Automatic separating device for aluminum bar clamp

An automatic detachment and fixture technology, which is applied in the direction of manufacturing tools, grinding machine parts, metal processing equipment, etc., can solve the problems of increasing labor intensity of operators, inconvenient loading and unloading, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

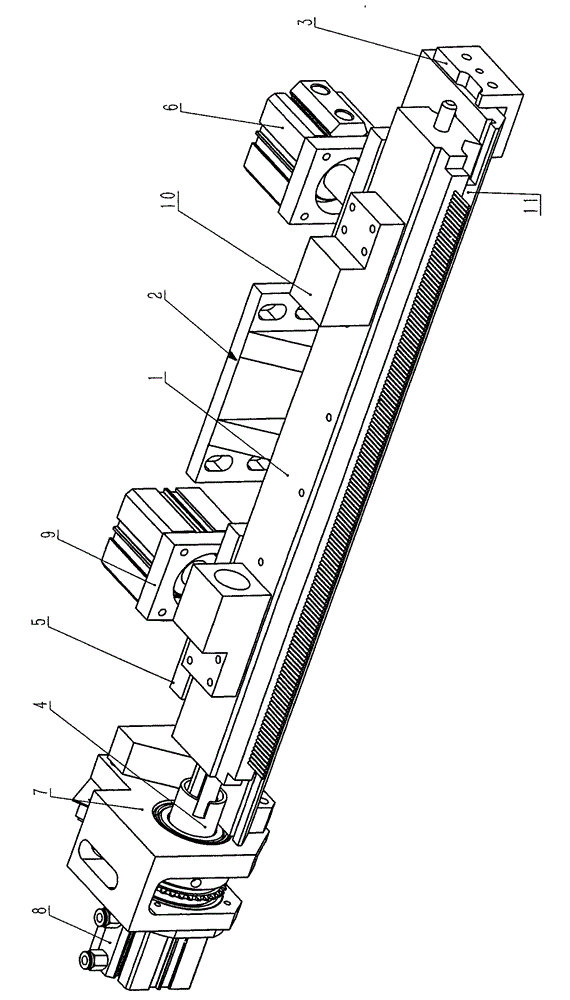

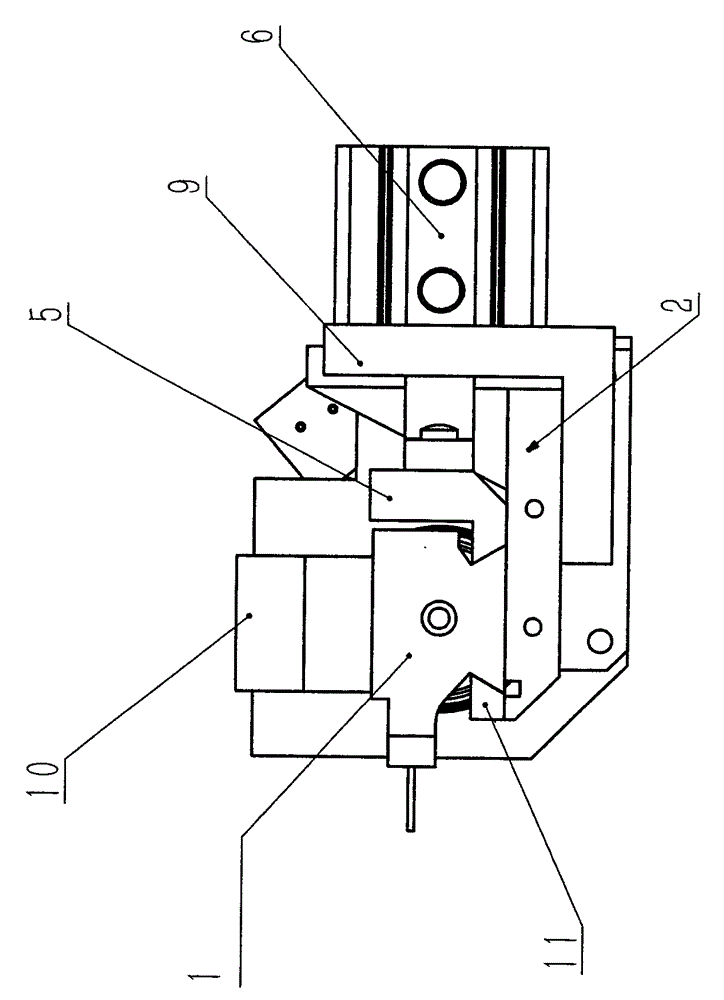

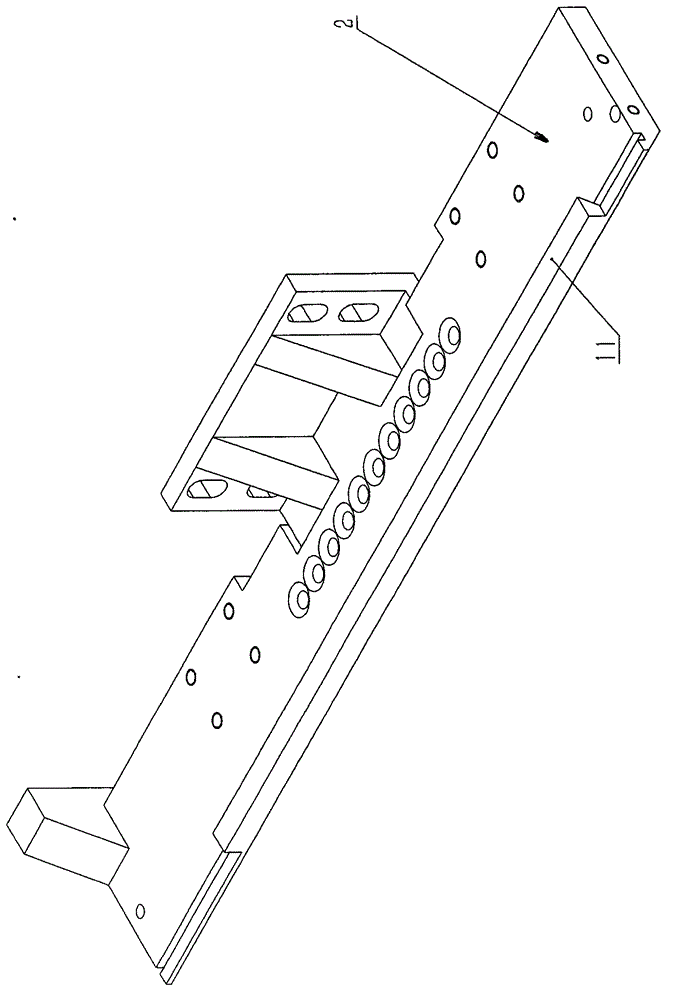

[0010] refer to Figure 1 to Figure 3 It can be known that the present invention is applied to the automatic detachment device of the aluminum row fixture of the water drill grinding and polishing machine, including the aluminum row fixture 1 (including the aluminum row for clamping the workpiece), the aluminum row seat 2, and the side of the aluminum row fixture 1 has a rotating head cover 4. On the aluminum row seat 2 and at the lower part of the aluminum row fixture 1, a horizontal top plate 5 is provided, and the horizontal top plate 5 is connected to the horizontal top plate limit cylinder 6; the rotating plug cover 4 (by rotating the plug seat 7) Link to each other with rotary head cylinder 8.

[0011] Wherein, there is no dovetail slot on the aluminum row seat 2, and the front end of the aluminum row seat 2 has a front top plate 11, which is used to withstand the front lower part of the aluminum row clamp; The lower part is limited laterally at the rear lower dovetail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com