Bamboo product production device

A production device and technology of bamboo products, applied in spraying devices, devices for coating liquid on the surface, decorative art, etc., can solve the problems of non-standard displacement, affecting the health of the craftsmen, and poor breathing of craftsmen, so as to increase the quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

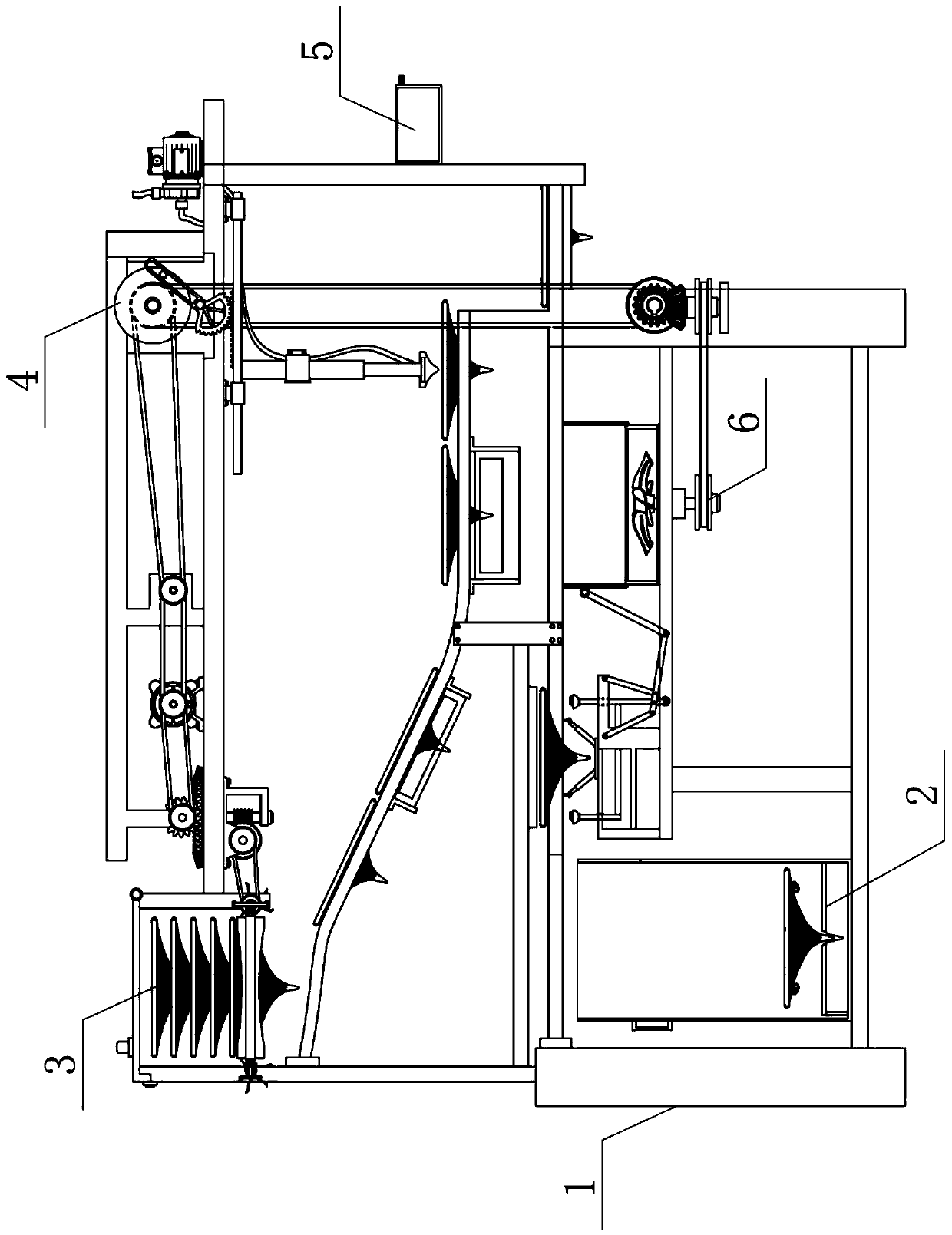

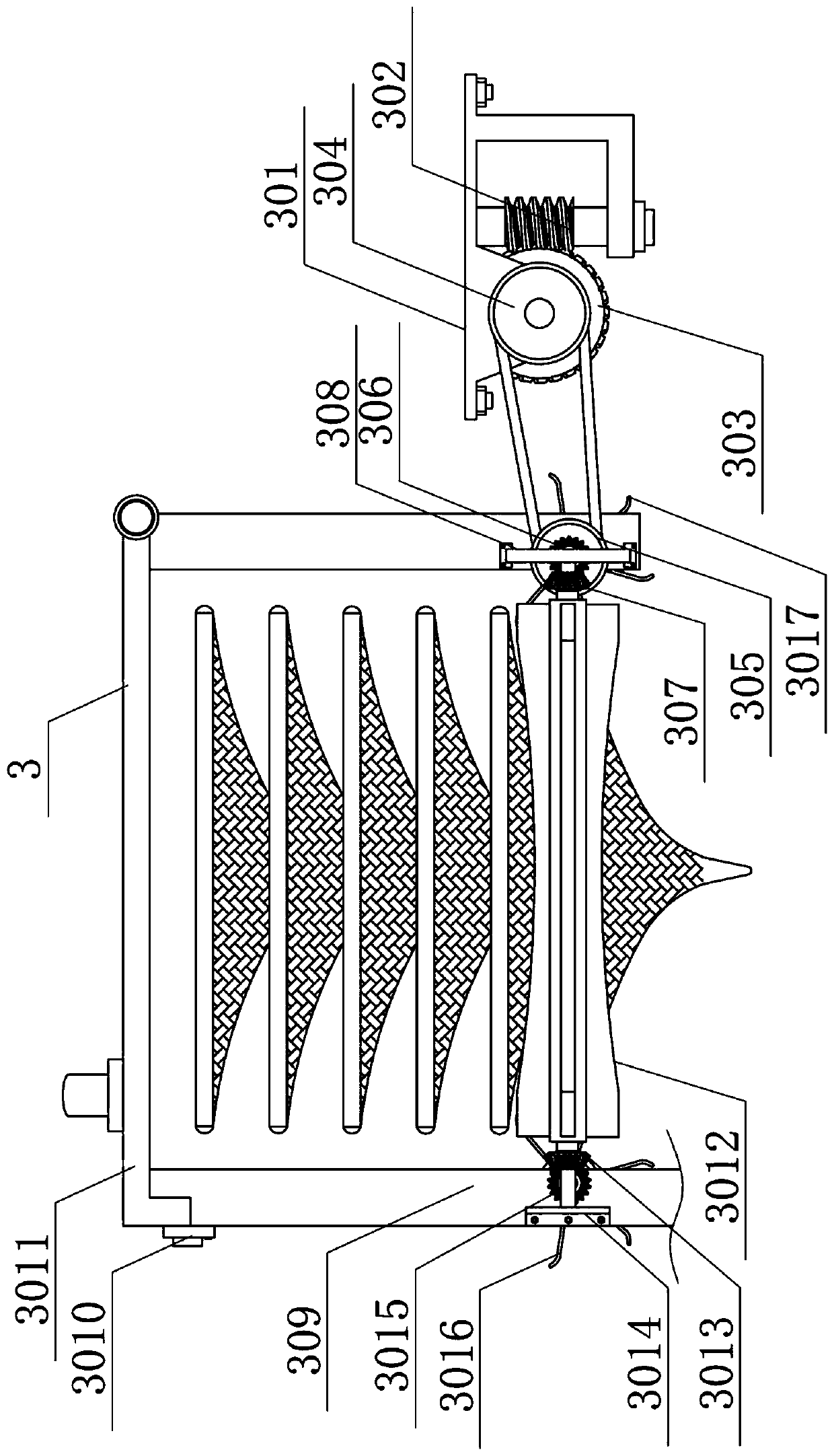

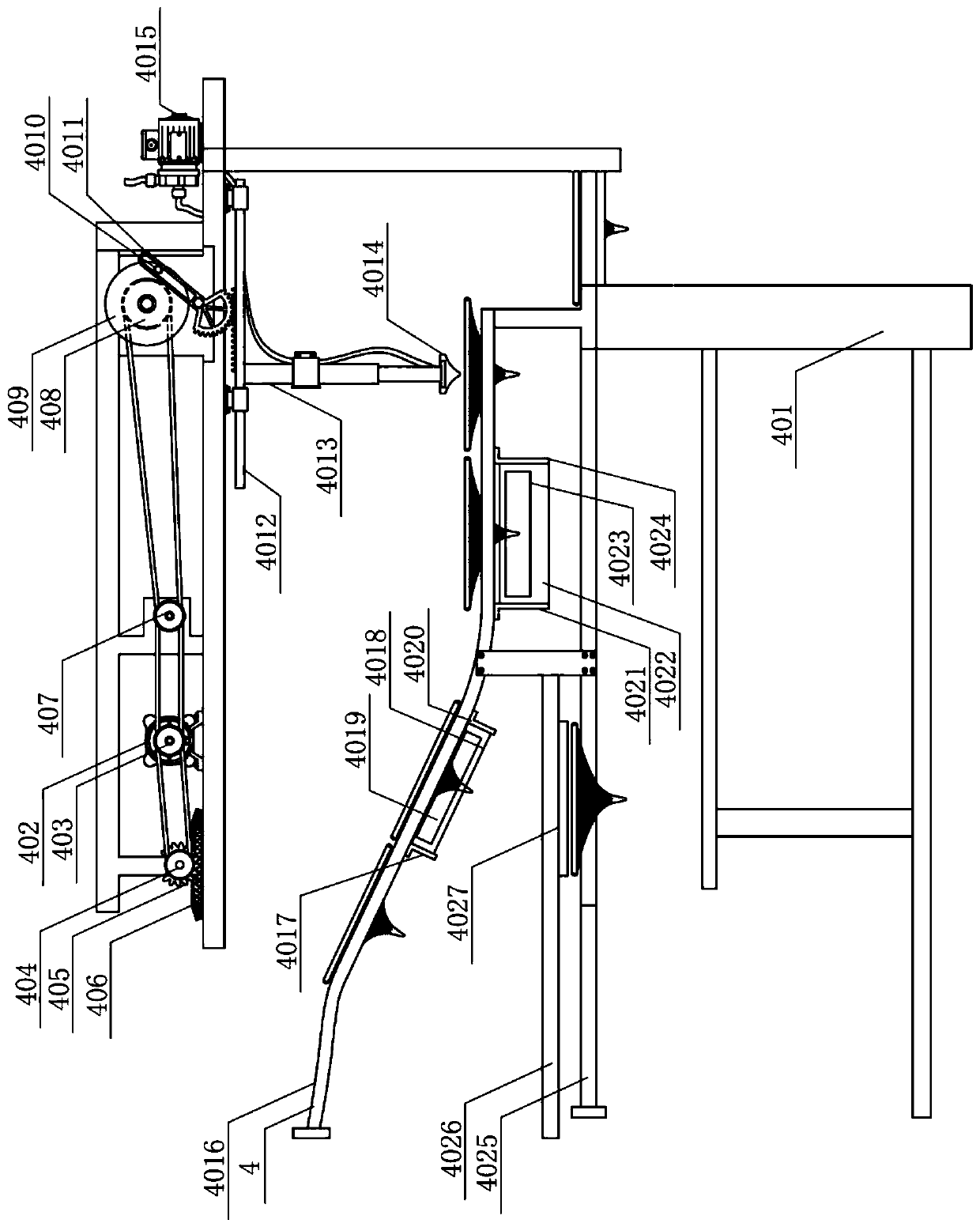

[0033] A bamboo product production device, such as Figure 1-9 As shown, it includes a side support column 1, a collection box 2, a positioning and feeding mechanism 3, a double-layer paint transfer mechanism 4, a control panel 5 and a drying and sticking mechanism 6; the top of the side support column 1 is provided with a positioning and feeding mechanism 3; The right side of the side support column 1 is provided with a double-layer paint transfer mechanism 4, and the left side of the double-layer paint transfer mechanism 4 is connected with the positioning feeding mechanism 3; the left side of the inner bottom of the double-layer paint transfer mechanism 4 is provided with a collection box 2. A control panel 5 is installed in the right middle of the double-layer paint transfer mechanism 4 ; a drying sticking mechanism 6 is arranged below the inner middle of the double-layer paint transfer mechanism 4 .

[0034] Working principle: When in use, first place the bamboo product p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com