Vision multi-station dispensing and rhinestone gluing machine

A multi-station, dispensing technology, applied in painting tools, processes for producing decorative surface effects, decorative arts, etc., can solve the problems of low production efficiency, high labor dependence, low degree of automation of spot drilling machines, etc. The effect of high yield and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The orientation words such as "X", "Y", "Z", "side", "front end" and "rear end" used in the present invention are all based on the direction of the drawings, in order to illustrate the technical solution more clearly , and should not be construed as a limitation to the technical solution.

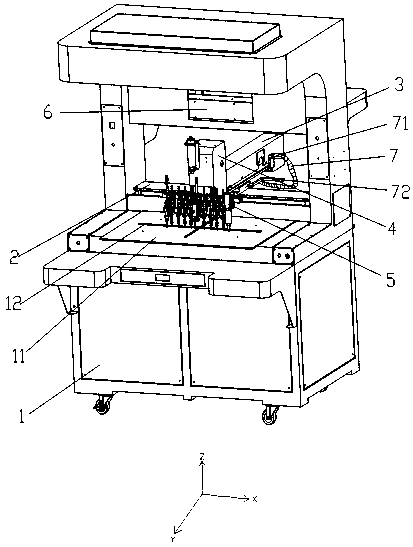

[0022] Such as figure 1 , figure 2 and image 3 As shown, a visual multi-station glue point drilling machine, including:

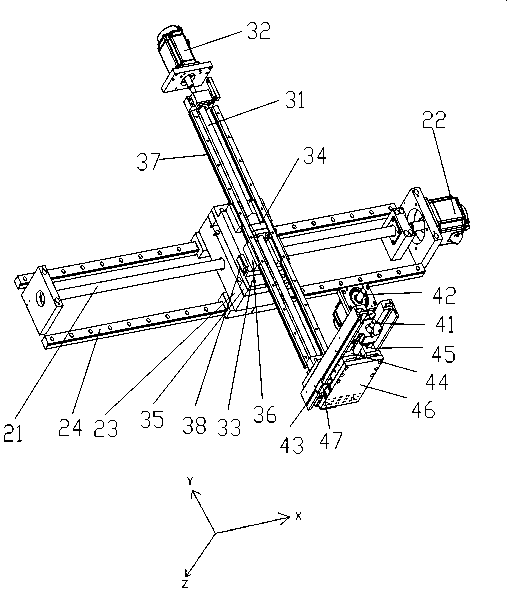

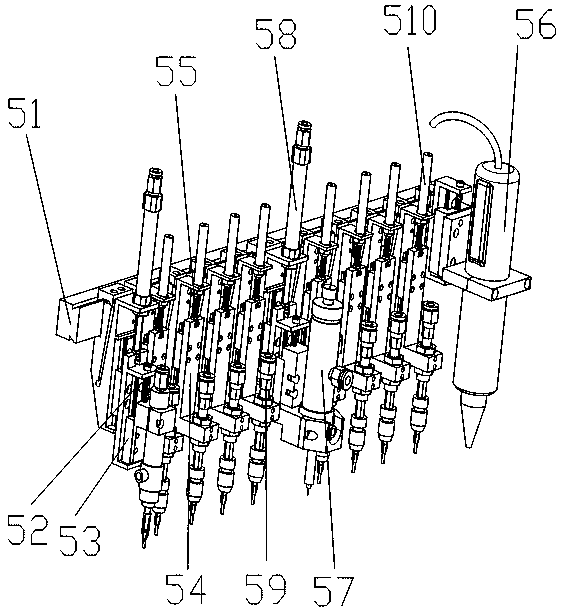

[0023] Frame 1, described frame 1 is provided with console 11; Point drill structure, comprises the crossbeam 2 fixed along X direction, is provided with the first screw mandrel 21 of X direction in the described crossbeam 2, and described first wire The rod 21 is connected to the first motor 22, the beam 2 is slidably connected with the moving arm 3 in the Y direction along the X direction, and the first screw nut on the first screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com