Processing method of wood material art

A technology of wooden materials and processing methods, which is applied in the processing field of wooden materials artworks, can solve problems such as poor aesthetic effect, easy falling off and fading of a single planed piece, short viewing life, etc., to achieve a profound sense of hierarchy and clear and clear expression of pictures , beautiful effect and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

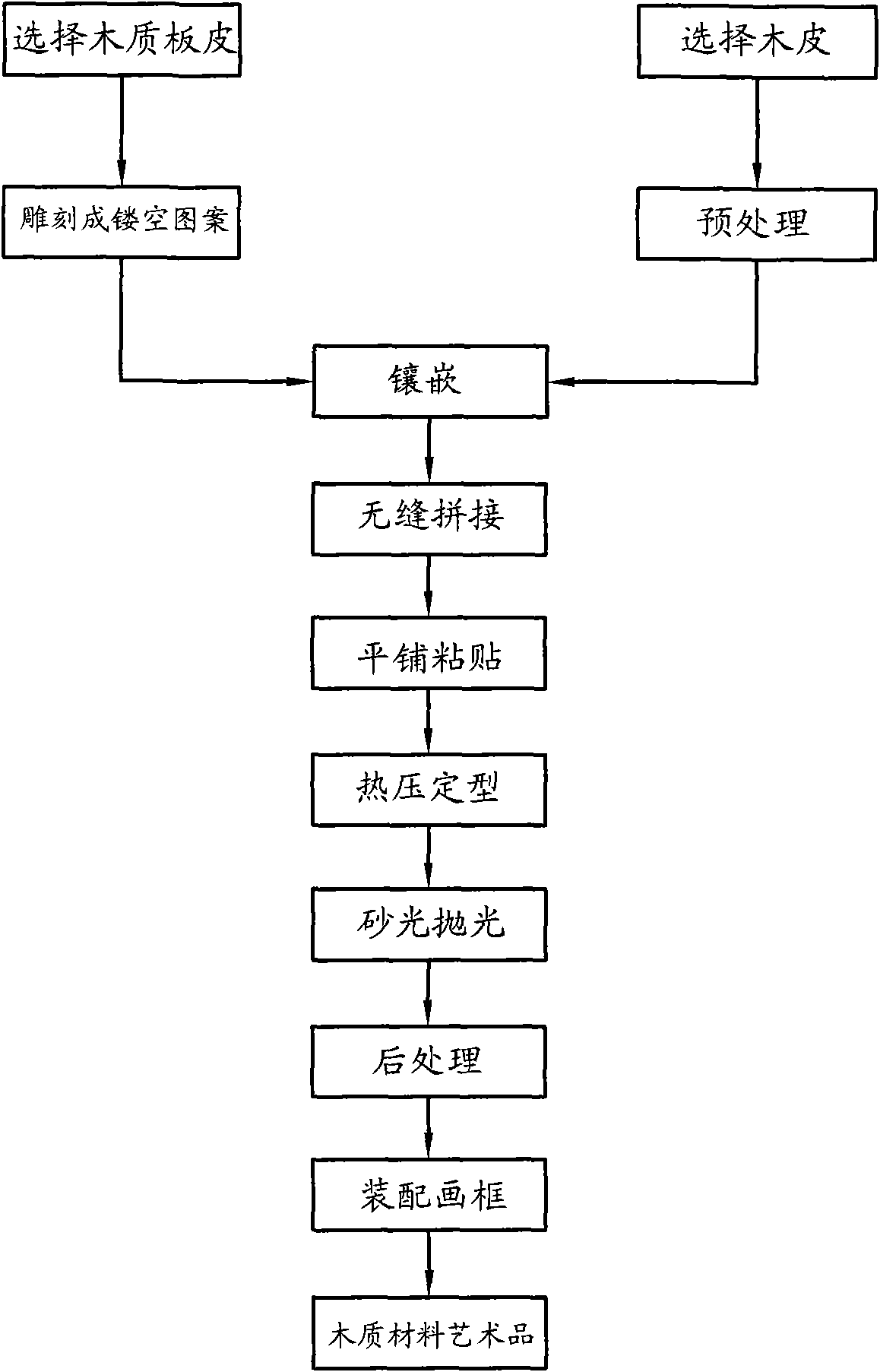

Image

Examples

Embodiment 1

[0026] Fresh logs of different tree species are sawn in sections, plane-planed, obliquely planed and cross-planed into wooden veneers of 0.3-1.0 mm, and the wooden veneers are carved into hollow patterns in ancient paintings, and then processed according to The pattern, color and artistic conception of ancient paintings are selected to match the veneer with color and luster and grain. First, use a utility knife to cut and classify it, and then use ordinary heat transfer technology for some of the wood veneer with color and grain. Under constant temperature conditions of 500°C, scalding is carried out. Then the veneer is inlaid into the wooden veneer, and it is tightly spliced together with a sewing machine, glue thread, and ordinary seamless splicing technology, and a complete natural veneer picture is formed by matching the edges of various tree pomegranates.

[0027] The veneer picture formed by splicing the above together is pasted on the solid wood board by using environ...

Embodiment 2

[0029] Fresh logs of different tree species are sawn in sections, plane-planed, obliquely planed and cross-planed into wooden veneers of 0.3-1.0 mm, and the wooden veneers are carved into hollow patterns in ancient paintings, and then processed according to The pattern, color and artistic conception of ancient paintings are selected to match the veneer with color and luster and grain. First, use a utility knife to cut and classify it, and then use ordinary heat transfer technology for some of the wood veneer with color and grain. Under the constant temperature condition of 550 ℃, scalding is carried out. Then the veneer is inlaid into the wooden veneer, and it is tightly spliced together with a sewing machine, glue thread, and ordinary seamless splicing technology, and a complete natural veneer picture is formed by matching the edges of various tree pomegranates.

[0030] The veneer picture formed by splicing the above together is pasted on the solid wood board by using envi...

Embodiment 3

[0032]Fresh logs of different tree species are sawn in sections, plane-planed, obliquely planed and cross-planed into wooden veneers of 0.3-1.0 mm, and the wooden veneers are carved into hollow patterns in ancient paintings, and then processed according to The pattern, color and artistic conception of ancient paintings are selected to match the veneer with color and luster and grain. First, use a utility knife to cut and classify it, and then use ordinary heat transfer technology for some of the wood veneer with color and grain. Under the constant temperature condition of 600 ℃, scalding is carried out. Then the veneer is inlaid into the wooden veneer, and it is tightly spliced together with a sewing machine, glue thread, and ordinary seamless splicing technology, and a complete natural veneer picture is formed by matching the edges of various tree pomegranates.

[0033] The veneer picture formed by splicing the above together is pasted on the solid wood board by using envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com