A robot lifting conveyor

A conveyor and robot technology, used in mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of huge equipment transfer points and high equipment maintenance requirements, and achieve simple and practical equipment mechanisms, less floor space, and more efficient equipment. Reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

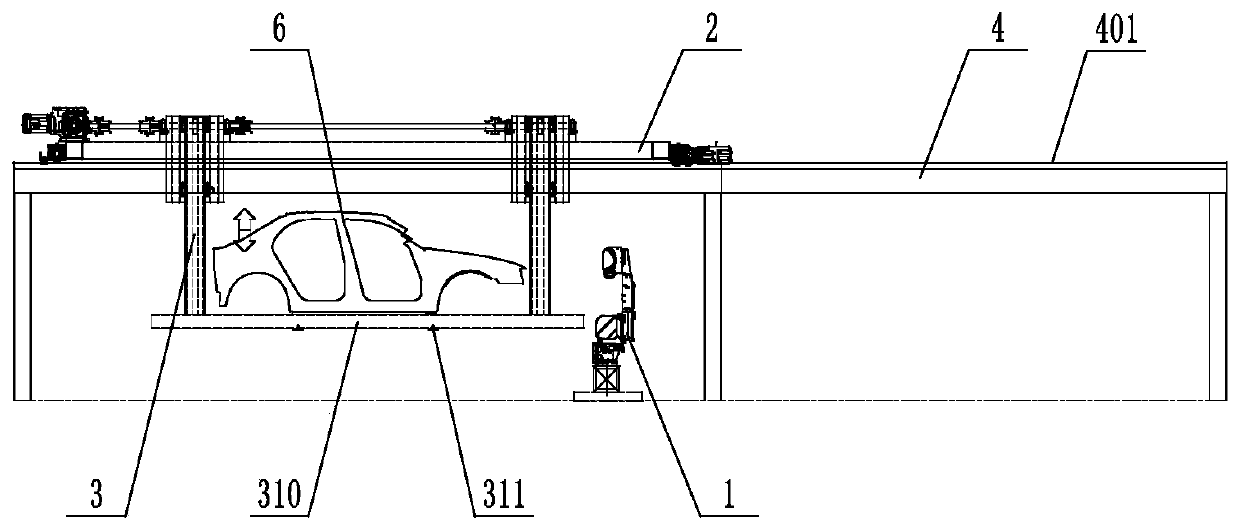

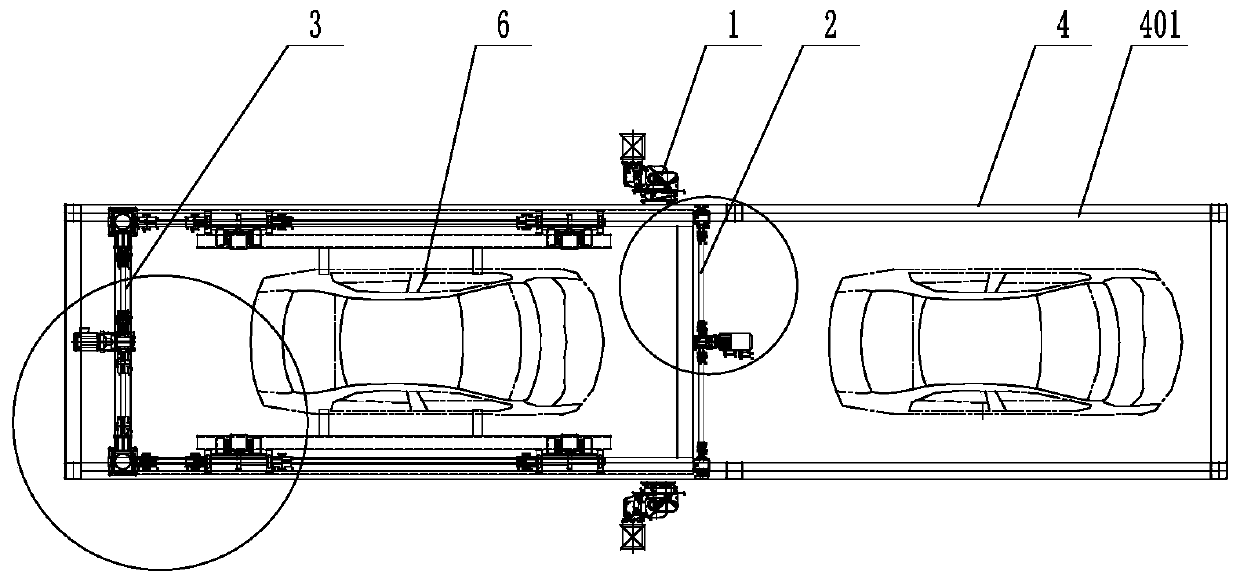

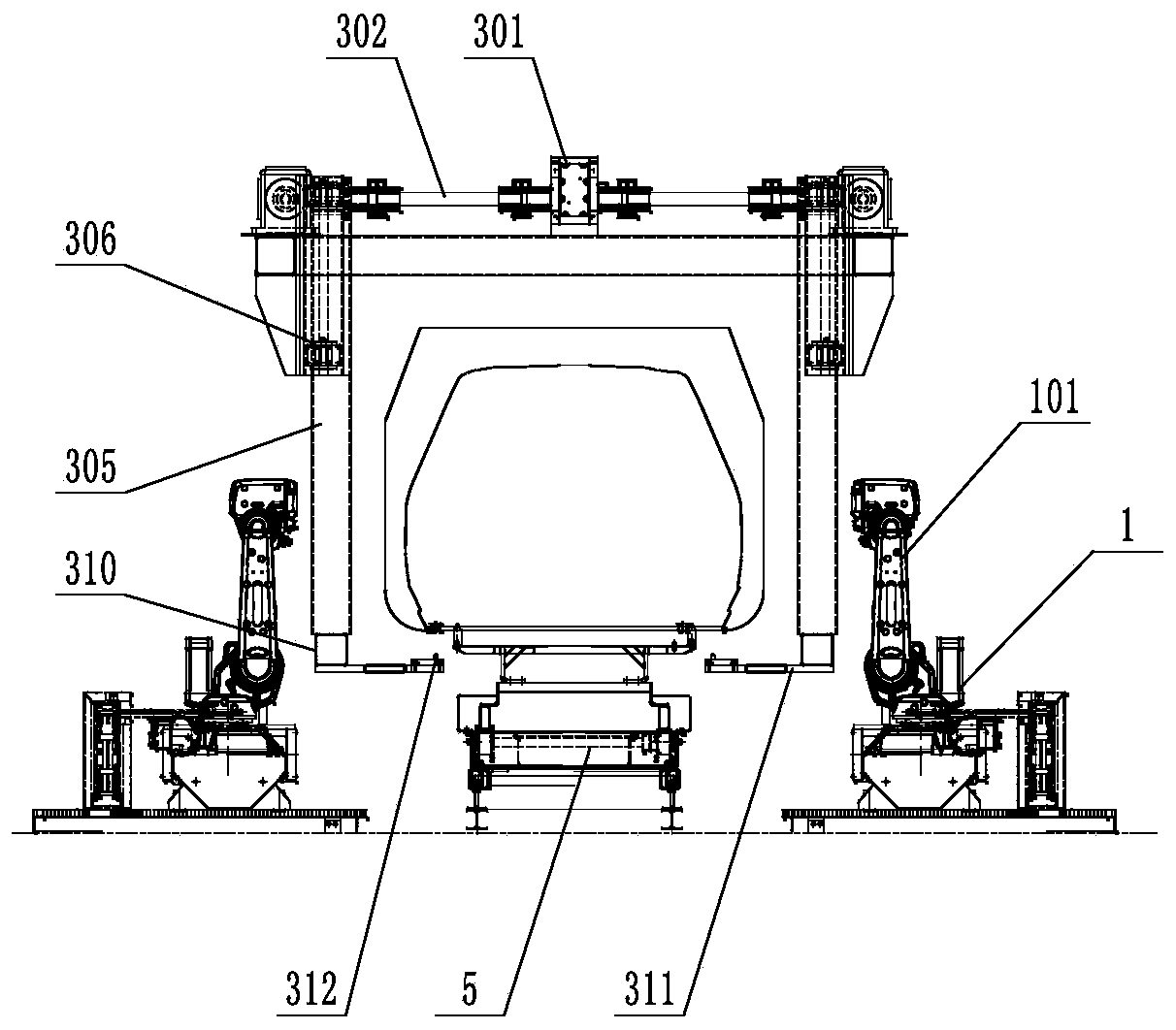

[0028] like Figure 1 to Figure 7 As shown, the conveyor includes a robot system 1, a walking system 2 and a lifting system 3, wherein the walking system 2 and the lifting system 3 are integrated, and cooperate with the robot system 1 to realize the automation of the primer station.

[0029] Robot system 1: includes a plurality of robots 101 distributed on both sides of the gantry 4, and its control system can be placed in a designated position of the production line according to the requirements of painting. Through profiling, the working trajectory of the robot 101 can be set in advance, and the position of the workpiece can be detected by the sensor. When the workpiece reaches the designated position, the robot 101 can automatically choose to work according to the programmed action through the vehicle model recognition.

[0030] Walking system 2: set on the upper end of the gantry 4 and drive the conveyor to move horizontally. In order to meet the technical requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com