Patents

Literature

44results about "Inlaying equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

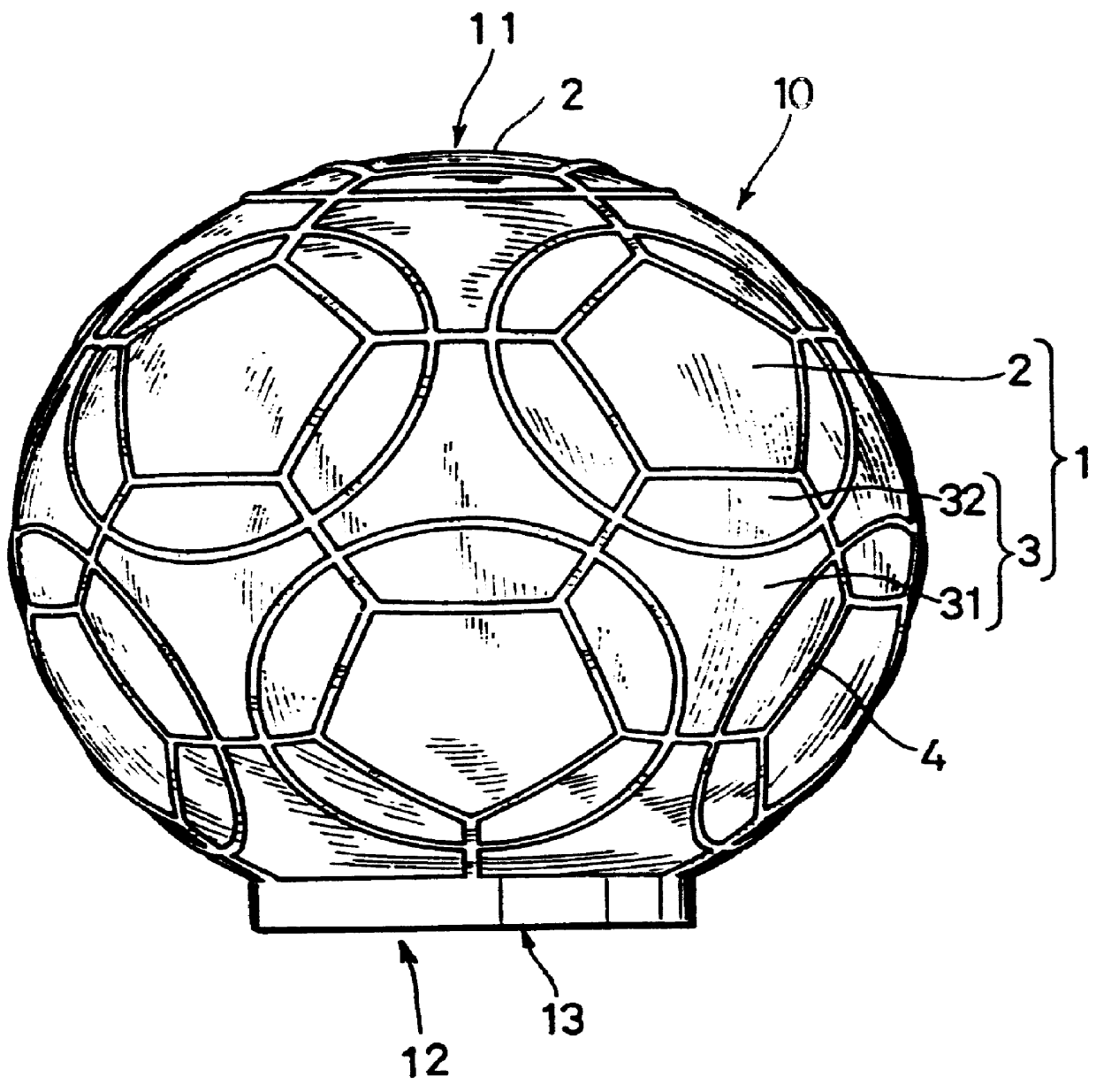

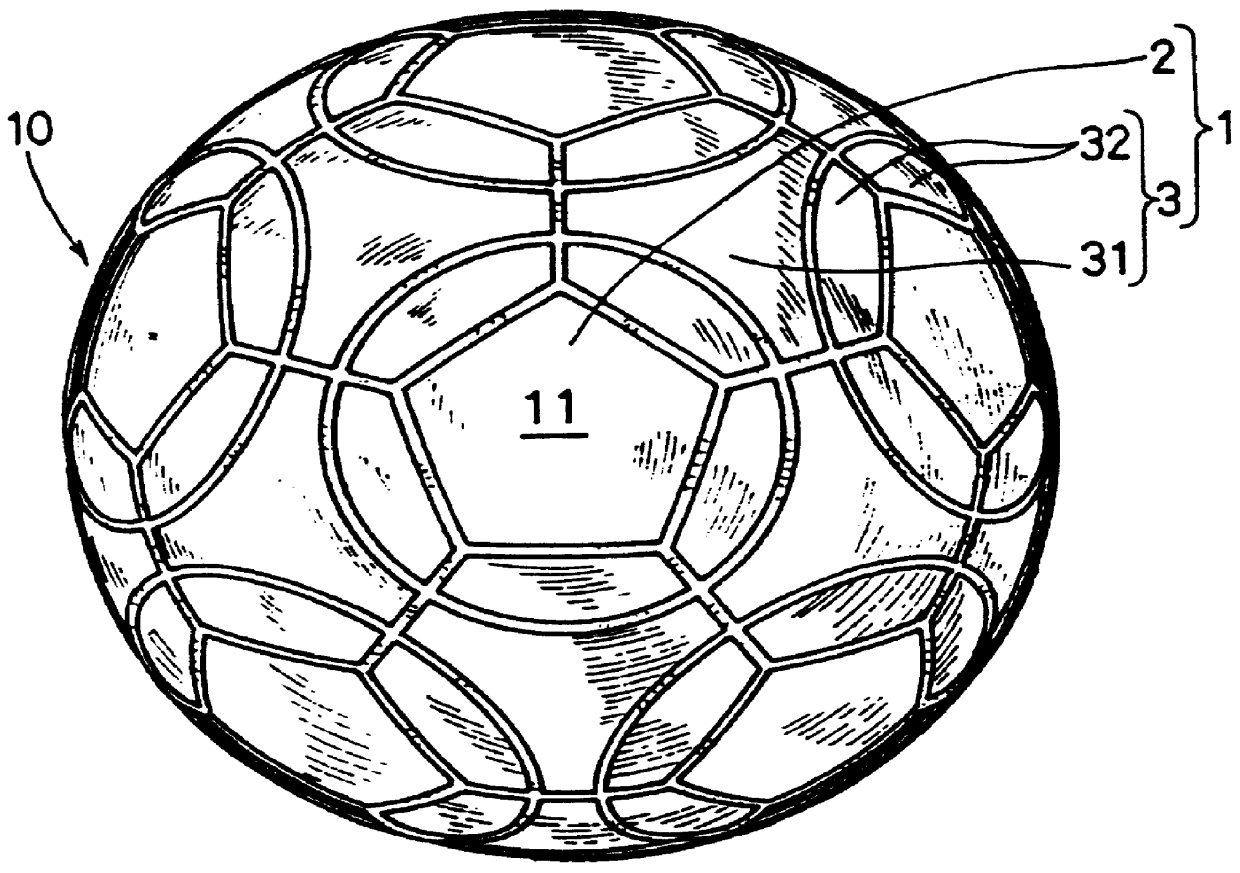

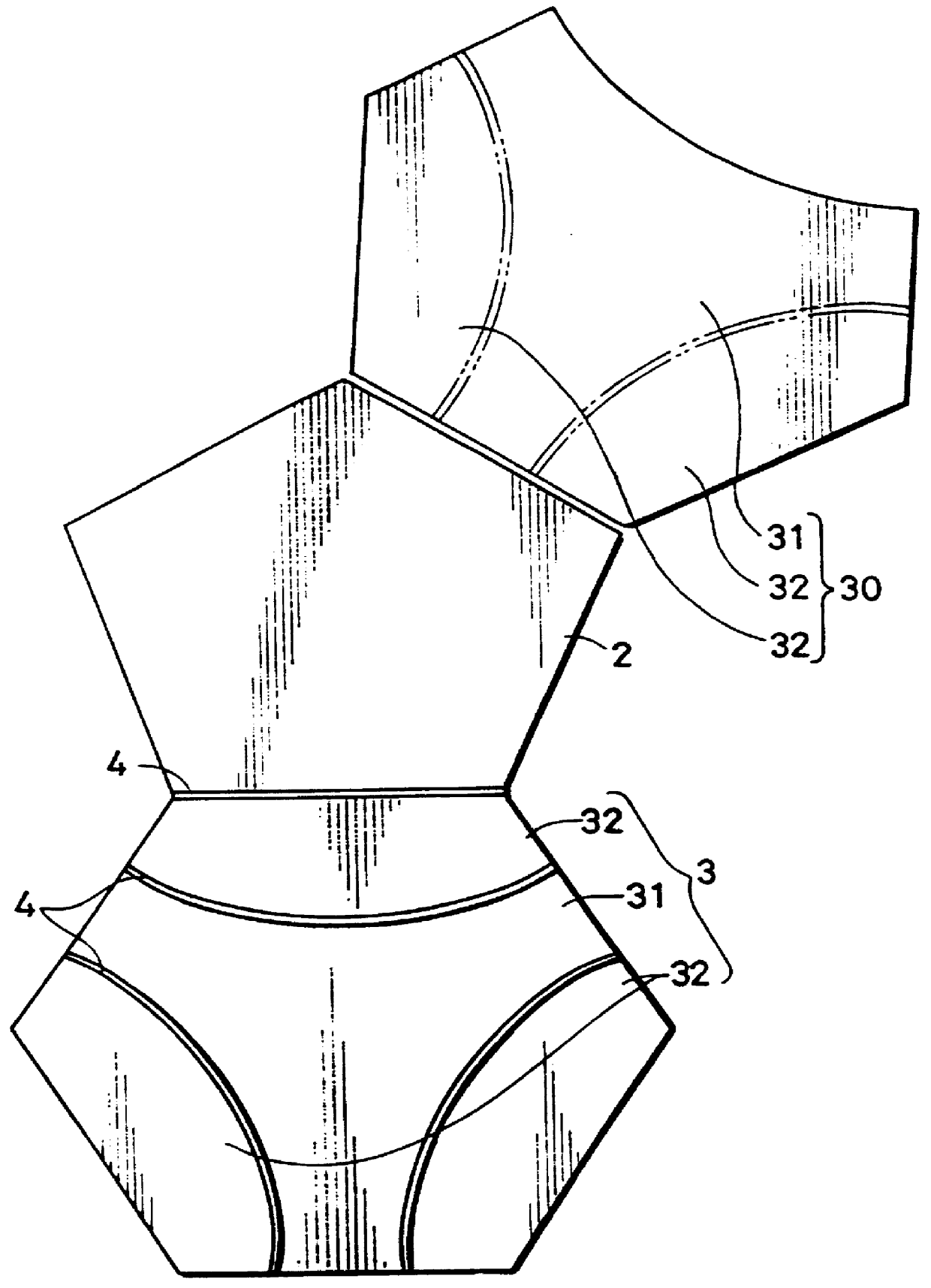

Three dimensional stained glass article and method for producing the same

InactiveUS6117504AEasy to shapeEasy to transformInlaying equipmentDecorative surface effectsThree dimensional shapeEngineering

This invention relates to a stained glass article of a three dimensional shape and a method for producing the same. A glass plate is cut into glass pieces of a certain shape including a pentagon member and a hexagon member. The hexagon member consists of one six-sided irregular member and three four-sided irregular members. The glass pieces of the certain shape are united together via a bonding agent to obtain the three dimensional stained glass imitating the shape of a soccer ball. The glass piece has a curved surface whose radius of curvature is set substantially equal to the radius of the soccer ball.

Owner:YOSHIKAWA KAZUHIDE

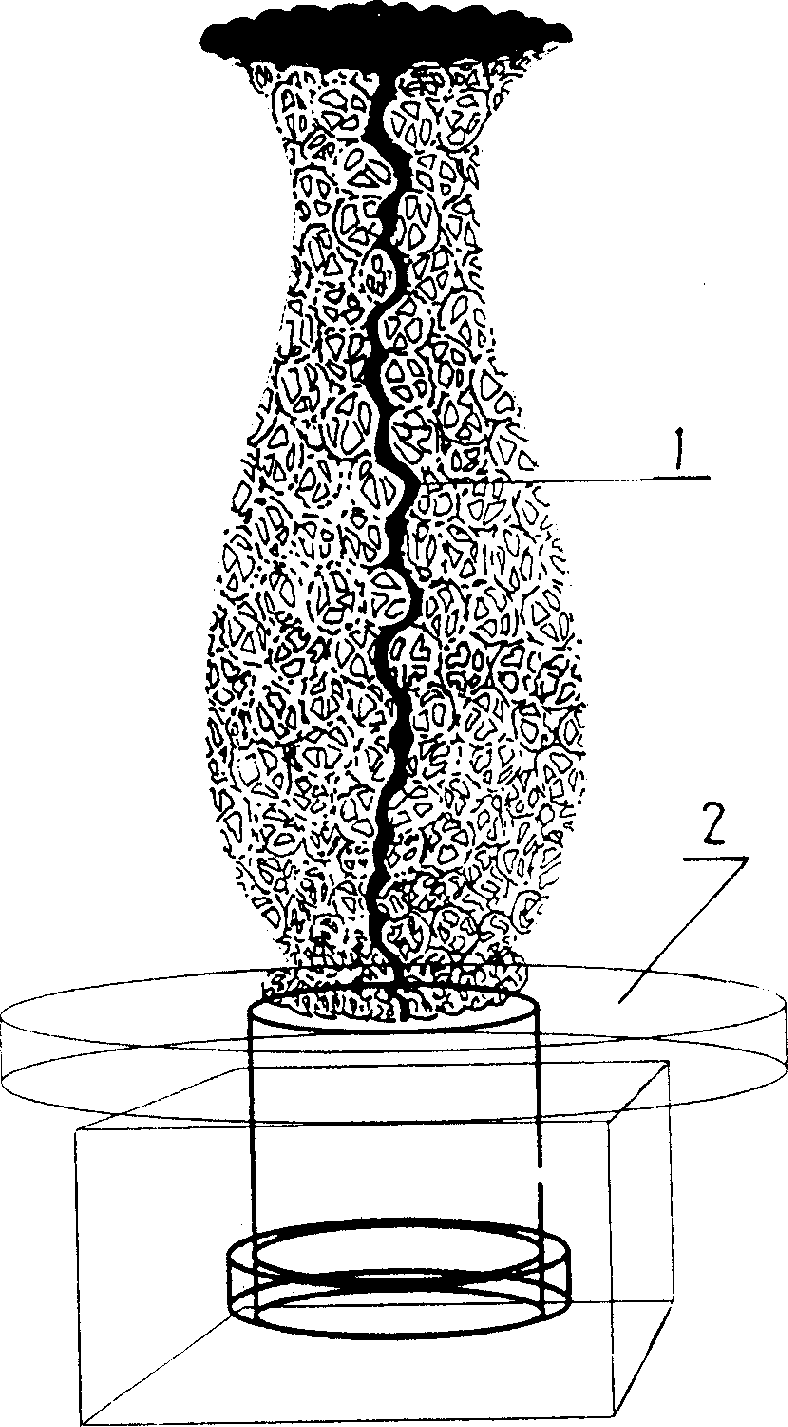

Method for fabricating artware by using pieces of hard walhut hull

InactiveCN1760045ANo deformationQuality improvementInlaying equipmentDecorative surface effectsWalnut NutEngineering

A technology for preparing the artwork from walnut shells includes such steps as providing a hard mould, putting it on a rotary table, coating demoulding agent on its surface, sequentially sticking walnut shells on its surface while slowly rotating the table, filling resin adhesive in the gaps between walnut shells except two symmetric central lines, solidifying, separating two halves of said artwork from the hard mould, and sticking two halves with resin adhesive to obtain an integral artwork.

Owner:马建禄

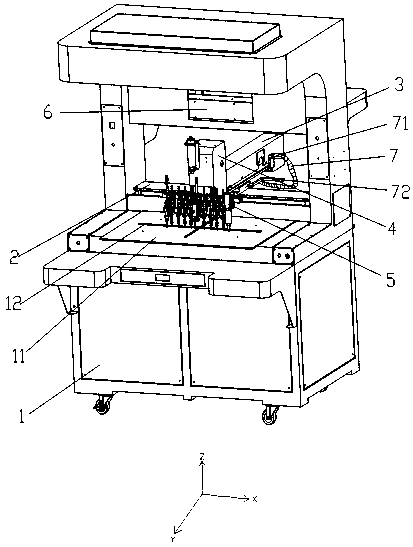

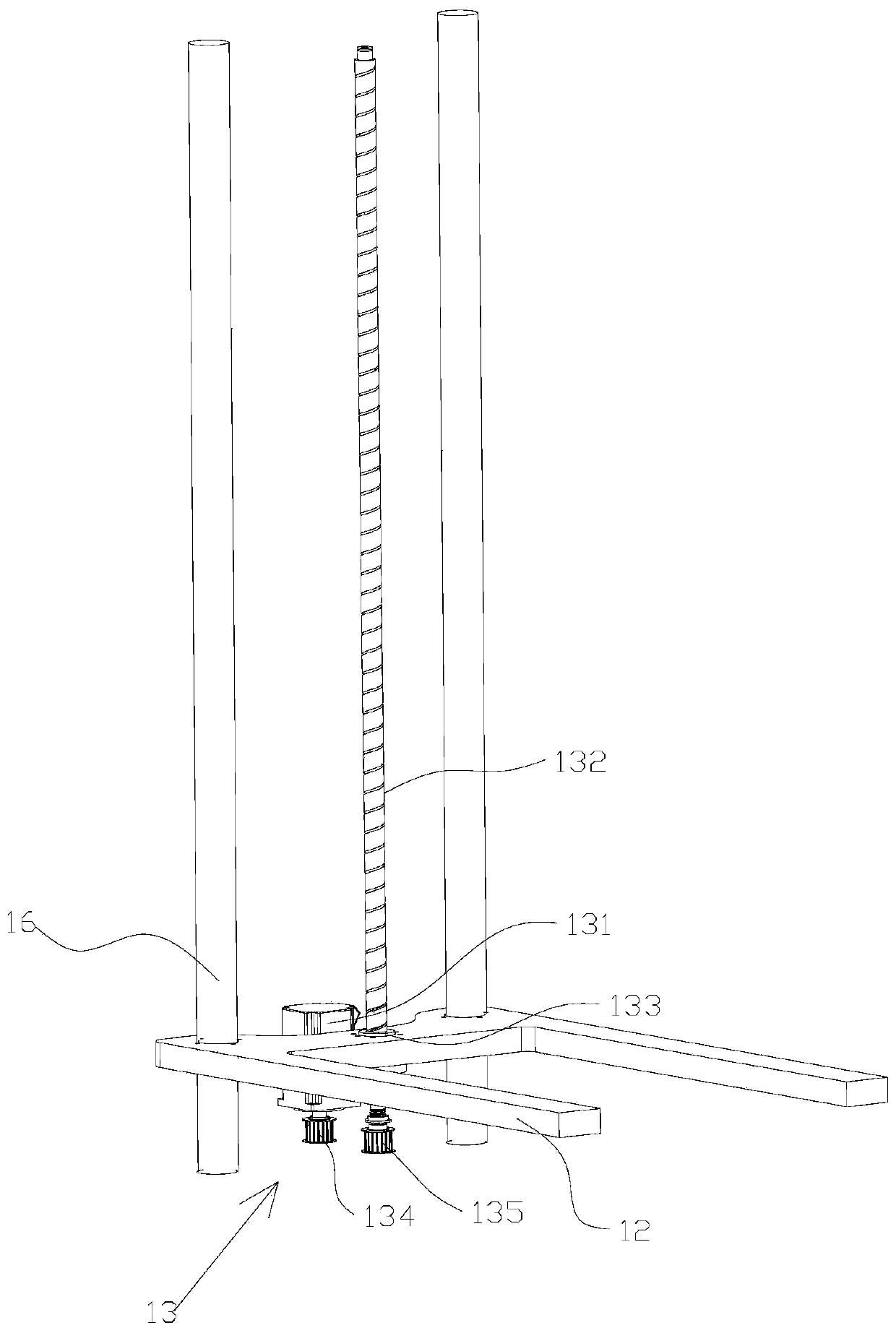

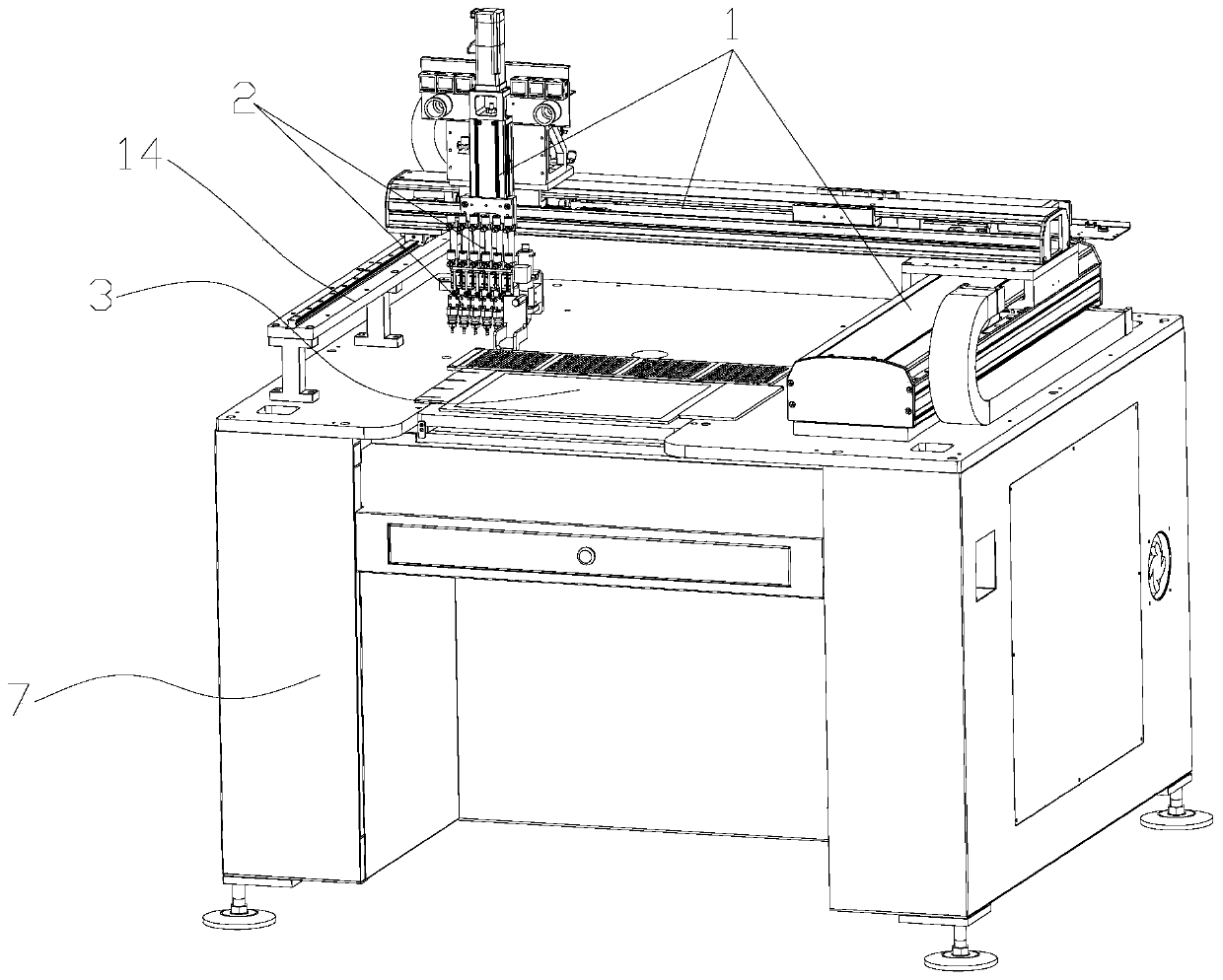

Vision multi-station dispensing and rhinestone gluing machine

PendingCN108674075AFully automatic mechanizationIncrease productivityLiquid surface applicatorsInlaying equipmentControl systemEngineering

The invention relates to a vision multi-station dispensing and rhinestone gluing machine which comprises a rack, a rhinestone gluing structure, a vision device and a control device. The rhinestone gluing structure comprises transverse beams in the X, Y and Z directions, a movement arm and a bearing block, in cooperation with linkage of a first lead screw, a second lead screw and a third lead screw, motion orienteering of a gun support on the movement arm in the three-dimensional direction is finally achieved, after a camera captures a workpiece on an operation table, a PLC control system controls an ultrasonic dispensing gun or a hot melt adhesive dispensing gun on the gun support to conduct dispensing and rhinestone pasting operation on the workpiece, full-automatic mechanization dispensing and rhinestone gluing are achieved, the production efficiency is high, and the yield is high.

Owner:东莞市柏锐智能科技有限公司

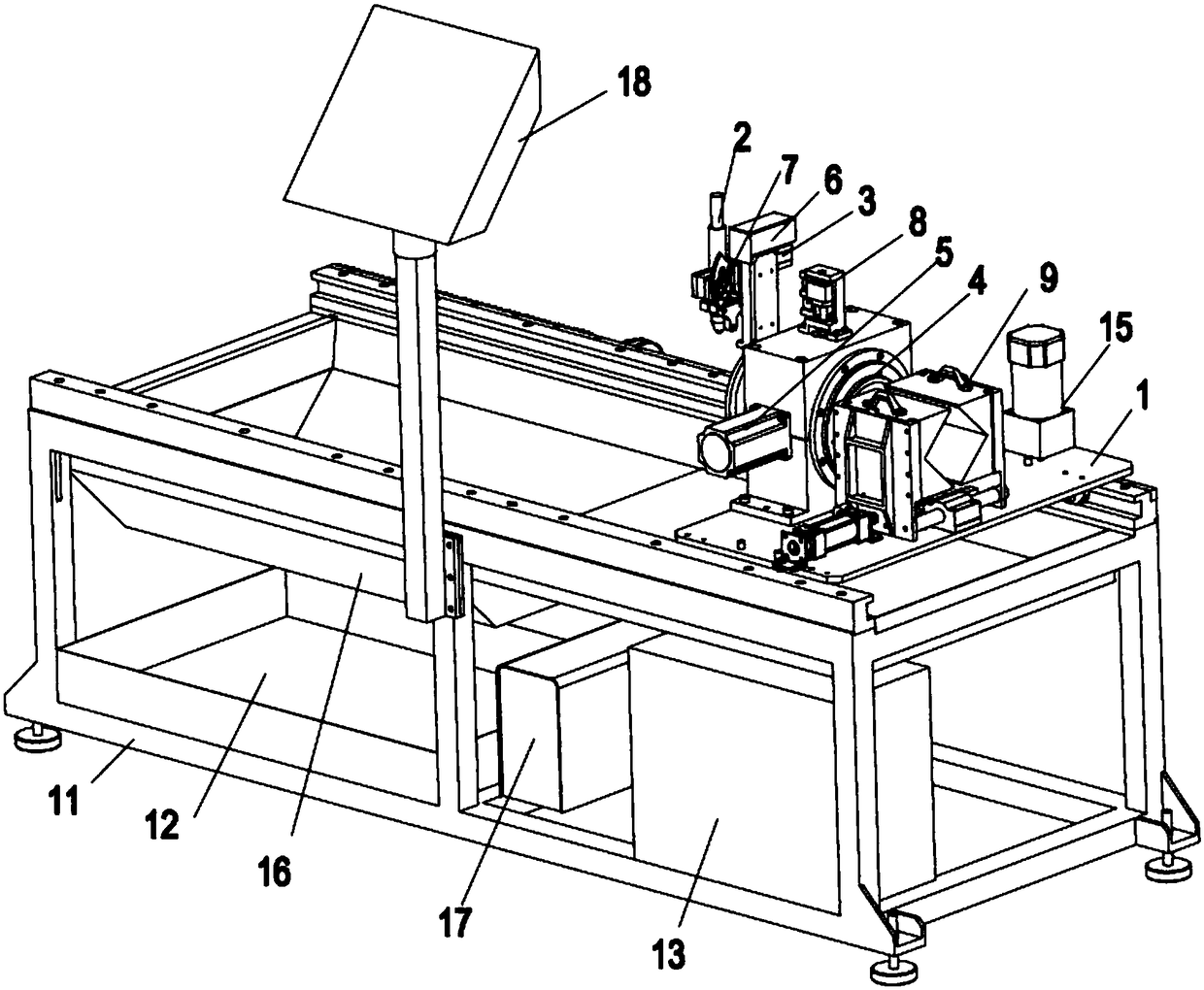

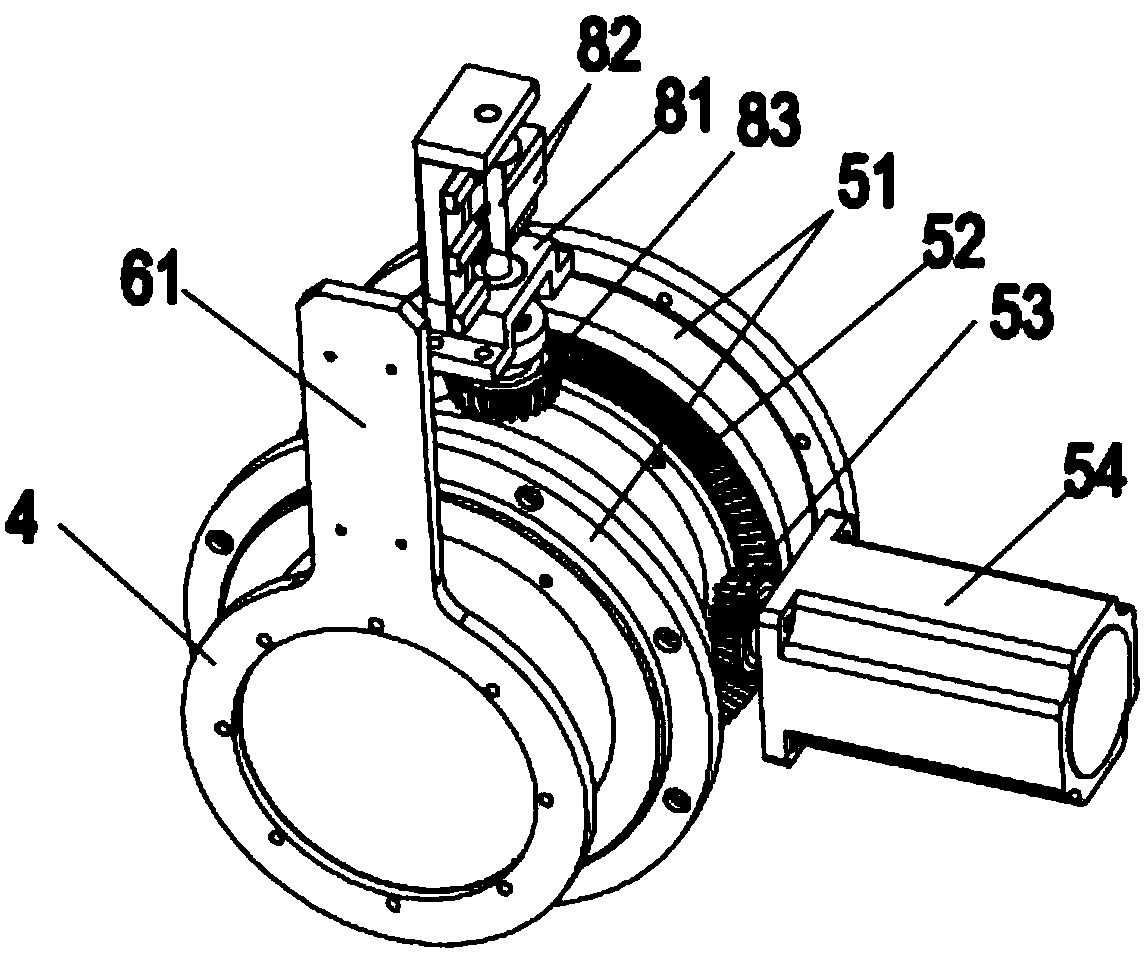

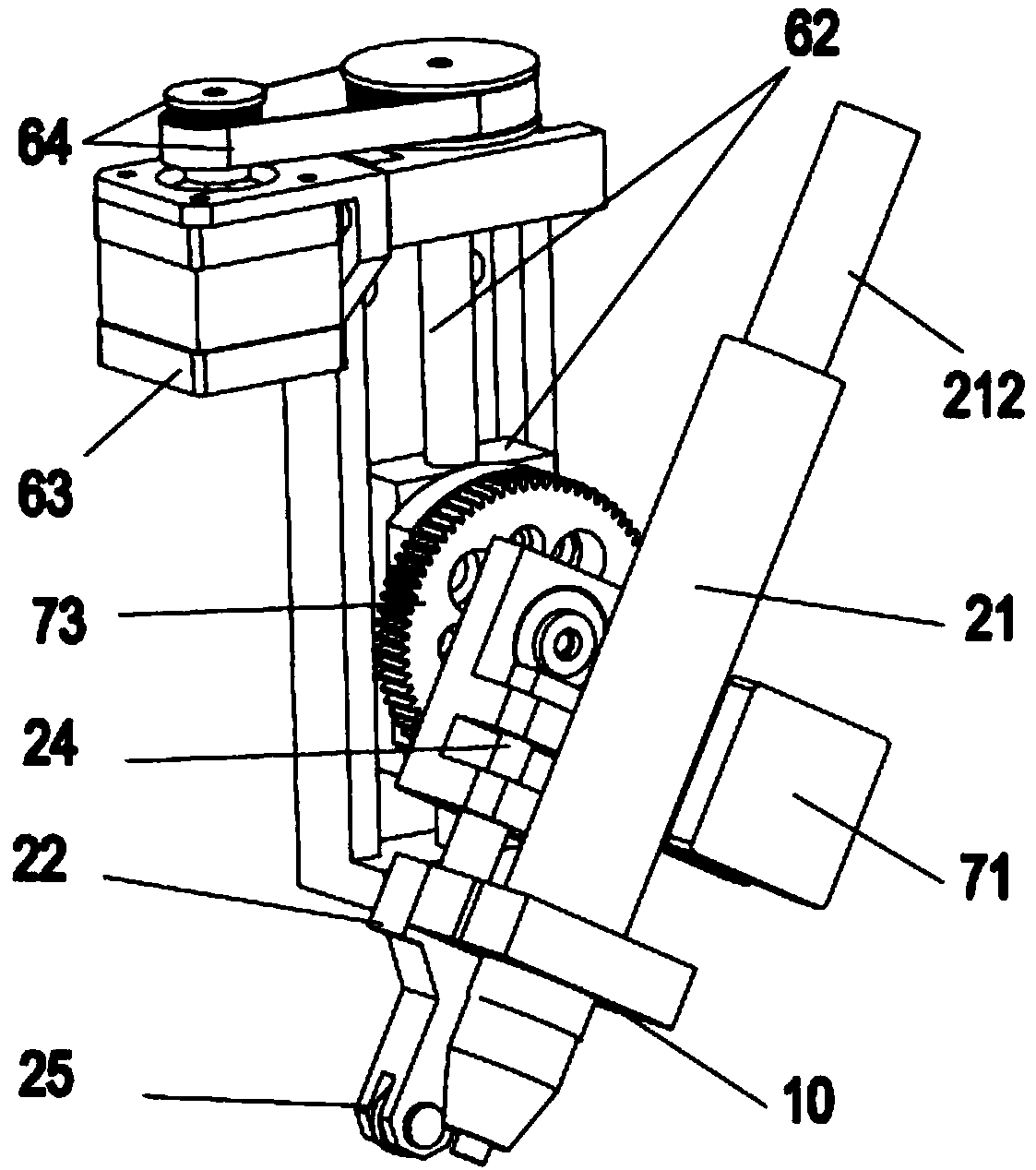

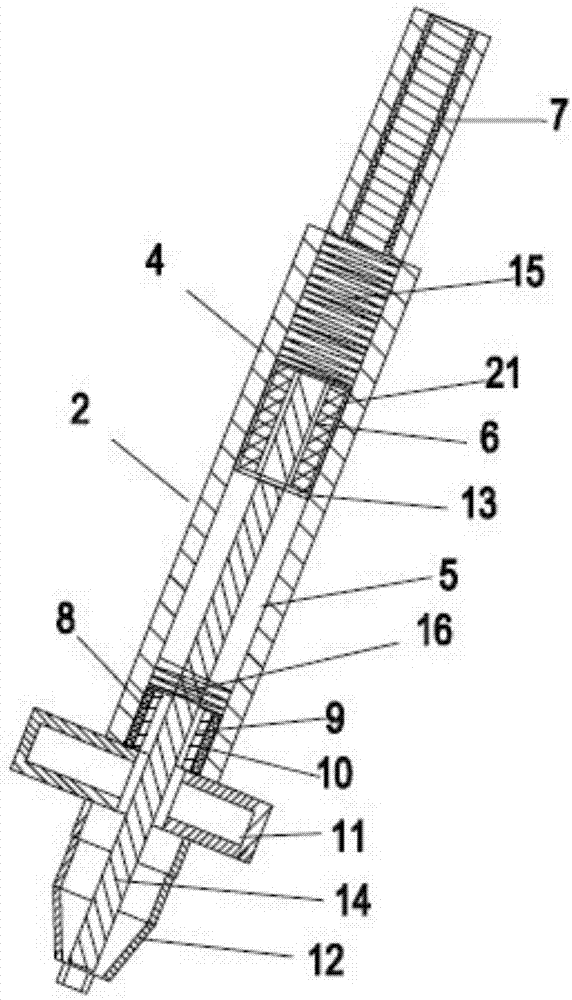

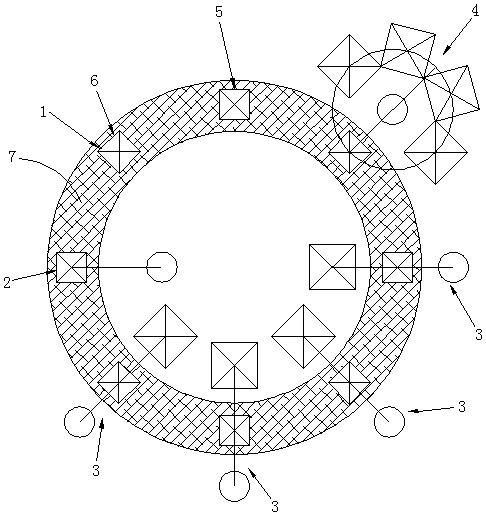

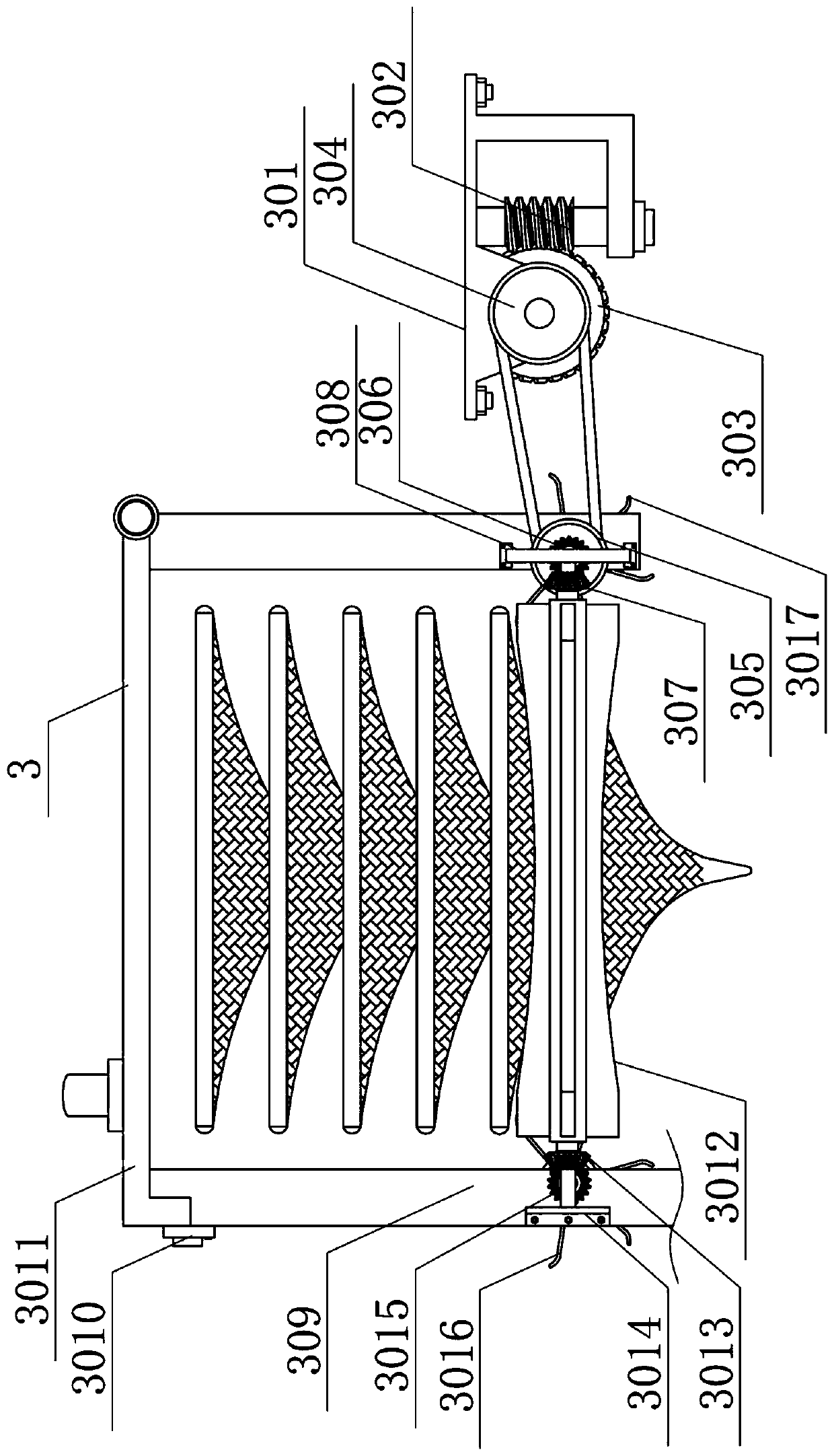

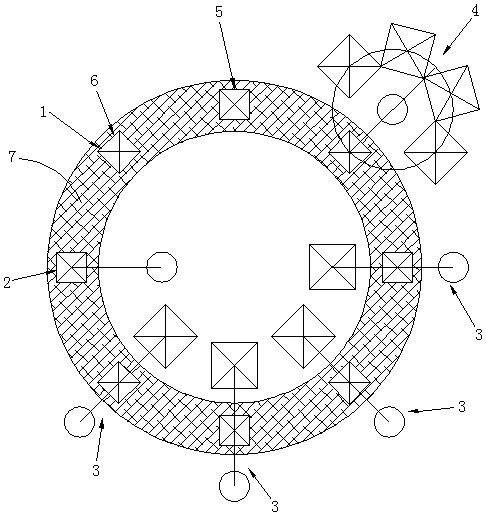

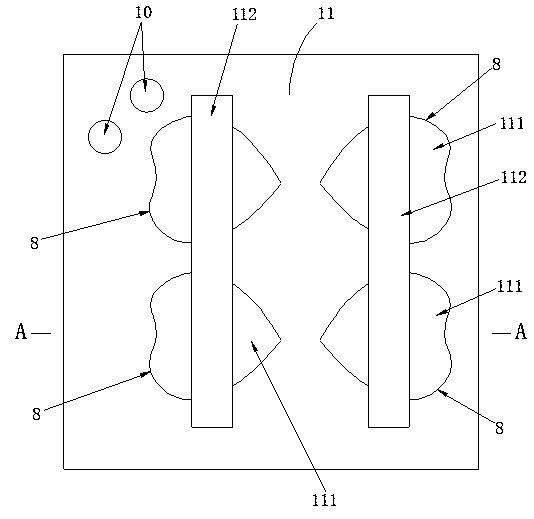

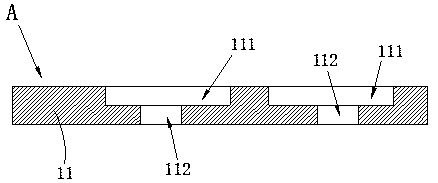

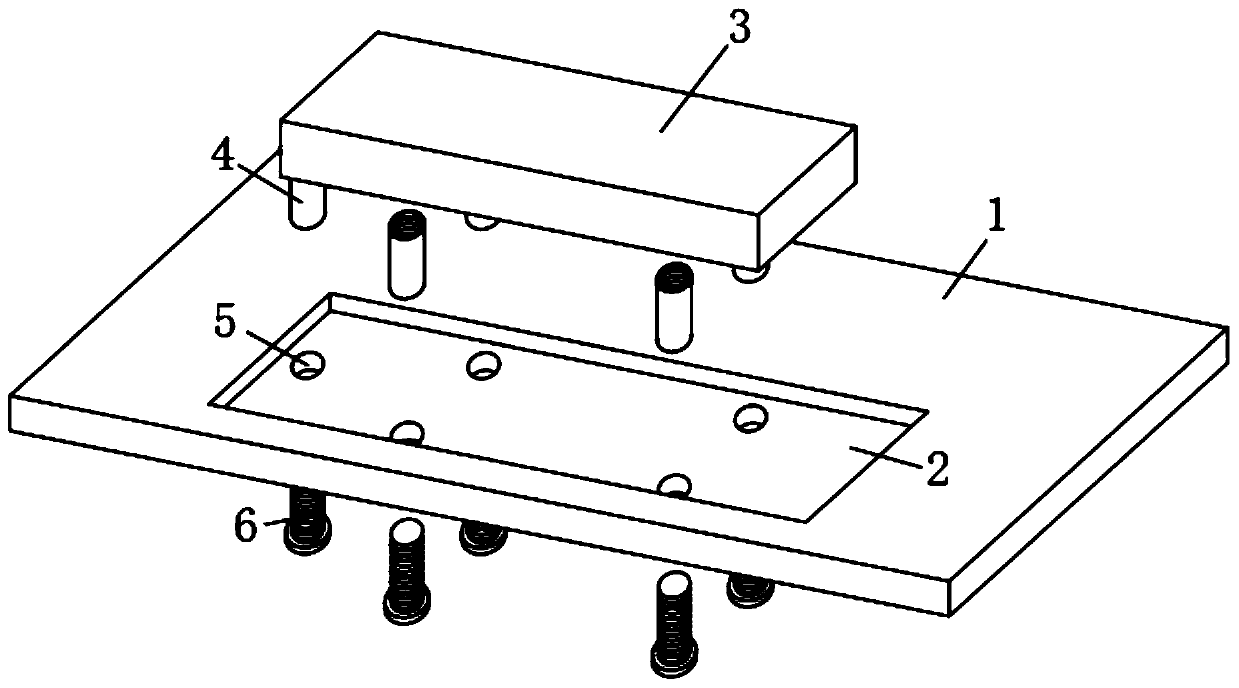

Arrayed nail engraving equipment used for wood pile column or plate

InactiveCN108162658AStructural scienceNovel methodStapling toolsInlaying equipmentEngravingEngineering

The invention discloses arrayed nail engraving equipment used for a wood pile column or plate. A movable carrying plate of the arrayed nail engraving machine is provided with a nail engraving rotatingmechanism for driving a hollow rotating shaft to rotate; a nail engraving feeding mechanism is arranged on a nail engraving machine head; a nail engraving angle adjusting mechanism is arranged on thenail engraving feeding mechanism; a nail engraving assembly is arranged on the nail engraving machine head; and an electromagnetic nail shooting gun of the nail engraving assembly comprises a gun body sliding bore, a starting electromagnet, an accelerating electromagnet, a nail box, a gun nozzle, a firing pin, a nail hammer, a reset spring pipe and a buffer spring pipe. The arrayed nail engravingequipment has the advantages that the structure is scientific; by controlling arrangement and display of nails in a wood column and the depths of parts, embedded in the wood column, of the nails, various concave-convex regular lattice patterns can be achieved, and unique art nail engraving is formed; nail engraving of the surface of the circle wood column, or the square wood column, or the rectangular wood column, or the special-shaped wood column or the plate can be achieved through a multi-axis movement mechanism, limitation of the shape of the wood pile column or the plate is avoided, nailengraving precision is improved, and close-range engraving can be achieved; and the nail engraving speed is high, operation is easy, the production efficiency is high, and the automation degree is high.

Owner:FOSHAN LANTU TECH CO LTD

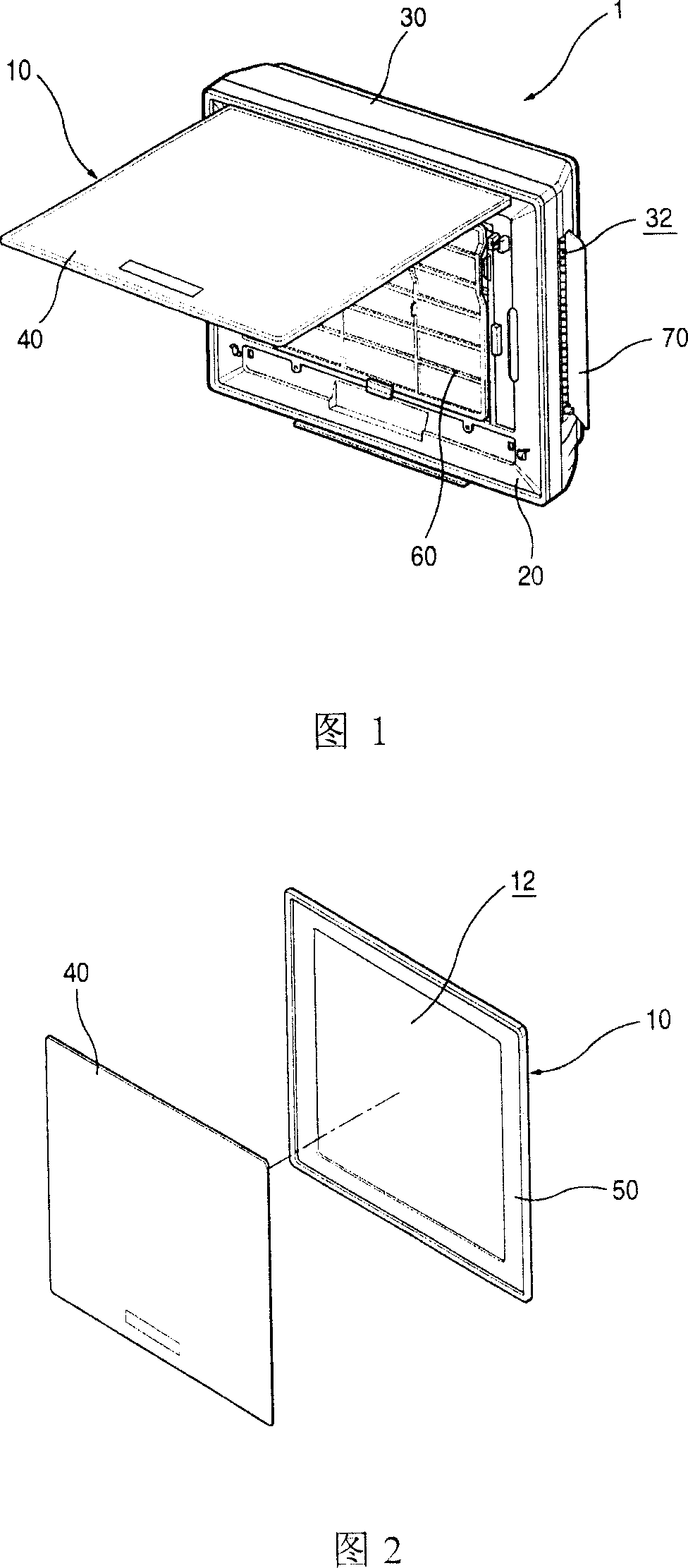

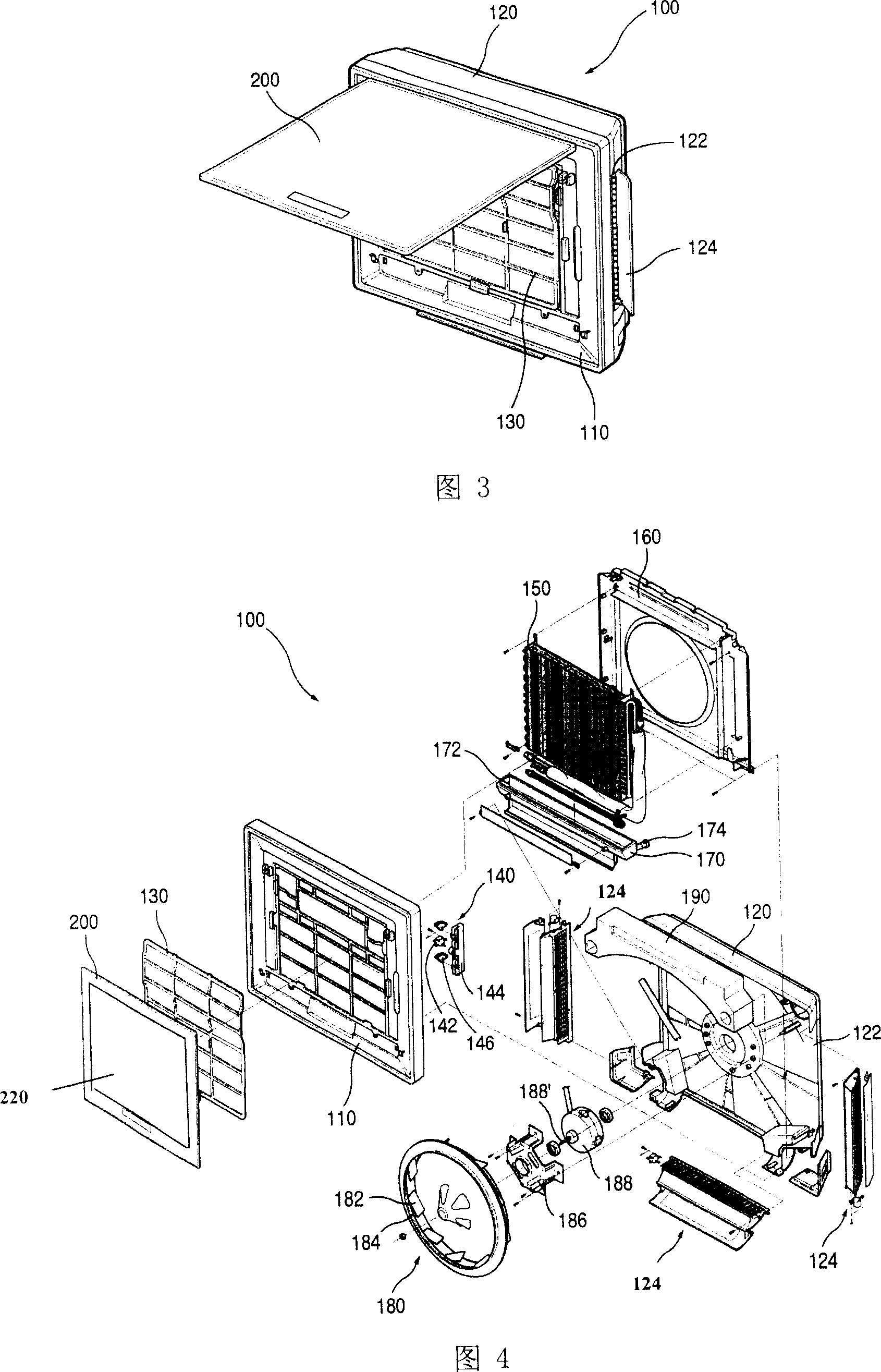

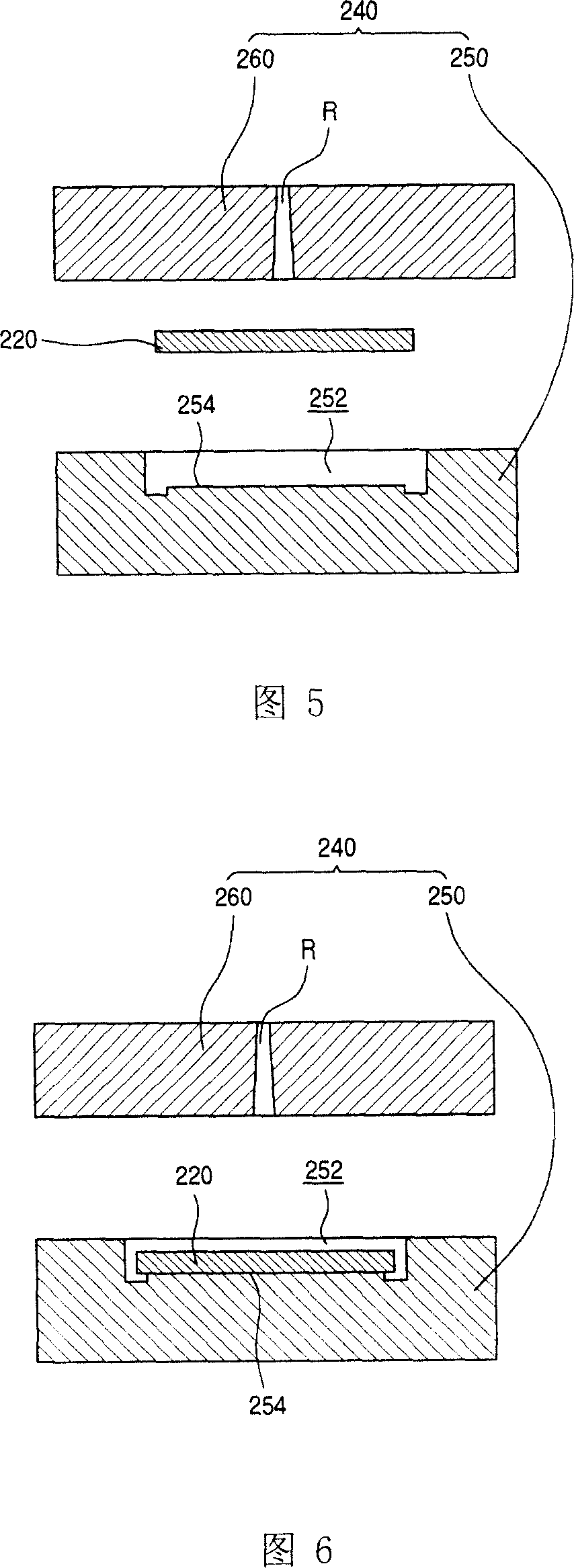

Decoration board mounting structure of air conditioner indoor machine

InactiveCN1987279AImprove aestheticsGuaranteed aestheticsInlaying equipmentHeating and ventilation casings/coversAgricultural engineeringInjection moulding

An installation structure of decorative plate for the indoor set of air conditioner is composed of a front panel and a decorative plate which is inlaid on the front surface of said front panel by injection molding.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

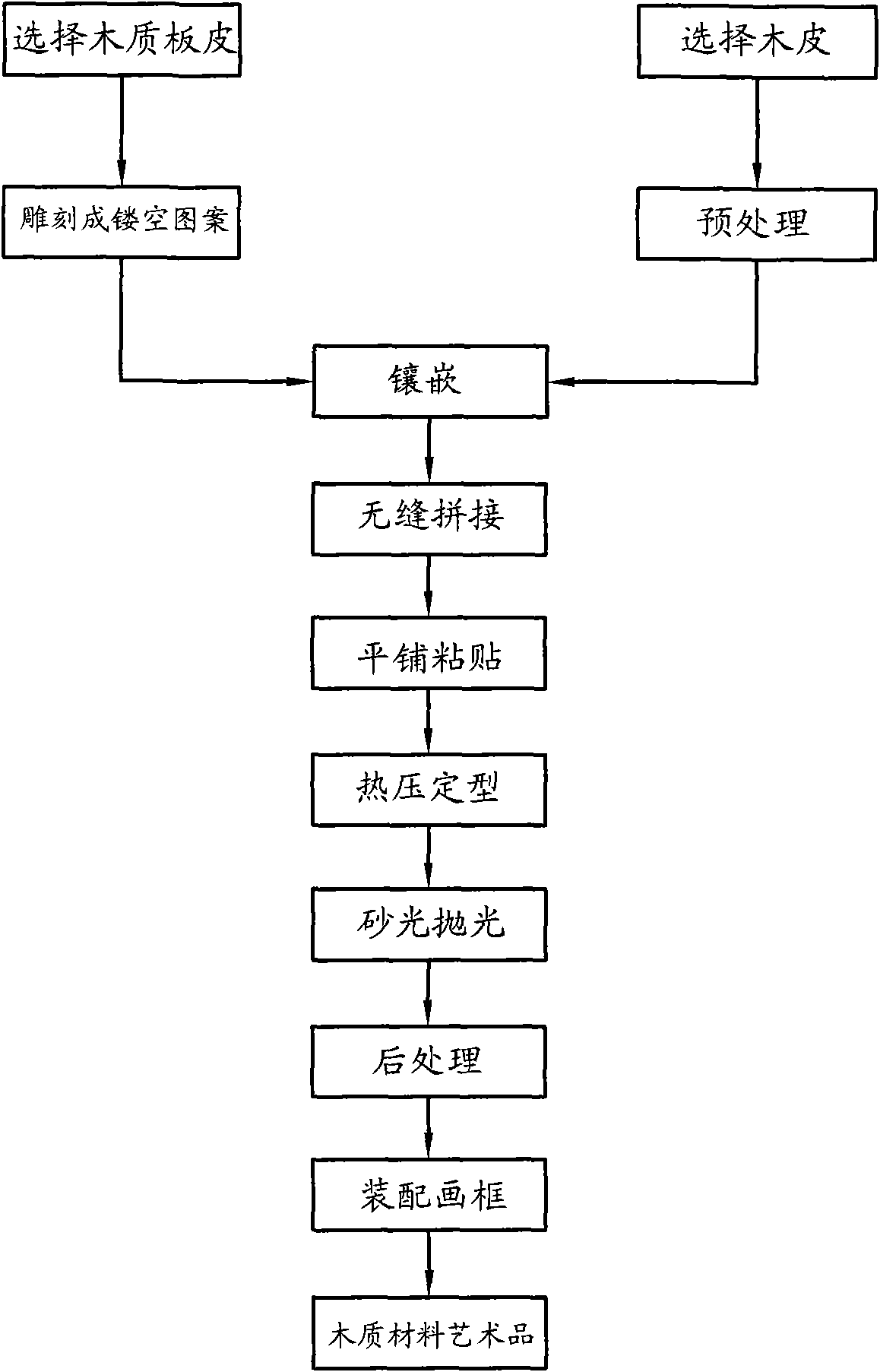

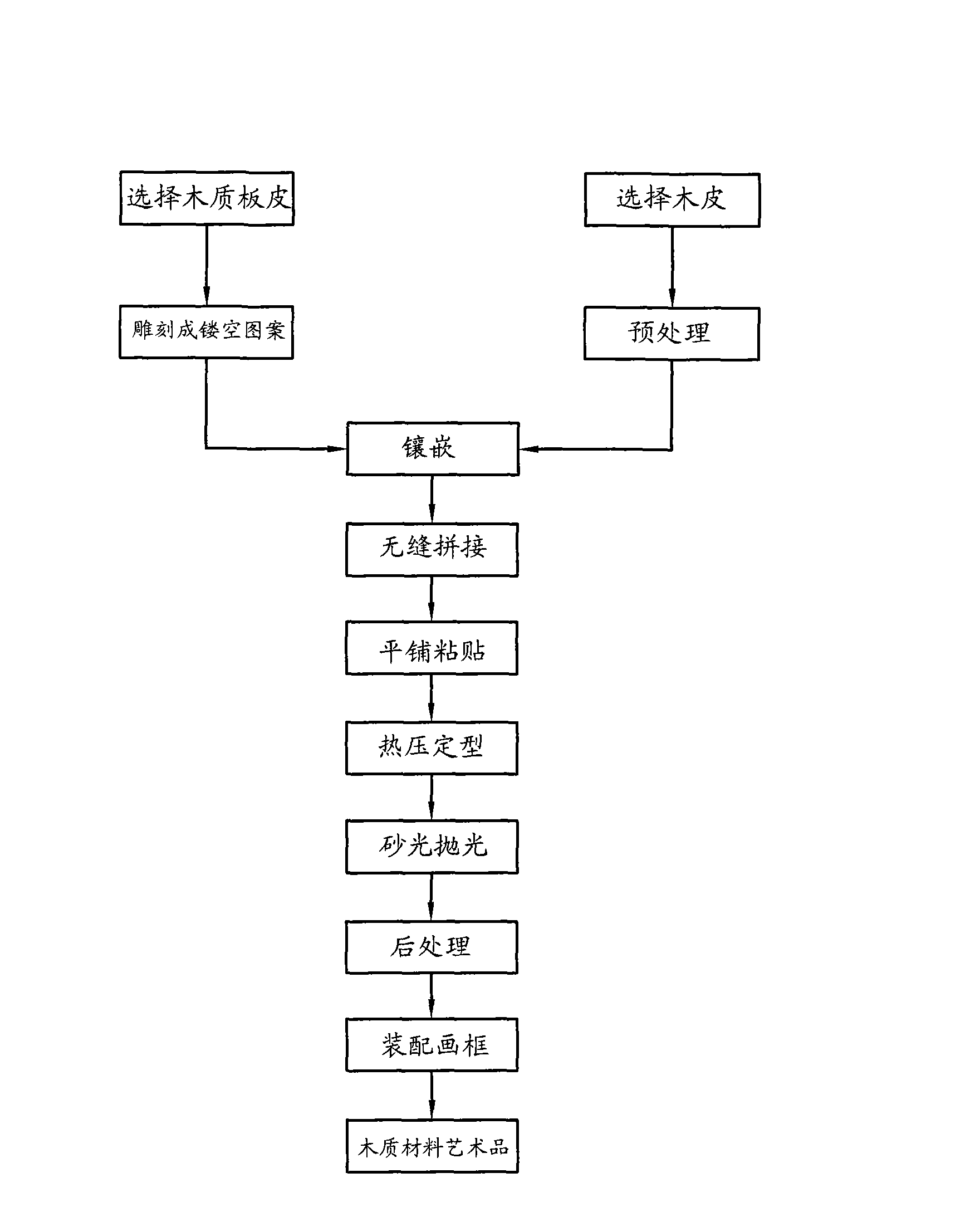

Processing method of wood material art

The invention provides a processing method of a wood material art, which solves the problem of poorer beautiful and artistic effects and shorter appreciation life of products prepared by the prior processing method of the wood material art. The processing method of the wood material art comprises the following steps: A. selecting materials; B. splicing in a seamless mode; C. forming by hot press; and D. post-processing. The wood material art prepared by the processing method has wide application range, good beautiful effect, long appreciation life, and the like.

Owner:玉环广源木业有限公司

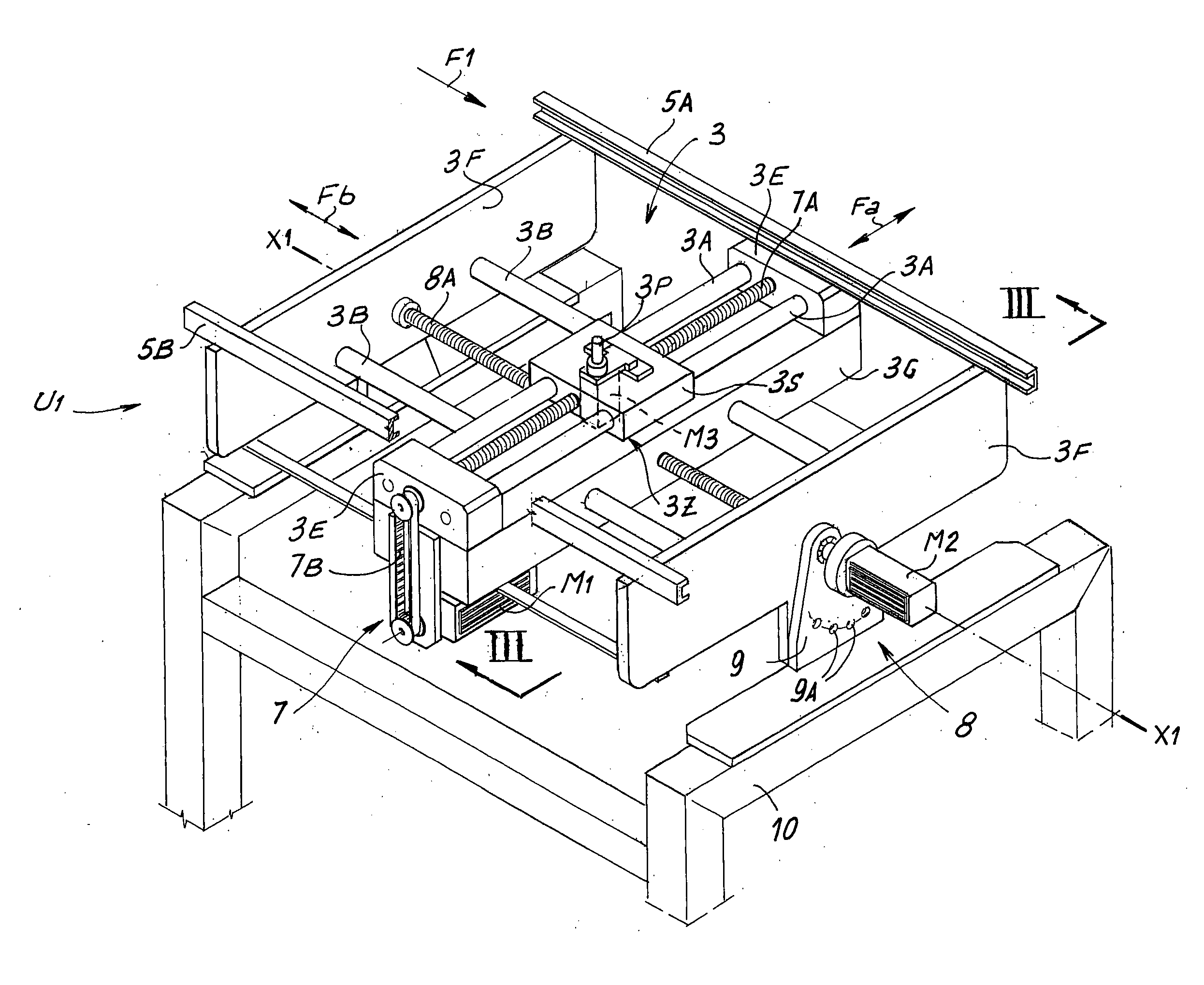

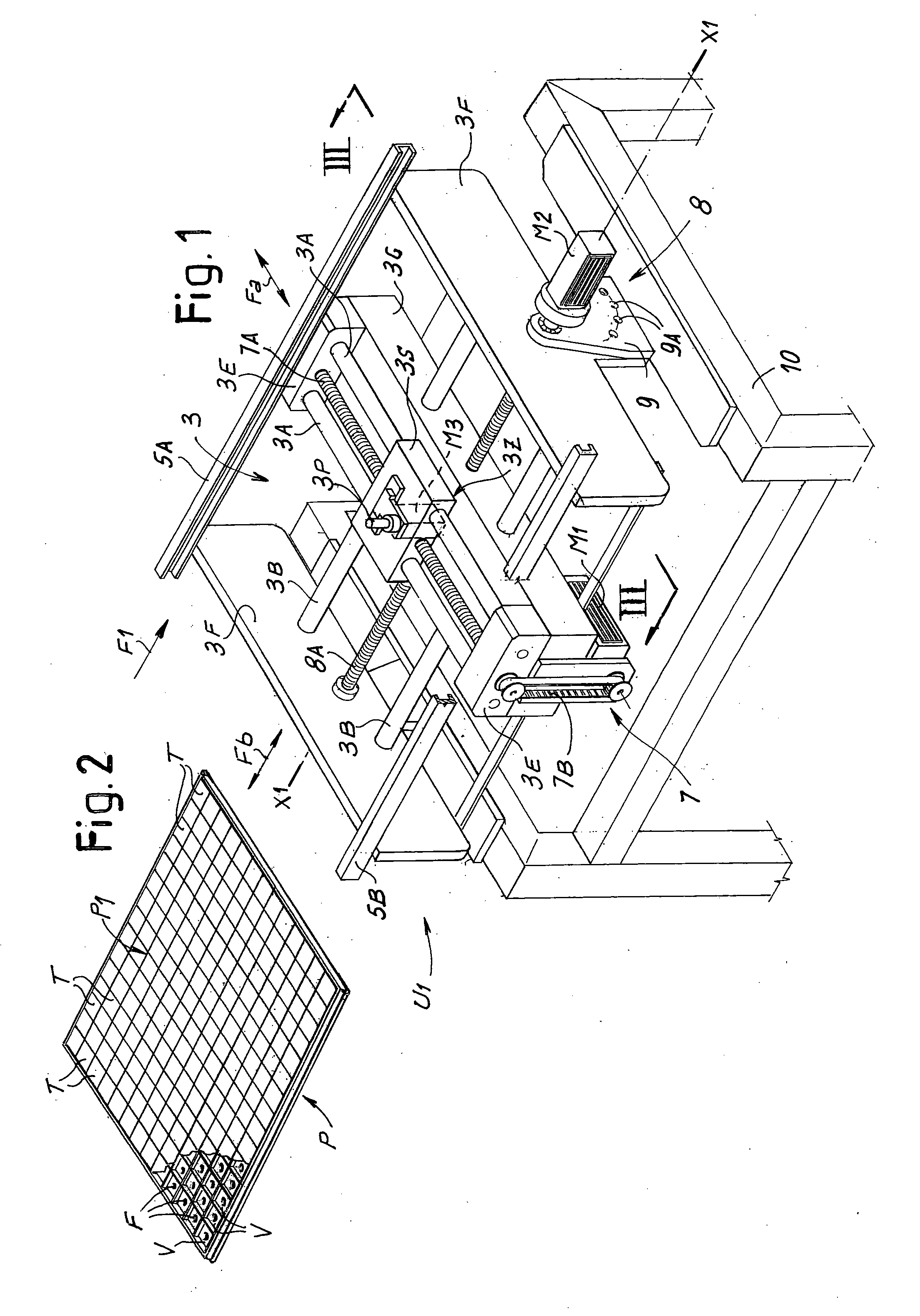

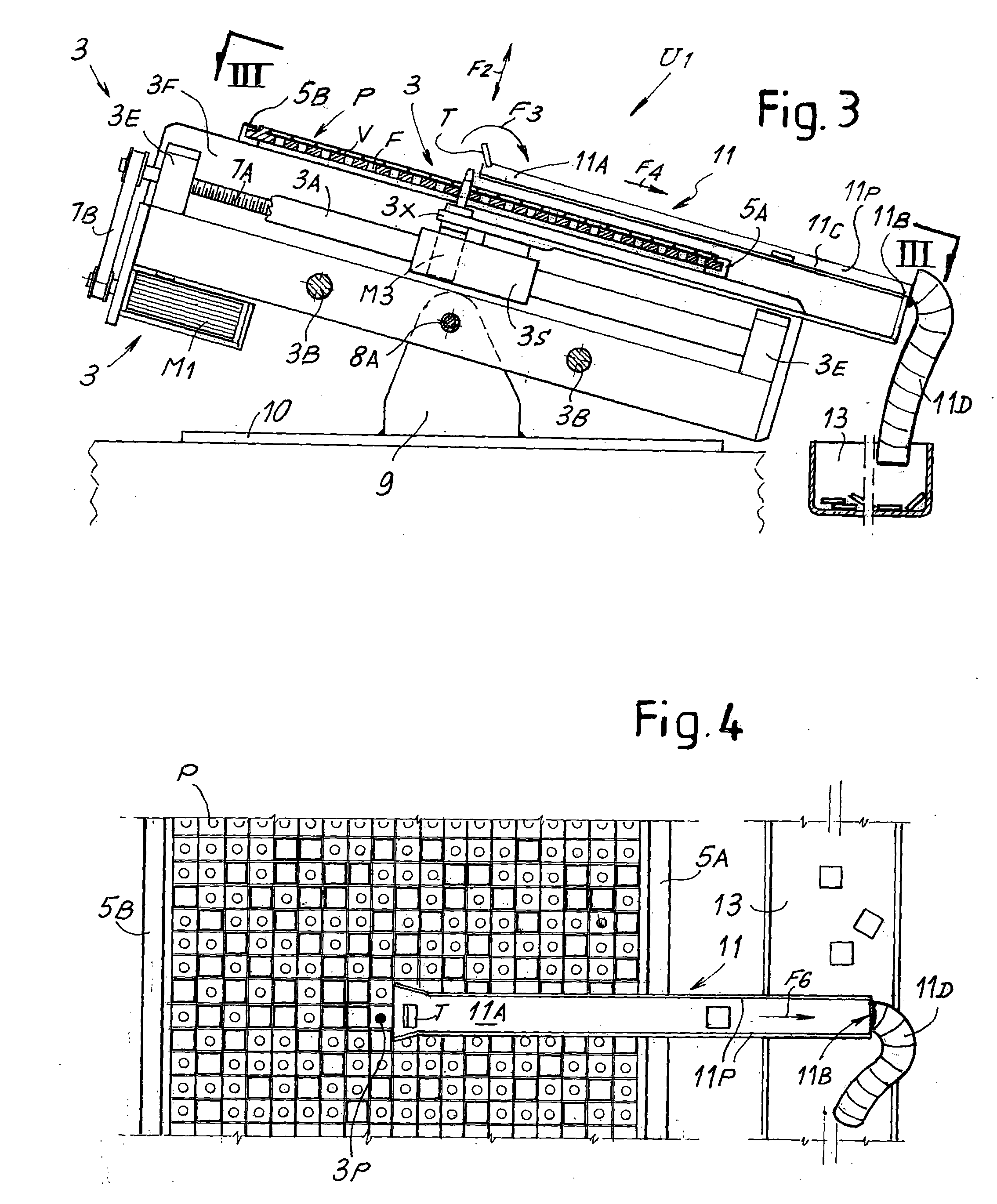

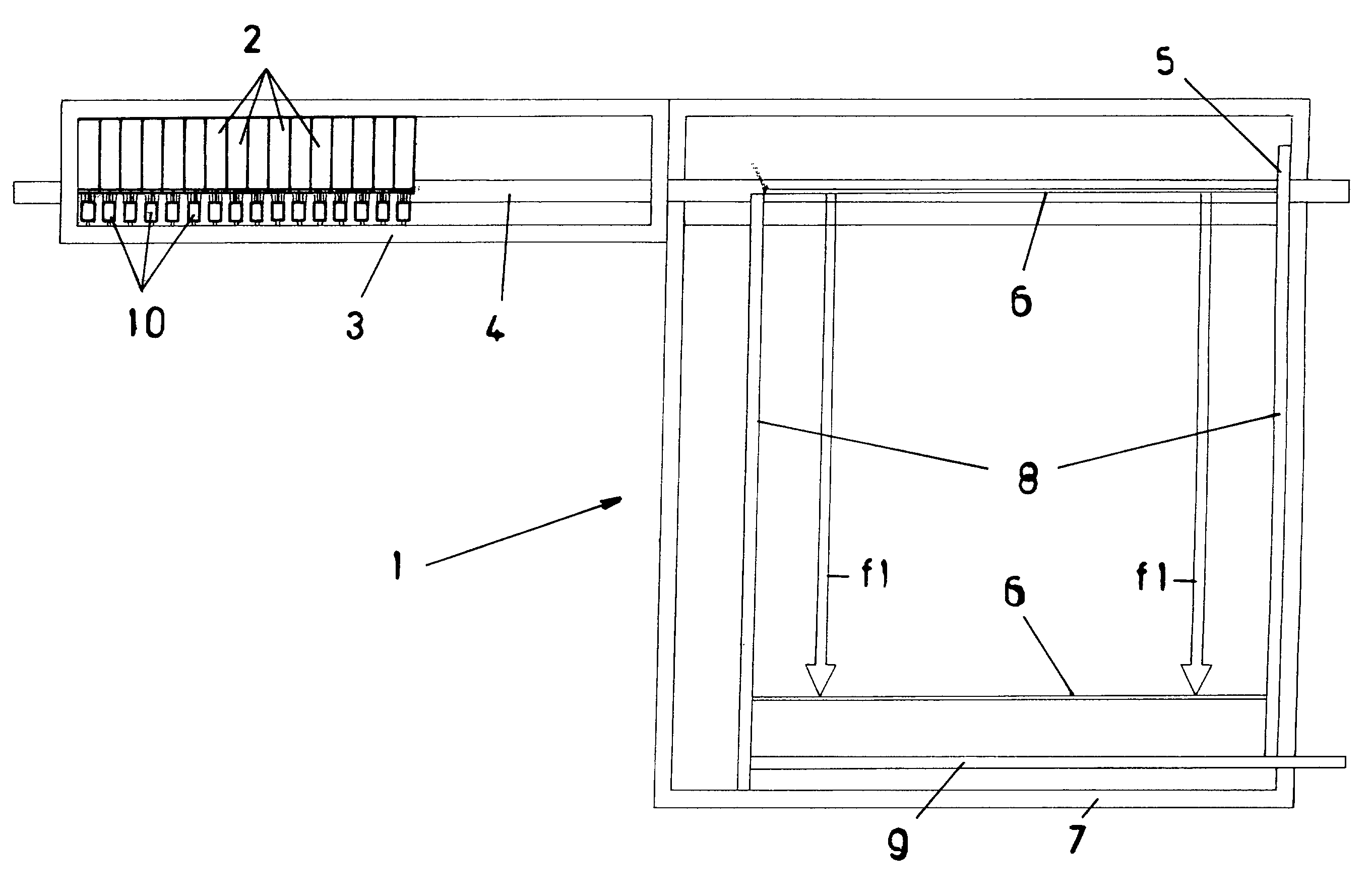

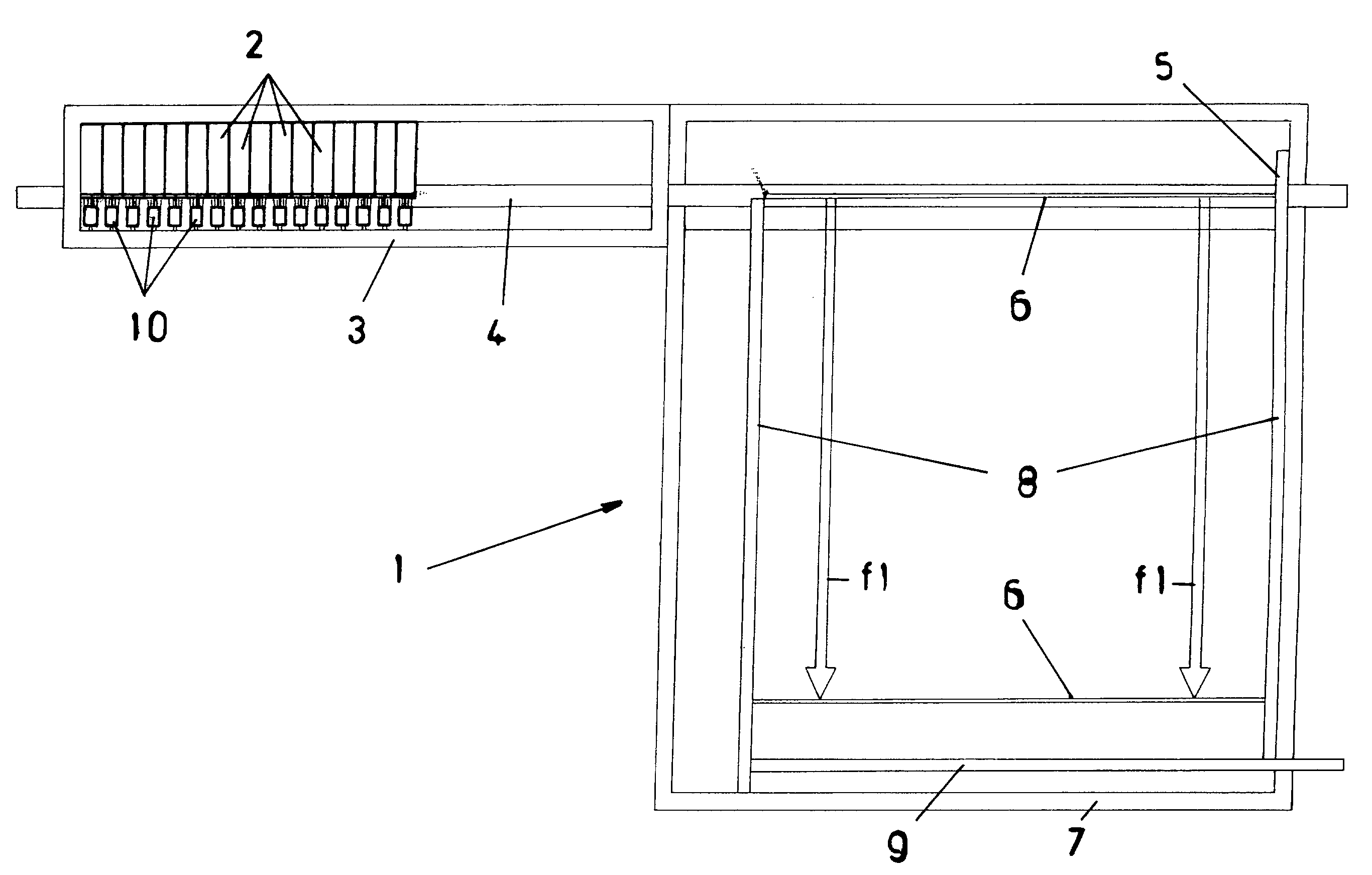

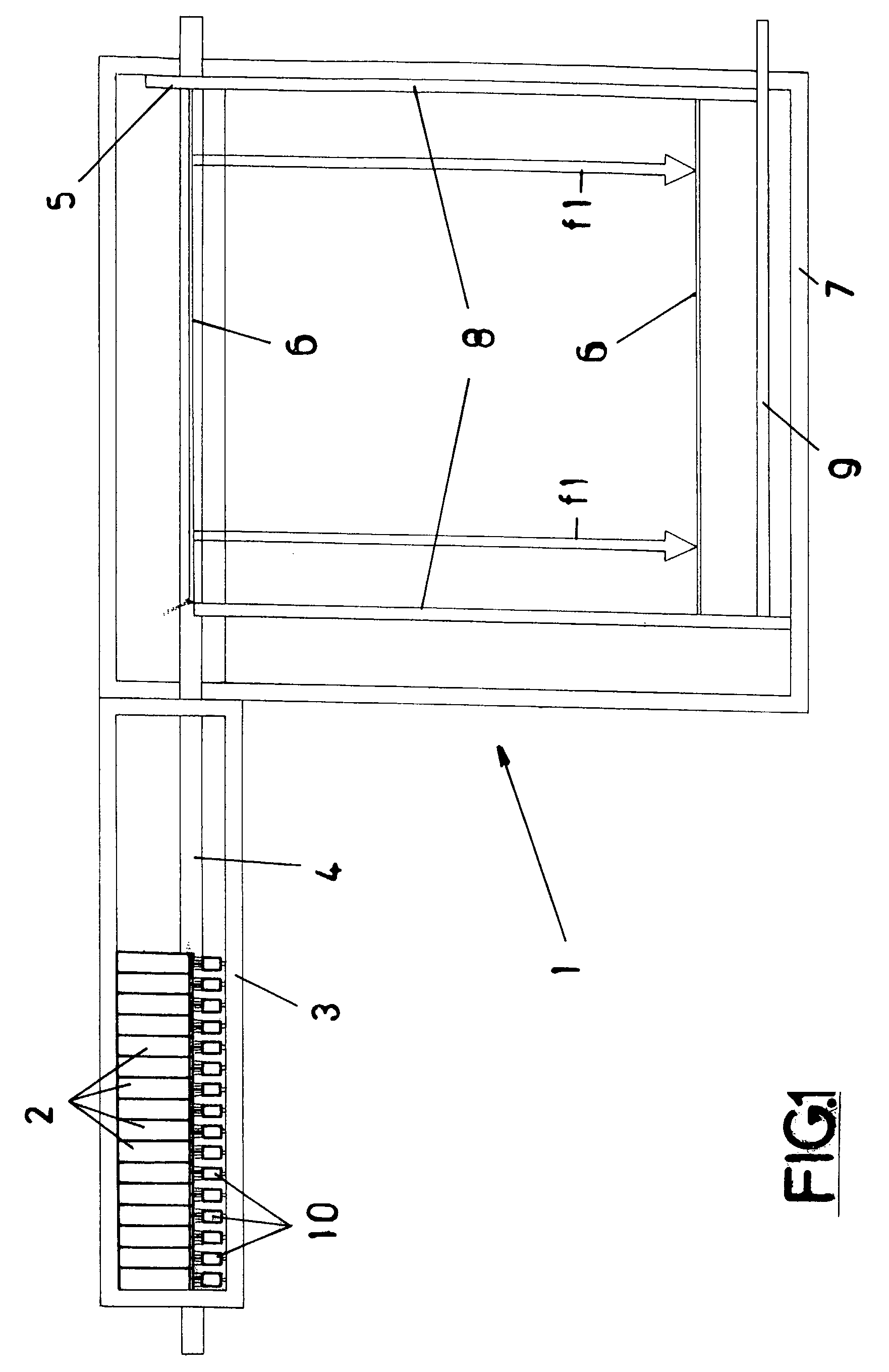

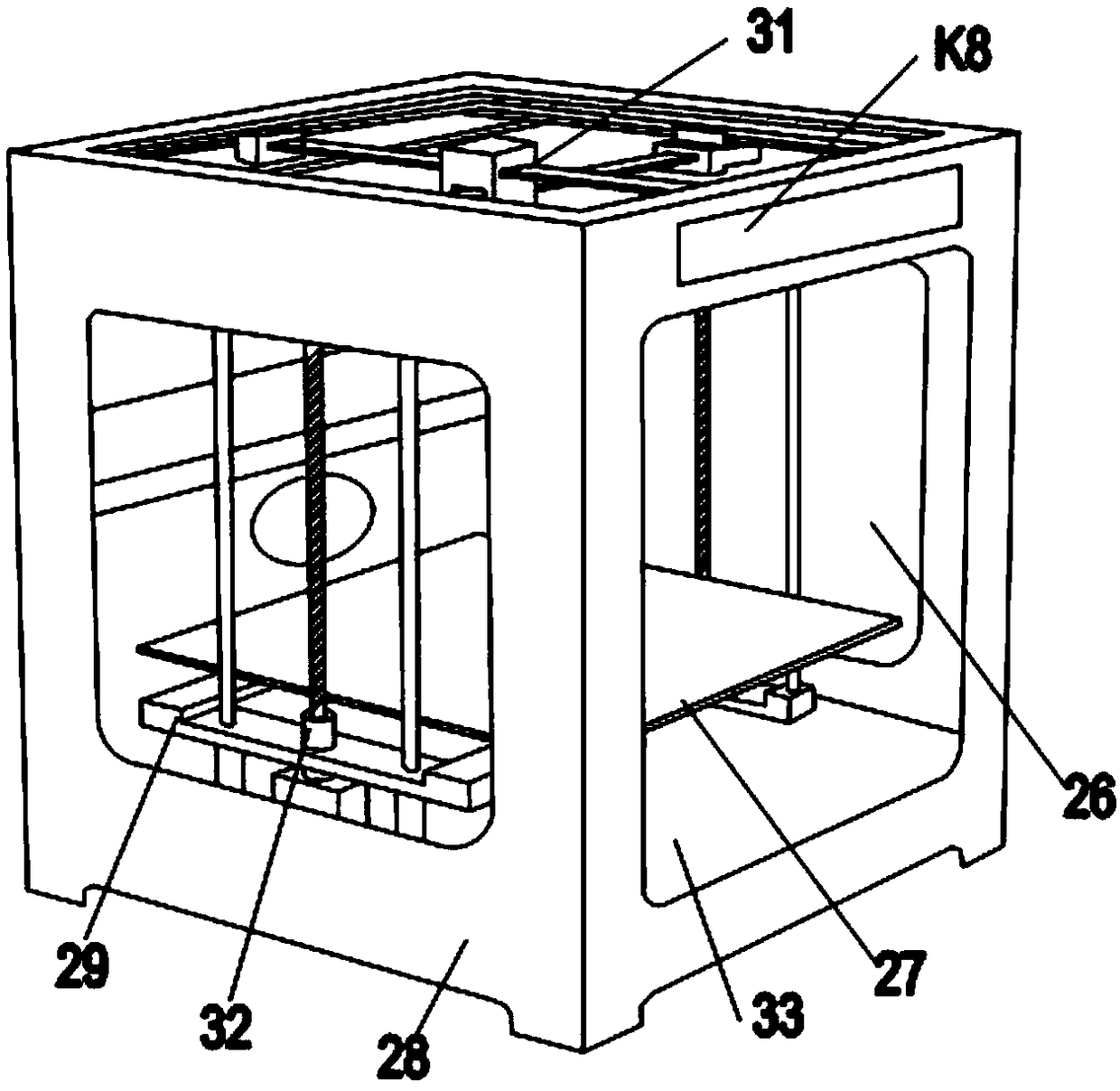

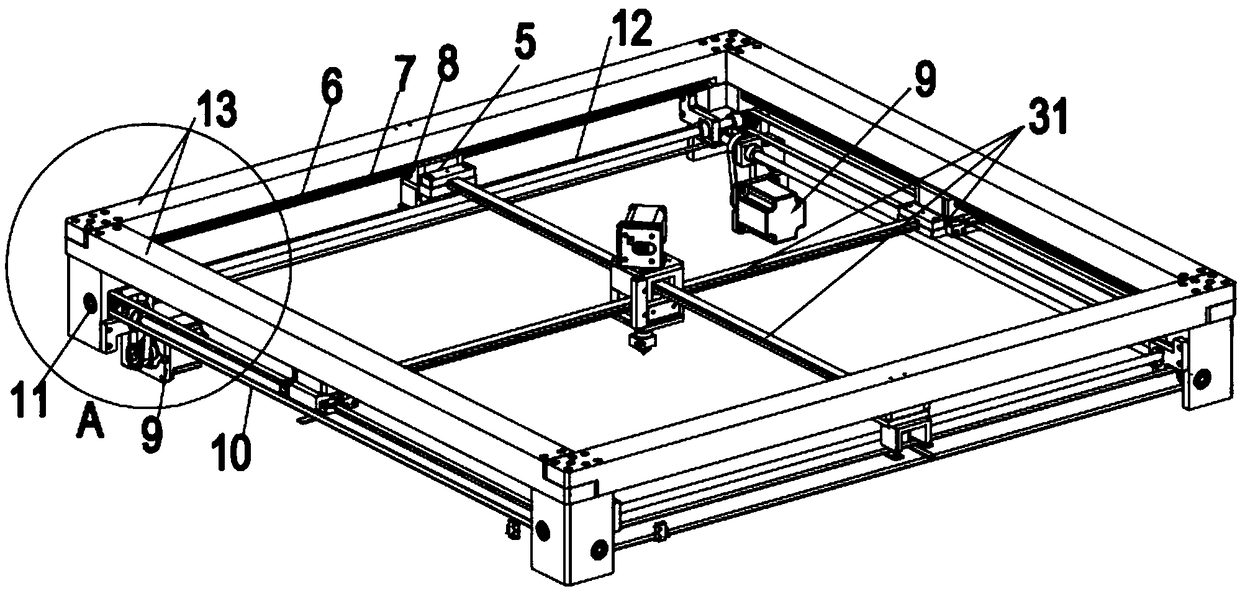

Machine and a method for filling containment panels with tiles to form mosaic patterns

InactiveUS20110088839A1Function increaseHigh level of customizationInlaying equipmentControlling laminationBrickEngineering

A machine fulfilling containment panels (P; P1-Pn) with a plurality of sets of tiles (T; T1, T2, T3), each of said sets of tiles (T; T1, T2, T3) having at least one previously selected characteristic in order to produce a mosaic pattern, comprising at least one remover system (3Z) suitable for removing from said panels (P) any of said tiles (T; T1, T2, 13) occupying positions other than as required.

Owner:VICTRIX GRP

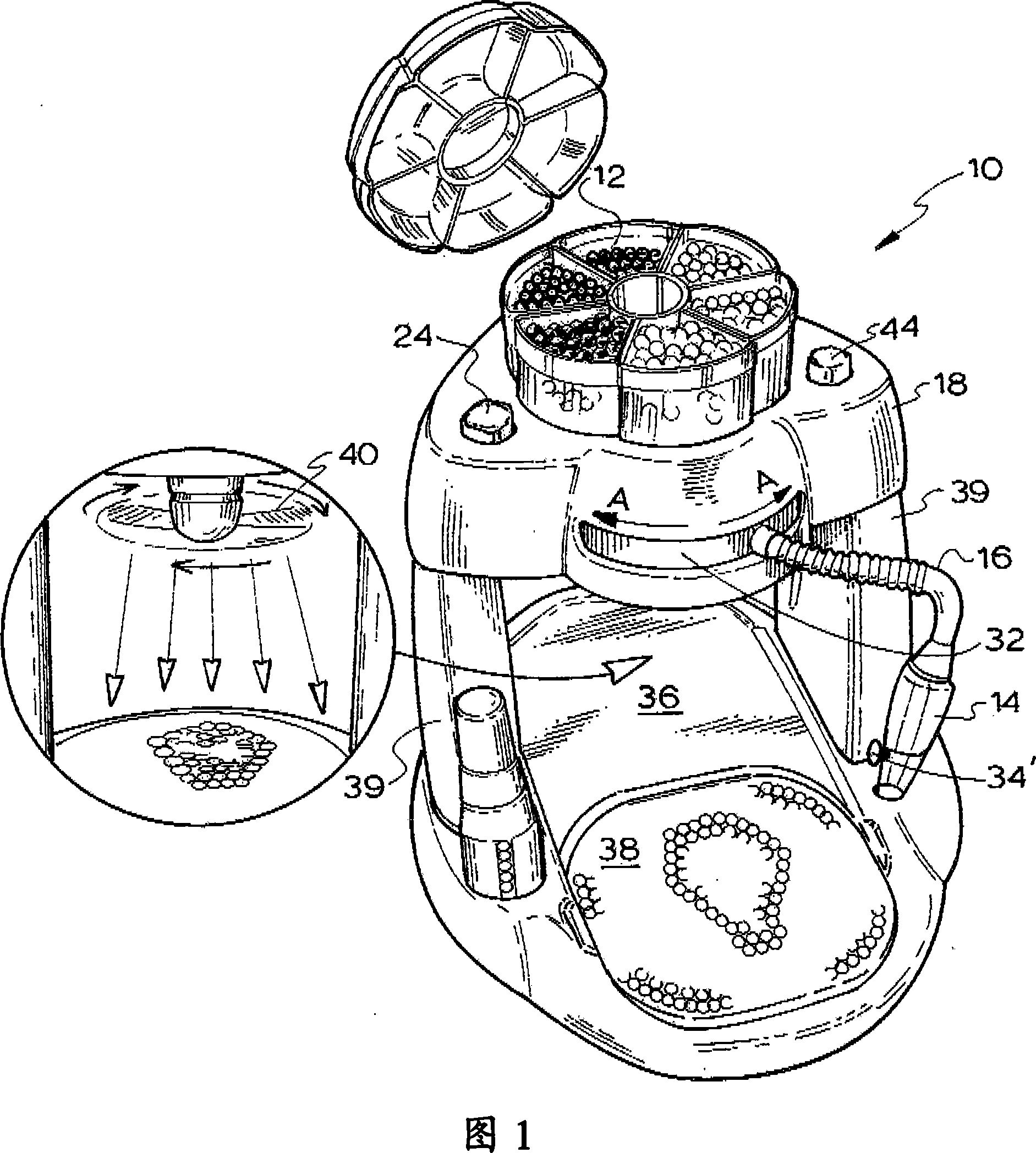

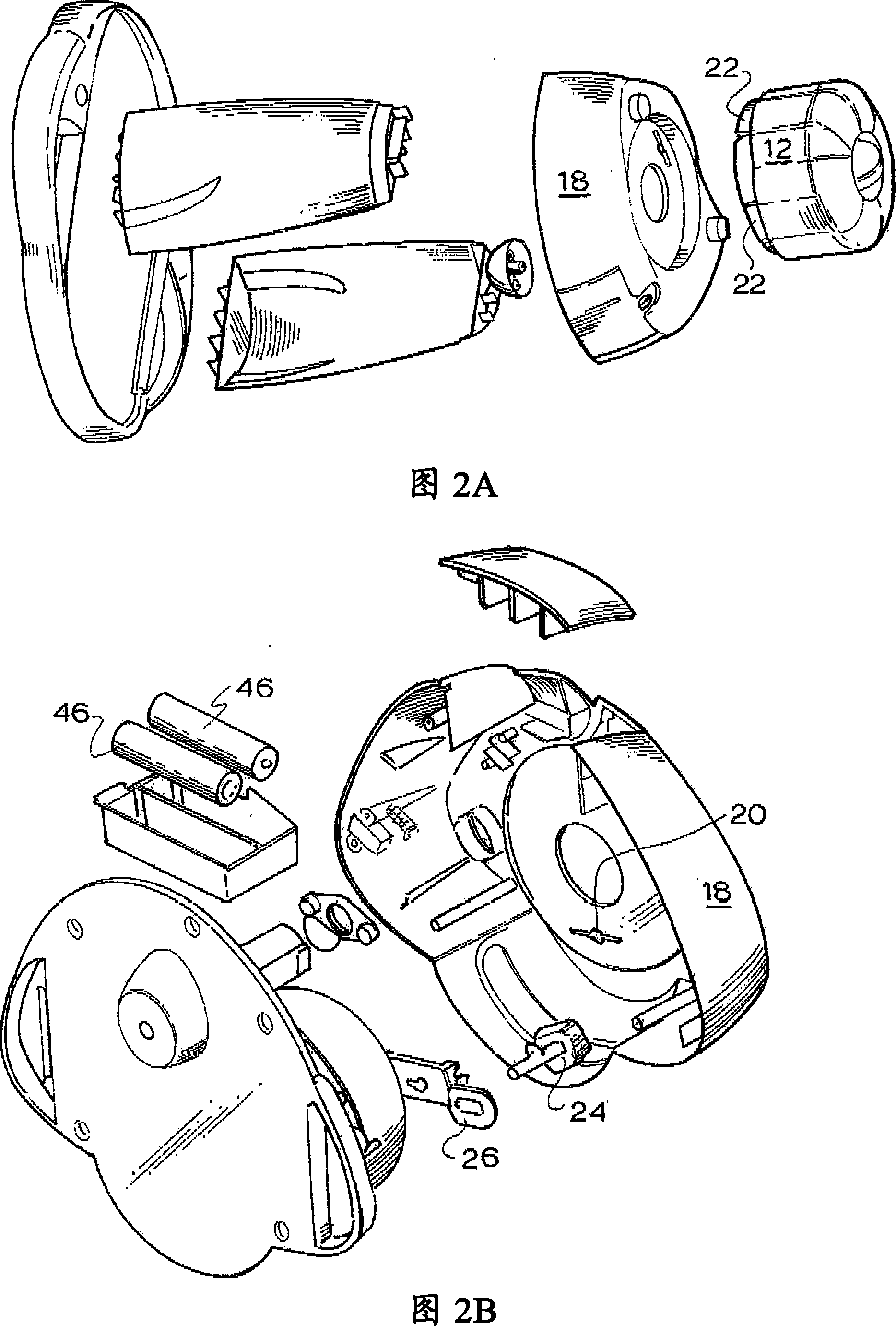

Bead dispensing system

A bead dispensing system including a storage device, a bead dispensing means which includes a bead release mechanism, a conduit for guiding beads from the storage device to the bead dispensing means and a related method of creating artwork, comprising the steps of releasing a row of beads from the storage device into the dispensing means via the conduit, and orderly dispensing the beads to form bead arrangement. By using the bead dispensing system of the invention, the beads can be conveniently controlled, and there is no need to frequently detach the dispensing means for refilling the dispensing means due to the storage device.

Owner:MOOSE ENTERPRISES AUST

Tiling device for mosaic tiles

PendingCN111827638AImprove efficiencyInlaying equipmentGripping headsEngineeringStructural engineering

The invention is suitable for the technical field of tiling, and discloses a tiling device for mosaic tiles. The tiling device for the mosaic tiles comprises suction cups and a handle, wherein the multiple suction cups are installed on the same vacuumizing shell, and fixing and loosening of the suction cups and mosaic tiles are achieved by changing the amount of gas in the vacuumizing shell; and the handle is connected to the vacuumizing shell. According to the tiling device, a plurality of suction cups are arranged at the bottom of the vacuumizing shell, each suction cup corresponds to each small tile on one mosaic tile, when gas in the vacuumizing shell is pumped out, the gas in the suction cups is slowly reduced, so that each small tile is adsorbed to the corresponding suction cup, andcarrying and tiling of the whole mosaic tile can be achieved through the handle; and during tiling, the whole mosaic tile can be kept relatively horizontal, and the tiling efficiency is higher.

Owner:JINHUA WANFENG TOOL FAB

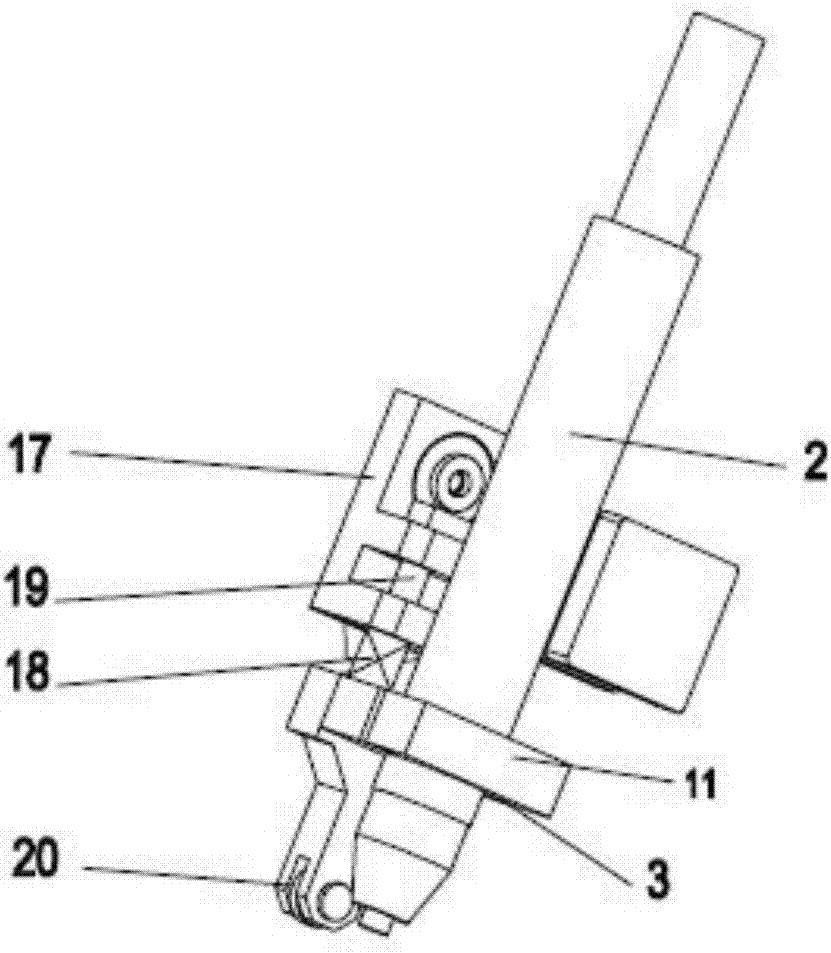

Nail carving gun

InactiveCN108000441AStructural scienceNovel methodInlaying equipmentNailing toolsPower flowEngineering

The invention discloses a nail carving gun comprising a gun boy; the gun body is internally provided with a smoothbore, a gun nozzle, a nail box, a nail hammer, a firing pin, a starting electromagnet,an accelerating electromagnet, a buffer spring tube, and a reset spring tube; the gun nozzle is arranged at the front end of the smoothbore; the nail box is arranged on the smoothbore of the tail endof the gun nozzle in a sleeving mode; the nail hammer is slidaly arranged in the smoothbore, and an annular strong magnet is arranged inside the nail hammer; the firing pin is fixed under the nail hammer; the starting electromagnet is arranged at the tail end of the smoothbore; the accelerating electromagnet is arranged on the starting electromagnet; the buffer spring tube is arranged in the smoothbore and is fixed on the upper end of the accelerating electromagnet; the reset spring tube is arranged in the smoothbore and fixed on the lower end of the starting electromagnet; and the outer surface of the annular strong magnet is sleeved with an elastic protective sleeve. The nail carving gun has the advantages of scientific structure and novel method; and according to the nail carving gun,regenerative natural wood or bamboo wood are used as materials, the display arrangement of nails in a carrier and the depth of embedding into the carrier are controlled, and a variety of concave lattice patterns can be realized to form a unique artistic nail carving; and the magnetic force of an electromagnet is controlled as power through electric current, the control is flexible, and the degreeof automation is high.

Owner:FOSHAN LANTU TECH CO LTD

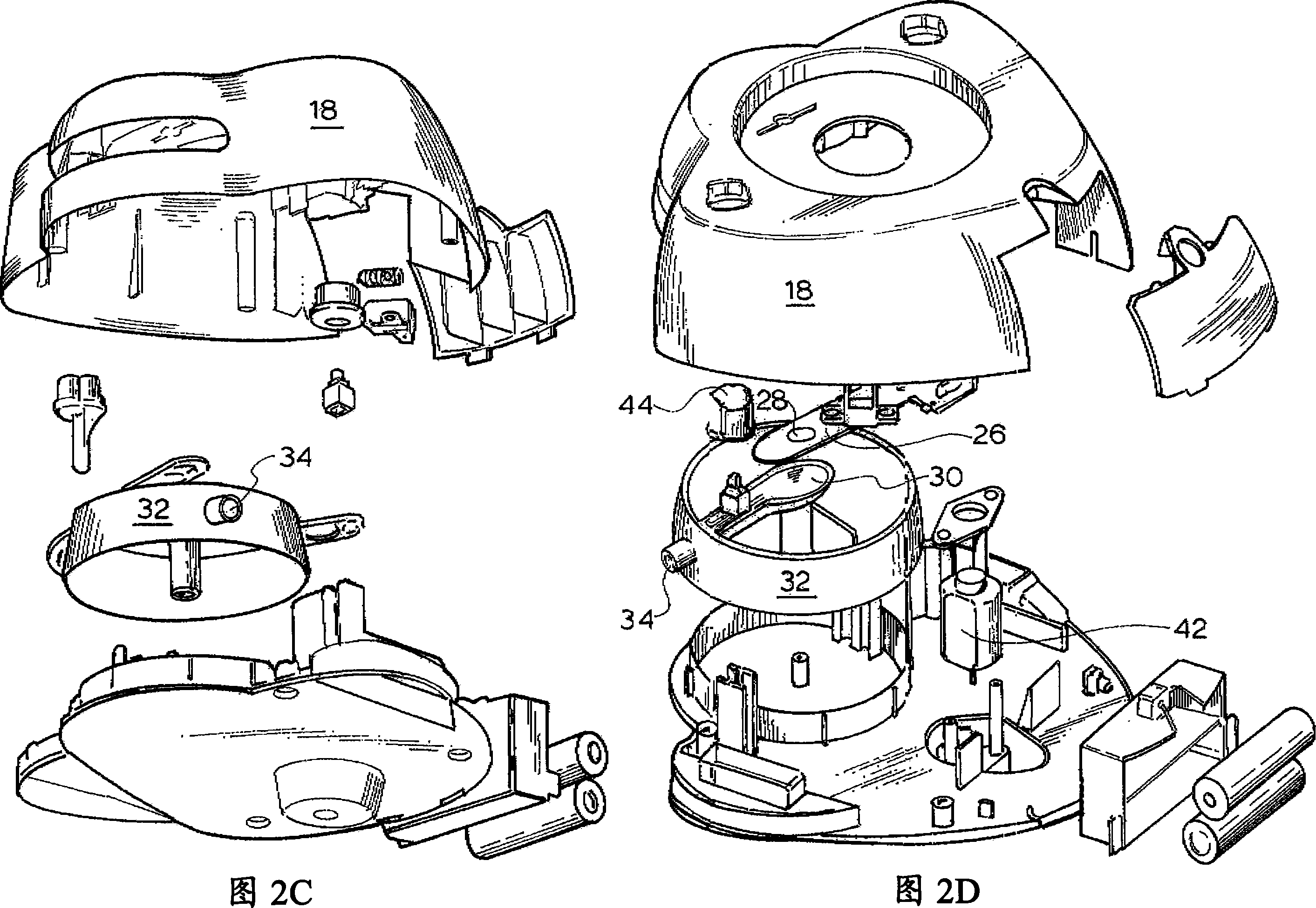

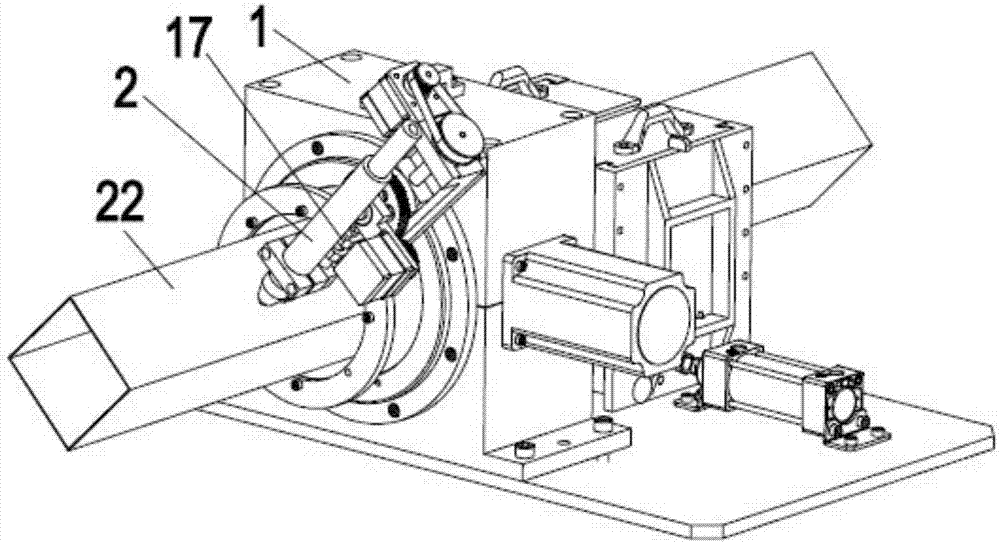

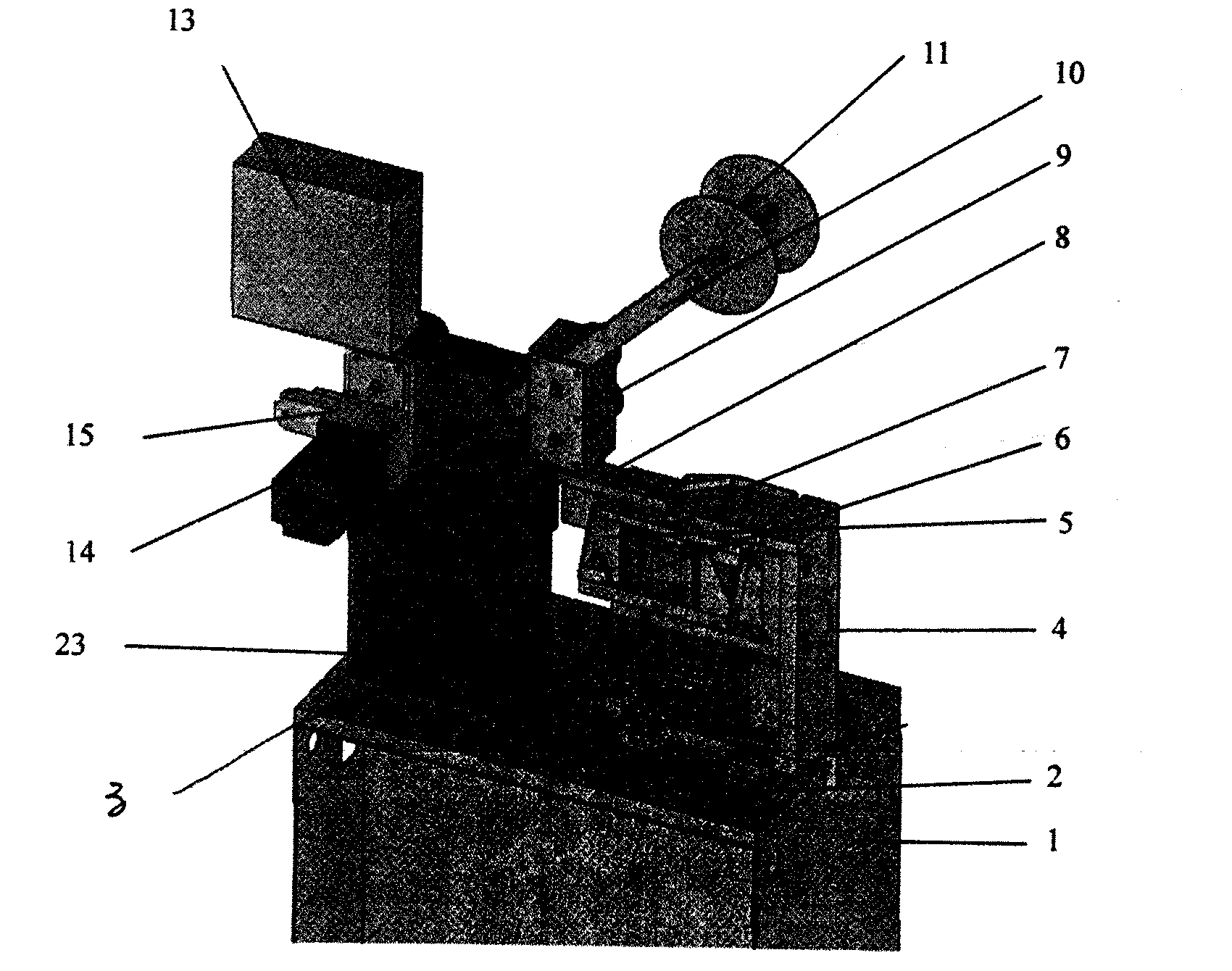

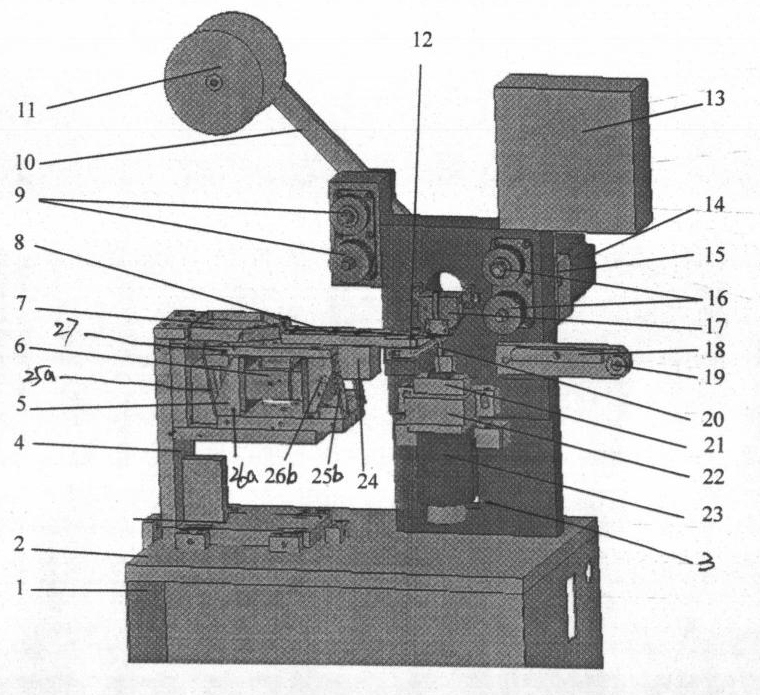

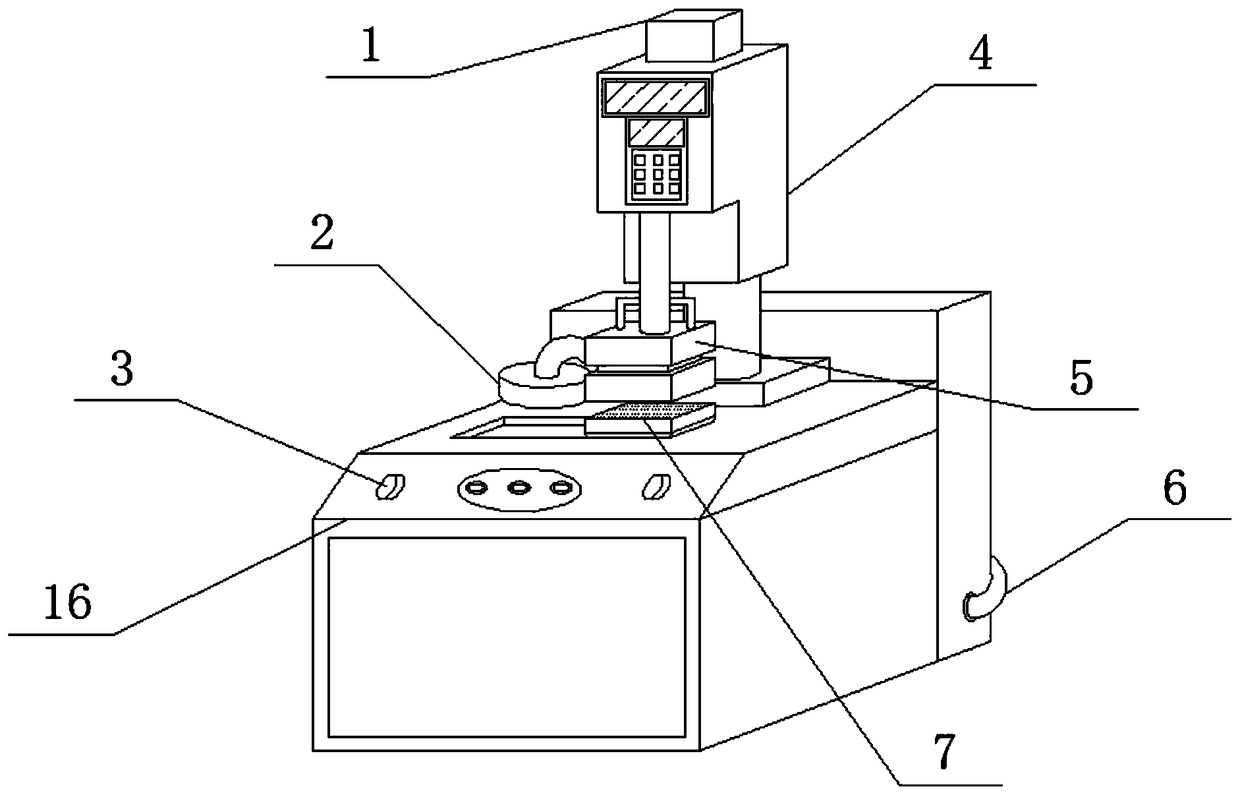

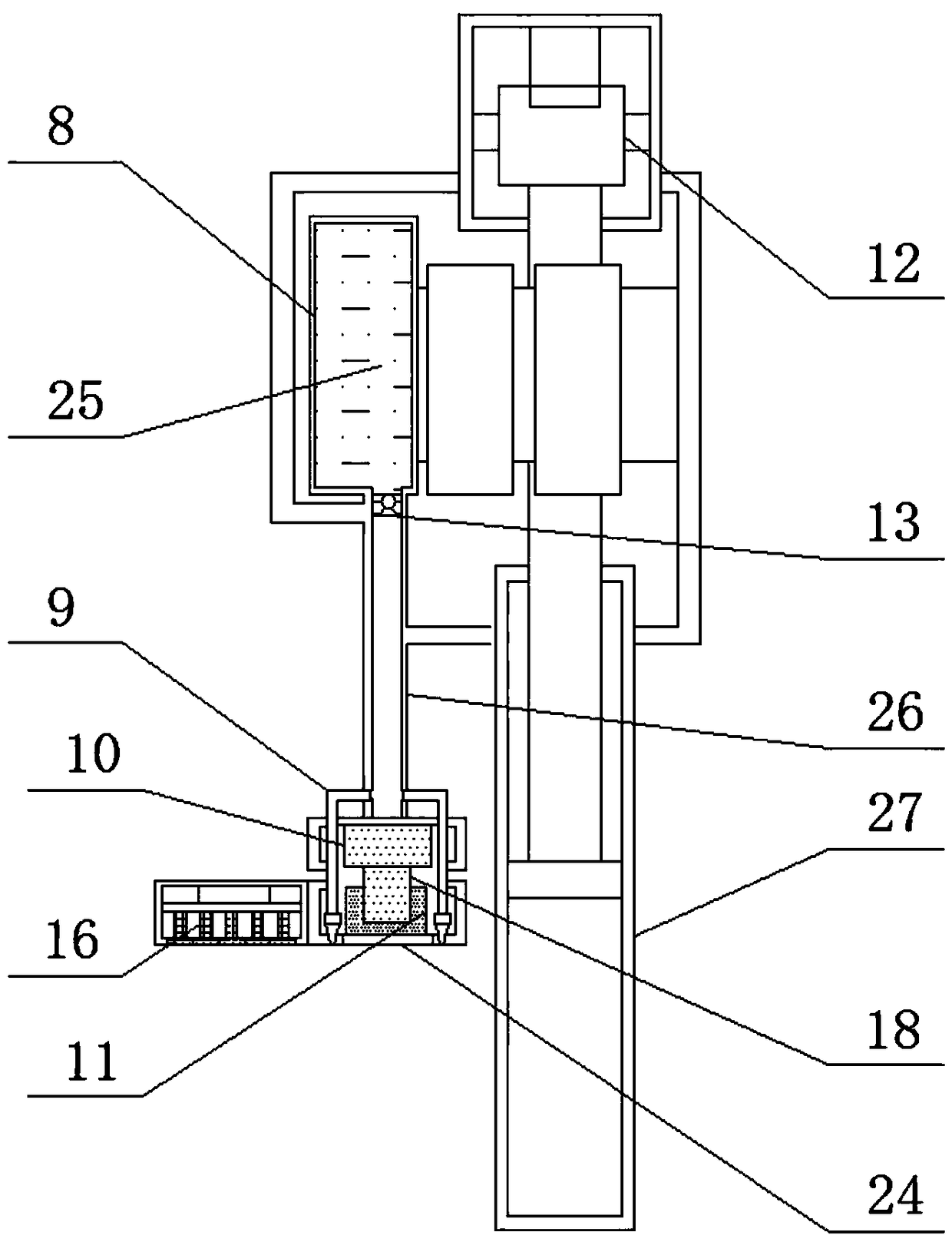

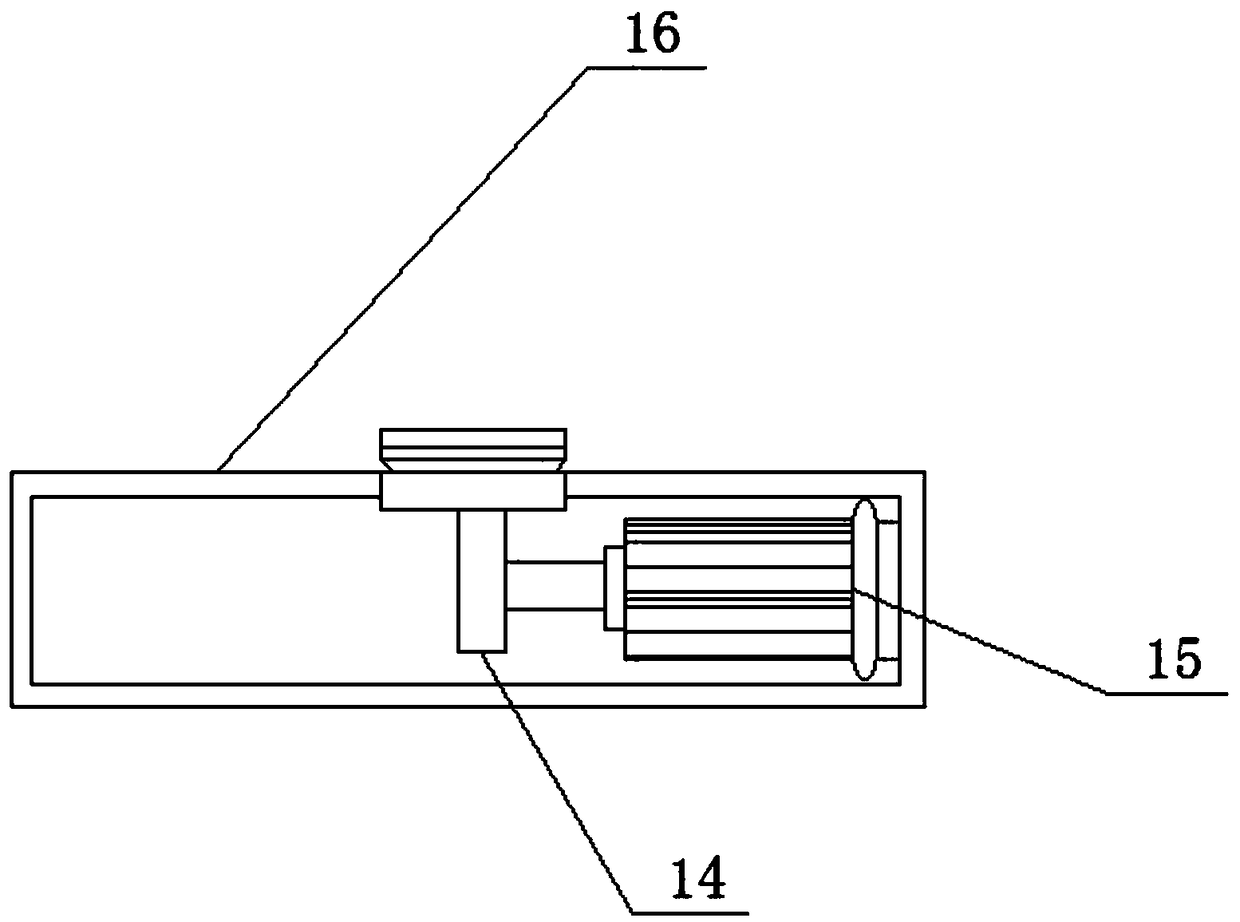

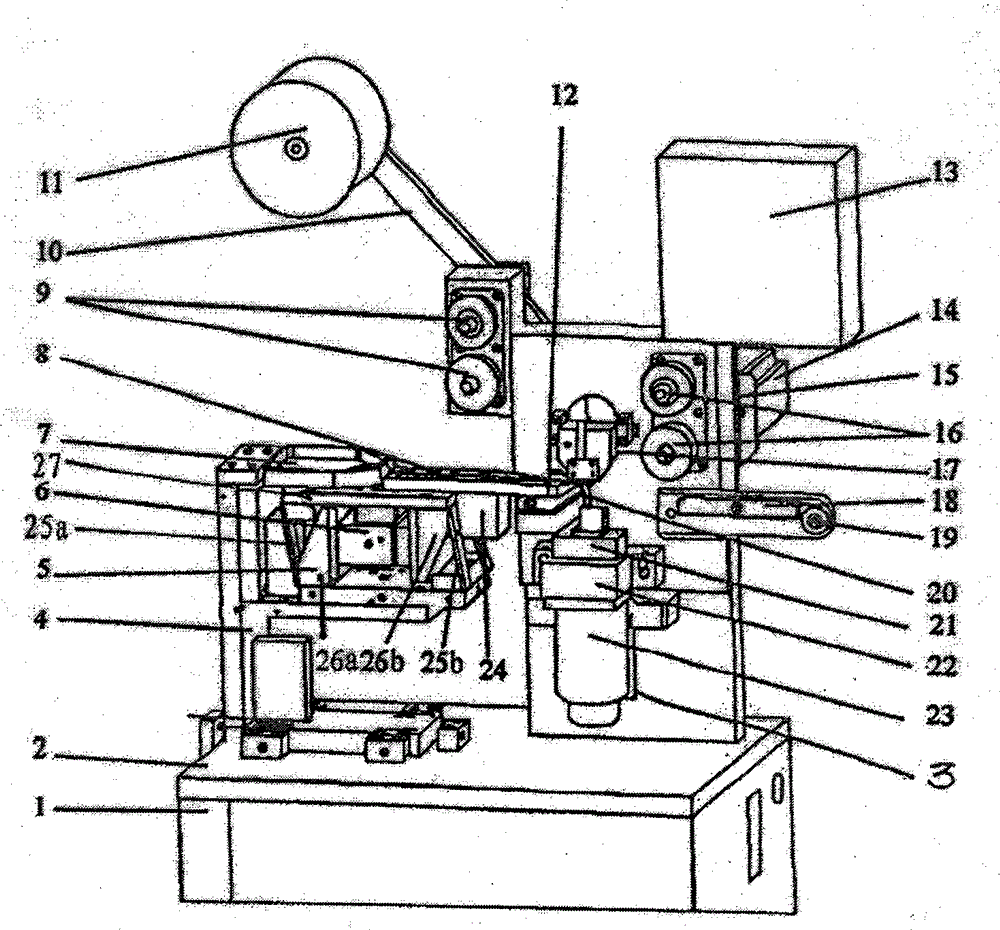

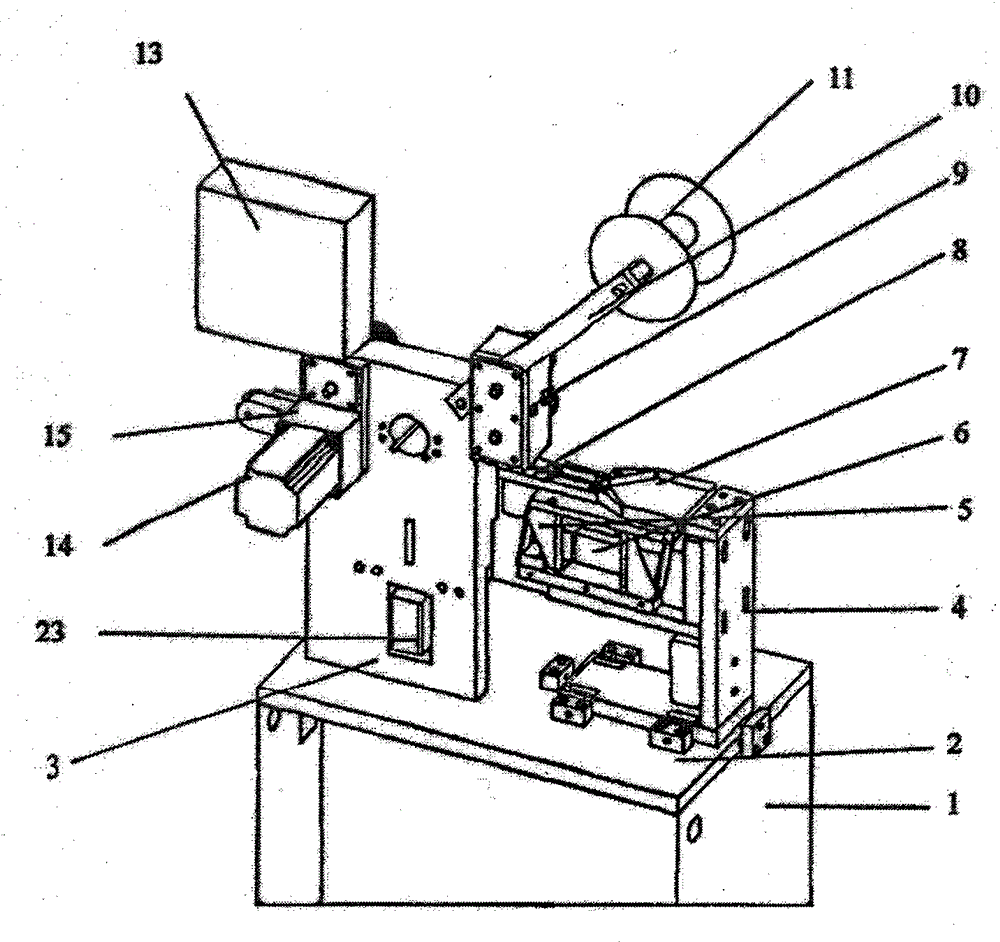

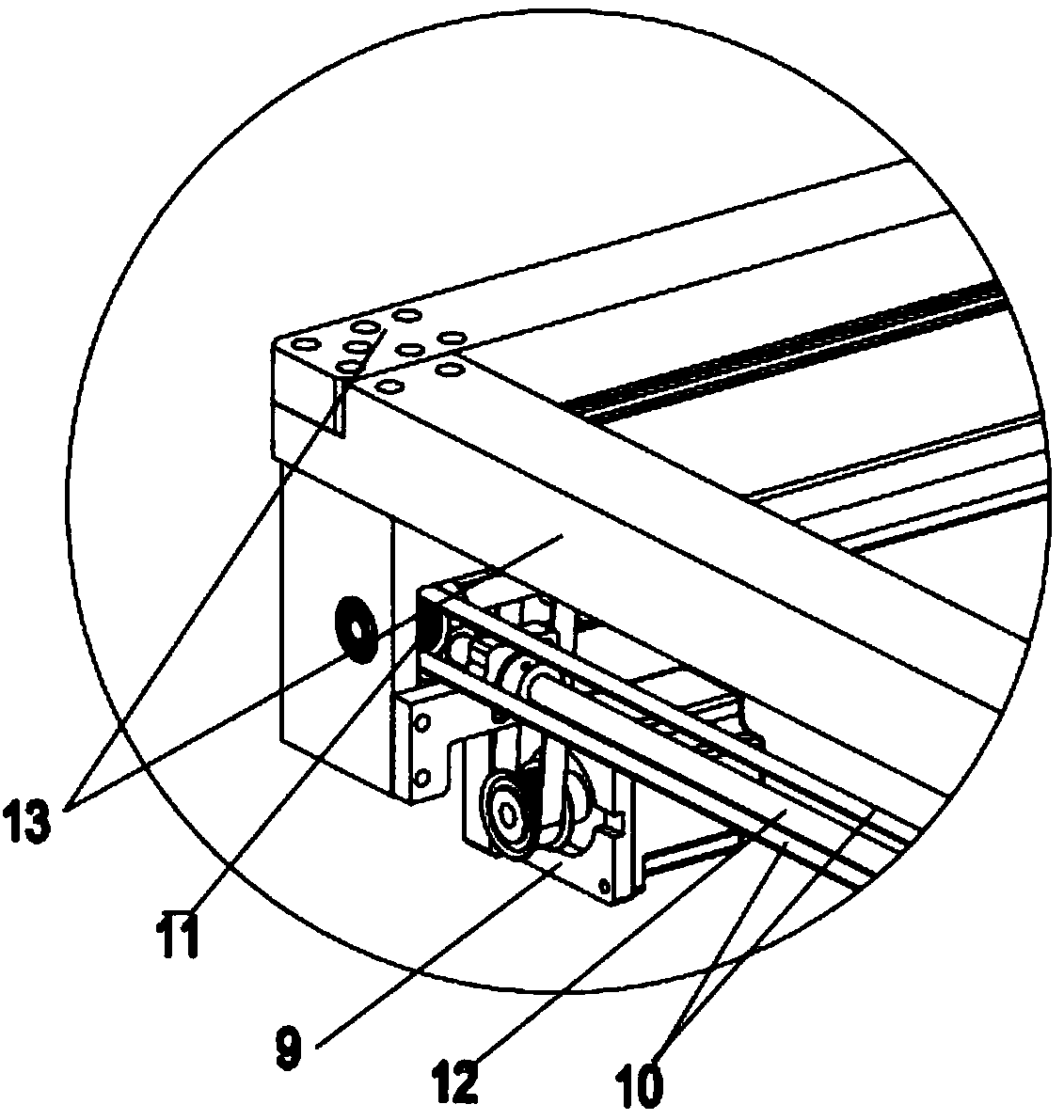

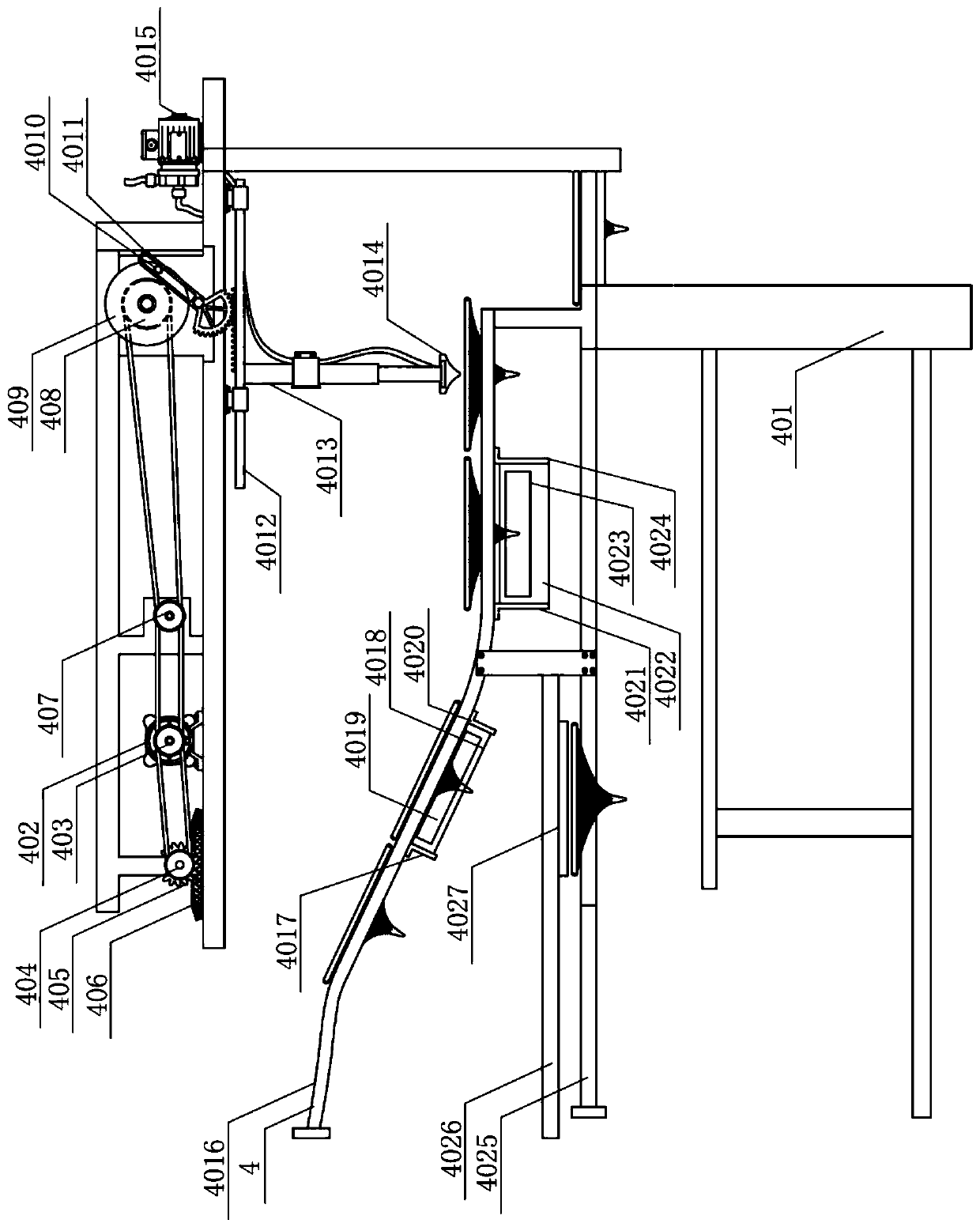

Crystal trinket embedding machine

InactiveCN102069670ASimple stand-alone structureReliable controlInlaying equipmentSprocketEngineering

The invention relates to a crystal trinket embedding machine, which consists of a rack, a feeding mechanism, a stamping mechanism, a control mechanism and a chain feeding mechanism, wherein the rack comprises a bottom plate and supporting components; the feeding mechanism comprises vibration wedges, a feeding trough, a feeding channel, a coil holder, a coil and leaf springs; the stamping mechanism comprises a punch head, a punch head seat, an electromagnet seat, an electromagnet, a photoelectric seat and a stamping seat; the control mechanism comprises a control panel 13 and a photoelectric sensor arranged below the output end of the feeding channel 8; and the chain feeding mechanism comprises a small chain feeding wheel and pedestal, a large chain feeding wheel, a long support bar, a stepped motor, a motor seat, a small chain feeding wheel, a short support bar and a chain discharge wheel. The crystal trinket embedding machine has the characteristics of simple single structure, reliable control way, no need of matching auxiliary equipment, whole-process running automation, embedding force adjustability and embedding speed controllability, and has high embedding speed, high efficiency and wide application.

Owner:ZHEJIANG NORMAL UNIVERSITY

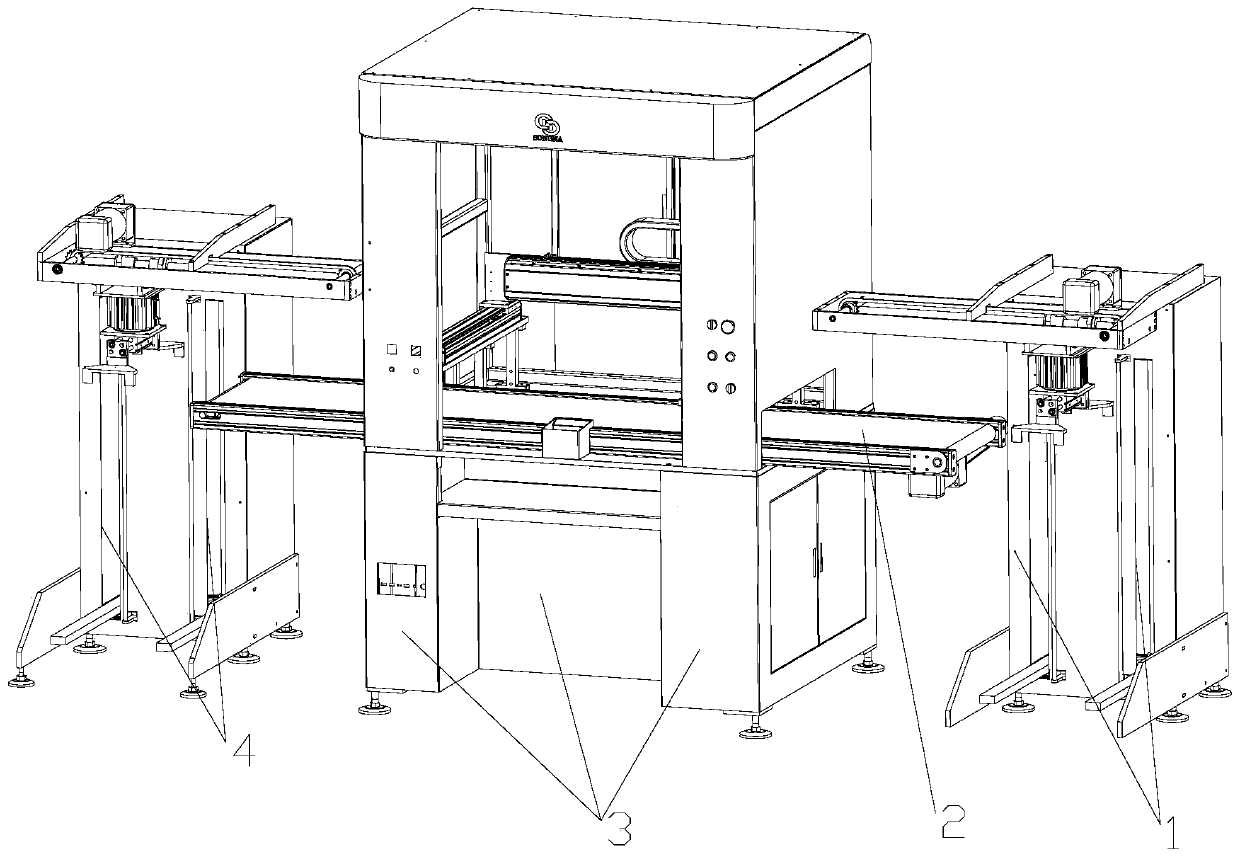

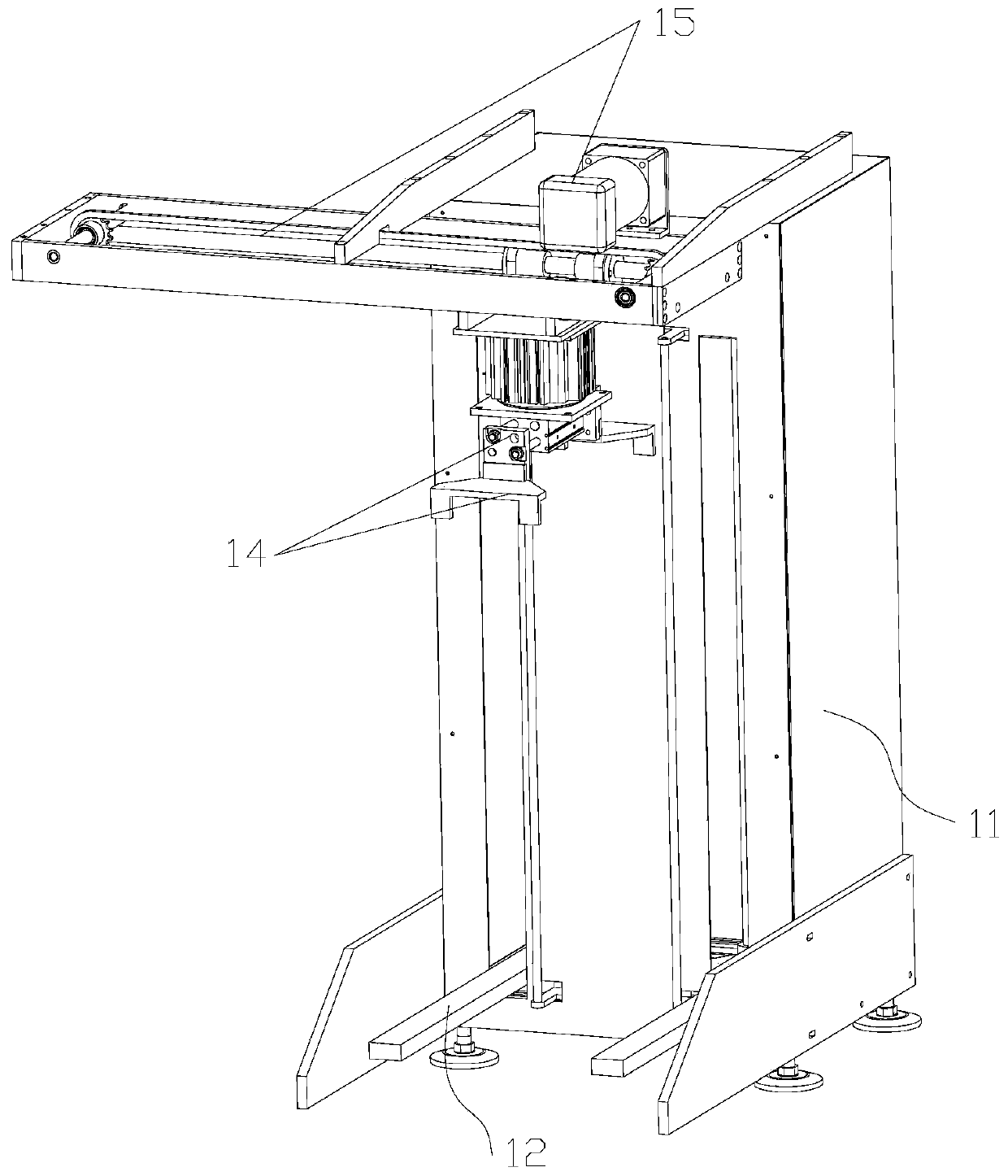

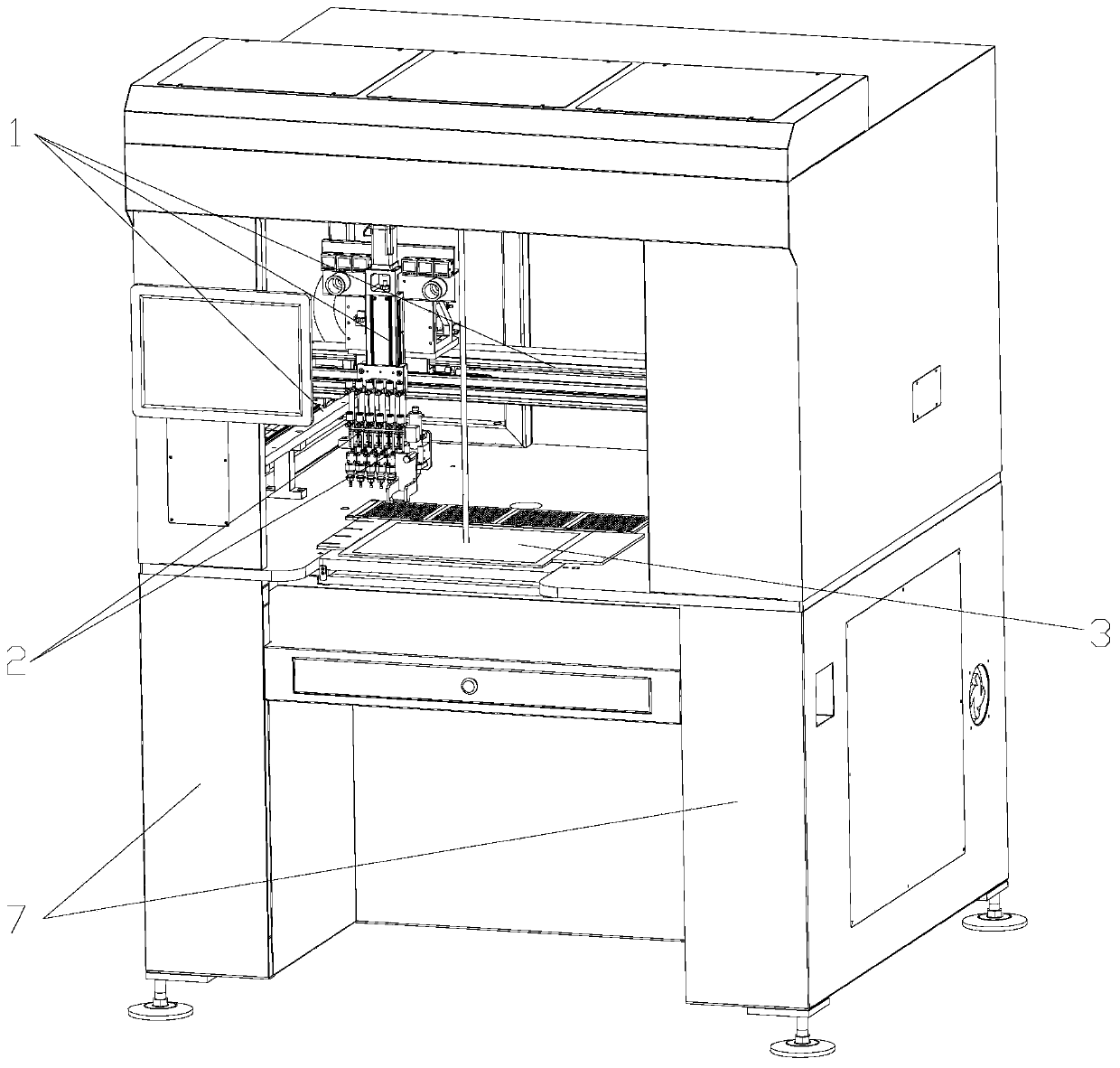

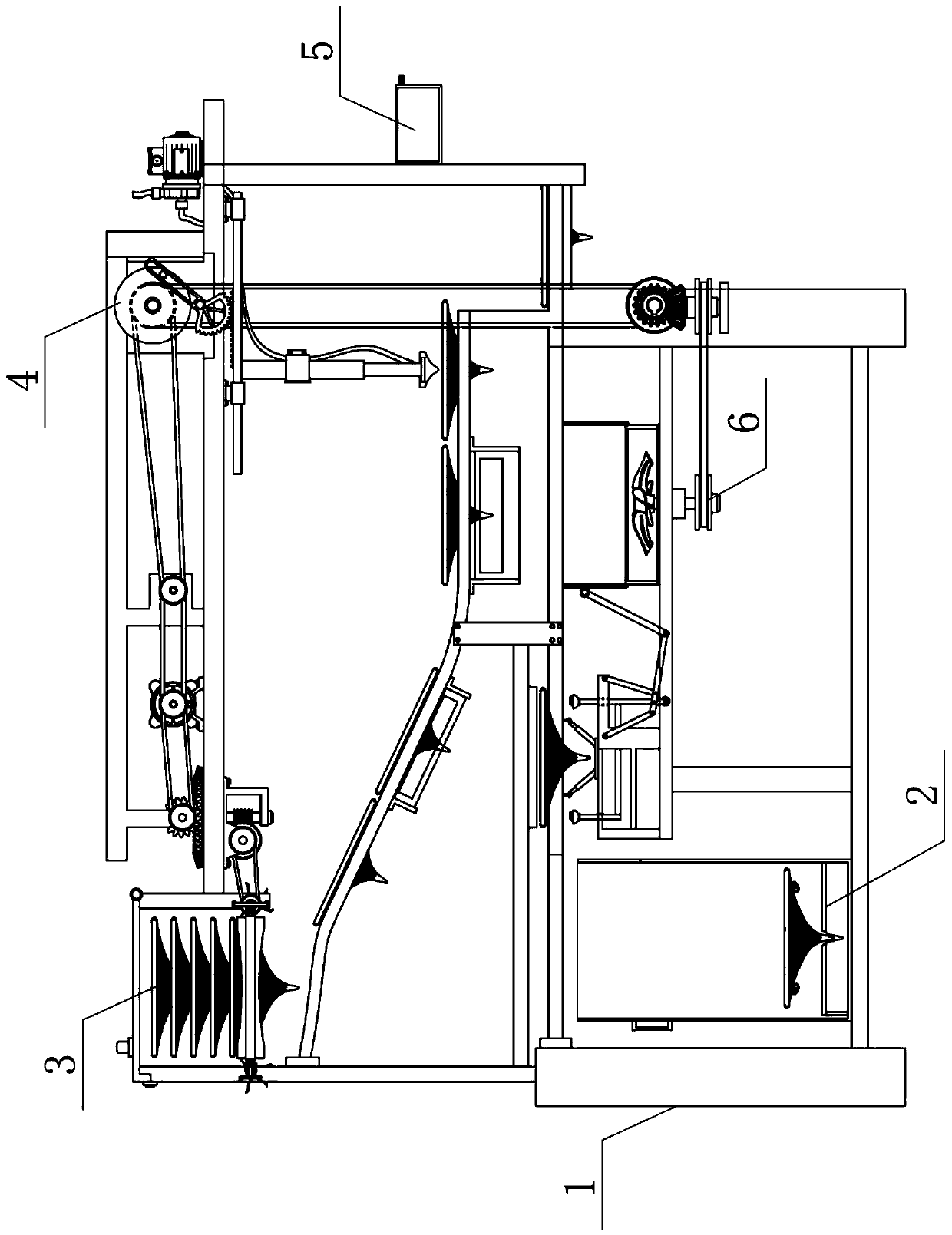

Automatic point drilling machine with loader and unloader

The invention discloses an automatic point drilling machine with a loader and unloader. The automatic point drilling machine comprises a loading device, a conveying device, a dispensing and drilling device and an unloading device, a workpiece is placed on the loading device, the loading device places the workpiece on the conveying device, the conveying device drives the workpiece to move to the dispensing and drilling device, the dispensing and drilling device conducts adhesive dispensing and spot drilling on the workpiece, the conveying device drives the workpiece to move to the unloading device, and the unloading device unloads the workpiece. According to the automatic point drilling machine with the loader and unloader, workpieces can be automatically loaded through the loading device,then conveyed to the dispensing and drilling device through the conveying device to be subjected to dispensing and drilling machining, and can be automatically unloaded through the unloading device after machining is completed, so that manual loading and unloading are not needed, and the working efficiency is improved.

Owner:广州尚纳智能科技有限公司

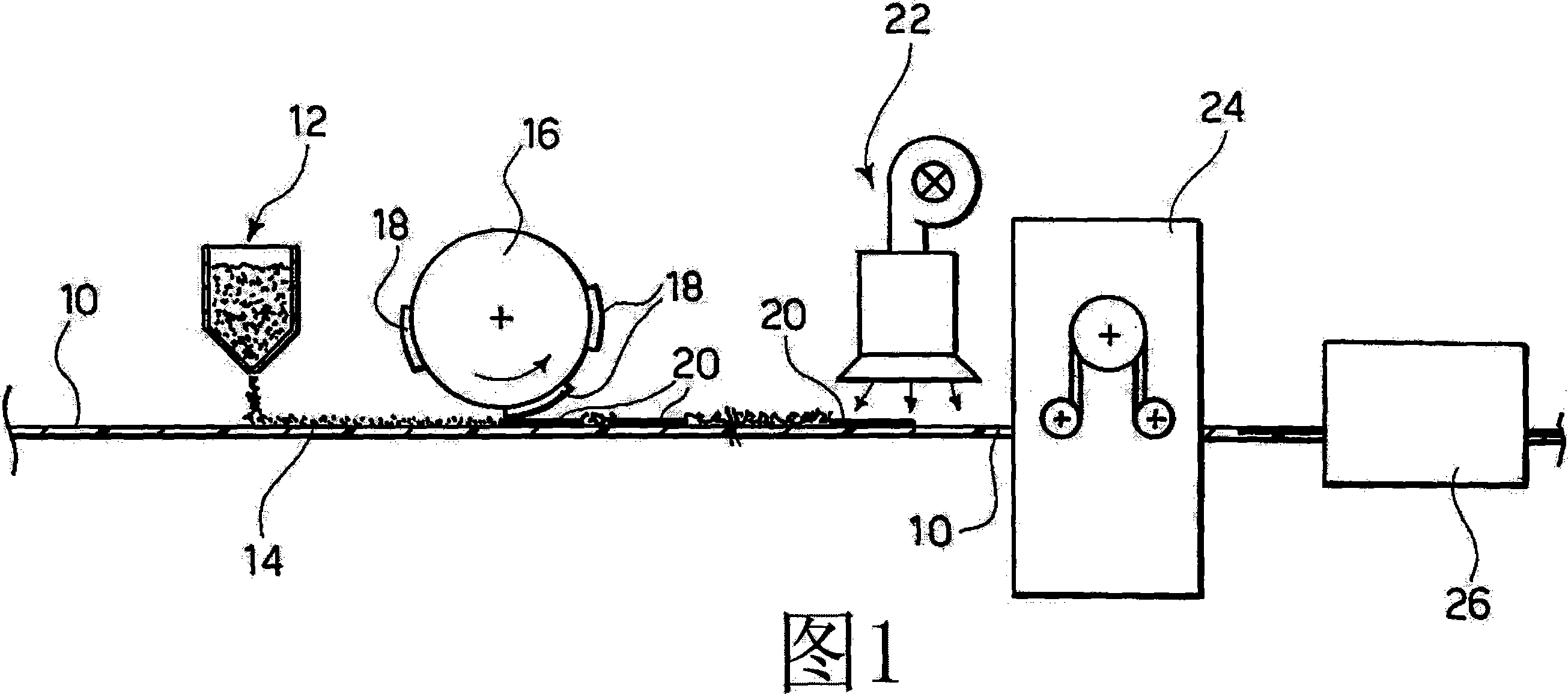

Method and device for the reproduction of images using glass pixels

A method and device are described for the reproduction of a certain image, previously digitalized and separated into a number of pixels and optimized into a number of colors below a certain limit, with the help of a specific software application. The method includes the construction of individual colored elements that correspond to each of the colors selected for the image, where these elements or pixels consist of small cubic parts made of glass or similar. The method and the device include the means for extracting said pixels from the individual containers and positioning them sequentially for the formation of successive rows which, placed next to each other, form the desired image. The desired image or mosaic is completed with the support for the pixels made of an appropriate material, where the pixels are bound to each other and / or to the support by means of a process of adhesion or the application of heat in an oven up to the temperature at which the material softens.

Owner:ALZABA

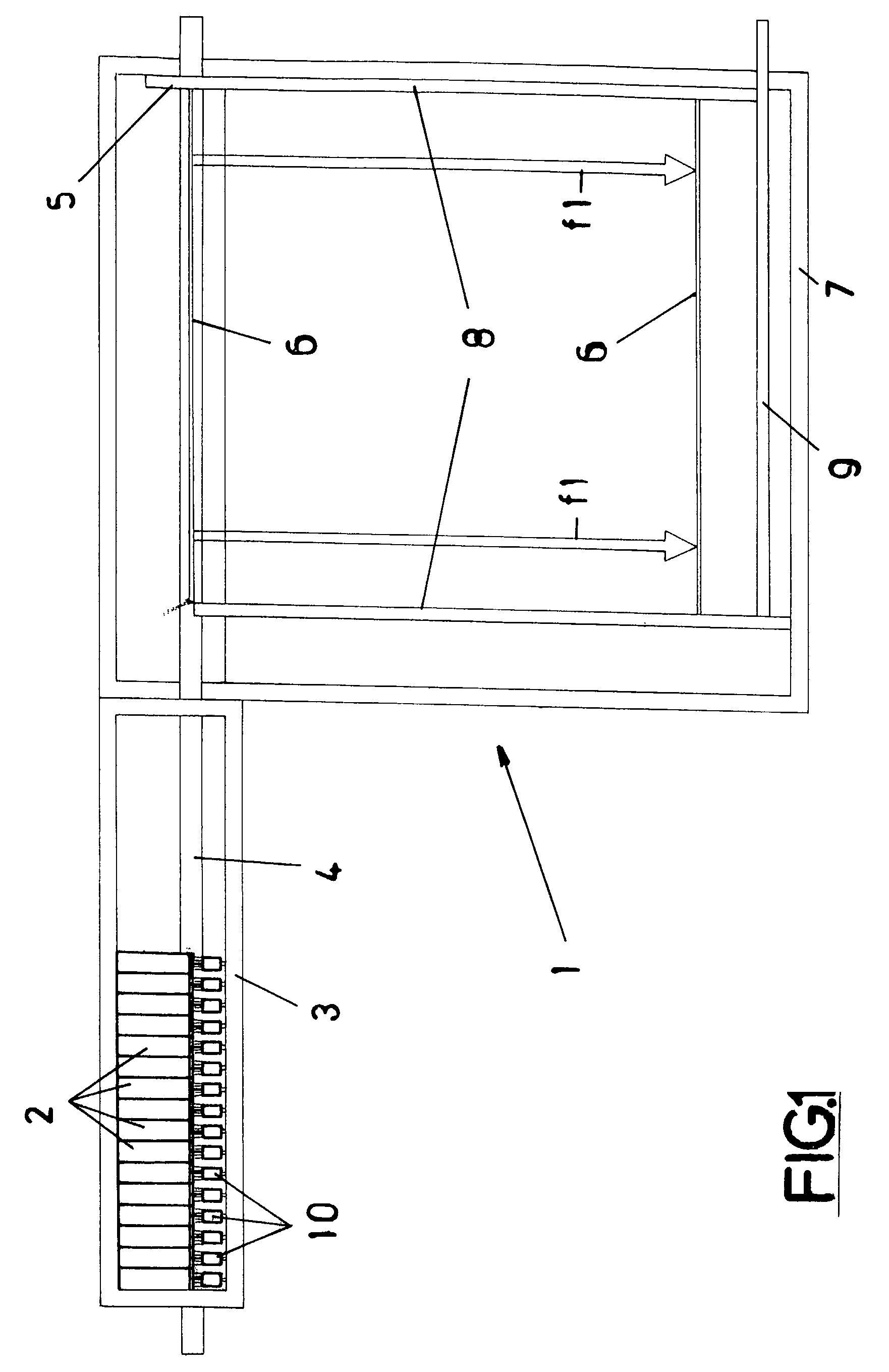

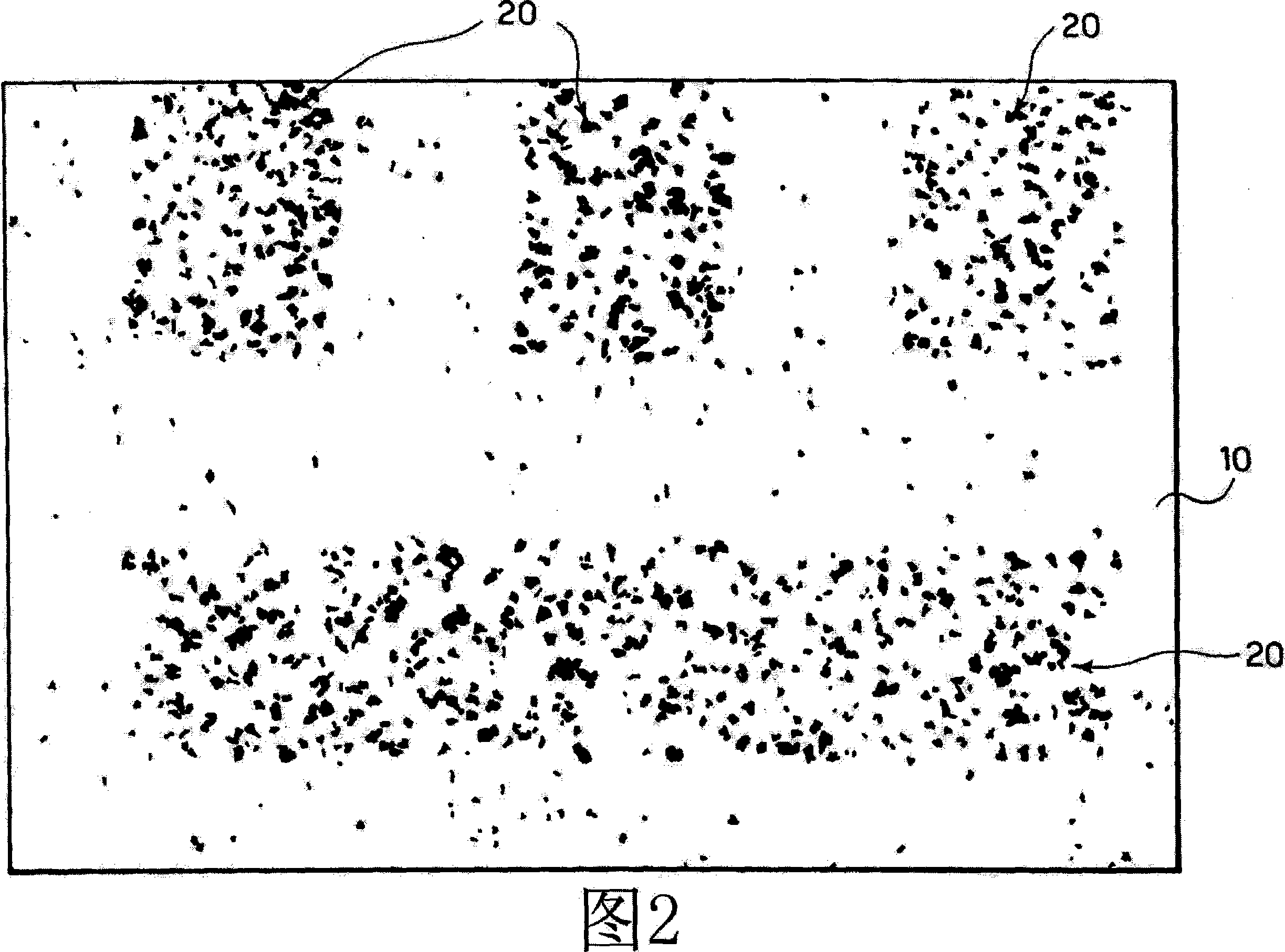

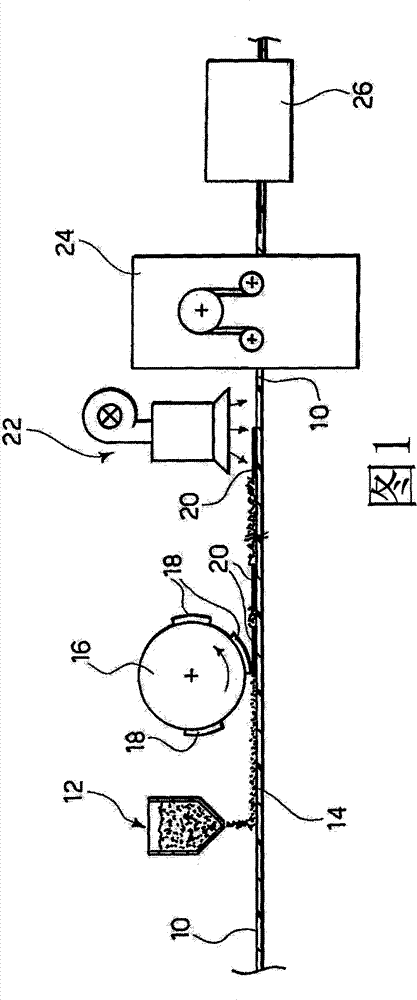

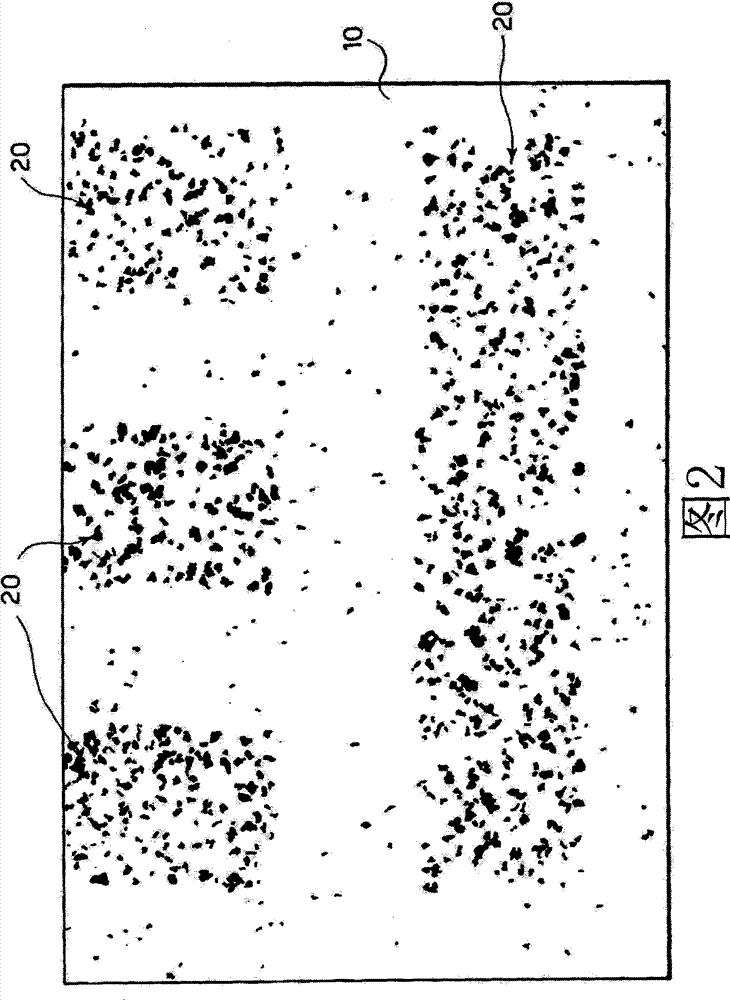

A method for producing graphic signs on covering materials, such as floorings, and related covering material

ActiveCN101125507AImprove bindingInlaying equipmentDecorative surface effectsMetallurgyParticulate material

A method for producing graphic signs on a covering material includes providing a substrate and depositing on the substrate a particulate material that is able to define the graphic sign. In a preferred way, the particulate material is deposited on the substrate in a substantially uniform way, and is then impressed selectively in the substrate so that where it is subjected to impression the particulate material is fixed to the substrate. The particulate material is removed from the areas where it is not fixed to the substrate. The particulate material is then anchored to the substrate so that the particulate material anchored to the substrate defines the desired graphic sign.

Owner:MONDO SPA

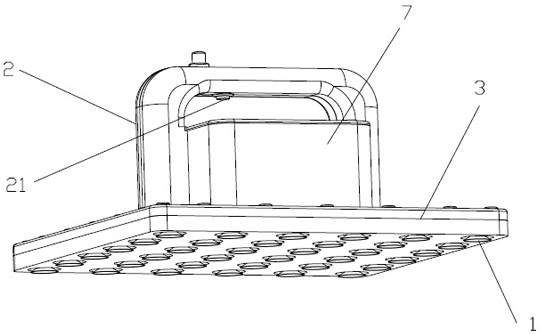

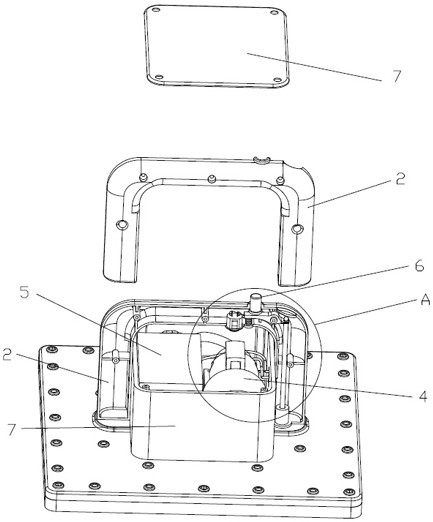

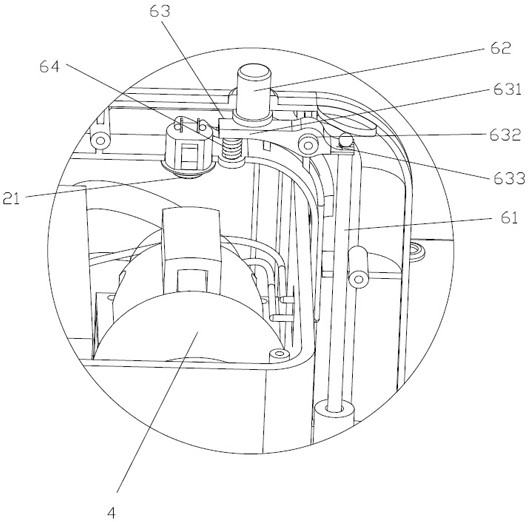

Ultrasonic hot drilling device with optical fiber laser lamp

ActiveCN109249735APrevent crushingPrevent affecting the welding effectInlaying equipmentLaser beam welding apparatusEngineeringUltrasonic generator

The invention provides an ultrasonic hot drilling device with an optical fiber laser lamp. The ultrasonic hot drilling device comprises an in intelligent system, a control box and a base. The intelligent system comprises a sensing device and a control device, the sensing device comprises a temperature sensor and a pressure sensor, the control device comprises the optical fiber laser lamp, a motor,an ultrasonic generator, a pneumatic telescopic rod and an electric valve, a motor box is welded on the control box, the pneumatic telescopic rod comprises an air cylinder and a telescopic rod, the air cylinder is welded on the inner side wall of the motor box via first motor bases, first mounting holes and second mounting holes are formed in the bottom of the control box, and the telescopic rodis welded on the inner side walls of the first mounting holes. The ultrasonic hot drilling device with the optical fiber laser lamp has the advantages that the ultrasonic hot drilling device is novelin design and has diversified functions, and the hot connection efficiency can be effectively improved.

Owner:永嘉思慧特工业设计有限公司

Efficient diamond dispensing process and efficient diamond dispensing device

ActiveCN108749442ALow implementation costEasy to implementLiquid surface applicatorsInlaying equipmentAdhesiveMaterials science

The invention relates to an efficient diamond dispensing process and an efficient diamond dispensing device. The diamond dispensing process comprises the steps of manufacturing an adhesive dispensingprofiling mould, a diamond absorbing profiling mould and a diamond dispensing profiling mould identical and adaptive to the shape and the diamond positions of a workpiece to be diamond-dispensed; andusing the profiling moulds for sequentially carrying out adhesive dispensing, diamond absorbing and diamond dispensing processes so as to efficiently accomplish diamond dispensing operation. The diamond dispensing device comprises an operating table, a workpiece feeding station, an adhesive applying station, a diamond dispensing station and a workpiece taking station, wherein the workpiece feedingstation, the adhesive applying station, the diamond dispensing station and the workpiece taking station are arranged on the operating table. According to the diamond dispensing process provided by the invention, one workpiece or multiple workpieces are synchronously dispensed with adhesives and diamonds at a time; the process can be carried out manually or manually and mechanically, and a full-intelligent automatic device implements and accomplishes the process manually or manually and mechanically, so that compared with an existing diamond dispensing process, the production efficiency is greatly improved; 15 to 25 thousand of diamonds can be daily dispensed manually, while 30 to 100 thousand of diamonds can be hourly dispensed mechanically; and the diamond dispensing process is low in implementation cost, easy to implement, high in diamond dispensing efficiency and good in effect.

Owner:石狮市冠鑫五金饰品厂

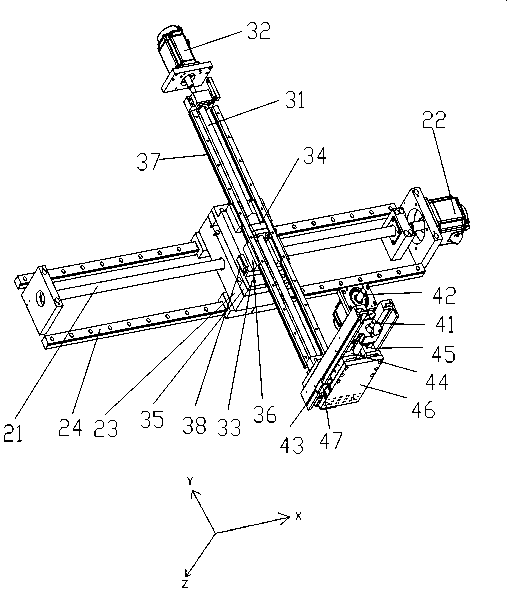

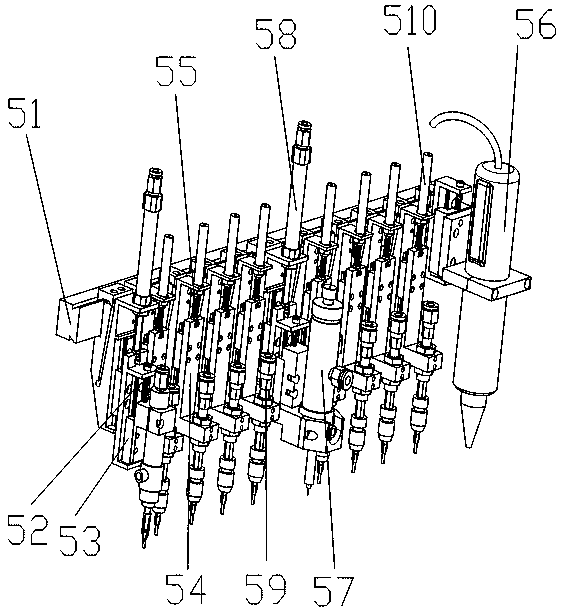

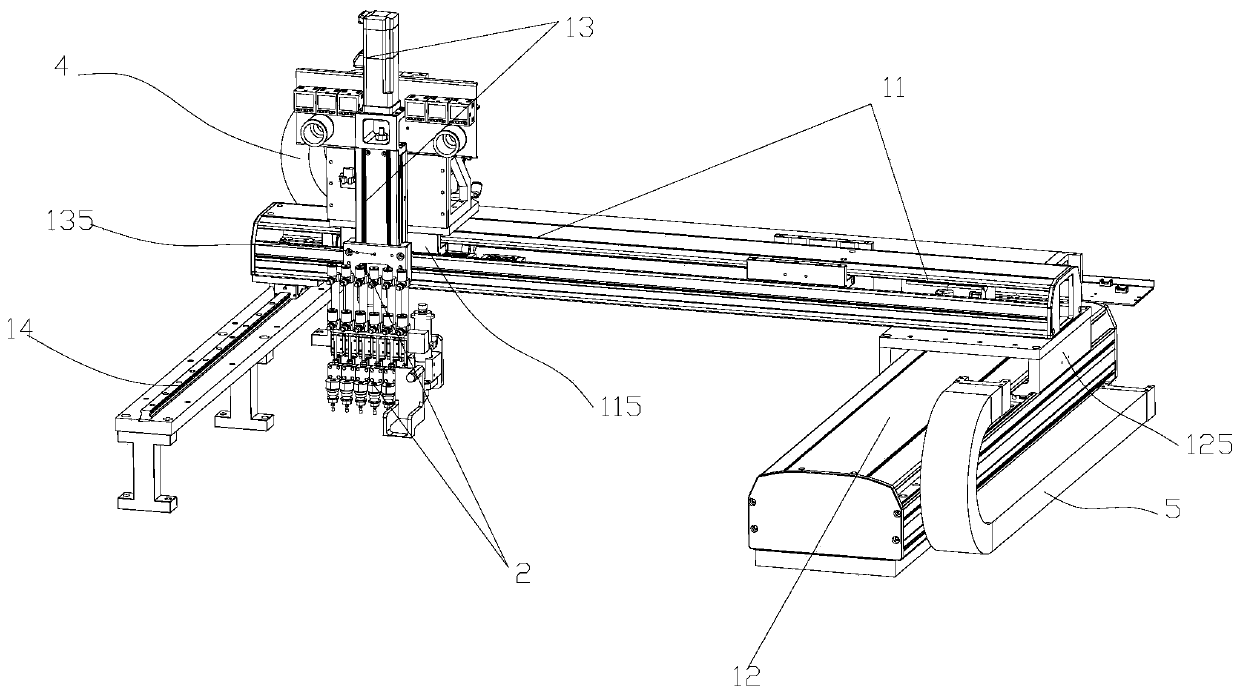

Planar six-head diamond dispensing machine

The invention discloses a planar six-head diamond dispensing machine. The planar six-head diamond dispensing machine comprises a 3D motion mechanism, a machine head and a workpiece placement table, wherein the 3D motion mechanism and the workpiece placement table are both arranged on a rack; the 3D motion mechanism drives the machine head to move to workpieces, and the machine head dispenses diamonds onto the workpieces after dispensing glue onto the workpieces; and the machine head comprises a glue dispensing device, six diamond dispensing devices, six diamond dispensing air cylinders and a support plate, the support plate is connected with the 3D motion mechanism and driven by the 3D motion mechanism for 3D motion, the glue dispensing device and the diamond dispensing devices are arranged on the support plate, an output shaft of each diamond dispensing air cylinder is connected with one diamond dispensing device, and the diamond dispensing air cylinders drive the diamond dispensing devices to move up and down and dispense diamonds onto the workpieces. In the device, the 3D motion mechanism drives the machine head to move to the workpiece positions, and the machine head dispensesglue onto the workpieces and then dispenses diamonds onto the workpieces. The device can perform glue dispensing and diamond dispensing operation on multiple workpieces once, and has the advantage ofhigh operation efficiency.

Owner:广州尚纳智能科技有限公司

Crystal trinket embedding machine

InactiveCN102069670BSimple stand-alone structureReliable controlInlaying equipmentControl mannerSprocket

Owner:ZHEJIANG NORMAL UNIVERSITY

Method And Device For The Reproduction Of Images Using Glass Pixels

A method and device are described for the reproduction of a certain image, previously digitalized and separated into a number of pixels and optimized into a number of colors below a certain limit, with the help of a specific software application. The method includes the construction of individual colored elements that correspond to each of the colors selected for the image, where these elements or pixels consist of small cubic parts made of glass or similar. The method and the device include the means for extracting said pixels from the individual containers and positioning them sequentially for the formation of successive rows which, placed next to each other, form the desired image. The desired image or mosaic is completed with the support for the pixels made of an appropriate material, where the pixels are bound to each other and / or to the support by means of a process of adhesion or the application of heat in an oven up to the temperature at which the material softens.

Owner:ALZABA

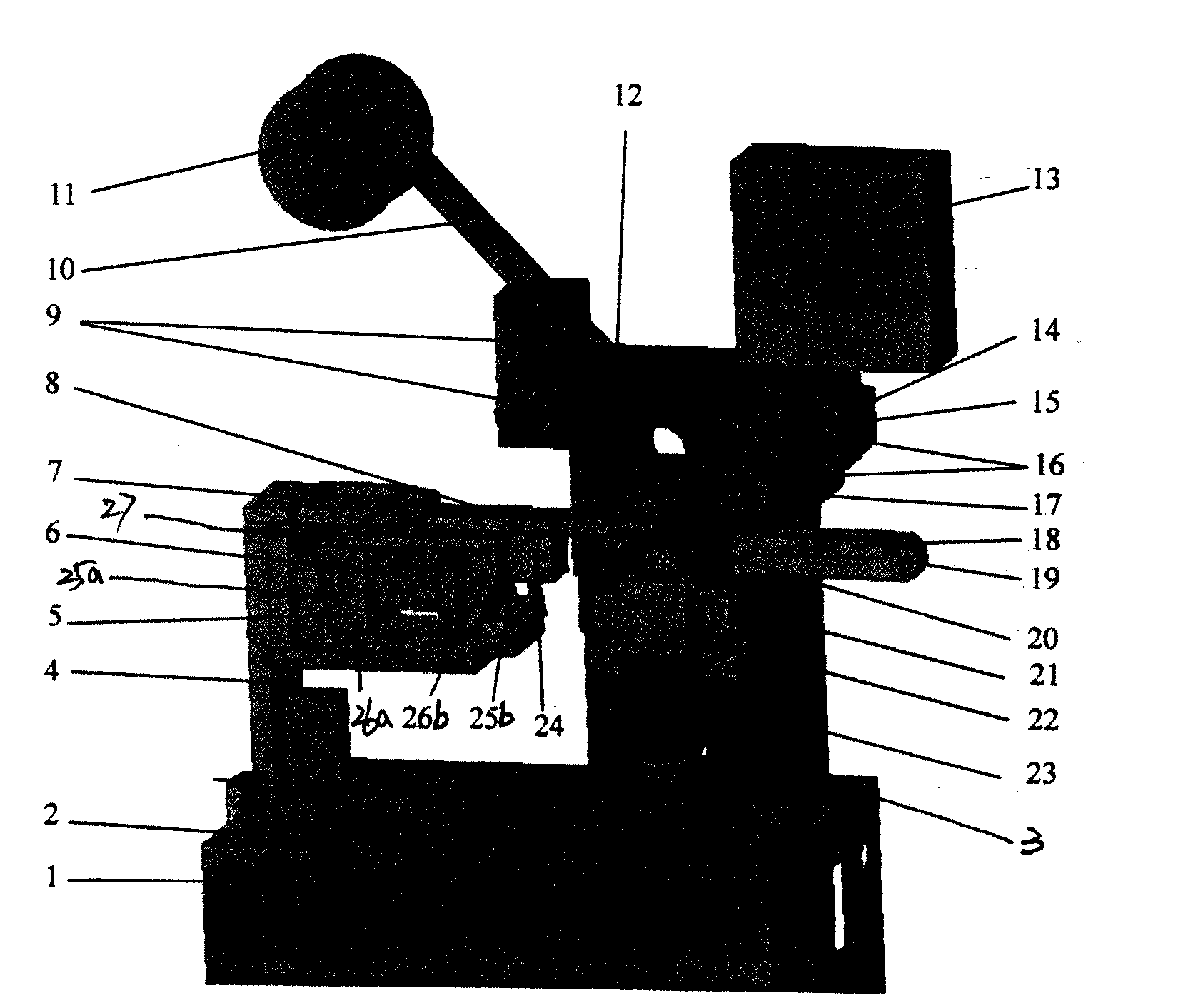

Nail carving method

InactiveCN108162660AReduce resistanceHigh precisionStapling toolsInlaying equipmentEngineeringPerpendicular direction

The invention discloses a nail carving method. According to the nail carving method, a cabinet, a clamp bracket for fixing a slab carrier, a Z-axis lifting mechanism for controlling the clamp bracketto make perpendicular precise lifting positioning, and an X-Y axis moving mechanism are adopted; a nail gun is driven to move on the X-Y plane and / or in the perpendicular direction, nails of differentcolors are arranged on a wood board in sequence, the embedding depths of the nails in the wood board are controlled, then a nail lattice pattern of different colors and regular embedding depths can be achieved, and a fashionable artistic nail carving of a unique style is formed. The nail carving method has the advantages that the method is novel; a reproducible natural wood material without radiation or pollution serves as a decorative art carrier; and the nails of different colors are adopted and arranged to form the required pattern, and the nail carving has a strong sense of fashion, seemsnoble and decent, has a high-grade decoration effect and is suitable for being used in certain high-end halls and guesthouses.

Owner:FOSHAN LANTU TECH CO LTD

Processing method of wood material art

ActiveCN101623972BStrong three-dimensional senseProfound layeringInlaying equipmentPulp and paper industryHorticulture

The invention provides a processing method of a wood material art, which solves the problem of poorer beautiful and artistic effects and shorter appreciation life of products prepared by the prior processing method of the wood material art. The processing method of the wood material art comprises the following steps: A. selecting materials; B. splicing in a seamless mode; C. forming by hot press; and D. post-processing. The wood material art prepared by the processing method has wide application range, good beautiful effect, long appreciation life, and the like.

Owner:玉环广源木业有限公司

Bamboo product production device

ActiveCN111545388AShortness of breathGood manual effectInlaying equipmentPretreated surfacesProcess engineeringTransfer mechanism

The invention relates to the field of plant product, in particular to a bamboo product production device. The technical aim to be achieved is to provide the bamboo product production device. The bamboo product production device comprises side supporting columns, a collection box, a locating and feeding mechanism, a dual-layer painting and transfer mechanism, a control screen and a drying and pasting mechanism. The locating and feeding mechanism is arranged at the tops of the side supporting columns, and the dual-layer painting and transfer mechanism is arranged on the right sides of the side supporting columns. By means of the bamboo product production device, automatic painting is achieved, meanwhile, dual-area multi-color adjusting painting can be achieved in a cooperation manner, and after even drying, dual-side synchronous pasting to bamboo hats is achieved through cooperation; and later semi-automatic machining is achieved, and the batched production quality of bamboo hats is greatly increased.

Owner:湖南汇元板业有限公司

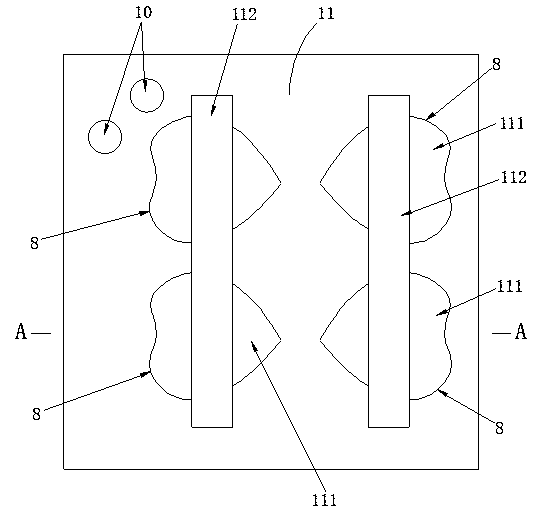

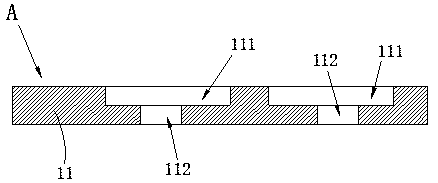

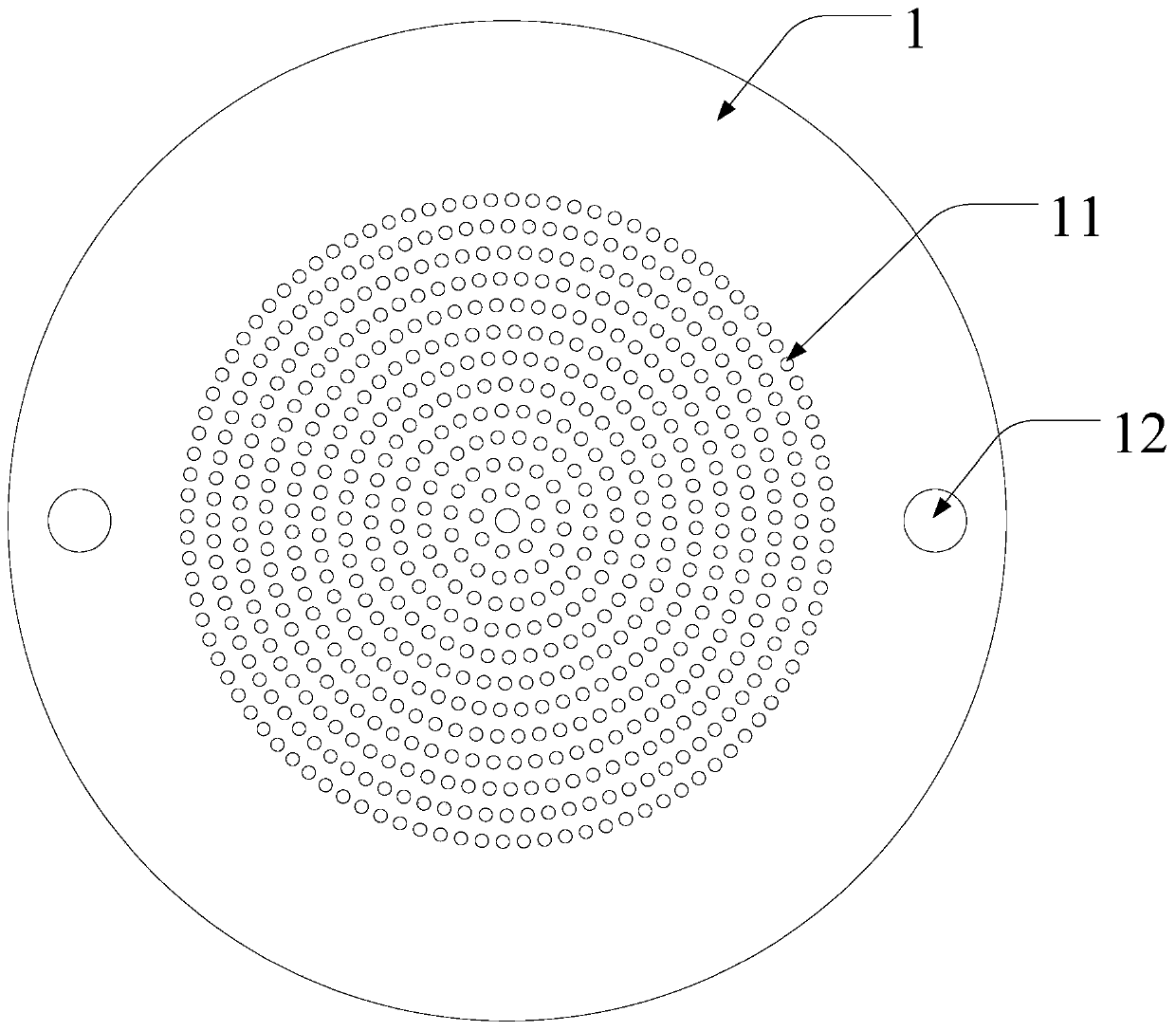

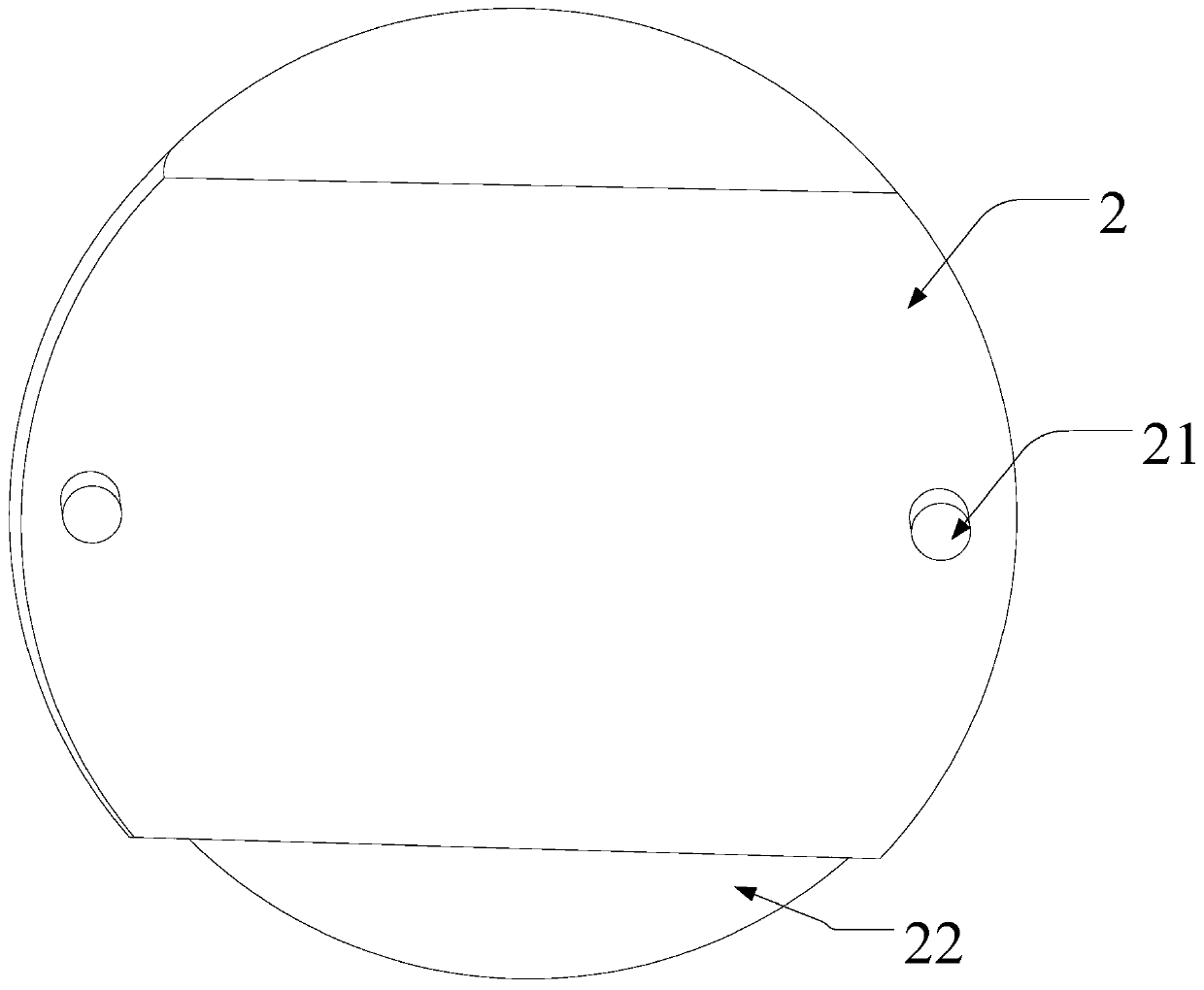

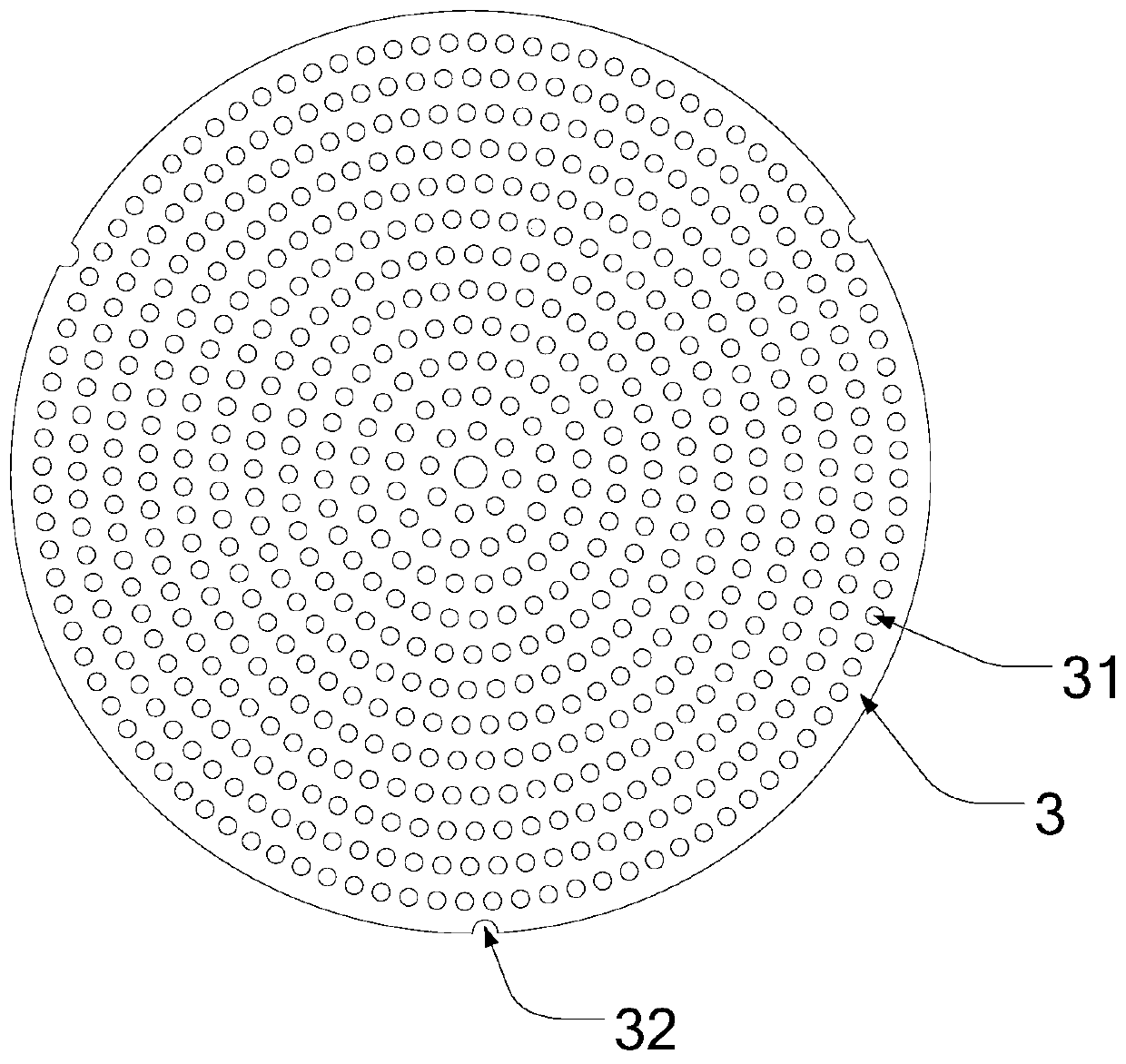

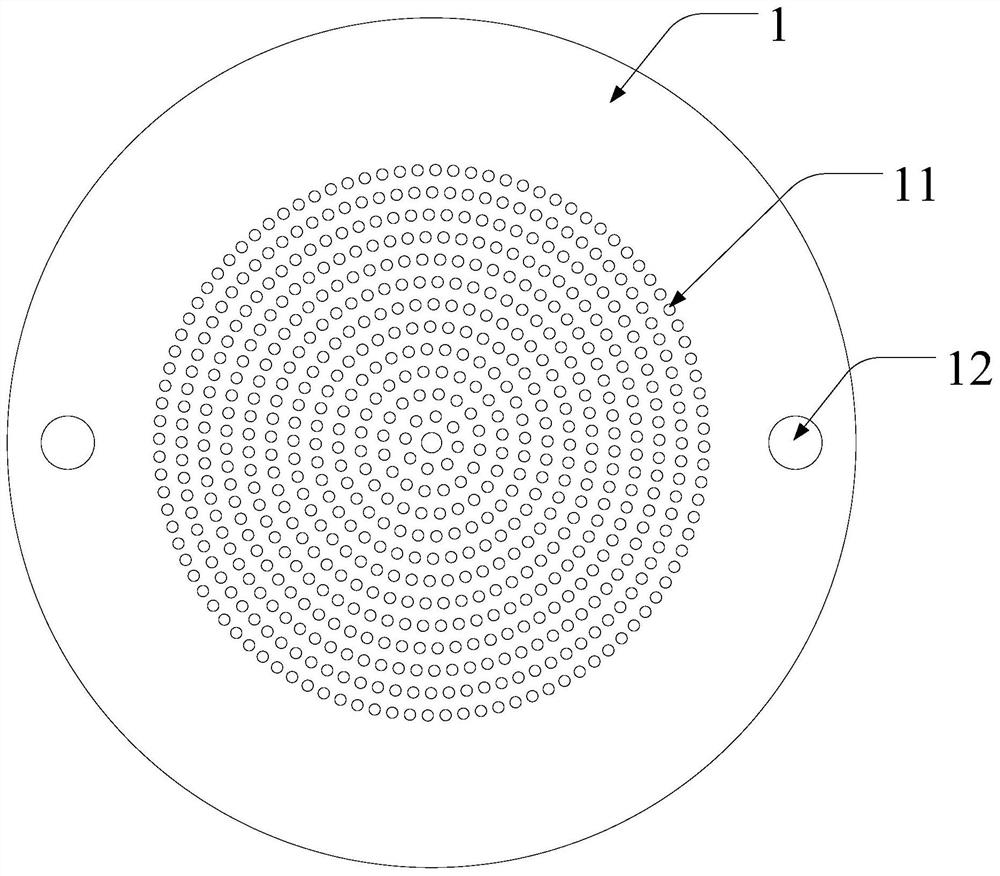

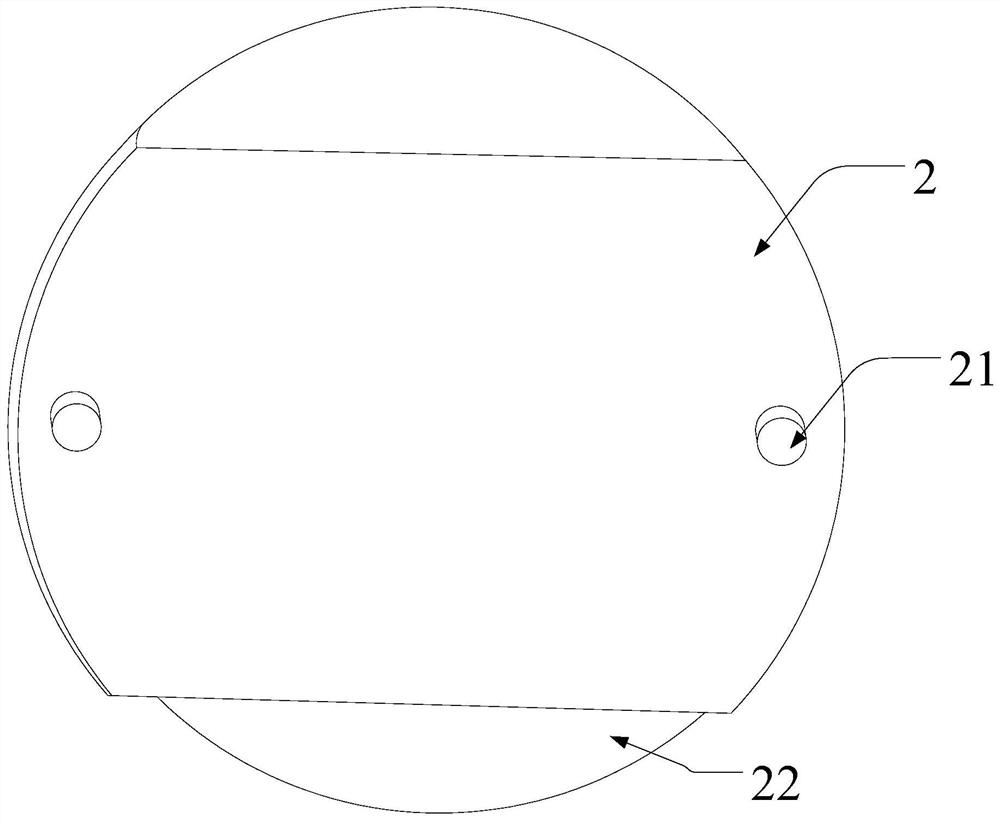

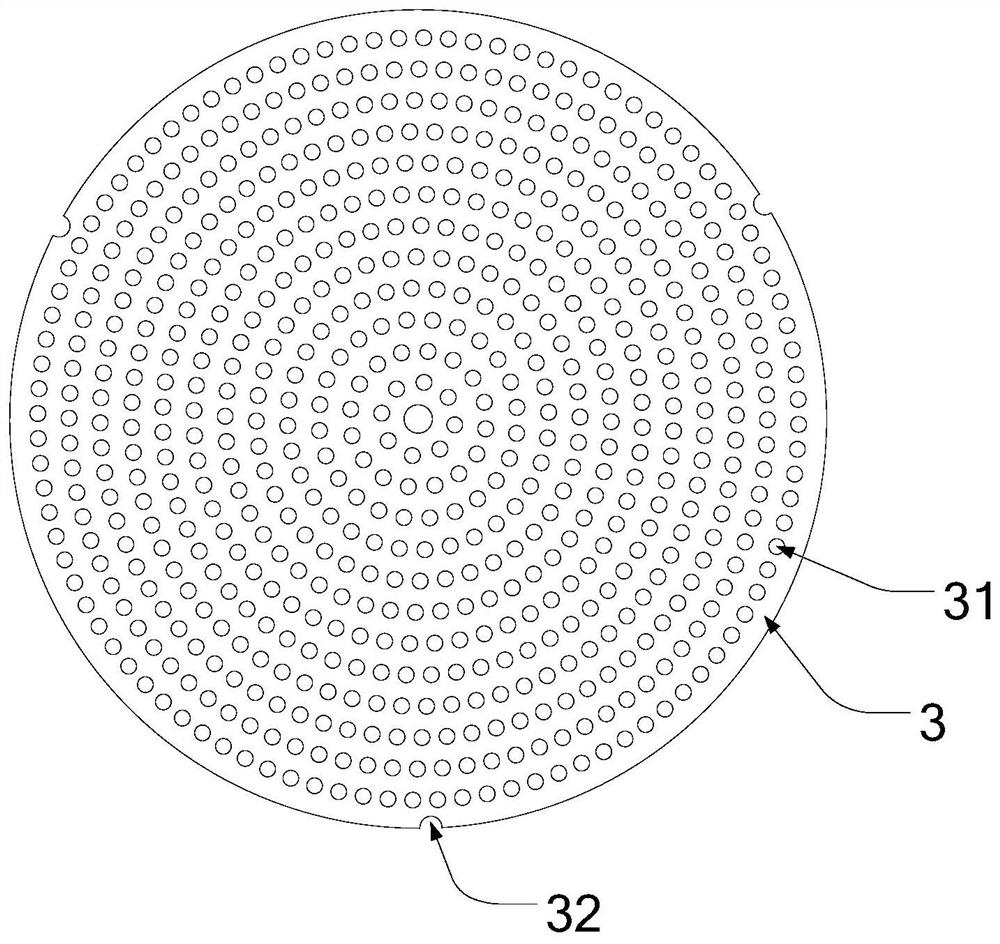

Device for implanting PP stones and method for implanting PP stones

ActiveCN110588224AWon't fall offImprove assembly efficiencyInlaying equipmentOther artistic work equipmentsEngineeringMechanical engineering

The invention discloses a device for implanting PP stones and a method for implanting the PP stones. The device for implanting the PP stones comprises a shaping jig, a location jig, a stone implantingcarrying plate, a transfer jig and an air suction plate, wherein a plurality of conical holes allowing the PP stones to be placed in are formed in the location jig; transfer holes allowing the tops of the PP stones to be partially exposed are formed in the transfer jig; a plurality of gas holes are formed in the air suction plate; a plurality of embedding holes are formed in the stone implantingcarrying plate; and the PP stones are coated on the shaping jig with the same direction, then the shaping jig is arranged on the location jig in a sleeved manner, the transfer jig is arranged on the shaping jig in a sleeved manner, the top ends of the PP stones are partially or completely exposed out of the transfer holes, adhesive paper is bonded onto the transfer jig, and the PP stones are transferred onto the transfer jig. Meanwhile, the stone implanting carrying plate is placed on the air suction plate, then the transfer jig is arranged on the stone implanting carrying plate in a sleeved manner, the PP stones on the transfer jig are transferred into the embedding holes via the air suction treatment of the air suction plate, then the adhesive paper is torn off, the transfer jig is takenout, and the back surface of the stone implanting carrying plate is glued and dried.

Owner:黄国良

A method for producing graphic signs on covering materials, such as floorings, and related covering material

A method for producing graphic signs on a covering material includes providing a substrate and depositing on the substrate a particulate material that is able to define the graphic sign. In a preferred way, the particulate material is deposited on the substrate in a substantially uniform way, and is then impressed selectively in the substrate so that where it is subjected to impression the particulate material is fixed to the substrate. The particulate material is removed from the areas where it is not fixed to the substrate. The particulate material is then anchored to the substrate so that the particulate material anchored to the substrate defines the desired graphic sign.

Owner:MONDO SPA

Method for manufacturing wool felt handmade artware capable of easily determining shape of finished product

ActiveCN114013206AGuaranteed aestheticsAvoid exposureInlaying equipmentSpecial ornamental structuresEngineeringProcess engineering

The invention relates to the technical field of handicraft manufacturing, in particular to a method for manufacturing a wool felt handmade handicraft capable of easily determining the shape of a finished product, which comprises the following steps: manufacturing a metal PU foaming mold by using a 3D digital model, and manufacturing a basic modeling blank of the wool felt handmade handicraft by using the metal PU foaming mold; attaching wool to the basic modeling blank, and using a special pricking needle for wool felt to prick the wool into the surface of the polyurethane basic modeling embryo to complete remodeling of the artware; and coloring the wool on the surface of the re-modeled handicraft according to the expectation to complete the manufacturing of the wool felt handmade handicraft. According to the manufacturing method, the polyurethane basic modeling blank is adopted as a basic model, after the wool is attached to the polyurethane basic modeling blank, the image of the wool is consistent with that of the polyurethane basic modeling blank, and an operator does not need to fail in artware modeling due to insufficient modeling capacity or insufficient experience. The manufacturing difficulty of the wool felt handicraft is reduced, and the attractiveness of the finished product can be basically guaranteed.

Owner:李琦宏

A device for planting pp stones and a method for planting pp stones

ActiveCN110588224BWon't fall offImprove assembly efficiencyInlaying equipmentOther artistic work equipmentsMechanical engineeringMaterials science

The invention discloses a device for implanting PP stones and a method for implanting the PP stones. The device for implanting the PP stones comprises a shaping jig, a location jig, a stone implantingcarrying plate, a transfer jig and an air suction plate, wherein a plurality of conical holes allowing the PP stones to be placed in are formed in the location jig; transfer holes allowing the tops of the PP stones to be partially exposed are formed in the transfer jig; a plurality of gas holes are formed in the air suction plate; a plurality of embedding holes are formed in the stone implantingcarrying plate; and the PP stones are coated on the shaping jig with the same direction, then the shaping jig is arranged on the location jig in a sleeved manner, the transfer jig is arranged on the shaping jig in a sleeved manner, the top ends of the PP stones are partially or completely exposed out of the transfer holes, adhesive paper is bonded onto the transfer jig, and the PP stones are transferred onto the transfer jig. Meanwhile, the stone implanting carrying plate is placed on the air suction plate, then the transfer jig is arranged on the stone implanting carrying plate in a sleeved manner, the PP stones on the transfer jig are transferred into the embedding holes via the air suction treatment of the air suction plate, then the adhesive paper is torn off, the transfer jig is takenout, and the back surface of the stone implanting carrying plate is glued and dried.

Owner:黄国良

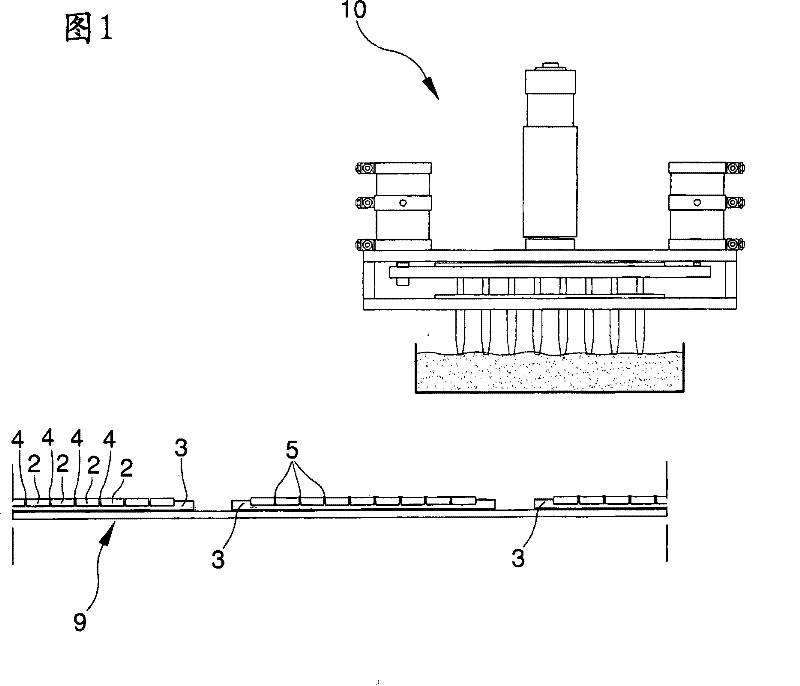

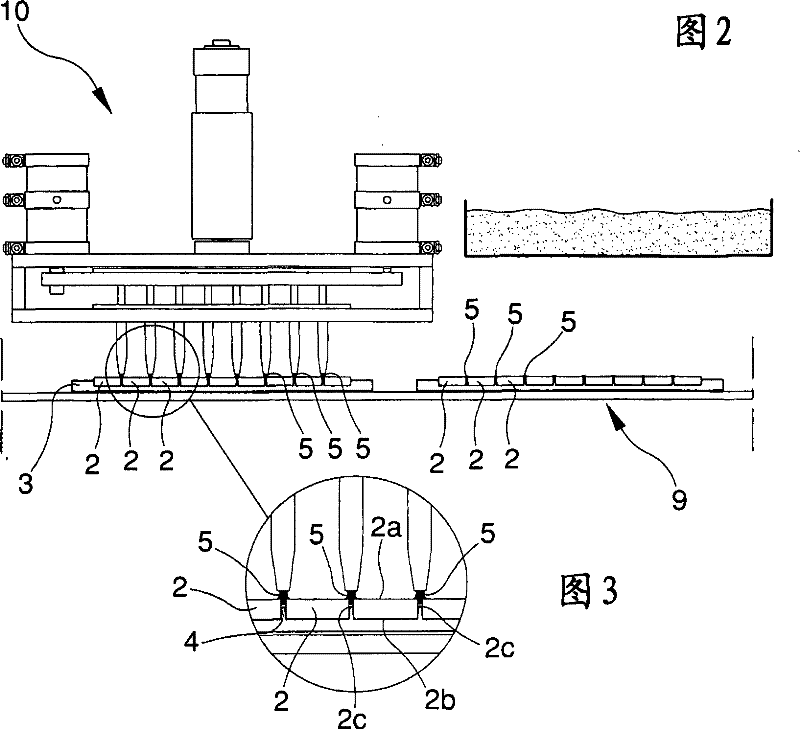

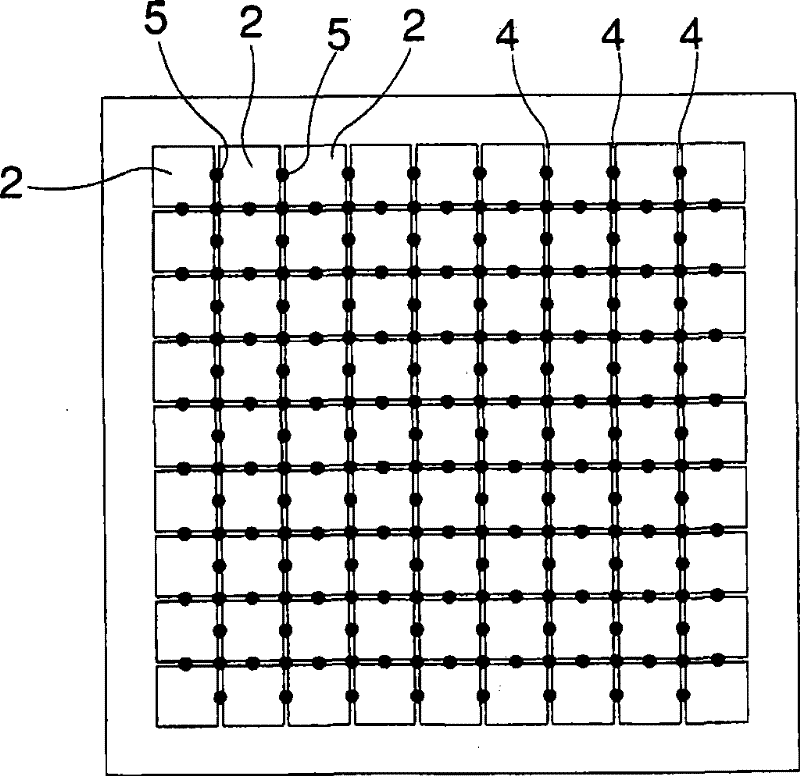

A method for connecting ceramic tesserae

The method for connecting ceramic tesserae comprises stages of: depositing ceramic tesserae (2) on a rest surface (3) in a predetermined order in which the ceramic tesserae (2) are distanced from one another by space lines (4) of a predetermined width, and are positioned with a laying surface (2a) thereof facing upwards; depositing at least a point of grout (5) in at least an intermediate tract of each space line (4) between the tesserae (2); heating at least the points of grout (5) to a drying or firing temperature of the grout.

Owner:KEMAC

High-efficiency spot drilling process and high-efficiency spot drilling device

ActiveCN108749442BLow implementation costEasy to implementLiquid surface applicatorsInlaying equipmentAdhesiveProcess engineering

The invention relates to an efficient diamond dispensing process and an efficient diamond dispensing device. The diamond dispensing process comprises the steps of manufacturing an adhesive dispensingprofiling mould, a diamond absorbing profiling mould and a diamond dispensing profiling mould identical and adaptive to the shape and the diamond positions of a workpiece to be diamond-dispensed; andusing the profiling moulds for sequentially carrying out adhesive dispensing, diamond absorbing and diamond dispensing processes so as to efficiently accomplish diamond dispensing operation. The diamond dispensing device comprises an operating table, a workpiece feeding station, an adhesive applying station, a diamond dispensing station and a workpiece taking station, wherein the workpiece feedingstation, the adhesive applying station, the diamond dispensing station and the workpiece taking station are arranged on the operating table. According to the diamond dispensing process provided by the invention, one workpiece or multiple workpieces are synchronously dispensed with adhesives and diamonds at a time; the process can be carried out manually or manually and mechanically, and a full-intelligent automatic device implements and accomplishes the process manually or manually and mechanically, so that compared with an existing diamond dispensing process, the production efficiency is greatly improved; 15 to 25 thousand of diamonds can be daily dispensed manually, while 30 to 100 thousand of diamonds can be hourly dispensed mechanically; and the diamond dispensing process is low in implementation cost, easy to implement, high in diamond dispensing efficiency and good in effect.

Owner:石狮市冠鑫五金饰品厂

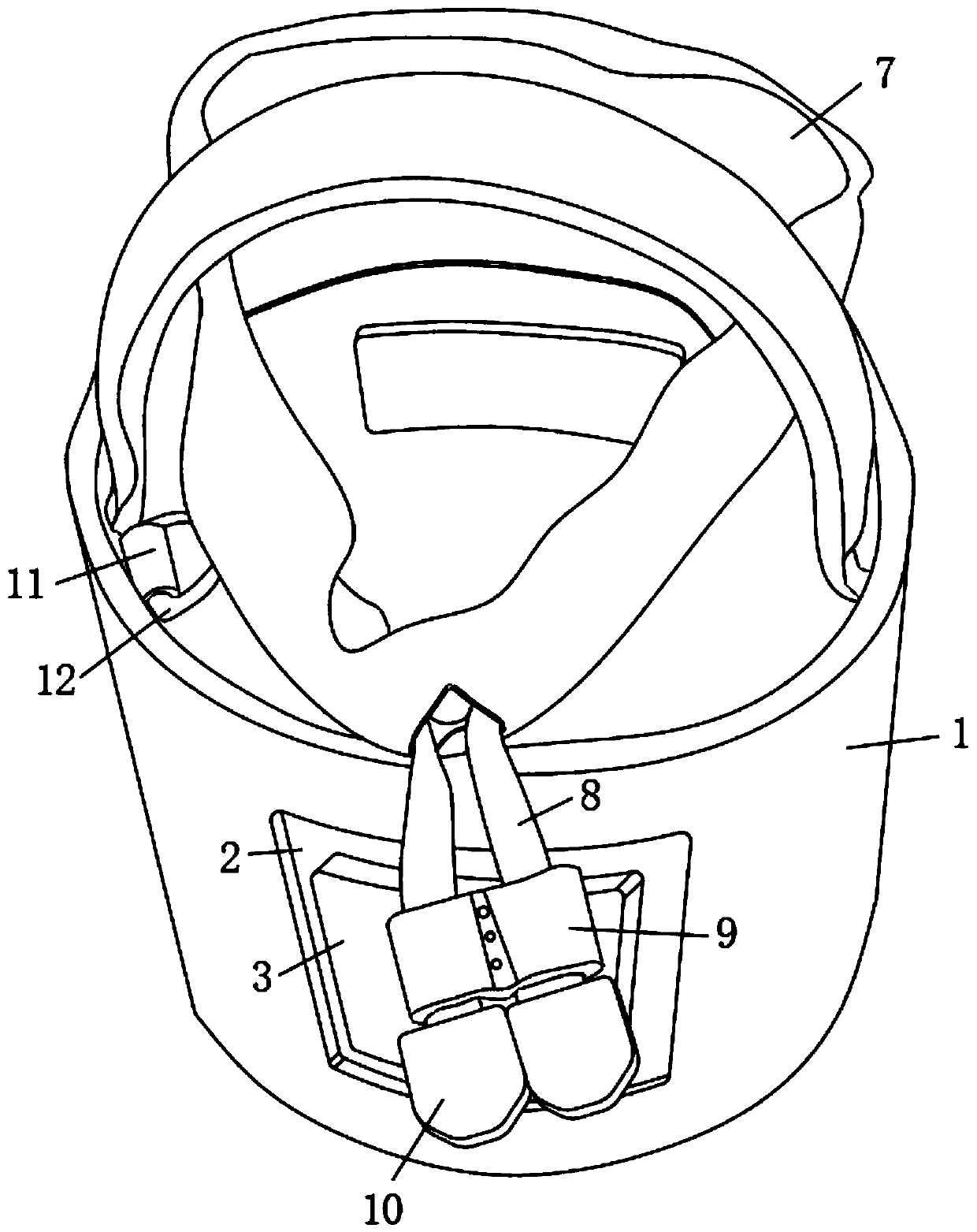

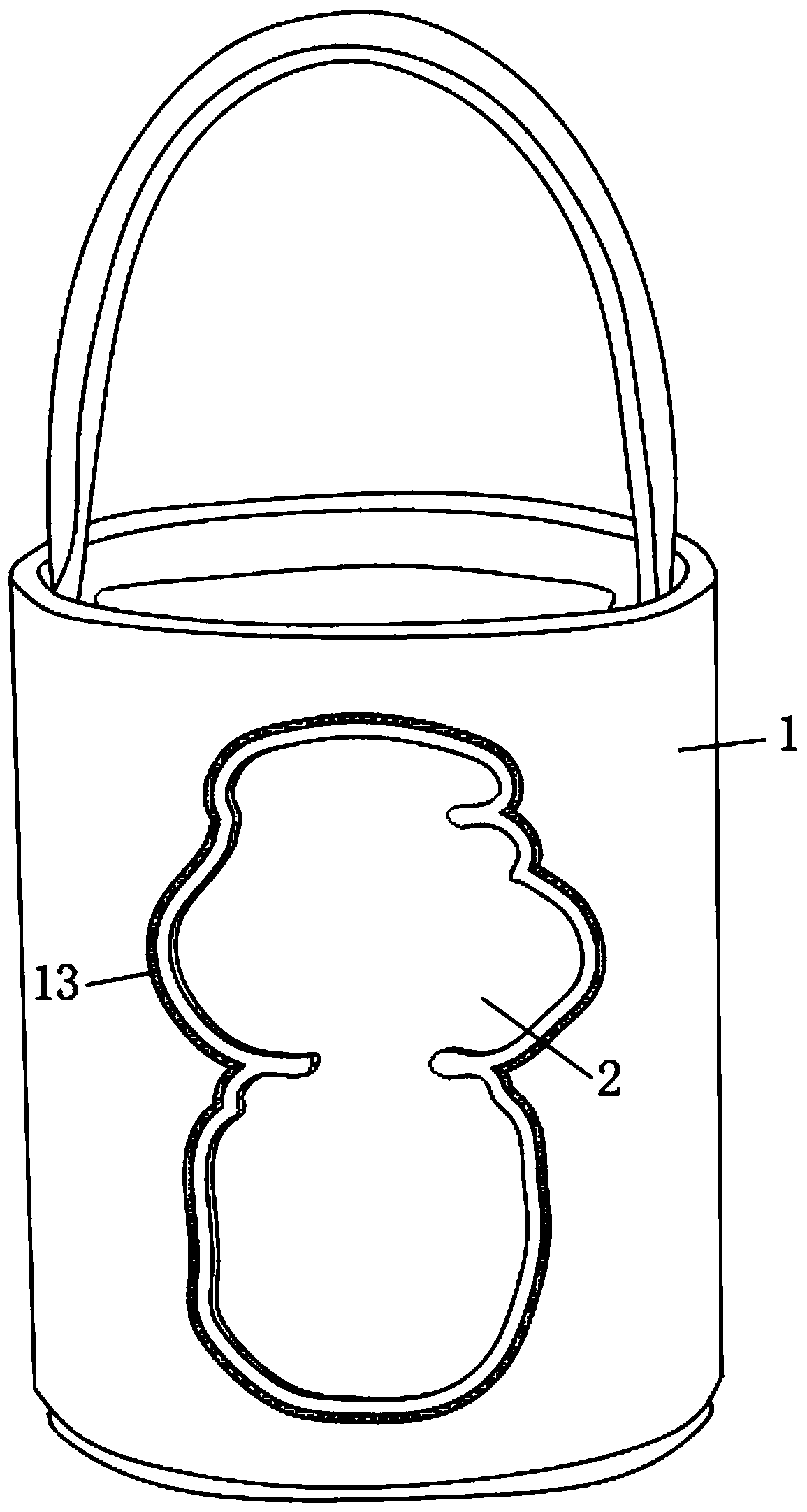

Portable bag inlaid with 3D embossment and 3D embossment inlaying method thereof

InactiveCN111568015AInhibit sheddingImprove experienceInlaying equipmentOther accessoriesThreaded pipeEngineering

The invention discloses a portable bag inlaid with 3D embossment and a 3D embossment inlaying method thereof. The bag comprises a bag body, an inlaying groove is formed in the outer surface wall of the bag body, the 3D embossment is fixed in the inlaying groove, threaded pipe mounting holes are formed in the inlaying surface of the 3D embossment, threaded pipes are fixed in the threaded pipe mounting holes, and fixing holes allowing the threaded pipes to penetrate through are formed in the inlaying groove; during fixing, the threaded pipes are inserted into the fixing holes and are outwards inserted into screw pipes from the interior of the bag body through screws to be screwed and fixed; in conclusion, according to the portable bag, the 3D embossment can be stably embedded into the portable bag body through cooperation of the screws and the threaded pipes, so that the problem that the 3D embossment falls off is effectively avoided, and the design sense and attractiveness of a productare improved.

Owner:深圳安娜澳斯特手袋设计有限公司

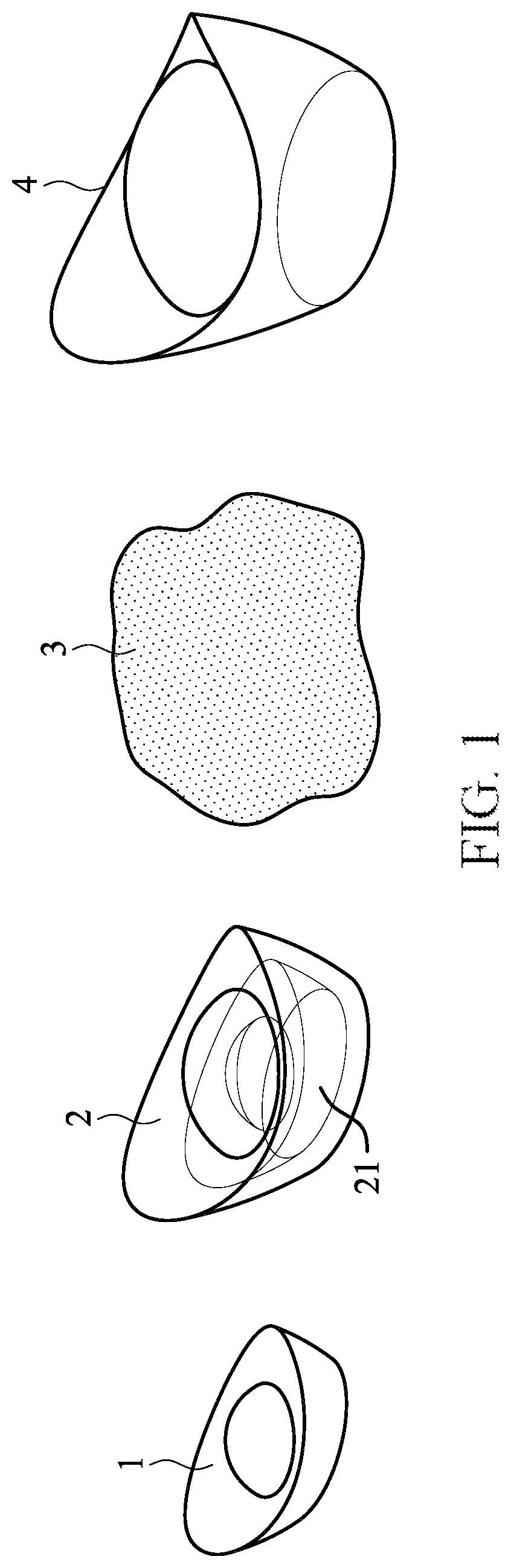

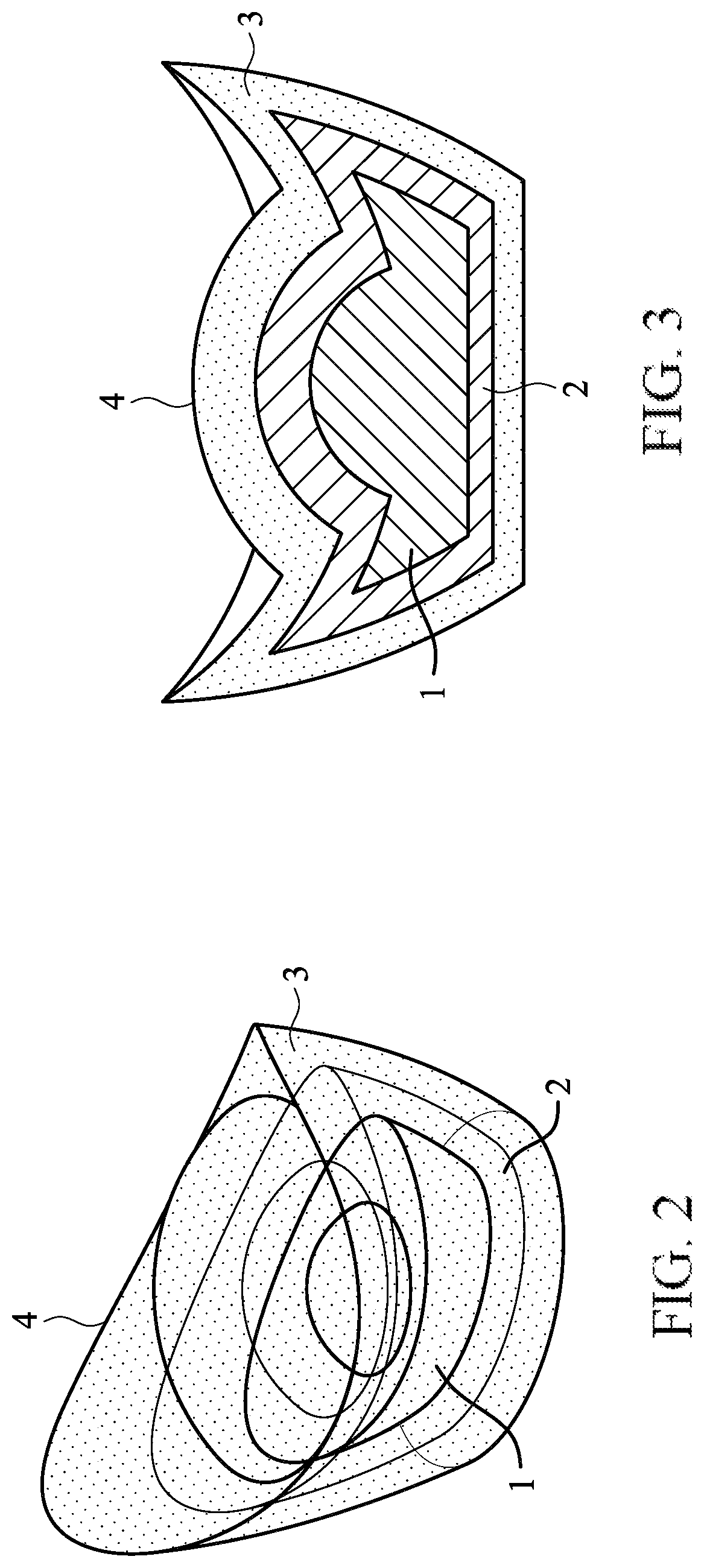

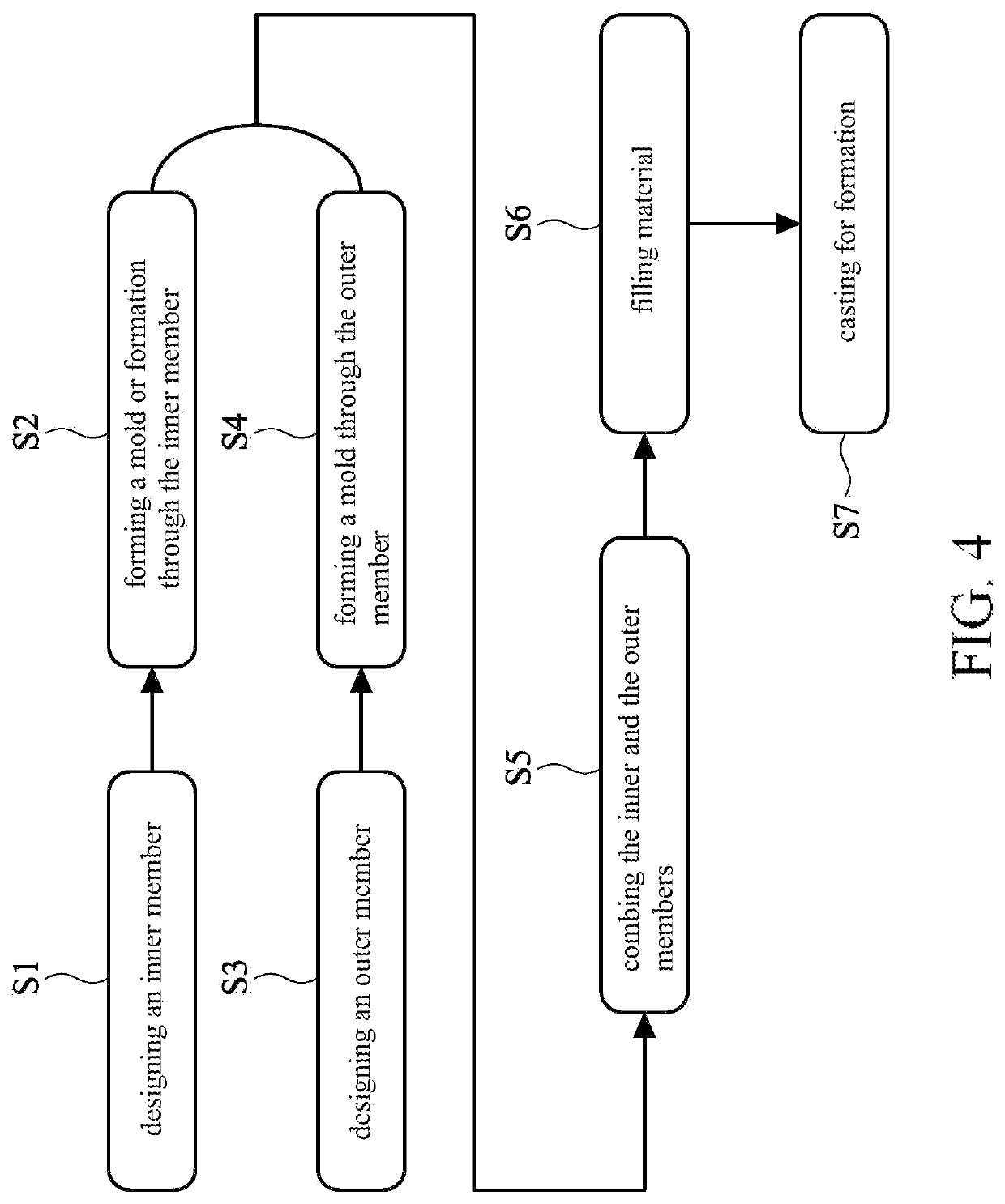

Casting structure allowing inlayed inner and outer member to be viewed

PendingUS20220153624A1Practical to useFunction increaseInlaying equipmentSpecial ornamental structuresFilling materialsStructural engineering

A casting structure allowing inlayed inner and outer member to be viewed includes: at least one inner member, formed as a three-dimensional shape; an outer member, formed with an inlaying space for allowing the inner member to be combined and inlayed therein, wherein the outer member is a three-dimensional shape formed through a material capable being viewed through; and a filling material member, made of a material capable of being viewed through and filled at an outer side of the outer member inlayed with the inner member so as to form a casting member; wherein, with the inner member being inlayed in the outer member, the filling material member is able to enclose and to be processed with a casting operation for forming the casting member capable of being viewed through.

Owner:LIN CHIH CHIEH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com