A glass fiber enhanced sand wheel mesh intelligent production method

A production method and technology of glass fiber cloth are applied in the field of intelligent production of glass fiber reinforced grinding wheel mesh cloth, which can solve the problems of low production efficiency of grinding wheel mesh cloth, and achieve the effects of improving coating effect, increasing strength and improving qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

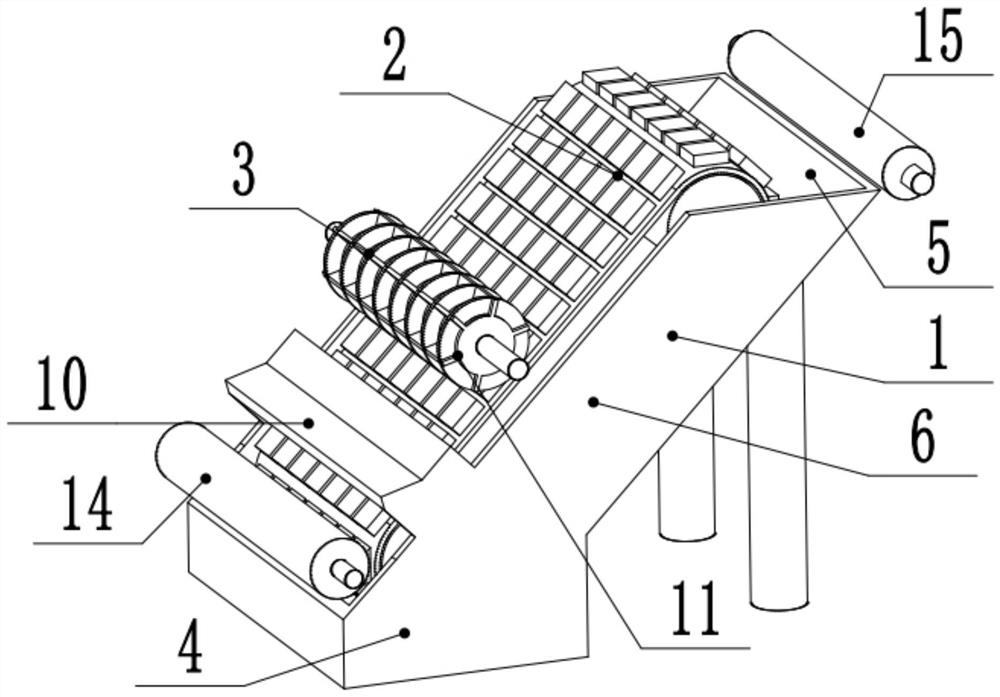

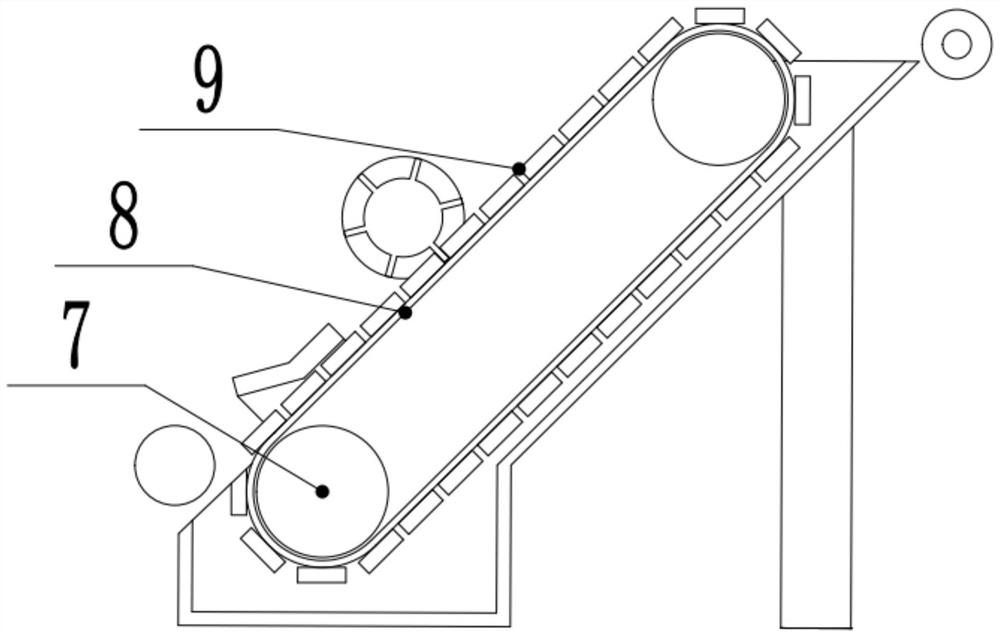

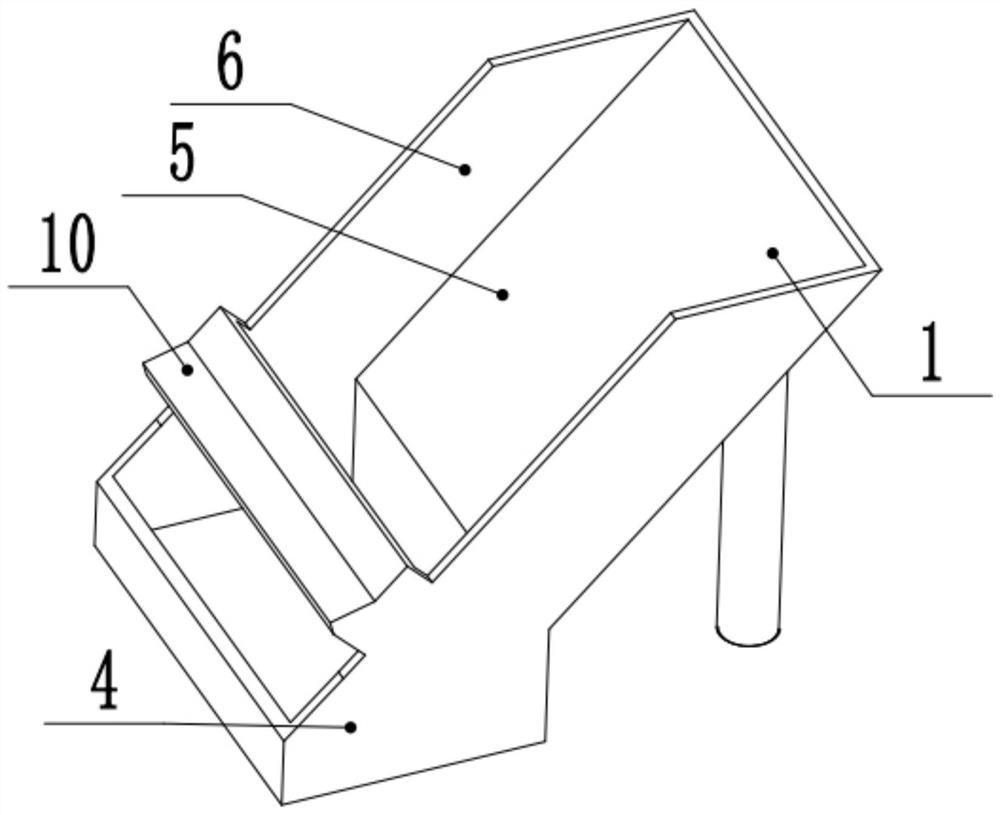

[0038] An intelligent production method for glass fiber reinforced glass fiber mesh cloth, comprising the following steps: S1. When pulling the glass fiber cloth roll, dipping the glass fiber cloth through a dipping device, so that the glass fiber cloth is soaked with phenolic resin glue, Obtain reinforced glass fiber mesh;

[0039] S2. Drying: The reinforced glass fiber mesh obtained in S1 is pressed out of excess glue by a pressure roller, and sent to a drying oven for drying. Using steam at 170 ° C for 2 minutes, drying is performed to obtain a dried reinforced glass fiber mesh. cloth;

[0040] S3, cutting: the drying reinforced glass fiber mesh obtained in S2 is cut by a cutting device to obtain the required size of the glass fiber mesh;

[0041] S4. Detection: The glass fiber mesh obtained in S3 is transported to the picking equipment through the conveyor belt, and a detection device is installed on one side of the conveyor belt to detect the defective points on the glas...

Embodiment 2

[0045] An intelligent production method for glass fiber reinforced glass fiber mesh cloth, comprising the following steps: S1. When pulling the glass fiber cloth roll, dipping the glass fiber cloth through a dipping device, so that the glass fiber cloth is soaked with phenolic resin glue, Obtain reinforced glass fiber mesh;

[0046] S2. Drying: The reinforced glass fiber mesh obtained in S1 is pressed out of excess glue by a pressure roller, and then sent to a drying furnace for drying, and dried at 180 ° C for 3 minutes with steam to obtain a dried reinforced glass fiber mesh. cloth;

[0047] S3, cutting: the drying reinforced glass fiber mesh obtained in S2 is cut by a cutting device to obtain the required size of the glass fiber mesh;

[0048] S4. Detection: The glass fiber mesh obtained in S3 is transported to the picking equipment through the conveyor belt, and a detection device is installed on one side of the conveyor belt to detect the flaws on the glass fiber mesh, a...

Embodiment 3

[0052] An intelligent production method for glass fiber reinforced glass fiber mesh cloth, comprising the following steps: S1. When pulling the glass fiber cloth roll, dipping the glass fiber cloth through a dipping device, so that the glass fiber cloth is soaked with phenolic resin glue, Obtain reinforced glass fiber mesh;

[0053] S2. Drying: The reinforced glass fiber mesh obtained in S1 is pressed out of excess glue by a pressure roller, and then sent to a drying furnace for drying, and dried at 180 ° C for 3 minutes with steam to obtain a dried reinforced glass fiber mesh. cloth;

[0054] S3, cutting: the drying reinforced glass fiber mesh obtained in S2 is cut by a cutting device to obtain the required size of the glass fiber mesh;

[0055] S4. Detection: The glass fiber mesh obtained in S3 is transported to the picking equipment through the conveyor belt, and a detection device is installed on one side of the conveyor belt to detect the flaws on the glass fiber mesh, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com