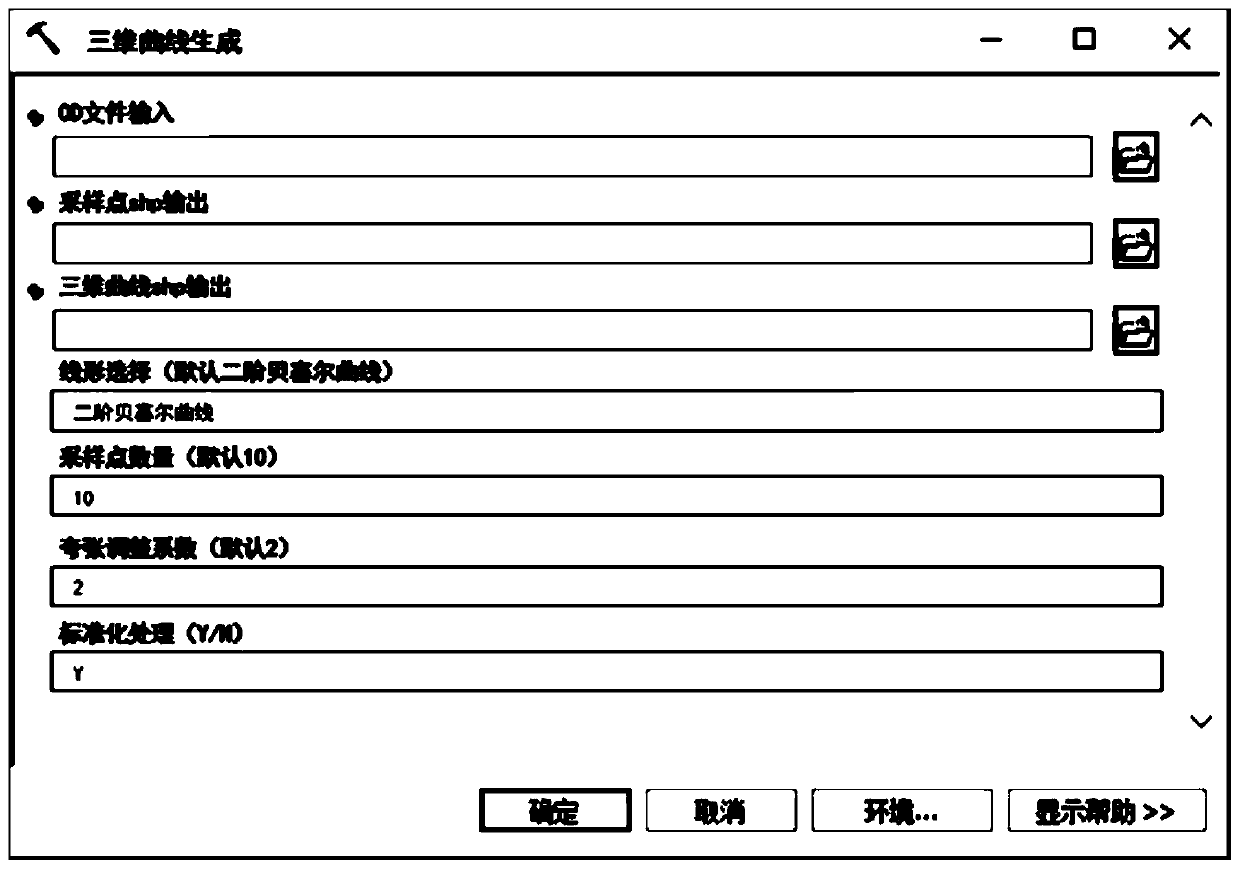

Three-dimensional visualization method and device for OD relations in GIS

ActiveCN111063035ASolve the problem of not supporting curve generationImprove visualizationImage data processingComputer graphics (images)Algorithm

The invention provides a three-dimensional visualization method and device for OD relations in a GIS. The method is used for generating a corresponding three-dimensional curve capable of being recognized by a GIS system according to input data of a user and carrying out three-dimensional visual display, and comprises the following steps: S1, obtaining OD relation statistical data used for reflecting the relation between two positions and places; S2, acquiring curve construction information input by a user; S3, generating a curve type; S4, calculating curve heights of the plurality of curves; S5, sampling each curve in sequence so as to calculate sampling point coordinates of a plurality of sampling points corresponding to each curve; S6, converting the data into a corresponding statisticalfile containing all the curves in the GIS according to the curves, the corresponding sampling point coordinates and the OD relation statistical data; and S7, visually displaying the statistical filethrough a three-dimensional visual application.

Owner:TONGJI UNIV

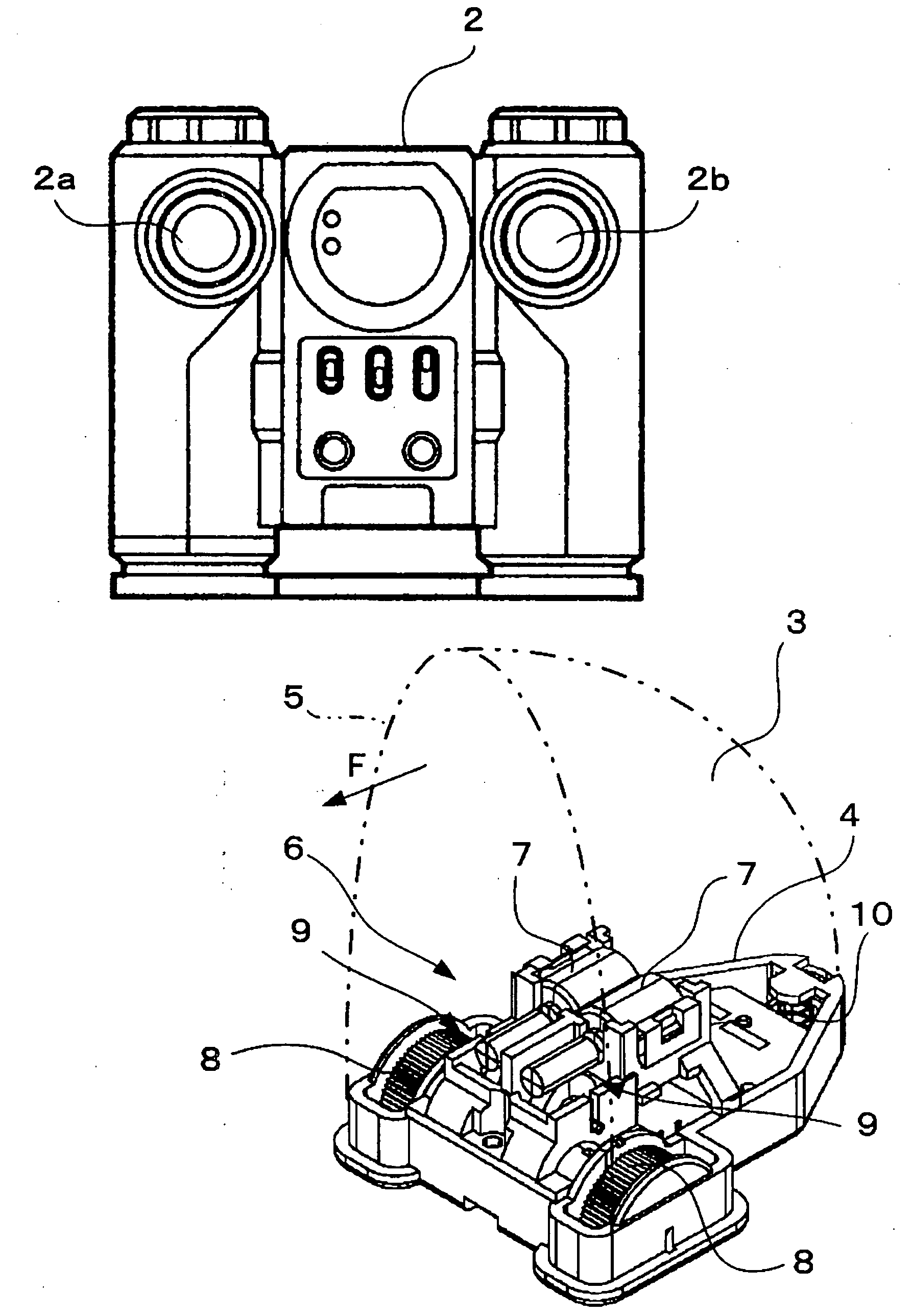

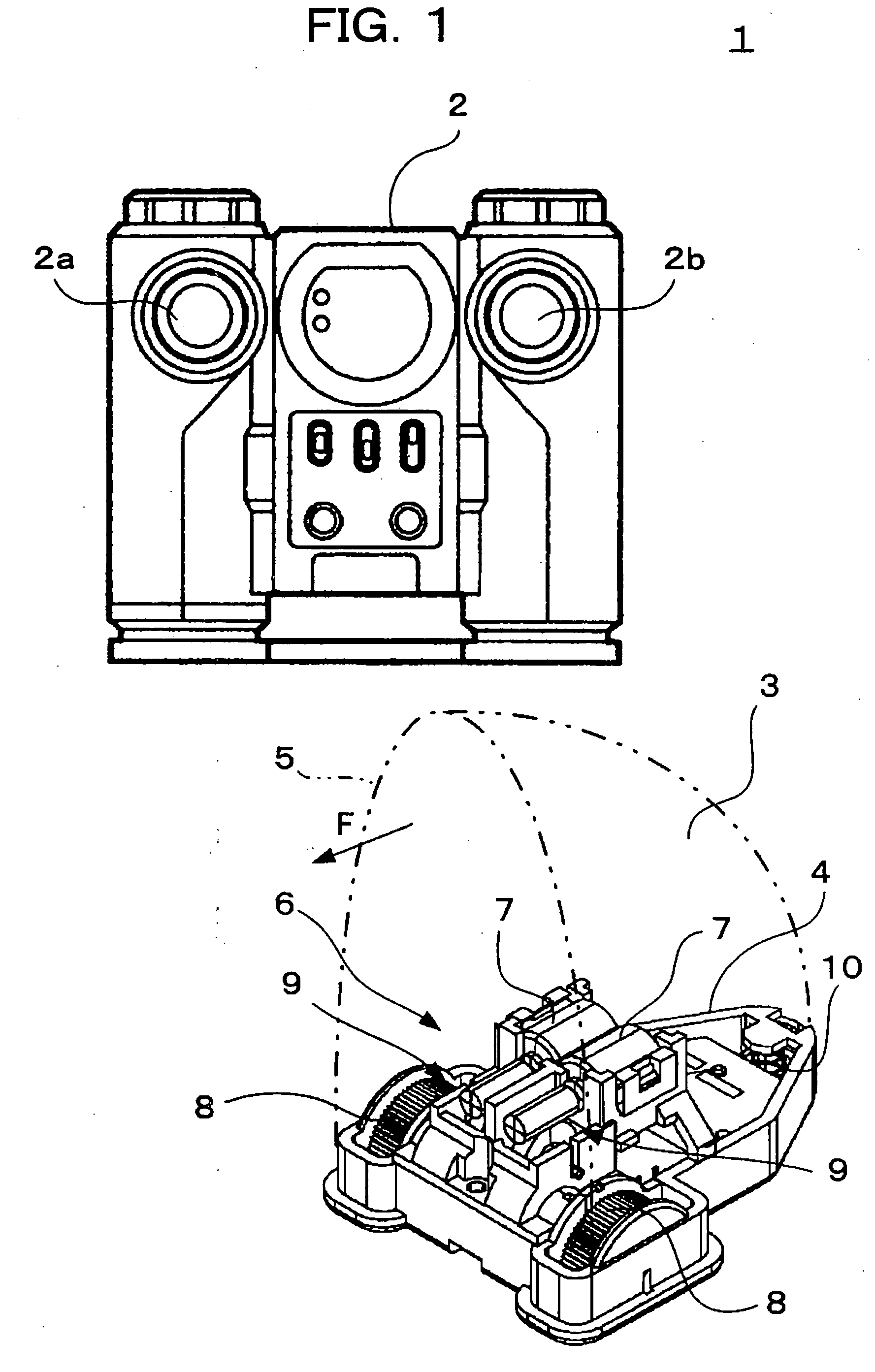

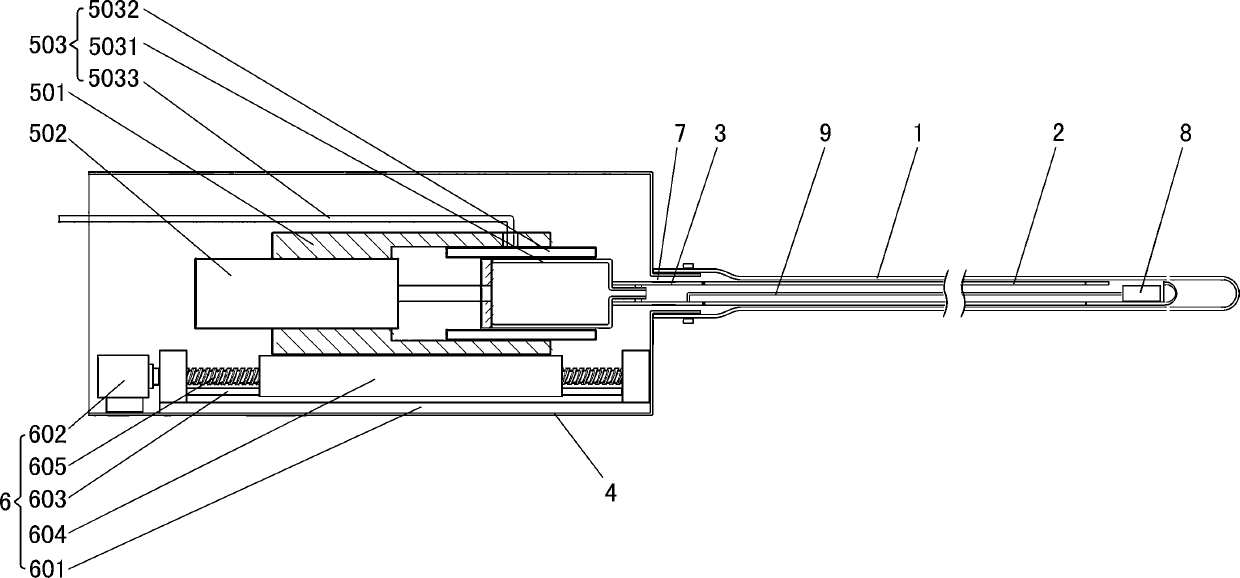

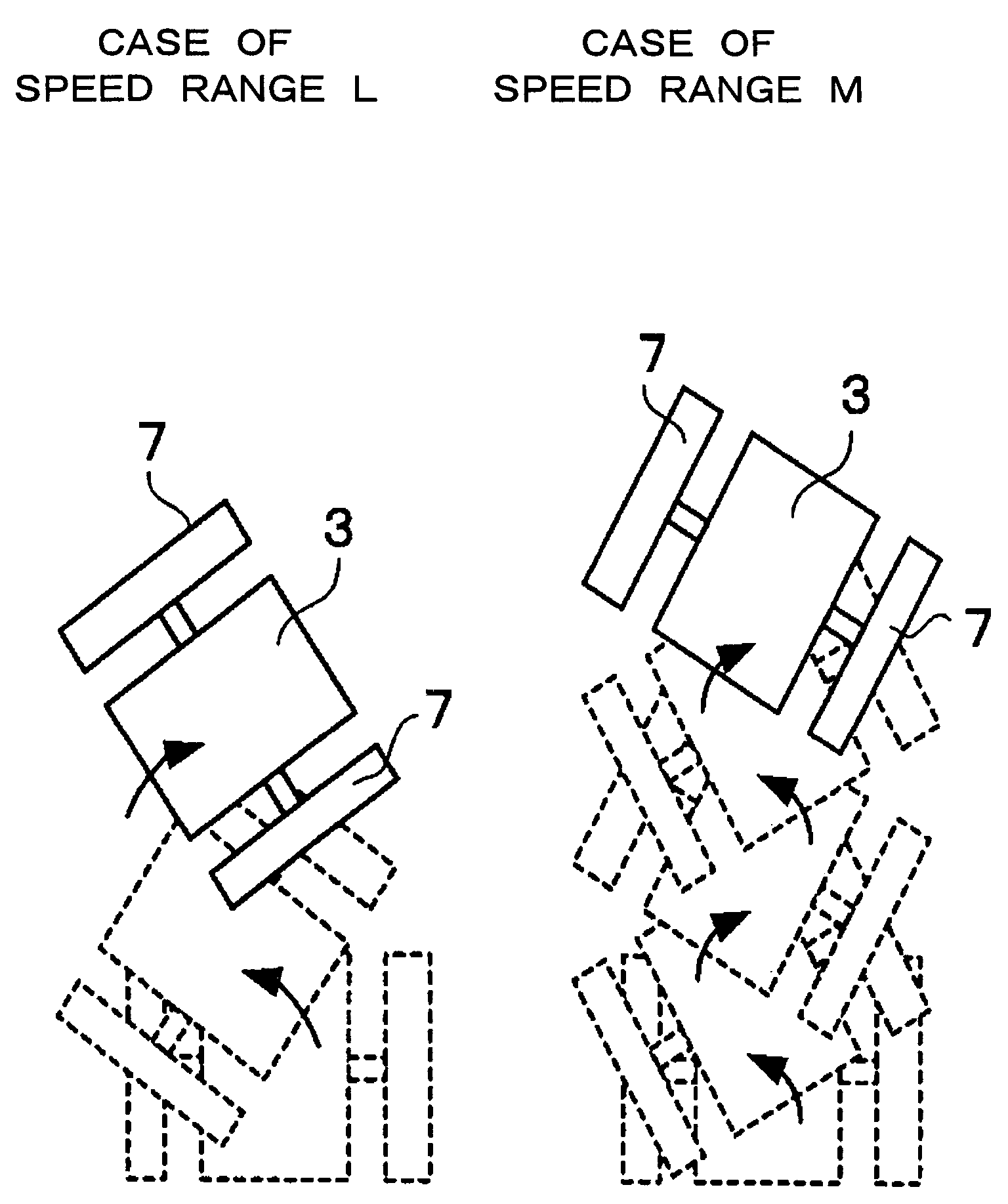

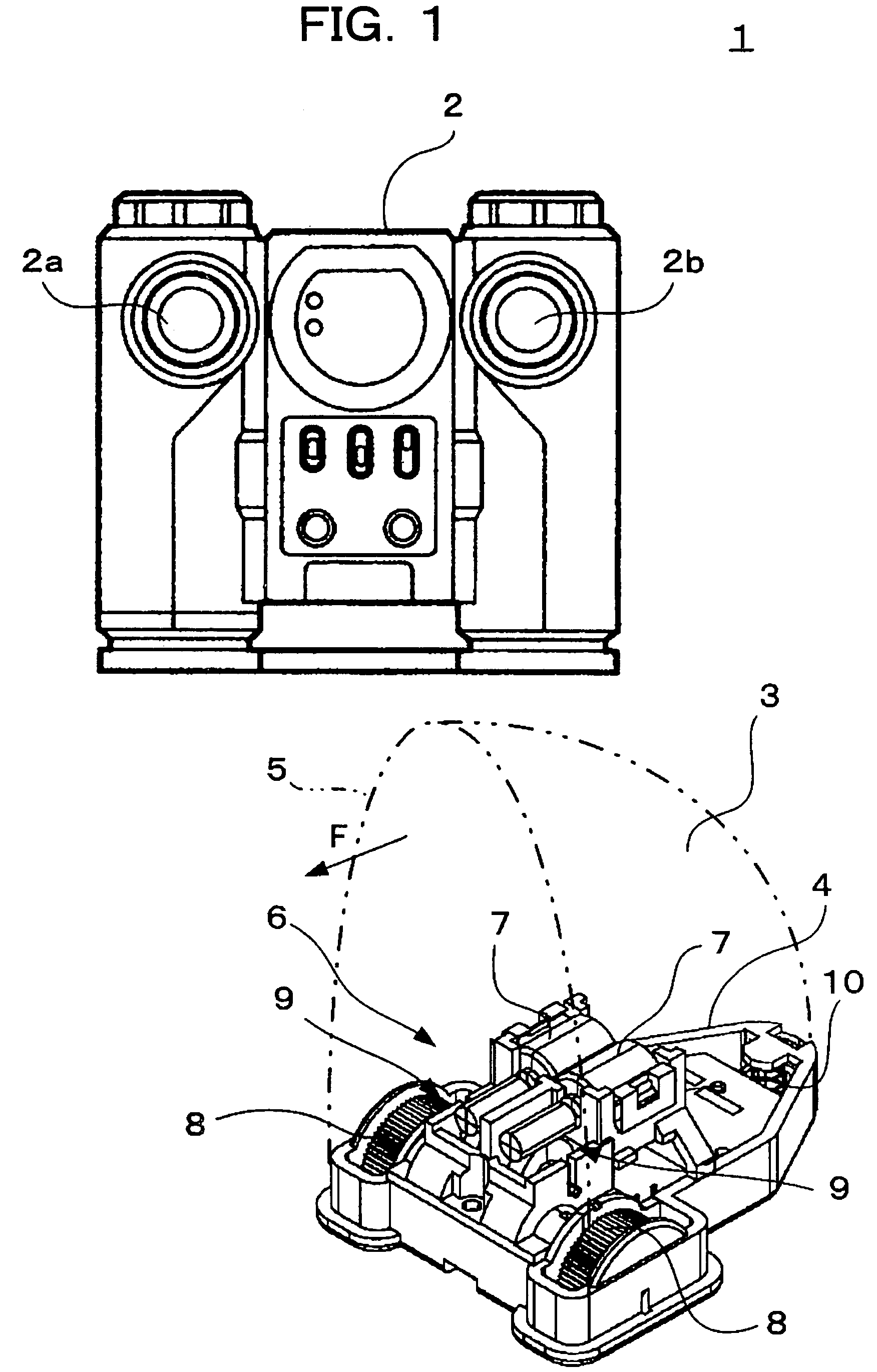

Model traveling device, model having such traveling device, and remote-controlled toy

ActiveUS20060154563A1Increase rotation speedIncrease speedSelf-moving toy figuresRemote-control toysLow speedRemote control

In a running device for a model (6) comprising a pair of motors (7), a pair of left and right wheels (8) which are independently driven by the pair of motors (7), and a control device (20) which controls operations of the pair of motors (7) based on instructions concerning speed and direction, the control device (20) controls the pair of motors (7) such that the pair of motors (7) are alternately rotated in an instructed direction when the instructed speed (Vm) is in a low speed range (L, M), and the pair of motors (7) are rotated in the instructed direction simultaneously when the instructed speed is in a high speed range (H) which is higher than the low speed range.

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

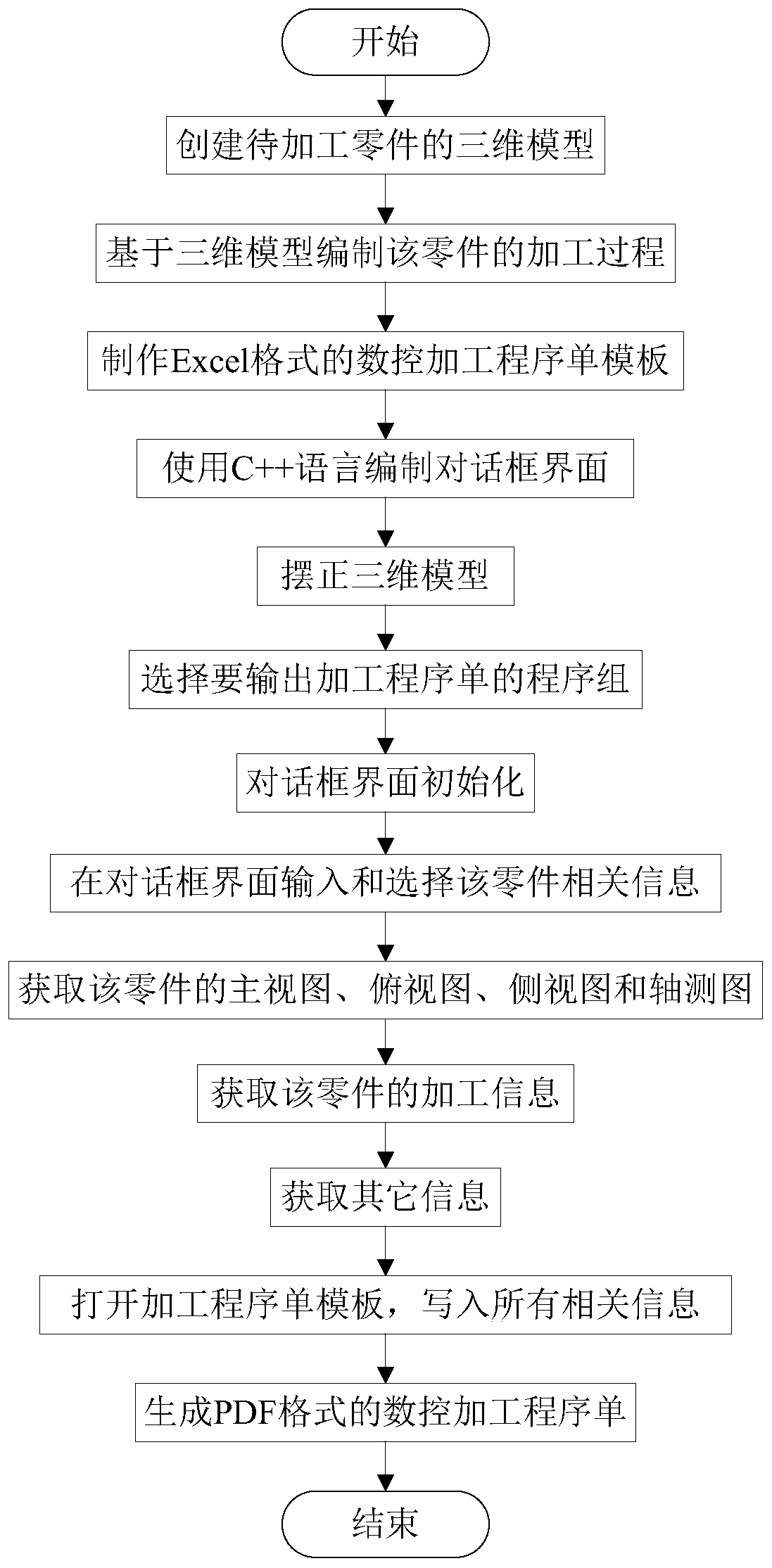

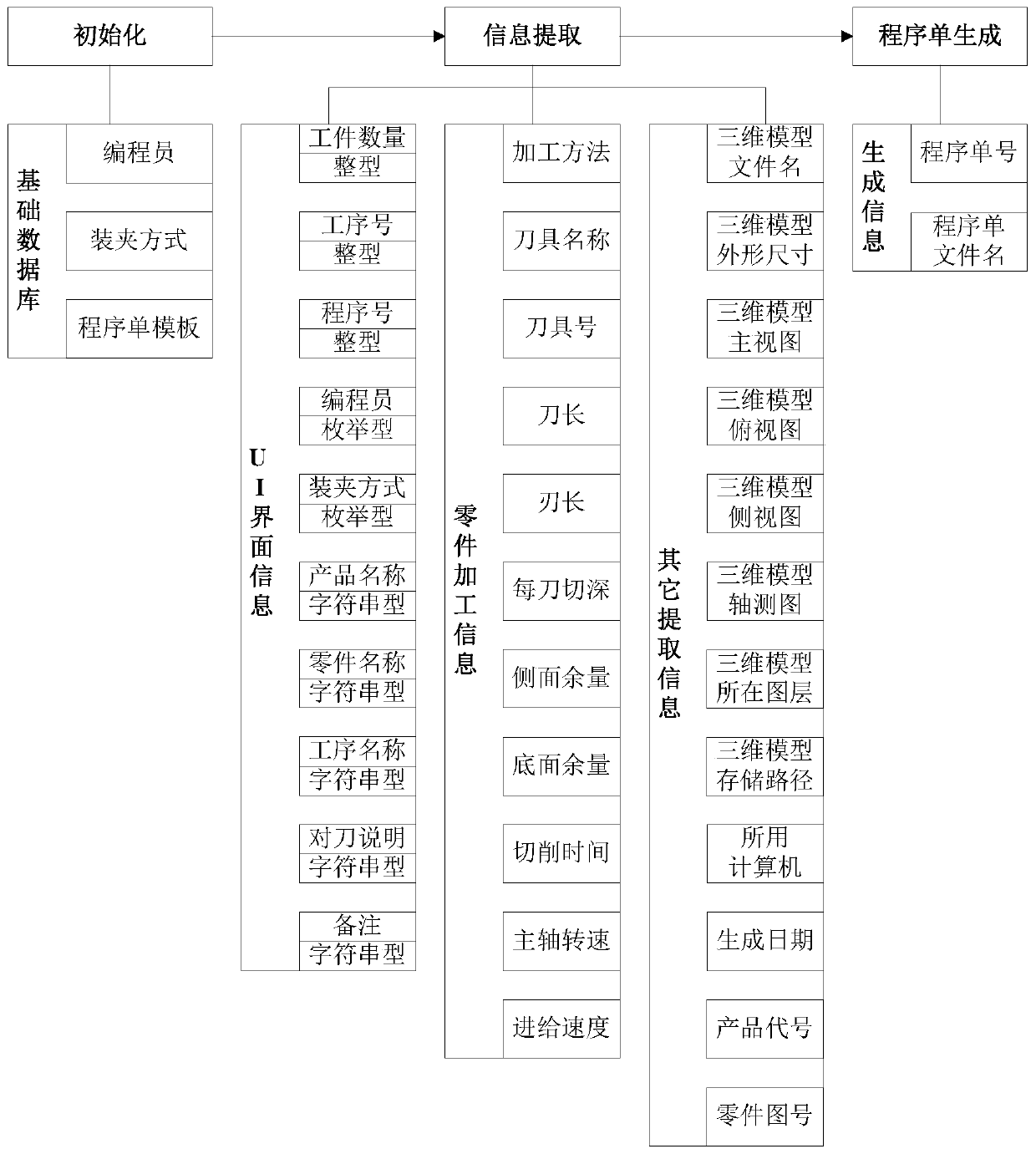

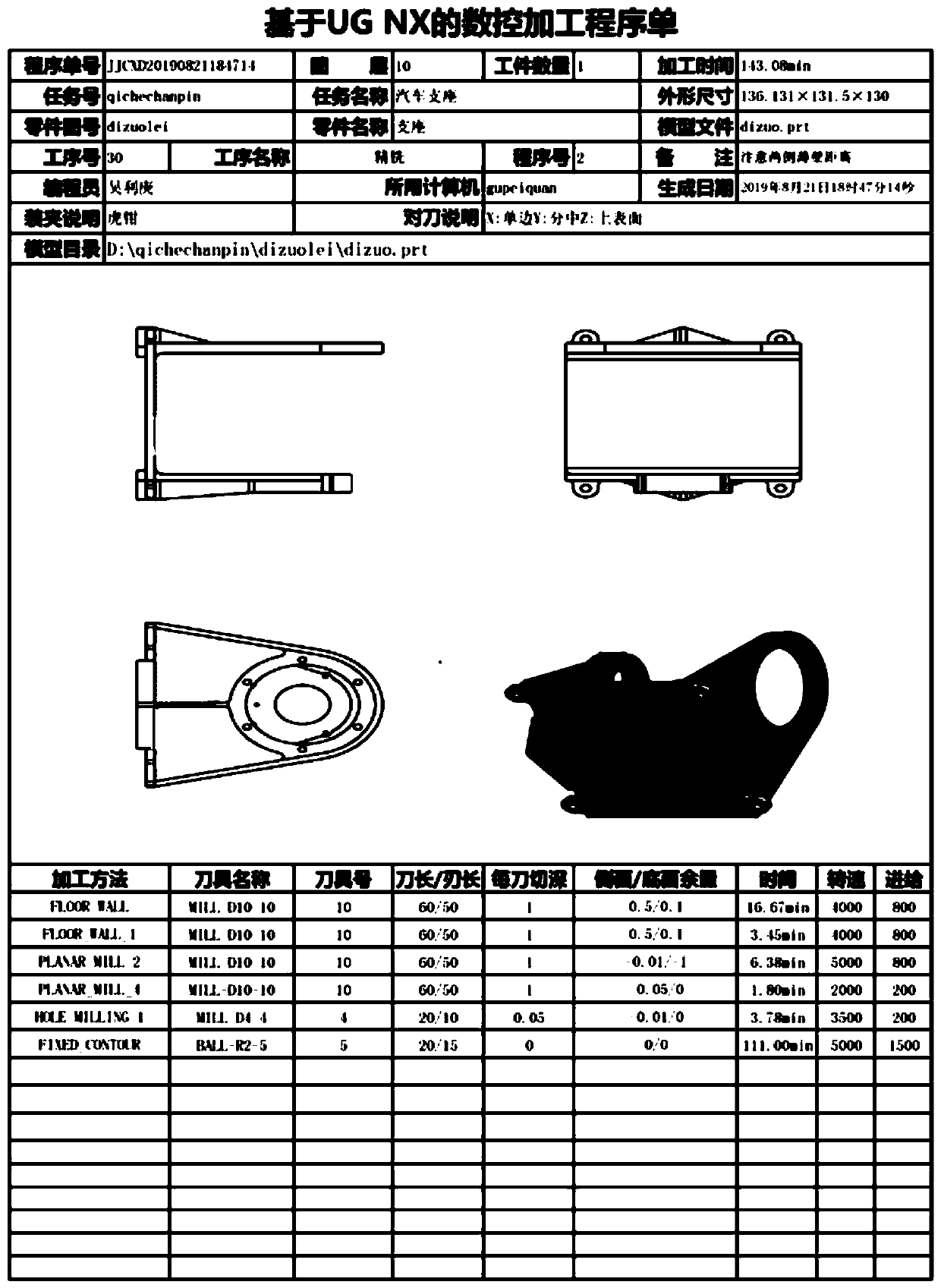

Numerical control machining program sheet generating method based on UGNX secondary development

ActiveCN110597187ARealize one-click extractionRealize automatic generationNumerical controlNumerical controlRelevant information

The invention provides a numerical control machining program sheet generating method based on UGNX secondary development, and belongs to the technical field of software development. The method comprises the following steps: a, creating a three-dimensional model of a part to be machined; b, compiling a machining process of the part based on the three-dimensional model; c, making a numerical controlmachining program sheet template of an Excel format; d, compiling a dialog box interface by using a C++ language; e, straightening the three-dimensional model; f, selecting a program group for outputting the machining program sheet; g, initializing the dialog box interface; h, inputting and selecting information relevant to the part in the dialog box interface; i, acquiring a main view, a top view, a side view and an isometric diagram of the part; j, acquiring machining information of the part; k, acquiring other information; l, opening the machining program sheet template, and writing all relevant information; and m, generating a numerical control machining sheet of a PDF format. Through adoption of a secondary development technology of UG NX, the communication between a programmer and an operator is reduced, and the knowledge consolidation of a product numerical control machining process is realized.

Owner:TIANJIN AEROSPACE ELECTROMECHANICAL EQUIP RES INST

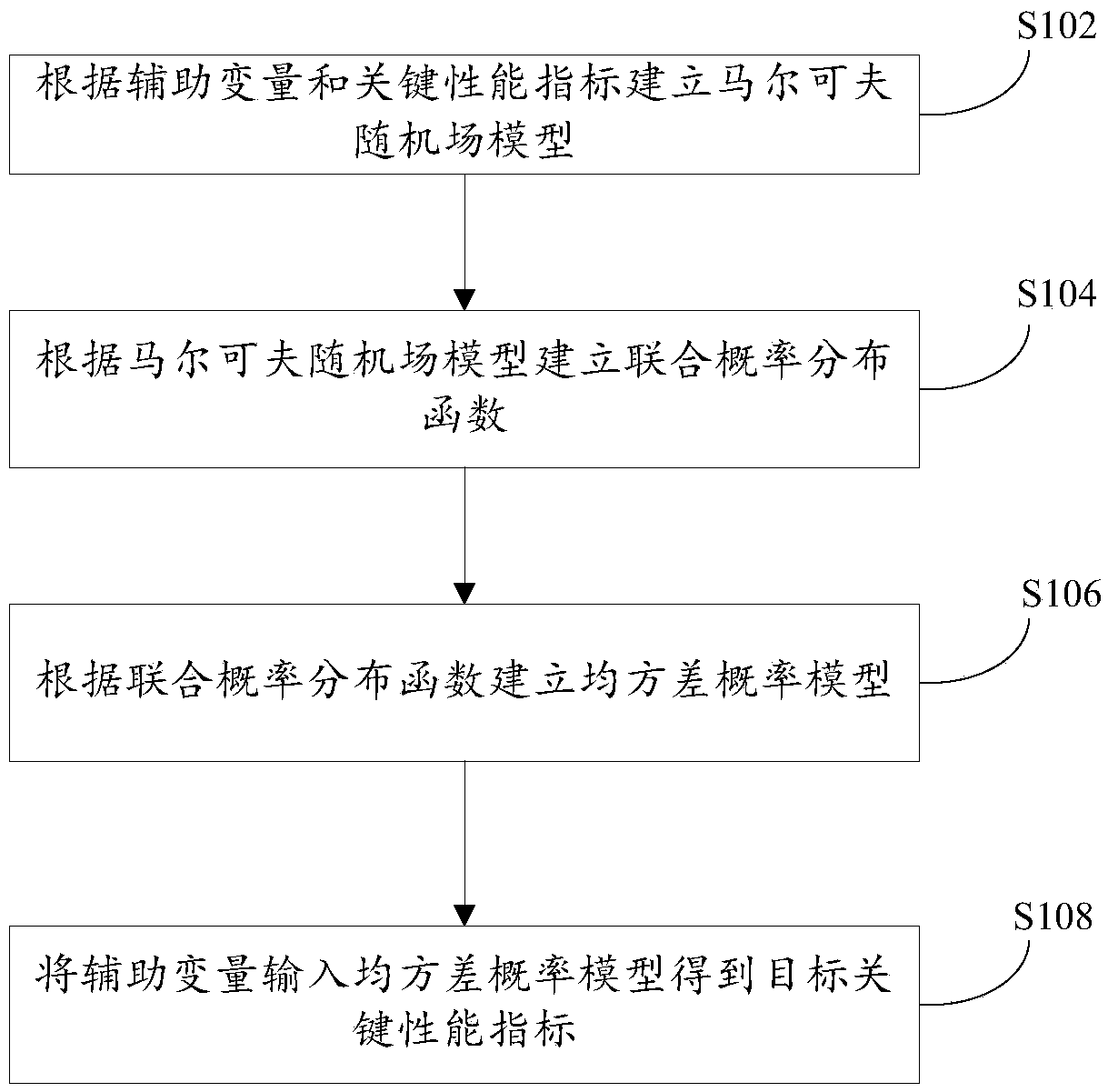

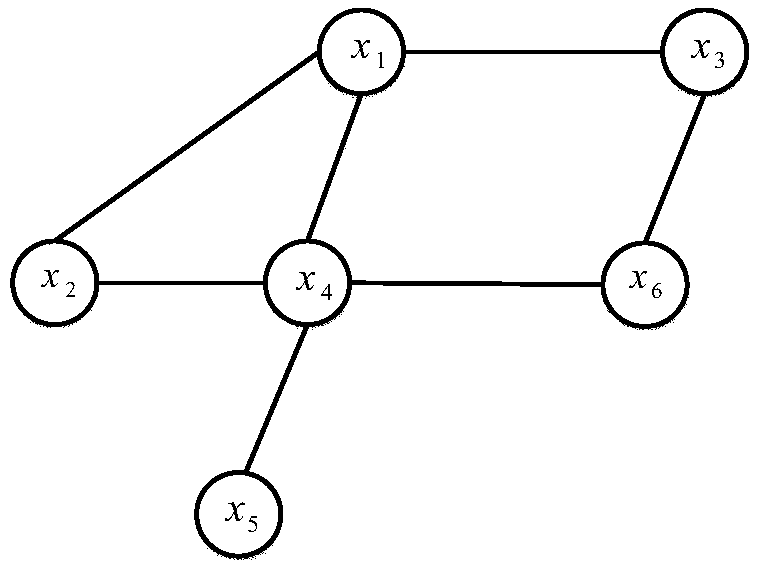

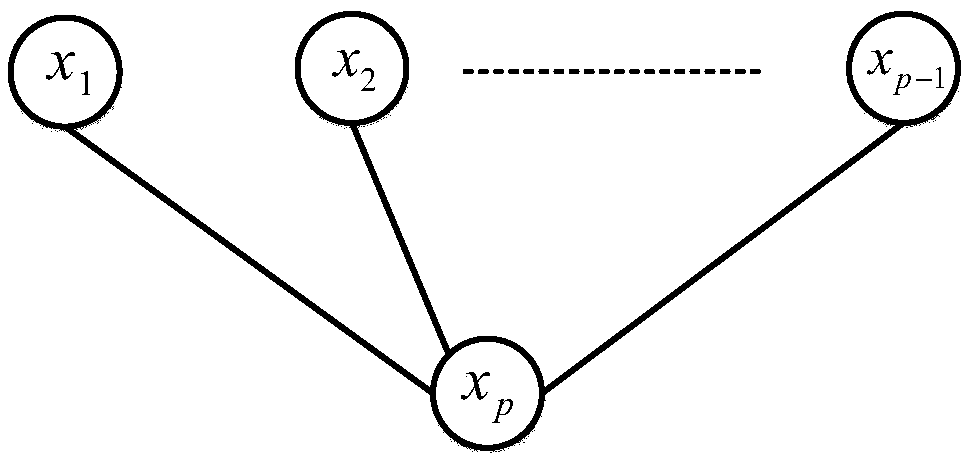

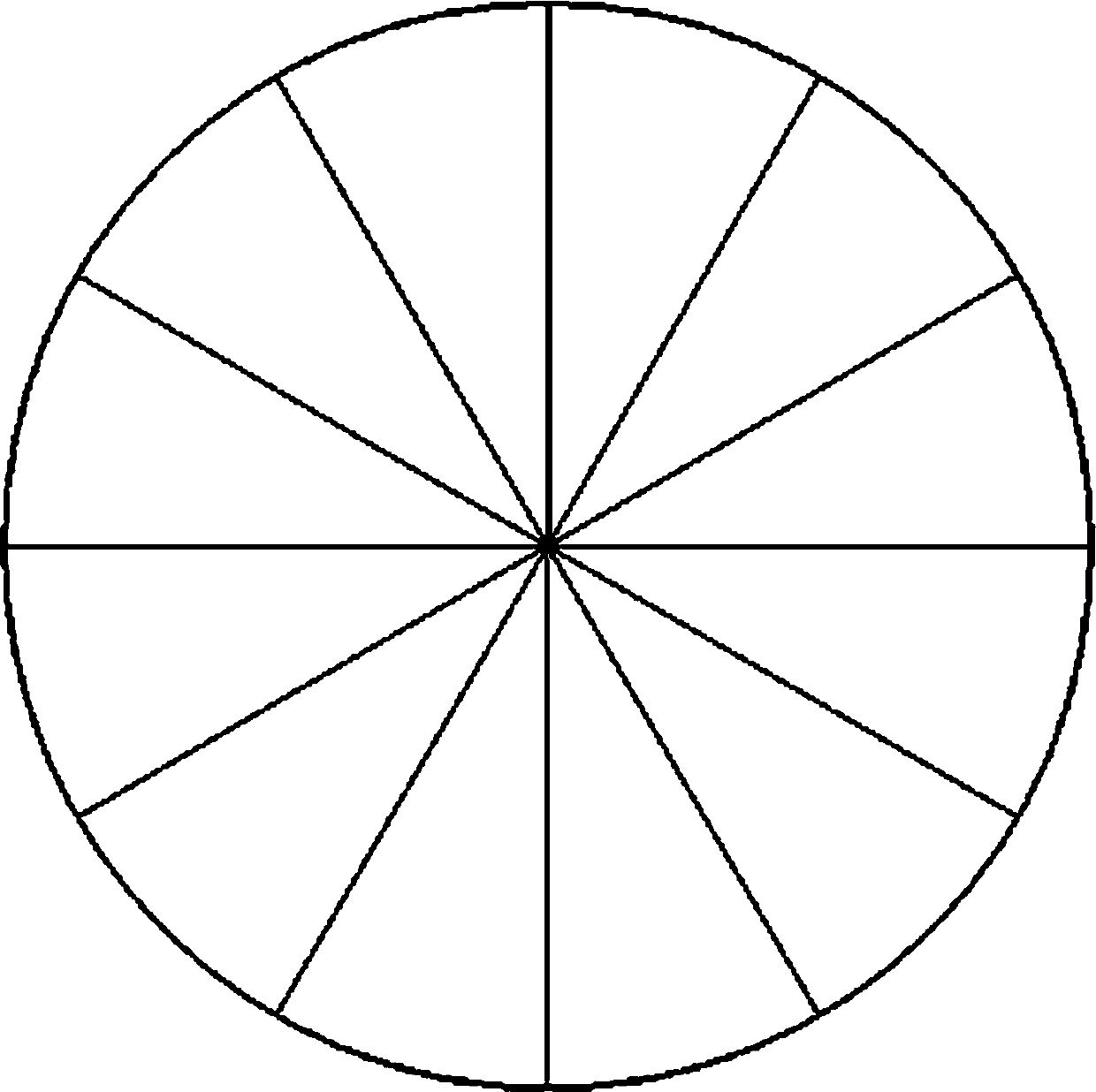

Soft sensing method based on Markov random field and EM algorithm

InactiveCN109241493ASimple structureClear expressionResourcesManufacturing computing systemsMean squarePerformance index

The invention discloses a soft sensing method of key performance index based on Markov random field and EM algorithm. The method comprises the following steps: firstly, establishing a Markov random field model according to auxiliary variables and key performance indicators, and then establishing a joint probability distribution function according to the Markov random field model, wherein, the joint probability distribution function is a joint probability distribution among auxiliary variables and / or a joint probability distribution among key performance indicators; According to the joint probability distribution function, the mean square deviation probability model is established, where the mean square deviation probability model is the relationship between the expectation of the key performance index and the target key performance index when the auxiliary variable is given, and the target key performance index is the key performance index when the mean square deviation probability model approaches zero; the auxiliary variables are inputted into the mean square deviation probability model to obtain the target key performance index, thus solving the technical problem of the prior art that the key performance index in the industrial process can not be accurately measured in real time.

Owner:UNIV OF SCI & TECH BEIJING

Mechanical spiral scanning ultrasonic imaging method

ActiveCN103340651AImprove fidelityHigh expressionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsLinear motionUltrasonic beam

The invention relates to a mechanical spiral scanning ultrasonic imaging method. An ultrasonic probe is installed on a spiral drive mechanism; the ultrasonic probe is driven by the spiral drive mechanism to simultaneously conduct rotation motion and front-and-back linear motion; the ultrasonic probe successively transmits and receives ultrasonic beams to conduct spiral scanning; image data acquired through spiral scanning are sequentially recorded; any image datum in the image data is optionally chosen as a start point; the image data are grouped according to the rotation period of the ultrasonic probe; each image datum in each group of image data is identified according to angles; an annular two-dimensional image is formed by any selected group of image data; rectangular longitudinal section images are formed by all image data which have the same angle and have 180-degree differences in all groups; all annular two-dimensional images are overlaid according to the time sequence to form a three-dimensional image. Therefore, the fidelity of the images is higher, the conditions of lesion tissue are more intuitively, more clearly and more accurately expressed, and diagnose can be more easily and more accurately conducted through the images.

Owner:SHANTOU INST OF UITRASONIC INSTR CO LTD

Running device for model, and model and remote control toy having the running device

ActiveUS7479055B2Shorten the overall cycleShort maintenance periodSelf-moving toy figuresRemote-control toysLow speedRemote control

In a running device for a model (6) comprising a pair of motors (7), a pair of left and right wheels (8) which are independently driven by the pair of motors (7), and a control device (20) which controls operations of the pair of motors (7) based on instructions concerning speed and direction, the control device (20) controls the pair of motors (7) such that the pair of motors (7) are alternately rotated in an instructed direction when the instructed speed (Vm) is in a low speed range (L, M), and the pair of motors (7) are rotated in the instructed direction simultaneously when the instructed speed is in a high speed range (H) which is higher than the low speed range.

Owner:KONAMI DIGITAL ENTERTAINMENT CO LTD

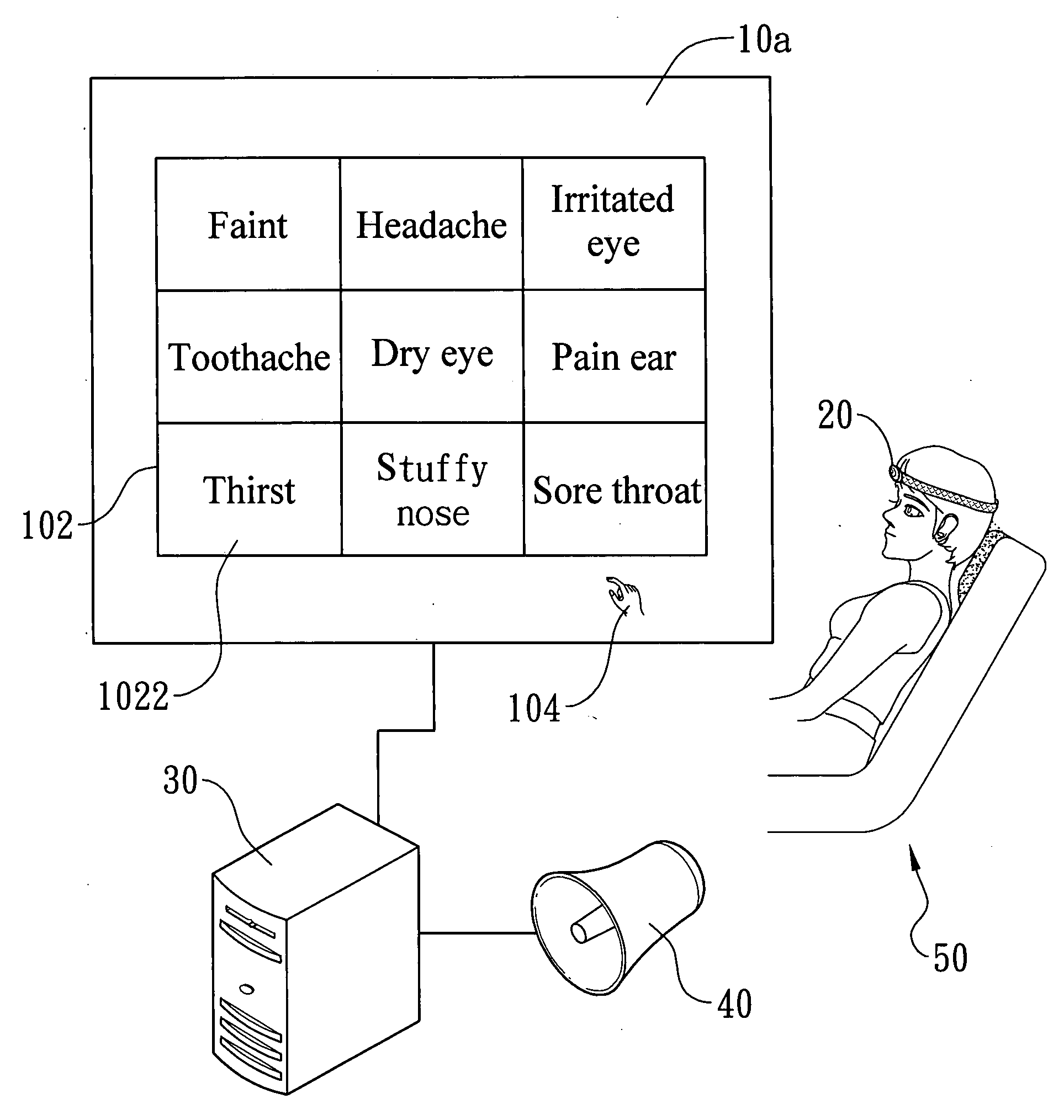

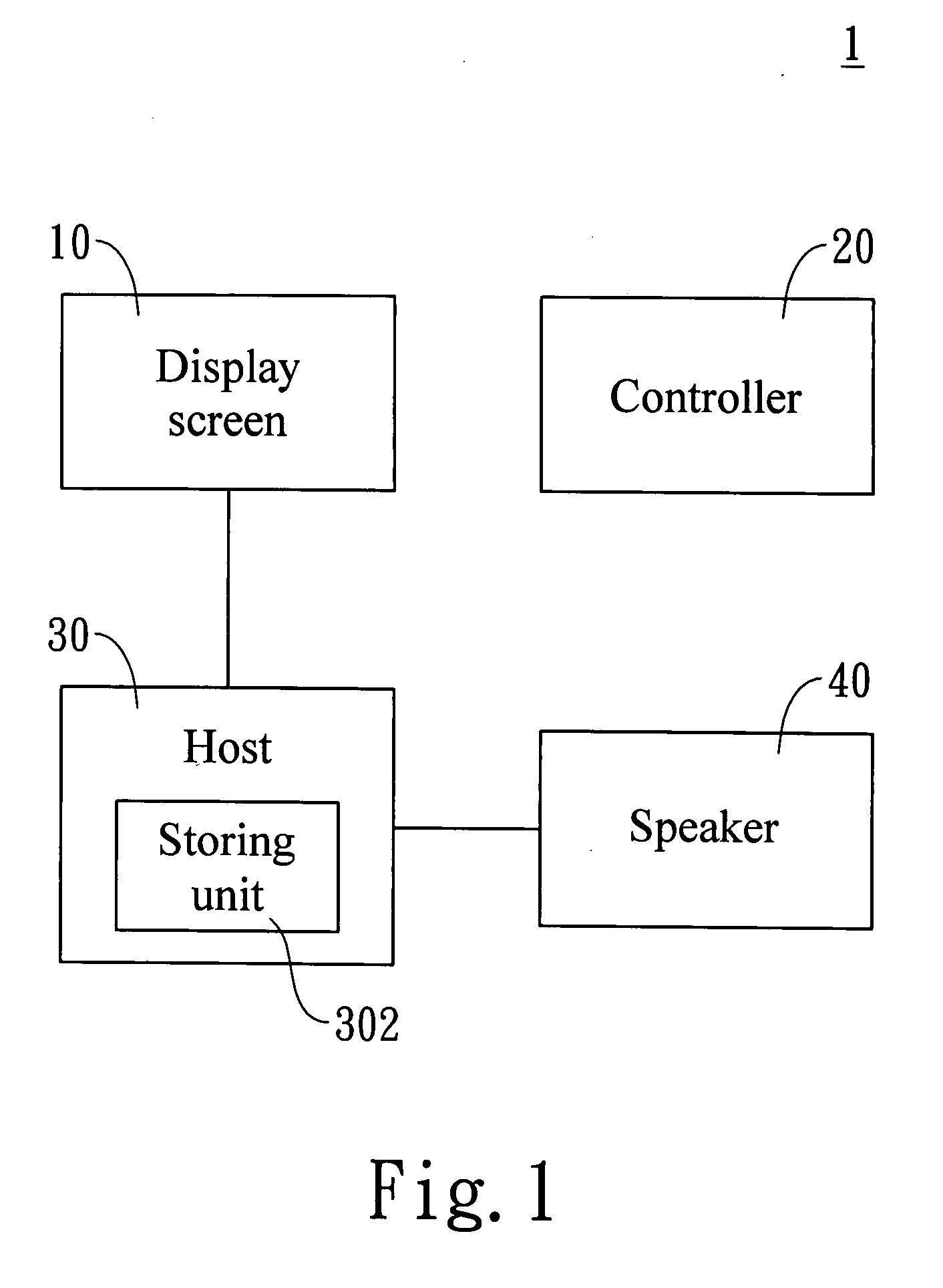

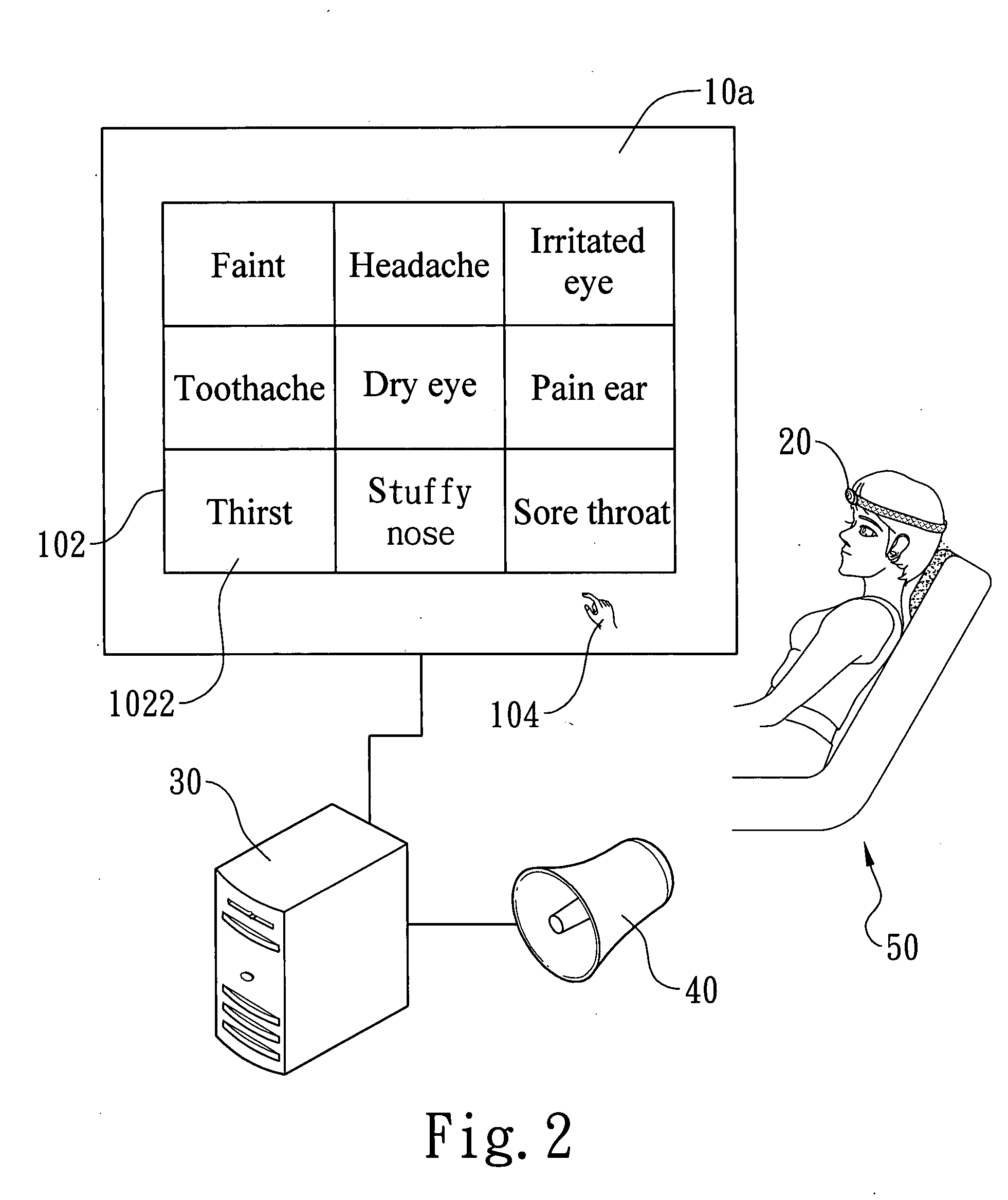

Speech communication system for patients having difficulty in speaking or writing

InactiveUS20080300885A1Clear expressionNatural language data processingSpeech synthesisCommunications systemSpoken language

A speech communication system for patients having difficulty in speaking or writing comprises a display screen, a controller, a host having a storage unit for storing specific software and connected with the display screen, and a speaker connected with the host. A plurality of choices is presented on the display screen in a nine-square form or an English keyboard form for patients to select according to their needs. The controller is used for patients having difficulty in speaking or writing to move a cursor on the display screen to select any choice they need. The speaker is designed to output speech sounds of words or simple sentences in different languages corresponding to the choices patients select via the controller and thus make it possible for patients to communicate with others.

Owner:SHIH CHUNG HUNG +1

Window glass for vehicle

ActiveUS20070128448A1Reduced strengthReduce tensile stressWindowsWindscreensElectrical conductorElectronic component

To provide a window glass for vehicles, which is obtained by fixing a conductor formed on the glass plate, and an electronic material, by means of a lead-free solder, thereby to secure sufficient adhesive strength and glass strength. A window glass for vehicles, which comprises a glass plate, a conductor formed on the glass plate, and an electronic component electrically connected to the conductor by means of a solder, wherein the solder comprises a buffer component and a conductive component containing no lead, and the proportion of the volume of the conductive component based on the volume of the entire solder is from 58 to 93%, or the proportion of the specific gravity of the entire solder based on the specific gravity of the conductive component is from 70 to 93%.

Owner:ASAHI GLASS CO LTD

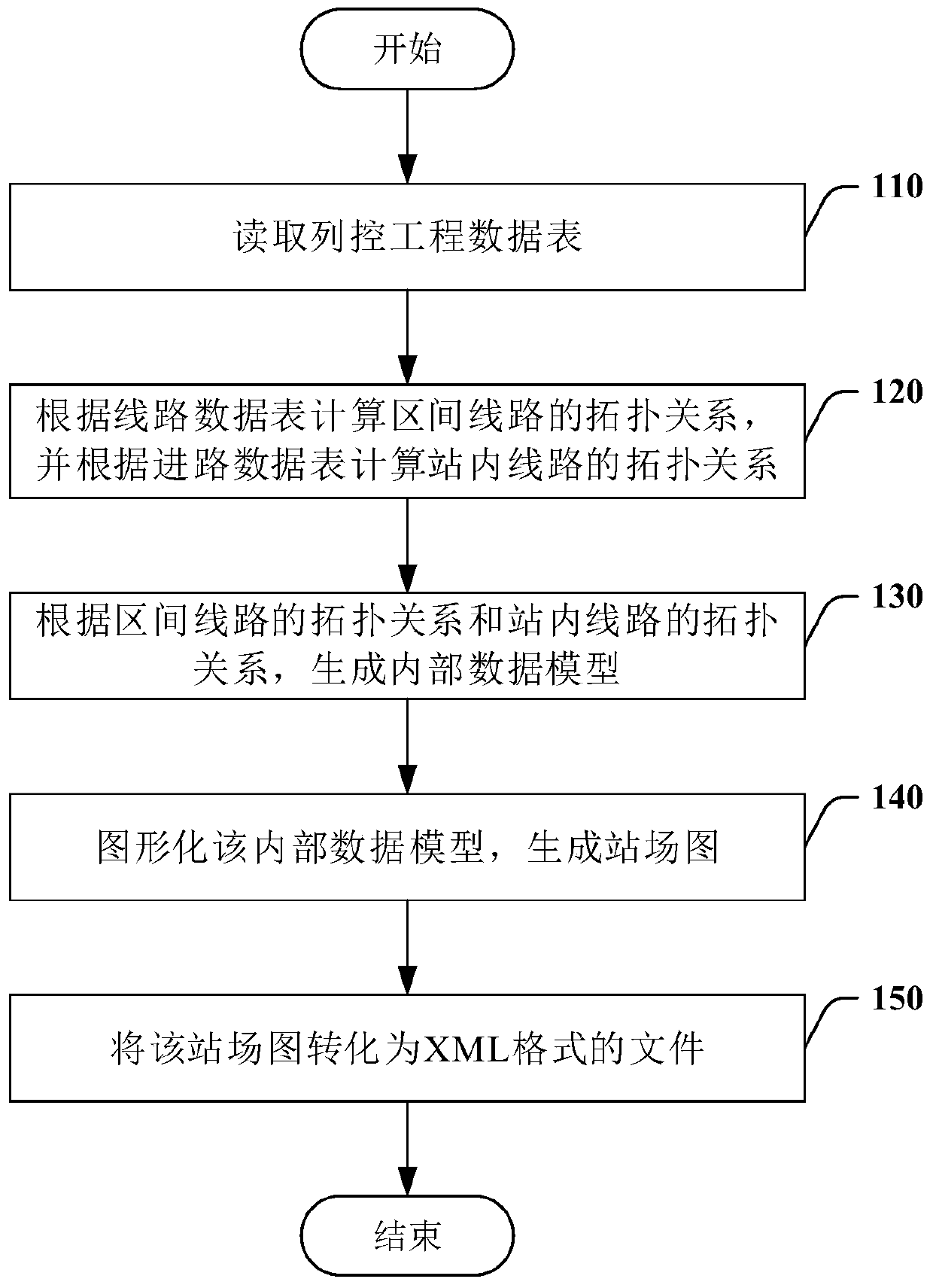

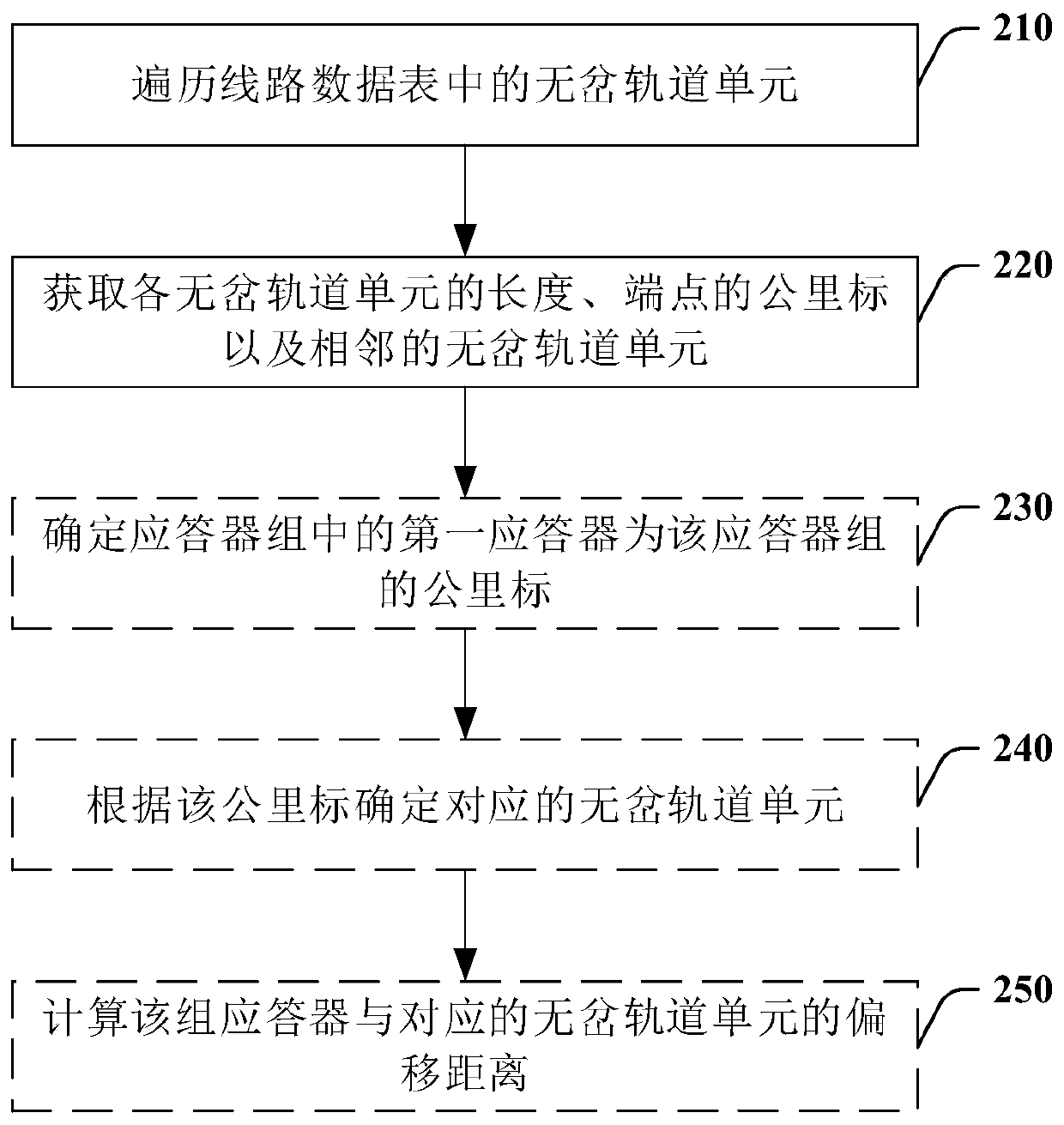

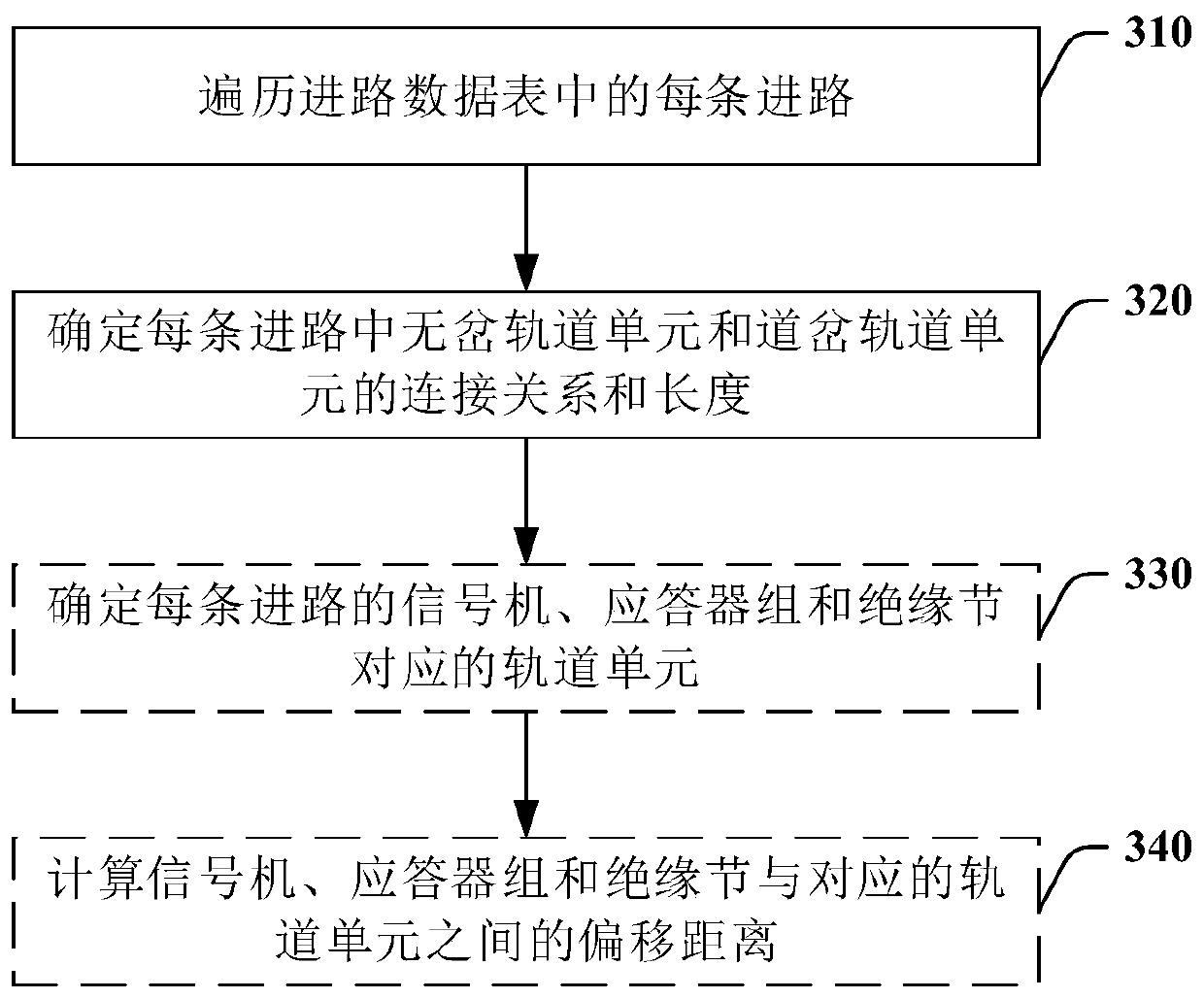

Method and device for automatically generating station yard graph and computer readable medium

PendingCN110516354AAutomate auditsImprove efficiencyRailway componentsSpecial data processing applicationsYardComputer science

The invention provides a method for automatically generating a station yard graph, which comprises the following steps of: reading a train control engineering data table which comprises a line data table and an access data table; calculating a topological relation of interval lines according to the line data table, and calculating a topological relation of in-station lines according to the accessdata table; generating an internal data model according to the topological relation of the interval lines and the topological relation of the instation lines; imaging the internal data model to generate a station yard graph; and converting the station yard graph into a file in an XML format. Compared with the prior art, the train control engineering data table can be directly read, the line topological relation is calculated, the machine language station diagram is generated, automatic auditing of the train control engineering data table can be achieved, and the auditing work efficiency and accuracy are improved.

Owner:HUNAN CRRC TIMES SIGNAL & COMM CO LTD

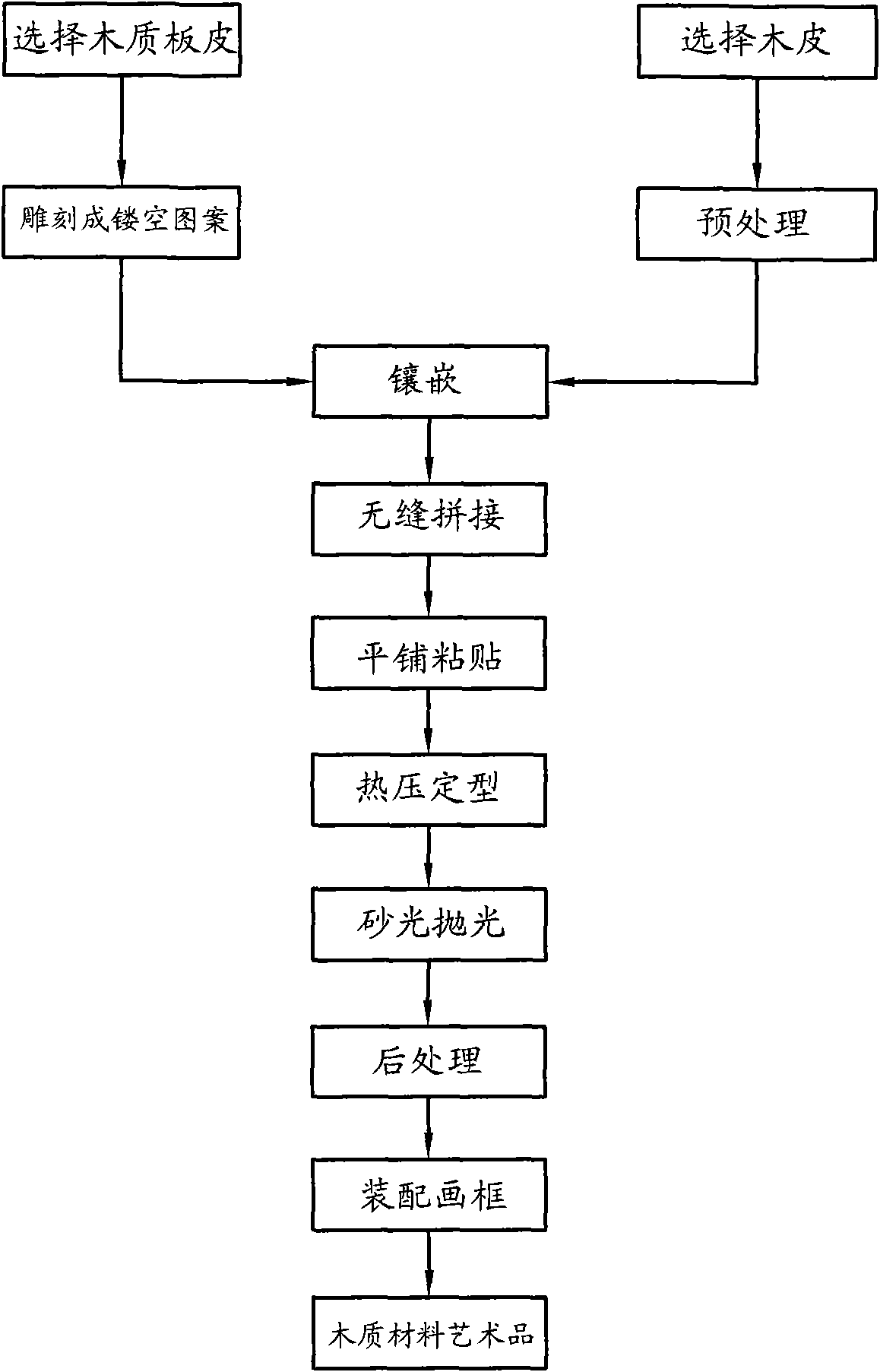

Processing method of wood material art

The invention provides a processing method of a wood material art, which solves the problem of poorer beautiful and artistic effects and shorter appreciation life of products prepared by the prior processing method of the wood material art. The processing method of the wood material art comprises the following steps: A. selecting materials; B. splicing in a seamless mode; C. forming by hot press; and D. post-processing. The wood material art prepared by the processing method has wide application range, good beautiful effect, long appreciation life, and the like.

Owner:玉环广源木业有限公司

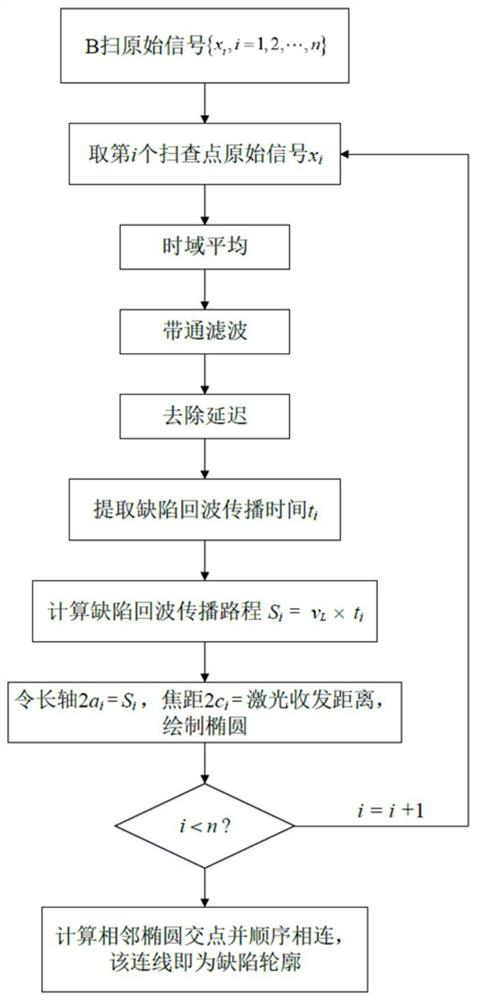

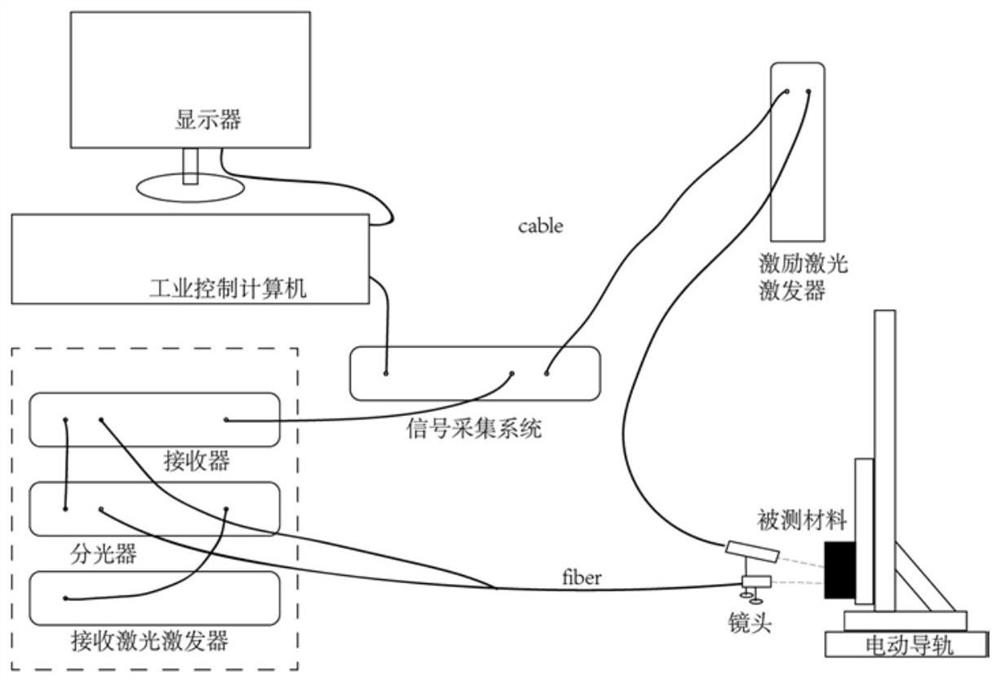

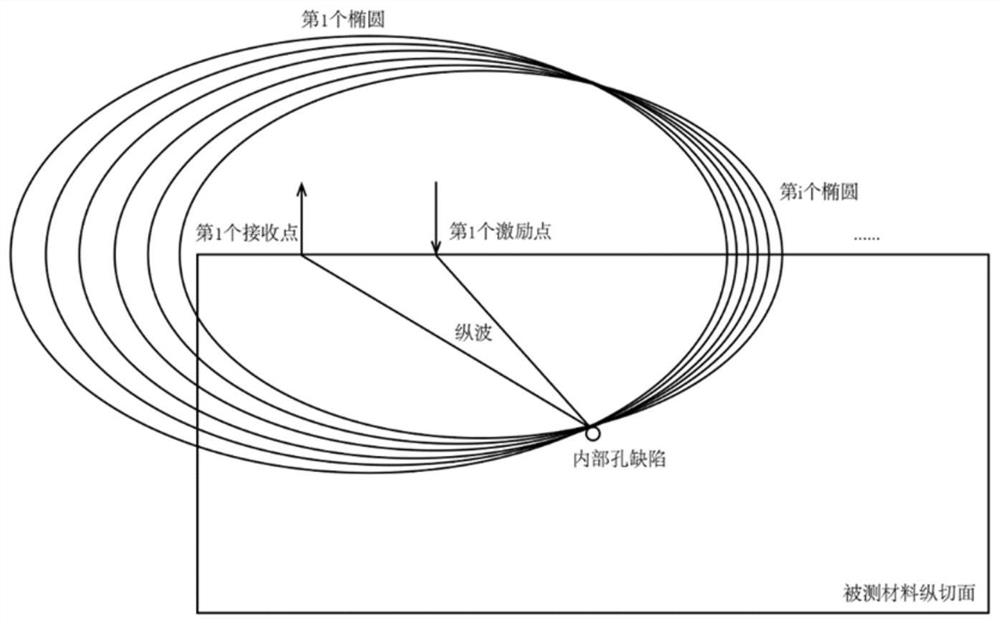

Defect positioning method based on laser ultrasonic B scanning

PendingCN112067697AAvoid cumbersomeAvoid errorsAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFeature extractionLongitudinal wave

A defect positioning method based on laser ultrasonic B scanning comprises the steps of carrying out B scanning on the surface of a metal material, and acquiring a B scanning signal; preprocessing theB scanning signal, decomposing the B scanning signal into different frequency bands, and extracting a wave crest moment of a longitudinal wave defect echo to obtain a propagation distance of the longitudinal wave of each scanning point; drawing n ellipses by taking an excitation laser point and a receiving laser point as two focuses of the ellipses and taking a longitudinal wave propagation pathas a long axis of the ellipses; and solving the intersection points of the adjacent ellipses, and connecting the intersection points in sequence to obtain the contour of the defect and the position coordinates of the defect. A metal material with internal defects is used as a target verification object, internal defects in a certain longitudinal section are detected through longitudinal waves in aB scanning mode by means of a laser ultrasonic detection platform, reconstruction of B scanning signals is achieved by means of signal noise reduction, feature extraction and the like, and information such as a shape, a size and a position of the defects is detected. And a purpose of visual quantitative identification of defects is achieved.

Owner:XI AN JIAOTONG UNIV

Visualization method based on natural environment factor data

ActiveCN111046260AClear visualizationClear expressionOther databases browsing/visualisationSpecial data processing applicationsData displayGraphics

The invention discloses a visualization method based on natural environment factor data. A visual display system is built through the combination of a time sequence change model and a space change model. Mapping from a data space to a graphic space is carried out by utilizing a 2.5-dimensional surface visual design idea and three coordinate conversions, visual display of natural environment factordata is realized, and a function of visually and clearly displaying key environment factor data display is achieved. Meanwhile, the visualization method realizes that multiple views display data frommultiple angles at the same time, and the views are linked, that is, when the views are modified and inquired in one view, information displayed in other views can also be correspondingly changed, sothat the visualization method has timeliness, accuracy and clarity, and is convenient for researchers to evaluate.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com