Automatic CPU alignment assembling machine

An automatic alignment and assembly machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as inaccurate alignment, skewed screws, easy locking deviation, etc., to achieve convenient use, reduced skew, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

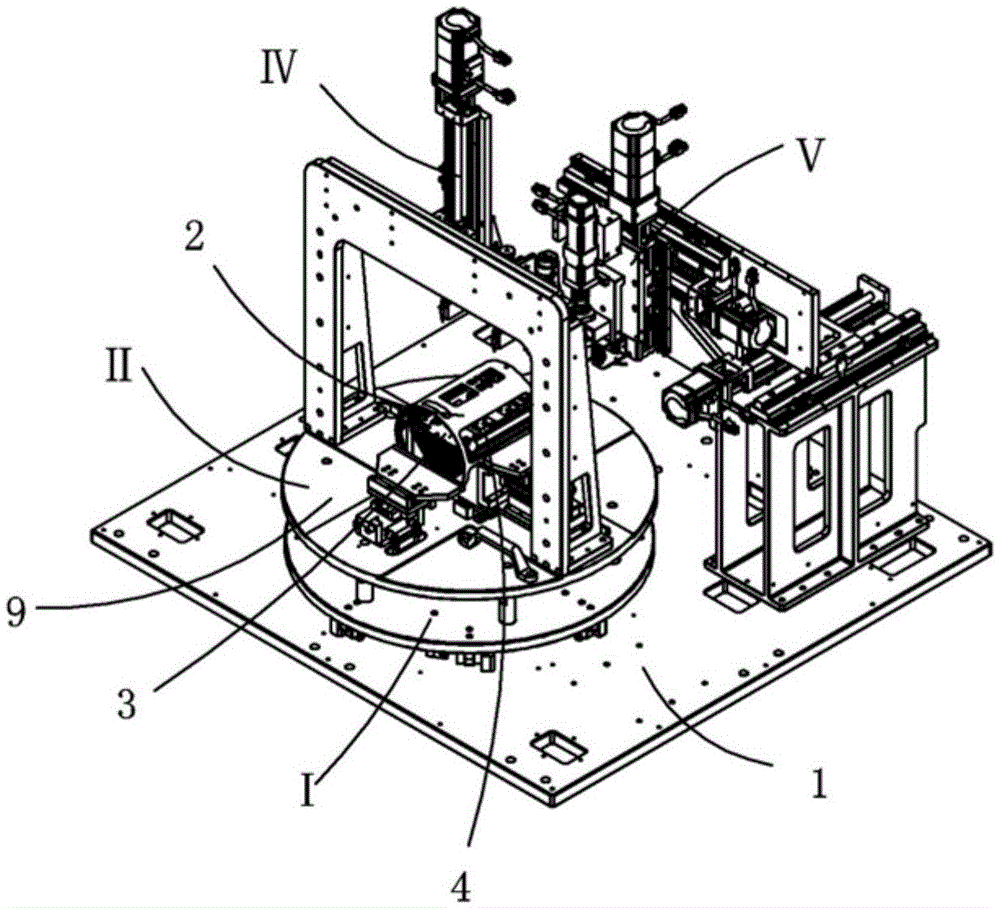

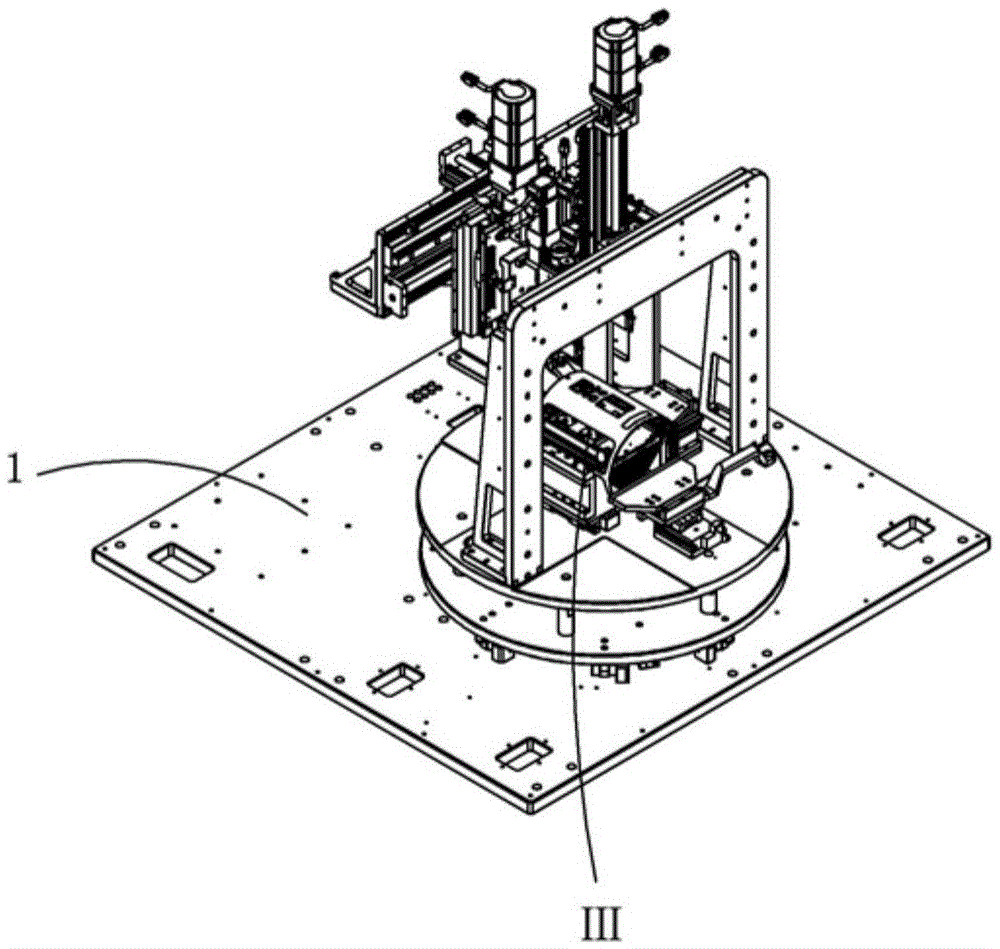

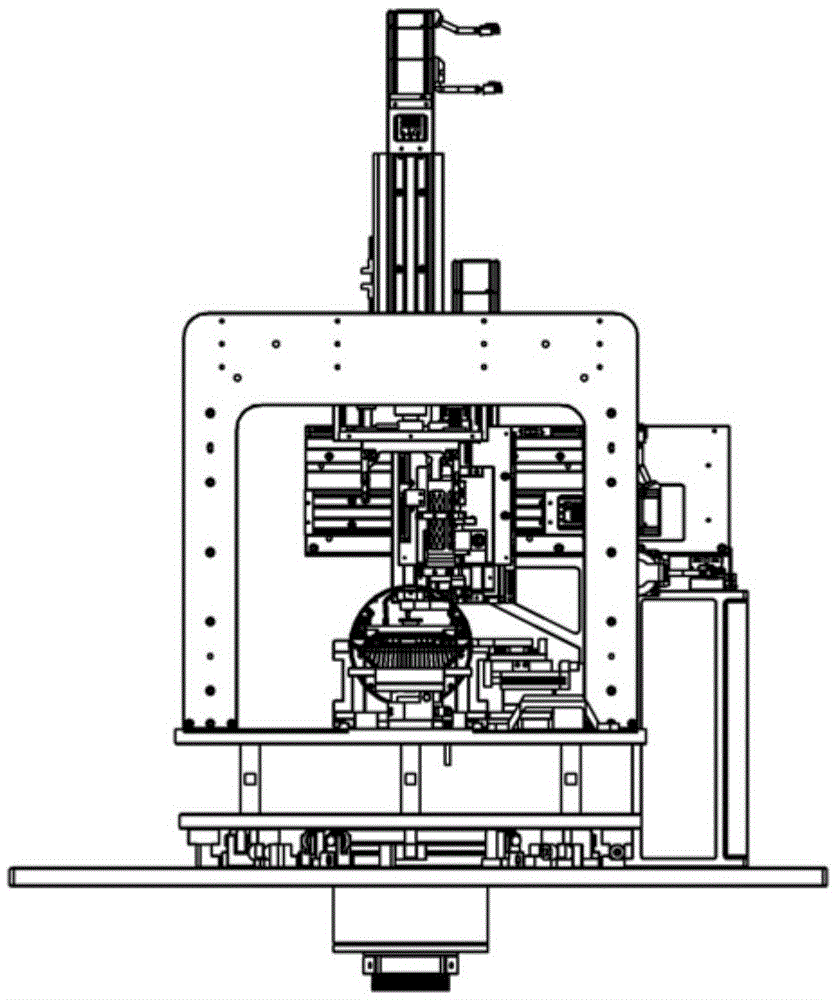

[0043] Examples, see attached Figure 1-21 , a CPU automatic alignment assembly machine, including a base plate 1, a rotating mechanism I for convenient manual loading and unloading is installed on the base plate, and a carrier mechanism II for positioning products is installed on the turntable of the rotating mechanism. The product 2 is positioned on the carrier mechanism, the CPU3 is placed inside the product, and the pressure plate 4 is placed on the CPU. There are multiple sets of screw positioning modules III installed on the pressure plate, and the screw positioning module corresponds to the position to be locked of the product; There is a pressing mechanism IV for pressing down the pressing plate; a locking mechanism V is installed on the bottom plate to lock the CPU to the product through screws.

[0044] The rotating mechanism includes a rotating bearing seat 5, a rotating shaft 6, a turntable base 7, a pillar 8, a support roller device and a rotating disk 9. The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com