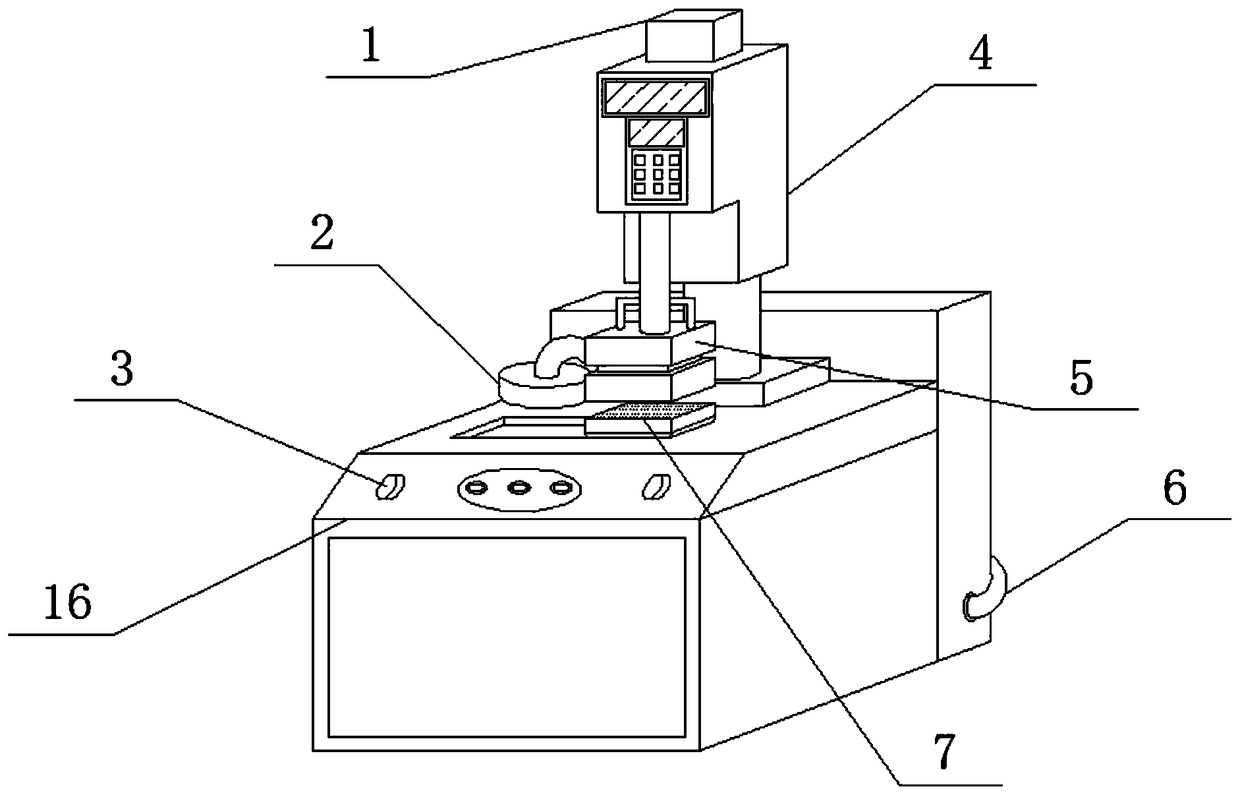

Ultrasonic hot drilling device with optical fiber laser lamp

A laser light and ultrasonic technology, applied in laser welding equipment, decorative art, manufacturing tools, etc., can solve the problems of lower work efficiency, difficulty in controlling strength for beginners, crushing of decorations, etc., to achieve reasonable design and improve ironing Efficiency and product quality, the effect of various functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

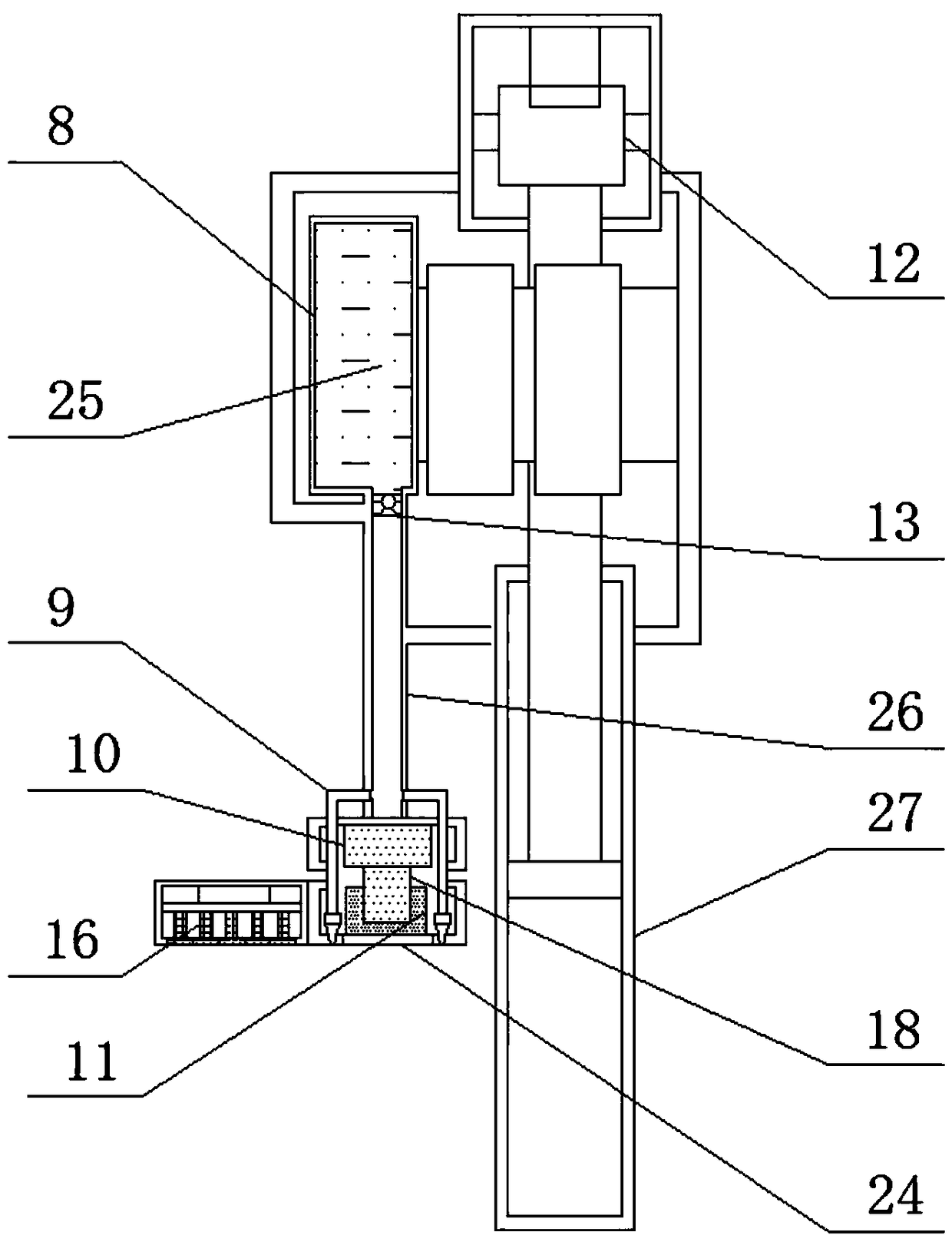

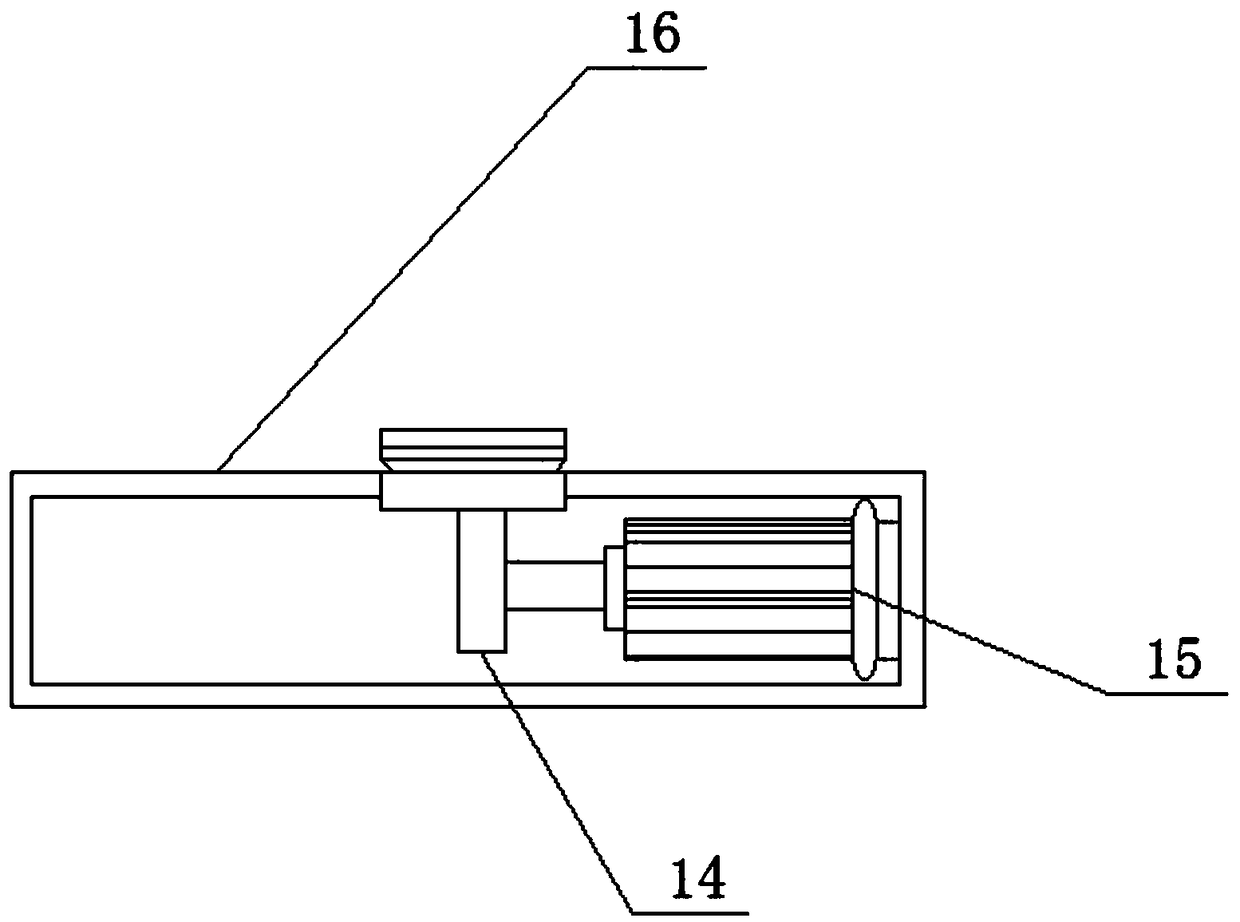

[0030] As a preferred embodiment of the present invention, the motor 15 is welded on the inner side wall of the base 16 through the motor base 2, the output shaft of the motor 15 is welded with a gear 14, and the base 16 has a mounting hole 5 , and the installation hole five is provided with a moving plate 17, the bottom of the moving plate 17 has an external gear, the moving plate 17 is installed on the gear 14 through the mutual cooperation of the external gear and the gear 14, and the moving plate 17 Welding socket 7 is arranged.

[0031] As a preferred embodiment of the present invention, one end of the telescopic rod 27 has a mounting hole 3, and the telescopic rod 27 is sleeved on the output shaft of the cylinder 12 through the mounting hole 3 .

[0032] As a preferred embodiment of the present invention, the control board 21 includes an intelligent processor 20 and a control switch 23, and the intelligent processor 20 includes a printed circuit main board and a micropro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com