Crystal trinket embedding machine

An inlaying machine and jewelry technology, which is applied in inlaying decorative structures, decorative arts, etc., can solve the problems of large equipment size, high environmental noise, and unsatisfactory reliability, and achieve fast inlaying speed, simple single-machine structure, and inlaying The speed can be controlled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the contents of the examples.

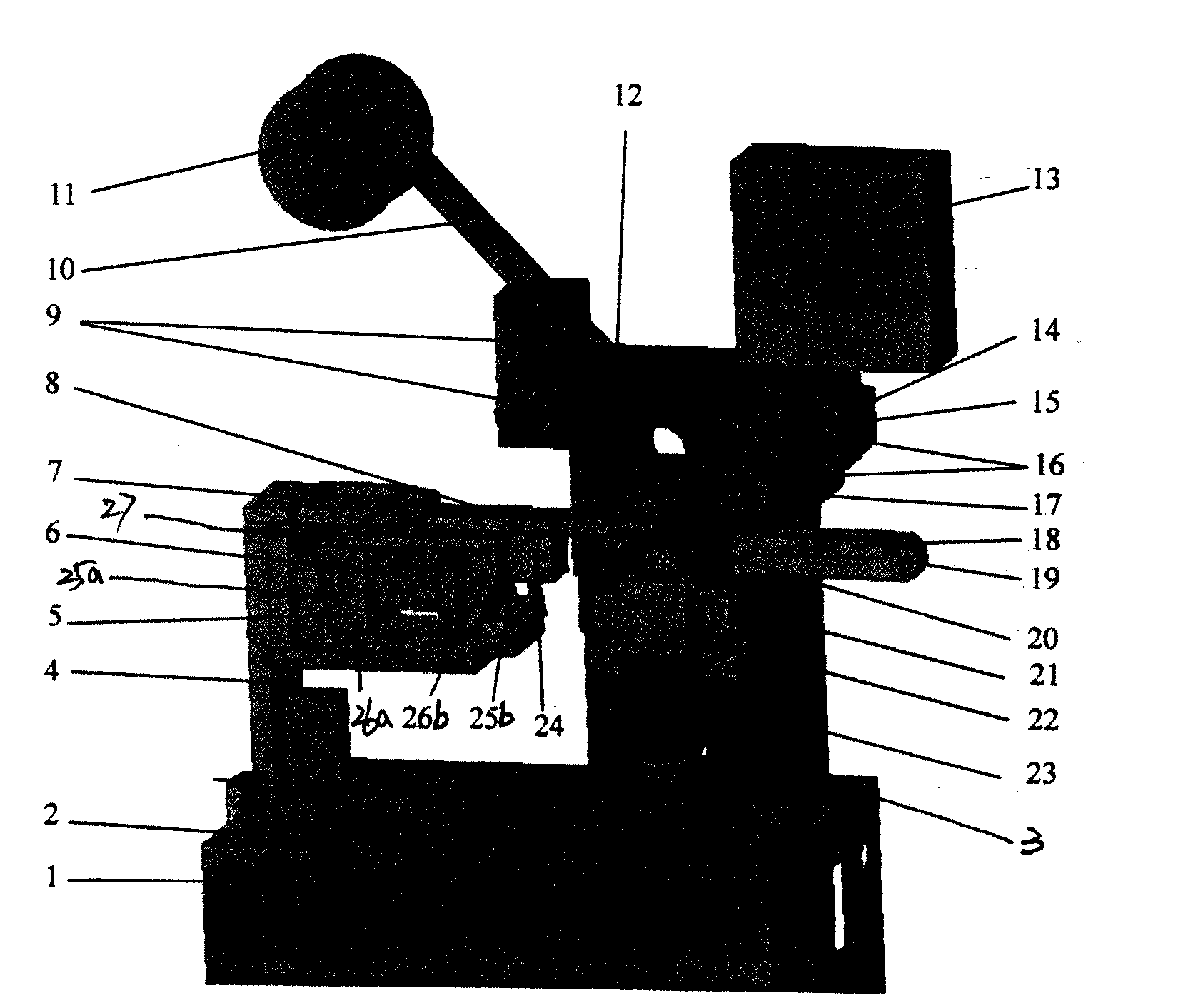

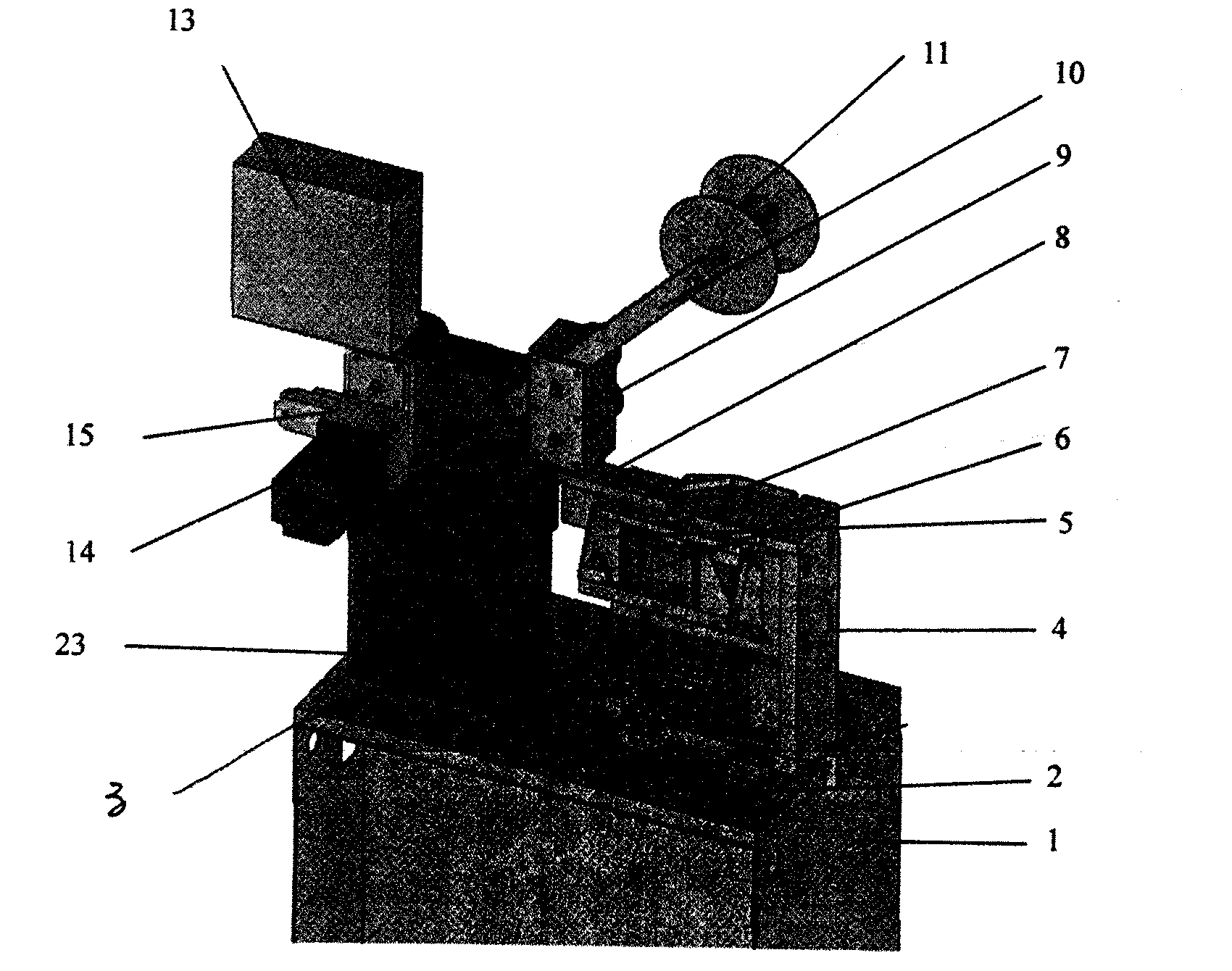

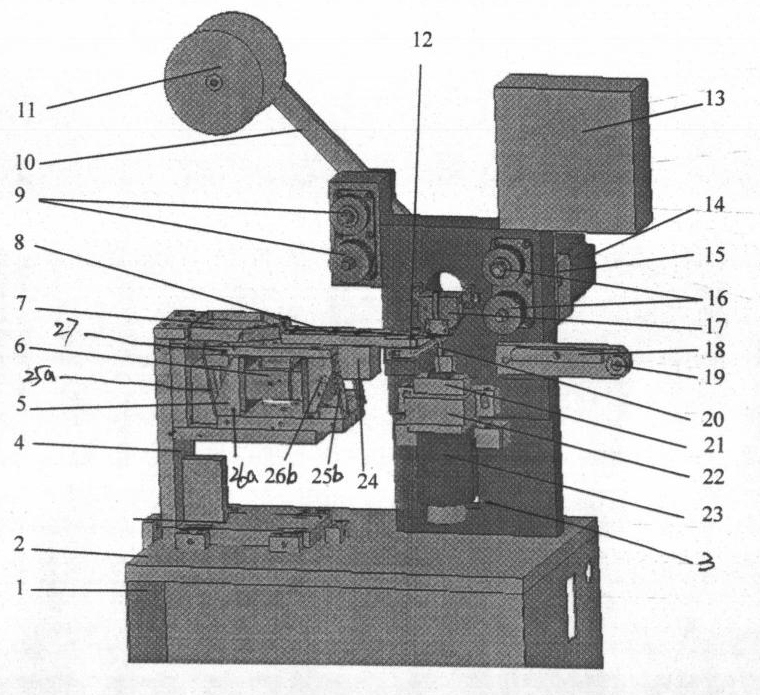

[0012] Such as figure 1 and figure 2 As shown, the crystal jewelry inlaying machine of the present invention is a small crystal jewelry inlaying machine, and it includes a frame, a feeding mechanism, a stamping mechanism, a control mechanism, and a chain feeding mechanism. Five major parts:

[0013] ①Rack, which includes a support member 3 and a support member 4 with a base 1 and legs 2 connected to the base 1 .

[0014] ②feeding mechanism, it comprises vibrating component, feeding channel 8, feeding trough 7, vibrating component is made up of coil base 5, coil 6, left vibrating oblique iron 26a, right vibrating oblique iron 26b, left spring leaf 25a, right spring leaf 25b, Connecting plate 27 is formed, and connecting plate 27 connects left spring leaf 25a and right spring leaf 25b to form " door " shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com