Patents

Literature

40results about How to "With automatic operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

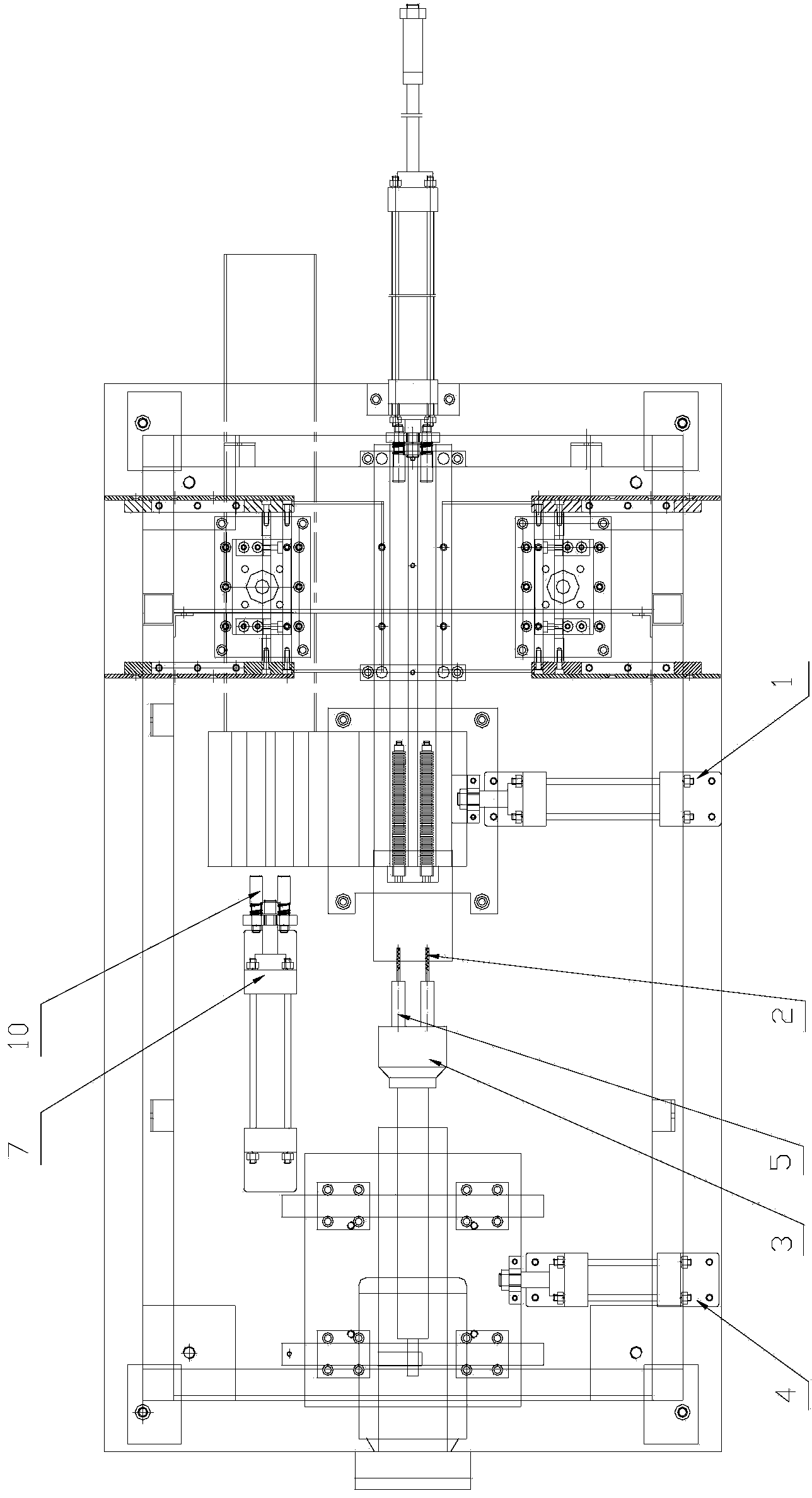

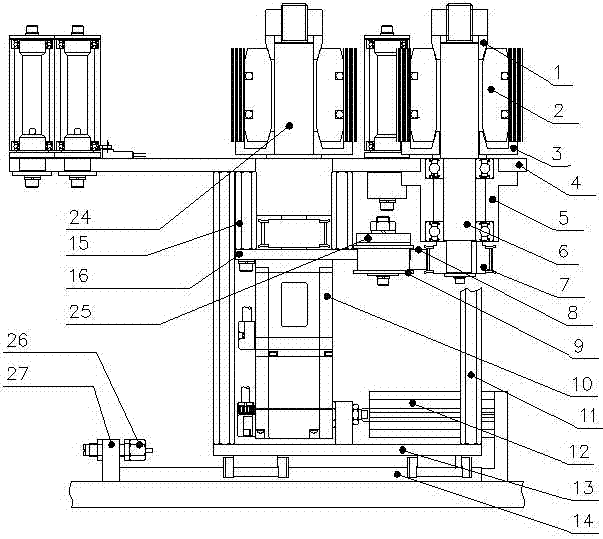

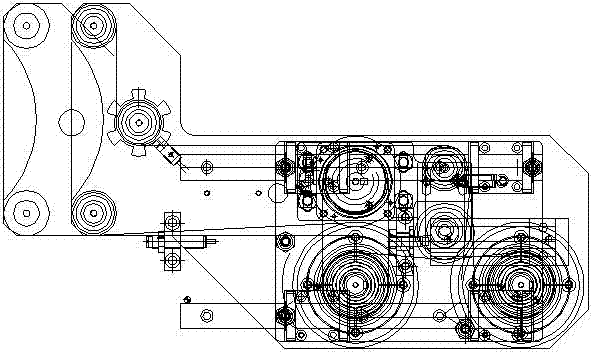

Automatic punching machine

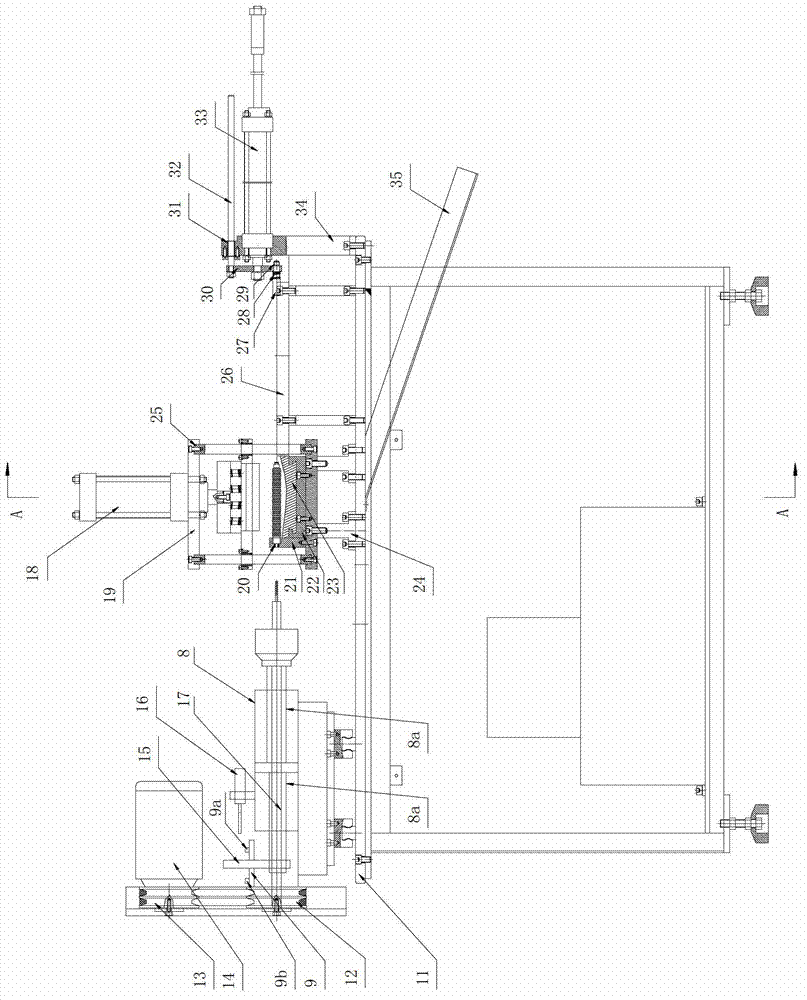

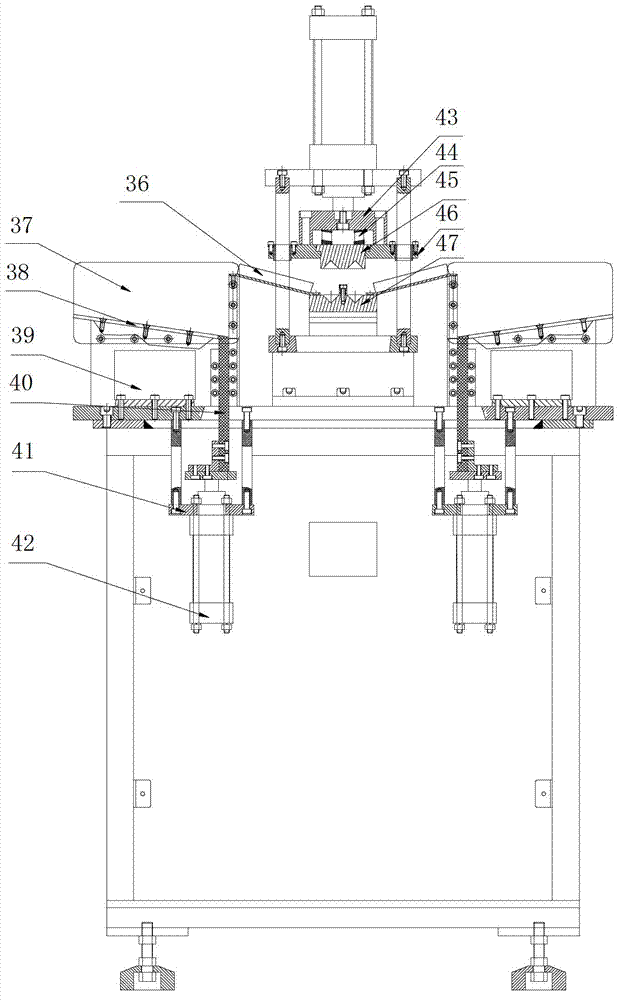

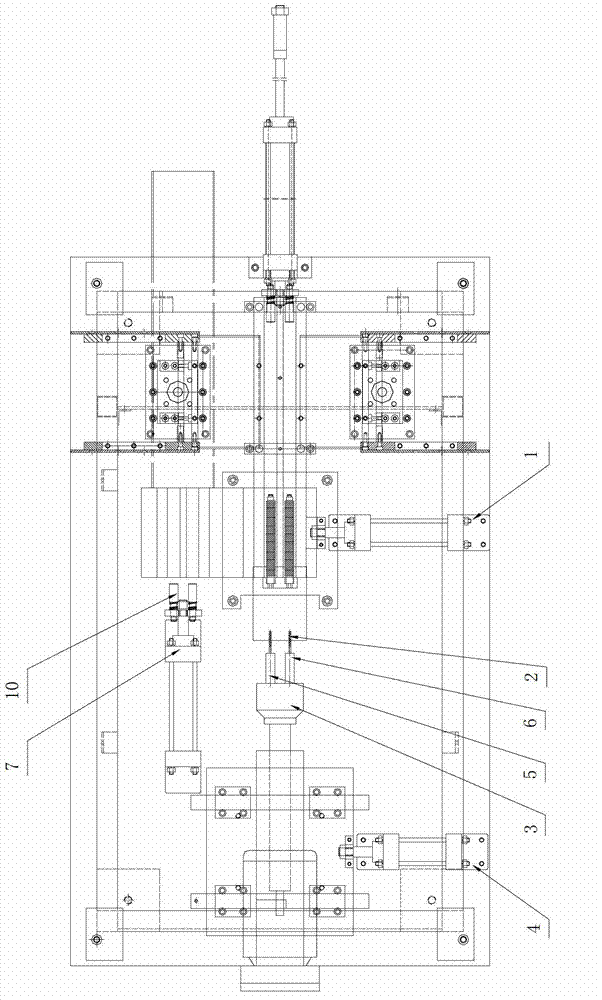

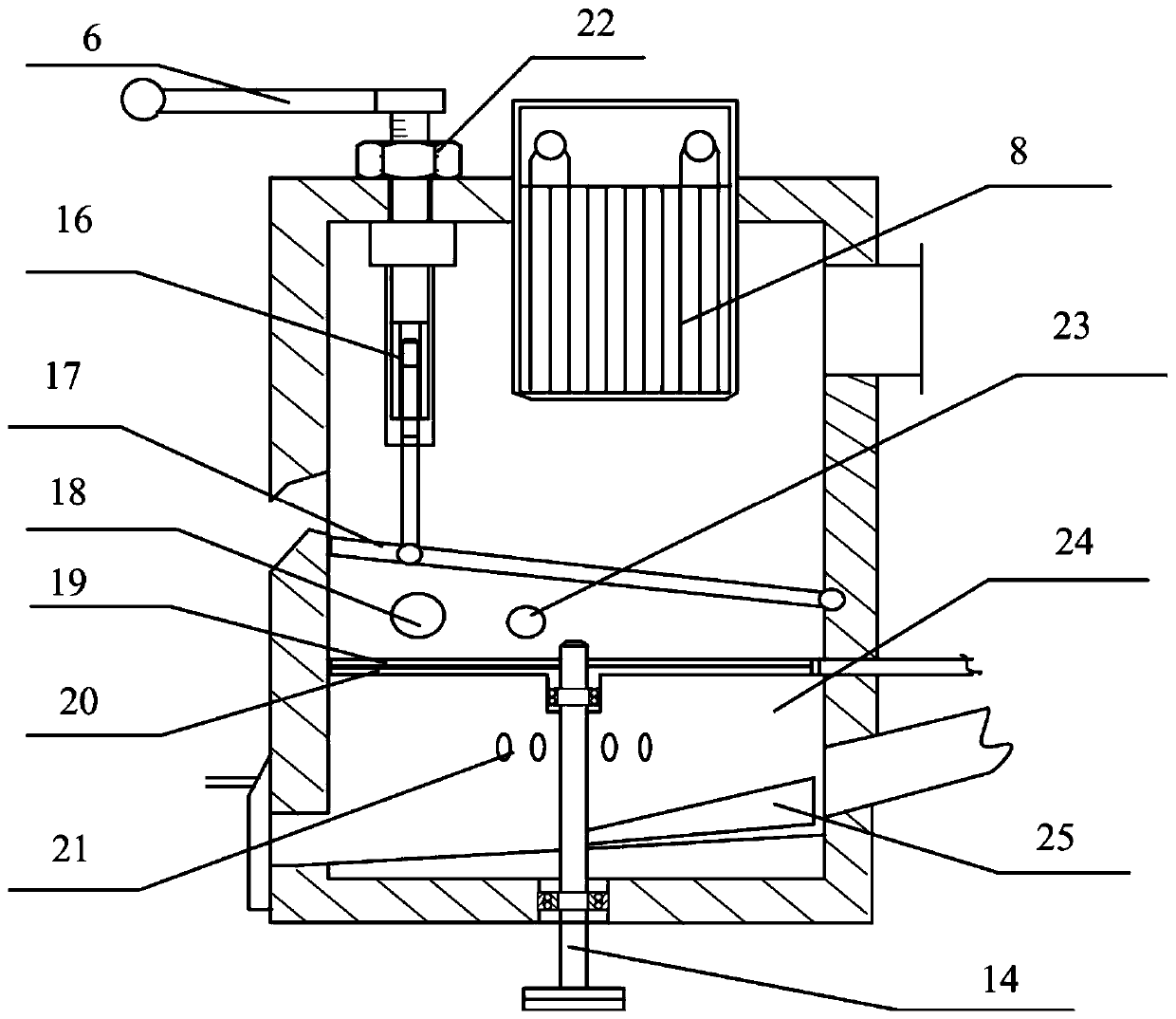

InactiveCN103157822ARealize double-head drilling functionGuaranteed positioning accuracyPositioning apparatusMetal working apparatusPunchingEngineering

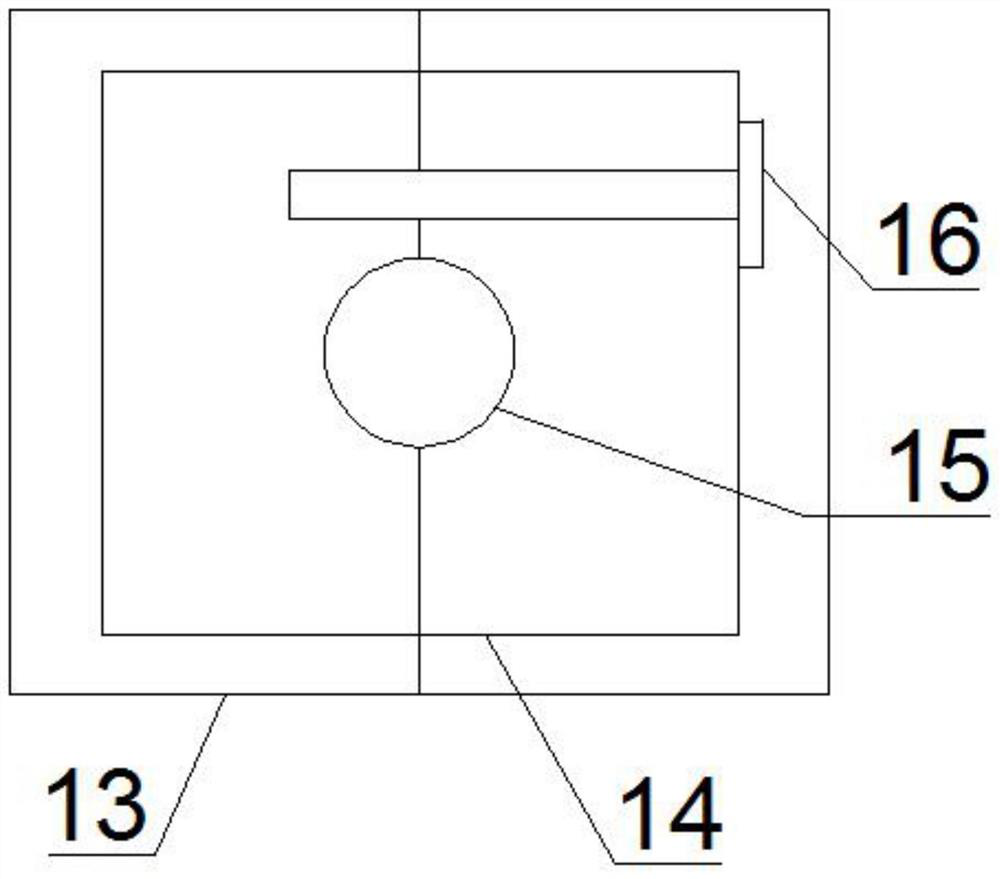

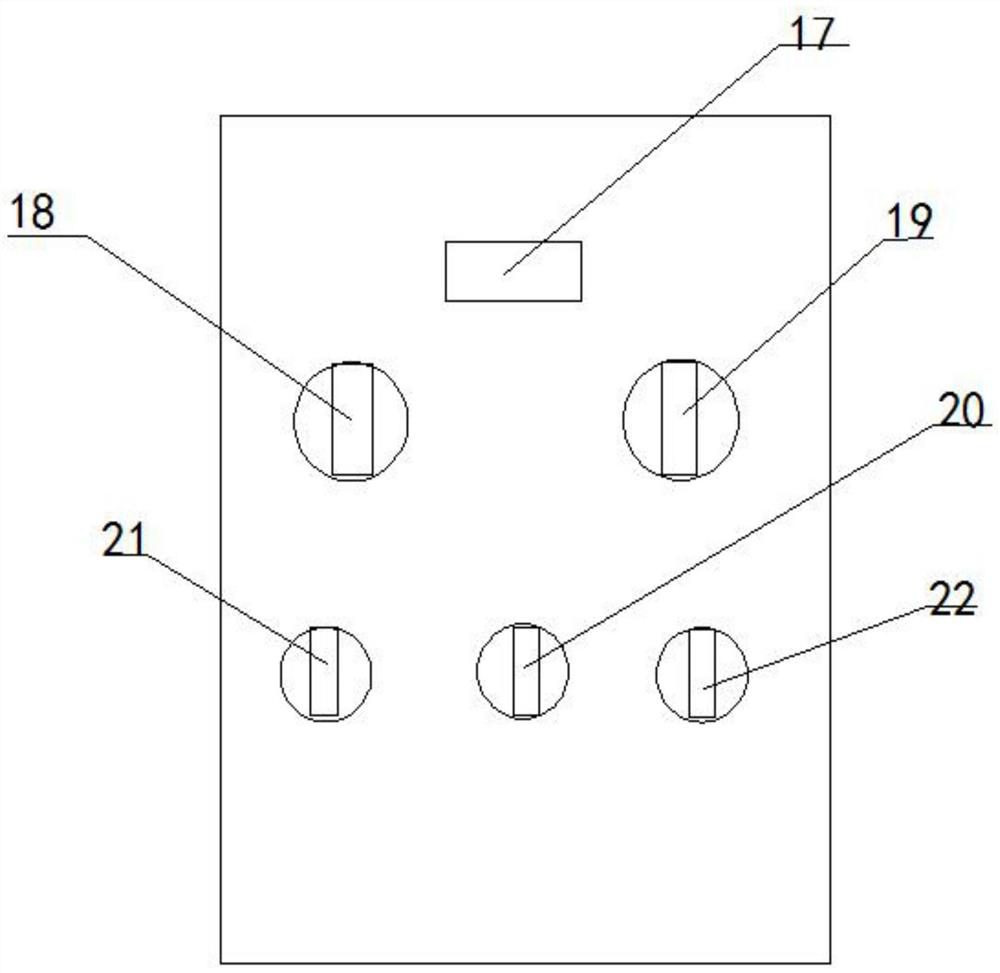

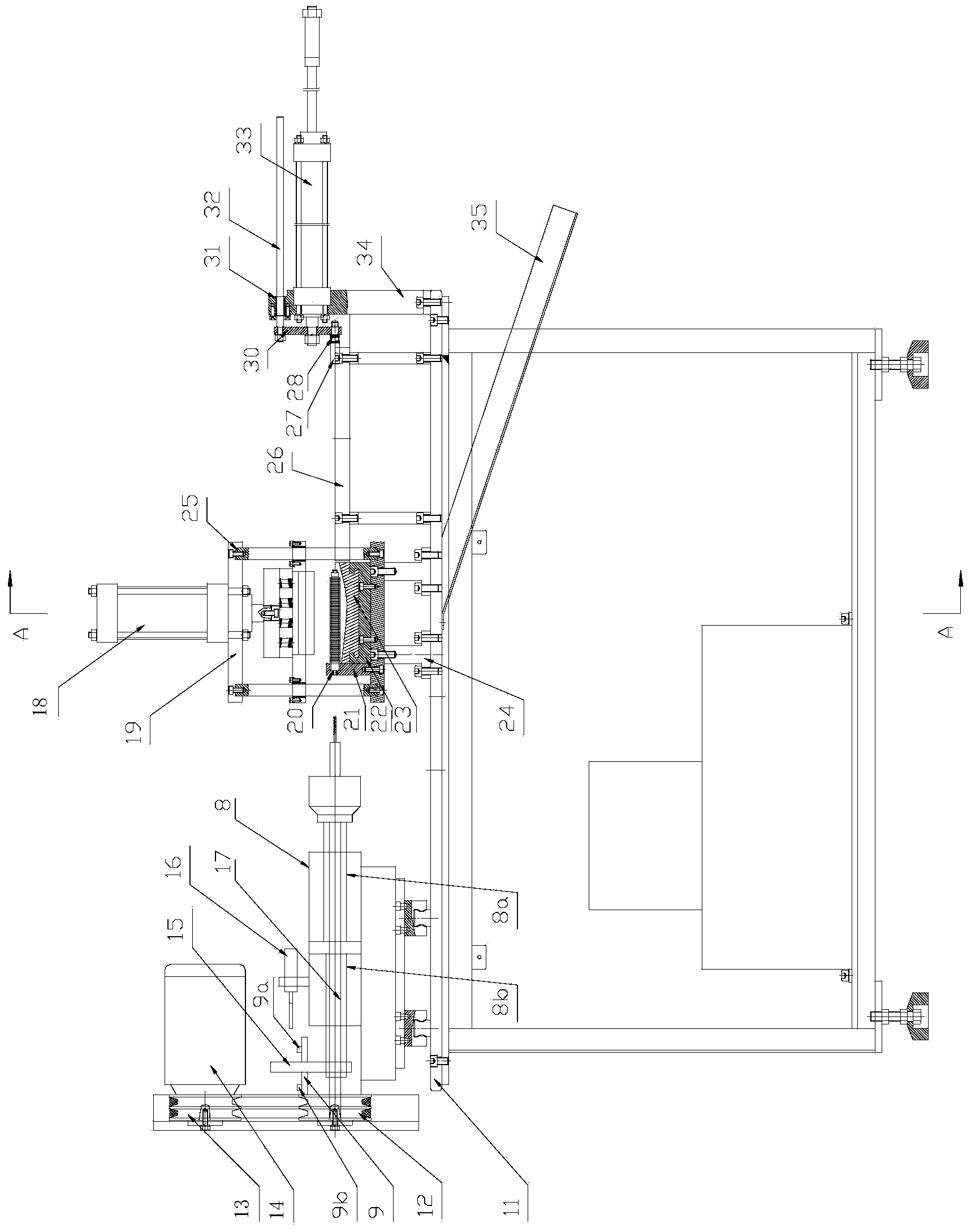

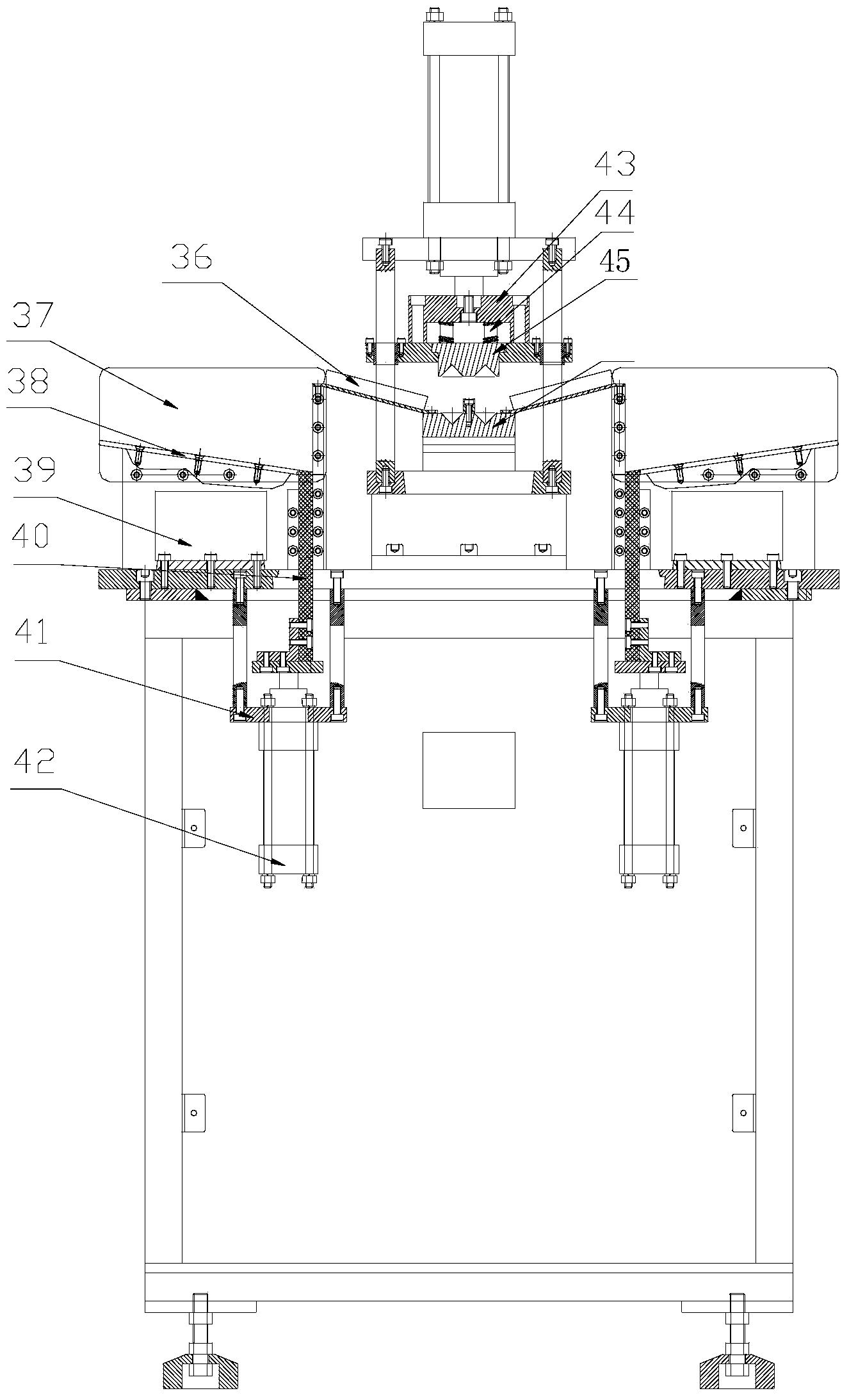

The invention relates to an automatic punching machine. A clamping mechanism opposite to a drilling cutting tool is placed on a work platform. The clamping mechanism comprises a support platform, a lower die device, a baffle, a guide column, a support plate, a pressing support platform, an upper die and a pressing oil cylinder. The lower surface of the support platform is fixed on the work platform, the lower die device is fixed on the upper surface of the support platform, the baffle is fixed on the upper surface of the support platform and is located on one side of the lower die device, and the baffle is provided with a through hole through which a workpiece to be machined penetrates. One end of the guide column is connected with the support platform, and the other end of the guide column is connected with the support plate. The pressing support platform is in sliding fit with the guide column. The upper die is connected with the lower portion of the pressing support platform, the upper portion of the pressing support platform is connected with the pressing oil cylinder which is fixed on the support plate, and both the lower die device and the upper die are provided with two material grooves for assembling the workpiece. By means of the automatic punching machine, two wirkpieces with the same axle can be automatically punched at the same time. The automatic punching machine has the advantages of being high in degree of automation, and improving product quality and production efficiency.

Owner:CHANGZHOU SHULE KITCHEN UTENSILS

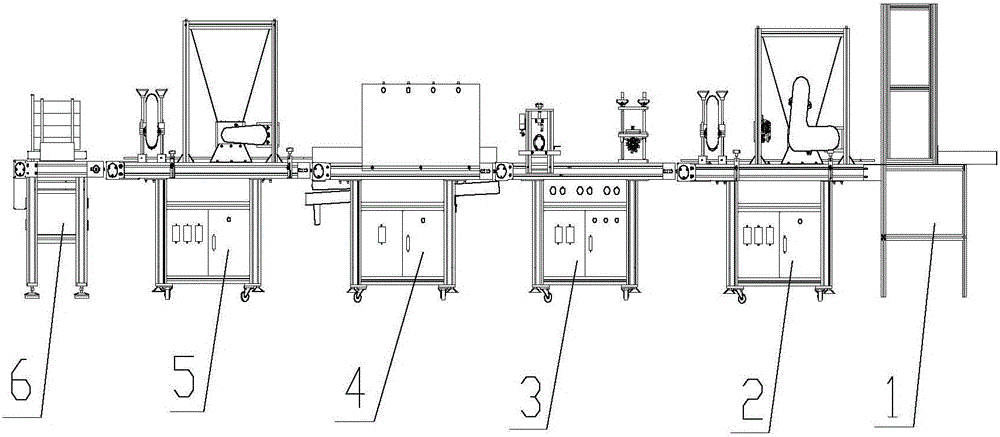

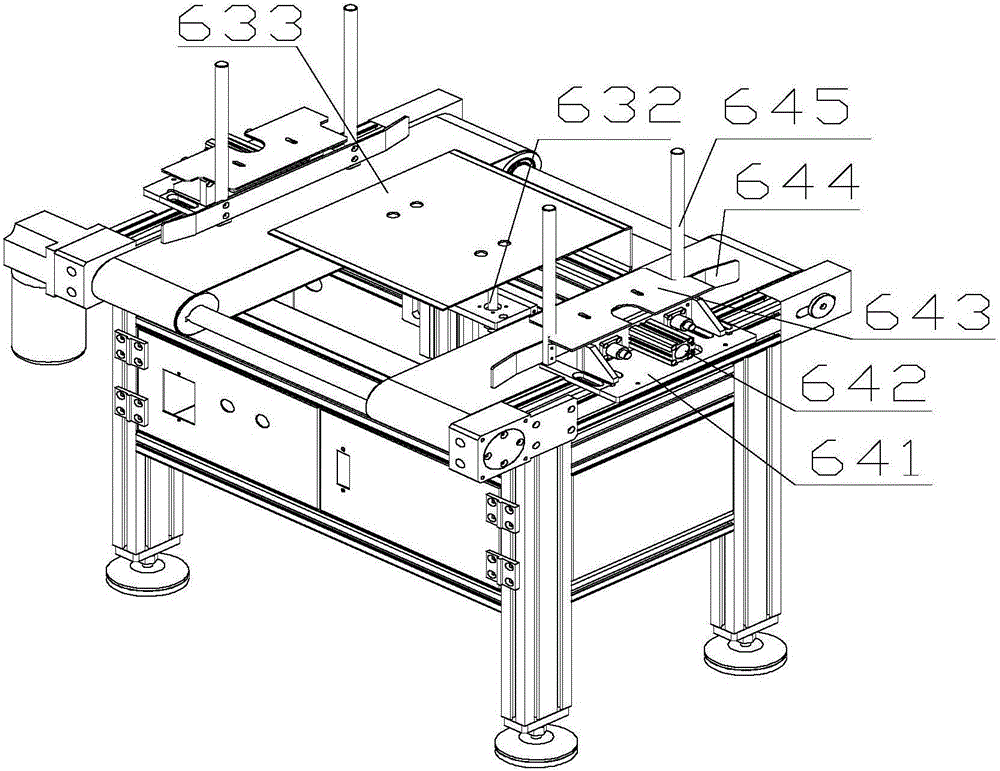

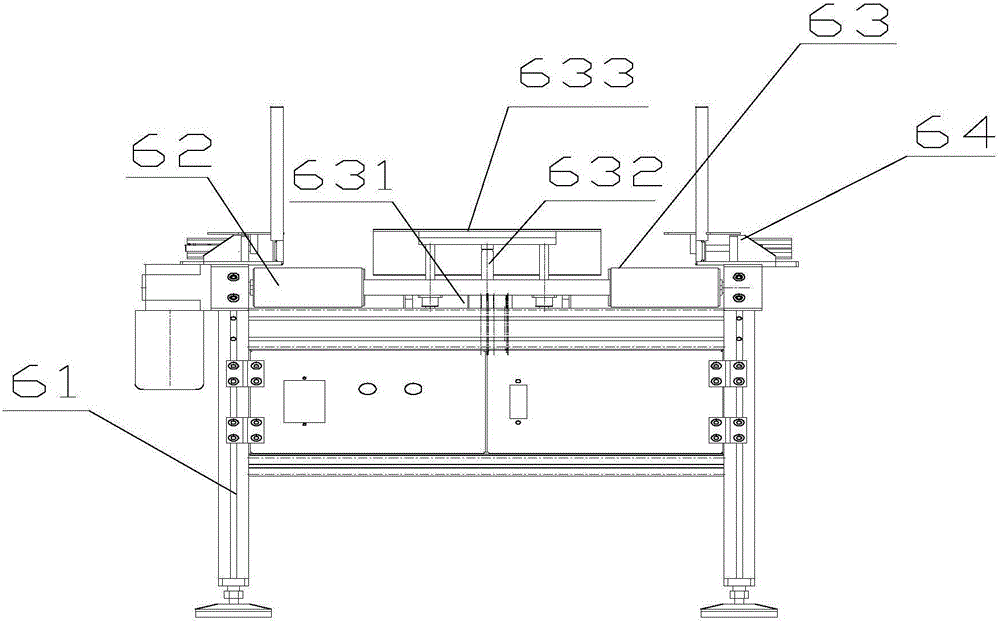

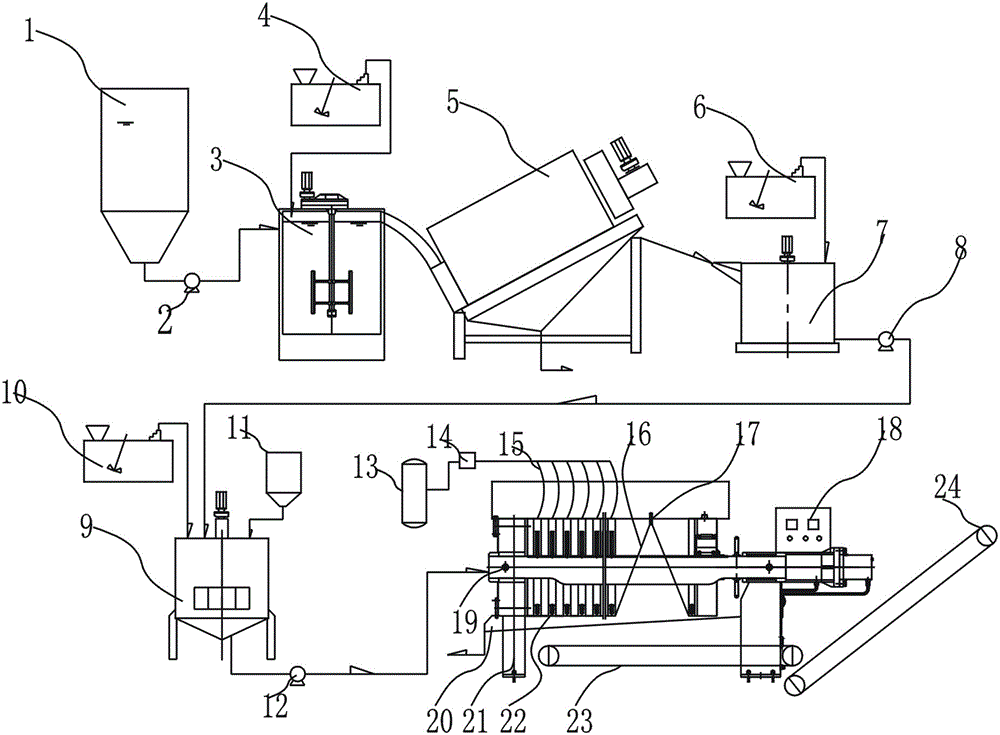

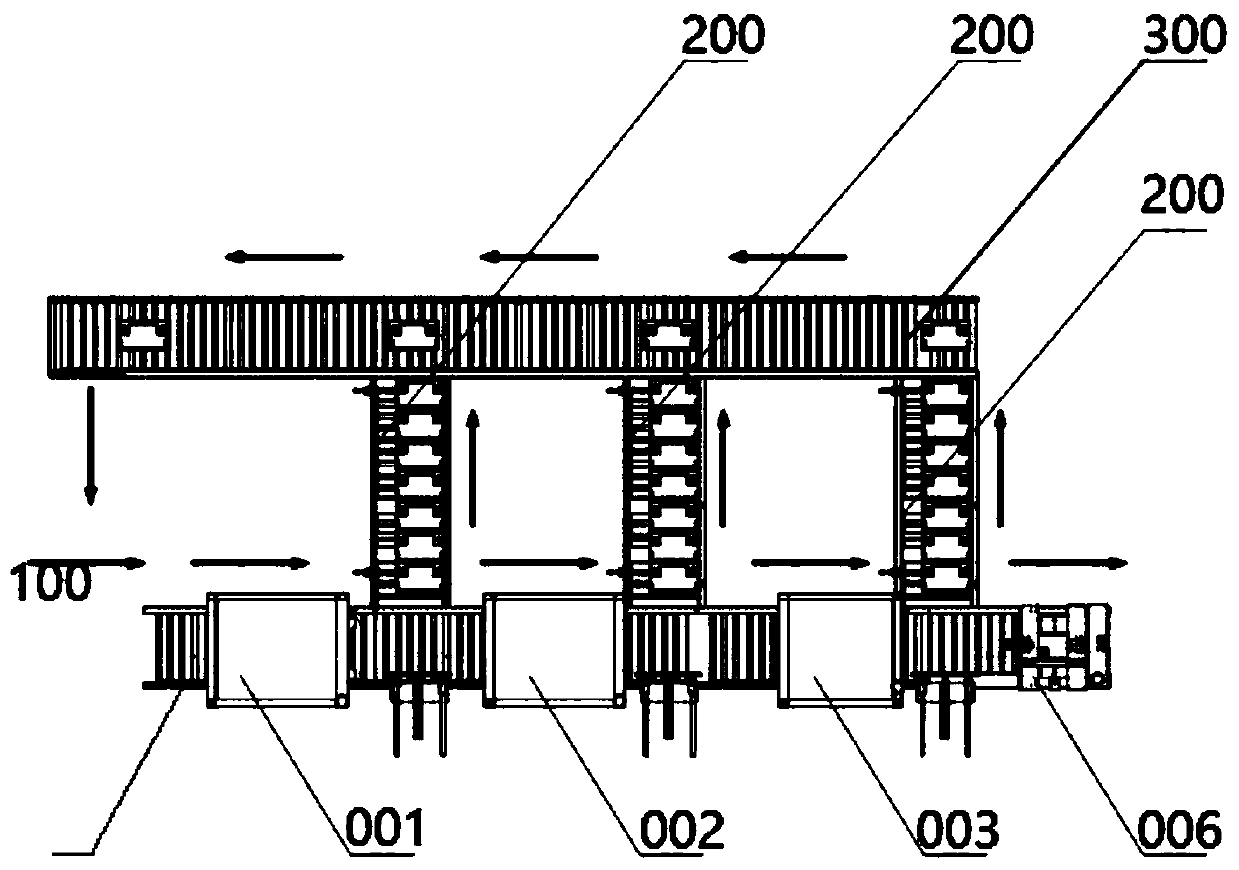

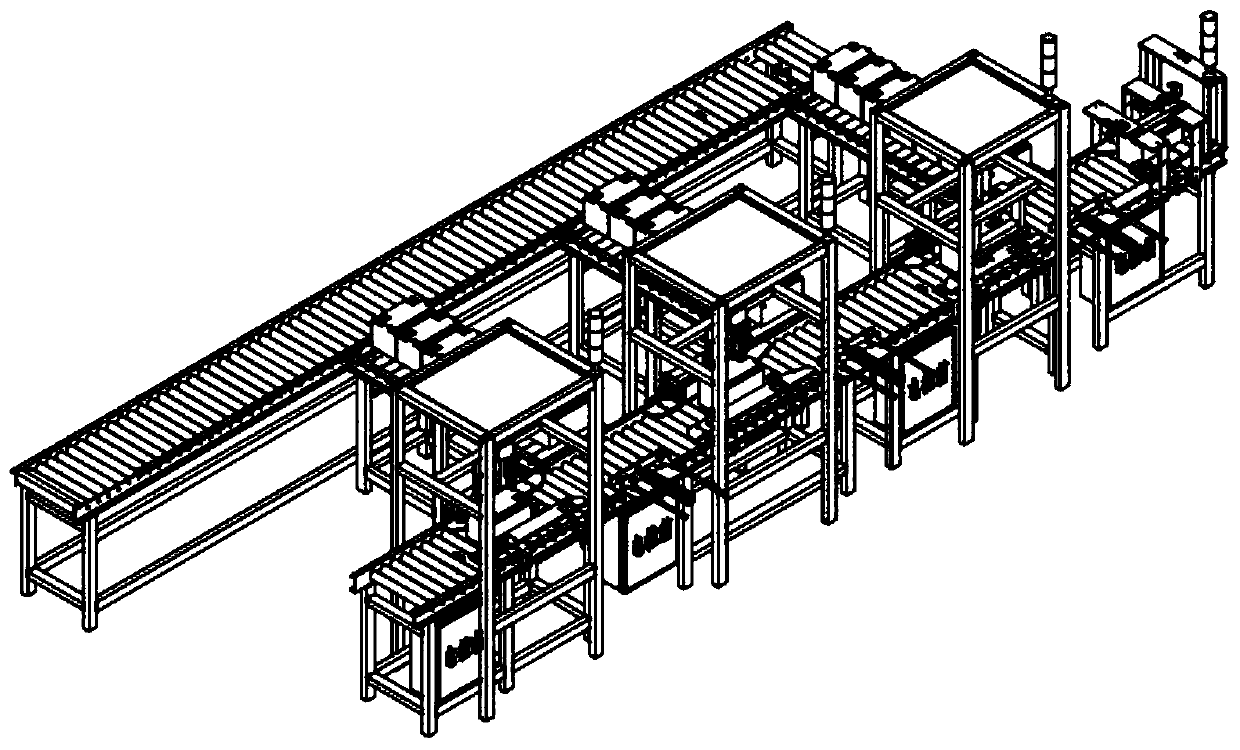

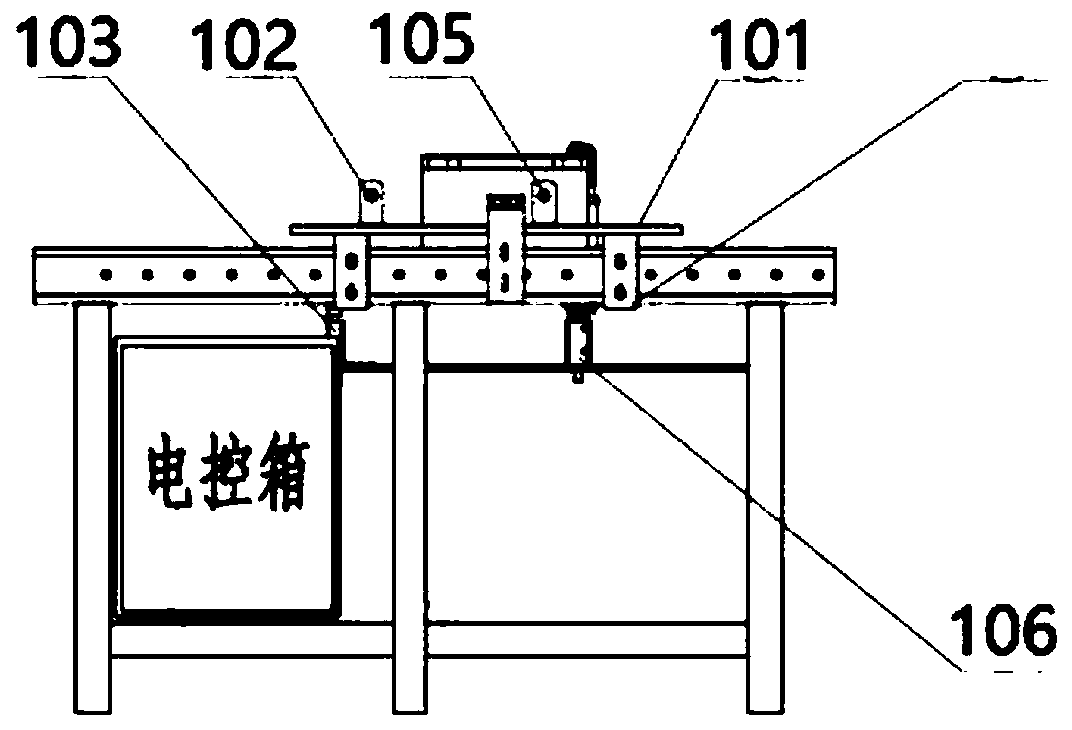

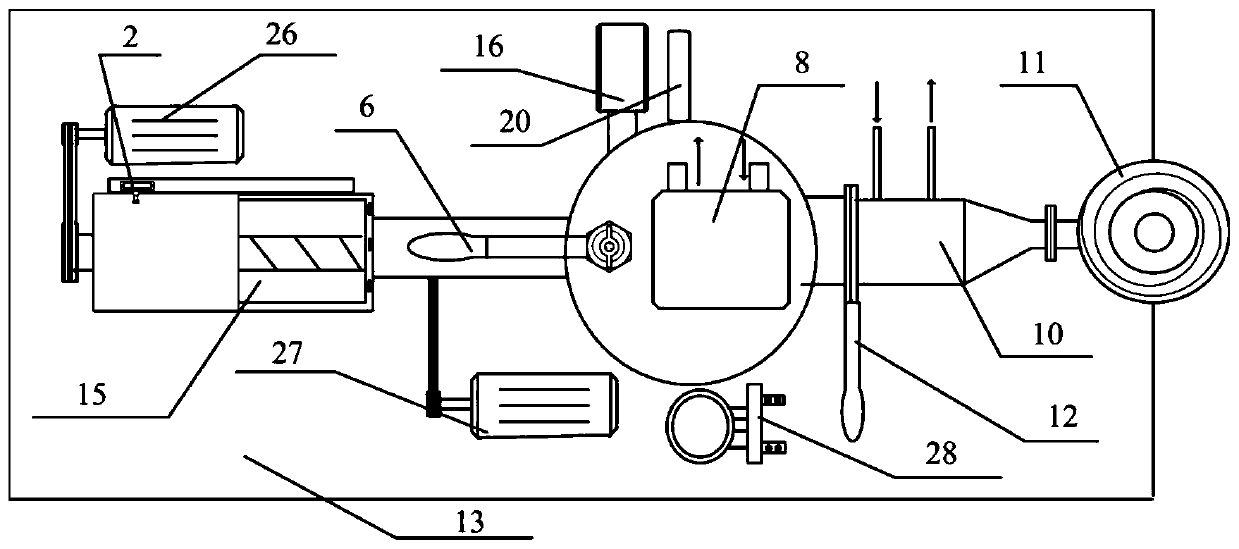

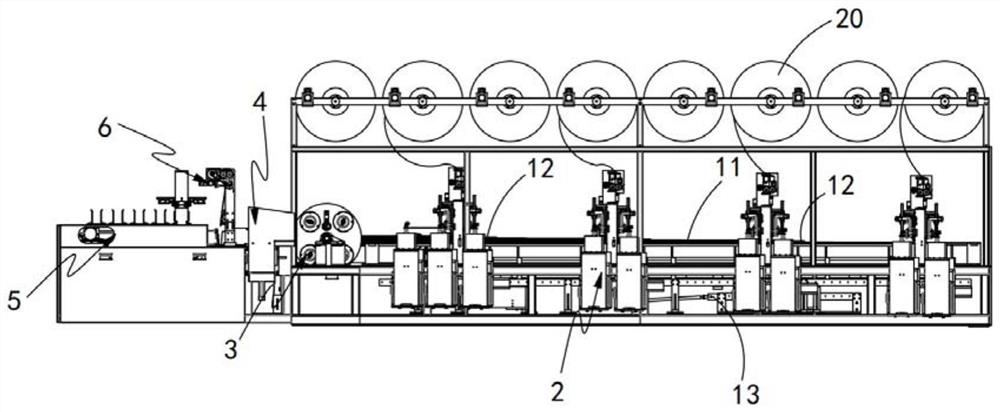

Automated sowing streamline for breeding plug tray

InactiveCN105830592AWith automatic operationImprove work efficiencyCultivating equipmentsSeed depositing seeder partsEngineeringConveyor belt

The invention discloses an automatic seedling tray seeding assembly line. The seeding assembly line is sequentially fixed with a seedling tray upper tray device, a substrate laying device, a precision roller sowing device, a spraying device, a substrate covering device, and a seedling tray stacking device. A seedling raising tray is placed above the seedling raising tray upper plate device, and the seedling raising tray is pushed to the sowing line along the conveyor belt. The working efficiency of the assembly line of the present invention is 10 times that of the traditional artificial seedling raising mode, reduces the labor cost by two-thirds, and can significantly improve the quality of seedling raising. The operation is simpler, the work efficiency and quality are higher, the commonality of parts is better, the reliability and safety are higher, and the market prospect is very broad.

Owner:山东中天盛科自动化设备有限公司

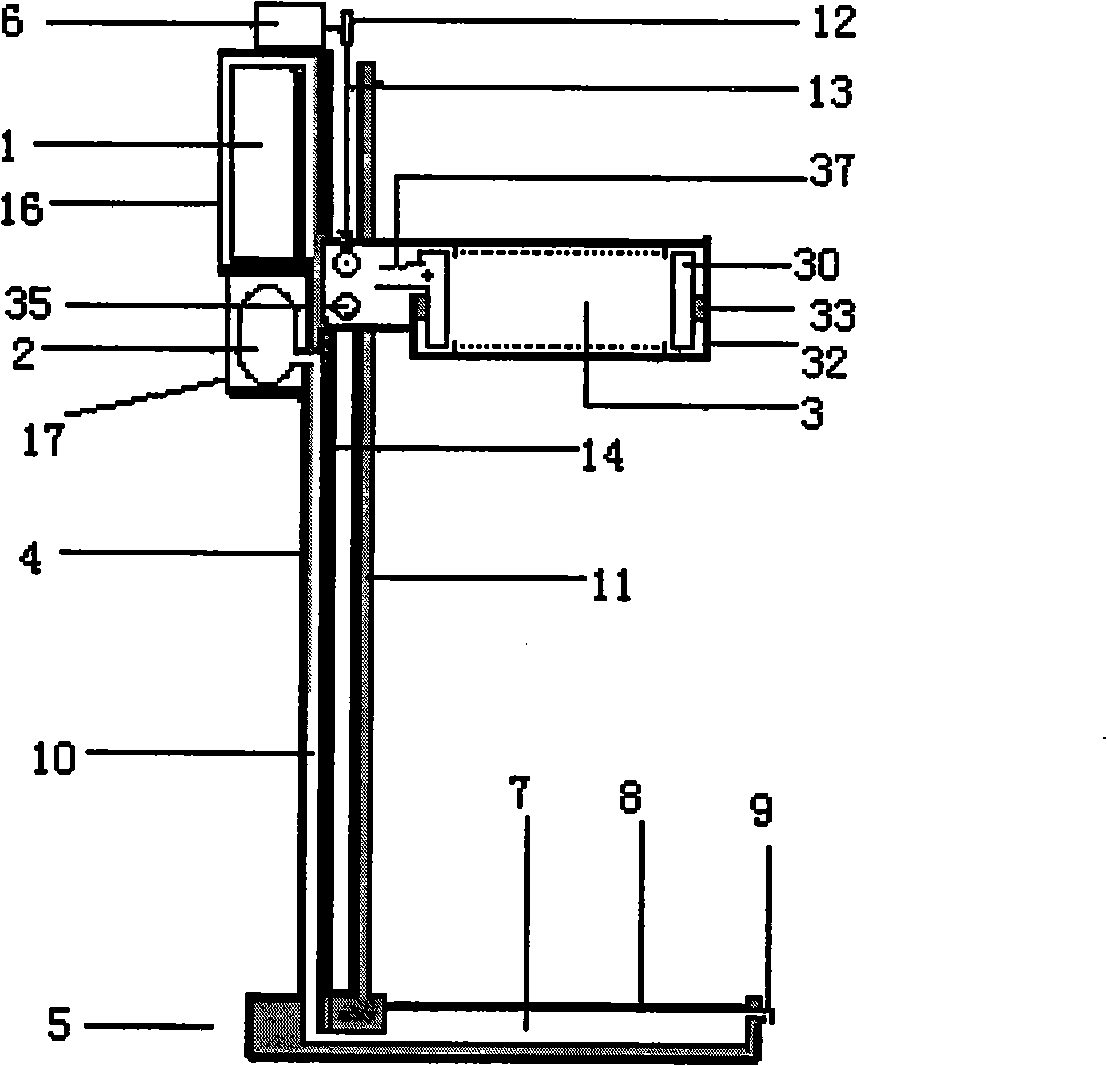

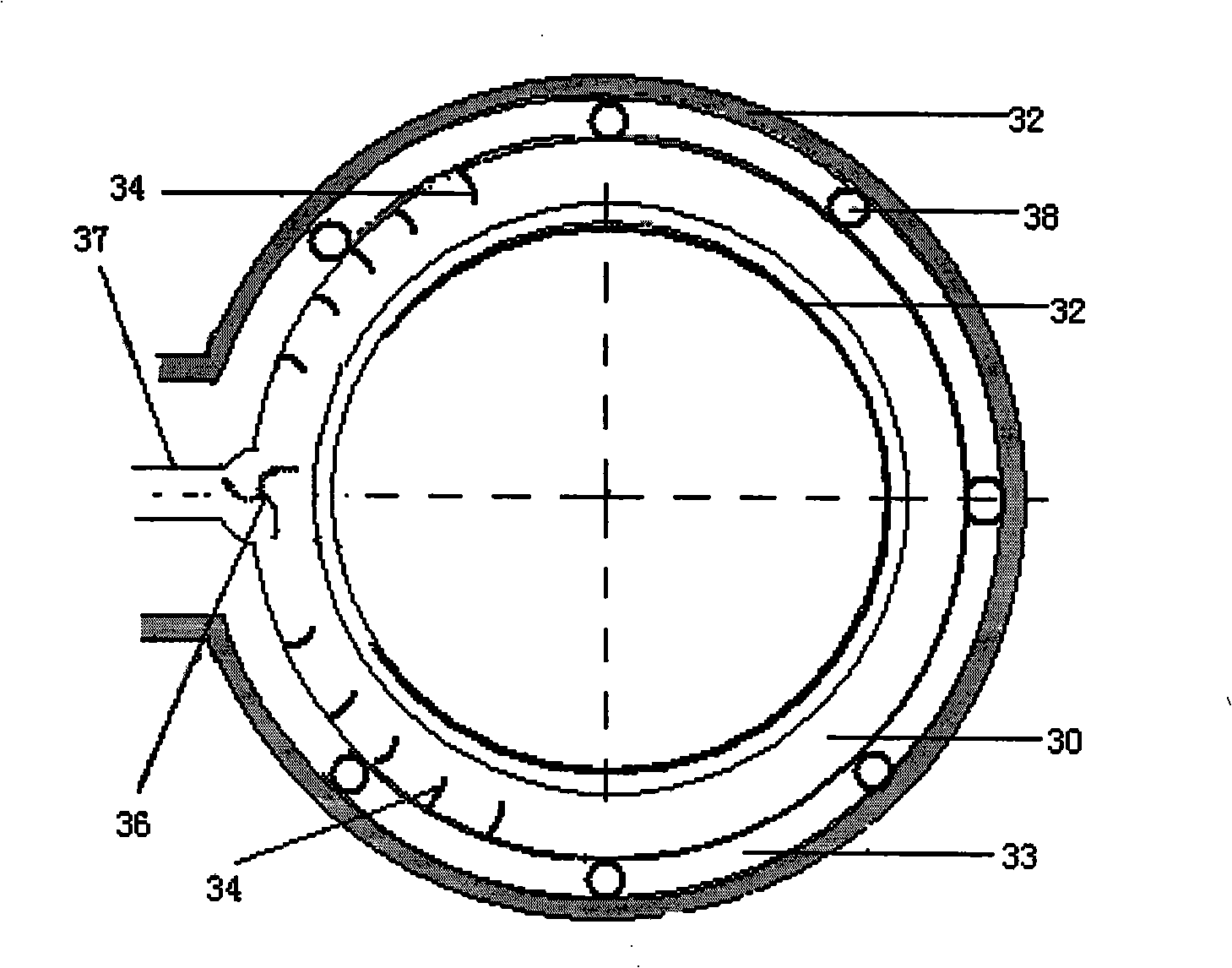

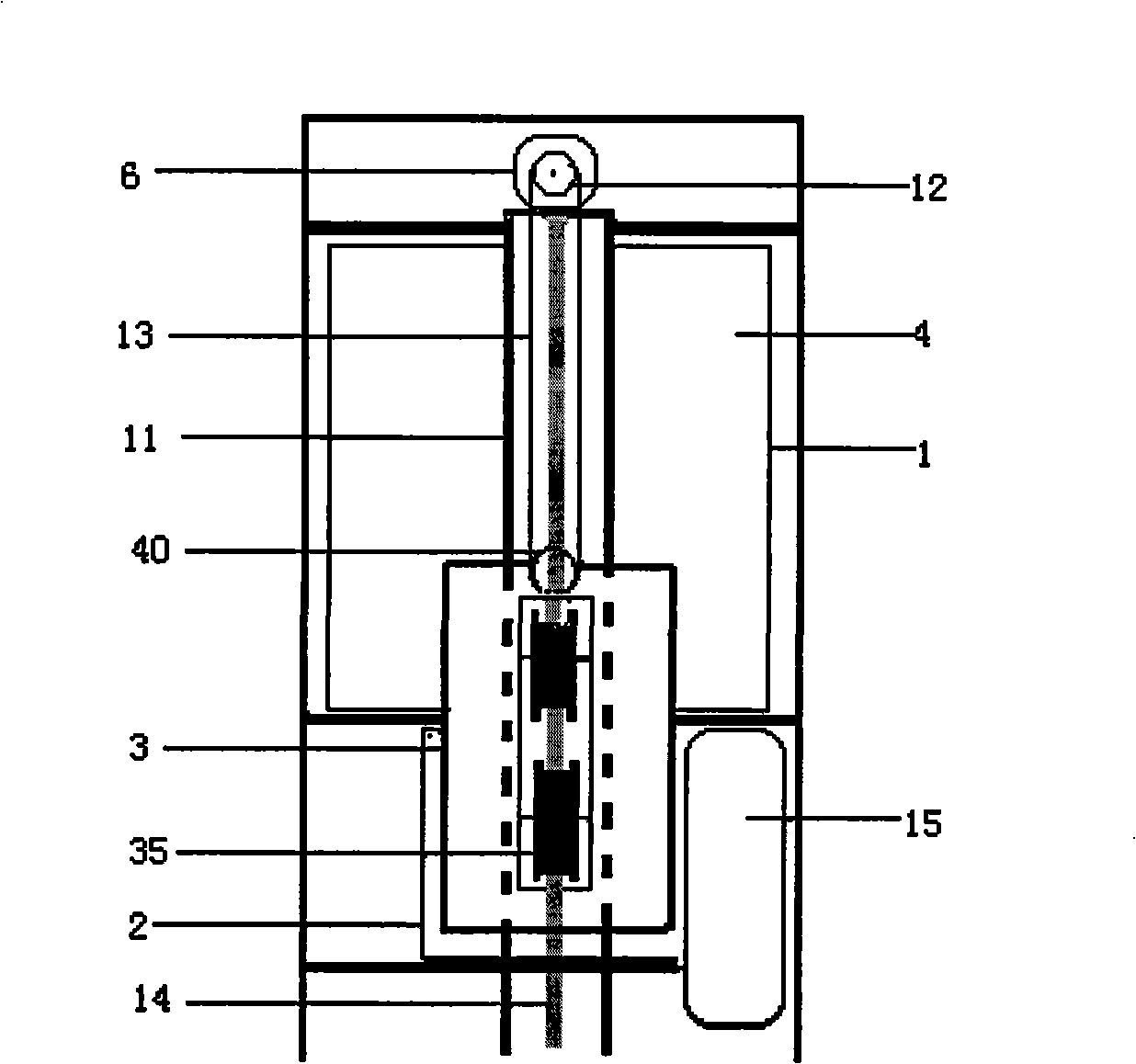

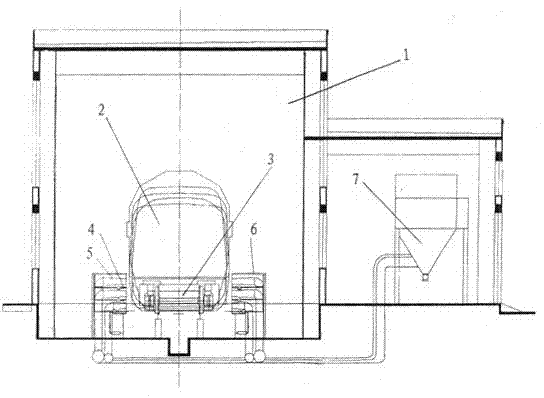

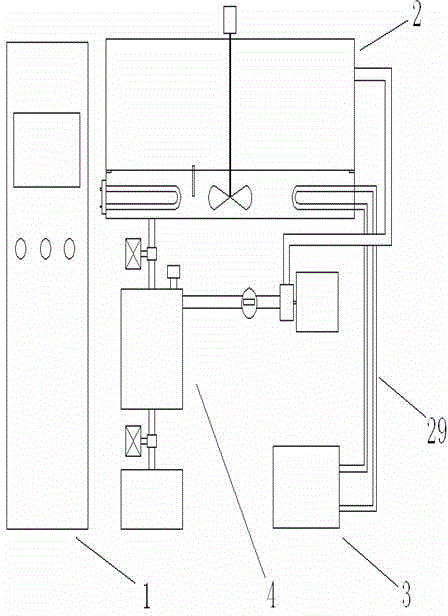

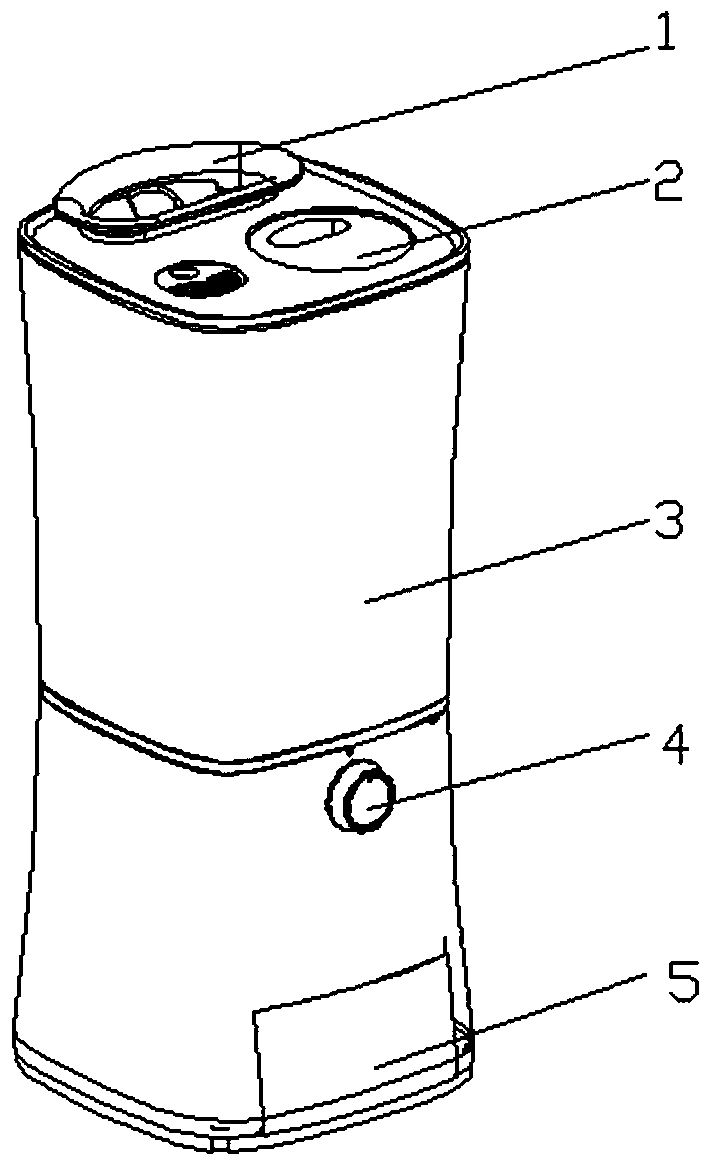

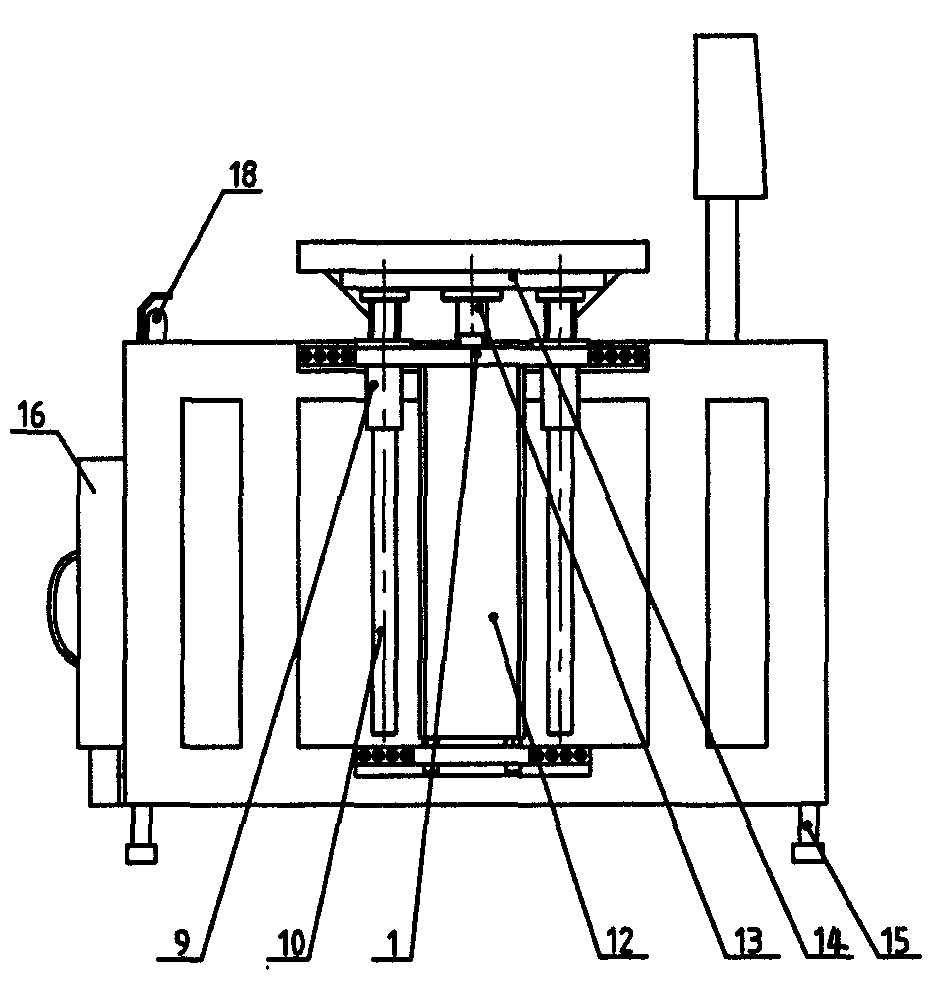

Automatic bathing machine

InactiveCN101288565AWith automatic operationWith automatic heatingBathsDouchesWater sourceMicro motor

The invention discloses a full automatic shower machine, which consists of a water heater part and a shower part. The water heater part is mainly a water heater (1); the water heater is a device for heating the water source. The shower is a device that can bathe people according to human instructions, which comprises a micro booster water pump (2), a spray-head (3), a bracket (4), a base (5), a micro motor (6), a bathtub (7), a tub cover (8), a guide arm (11), a electric block (12), a hoisting cable (13), a lead rail (14), a computer control panel (15) and a heater, etc. The water heater heats and delivers the water into the shower; hot water sprays from the spray-head of the shower; the to-and-fro movement of the spray-head of the shower can lead the sprayed hot water to scour the skin by turning from left to right, from top to bottom. The mutual striking and friction between the water and the skin achieves the aim of showering.

Owner:袁哲

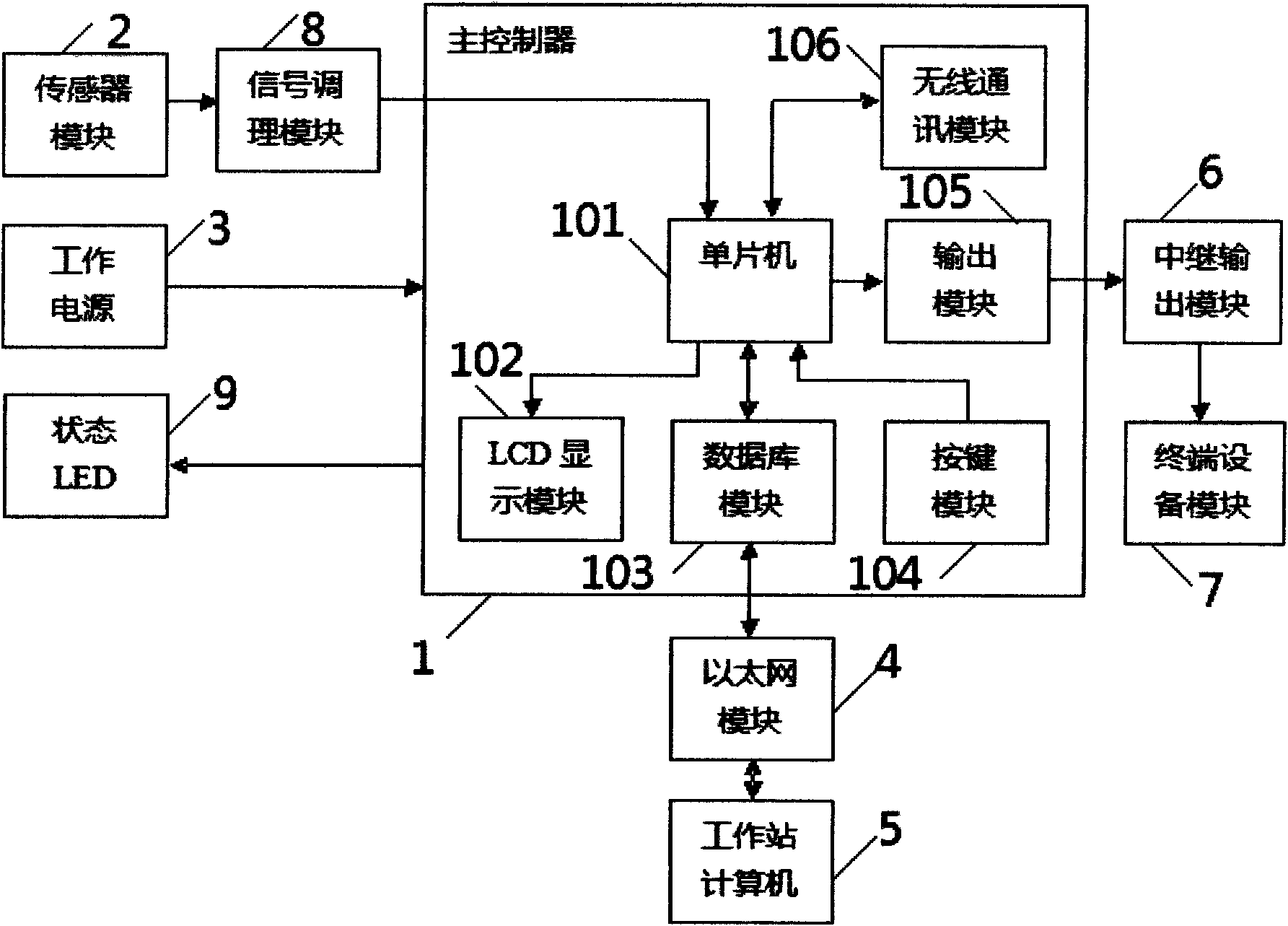

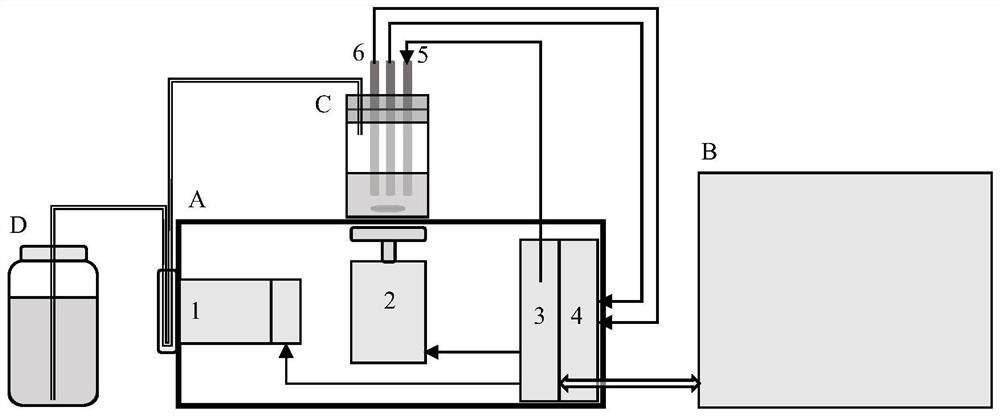

Multipath water quality online monitoring system

InactiveCN102736569AAvoid water quality deteriorationEasy to maintainPisciculture and aquariaTotal factory controlWater qualityAquatic product

The invention discloses a multipath water quality online monitoring system which comprises a main controller. The main controller comprises a single chip computer, an LCD display module, a database module, a keyboard module and an output module. The single chip computer is connected with the LCD display module, the database module, the keyboard module and the output module. The single chip computer also is connected with a sensor module through a signal conditioning module. The database module is connected with a workstation computer through an Ethernet module. The output module is connected with a terminal equipment module through a relay output module. The main control unit is connected with a working power supply. According to the invention, the real-time monitoring of water quality can be realized, and the multipath water quality online monitoring system satisfies requirements of aquatic product scientific research, a large-scale aquaculture plant using recycled water culture, and industrialization.

Owner:苏州滨特尔水处理有限公司

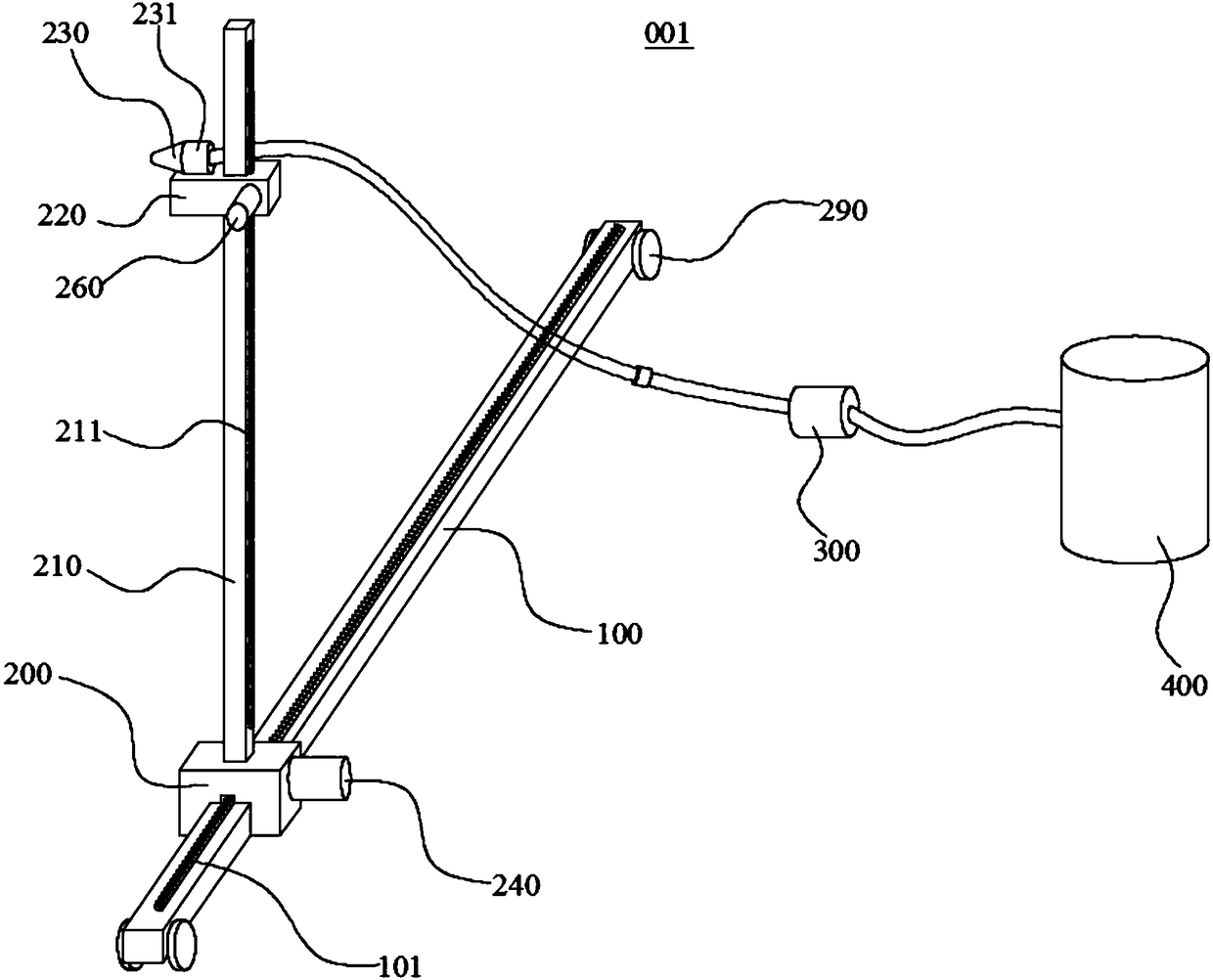

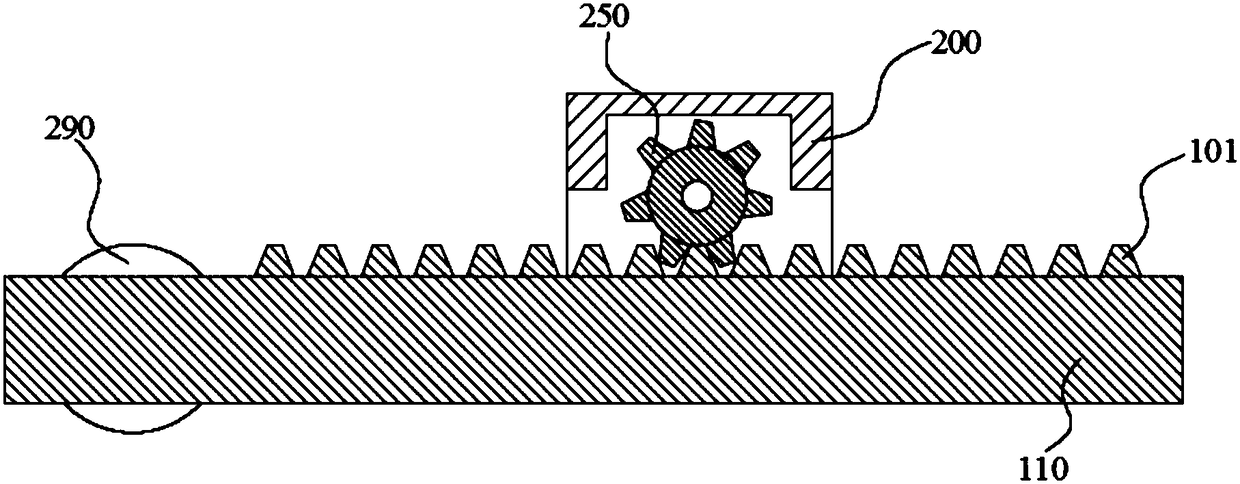

Spraying maintaining device and system

PendingCN108582446AWith automatic operationReduce labor costsCeramic shaping apparatusSpray nozzleEngineering

The invention provides a spraying maintaining device and system, and belongs to the field of concrete maintaining. The device comprises a track, and at least one base which can move along the track, wherein each base is connected to a supporting rod, and each supporting rod is provided with at least one spraying seat which can move along the corresponding supporting rod; the spraying seats are connected to at least two spraying nozzles; and the spraying nozzles are connected to a water tank through a water pump. The spraying maintaining device is convenient to mount and move and is capable ofautomatically spraying and maintaining concrete for a long time, so that the spraying maintaining effect is improved while the labor cost is decreased. The invention also provides a spraying maintaining system comprising the abovementioned spraying maintaining device.

Owner:NO 2 ENG CO LTD OF CHINA RAILWAY CONSTR 11 BUREAU GRP +1

Sludge concentration, desiccation and filter pressing system

InactiveCN104529128AWith automatic operationWith automatic unloadingSludge treatment by de-watering/drying/thickeningFilter pressDesiccation

The invention discloses a sludge concentration, desiccation and filter pressing system. The sludge concentration, desiccation and filter pressing system is mainly formed by connecting a sludge gravity concentration basin, a dewatered sludge feed pump, a reaction mixer, a folded screw type sludge dewaterer, a sludge specific resistance conditioning device, a middle delivery pump, a sludge reaction tank, a fed sludge pressing pump and a diaphragm type plate-frame filter press in sequence. The sludge concentration, desiccation and filter pressing system is characterized in that a dosing opening of the sludge specific resistance conditioning device is connected with a conditioner dosing device through a pipeline; the diaphragm type plate-frame filter press is provided with a diaphragm type plate frame wrapped by filter cloth, an inner cavity of the diaphragm type plate frame is connected with a pressurization water tank through a pressurization branch pipe, and a pressure regulating device is arranged on the position, between the pressurization branch pipe and the pressurization water tank, of a header pipe. The system integrates the processes of sludge concentration, mechanical dewatering, specific resistance conditioning, curing conditioning and desiccation, lowers sludge moisture content to below 60%, and has the advantages of automatically running, automatically discharging and saving energy.

Owner:成都绿源新创环保科技有限公司

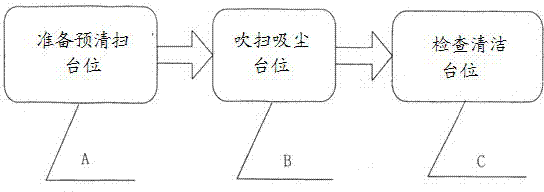

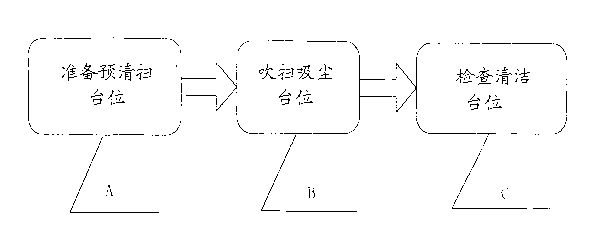

Method for cleaning bottom equipment of bullet trains

ActiveCN102343890ADoes not affect other jobsGuarantee checkCleaning apparatus for vehicle exteriorsHigh pressureWaste management

Owner:CHINA RAILWAY DESIGN GRP CO LTD

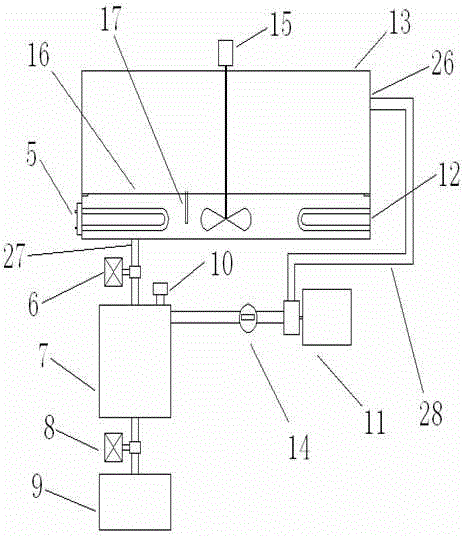

Concrete acid and alkali resistance testing device

InactiveCN104697922ASolve the problem of acid and alkali resistance testImprove purification effectWeather/light/corrosion resistanceFailure rateControl system

A concrete acid and alkali resistance testing device comprises a host, a concrete reaction chamber, a refrigerating device and a solution circulating water path. A PLC control system serves as the host. The concrete reaction chamber comprises a box body, a heater, a refrigerating tube, a temperature sensor, a concrete test piece supporting plate, a stirrer, a fixed cover and a movable cover. A low-temperature constant-temperature groove serves as the refrigerating device, and low-temperature antifreezing liquid can be sent into the refrigerating tube in a circulating mode. The solution circulating water path comprises a solution tank, an air pressure balancing valve, an impurity tank, an electric drainage valve, an electric blow-down valve, a PPR tube, an electronic water meter and a water pump. The concrete acid and alkali resistance testing device is novel in design, can simulate the PH value and temperature of acid and alkali solutions, and has the advantages of being capable of automatically running, saving energy and protecting the environment, low in failure rate, high in solution purifying capacity and the like. The concrete acid and alkali resistance testing device can play a great role in promoting the development and detection of concrete.

Owner:英贝儿(天津)测控设备有限责任公司

Battery quality traceable production method

InactiveCN109782179AAutomatic detection hasWith automatic operationFinal product manufactureElectrical testingAutomatic testingControl unit

The invention discloses a battery traceable quality detection method. The method comprises the steps that system self-inspection and battery positioning are carried out, after a battery is positioned,detection equipment automatically detects performance parameters of a storage battery, after detection by to-be-detected equipment is completed, the detection equipment sends a detection completion signal to a control unit PLC, and meanwhile detection data are stored in a memory area of the detection equipment; at the moment, a positioning cylinder resets, and a front blocking cylinder and a backblocking cylinder are in the front position; after the control unit PLC receives the detection completion signal, a pulse signal is sent out to trigger a code scanner to read the QR code successfully, the three-color yellow lamp is turned on, the code scanner transmits the read QR code value to the DM area of the control unit PLC, meanwhile, the reading mark of the of the control unit PLC is setto be 1, and at the moment, the numerical value of the DM memory area is changed. According to the scheme, the related performance of the battery can be automatically detected, the performance parameters of the related battery are traced through a server, and meanwhile the characteristics of automatic operation, automatic detection and high-speed operation are achieved.

Owner:DUIZHI BEIJING TECH

Automatic mop cleaning machine and special mop thereof

PendingCN109730602AStrong linkageReduce manufacturing costCarpet cleanersFloor cleanersAutomatic controlPower switching

The invention discloses an automatic mop cleaning machine, relates to a daily appliance, and in particular belongs to an automatic cleaning machine and a plate mop matched with the cleaning machine. The automatic mop cleaning machine is characterized by comprising a cylindrical shell, a mop support, a wipe-washing component, a motion and reciprocating control mechanism, a water injection and automatic control device and a complete start and stop control mechanism, wherein the mop support comprises a mop fixing rack and vertical guide rails; the mop fixing rack is arranged on the upper end faceof the shell; the vertical guide rails are arranged on inner side walls of the shell below the fixing rack; the wipe-washing component is arranged on a surface, which corresponds to the mop position,of the interior of the shell; the wipe-washing component comprises a water holding box and a water-squeezing roller shaft; the wipe-washing component is aligned at and contacted with the mop cloth ofthe mop; the complete start and stop control mechanism is a manual power switch or an automatic response switch; a drain outlet is formed in the bottom of the shell; and the drain outlet is connectedwith an external drainage pipe or communicated with a sewage box communicated with the bottom of the shell. The automatic mop cleaning machine disclosed by the invention has positive effects on mop cleaning such as automation in operation, low in water consumption, mechanical drive, simplicity, reliability and low manufacturing cost.

Owner:日照未来模塑科技有限公司

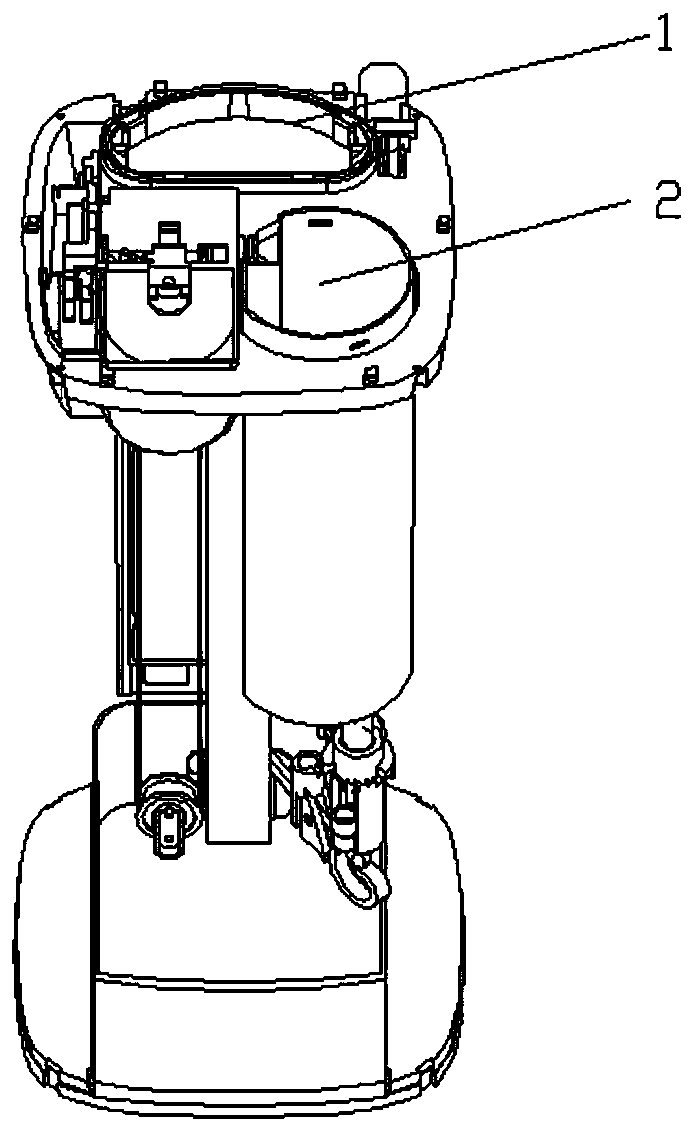

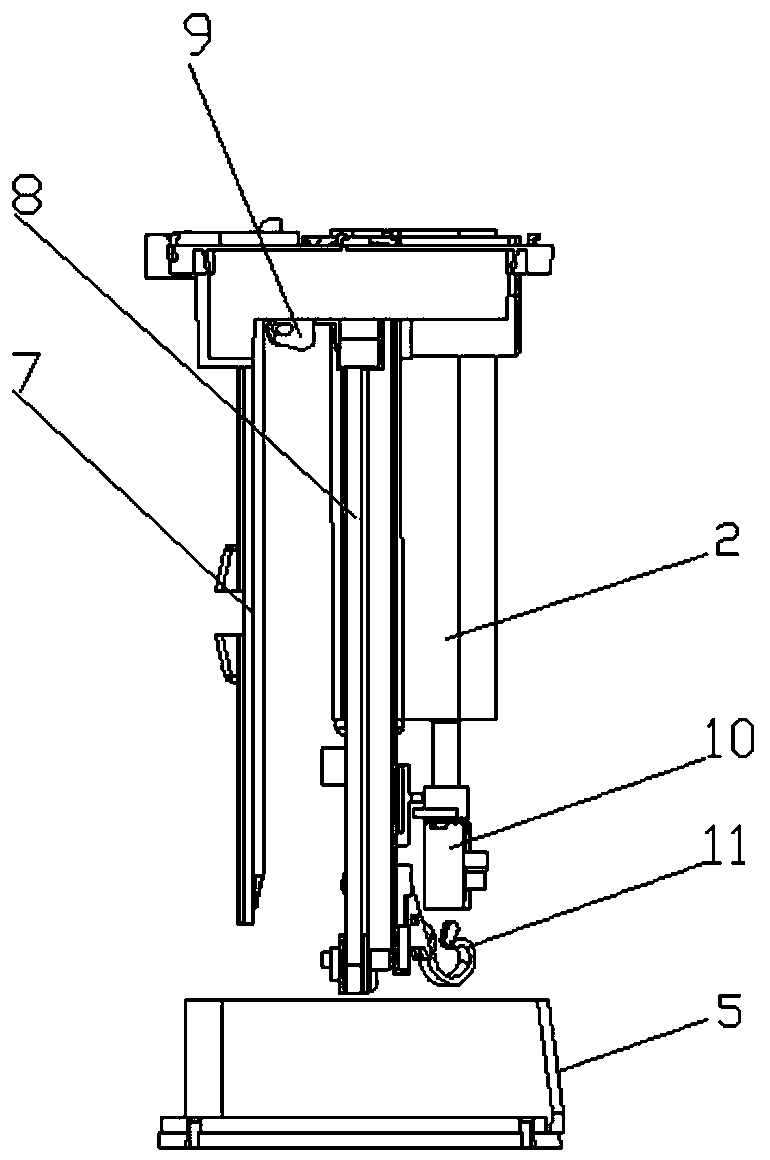

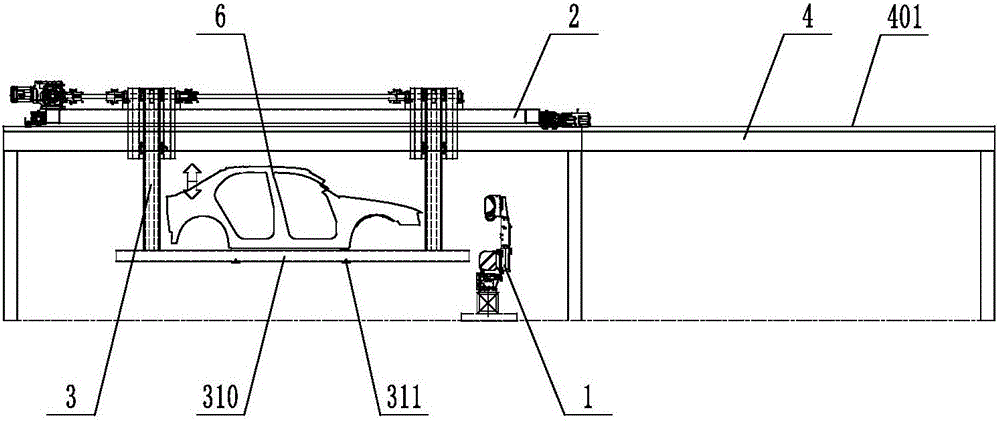

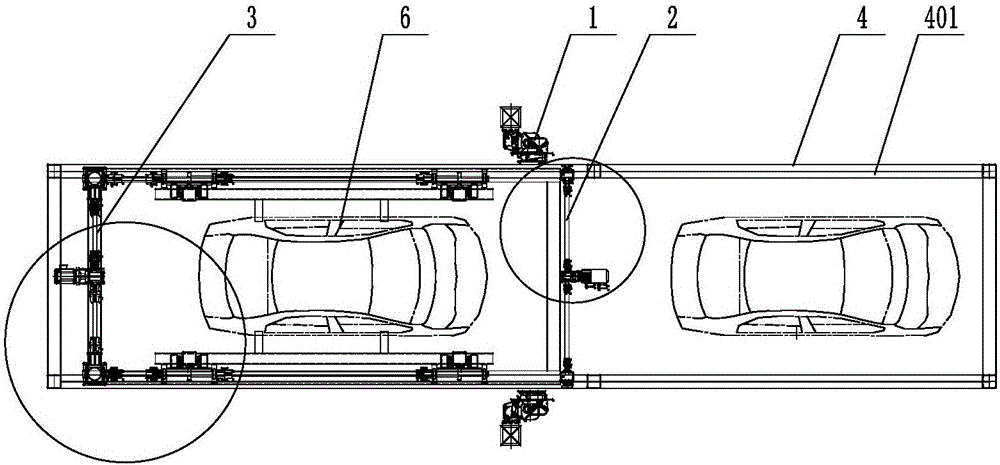

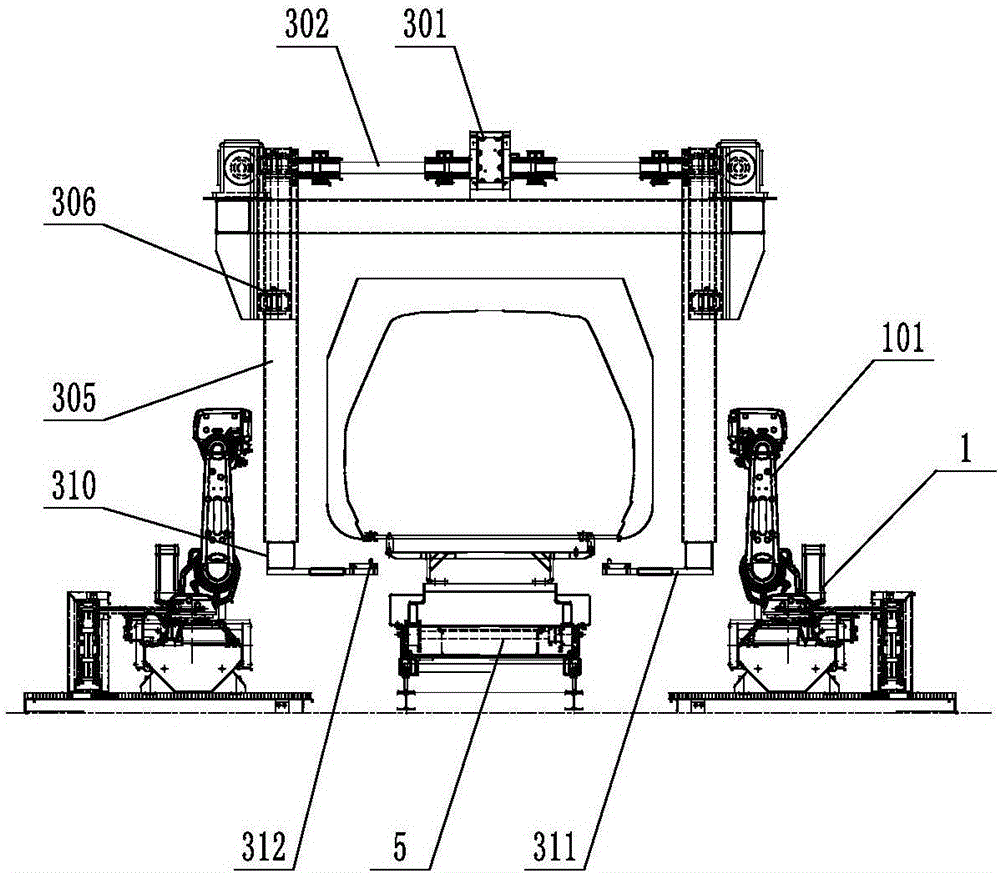

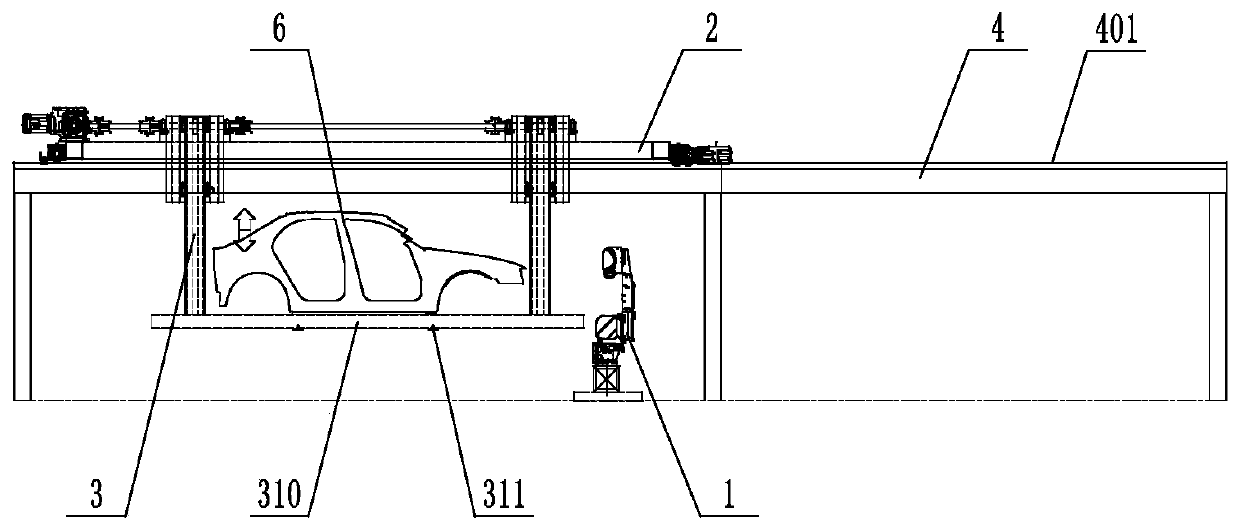

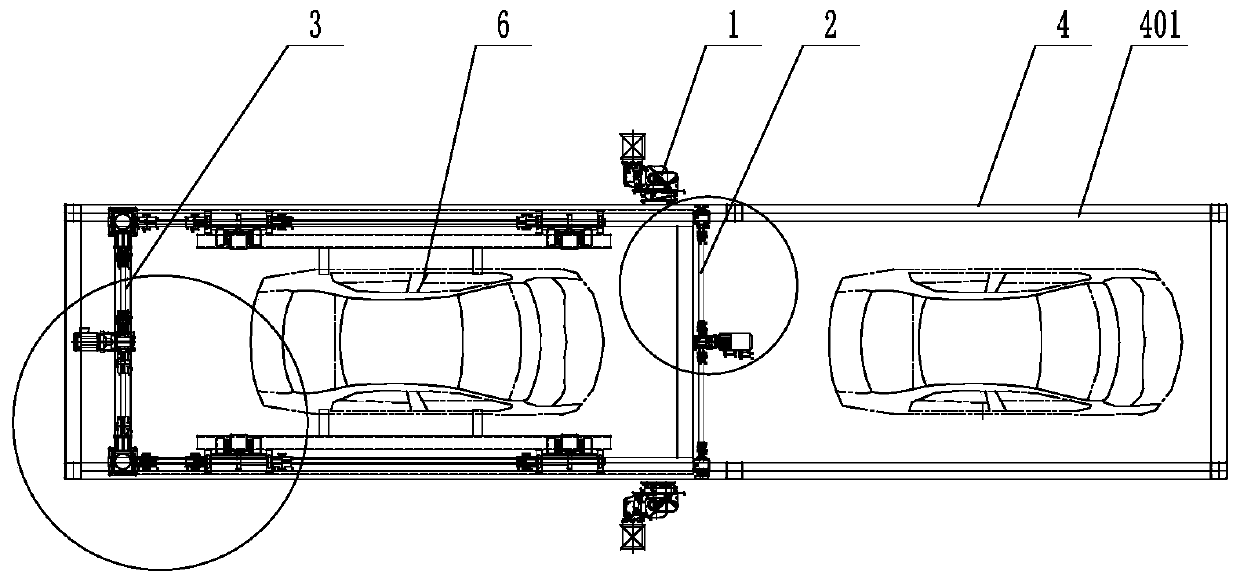

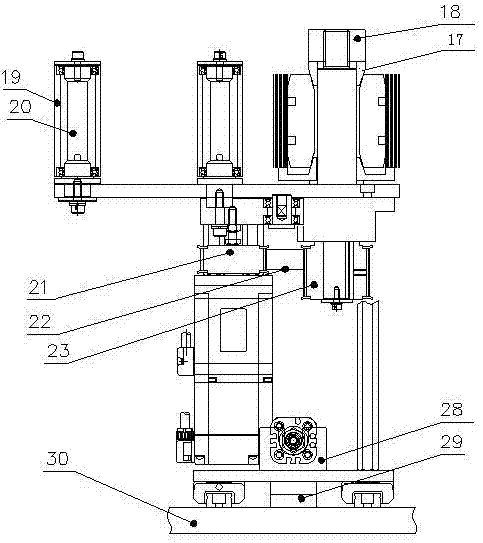

Robot lifting conveyer

ActiveCN106628906AMeet the problem of insufficient length before and afterSolve the problem of insufficient front and rear lengthMechanical conveyorsSpraying apparatusRobotic systemsEngineering

The invention discloses a robot lifting conveyer which comprises a robot system, a walking system and a lifting system. The walking system and the lifting system are integrated into a whole and cooperate with the robot system to achieve automation of a prime coating station. The conveyer is simple in overall structure, relatively low in cost, compact and reasonable in structure, reliable and stable in operation and high in integral running efficiency, replaces manual prime coating, can be applied to multiple different kinds of stations and improves the prime coating efficiency and quality.

Owner:MH ROBOT & AUTOMATION

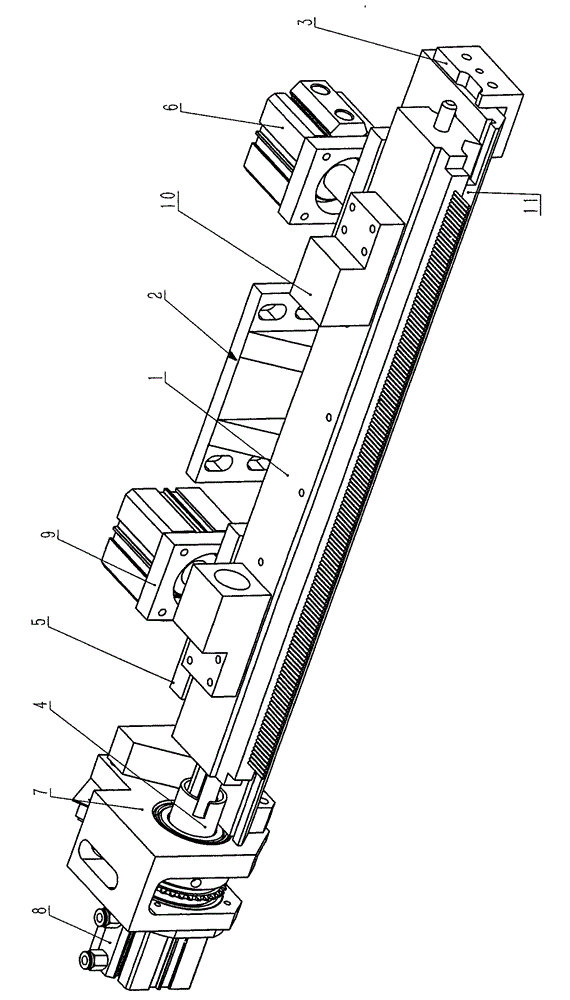

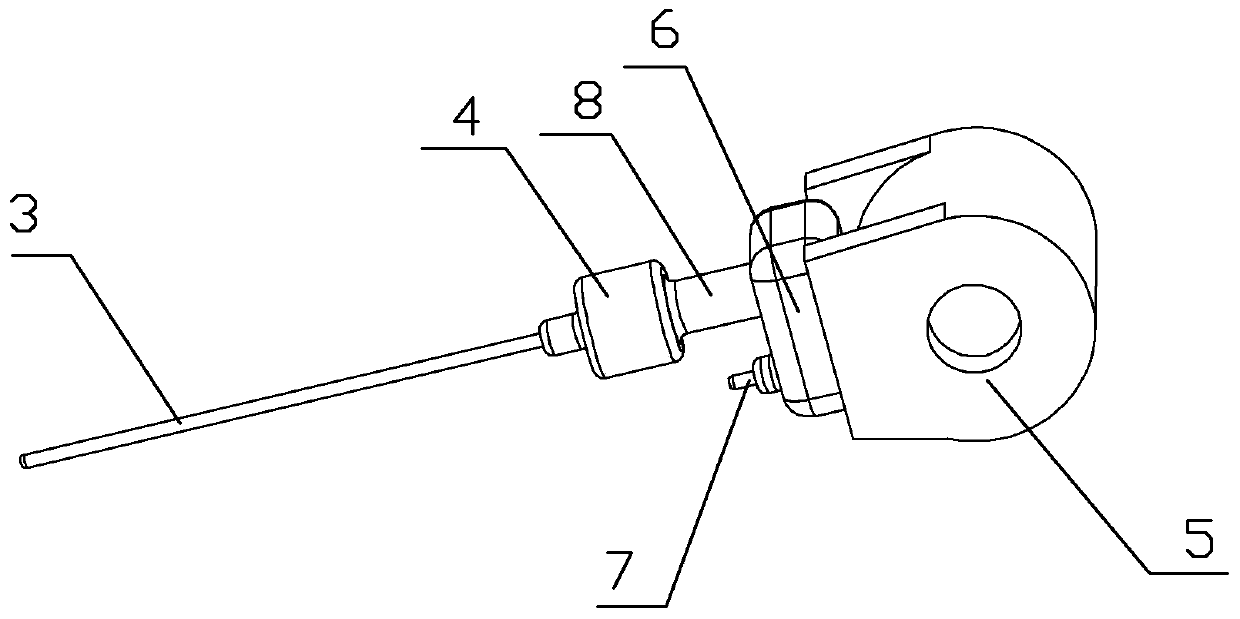

Automatic separating device for aluminum bar clamp

InactiveCN103331695AEasy to extract and removeLoading and unloadingGrinding machine componentsEngineeringManipulator

The invention discloses an automatic separating device for an aluminum bar clamp. The automatic separating device comprises the aluminum bar clamp (1) and an aluminum bar base (2), wherein the side edge of the aluminum bar clamp (1) is provided with a rotary jacking head sleeve (4); on the aluminum bar base (2), a transverse jacking plate (5) is arranged on the lower part of the aluminum bar clamp; the transverse jacking plate (5) is connected with a transverse jacking plate limiting air cylinder (6); and the rotary jacking head sleeve (4) is connected with a rotary jacking head air cylinder (8). According to the automatic separating device, the transverse jacking plate limiting air cylinder is used for driving the transverse jacking plate to loosen the aluminum bar clamp transversely, and the rotary jacking head air cylinder works to laterally loosen the rotary jacking head sleeve, so that the aluminum bar clamp and the aluminum bar base are in an automatic separate state, and the aluminum bar clamp can be extracted and moved away conveniently by using a manipulator device. Therefore, the aluminum bar clamp is more convenient and easy to load and unload, and has the advantages of automatic operation, no need of operating personnel, remarkable increase in the working efficiency and lowering of the production cost.

Owner:ZHEJIANG ZHENGWEI MACHINERY

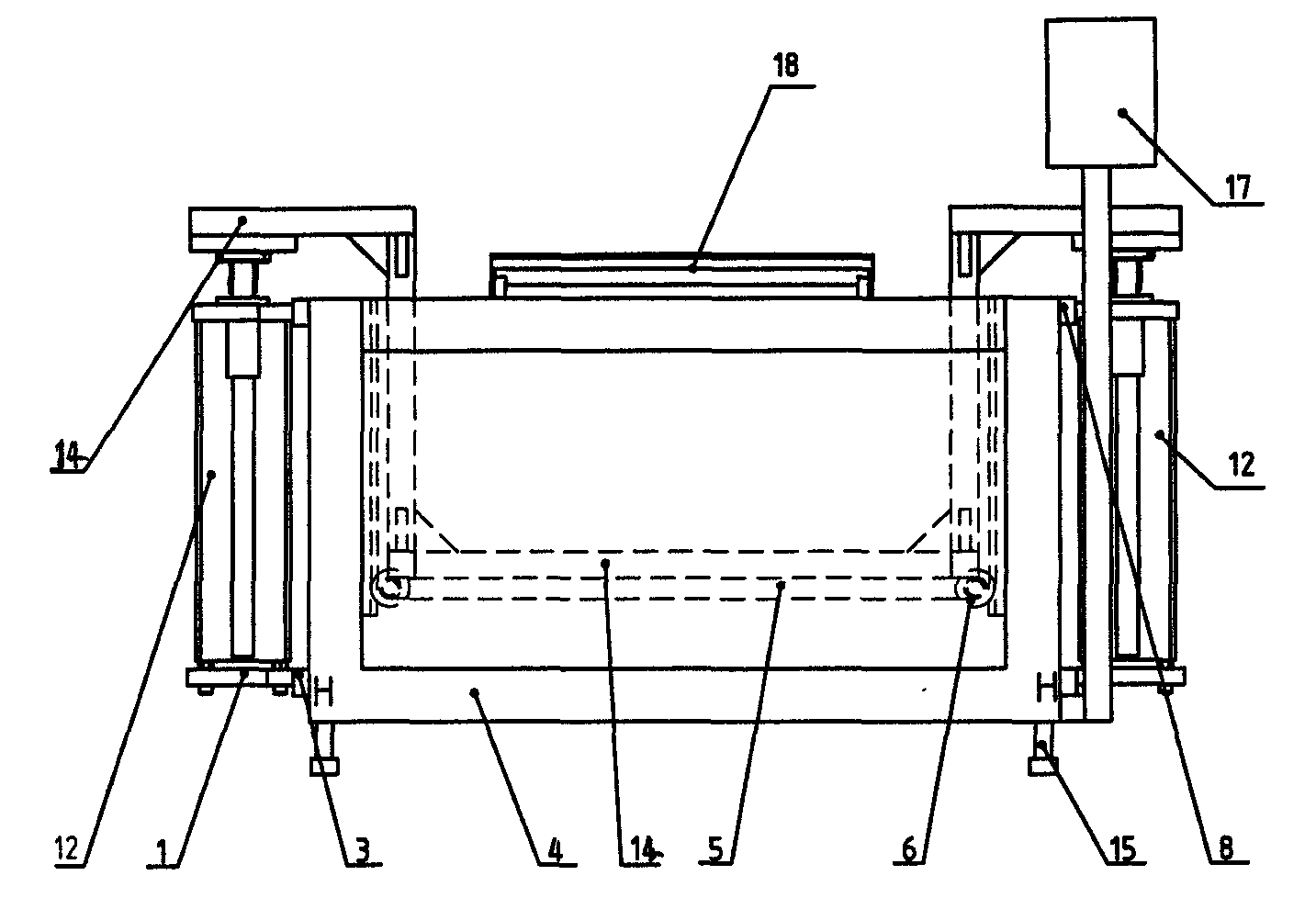

General type cavity wet-type leakproofness leakage testing workbench

InactiveCN103712753ASolve the problem of air tightness defectImprove general performanceDetection of fluid at leakage pointProduction lineEngineering

The invention discloses a general type cavity wet-type leakproofness leakage testing workbench. Air cylinders (12) are arranged on the two outer sides of a box body (4) respectively through air cylinder mounting seats (1), and trays (14) are arranged in the box body and on piston rods of the air cylinders. An air pipe connector (18) is arranged on the rear side portion of the box body. The sealing problem of a part cavity can be accurately found out, and the workbench has the advantages of achieving automatic operations, being simple in structure and low in manufacturing cost and the like, and is generally used for manufacturing production lines of automobile engine parts.

Owner:WENZHOU RUIMING IND

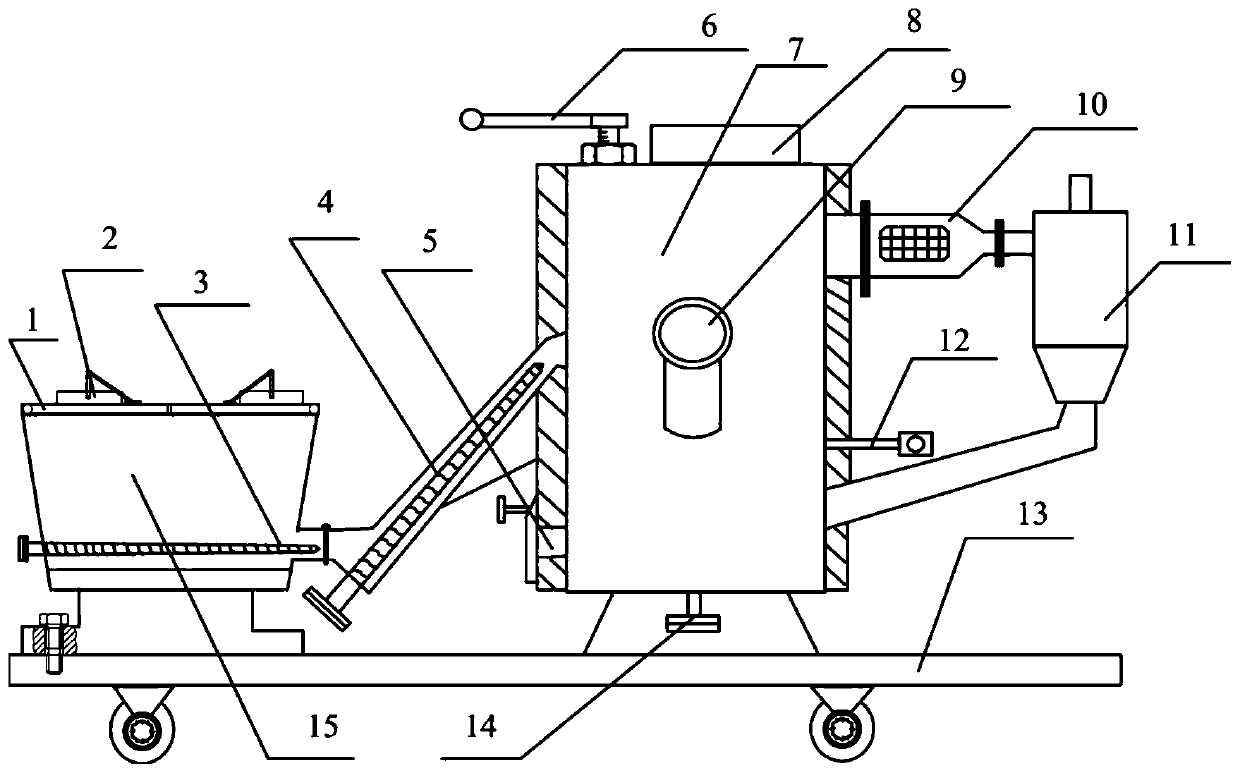

Inclined feeding type agricultural and forestry biomass particle combustion furnace

InactiveCN110454772ASolve the problem of backfire and smokeSolve operational safety issuesFuel feeding arrangementsSolid fuel combustionThermal insulationBiomass combustion

The invention discloses an inclined feeding type agricultural and forestry biomass particle combustion furnace. A feeding bin, a biomass combustion furnace body, an external heat exchange and waste heat utilization device and a tail gas purification device are all installed on a movable base; a fireproof and thermal-insulation partition board is arranged at the upper part of the feeding bin, a primary feeding device is arranged at the bottom of the feeding bin, and the tail part of the primary feeding device is connected with a biomass combustion furnace body by a secondary feeding device; theexternal heat exchange and waste heat utilization device is connected to an outlet of the biomass combustion furnace body, and the tail gas purification device is connected to the back of the external heat exchange and waste heat utilization device; an internal heat exchanger is arranged in the biomass combustion furnace body; the fireproof and thermal-insulation partition board is installed at the upper end of the feeding bin, and an automatic door closer is also installed on the fireproof and thermal-insulation partition board. The combustion furnace has the characteristics of being energy-saving and environmentally friendly and operating automatically, and can have broad prospects in rural heating in mountainous areas of China.

Owner:SHANDONG UNIV OF TECH

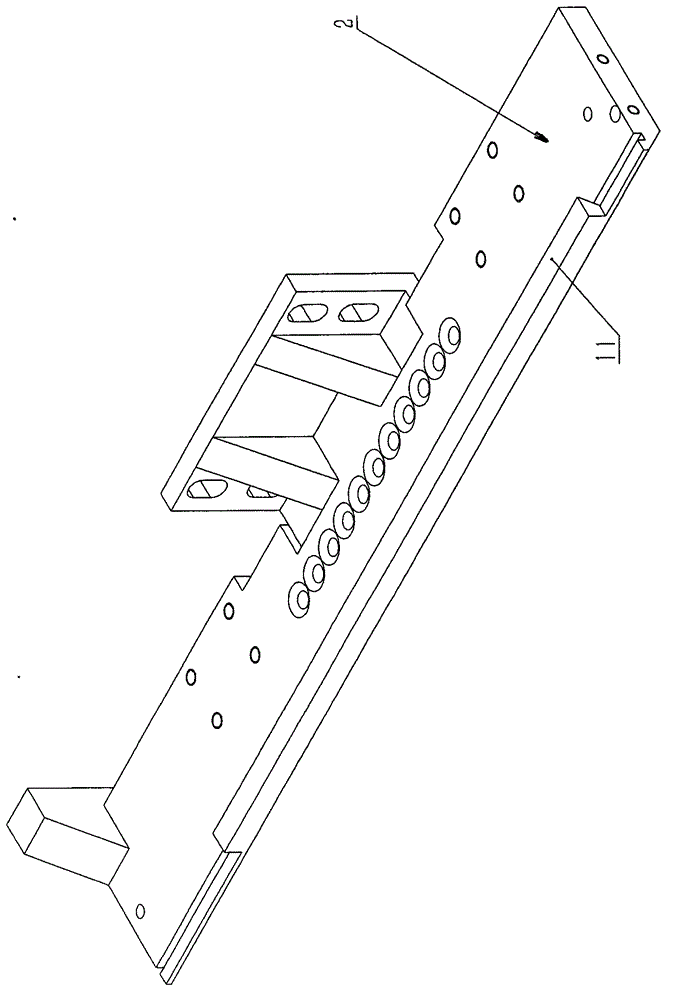

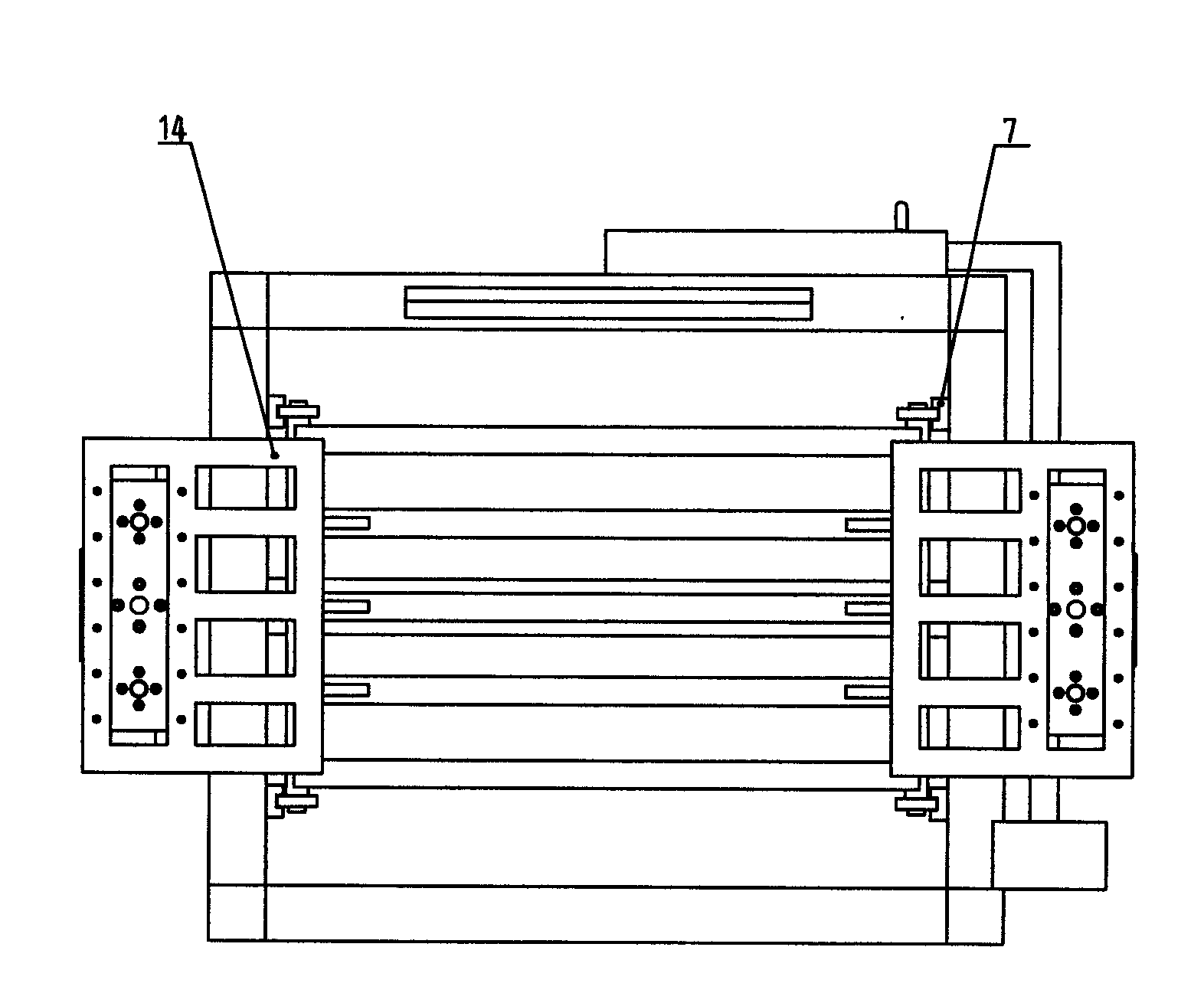

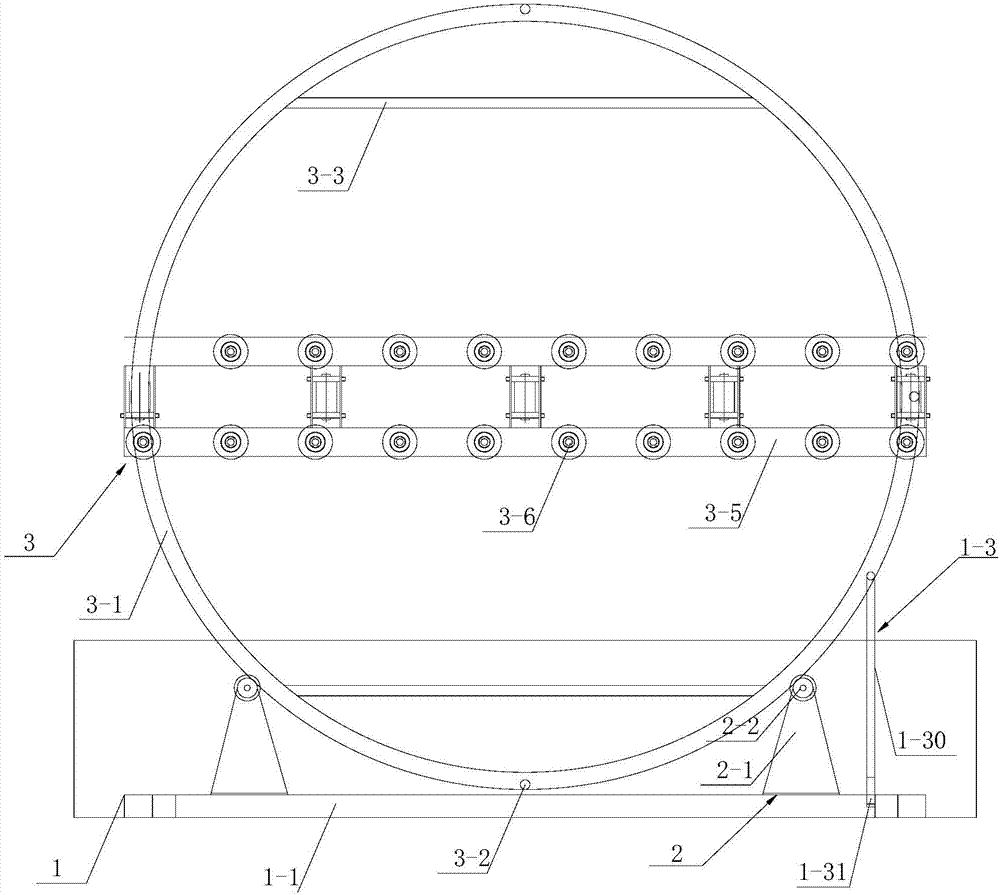

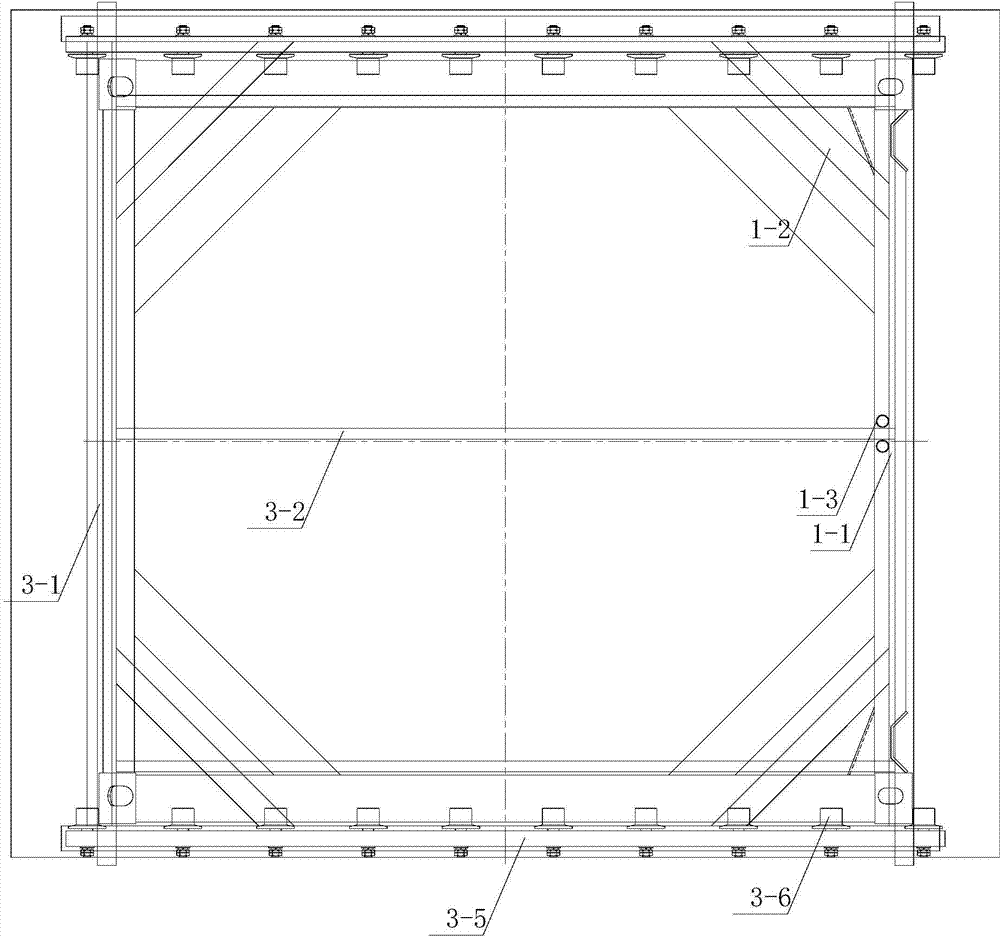

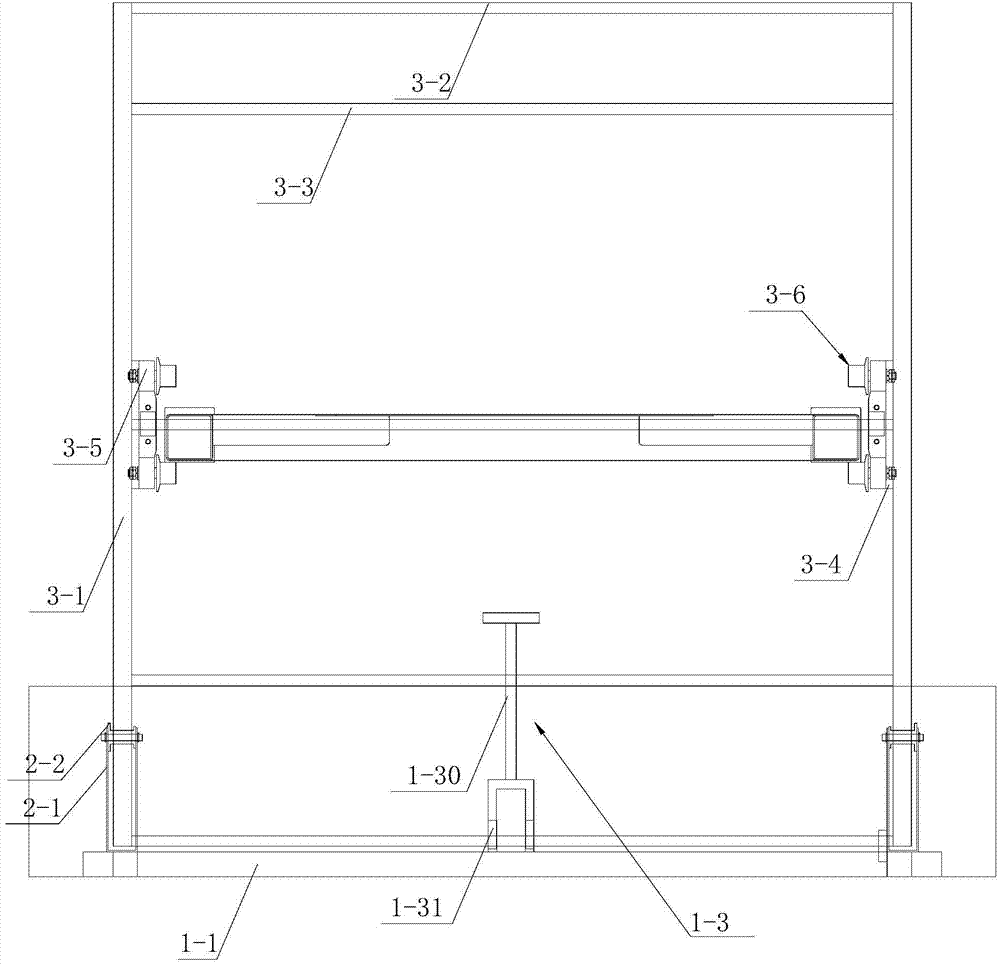

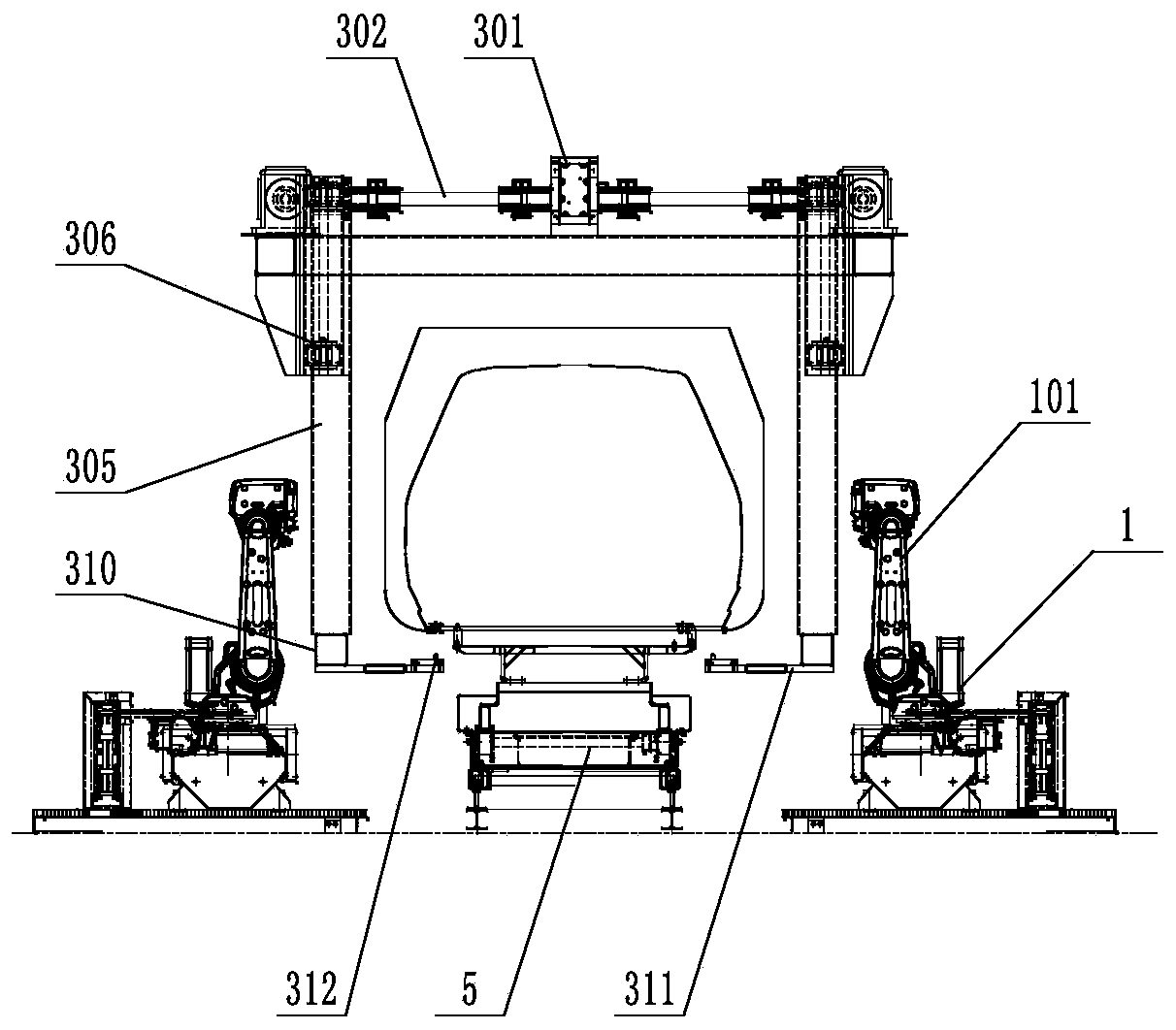

Rotary tank container end frame welding assembly system

ActiveCN104325254AReduce labor intensityGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineTank container

The invention relates to a rotary tank container end frame welding assembly system, which comprises a foundation beam, supports and a rotary assembly rack, wherein four cross beams are squarely welded to form the foundation beam, and each cross beam is connected and reinforced by a bracing piece; a locking device for fixing the rotary assembly rack is welded on the cross beam, and the supports are distributed at the four corners of the foundation beam; the upper parts of the supports are provided with rotating shaft assemblies in a penetrating way, and the rotary assembly rack is supported by the upper parts of the supports; a mounting beam is respectively arranged in the middle of each turntable, and transverse roller assemblies are symmetrically arranged on each mounting beam; five longitudinal roller assemblies are arranged between the upper and lower mounting beams. With the technical scheme, when an end frame only needs to slide to a welding assembly system during the actual welding of the tank container end frame, weld passes on front and back surfaces are fully welded by rotation, a rolling shaft slides to the next working procedure after full welding, so that the labor intensity of welding personnel is reduced, and the welding quality of each welding point can also be ensured; in addition, the rotary tank container end frame welding assembly system provided by the invention also has the advantages of simple structure, easiness in manufacturing, safety, firmness and reliability, and rapid welding of the end frame, and also lays a foundation for the automated production line of the tank containers.

Owner:天津新华昌运输设备有限公司

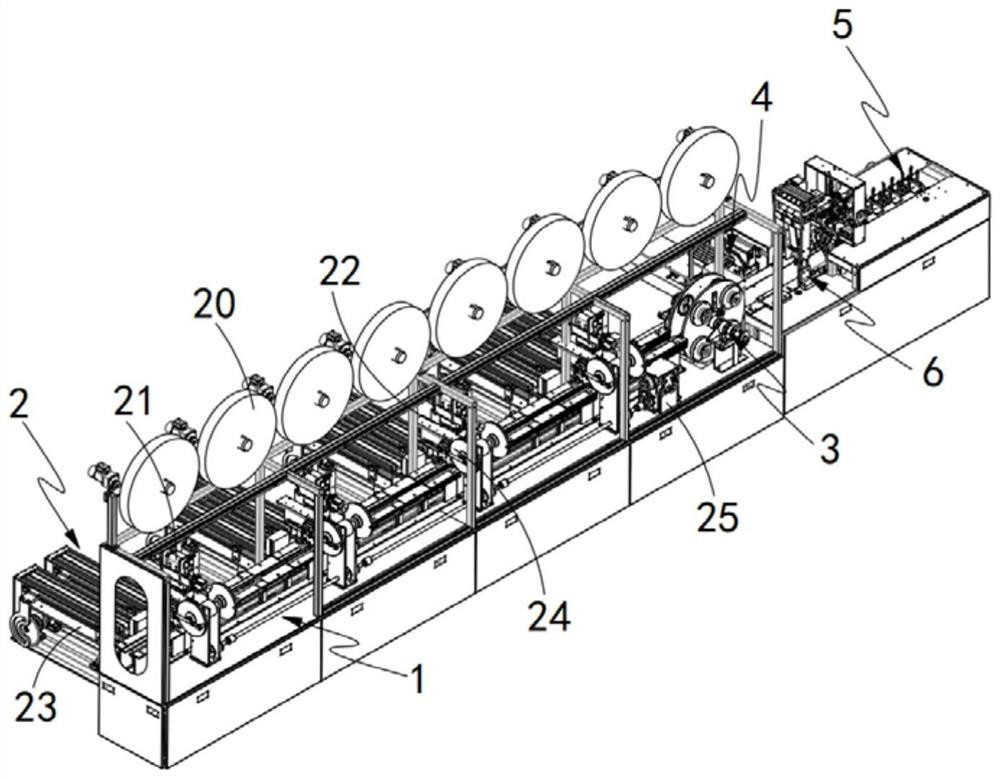

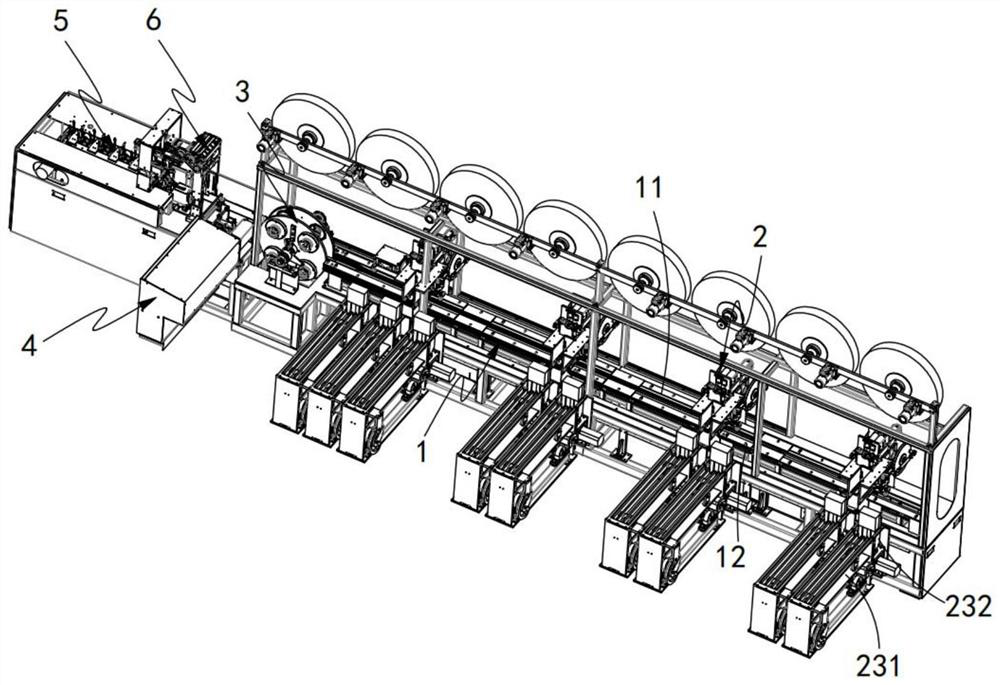

Storage battery pole plate wrapping mechanism and automatic storage battery pole group wrapping production line

PendingCN113410504ALabor savingImprove efficiencyAssembling battery machinesFinal product manufactureStructural engineeringManufacturing engineering

The invention provides a storage battery pole plate wrapping mechanism and an automatic storage battery pole group wrapping production line. The mechanism comprises continuously supplied separator paper, and further comprises a stacking assembly; the stacking assembly respectively bears a positive pole plate and a negative pole plate on the two sides of the vertically conveyed separator paper, a height difference is formed between the positive pole plate and the negative pole plate borne by the stacking assembly, in the process that the positive / negative plates are pushed to point to the negative / positive plates to be inserted to form the wrapping single bodies, the partition paper wraps the outer sides of the pushed positive / negative plates. The production line comprises a laminated sheet conveying mechanism, a plurality of sheet wrapping mechanisms arranged on a conveying channel of the laminated sheet conveying mechanism, and a transfer mechanism arranged at the conveying tail end of the laminated sheet conveying mechanism. The stacking assembly is used for bearing the positive plate and the negative plate, when the pushing assembly is matched to push the positive plate to the negative plate, the partition paper wraps the positive plate and is used for being isolated relative to the negative plate to form wrapping single bodies, and the wrapping single bodies are pushed to pass through the wrapping mechanisms in sequence to form a plate group.

Owner:长兴金润科技有限公司

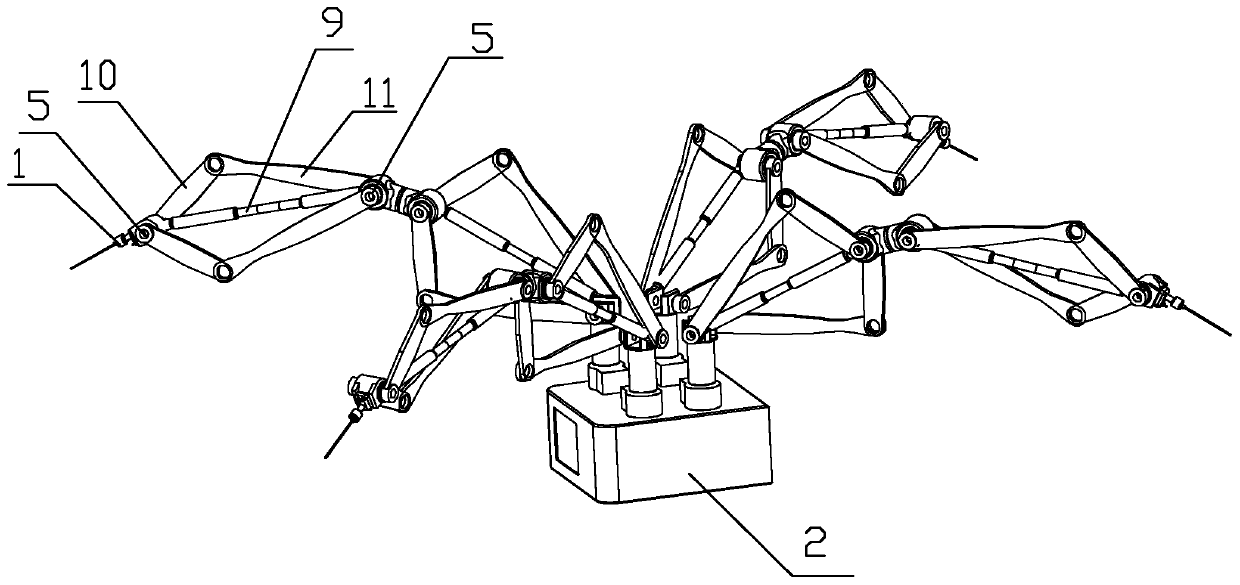

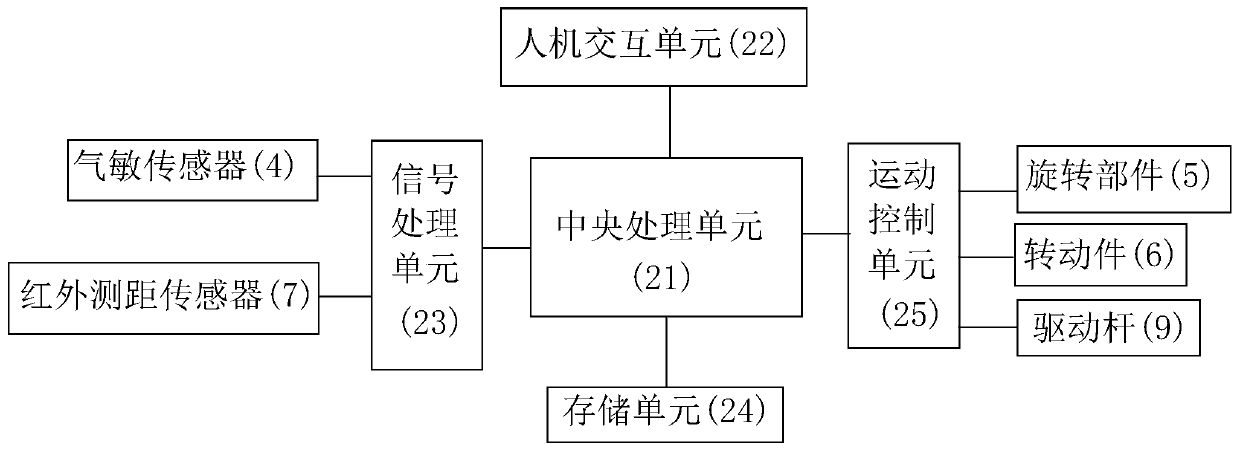

Multi-probe automatic leak detection system and leak detection method

ActiveCN111579168AHigh sensitivityImprove detection accuracyDetection of fluid at leakage pointAviationEngineering

The invention relates to a multi-probe automatic leak detection system and a leak detection method. The system comprises a control platform, a plurality of mechanical arms connected with the control platform, and leak detection devices which are installed at the arm ends of the mechanical arms and composed of suction pipes and gas sensitive sensors. The leak detection devices are connected with the mechanical arms through rotating parts; a rotating piece is arranged on each rotating part, and an infrared distance measuring sensor is arranged on the rotating piece; the gas sensitive sensors areconnected with the rotating pieces through aviation plug connectors; and all the sensors and wires connected with the rotating pieces are connected with the control platform through the mechanical arms. The control platform controls the mechanical arms to drive the suction pipes to reach the set position according to the setting in combination with the measured value of the infrared distance measuring sensors, and once the signal peak value sensed by a gas sensitive sensor is larger than a leak point threshold value, the control platform gives an alarm. Gas is used as a tracing medium, multiple workpieces or multiple parts of the workpieces can be detected at the same time, the detection process is fully automatic, time and labor are saved, and the leak detection efficiency and the leak detection accuracy are improved.

Owner:杭州超钜科技有限公司

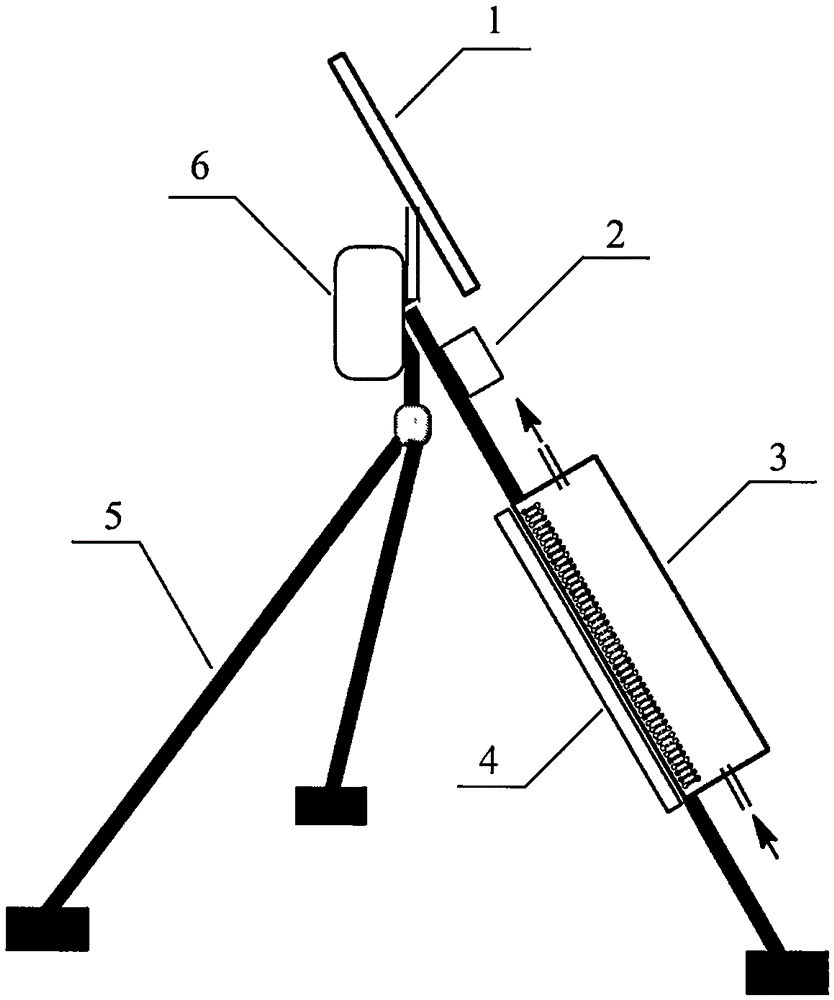

Visible light photocatalysis apparatus

InactiveCN105597519AEnergy savingWith automatic operationWater/sewage treatment by irradiationGeneral water supply conservationControl systemWastewater

A visible light photocatalysis apparatus is composed of a solar cell panel, a storage cell, a light reactor, a light intensity control system, a self-contained light source and a support. The solar cell panel uses the storage cell to charge, and the storage cell can provide power for the light intensity control system and the self-contained light source; the light intensity value of the light intensity control system can be set, the self-contained light source is automatically powered on when the light intensity of sunshine is smaller than a preset value in order to provide sunshine for the light reactor, and when the light intensity of sunshine is greater than a preset value, the self-contained light source is powered off, and the sunshine is used as light reactor irradiation light; and a photocatalyst is arranged in the light reactor, the shell of the light reactor adopts a light transmission material and is fixed on the support, wastewater or exhaust gas is purified in the light reactor, and the purified wastewater or exhaust gas flows out of the light reactor. The visible light photocatalysis apparatus fully uses sunshine as a photoreactor light source, and uses the sunshine to charge the storage cell in order to provide the power supply used by the apparatus, and has the characteristics of energy saving, low use cost and automatic running, so the apparatus can be used in fields of factories and town wastewater or exhaust gas treatment.

Owner:徐志兵

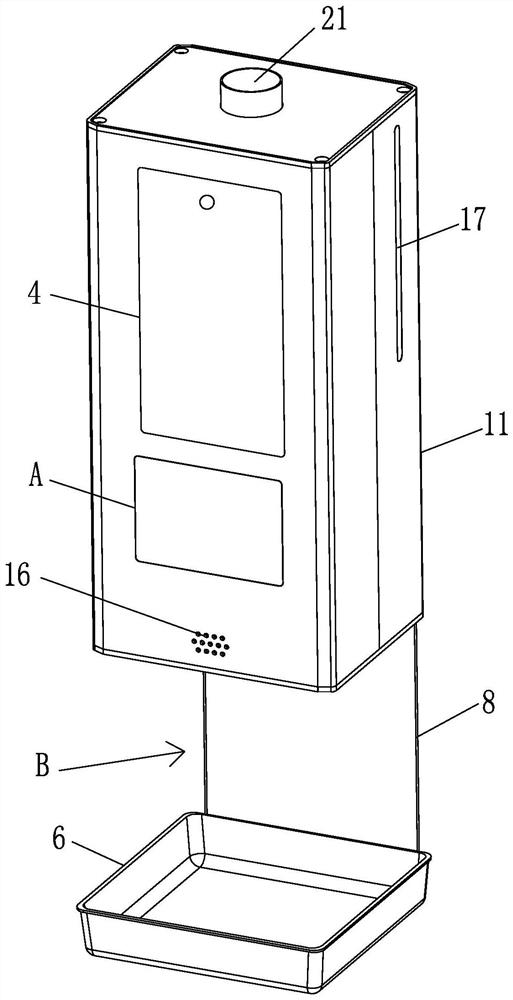

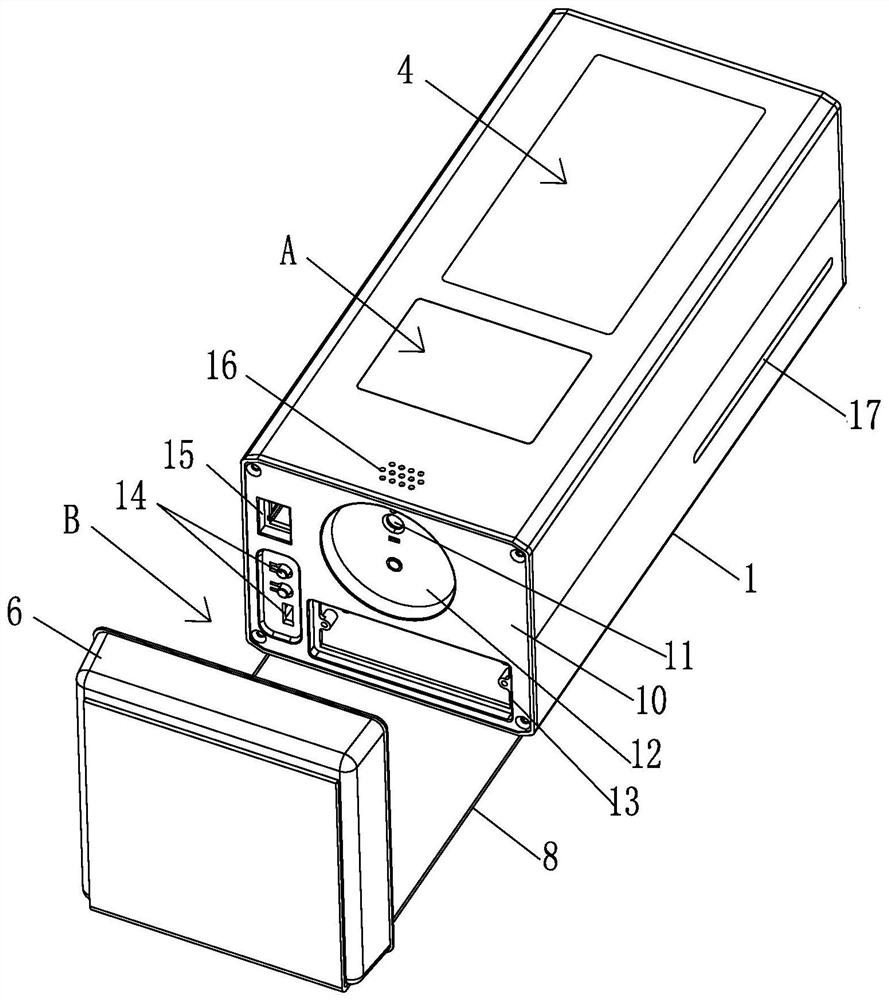

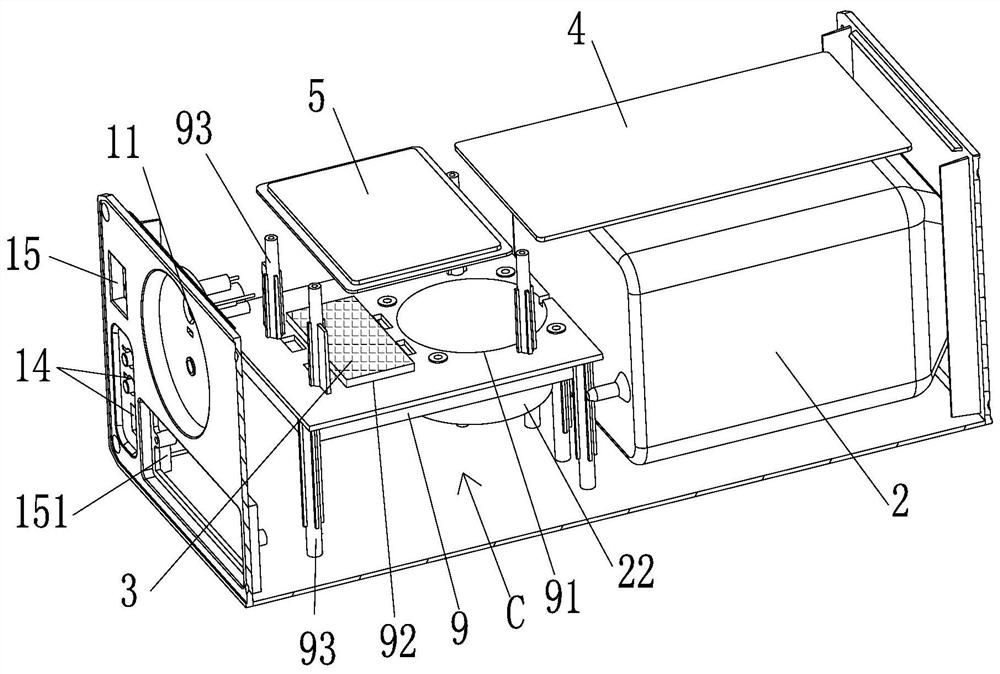

Intelligent liquid soap machine

PendingCN113440037AWith automatic operationNon-contactHolders and dispensersSensing radiation from moving bodiesEngineeringRisk identification

The invention discloses an intelligent liquid soap machine which comprises a machine body, a liquid box used for containing disinfectant, a liquid supply pump in driving connection with the liquid box, and a loudspeaker located on one side of the liquid supply pump are arranged in the machine body, a camera video screen which is electrically connected with the loudspeaker and can shoot the portrait of a detected person is embedded in the front face of the machine body, and a temperature measuring area located below the camera video screen, an induction temperature measuring device is embedded in the inner side of the temperature measuring area and can detect the body temperature of a detected person in the temperature measuring area in an unobstructed and non-contact manner; a liquid inlet is formed in the top of the liquid box, a liquid outlet communicated with the liquid box is formed in the bottom of the machine body, liquid receiving plates are arranged below the liquid outlet at intervals, and a disinfection area for human hands to move is formed between the liquid receiving plates and the machine body; and a controller which is respectively connected with the liquid supply pump, the loudspeaker, the camera video signal screen and the induction temperature detector. The intelligent soap dispenser can realize operations such as temperature measurement and liquid spraying, bidirectional feedback, video playing, risk identification and the like, and has the characteristics of automatic operation, non-contact performance, real-time feedback and the like.

Owner:深圳金海智控科技有限公司

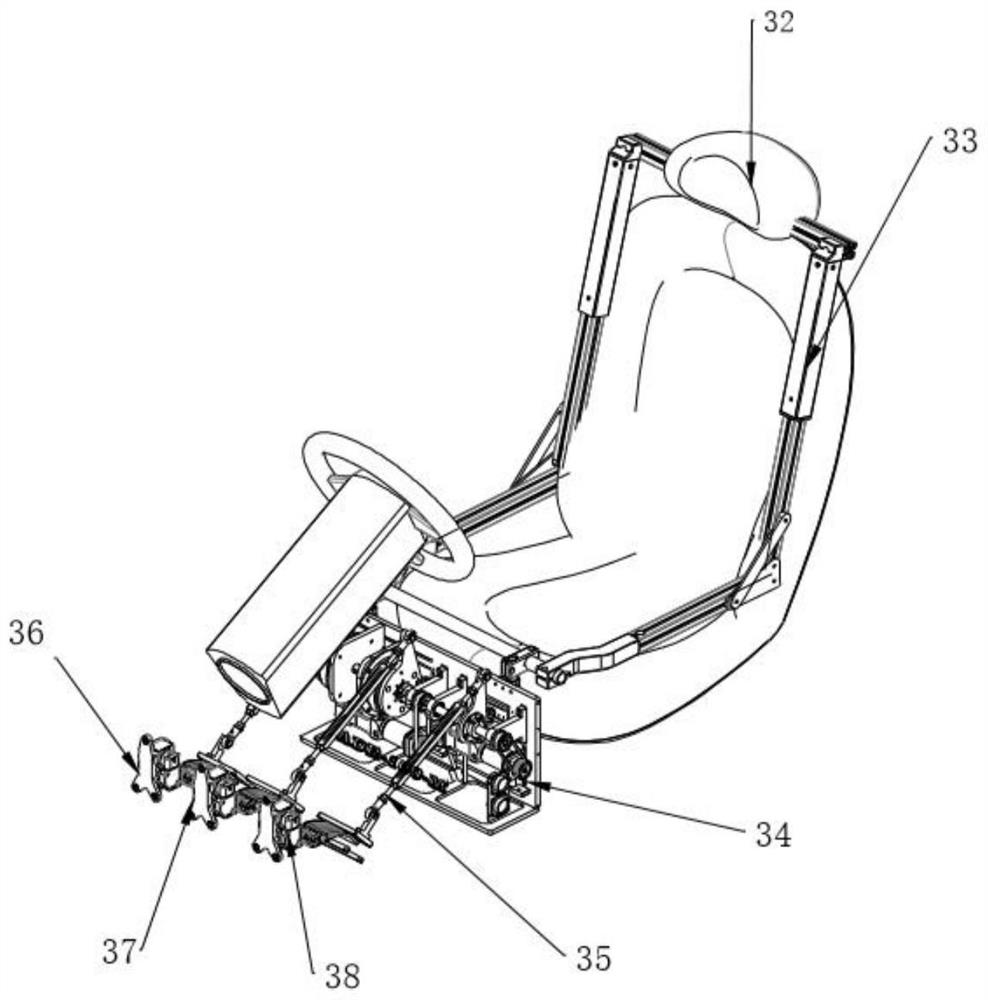

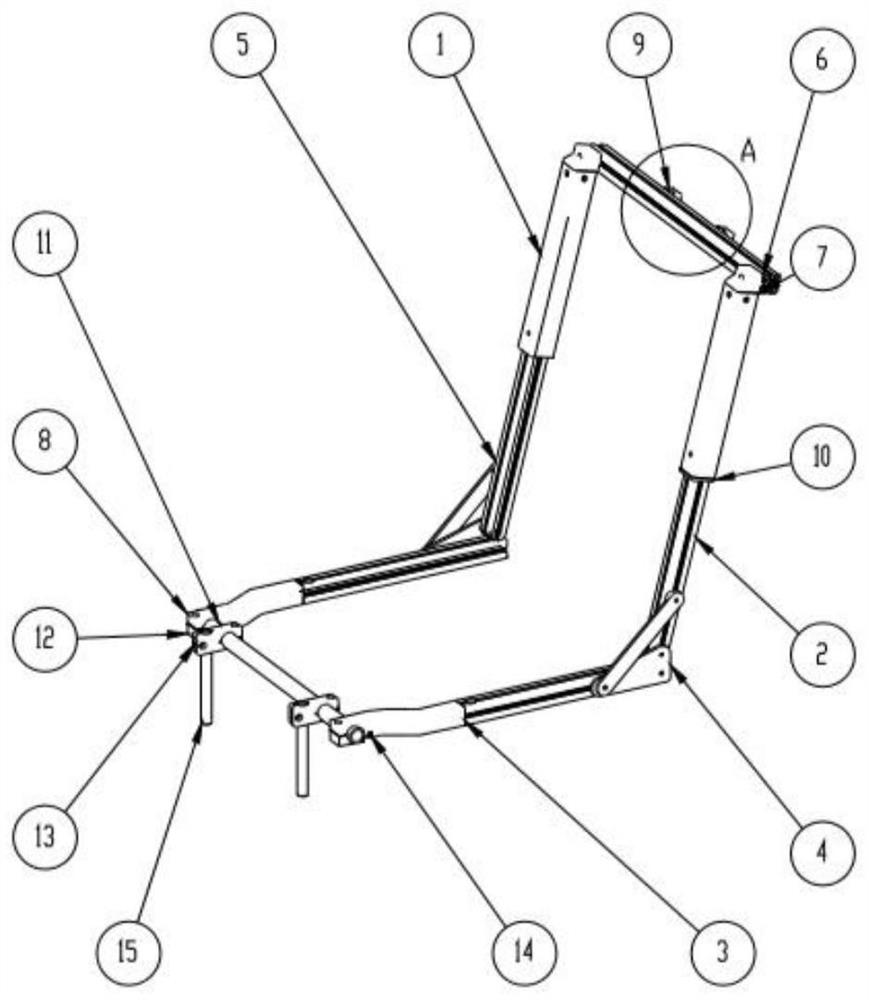

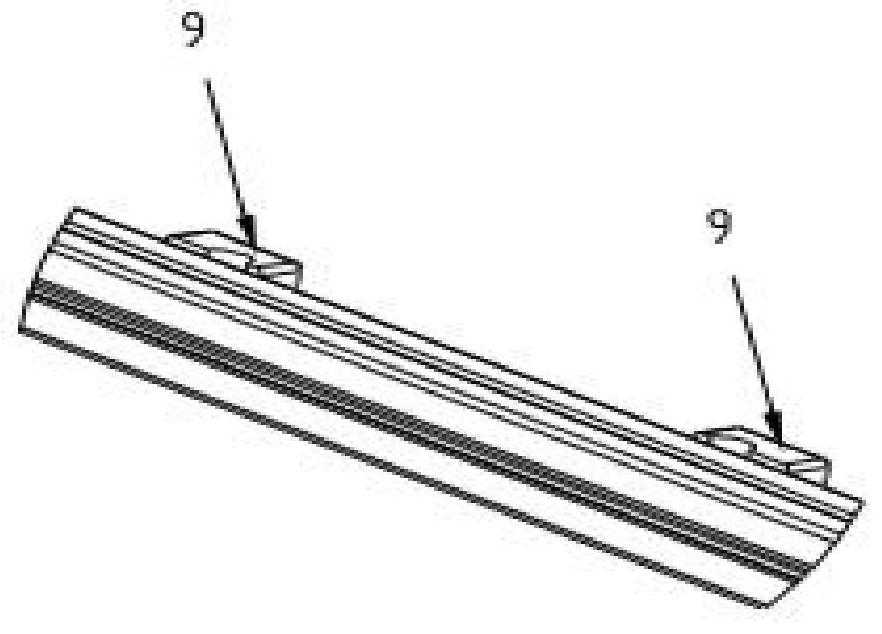

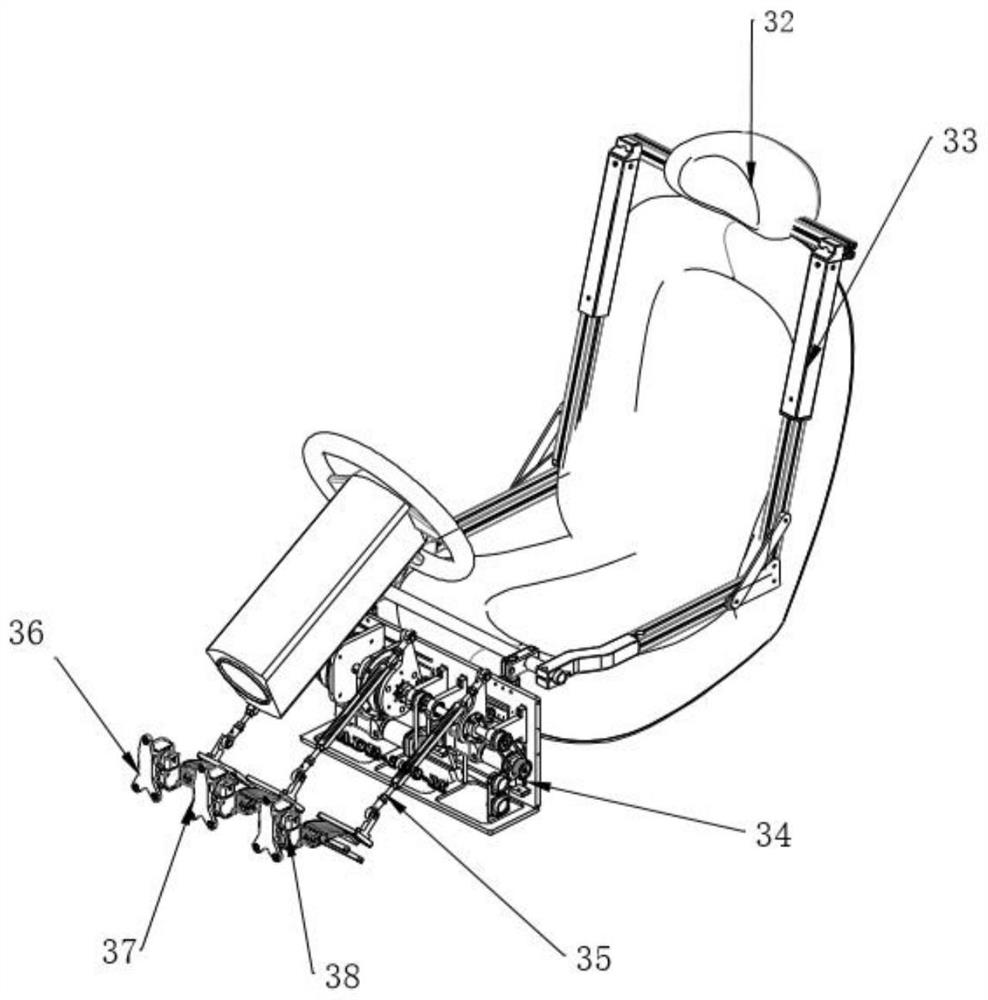

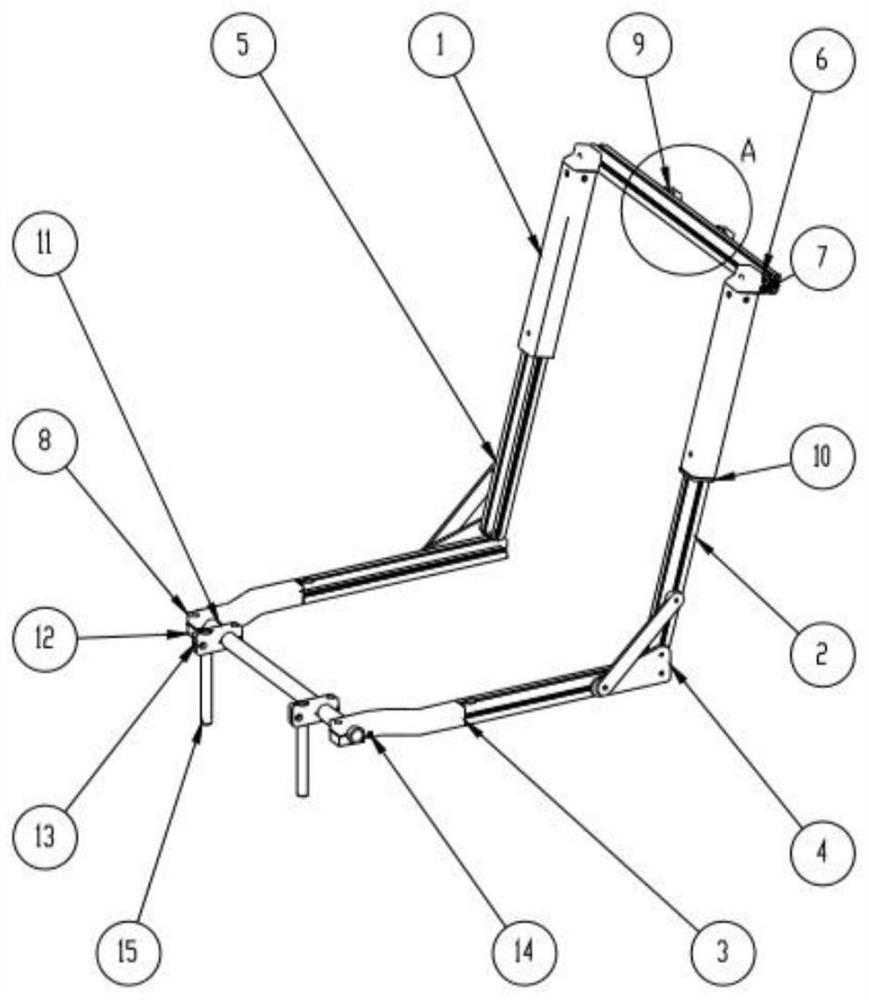

Automatic pedal manipulator

ActiveCN112874297ASimple structureShort preparation timeVehicle seatsFoot actuated initiationsManipulatorClutch

The invention discloses an automatic pedal manipulator. The pedal manipulator comprises a seat main body, a mounting and fixing assembly, a power driving assembly and an arm transmission assembly; the mounting and fixing assembly is mounted on the seat main body, and the power driving assembly is mounted on one side below the mounting and fixing assembly; the arm transmission assembly is mounted on one side of the power driving assembly; and an accelerator pedal, a brake pedal and a clutch pedal are arranged on one side of the arm transmission assembly. The pedal manipulator is simple in structure and can be produced in batches; and the manufacturing time is short, operation is easy, and the automatic operation function is achieved.

Owner:SHENZHEN BOHUITE TECH CO LTD

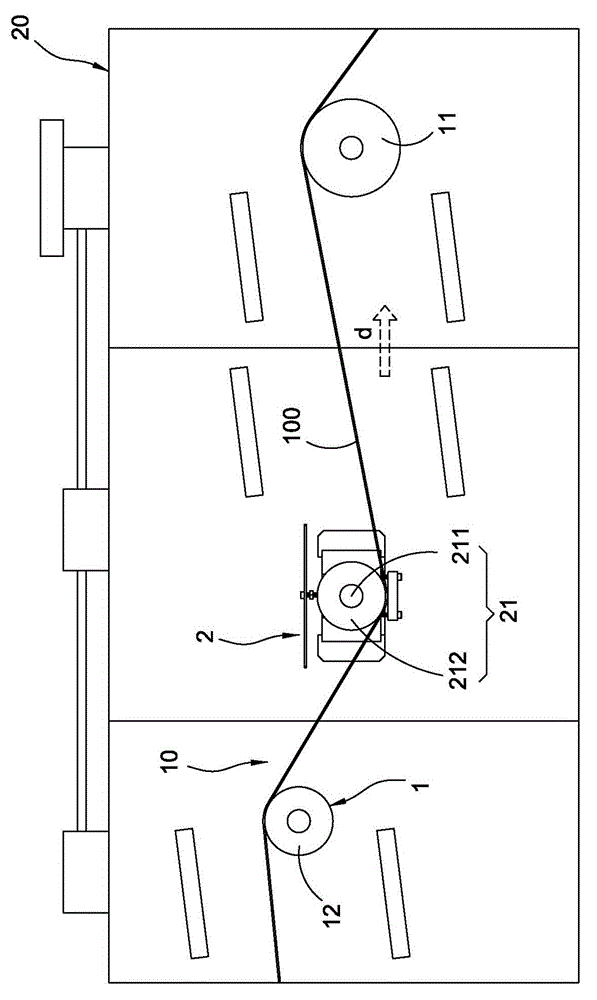

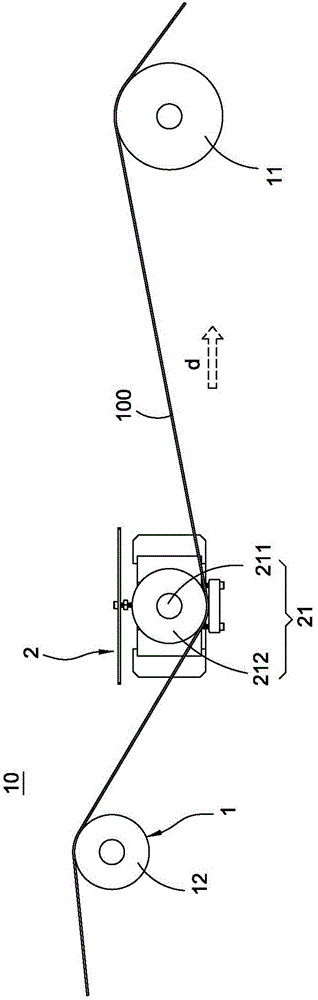

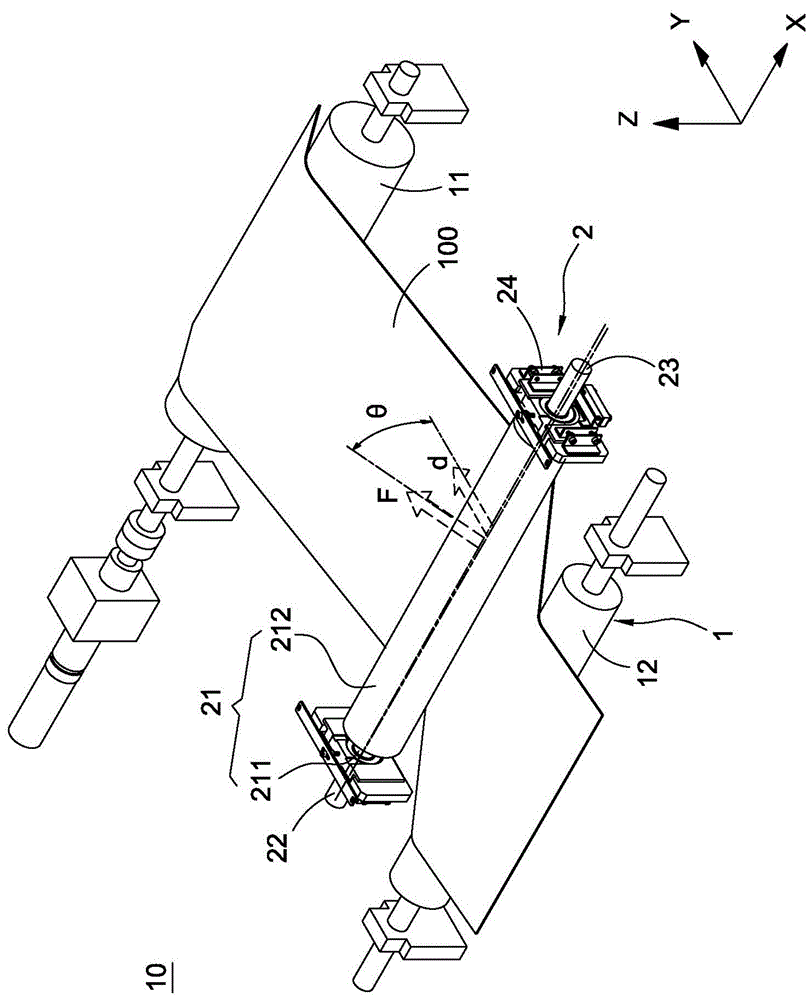

Transmission system capable of adjusting tension of base materials and control method thereof

The invention discloses a transmission system capable of adjusting tension of base materials and a control method thereof. The transmission system comprises a transmission mechanism and a roller assembly. The transmission mechanism drives the base materials to move along a transmission method. The roller assembly comprises an adjusting roller provided with a first end and a second end. The second end moves relative to a first end selectively. The adjusting roller is used for abutting against with the base materials and allowing the base materials to be arranged between the second end and the first end in a crossed manner. When the second end moves relative to the first end, the axis of the adjusting roller deviates so as to provide component force on the surfaces of the base materials and adjust the tension of the base materials, wherein an included angle is formed between the component force and the transmission direction. Thus, the tension borne by the base materials is evened and the base materials are effectively led to move along the transmission direction, so yield rate of the finished products of follow-up manufacture procedures or processing of the base materials is increased.

Owner:MANZ TAIWAN

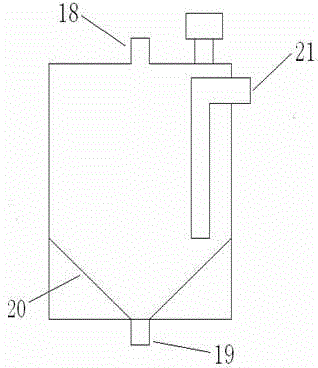

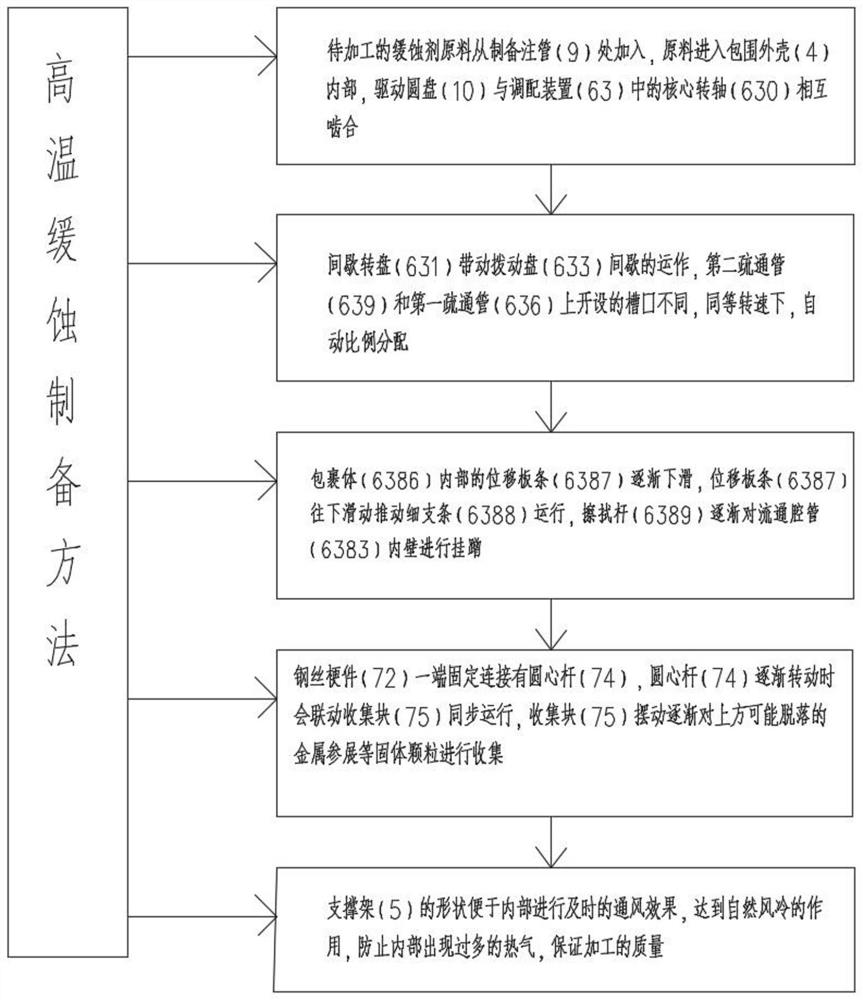

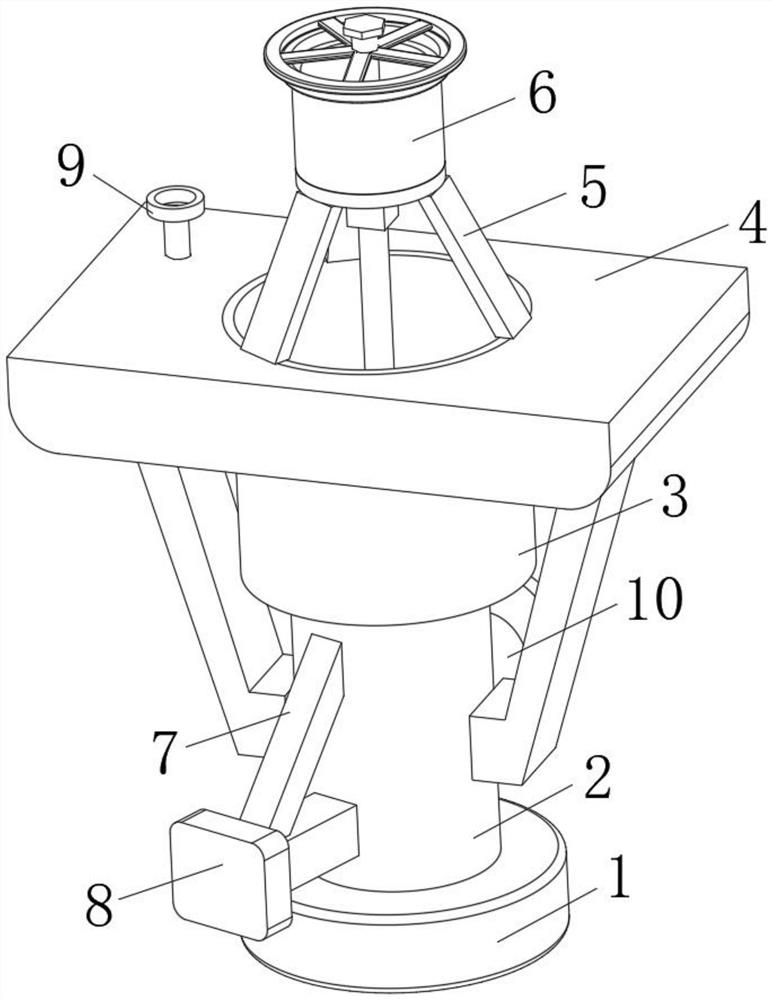

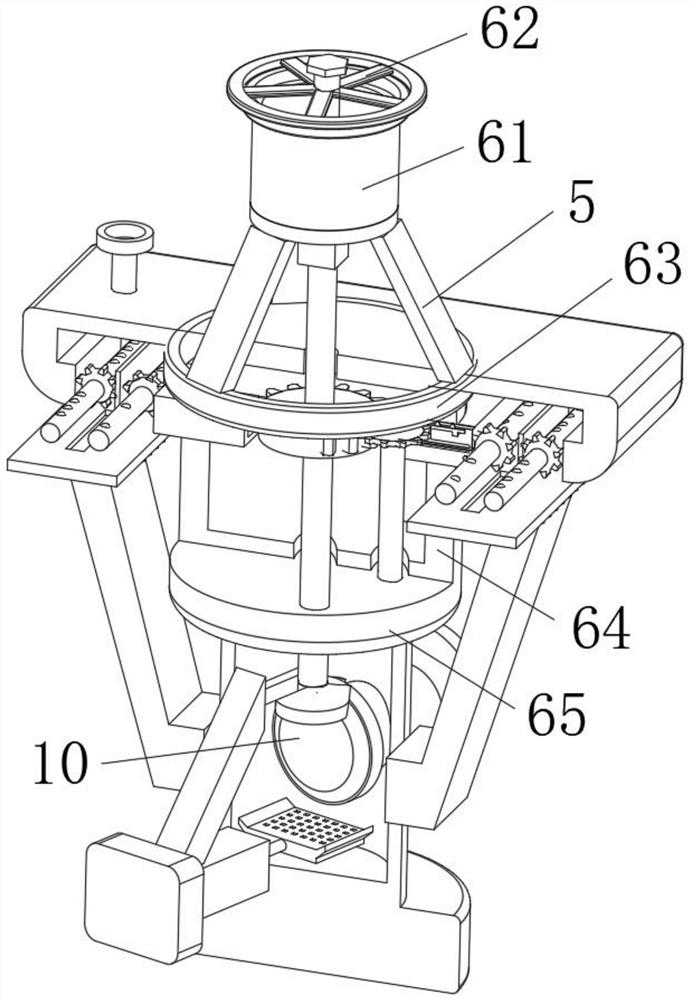

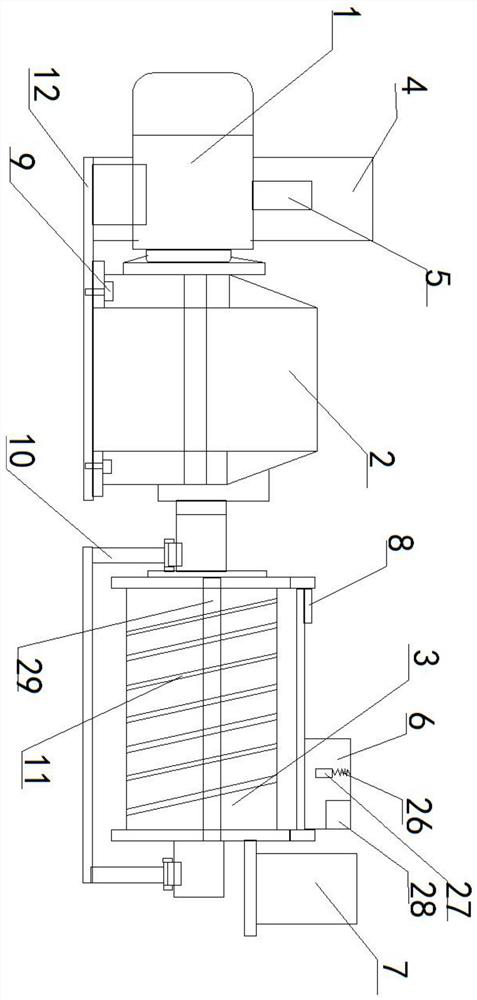

Preparation device and preparation method of high-temperature corrosion inhibitor

InactiveCN114682154AWith automatic operationHas a mixing effectTransportation and packagingMixer accessoriesSoil sciencePipe

The invention relates to the technical field of corrosion inhibitors, and discloses a high-temperature corrosion inhibitor preparation device and method.The high-temperature corrosion inhibitor preparation device comprises a metal base, a supporting table column is fixedly connected to the top of the metal base, a mixing pipeline is fixedly connected to the top of the supporting table column, and a mixing device is fixedly connected to the top end of a supporting frame; the left side of the upper surface of the surrounding shell is fixedly connected with a remark making pipe, and the remark making pipe penetrates through the surrounding shell and extends to an inner cavity of the surrounding shell. According to the high-temperature corrosion inhibitor preparation device and method, the first dredging pipe and the second dredging pipe rotate mutually, raw material solutions in the first dredging pipe and the second dredging pipe are spilled out from notches of the first dredging pipe and the second dredging pipe, and the notch of the second dredging pipe is larger than that of the first dredging pipe, so that the proportions of raw materials injected into the first dredging pipe are different; finally, the effect of automatically blending the raw materials is achieved through the automatic adjustment effect, and compared with manual blending in the prior art, the working efficiency is improved.

Owner:山东晨煜石油技术有限公司

An automatic pedal manipulator

ActiveCN112874297BSimple structureShort preparation timeVehicle seatsFoot actuated initiationsRobot handControl engineering

The invention discloses an automatic pedal manipulator, comprising a seat main body, a mounting and fixing assembly, a power driving assembly and an arm transmission assembly; the mounting and fixing assembly is installed on the seat main body, and the power driving assembly is installed on the lower side of the installation and fixing assembly The arm transmission assembly is installed on one side of the power drive assembly; one side of the arm transmission assembly is respectively provided with an accelerator pedal, a brake pedal and a clutch pedal. The invention has a simple structure and can be produced in batches; the production time is short, easy to operate, and has the function of automatic operation.

Owner:SHENZHEN BOHUITE TECH CO LTD

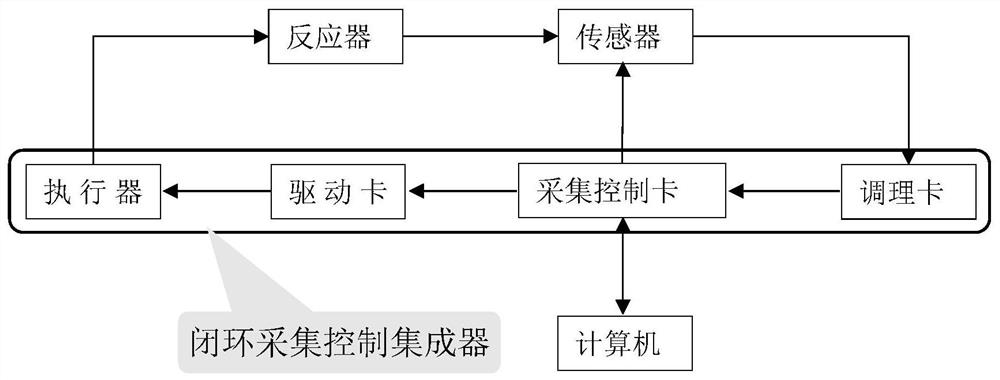

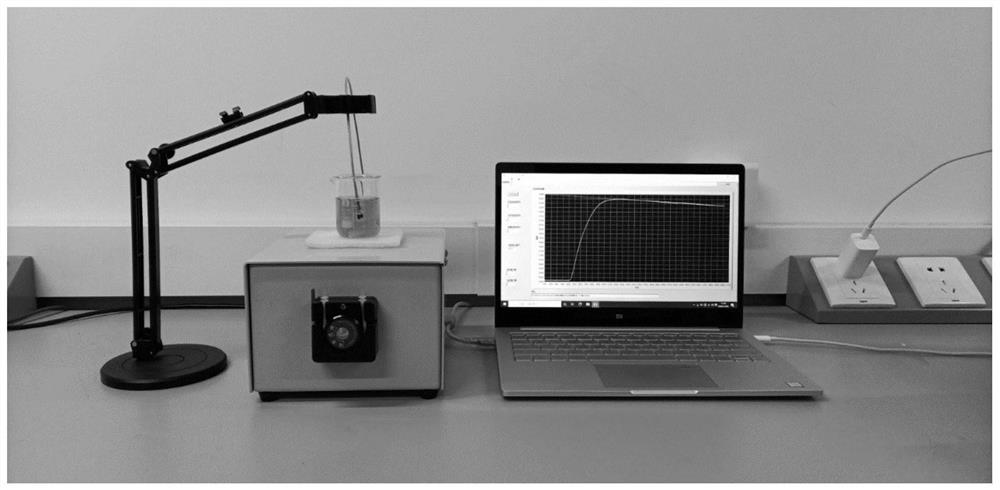

Chemical digital experiment system

PendingCN113506499ACan measure and control temperatureMeasurable and controllable concentrationCosmonautic condition simulationsEducational modelsControl setInformatization

The invention belongs to the field of scientific education, and discloses a novel chemical digital experiment system. The system comprises a reactor, a sensor, a closed-loop acquisition control integrator, a computer and characterization software to form a computer-integrator-reactor-sensor-integrator-computer closed-loop system. The integrator comprises a signal conditioning card, an acquisition control card, a driving card and an actuator, wherein the acquisition control card comprises a data acquisition card and an automatic control card, and the actuator comprises a medicine conveyor, a magnetic stirrer, a constant temperature controller, a signal generator, a potentiostat, a constant current source, an LED light source and the like. The novel chemical digital experiment system can quantitatively convey drugs, perform magnetic stirring and constant-temperature heating, measure and control temperature, potential, current, conductivity, concentration, acidity, luminosity, turbidity, fluorescence, air pressure and the like, and realize digitalization, informatization, automation and platformization of chemical experiments, and has the remarkable advantages of automatic operation, rapid experiment, clear process, visual trend and accurate quantification.

Owner:张明晓

A robot lifting conveyor

ActiveCN106628906BMeet the problem of insufficient length before and afterSolve the problem of insufficient front and rear lengthMechanical conveyorsSpraying apparatusRobotic systemsEngineering

The invention discloses a robot lifting conveyor, which includes a robot system, a walking system and a lifting system. The walking system and the lifting system are integrated and cooperate with the robot system to realize the automation of the primer station. The overall structure of the conveyor is simple , the cost is relatively low, the structure is compact and reasonable, the operation is reliable and stable, and the integrated operation efficiency is high. It replaces manual primer and can be applied to many different types of work stations, improving the efficiency and quality of primer.

Owner:MH ROBOT & AUTOMATION

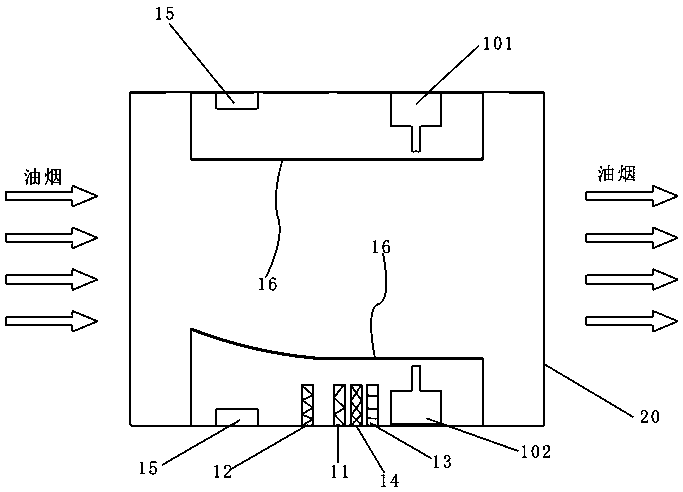

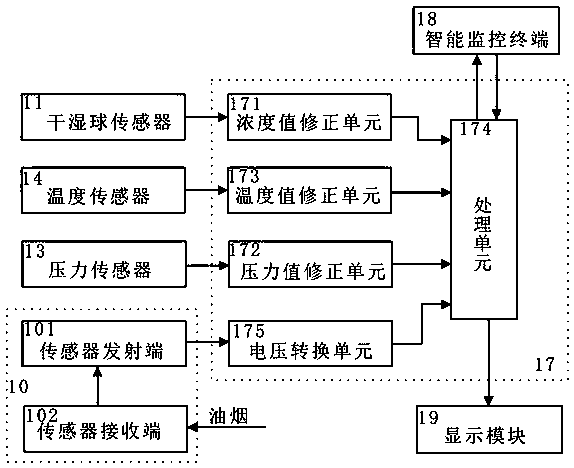

Oil fume online detection system and online detection method of oil fume concentration

ActiveCN104655536BReduce distractionsPromote degradationMaterial moisture contentParticle suspension analysisMicrocontrollerDifferential pressure

The invention discloses an online oil fume detection system and an online detection method for oil fume concentration. The system includes an oil fume concentration detector installed in an air duct, an anemometer, purification equipment, a single-chip microcomputer, and a communication terminal interactively connected with the single-chip microcomputer. Intelligent monitoring terminal; oil fume concentration detector includes photosensitive oil fume sensor and wet and dry bulb sensor; anemometer includes micro pressure difference sensor, pressure sensor and temperature sensor; purification equipment includes photosensitive oil smoke sensor, dry and wet bulb sensor, UV lamps and photocatalyst layers for sensors and temperature sensors. The invention has a strong catalytic degradation function produced by the photocatalyst layer, which can effectively reduce the interference of ambient light on all sensors, and can degrade and purify all sensors and the oil fumes adsorbed on their probes, which enhances the purification effect and meets the multi-functional requirements of the purification equipment. And the effect of energy saving; and can realize the online real-time detection of oil fume concentration and oil fume exhaust efficiency.

Owner:SHENZHEN TIANDEYI ENVIRONMENT TECH

A mine rope changing automatic rope winding machine and its use method

The invention discloses a mine rope changing and automatic winding machine and a using method thereof. The mine rope changing and automatic winding machine comprises a base, a roller and a roller support. The roller support is fixedly connected to the base. The roller is connected to the roller support through a shaft penetrating through an inner cavity of the roller. A motor and a speed reducingbox are fixedly connected to the base through bolts. The motor and the speed reducing box are connected through a gear. The roller and the speed reducing box are connected through a transmission shaft. The roller support is provided with an oil filling device and an emergent rope clamping device. A rope fixing device is arranged on one side of the roller support. An electronic control box is arranged on the other side of the roller support. According to the mine rope changing and automatic winding machine, the old rope winding and maintaining manner is changed, only one person is needed for recovering old ropes, and the speed is adjusted according to the rope releasing speed. According to the practical technology, a large number of operators are reduced, labor intensity of the operators isreduced, safety and reliability of rope recovering are improved, and the working efficiency is improved.

Owner:SHANDONG LINENG LUXI MINING IND CO LTD

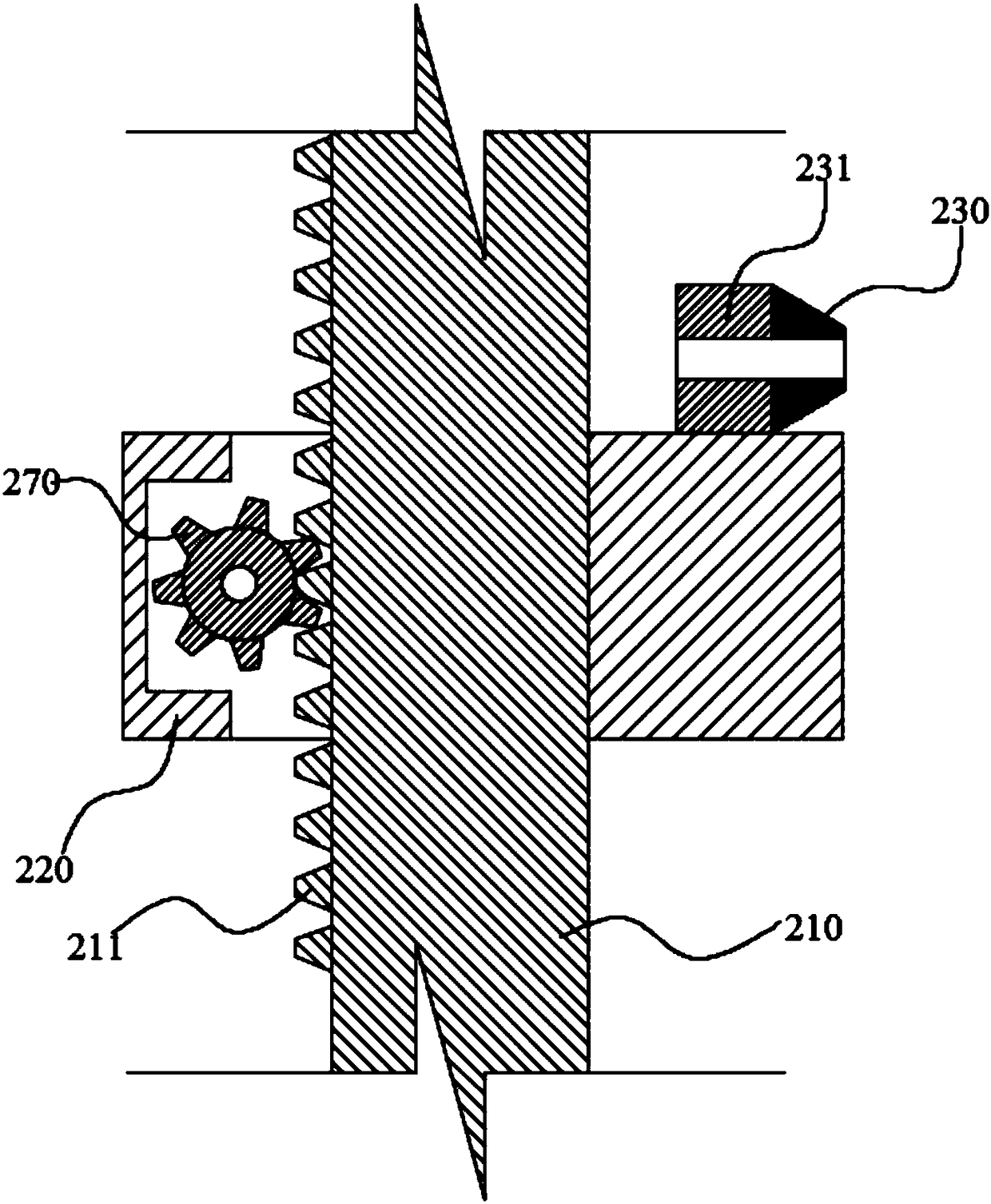

Automatic punching machine

InactiveCN103157822BRealize double-head drilling functionGuaranteed positioning accuracyPositioning apparatusMetal working apparatusPunchingEngineering

The invention relates to an automatic punching machine. A clamping mechanism opposite to a drilling cutting tool is placed on a work platform. The clamping mechanism comprises a support platform, a lower die device, a baffle, a guide column, a support plate, a pressing support platform, an upper die and a pressing oil cylinder. The lower surface of the support platform is fixed on the work platform, the lower die device is fixed on the upper surface of the support platform, the baffle is fixed on the upper surface of the support platform and is located on one side of the lower die device, and the baffle is provided with a through hole through which a workpiece to be machined penetrates. One end of the guide column is connected with the support platform, and the other end of the guide column is connected with the support plate. The pressing support platform is in sliding fit with the guide column. The upper die is connected with the lower portion of the pressing support platform, the upper portion of the pressing support platform is connected with the pressing oil cylinder which is fixed on the support plate, and both the lower die device and the upper die are provided with two material grooves for assembling the workpiece. By means of the automatic punching machine, two wirkpieces with the same axle can be automatically punched at the same time. The automatic punching machine has the advantages of being high in degree of automation, and improving product quality and production efficiency.

Owner:CHANGZHOU SHULE KITCHEN UTENSILS

Method for cleaning bottom equipment of bullet trains

ActiveCN102343890BDoes not affect other jobsGuarantee checkCleaning apparatus for vehicle exteriorsHigh pressurePollution

The invention discloses a method for cleaning bottom equipment of bullet trains. Bottom equipment of three bullet trains are simultaneously subjected to a cleaning flow process in different stages by utilizing three station positions arranged by a bullet train cleaning bank. When a train after being subjected to a first station position cleaning enters into a second station position, the next train enters into a first station position, and when the train after being subjected to a second station position cleaning enters into a third station position, the next train enters into the second station position and the train after the train which enters into the second station position enters into the first station position. A whole set of flow process system used for cleaning the bottom equipment of the bullet trains comprises the main units, such as an industrial dust-absorption system, a high-pressure air blowing system, a high-pressure cleaning system, a control console, an ultrasonic dust cleaner, a mobile dust-absorption device, a fixed pipe net, an intelligent dust-absorption socket, and the like. The system combines high-pressure cleaning with dust absorption and injecting blowing dust absorption, is excellent in integrity, is safe and high-efficient as well as convenient, is conveniently used, can avoid pollution, and meets the demand of automatic modern development.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

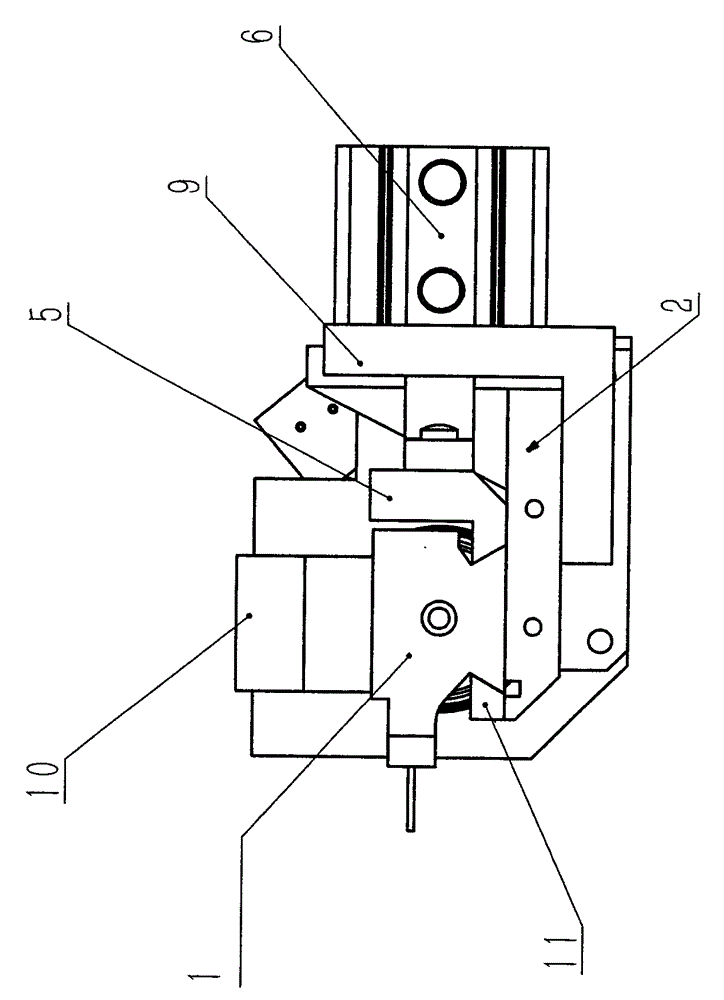

Dust removal unit

ActiveCN104716795BWith automatic operationReasonable structureManufacturing stator/rotor bodiesDrive shaftDrive motor

The invention relates to automatic assembly production equipment for the internal rotor structure of a DC motor of a household appliance, specifically a dust removal unit of a motor rotor assembly line. The base plate is provided with a linear guide rail, and the base plate is provided with a tape clamping mechanism and a tape roller transmission mechanism. and the dust removal drive mechanism, the bracket of the tape clamping mechanism is set on the base plate, the support plate is provided on the support plate, and the first driven shaft and the second driven shaft are arranged side by side on one side of the support plate, the first driven shaft and the second driven shaft The driven shafts are respectively provided with pulleys and are connected by belts. The first driven shaft and the second driven shaft are respectively covered with sleeves. The drive motor is installed on the bracket. The driven shaft and the fourth driven shaft, the third driven shaft and the fourth driven shaft are respectively provided with sleeves, the first driven shaft or the second driven shaft is provided with a tape roll on the tension sleeve, and the The base plate is provided with a cylinder support, and the compression cylinder is installed on the cylinder support, which has the advantages of reasonable structure and high working efficiency.

Owner:东莞市森江机电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com