Patents

Literature

314results about How to "Improve sowing quality" patented technology

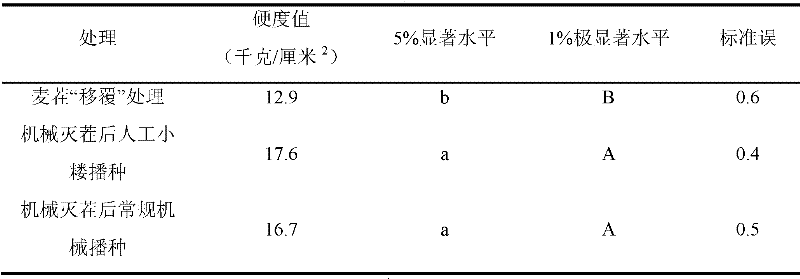

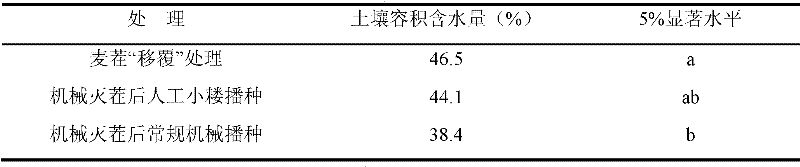

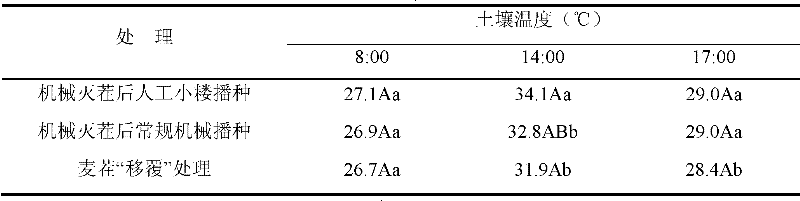

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic seeding device for agricultural tillage

InactiveCN109005797AAvoid cloggingImprove stabilityPlantingFurrow making/coveringAgricultural engineeringTillage

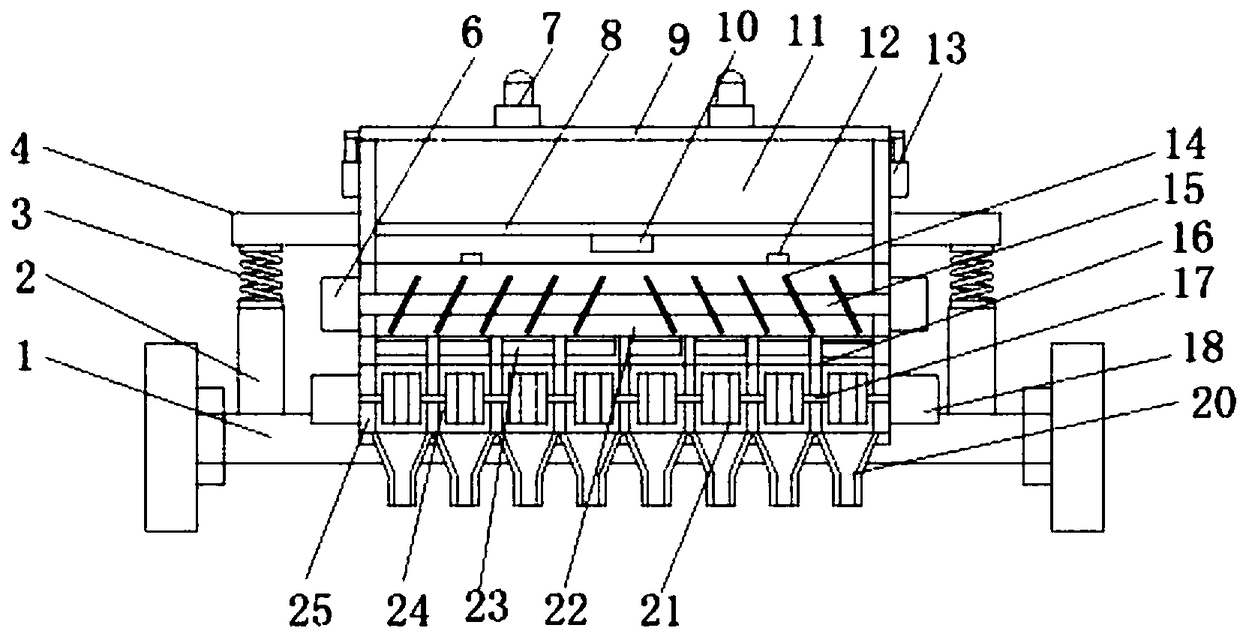

The invention belongs to the field of agricultural technology and particularly relates to an automatic seeding device for agricultural tillage. The automatic seeding device solves the problem of uneven seed dispersion and poor seeding quality of the existing agricultural seeding device in work. The automatic seeding device comprises a vehicle body support, a seed storage tank is arranged in the vehicle body support, two sides of the seed storage tank are welded to support plates, one side of the top of the seed storage tank is hinged to a tank cover, the top of the tank cover is connected to two sound and light alarms through bolts and the bottom of the seed storage tank is connected to a dispersing bucket by bolts. A sieve plate screens and oscillates seeds so that seeding device blockingcaused by seed adhesion caking is avoided, the normal seeding is avoided and the seeding device stability is improved. A processor can adjust a rotation rate of a second stepping motor so that the seeding density is adjusted, the seeding process is simple and convenient and a degree of automation is high.

Owner:深圳市创颉科技有限公司

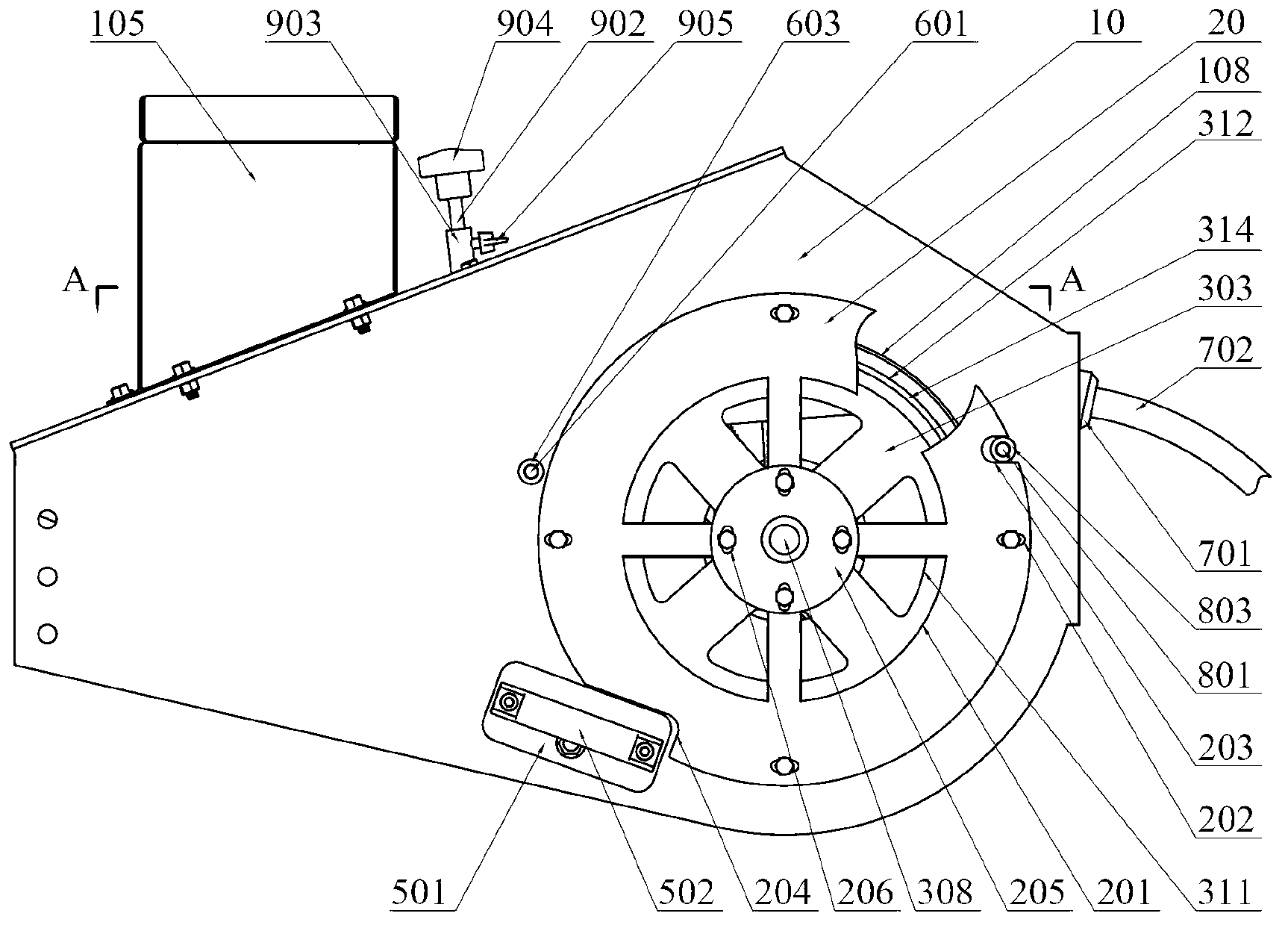

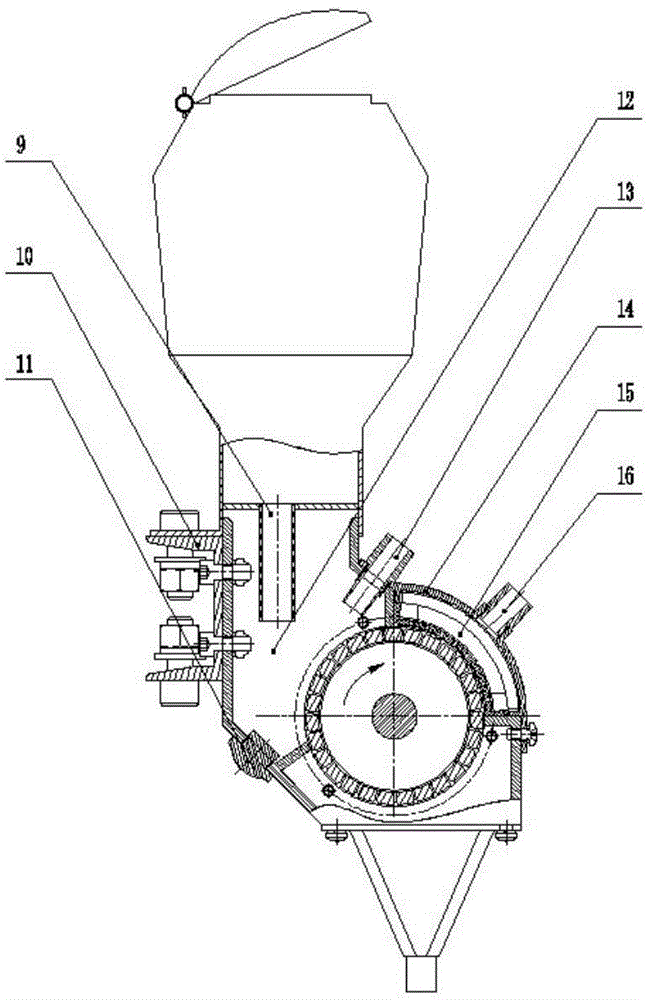

Air power collecting and discharging type precision seed sowing device

InactiveCN103004338AStrong shape adaptabilityReduce vibrationSeed depositing seeder partsRegular seed deposition machinesPositive pressureCritical position

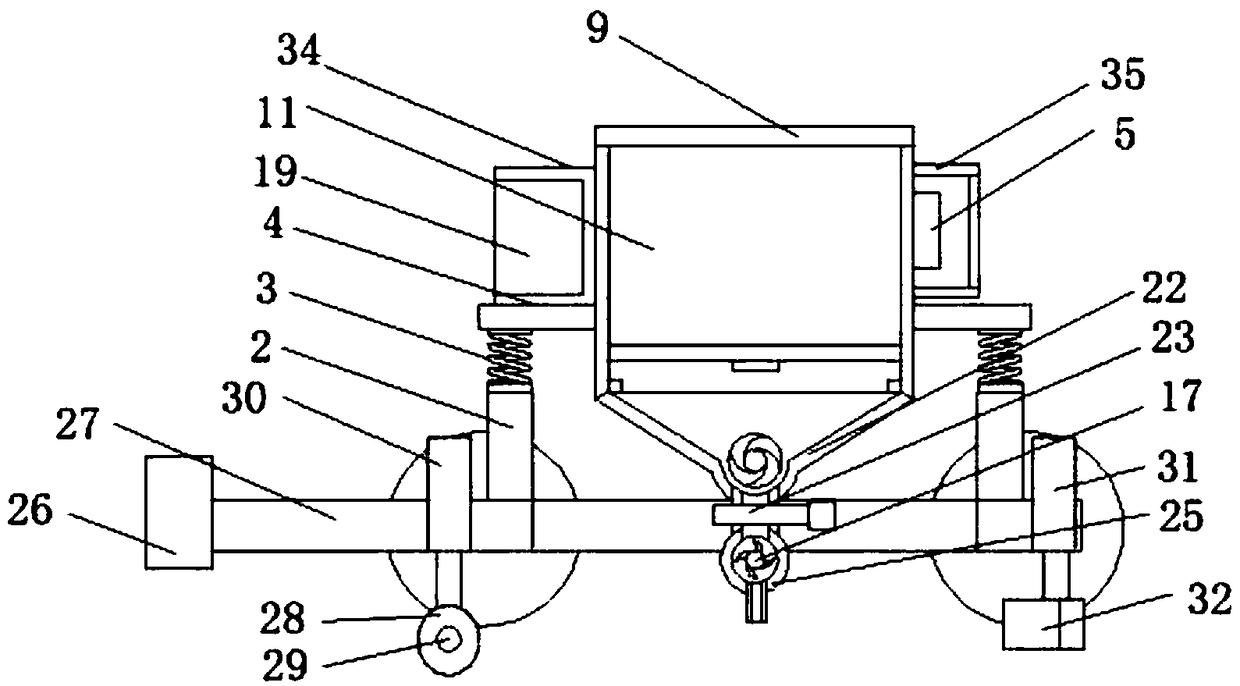

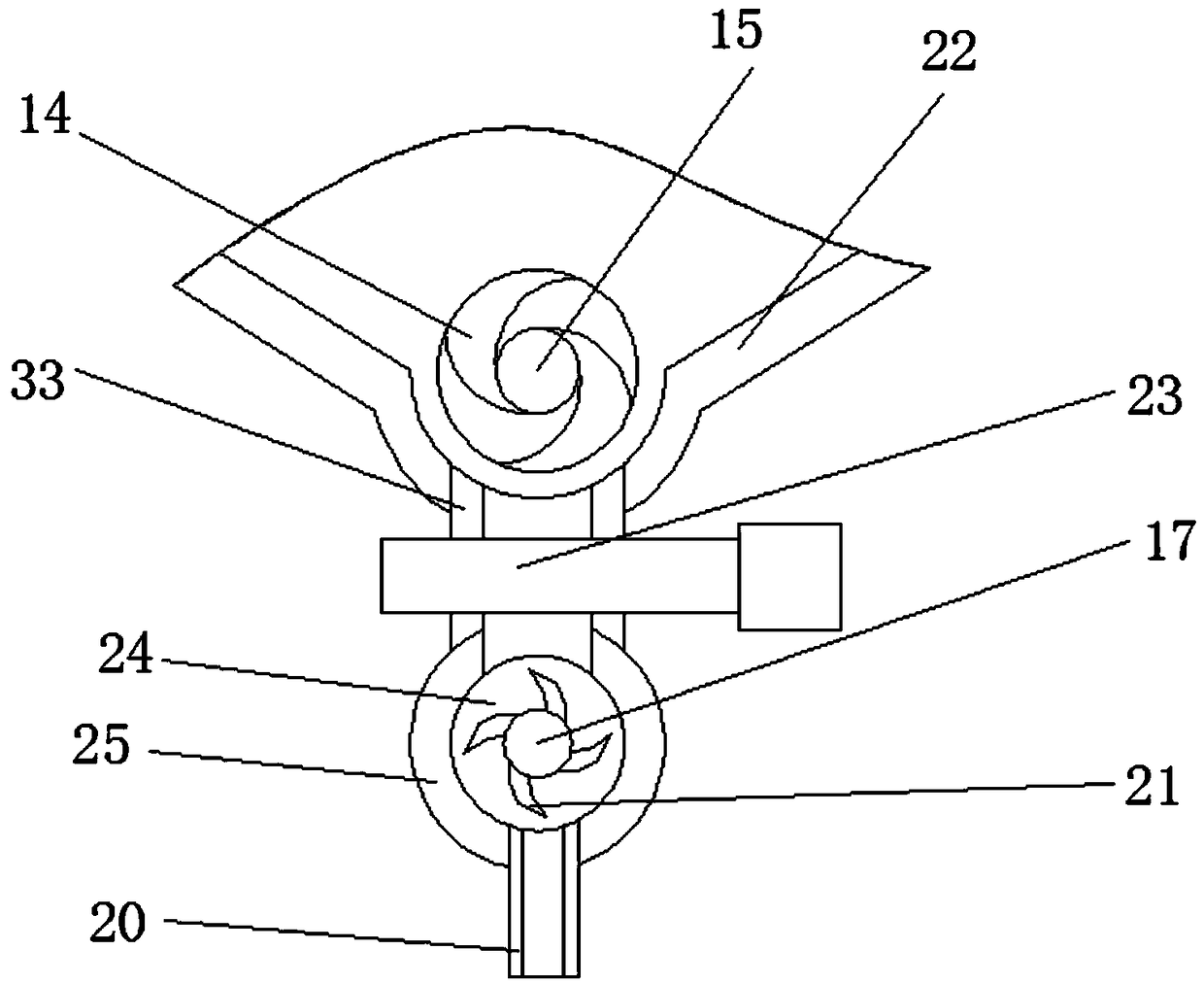

The invention relates to an air power collecting and discharging type precision seed sowing device, which is characterized by comprising a shell, a sealing cover plate, a seed sowing roller, a pressure relief wheel, a seed bed screen, a seed cleaning shifting finger, a seed guiding pipe, an impurity collecting plate and a seed stopping plate, wherein the shell is connected with the sealing cover plate by virtue of bolts, the seed sowing roller is arranged in the shell to form an operation air chamber, an air supply chamber and a seed chamber, the seed chamber is internally provided with an air supply pipe, the seed bed screen is arranged at a critical position of the air supply chamber and the operation air chamber, and the air supply chamber provides air flow for the operation air chamber by virtue of the seed bed screen and the air supply pipe; the seed cleaning shifting finger is arranged in the operation air chamber, is close to the roller in a gap and is in an L shape, a shorter side of the seed cleaning shifting finger is in a right trapezoid shape, and relative position between a bevelled edge of the trapezoid and a seed attaching hole can be adjusted by virtue of a seed cleaning shaft fixedly connected with the shorter side; the pressure relief wheel is arranged inside the seed sowing roller and is close to the interior of the roller by virtue of a tension spring; and the inlet of the seed guiding pipe is close to the roller in the gap and is dead against a contact point of the pressure relief wheel and the roller. The precision seed sowing device realizes centralized precision seed sowing, seed attaching pressure difference and a seed sending air flow are provided by virtue of a positive pressure system, a seed layer is disturbed by utilizing the air flow, and seed filling probability is improved. The precision seed sowing device is applicable to precision seed sowing of large-row-spacing crops such as corn and soybean.

Owner:CHINA AGRI UNIV

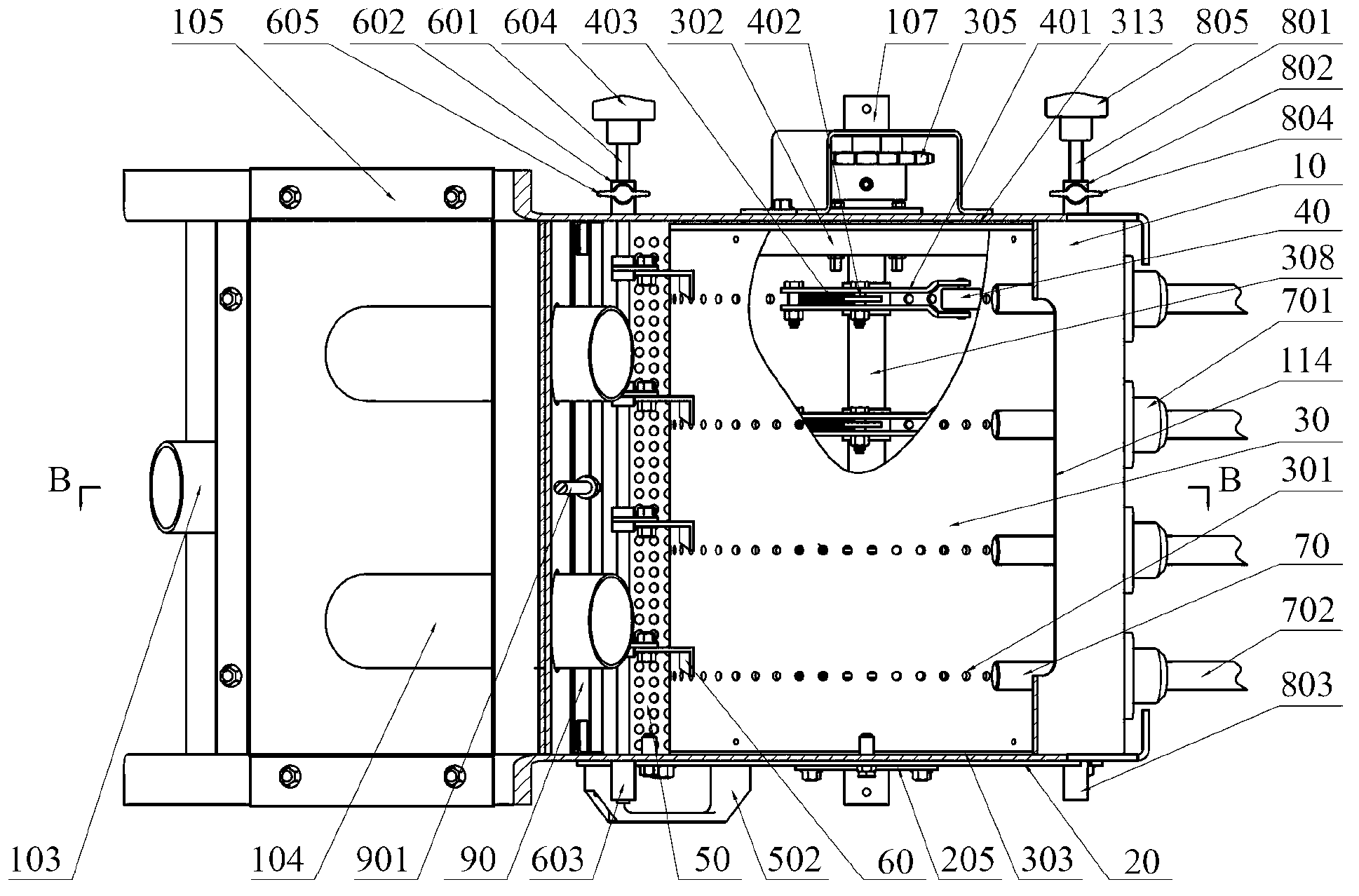

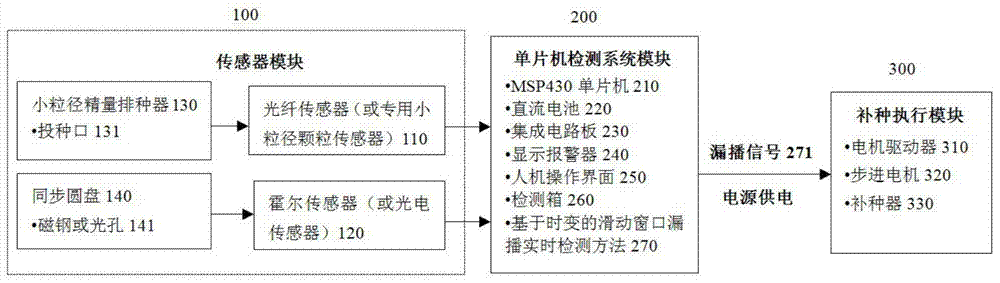

Miss-seeding real-time detection and automatic seed supplying system of small grain size precise seeding apparatus

ActiveCN104488419AReal-time detection of missing broadcastShort detection hysteresisAgriculture gas emission reductionSeed depositing seeder partsMicrocomputerMicrocontroller

The invention discloses a miss-seeding real-time detection and automatic seed supplying system of a small grain size precise seeding apparatus. The system comprises a sensor module, a singlechip microcomputer detection system module and a seed supplying executing module. By adopting a miss-seeding real-time detection method of the small grain size precise seeding apparatus with a time-varying sliding window, the system transfers a standard seeding pulse sequence and a seeding seed flow sequence detected to a singlechip microcomputer control system by virtue of a sensor for statistic analysis so as to obtain a broken bar coefficient, a spare missing seedling coefficient and a miss-seeding coefficient and can be used for precisely judging the miss-seeding state according to a miss-seeding coefficient threshold vale and a miss-seeding judging rule for displaying and alarming, and meanwhile, the system drives a seed supply system to compensate seeds after miss seeding. The system disclosed by the invention can be used for immediately and accurately compensating the seeds, so that the seeding quality and the production efficiency of a small grain seed precise direct seeding machine, such as oilseed rape, are improved, and the mechanical and intelligence levels of a oilseed rape seeder is gradually improved.

Owner:HUAZHONG AGRI UNIV

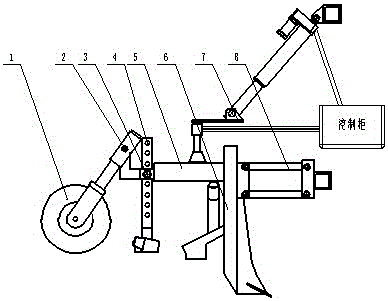

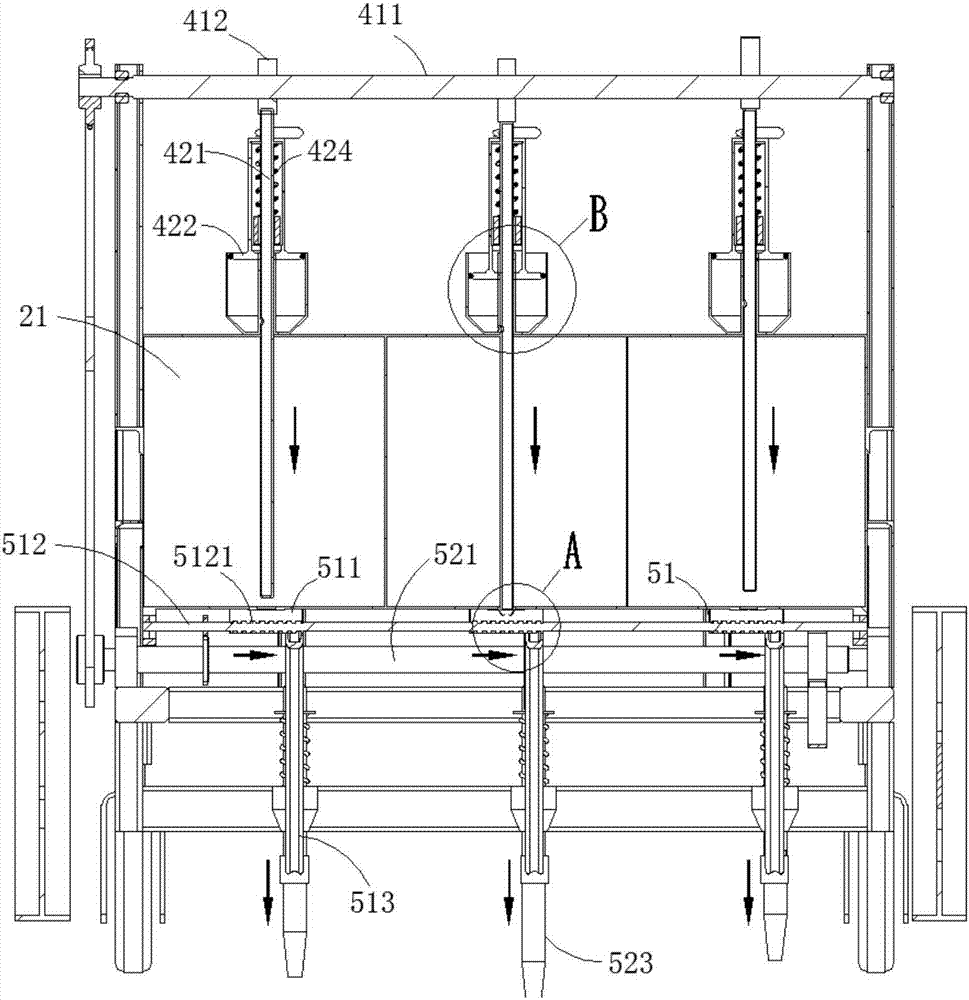

Novel intelligent regulating isobathic seeding device for wide seedling zone

InactiveCN105103725AEnsure consistencyHigh sensitivityPlantingFurrow making/coveringEngineeringSeedling

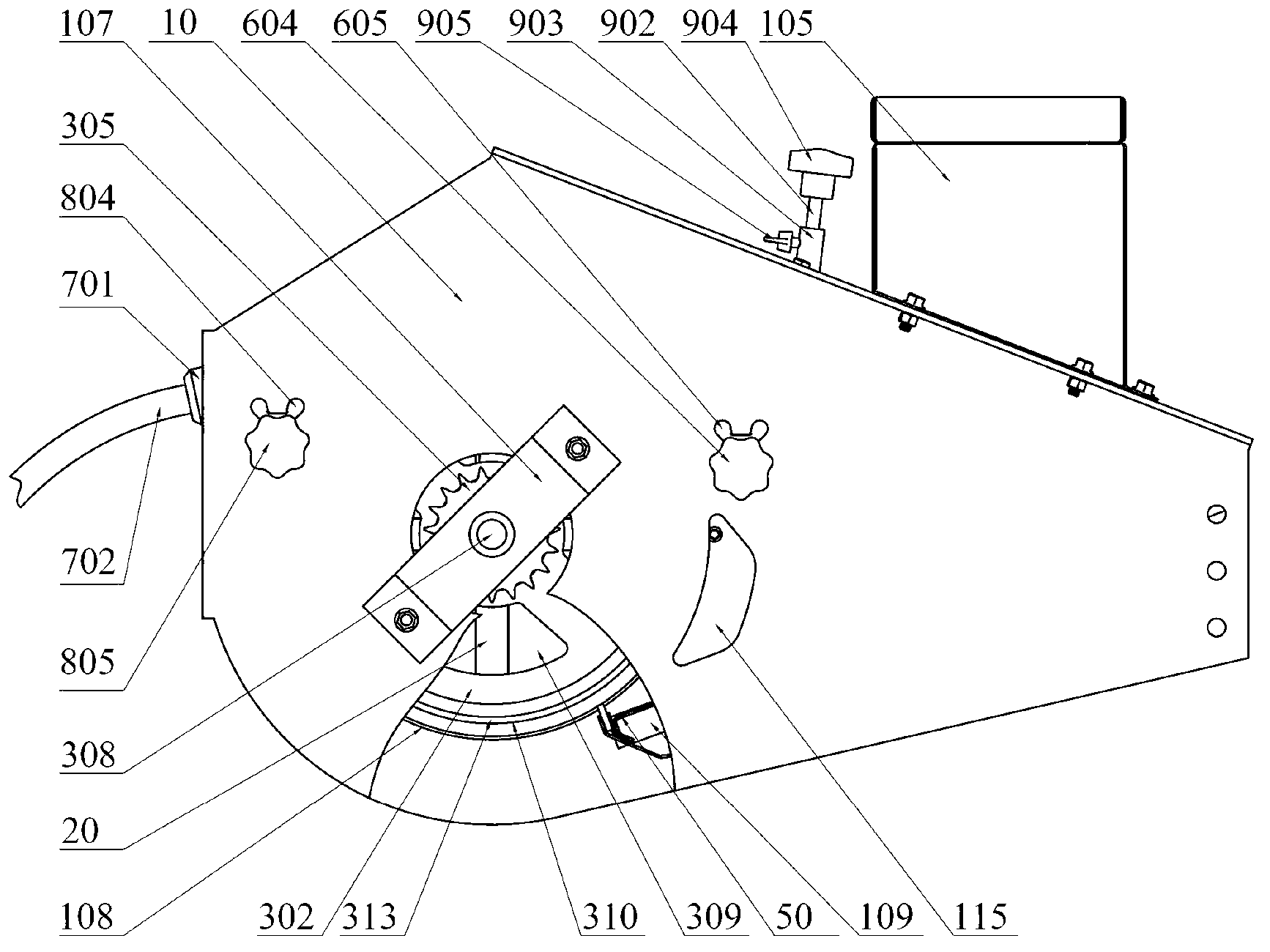

The invention relates to a novel intelligent regulating isobathic seeding device for a wide seedling zone and belongs to the technical field of agricultural machinery. The device comprises a press wheel device, an adjusting bolt 1, an adjusting bolt 2, a post-seedling furrowing and scraping hostling device, a connecting plate, a deep fertilizing isobathic wide-width seeding opener, an intelligent regulating system, a parallel four-rod mechanism and the like and can be used for no-tillage seeding and wide-width seeding of crops such as wheat, rice and the like, so that the problems that the seeding depths of no-tillage seeding and wide-width seeding are inconsistent and the emergence time difference is great and the like are solved. The deep fertilizing isobathic wide-width seeding opener is used for leveling a rotary tillage groove to form a flat seed bed; the post-seedling furrowing and scraping hostling device scraps soil and uniformly earths, so that the seed earthing depths are consistent; the intelligent regulating system senses surface relief according to signal change of a pressure sensor, controls retraction of an electric push rod, and moves up and down with the parallel four-rod mechanism connected with the isobathic seeding system to realize quick and accurate profiling with ground so as to achieve a purpose of intelligently regulating the seeding depth.

Owner:SHANDONG UNIV OF TECH

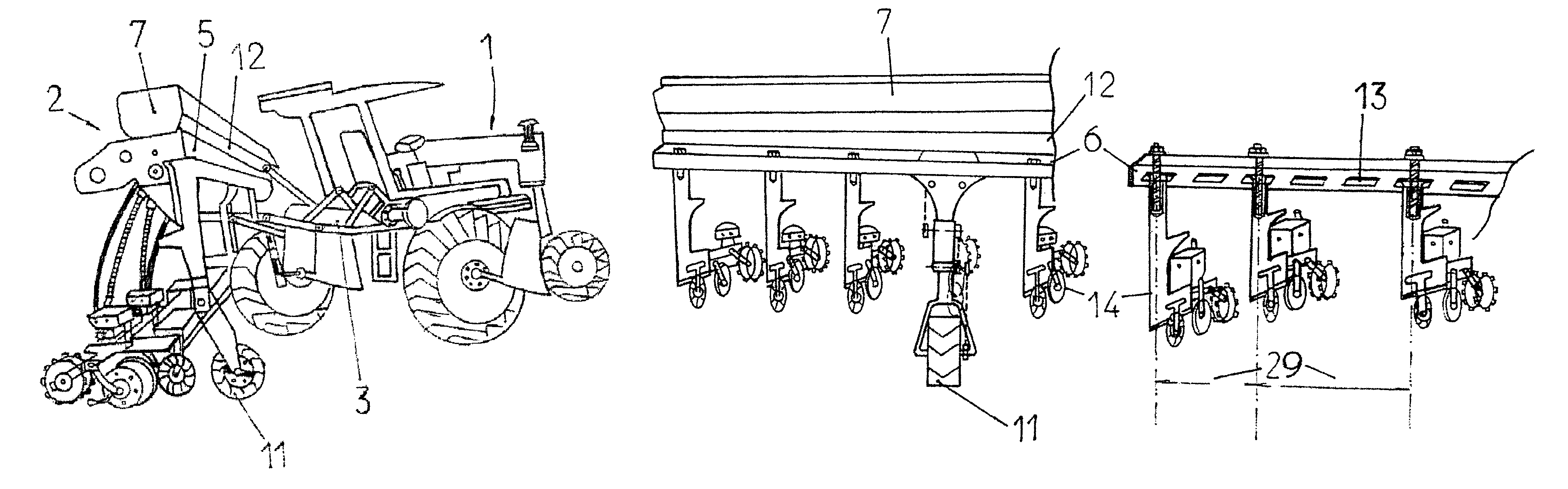

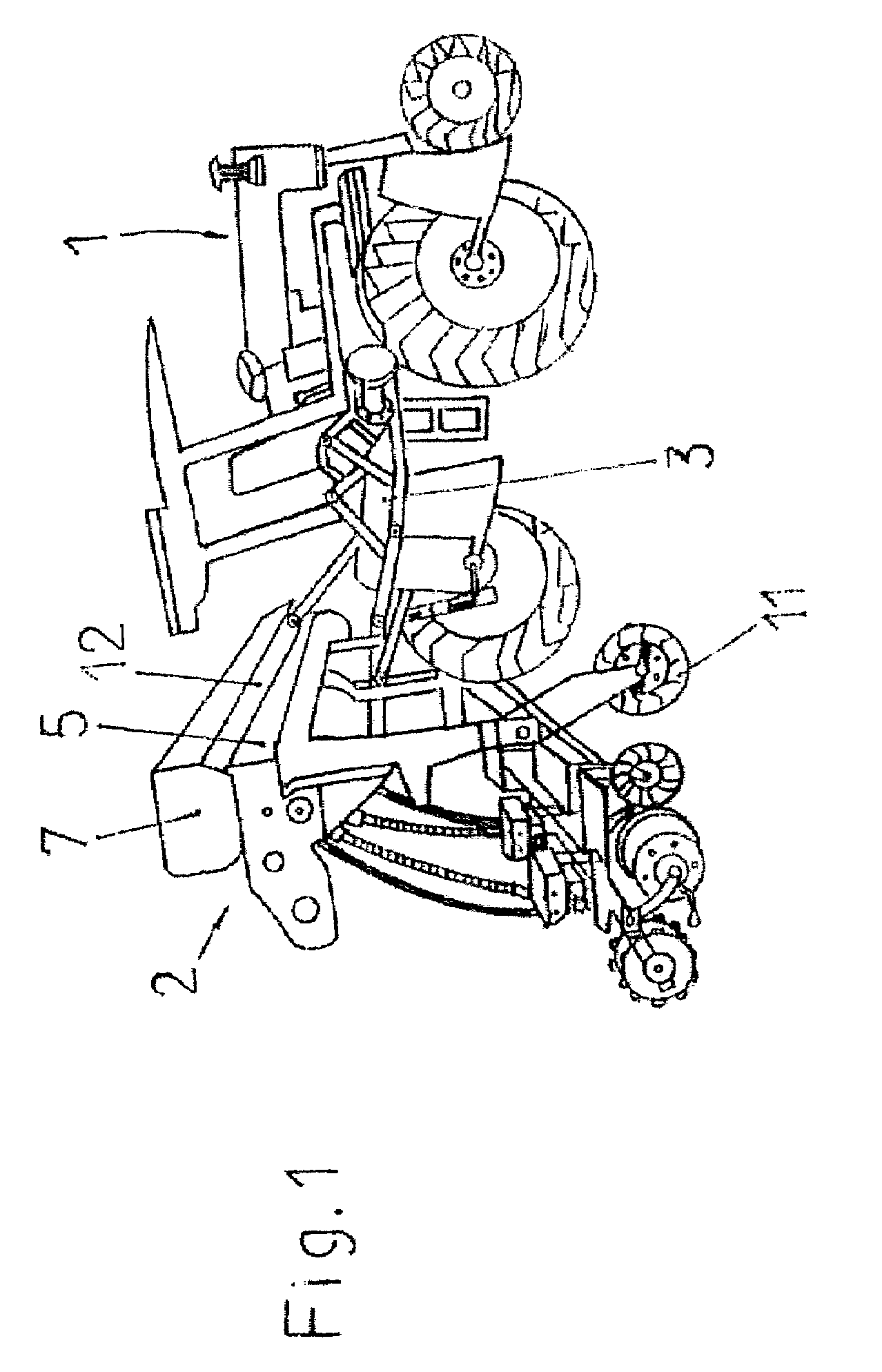

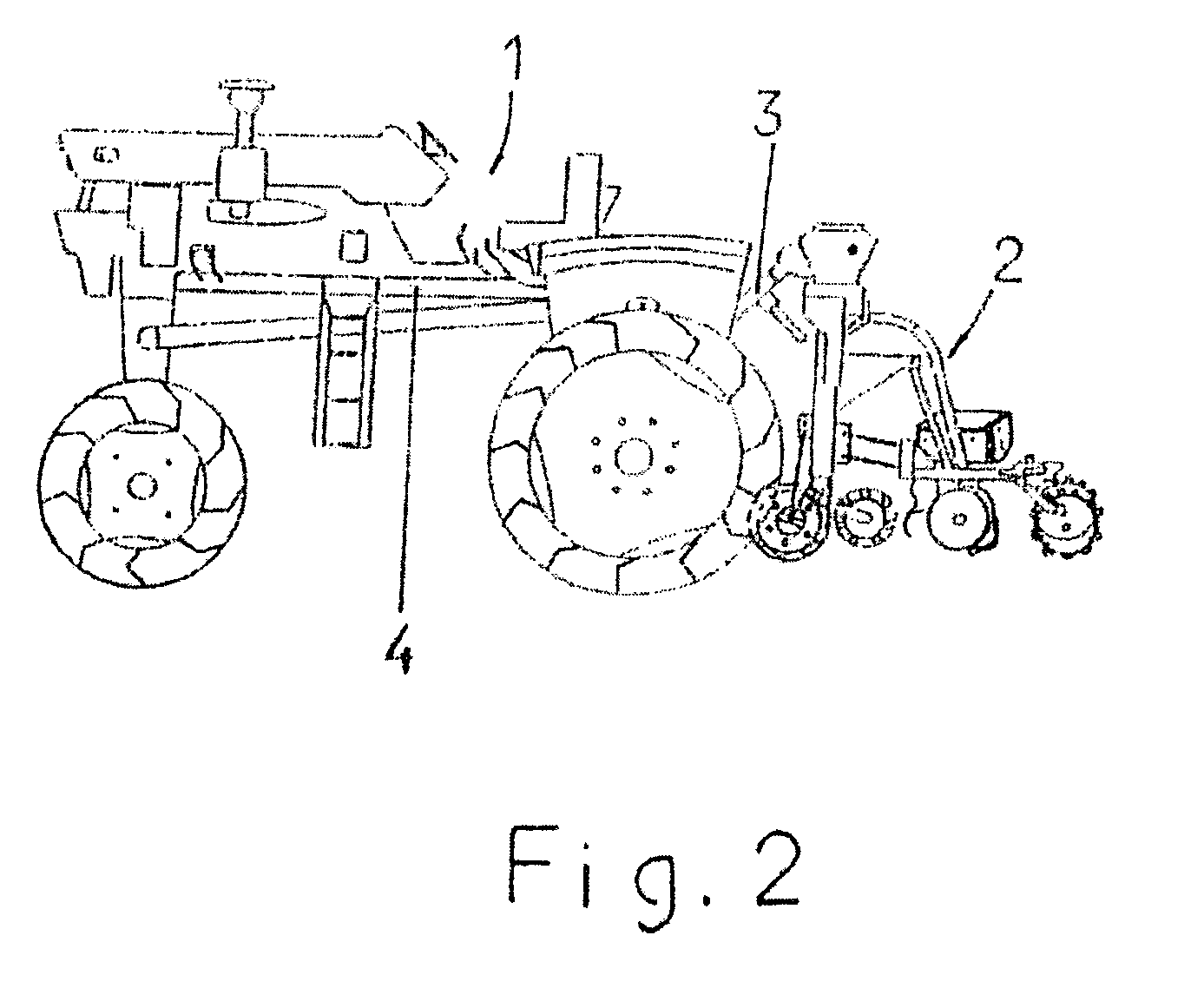

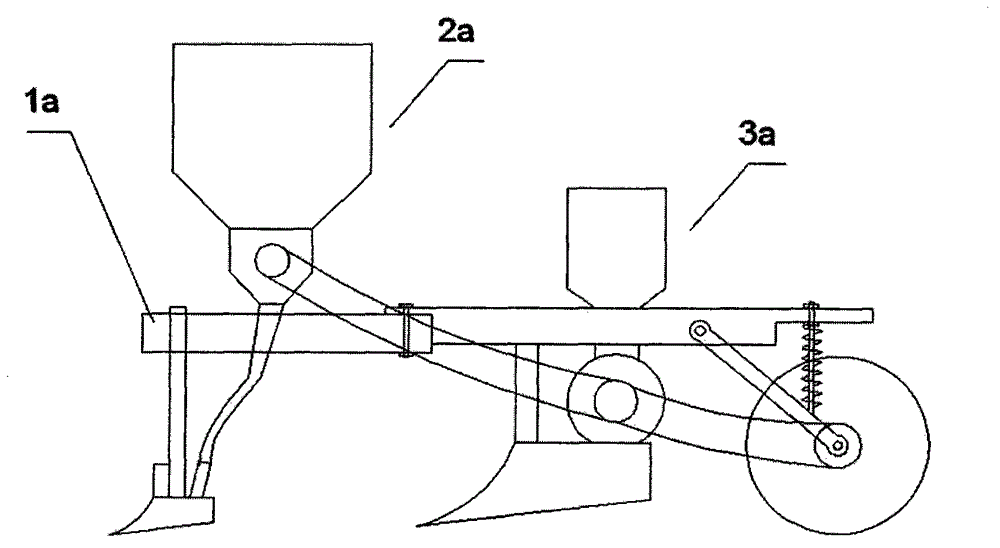

Agricultural machine for crop interseeding

InactiveUS7597055B2Minimum damage and deteriorationImprove sowing qualitySpadesPlantingMetal frameworkAgricultural engineering

An agricultural machine apt for crop interseeding, of the type that is self-propelled, comprising a unit with a drawing drive unit and a draw unit, both operatively linked to each other. The drawing drive unit comprises a land vehicle including an elevated chassis disposed at a substantial height for passing over tall mature crops such as corn, wheat, sunflowers and other similar crops, without causing any damage. The drawn unit comprises a structure mounted on a metal frame of a single hopper housing seeds and / or fertilizers with its corresponding dosage dispensers and mechanically actuated drop chutes. A transversal longitudinal member is positioned over the frame and the lower part thereof is provided with multiple cavities with anchoring guides for housing and positioning a number of modules of independent bodies of planting / fertilizing of easy assembly and disassembly changing the distance between the bodies en discrete y selective form according to the distance between the furrows of the primary mature working crop.

Owner:CHOULET ALBERTO OSCAR

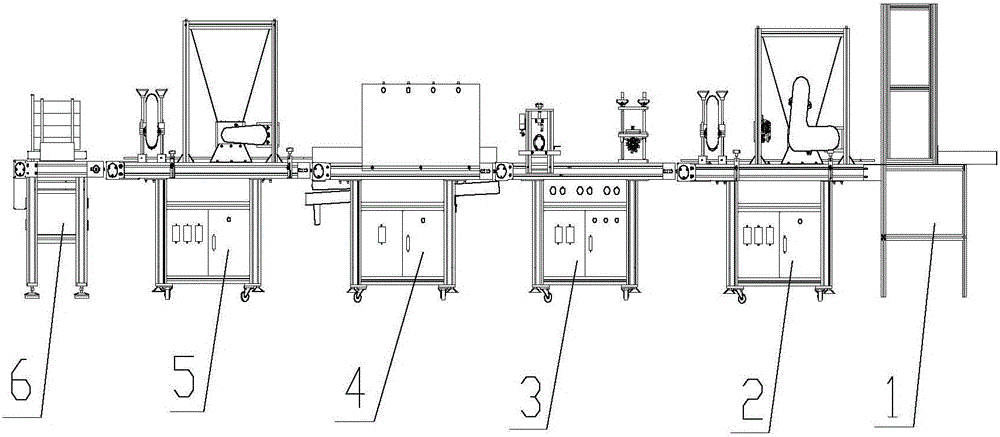

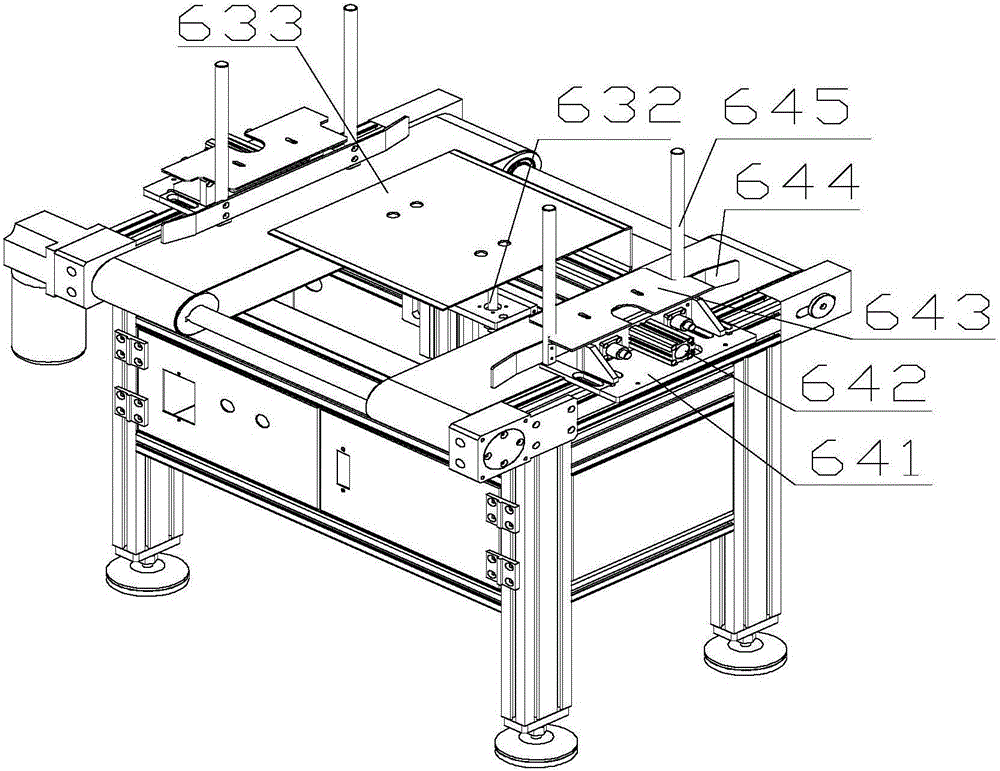

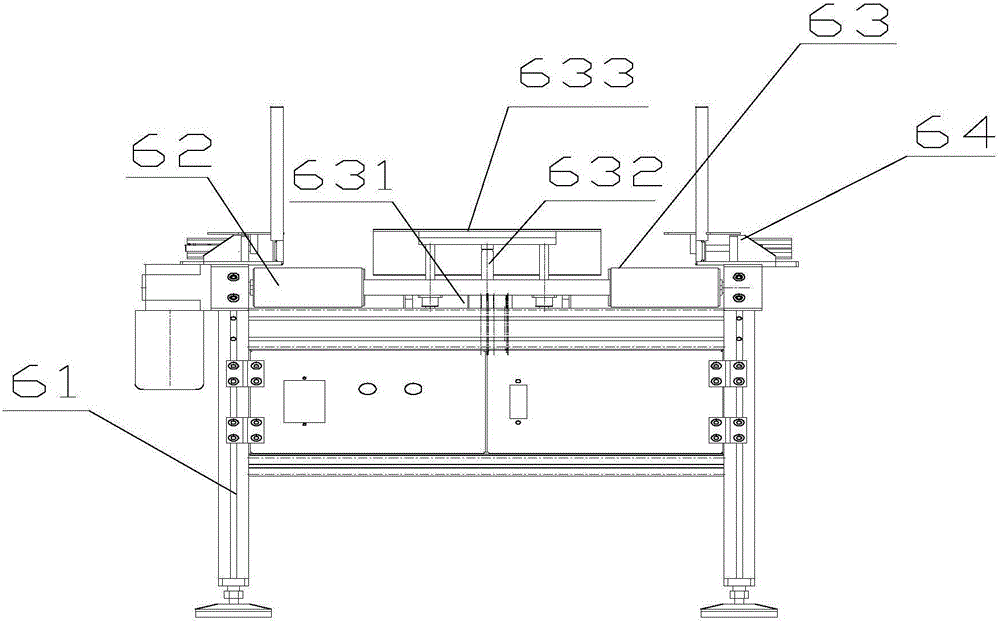

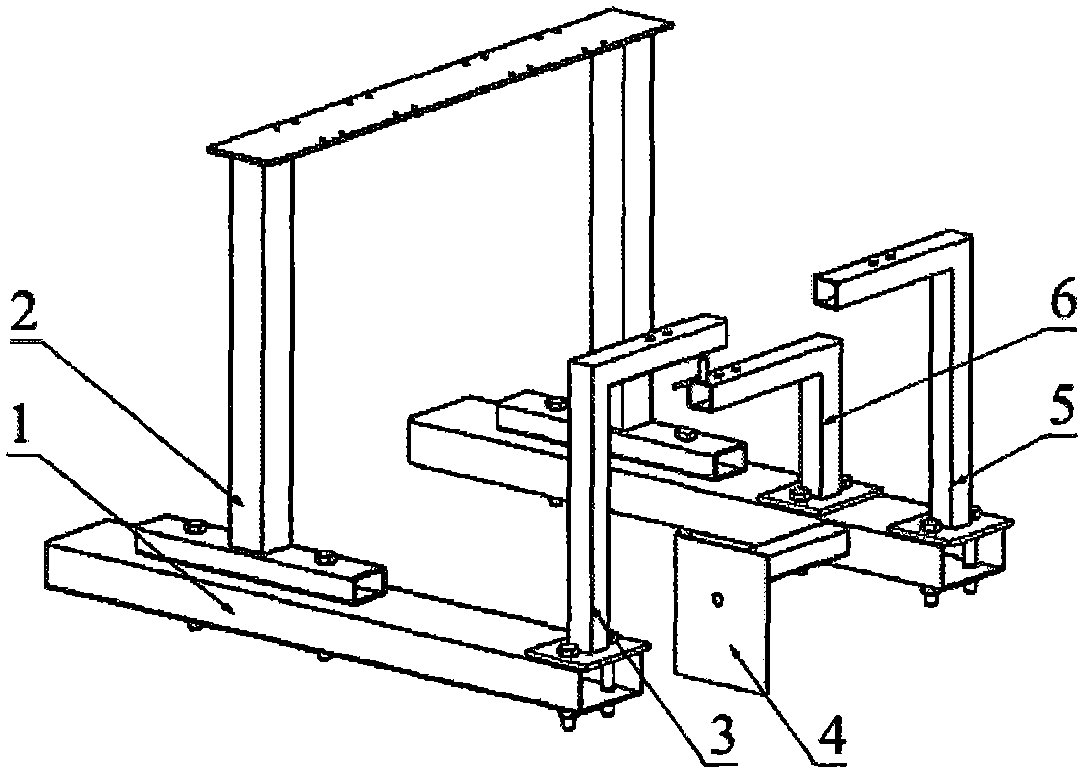

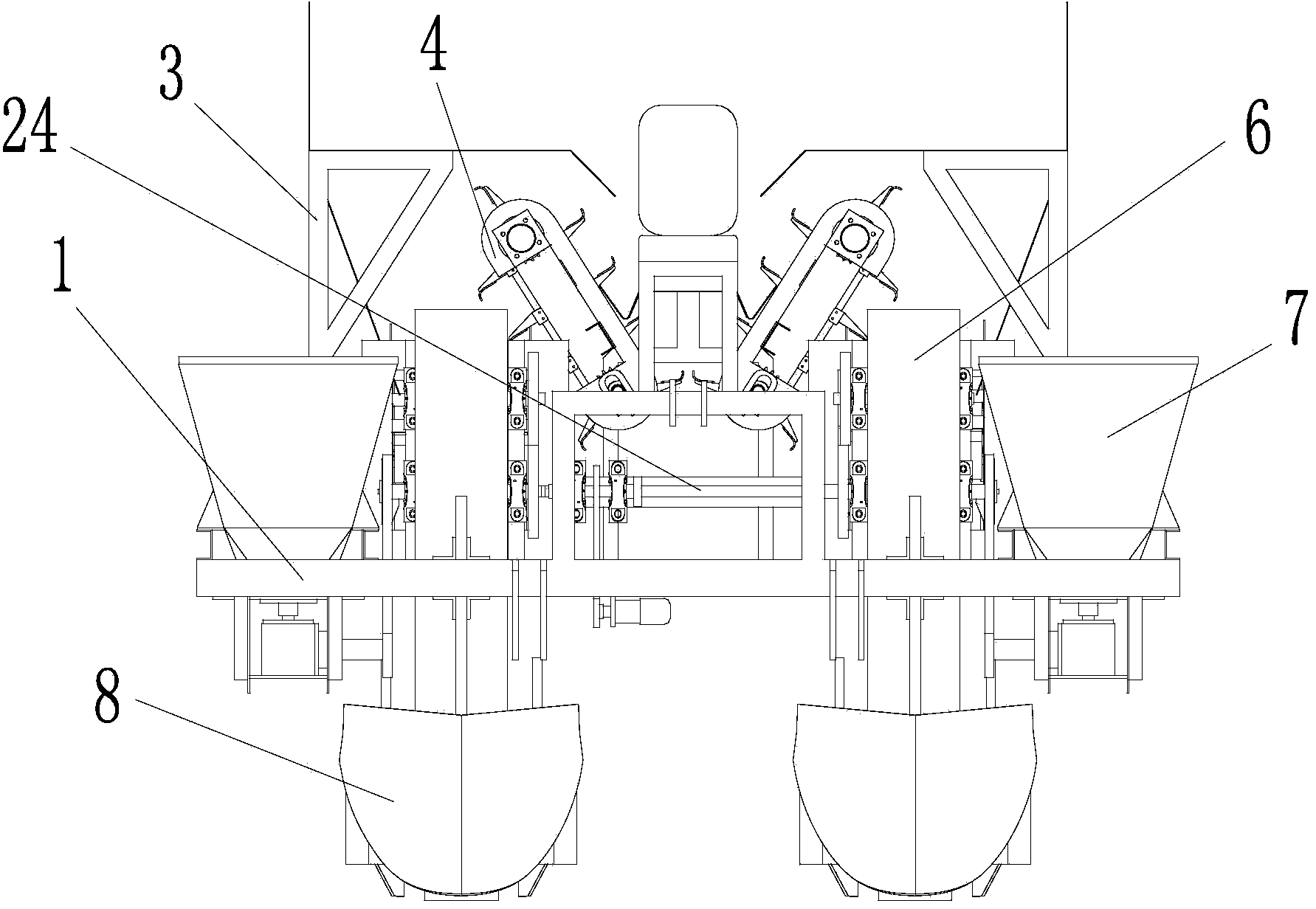

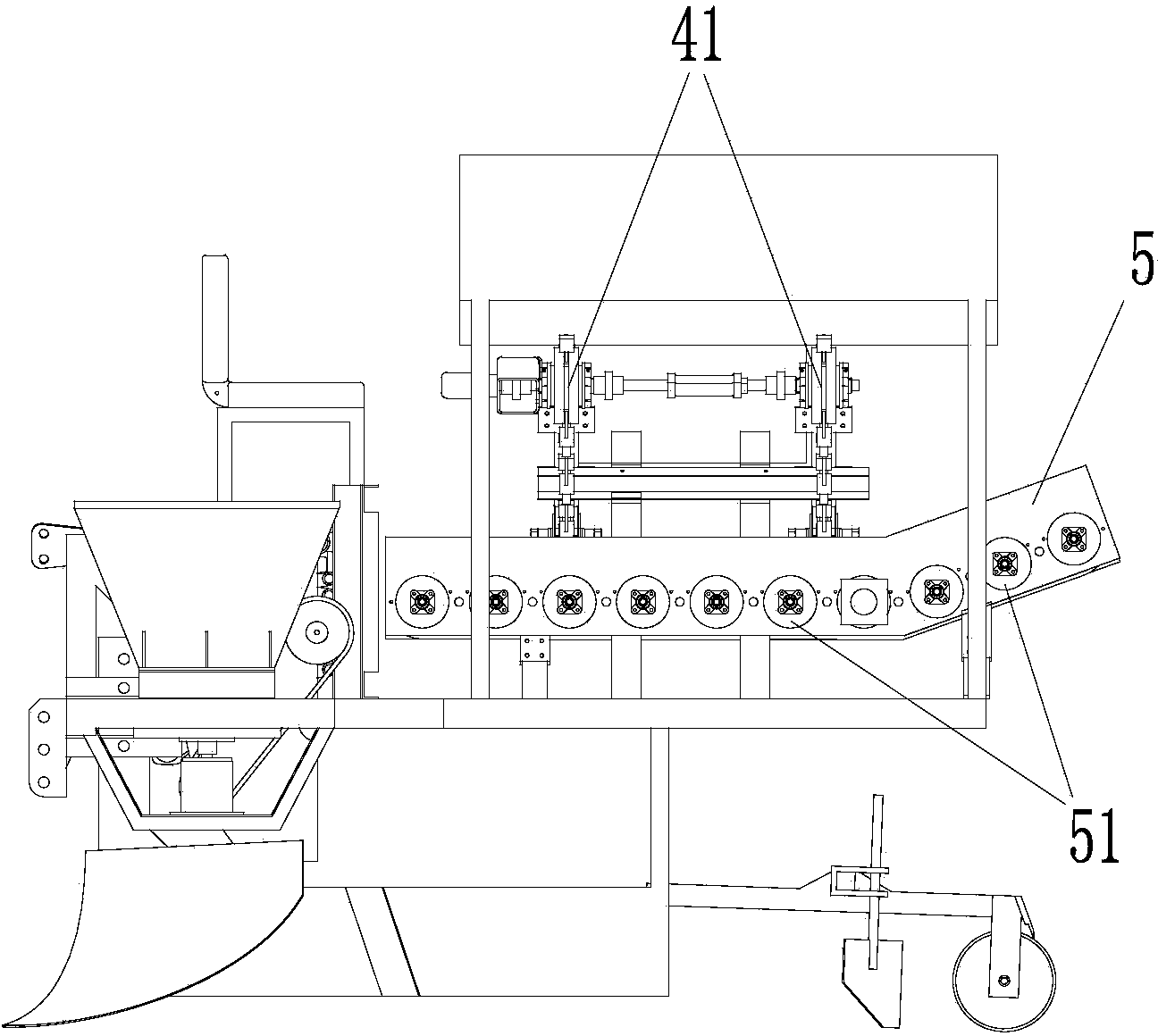

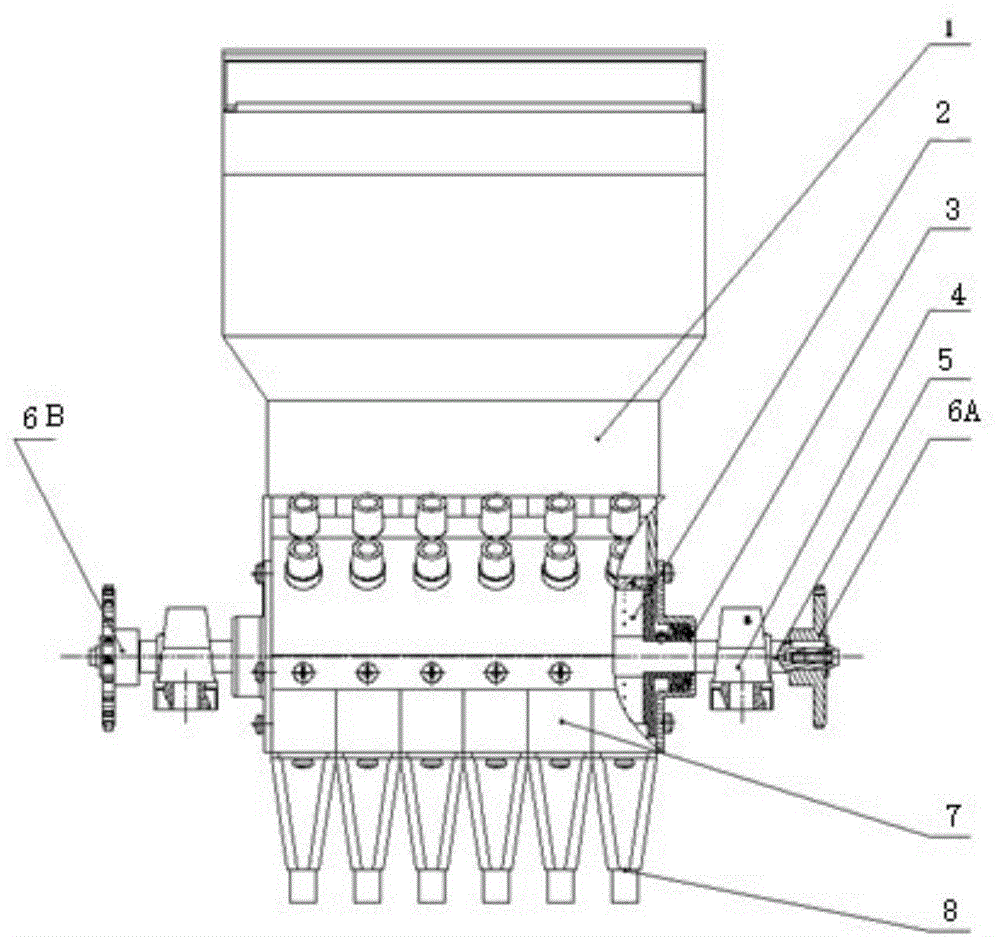

Automated sowing streamline for breeding plug tray

InactiveCN105830592AWith automatic operationImprove work efficiencyCultivating equipmentsSeed depositing seeder partsEngineeringConveyor belt

The invention discloses an automatic seedling tray seeding assembly line. The seeding assembly line is sequentially fixed with a seedling tray upper tray device, a substrate laying device, a precision roller sowing device, a spraying device, a substrate covering device, and a seedling tray stacking device. A seedling raising tray is placed above the seedling raising tray upper plate device, and the seedling raising tray is pushed to the sowing line along the conveyor belt. The working efficiency of the assembly line of the present invention is 10 times that of the traditional artificial seedling raising mode, reduces the labor cost by two-thirds, and can significantly improve the quality of seedling raising. The operation is simpler, the work efficiency and quality are higher, the commonality of parts is better, the reliability and safety are higher, and the market prospect is very broad.

Owner:山东中天盛科自动化设备有限公司

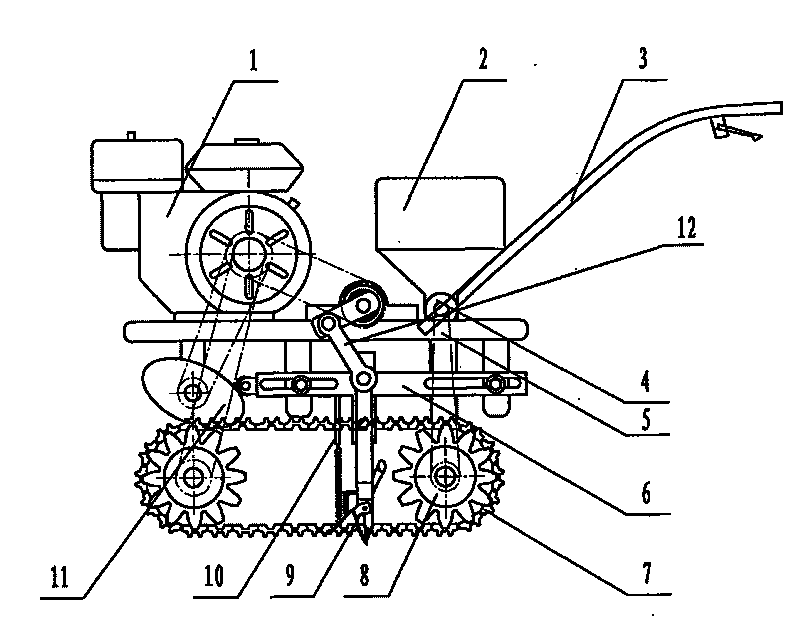

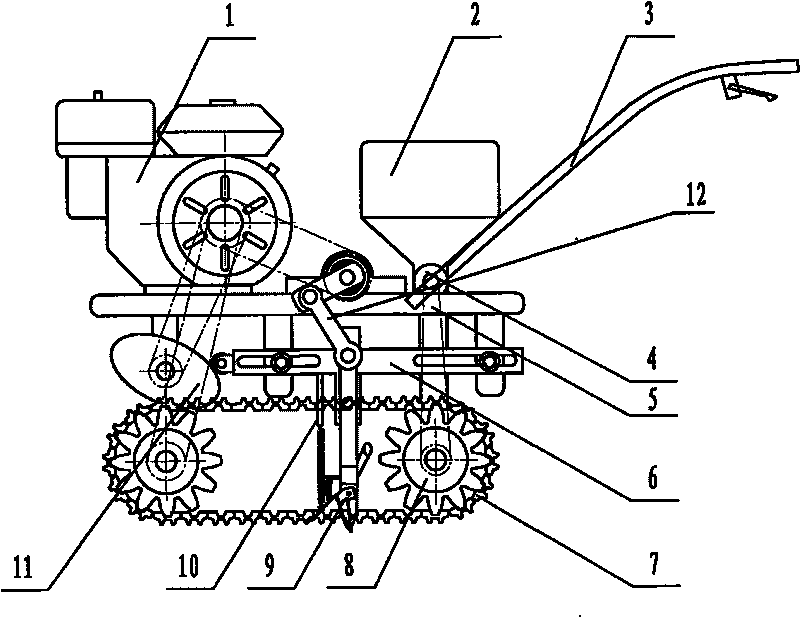

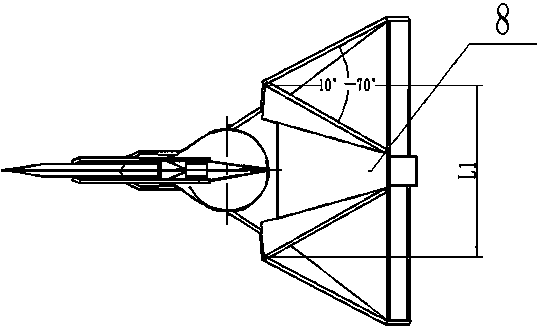

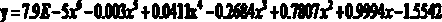

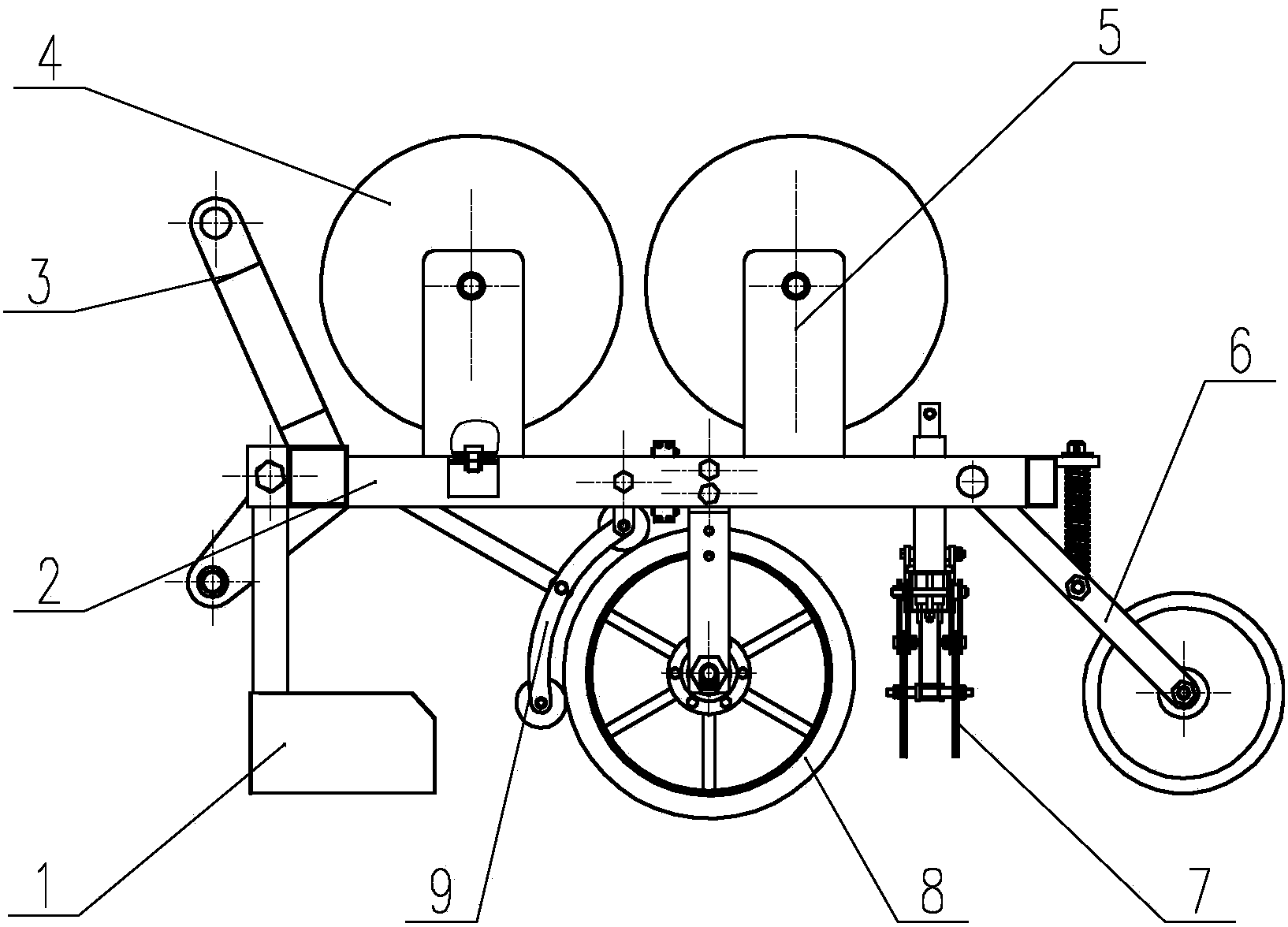

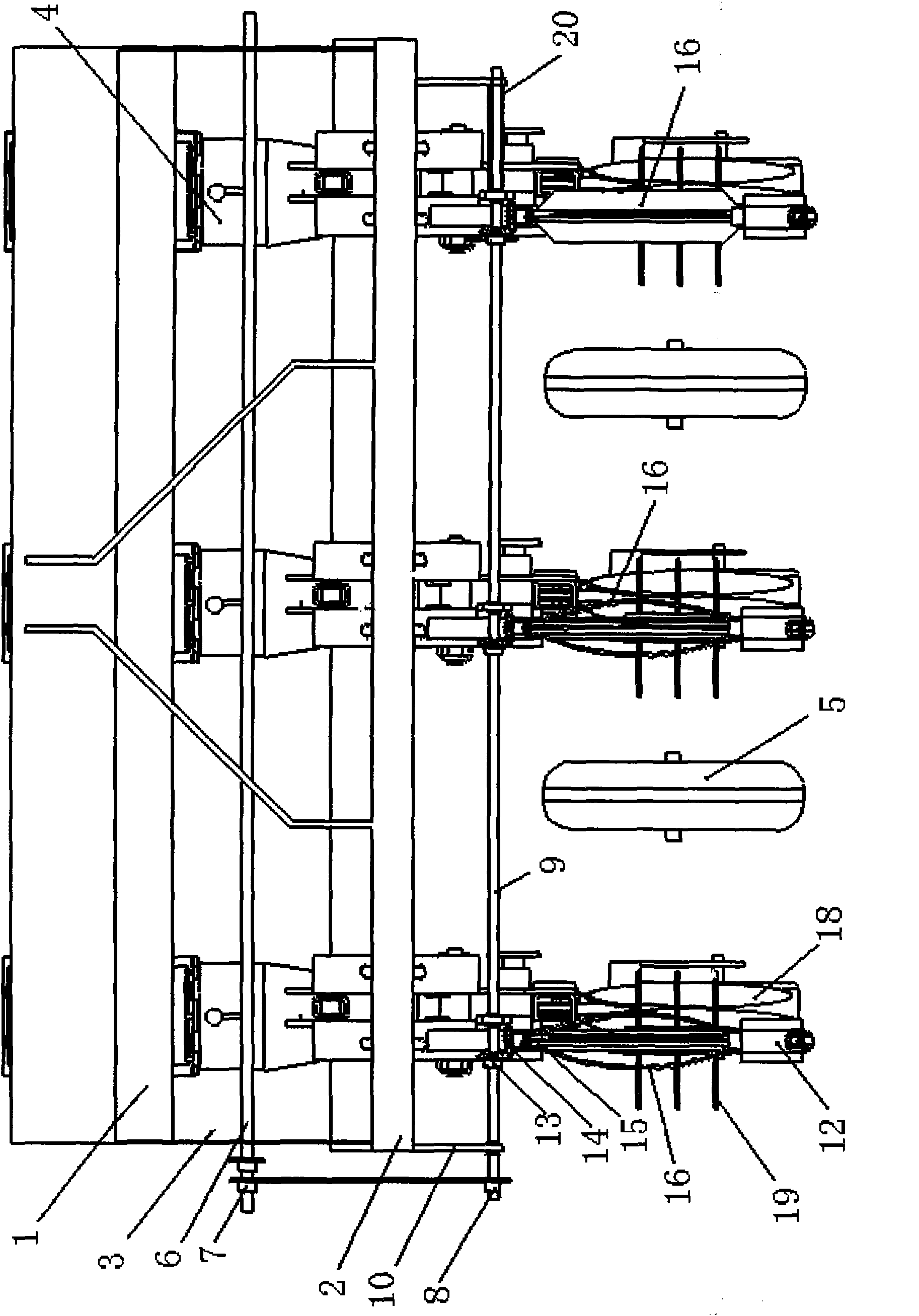

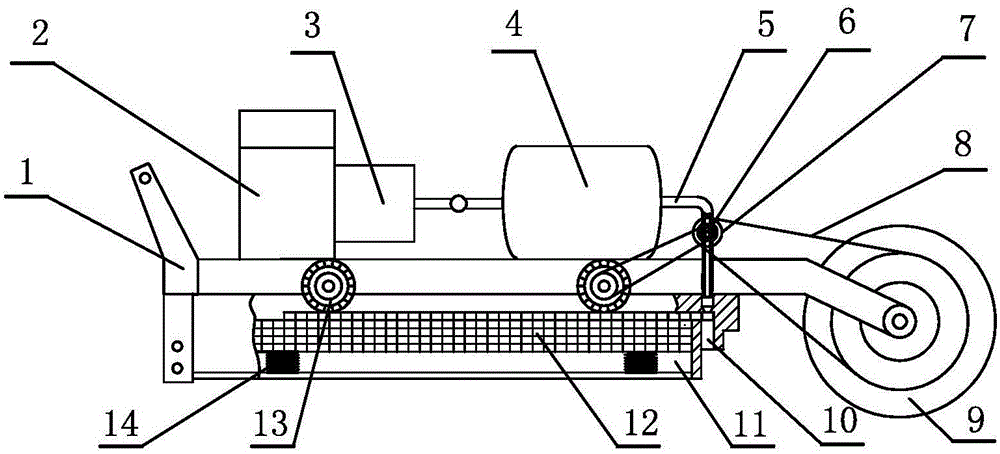

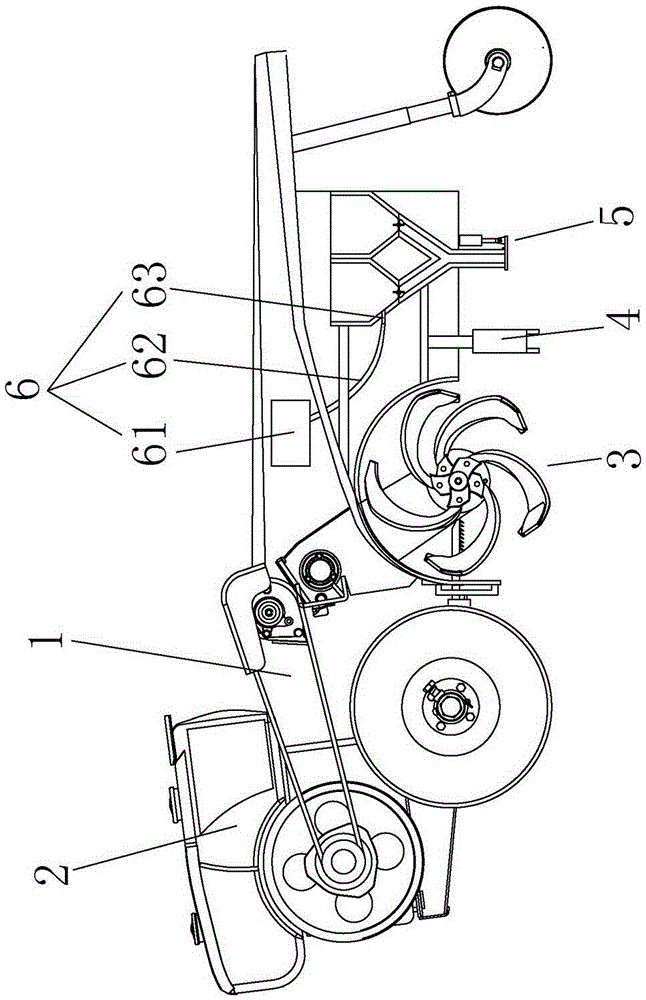

Arid land corn precision seeder with full membrane coverage double-earth furrow sowing

InactiveCN101755524AImprove sowing qualityTroubleshoot damage, etc.Seed depositing seeder partsRegular seed deposition machinesAridSeeder

The invention relates to the technical field of corn planter equipment, in particular to an arid land corn precision seeder with full membrane coverage double-earth furrow sowing. The precision seeder comprises a chassis (5), power equipment (1), and an inoculation chamber (2) installed on the chassis (5). The precision seeder is characterized in that a handle (3) is installed on the chassis (5); a seeding apparatus (4) is installed on the inoculation chamber (2); vertical-style planting equipment (6) is installed at the lower part of the chassis (5) corresponding to the seeding apparatus (4); a pulley (8) is also installed at the lower part of the chassis (5); a rubber crawler (7) is installed on the pulley (8); and the pulley (8) is connected to the power take-off shaft of the power equipment (1) by a strap. The equipment adopts a cam mechanism to compensate the advance speed of the machine. The seeding apparatus can achieve precision seeding, thus solving the problems of plastic film damage, seeder dyestripping and the like resulted from road wheel driving of the seeder, and improving the quality of corn seeding and reducing the production cost.

Owner:GANSU AGRI UNIV

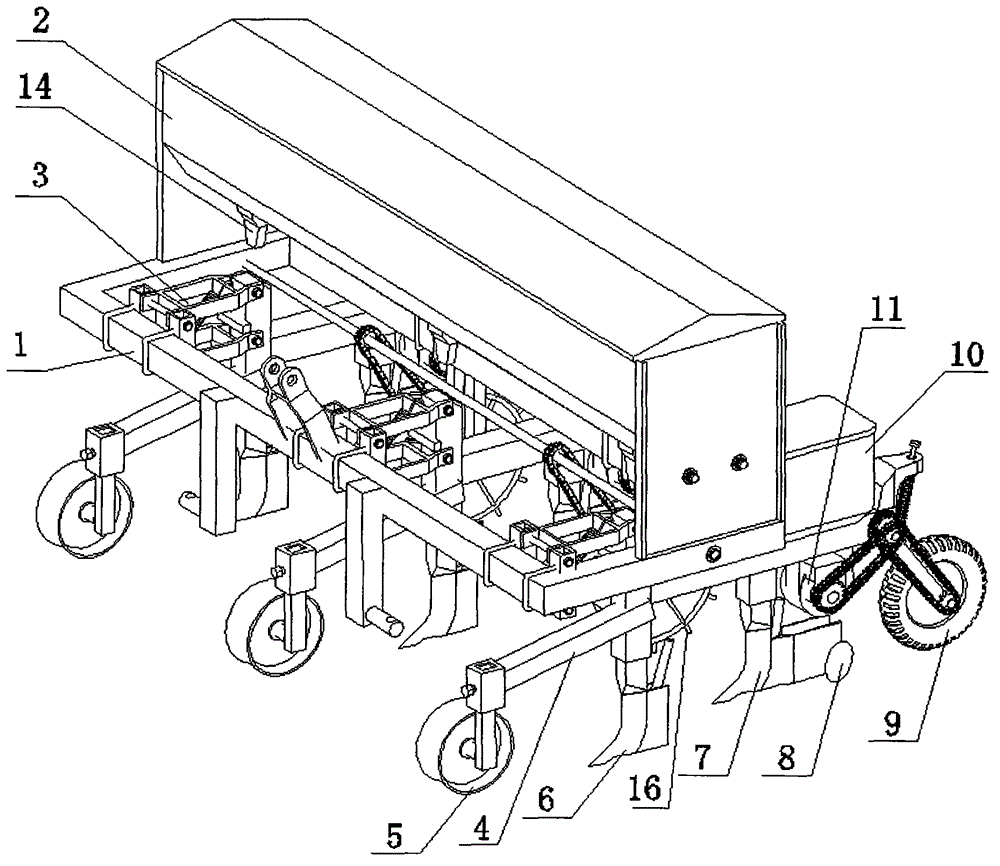

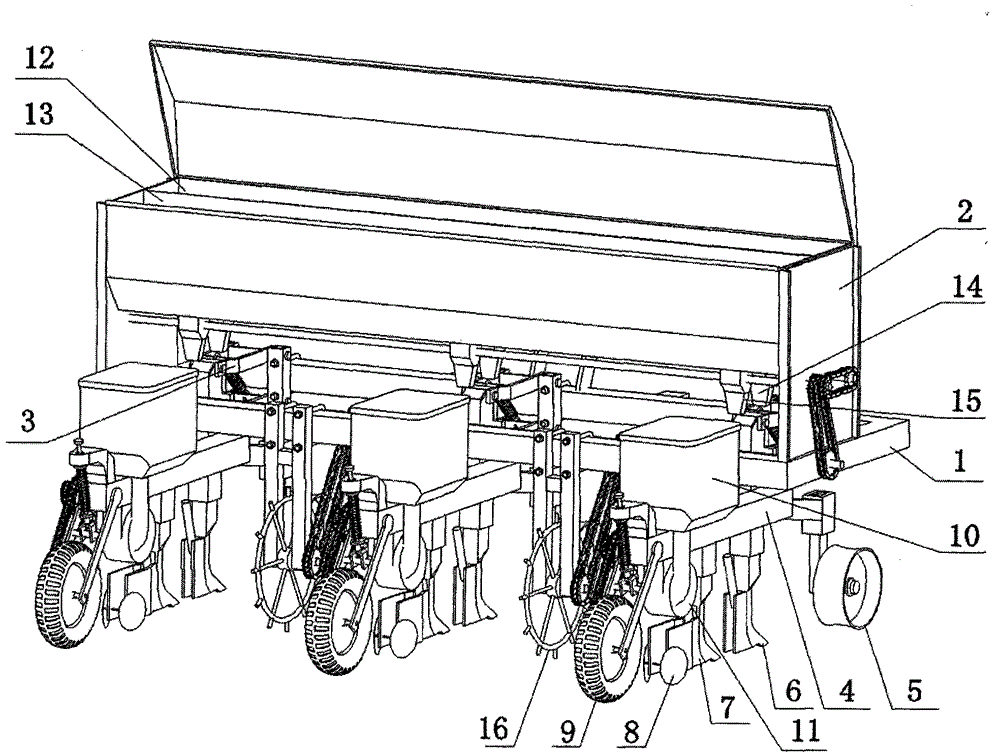

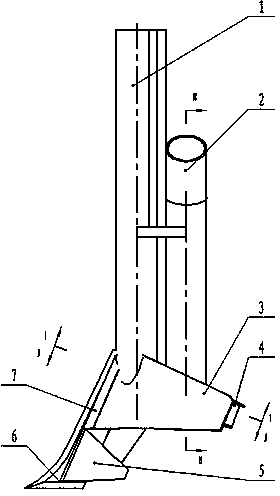

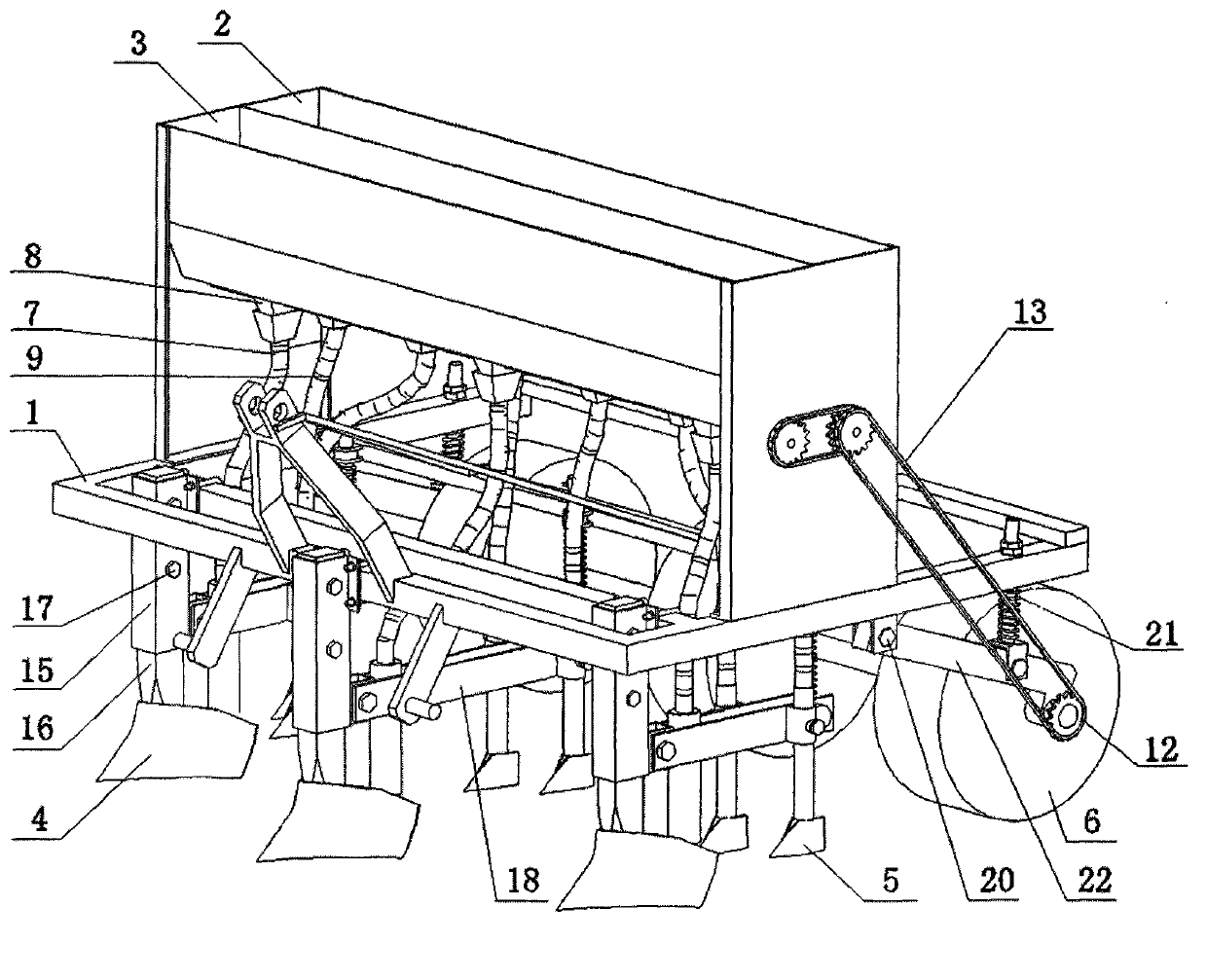

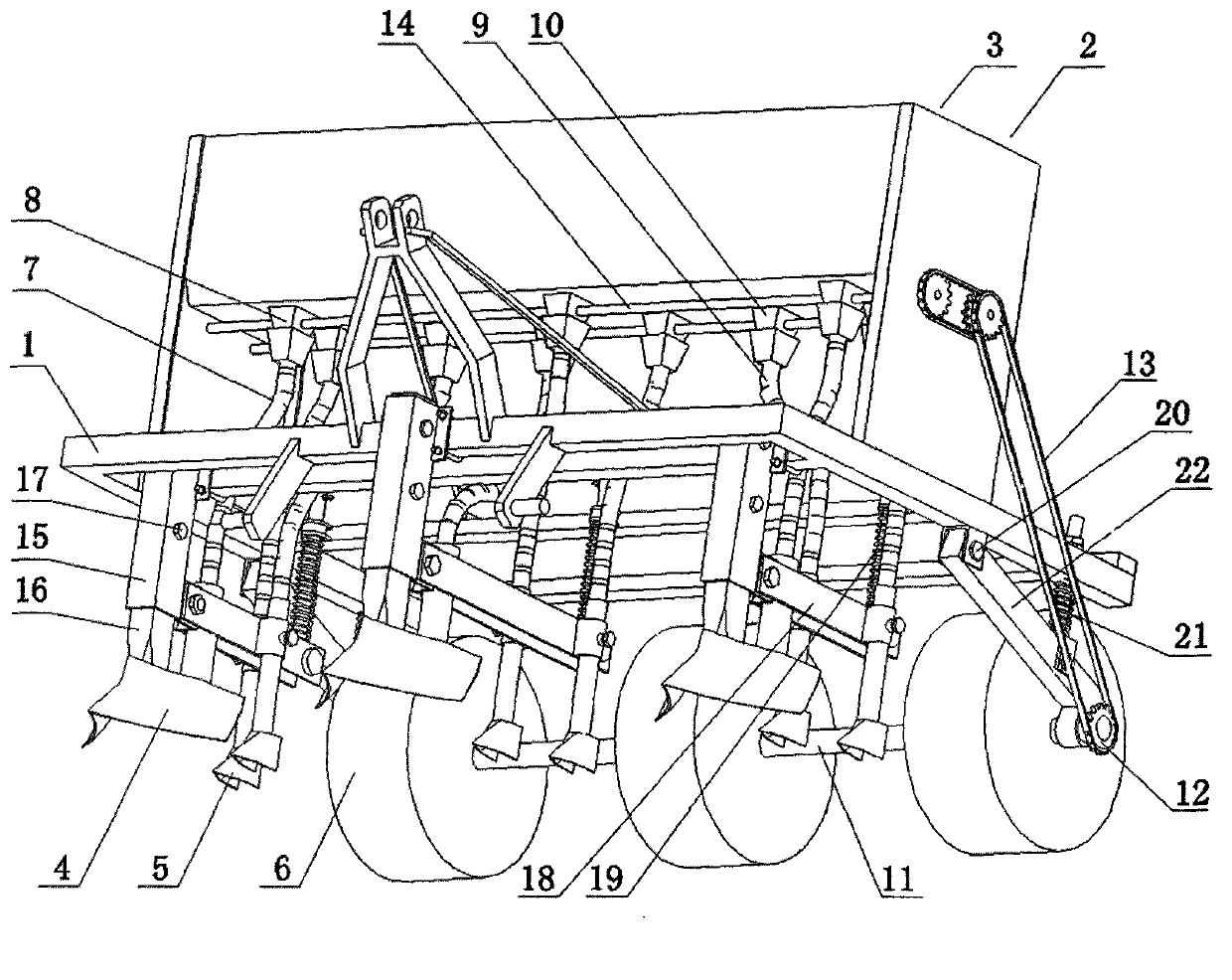

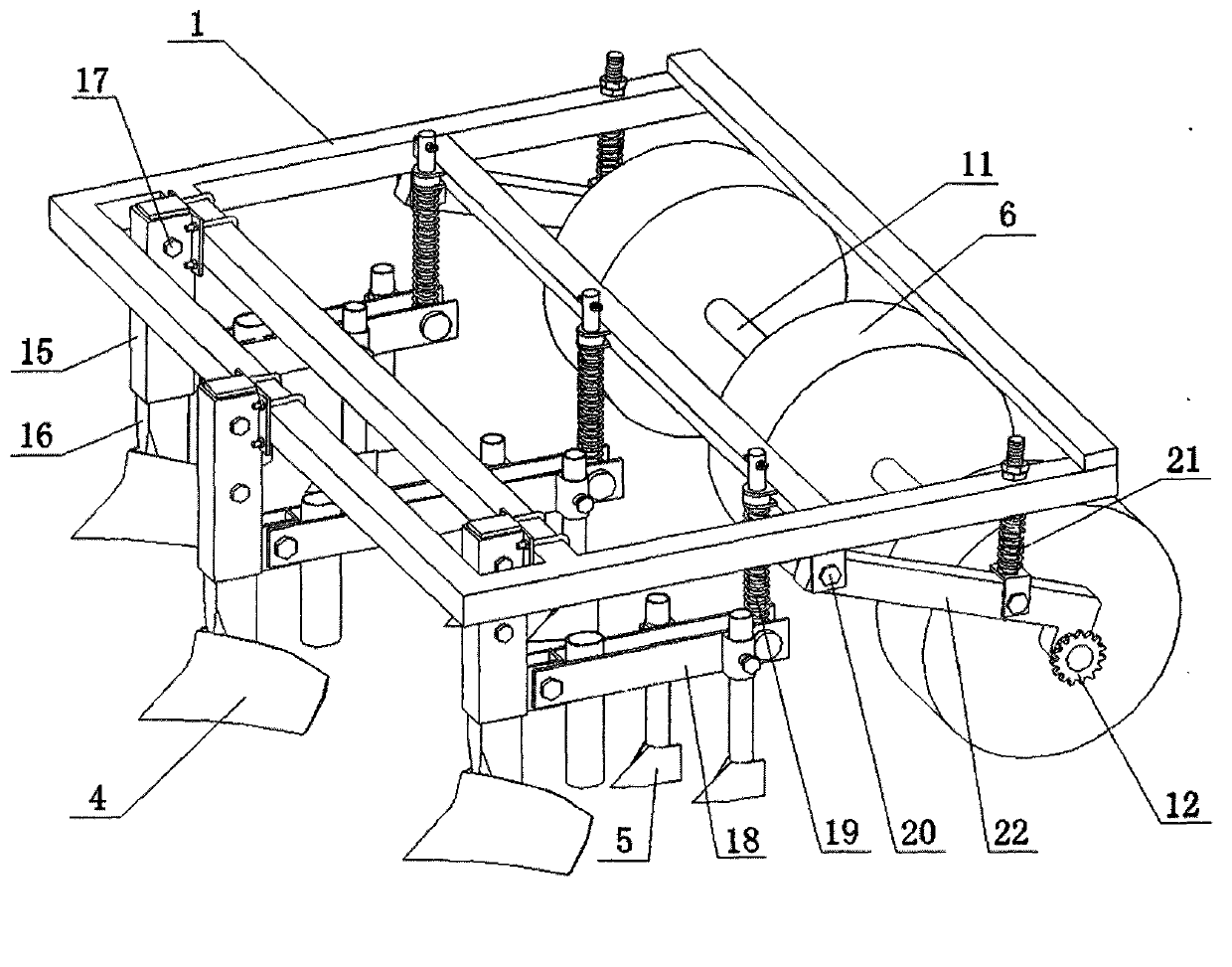

No-tillage profiling precision seeder

InactiveCN102714954AEnsure consistencyPrevent jumpingAgriculture gas emission reductionSeed depositing seeder partsSeederAgricultural engineering

The invention discloses a no-tillage profiling precision seeder, which comprises a main rack. A fertilizer box is arranged on the main frame. A seeding rack is fixedly arranged in each seeding row below the main rack through a profiling four-link mechanism. A depth limiting wheel, a base fertilizer furrow opener, a seed furrow opener, a soil covering device, a compaction wheel, a seed box and a seed feeder are installed on each seeding rack. The internal part of the fertilizer box is divided into a front base fertilizer hopper and a rear seed fertilizer hopper. Base fertilizer feeders and seed fertilizer feeders are arranged at the bottoms of the front base fertilizer hopper and the rear seed fertilizer hopper at positions corresponding to each seeding row. Fertilizer feeding pipes below the base fertilizer feeders are communicated with the base fertilizer furrow openers. Fertilizer feeding pipes below the seed fertilizer feeders are communicated with the seed furrow openers. The no-tillage profiling precision seeder can adapt to and meet the requirements on seeding operation on sloping farmlands or uneven lands, can realize no-tillage precision seeding, and has the characteristics of consistent depth, high operation quality, strong adaptability, few fault and high use safety and reliability.

Owner:赵玉茹

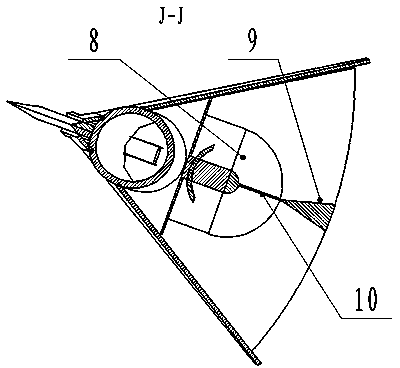

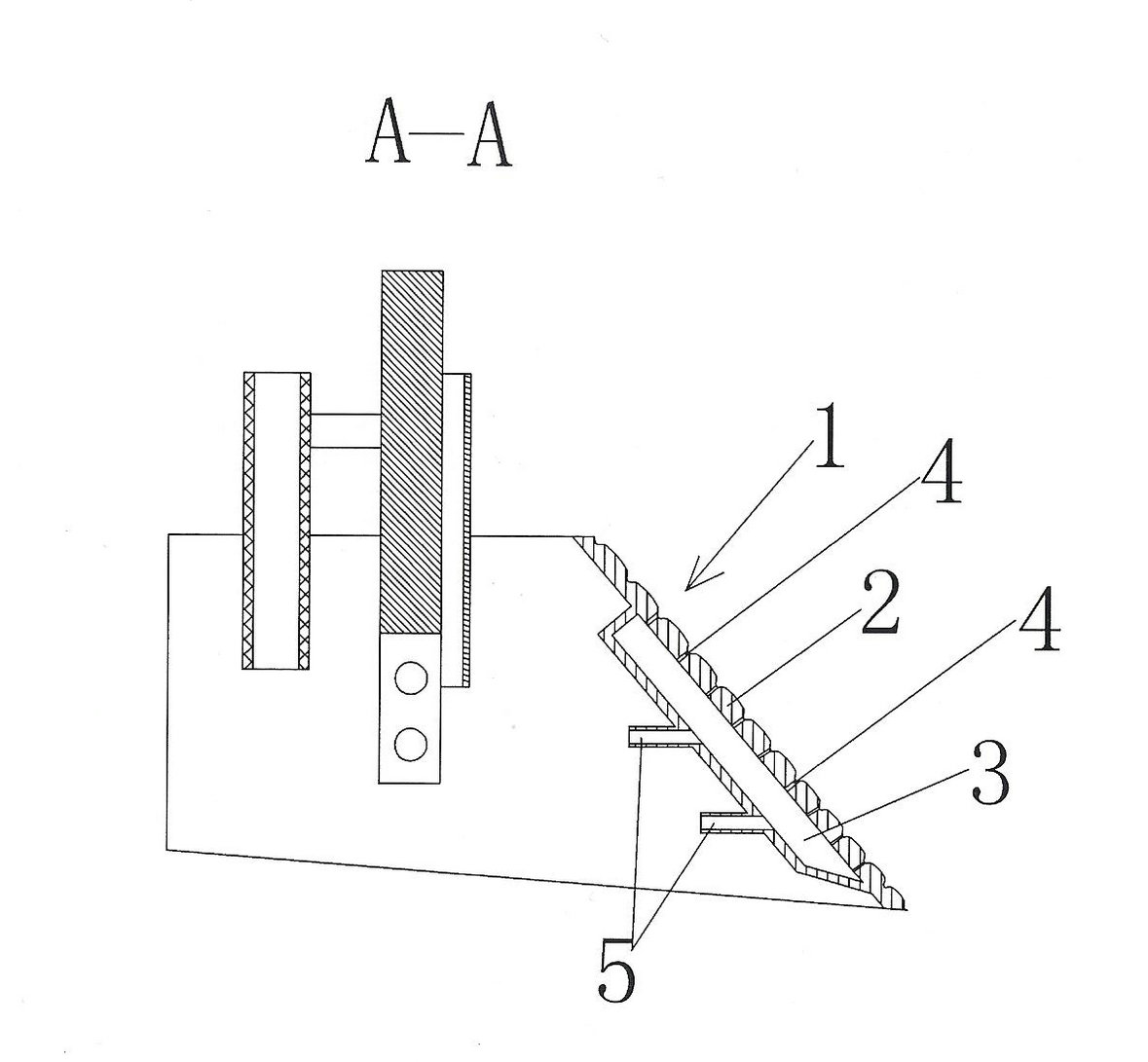

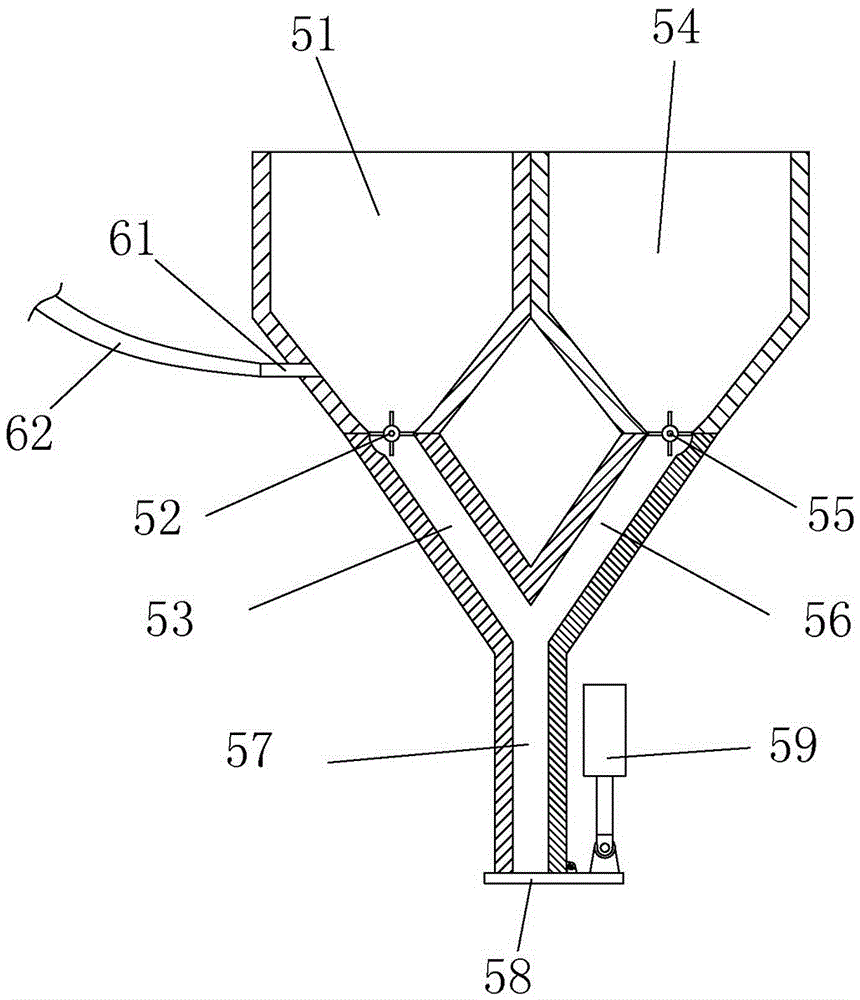

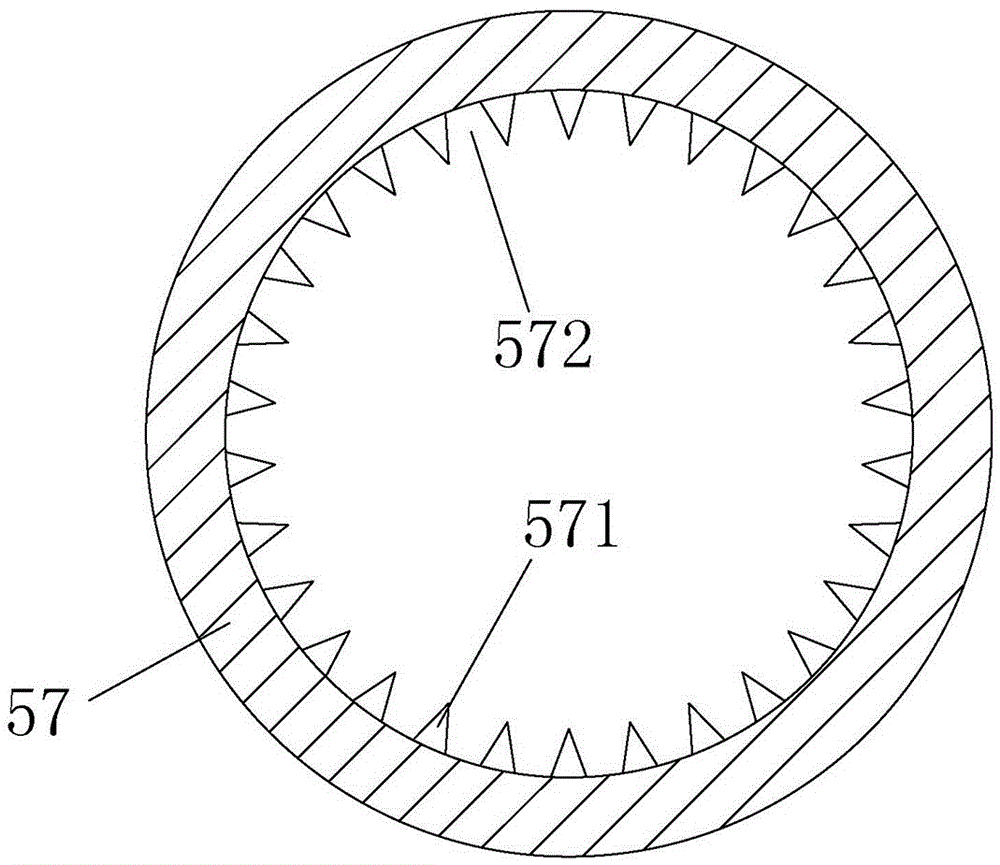

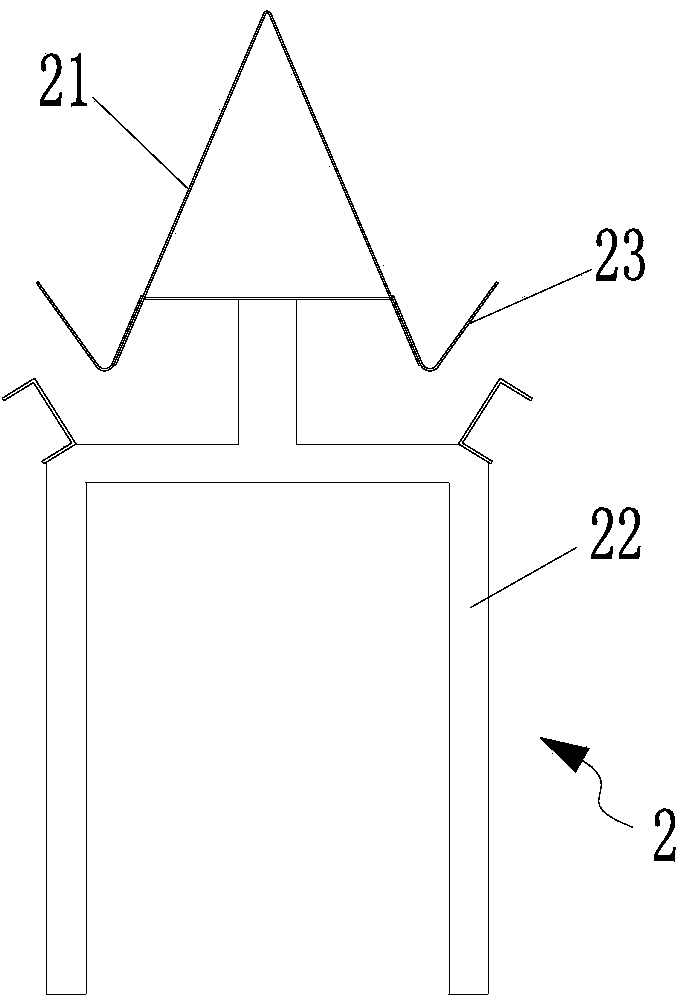

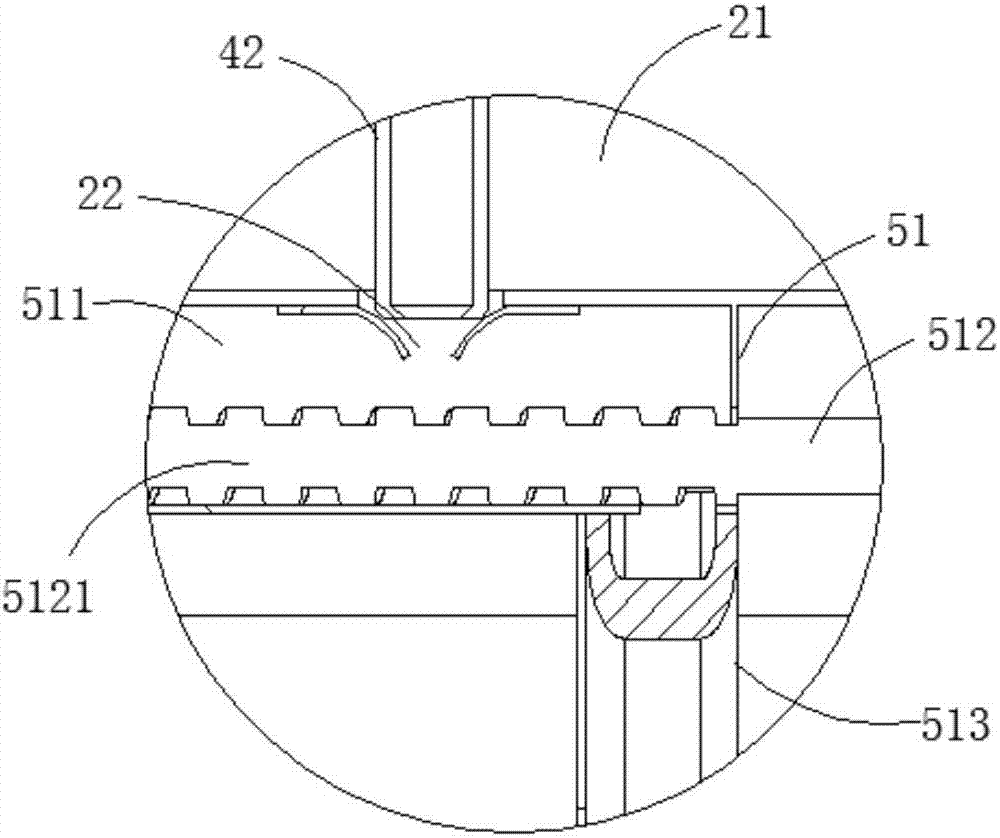

Equal-depth and wide seeding opener for deep fertilization of wheat

InactiveCN104335736AEnsure consistencyAdapt to growthPlantingFurrow making/coveringSeederEngineering

The invention relates to an equal-depth and wide seed opener for deep fertilization of wheat and belongs to the technical field of agricultural machinery. The opener comprises a front cutting edge, a fertilization pipe, a seed conveying pipe, a seed distributing box, and seedbed reconditioning machines for equal-depth seeding operation by a no-tillage and wide zone seeder. The front cutting edge and the fertilization pipe are integrally welded and soil in the operating process moves toward two sides to form a seed channel for the deep fertilization; the three-way seed conveying pipe is separated in the middle, so that the independent wide seeding at two sides is achieved; the seed distributing box and the seedbed reconditioning machines follow the fertilization pipe to move forward, the M type seed bed reconditioning machines are symmetrically arranged below the seed distributing box in forms of sharp corners, and a seed scattering plate on the bottom surface is provided with an ejecting bump. During work, the M type seed bed reconditioning machines on the bottoms of tow sides of the seed distributing box level the bottom of a trench with the uneven surface so as to form a wide dustpan-shaped plane with a trench cross section, and meanwhile, seeds fall into the seed distributing box by virtue of the three-way seed conveying pipe and are repeatedly ejected and uniformly scattered to a level seedbed by virtue of the seed scattering plate, so that the equal-depth uniform seeding is achieved.

Owner:SHANDONG UNIV OF TECH

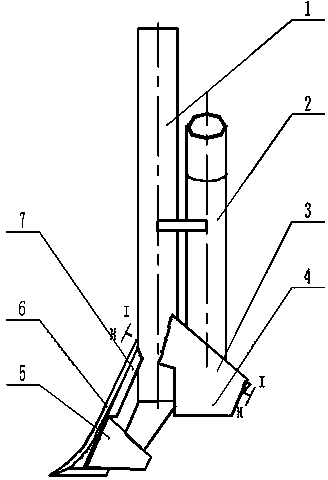

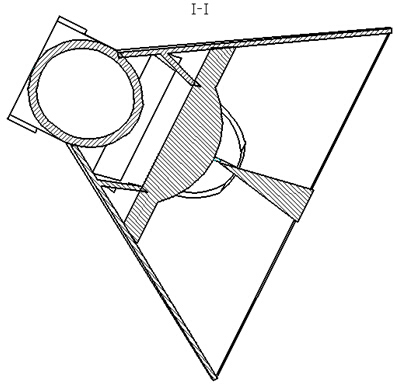

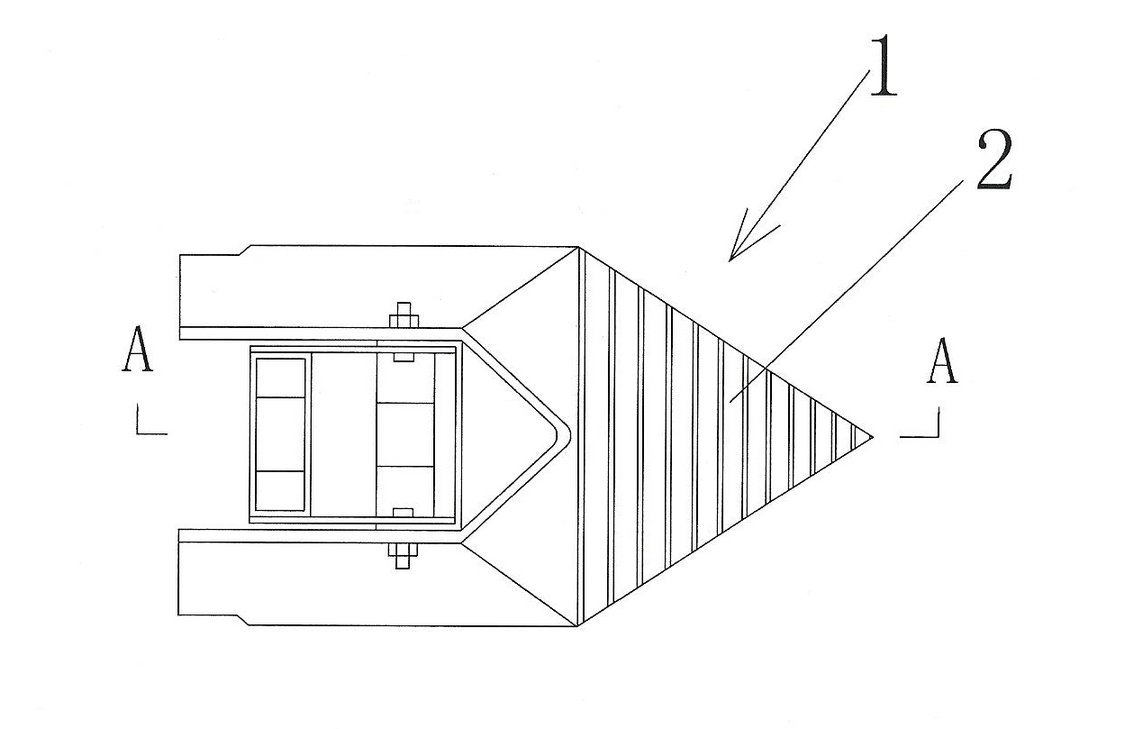

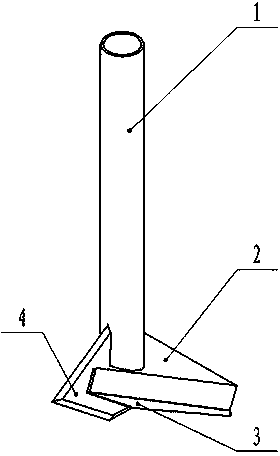

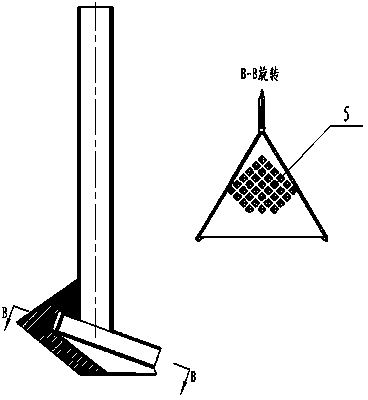

Bionic narrow-fertilizer ditch and wide-seed band double-seed path opener

The invention relates to a bionic narrow-fertilizer ditch and wide-seed band double-seed path opener and belongs to the technical field of agricultural machinery. The bionic narrow-fertilizer ditch and wide-seed band double-seed path opener comprises a fertilizer conveying pipe, a double-seed-path seed conveying pipe, a seed distribution box, a narrow-fertilizer ditch shovel wing, a wide-seed band shovel wing, a transition shovel wing, a sword type front cutting edge, a scattering plate, a seed baffling plate and the like; the bionic narrow-fertilizer ditch and wide-seed band double-seed path opener can be used for working conditions of rotary tillage type tillage, blocking prevention, ditching and the like of a no-tillage seeder, a wide-seed band seeder and the like, and can also be applicable to the working condition of directly breaking stubbles and ditching on a cultivated land or an uncultivated land by a common no-tillage seeder; seed fertilizer application, equal-depth accurate seeding and uniform distribution of seeds in the seed band are realized; the seeding quality and the fertilization quality are guaranteed; a foundation is laid on the yield improvement of crops; the head-on space of the opener is greatly increased and the problems of grass hanging and congestion are solved.

Owner:SHANDONG UNIV OF TECH

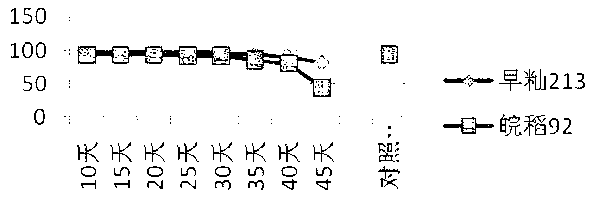

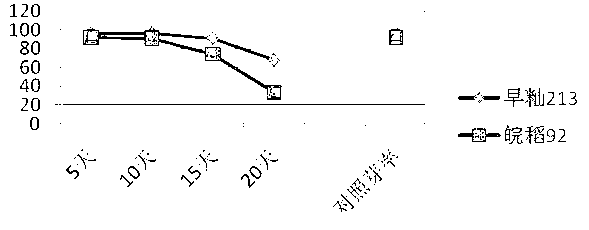

Paddy rice seed pregermination method

InactiveCN103004321APass smoothlyImprove sowing qualitySeed and root treatmentAgricultural scienceGermination

The invention discloses a paddy rice seed pregermination method. When radical buds of paddy rice grow up to a specified standard, a physical method is used to control the growth of the radical buds, thereby widening the optimal period of seeding, so that the aims of labor conservation, cost conservation, effect enhancement and labor intensity relief are achieved. Compared with the traditional paddy rice pregermination seeding, the method can improve the seeding quality remarkably, and in particular to applying the method to mechanized direct seeding of paddy rice, the resistance of the machinery transmission of the seeds can be reduced obviously, so that the sprouts can pass through a seed passage smoothly and the seeding quality is guaranteed; when the paddy rice seed sprouts are prepared, the 'seed soaking-germination accelerating' process does not need to be repeated everyday; and the method has the characteristics of simplicity, convenience, easiness for mastering the technology and the like, and can be widely applied to paddy rice cultivation.

Owner:程太平

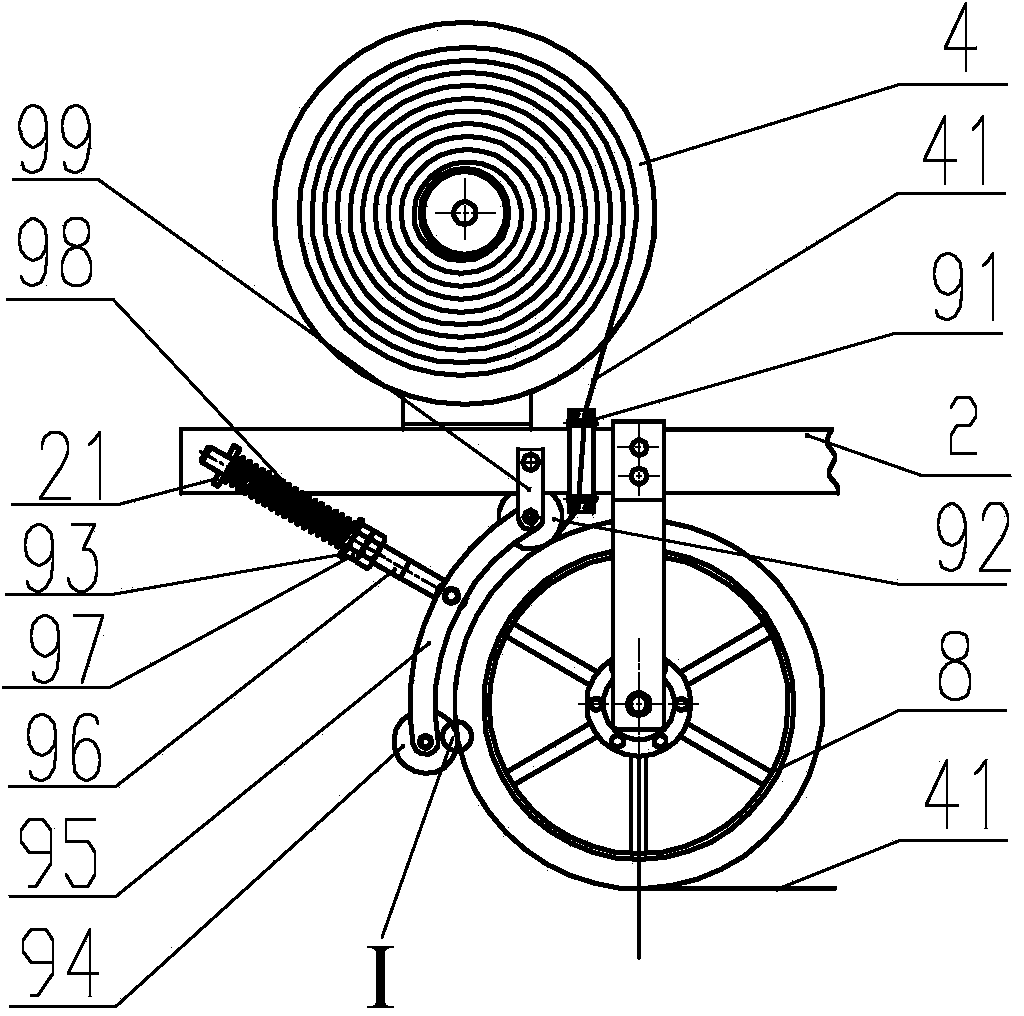

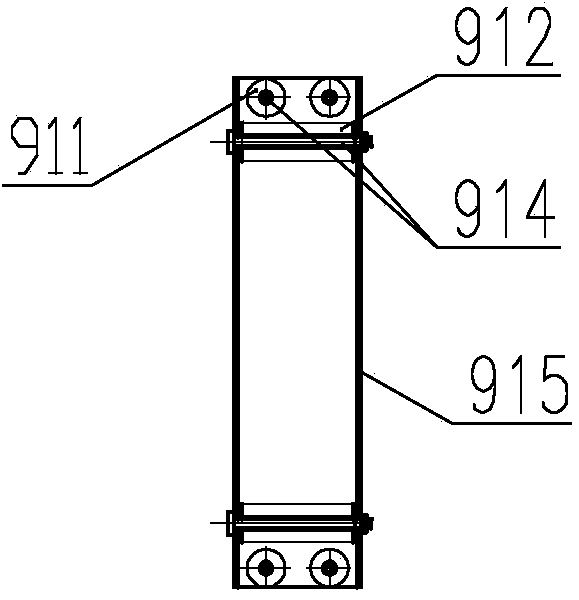

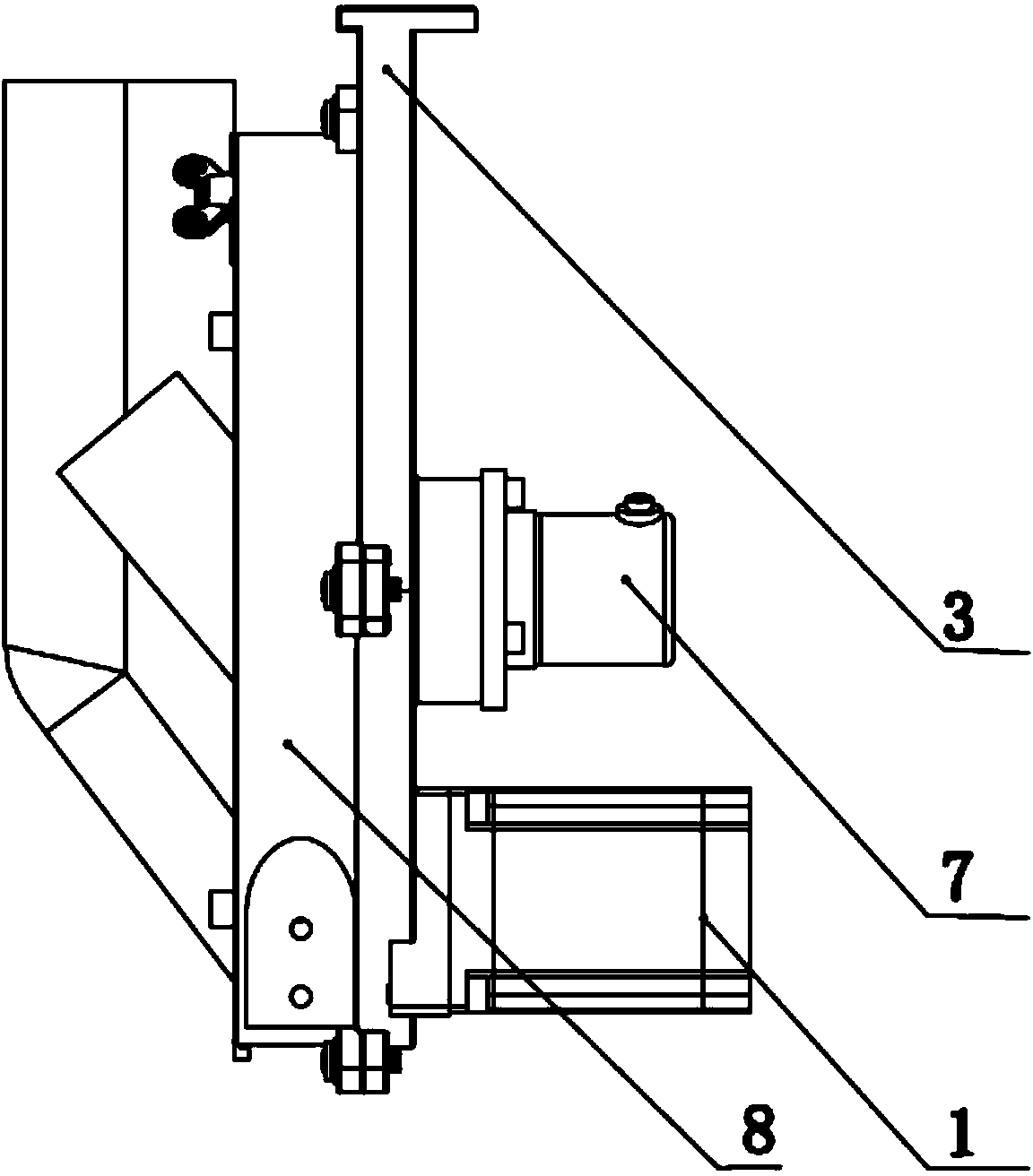

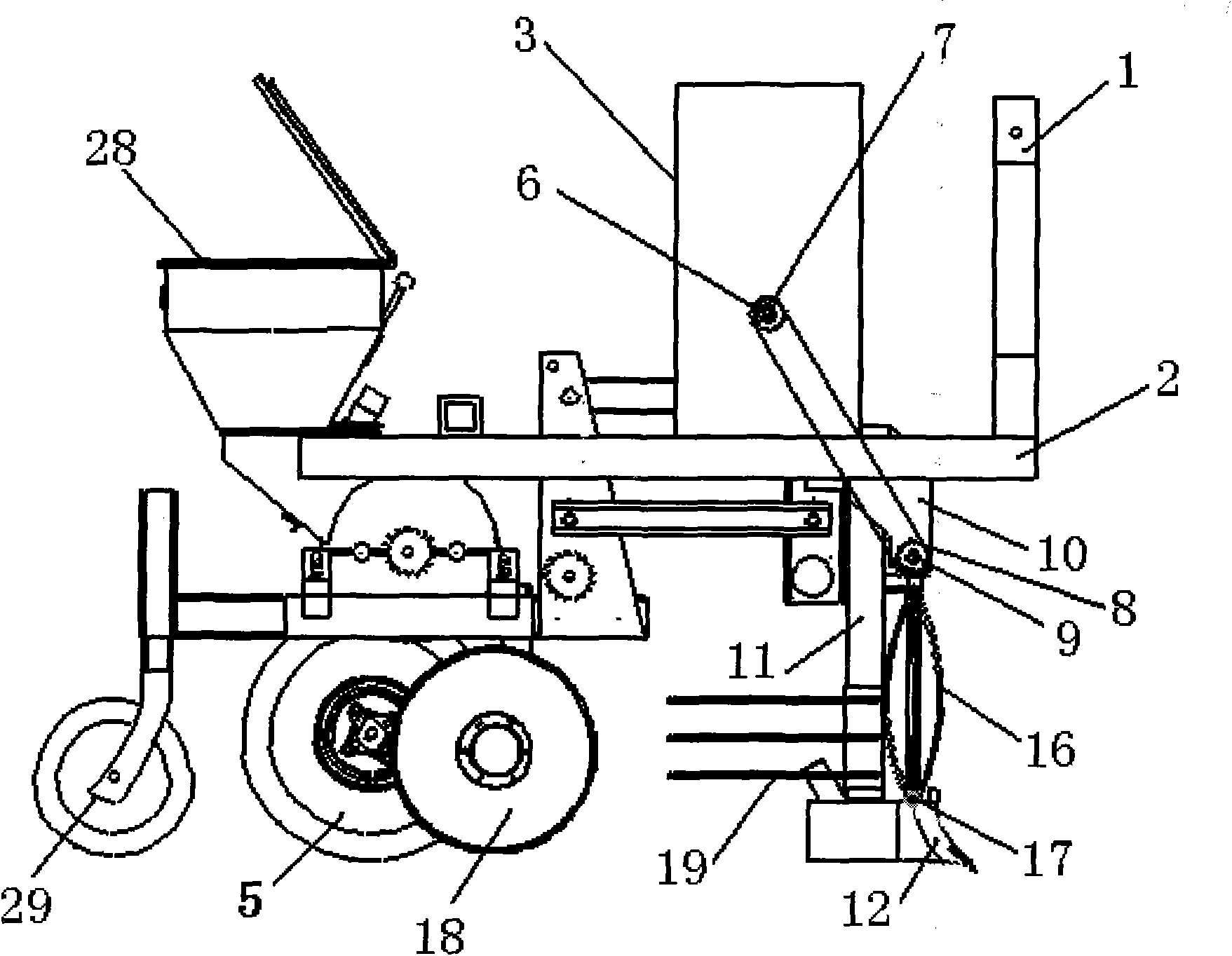

Crop seed rope direct sowing machine

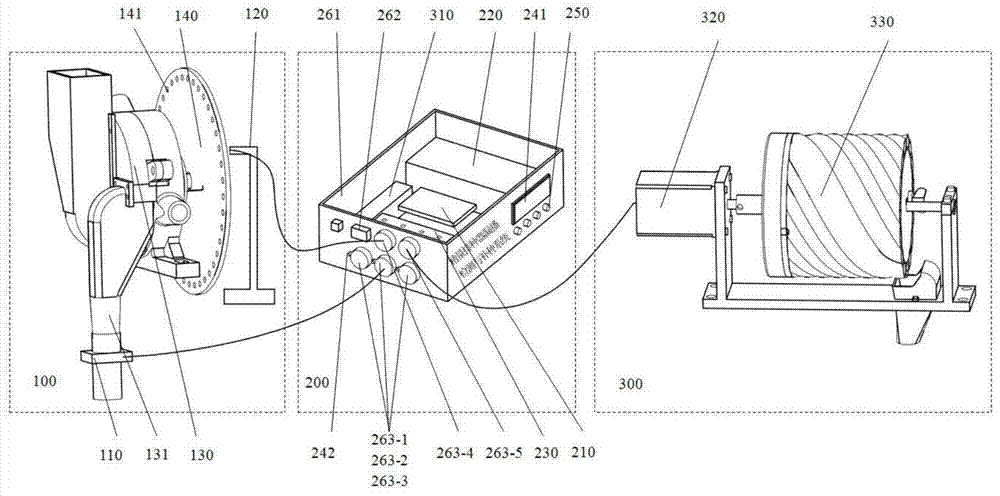

ActiveCN103858566ASolve the problem of manual rope release and pressureRealize automatic rope releaseSowingAgriculture gas emission reductionAgricultural engineeringSowing

The invention relates to a crop seed rope direct sowing machine, belonging to the technical field of an agricultural sowing machine. The crop seed rope direct sowing machine comprises a stand, a seed rope coil, an automatic rope releasing device, a furrow pressing wheel and a compacting soil covering device, wherein the automatic rope releasing device, the furrow pressing wheel and the compacting soil covering device are sequentially connected with the stand; the seed rope coil is arranged on the stand; a seed rope end on the seed rope coil comes round the furrow pressing wheel by the automatic rope releasing device and is arranged in a seed furrow formed by the furrow pressing wheel; when seeds are sown, the stand is connected with a tractor by a suspension bracket, and the furrow pressing wheel and the compacting soil covering device are respectively contacted with the field; the compacting soil covering device is used for compacting the seed furrow so as to cover soil on the seed rope and compact. The crop seed rope direct sowing machine is provided with the automatic rope releasing device, so that the problem of manually releasing and pressing the rope at the edge of the field can be solved, and the degree of automation is improved. The crop seed rope direct sowing machine is provided with a seed rope shearing device, so that the problem of manually shearing the rope at edge of the field can be solved, and the degree of automation is improved. The crop seed rope direct sowing machine is provided with a flattening shovel which is used for flattening the surface of the ground, cleaning stubbles and the like, so that the sowing quality is guaranteed.

Owner:SHENYANG AGRI UNIV

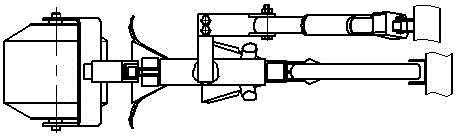

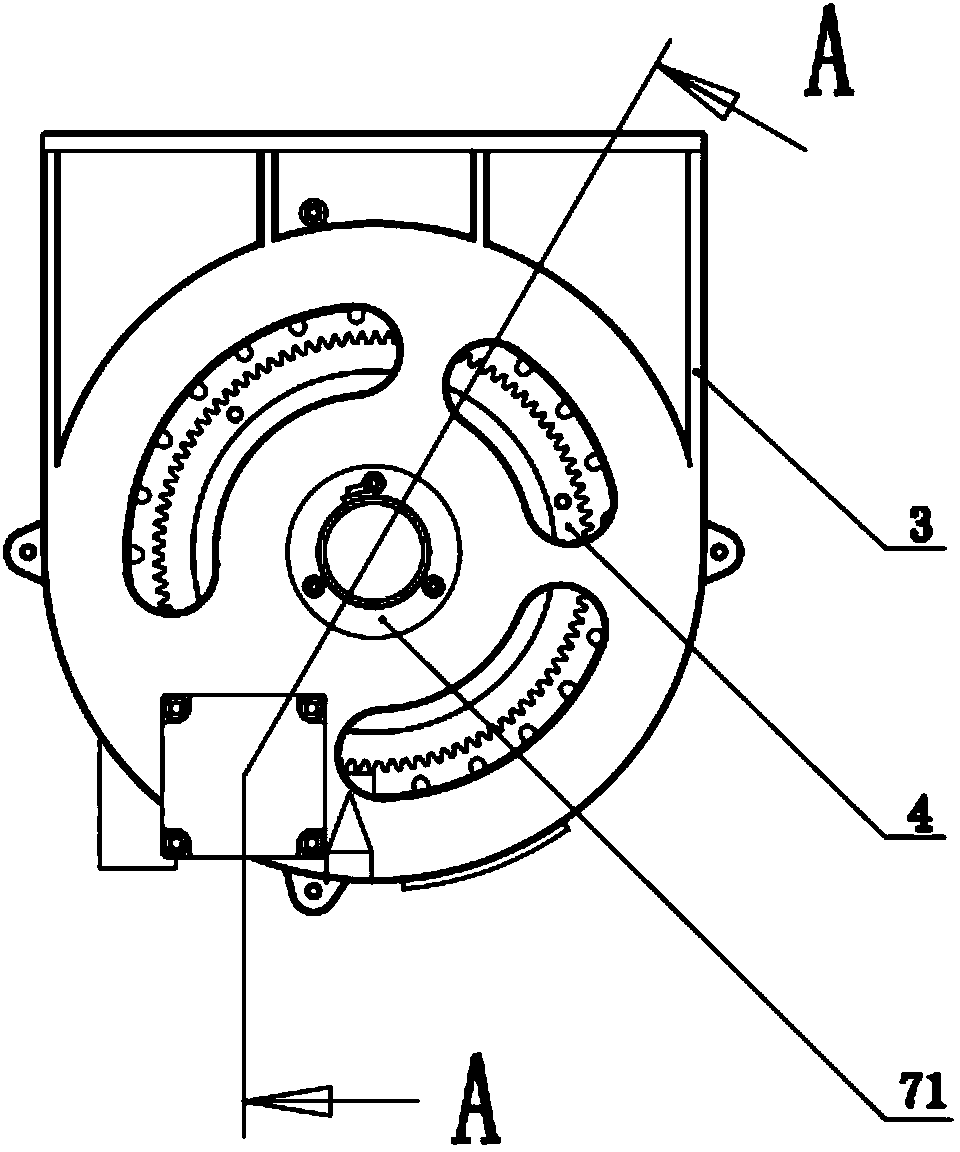

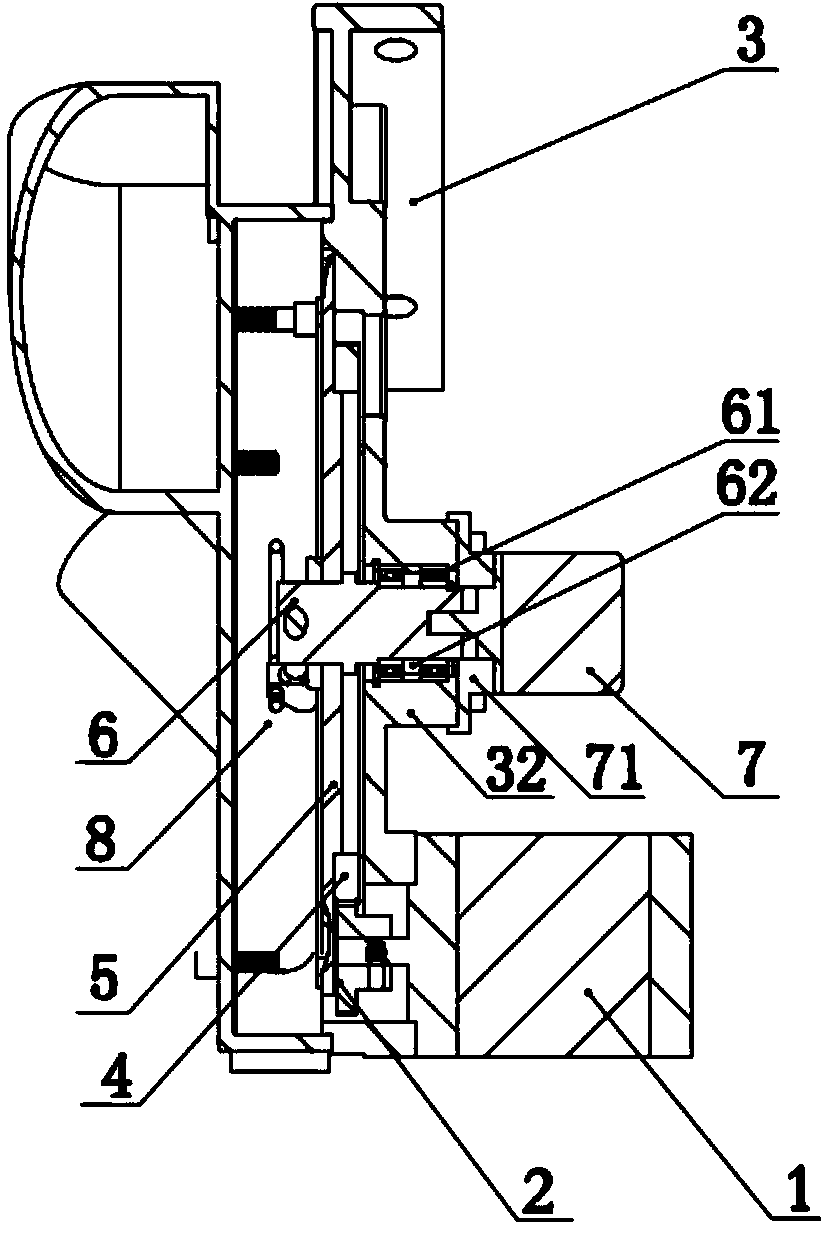

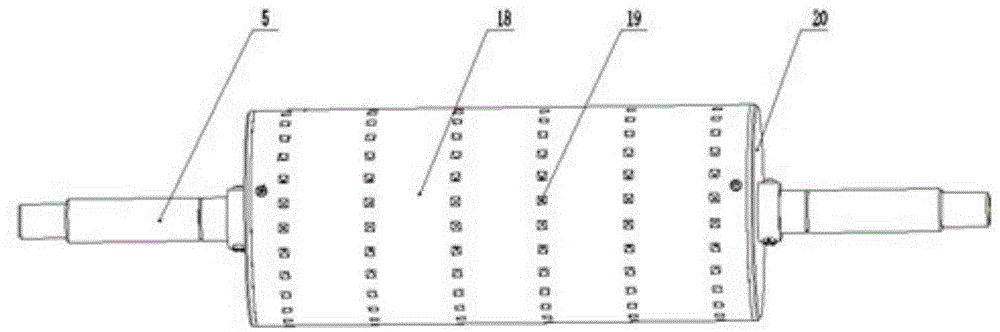

Peripheral motor direct-drive device and control method of pneumatic type precise corn seed-metering device

ActiveCN103858571AAchieve individual controlAvoid missed broadcastsSeed depositing seeder partsFertiliser equipmentsAgricultural engineeringUltimate tensile strength

The invention belongs to the field of automatic agricultural equipment and in particular relates to a peripheral motor direct-drive device, a pneumatic type precise corn seed-metering device with the same, and a control method of the pneumatic type precise corn seed-metering device. The peripheral motor direct-drive device is suitable for a conventional pneumatic type precise corn seed-metering device, can perform seeding filling in advance and variable sowing and is convenient to adjust, is suitable for high-speed operation, and can be used for controlling the seed-metering device and the sowing amount thereof independently. The pneumatic type precise corn seed-metering device comprises the peripheral motor direct-drive device. Miss-seeding caused by slip of land wheels can be fundamentally avoided, and the sowing quality is improved; a seed-metering transmission system is simplified, and the production cost of a corn planter is reduced; the intelligent degree and automation degree of the corn planter are improved, the working efficiency is improved, and the labor intensity is reduced.

Owner:CHINA AGRI UNIV

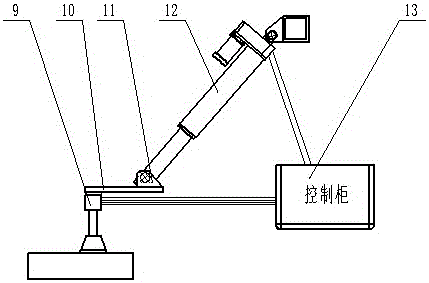

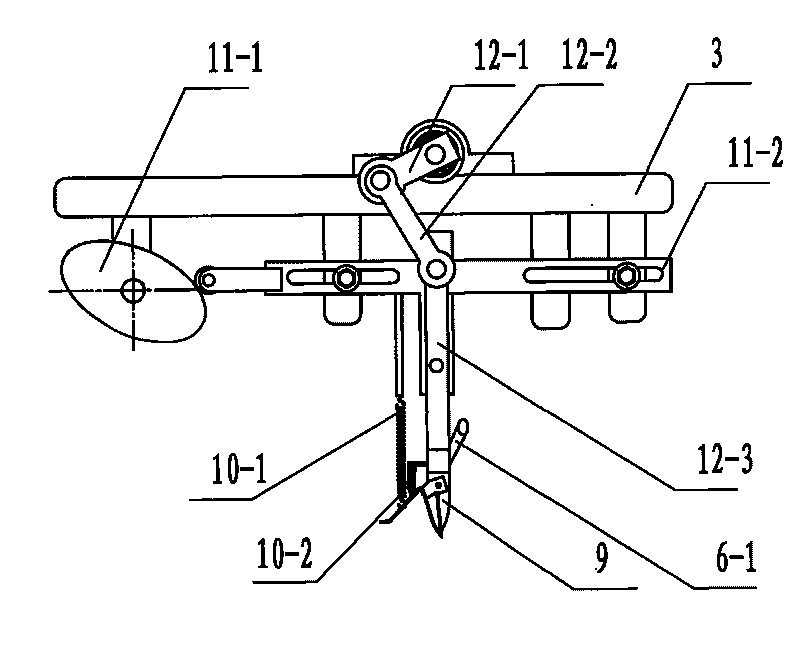

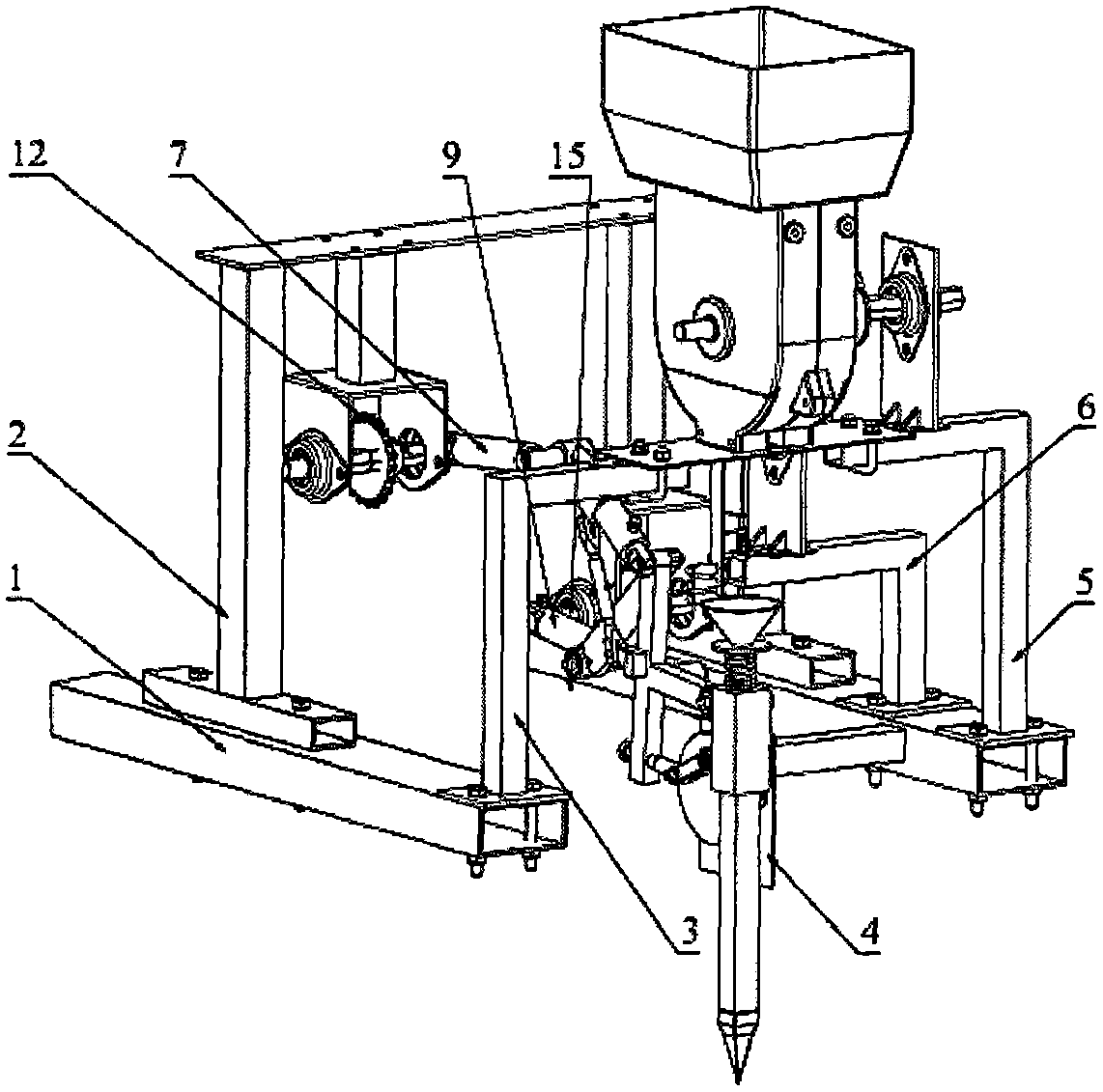

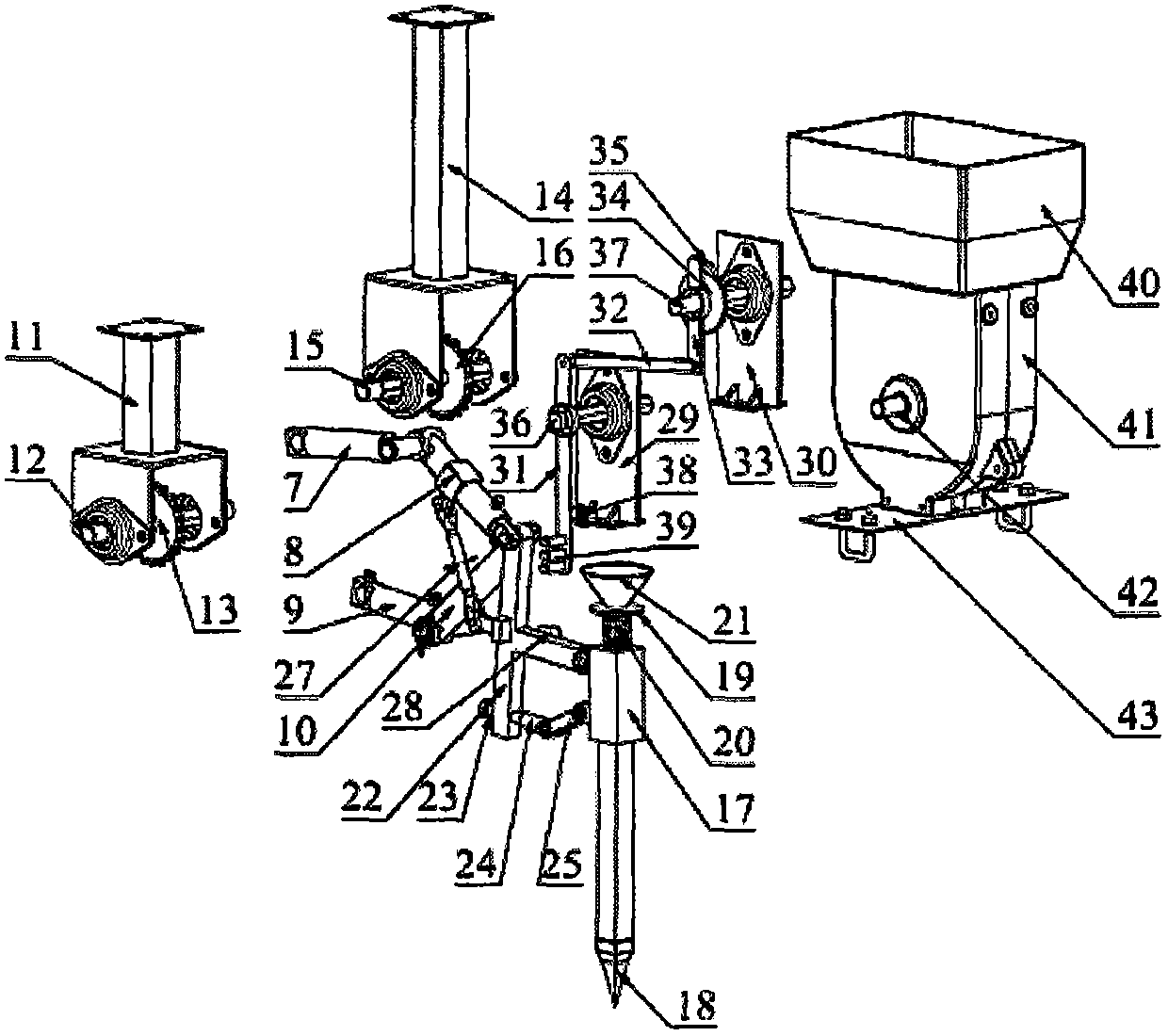

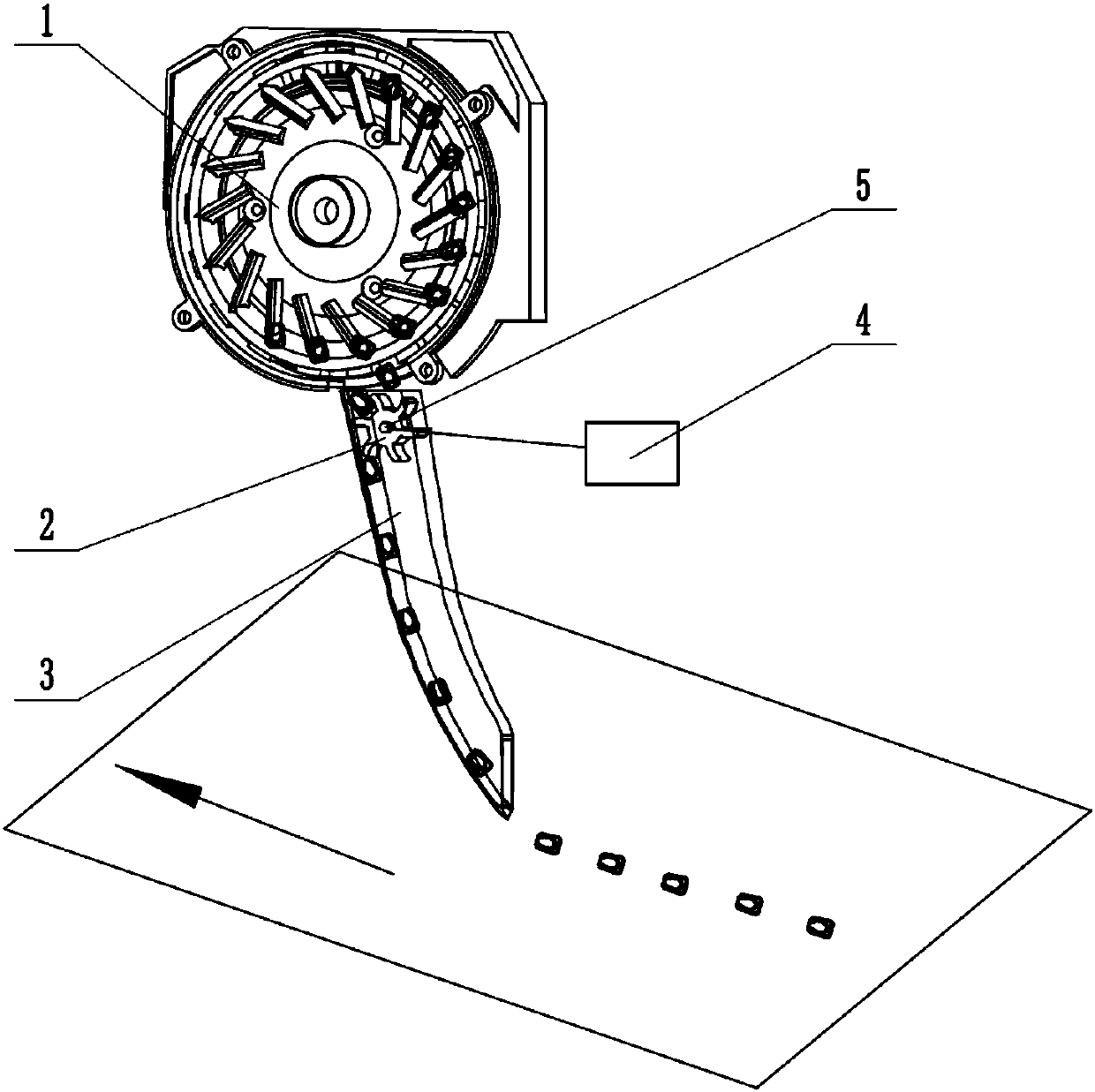

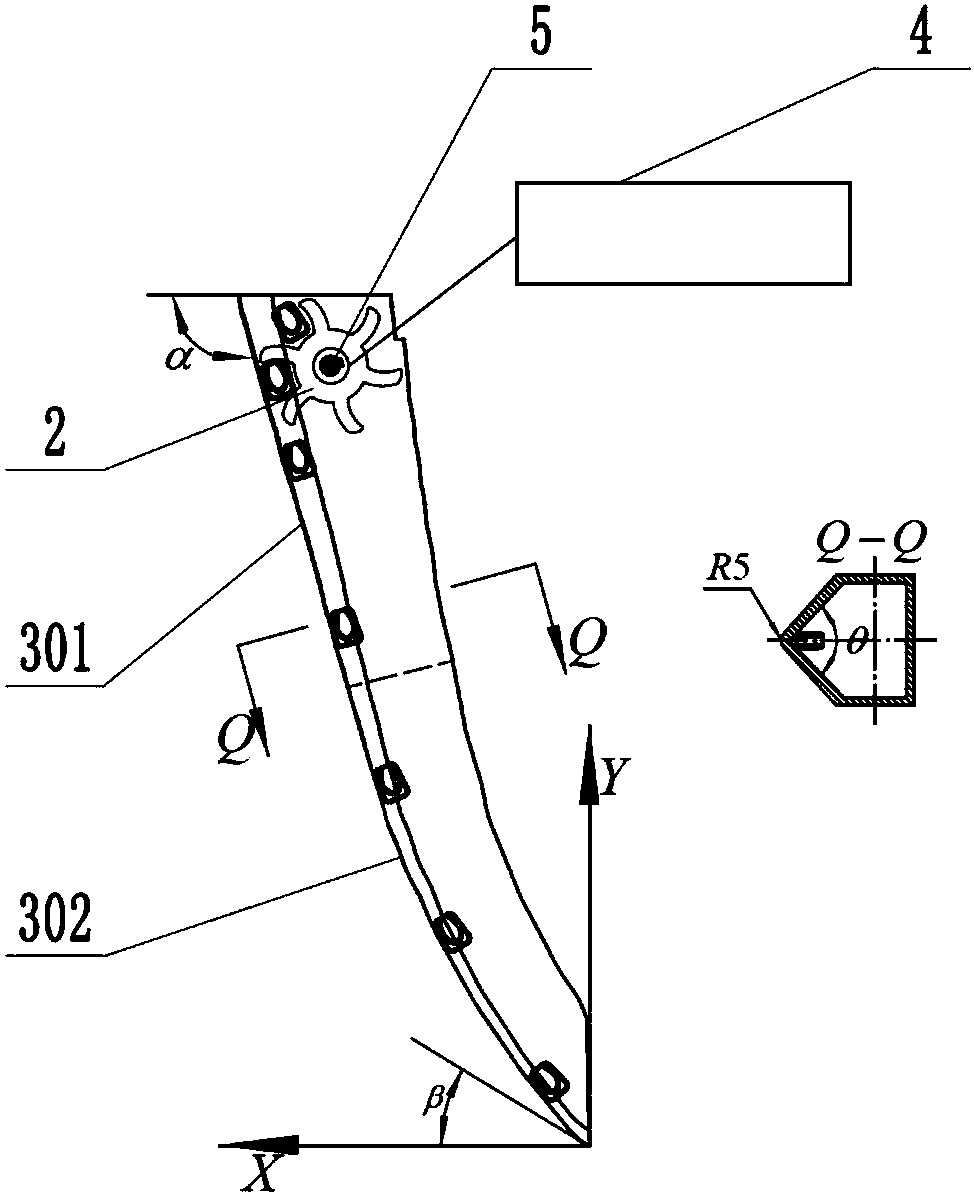

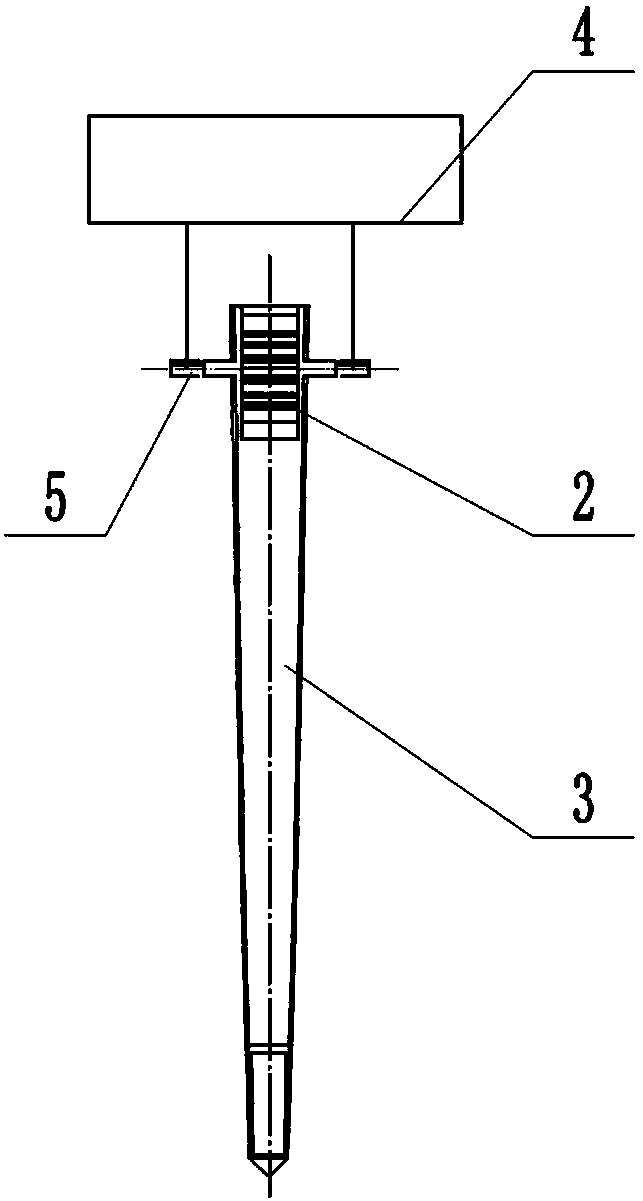

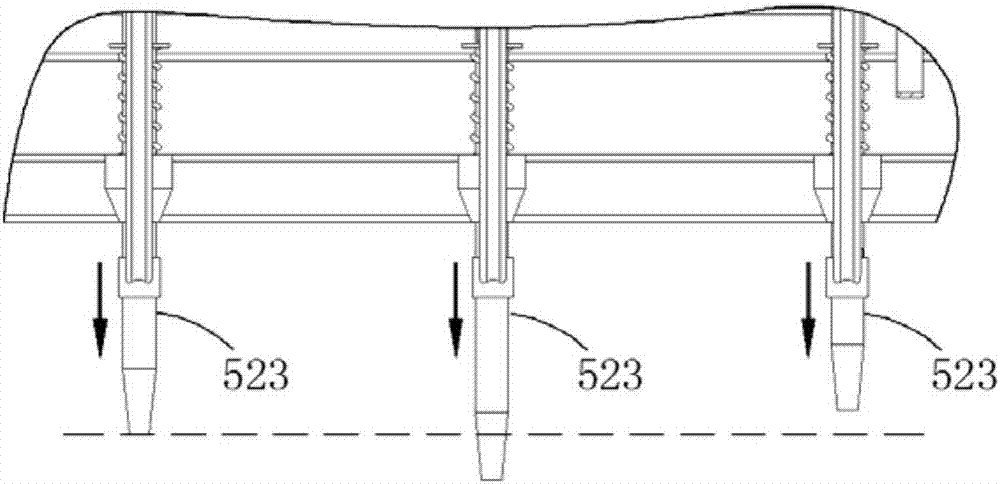

Five-rod hole forming type no-tillage hole sowing mechanism

InactiveCN105493700AReduce pollutionImprove sowing qualityTill seedingDibble seedersEngineeringMechanical engineering

The invention discloses a five-rod hole forming type no-tillage hole sowing mechanism and belongs to agricultural machines. The five-rod hole forming type no-tillage hole sowing mechanism comprises a rack, a left supporting part, a right supporting part, a five-rod hole forming part, a ratchet wheel intermittent mechanism and a seed discharging mechanism. The five-rod hole forming part comprises a five-rod mechanism and a duckbilled hole forming mechanism, the five-rod mechanism serves as a track forming mechanism, drives the duckbilled hole forming mechanism during motion, and is matched with the ratchet wheel intermittent mechanism and the seed discharging mechanism, and the no-tillage sowing process of seed discharging, seed receiving, hole forming and seed falling can be repeatedly completed. The five-rod hole forming type no-tillage hole sowing mechanism has the advantages that the structure is simple, mounting and maintenance are easy, duckbilled hole forming can be directly carried out on the premise of not touching straw stubbles or distributing soil, no-tillage sowing is completed, and the problems that when an existing no-tillage sowing machine carries out sowing in a shearing mode and a removing mode, power consumption is large, environment pollution is serious, and winding and blocking are prone to be caused when a large amount of straw exists are avoided.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Anti-blockage corn no-tillage seeder

InactiveCN101965768AAvoid cloggingPrevent entanglement of strawPlantingAgriculture gas emission reductionDrive shaftAgricultural engineering

The invention relates to an anti-blockage corn no-tillage seeder, which comprises a machine frame, a fertilizer tank, a plurality of no-tillage seeder single bodies and ground wheels. The fertilizer tank and the plurality of no-tillage seeder single bodies are arranged on the machine frame. The fertilizer tank is provided with a fertilizing shaft which is connected with the ground wheels by chain transmission. Each no-tillage seeder single body comprises a seeding box and a furrowing blade handle, which are arranged on the machine frame, wherein the bottom of the furrowing blade handle is connected with a fertilizing furrower; and a seeding furrower and a press wheel are connected with the machine frame at the rear side of each fertilizing furrower. The anti-blockage corn no-tillage seeder is characterized in that: a driving shaft parallel to the fertilizing shaft is connected below the machine frame and in front of the furrowing blade handles by a plurality of supporting frames; one end of the driving shaft is connected with the fertilizing shaft through chain transmission; the driving shaft is provided with driving bevel gears corresponding to the no-tillage seeder single bodies; the centers of driven bevel gears meshed with the driving bevel gears are fixedly connected with roller shafts; each roller shaft is provided with a roller for pushing straw aside; and the lower ends of the roller shafts are connected with the fertilizing furrowers rotationally.

Owner:CHINA AGRI UNIV

No-tillage seeding method of wheat stubble of summer seeding crops

ActiveCN102487680AImprove sowing qualityImprove processing efficiencyHorticulturePlanting seedProcess efficiency

The invention discloses a no-tillage seeding method of wheat stubble of summer seeding crops, which comprises the following steps: not ploughing soil after previous crop straw is moved out of a seeding area, and directly sowing plant seeds in the seeding area; and enabling the previous crop straw moved out to be covered on the seeding area along the direction perpendicular to the seeding area after seeding. By means of the no-tillage seeding method of the wheat stubble of the summer seeding crops, processing efficiency of the wheat stubble of Huang-Huai-Hai areas can be improved, seeding quality of the summer seeding crops of the Huang-Huai-Hai areas is improved, weeding effects of chemical herbicide are improved, soil moisture content is improved, soil hardness and temperature are reduced, growth of plants is promoted, the fact that all the straw returns to the field is achieved, soil fertility is improved, and processes and costs are reduced. The no-tillage seeding method of the wheat stubble of the summer seeding crops adapts to the Huang-Huai-Hai areas and is a scientific method for summer seeding crop production.

Owner:INST OF CROP SCI CHINESE ACAD OF AGRI SCI

Bionic fertilizer placer

InactiveCN102612896AReduce resistanceReduce power consumptionPlantingFurrow making/coveringSoil resistanceMaterials science

The invention discloses a bionic fertilizer placer. A bionic ripple structure is distributed on the core ploughshare surface of the placer and is of a diamond bionic geometric structure. A diamond bionic geometric structure unit and a core ploughshare base body which are positioned on the diamond geometric structure are both made of superhigh molecular weight hydrophobic materials of polyethylene, compound materials or the like. A cavity is positioned at the back of the core ploughshare base body, a plurality of through holes communicated with the cavity are arranged on the diamond bionic geometric structure unit, and the cavity is provided with an air / liquid inlet pipe. The bionic fertilizer placer has the effect of reducing soil resistance and power consumption, can improve quality of sowing and fertilizing and reduces working resistance of ditching parts.

Owner:JILIN UNIV

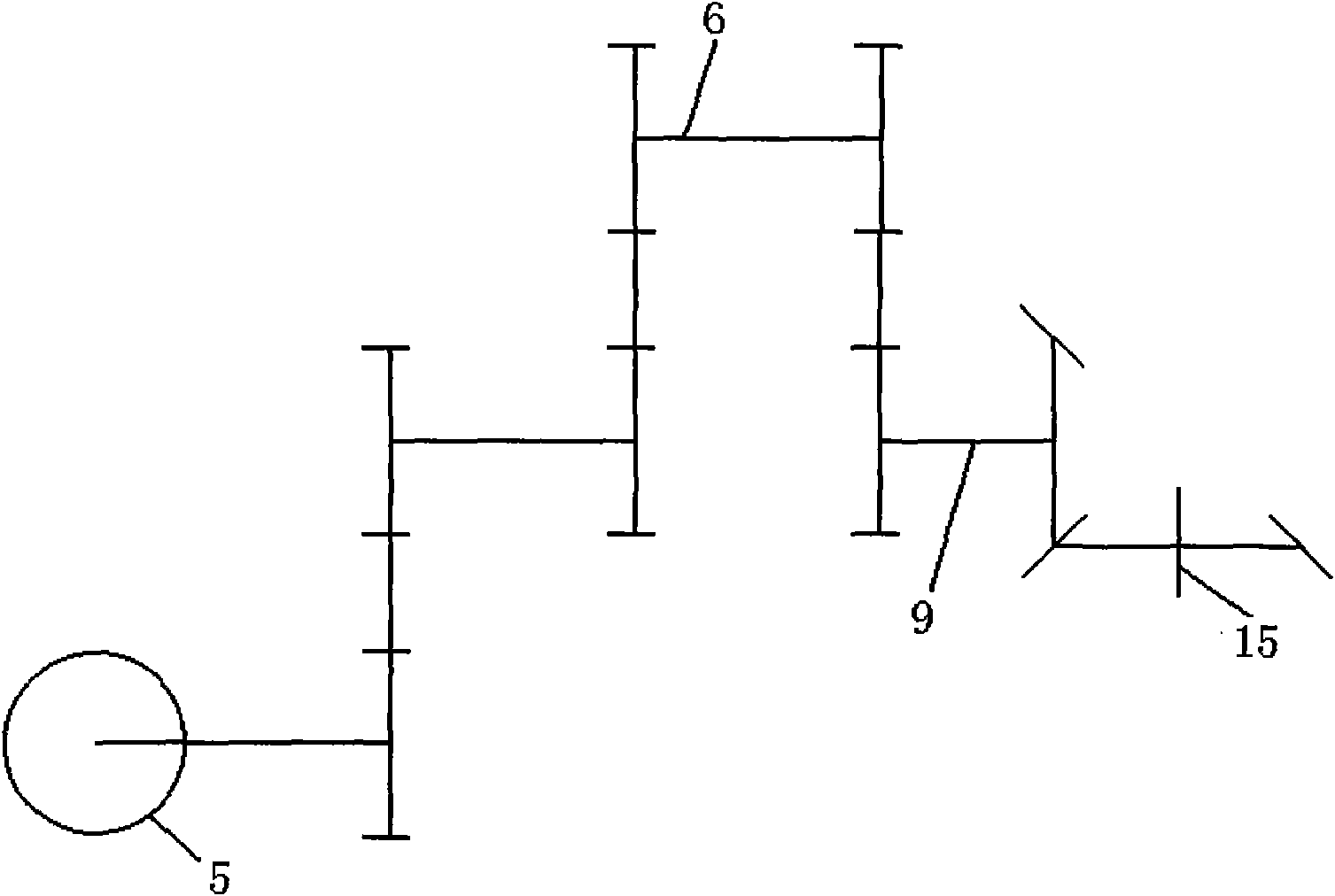

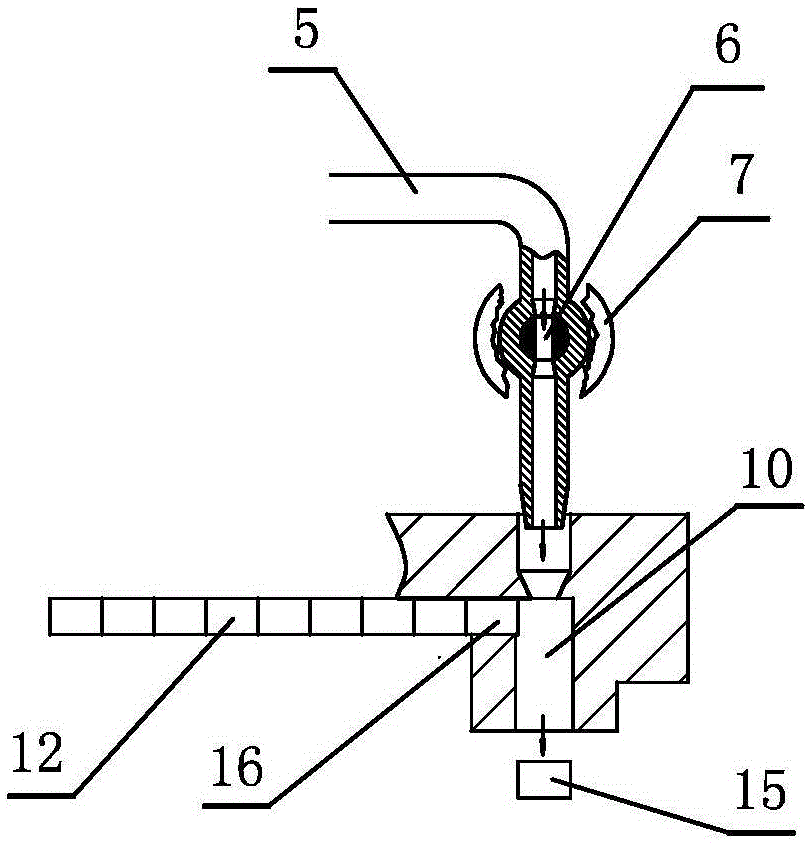

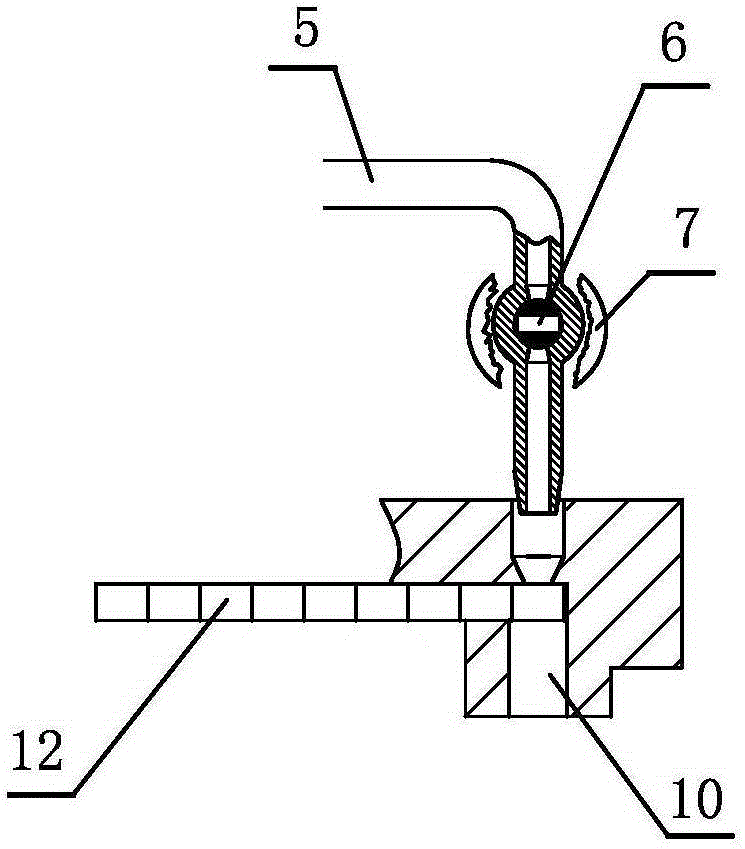

Pneumatic precise seeder

ActiveCN105103732AHigh single species rateAcupoints are accurateSeed depositing seeder partsRegular seed deposition machinesSeederEngineering

The invention relates to an agricultural machine, in particular to a pneumatic precise seeder. The pneumatic precise seeder is characterized in that an air bag (4) which can be filled with high-pressure air is arranged on a rack (1); an opening in one side of the air bag (4) is connected with an air ejection pipe (5); a switching valve (6) is arranged on the air ejection pipe (5); one end of the air ejection pipe (5) is opposite to a percussion port (10); the rack (1) is provided with a seed box (11) and a seed conveyor used for conveying seeds (15), and a seed conveying port (16) of the seeds (15) is opposite to the percussion port (10). The air-blasting precise seeder has the advantages that high-pressure air is adopted for percussion so that the seeds can be discharged, hole positions are precise, the single seed rate is high, furrowing is not required for soft soil, the seeds are directly hit into a plough layer, in this way, the preservation performance of soil moisture is better, and the operation cost is lowered; besides, the pneumatic precise seeder is simple in structure, stable in performance, convenient to use and capable of remarkably improving seeding quality, thereby being expected to become a new-generation seeder in place of existing products.

Owner:冯成伟

Sowing machine

ActiveCN105814992AImprove the sowing environmentImprove survival rateSpadesPloughsFertilizerTurning frames

The invention relates to the technical field of agricultural machinery and specifically relates to a sowing machine. The sowing machine comprises a frame, wherein a power draft gear, a rotary tillage device, a flat caking device and a sowing device are successively arranged on the frame along a driving direction; the rotary tillage device comprises a gear frame, a transmission mechanism, a rotary blade component and a protecting cover; the sowing device comprises a seed storage box, a fertilizer storage box, a seed conveying channel, a fertilizer conveying channel, a discharging channel, a seed rotary dialing piece and a fertilizer rotary dialing piece; the seed conveying channel is used for conveying seeds; the fertilizer conveying channel is used for conveying the fertilizer; the discharging channel is used for conveying the mixture of the seeds and fertilizers; the seed rotary dialing piece is arranged at an inlet of the seed conveying channel; the fertilizer rotary dialing piece is arranged at the inlet of the fertilizer conveying channel; the outlet of the seed conveying channel and the outlet of the fertilizer conveying channel are both communicated with the discharging channel; a valve is arranged on the discharging channel. The sowing machine can be used for rotary tillage, leveling, sowing and fertilization; the labor intensity of the peasant is relieved; the production efficiency is increased; the rotary tillage effect is excellent; the hack and weeding effects are excellent; the fertilization is uniform; the fertilizer utilization ratio is high; the survival rate of seeds is high.

Owner:GUANGDE COUNTY SHIJIE TOWN WENCAI RICE PLANTING FAMILY FARM

Feeding-type real-time seedling-cutting planting machine of sugarcane

ActiveCN103999618AReduce in quantityReduce labor intensityPlantingEngineeringUltimate tensile strength

The invention discloses a feeding-type real-time seedling-cutting planting machine of sugarcane, which comprises a frame, and a seedling guide rack, a feeding unit and a power system, which are arranged on the frame, wherein the power system is connected with the feeding unit; the feeding unit also comprises a finger-chain feeding device, a feeding roller device and a section cutting roller; the finger-chain feeding device is arranged at the side part of the seedling guide rack; the input end of the feeding roller device is arranged below the finger-chain feeding device; the section cutting device is arranged at the output end of the feeding roller device; a guide slot for throwing the cut sugarcane seedlings in a planting furrow is formed under the section cutting roller. The finger-chain feeding device and the feeding roller device are combined to replace artificial feeding of the existing technology, and due to the automatic sugarcane seedling feeding, the amount of feed workers is reduced, the seeding labor intensity is alleviated, and the production cost is lowered and the planting is continuous and uniform; the seedling-cutting planting machine of sugarcane is suitable for planting sugarcanes with different line spacing.

Owner:SOUTH CHINA AGRI UNIV

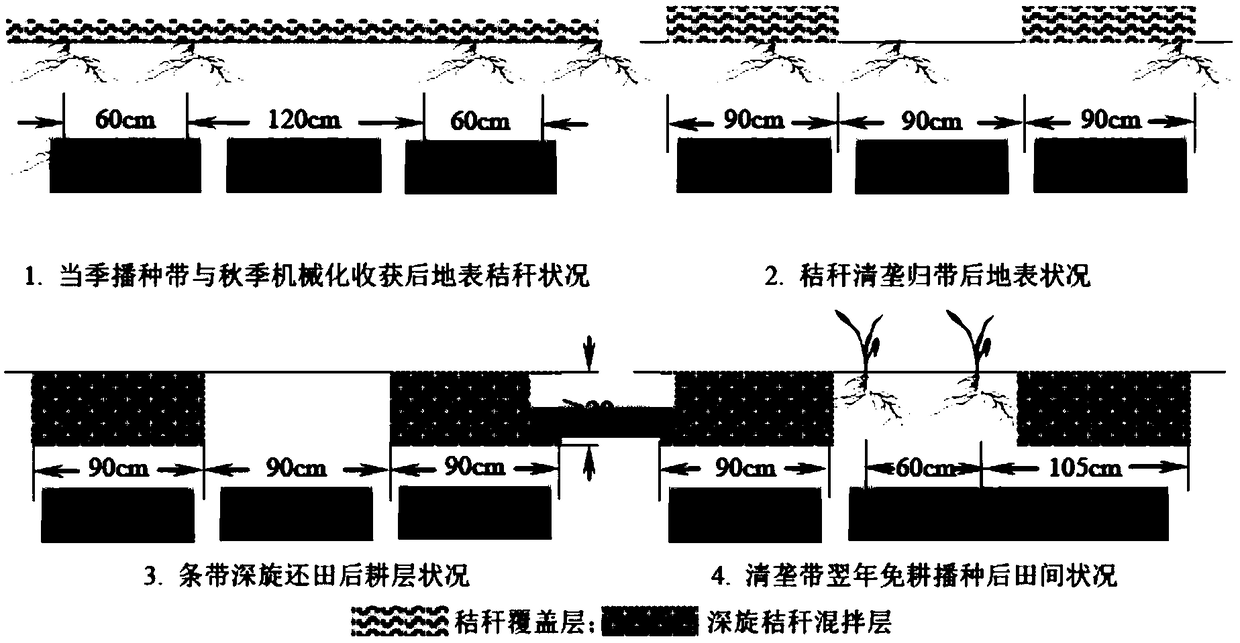

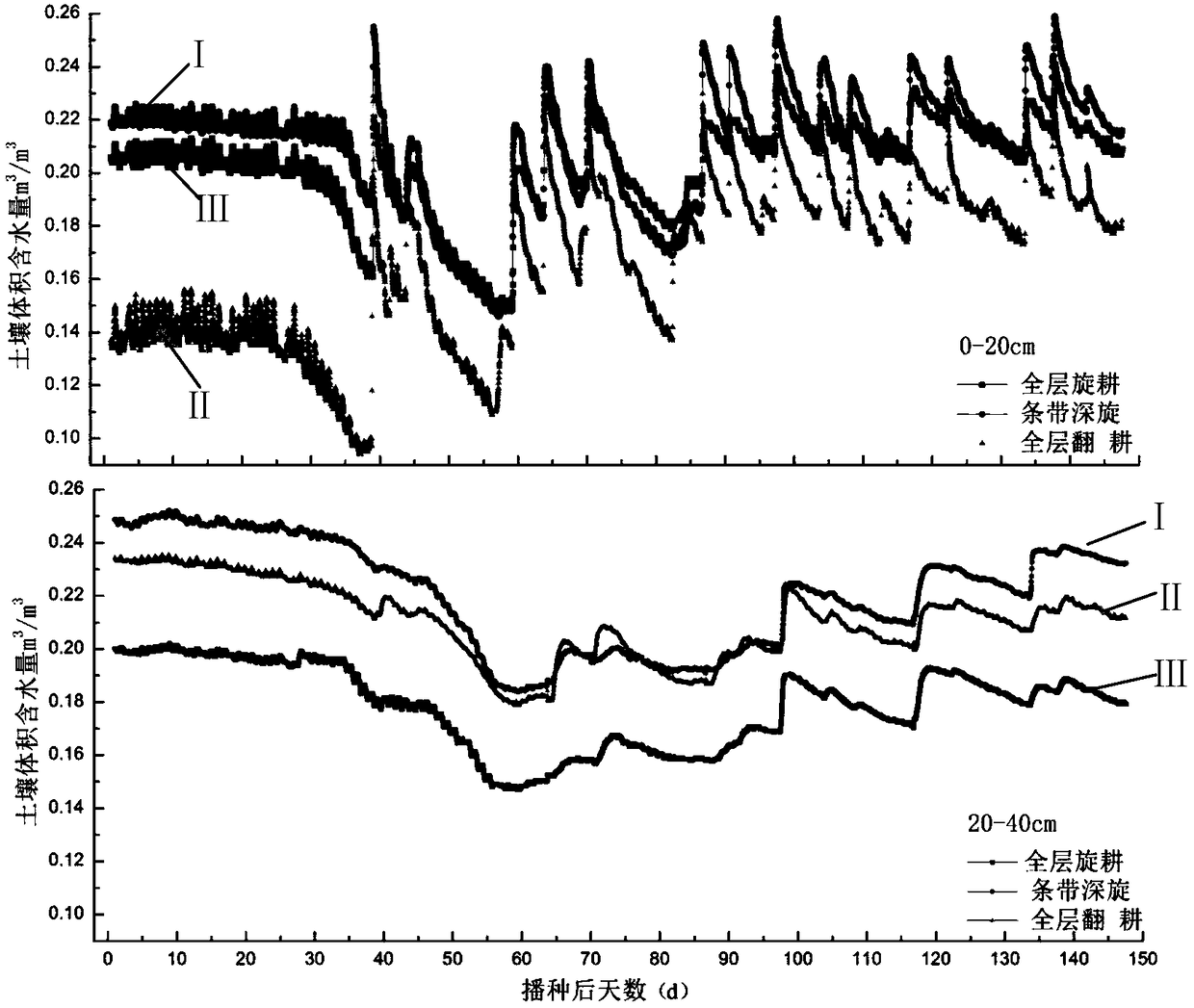

Intersecting-free straw strip-shaped return-to-field cultivation method for maize tillage

ActiveCN108934842AImprove sowing qualityPromote high and stable productionCrop conditionersMowersBand shapeSoil fertility

The invention discloses an intersecting-free straw strip-shaped return-to-field cultivation method for maize tillage. The method includes the steps that 1, before crop seeding is performed, crop strawof a last season is smashed in situ, ridge clearing and strip gathering are performed for the first time, straw at strip gathering positions is mixed and stirred in a soil layer, first seeding stripsare formed at ridge clearing positions, and first return-to-field strips are formed at the strip gathering positions; 2, before crop seeding of a next season is performed, crop straw is smashed in situ, ridge clearing and strip gathering are performed for the second time, the straw at strip gathering positions is mixed and stirred in a soil layer, second seeding strips are formed at ridge clearing positions, and second return-to-field strips are formed at the strip gathering positions; in the two adjacent planting seasons, the positions of seeding strips and the return-to-field strips are interchanged or the second seeding strips horizontally move to the first return-to-field strips to form strip spacing tillage. The arable layer structure of virtuality and reality alternating is created,and the method has the advantages of non-tillage and deep tillage, effectively solves the key problems in straw returning to the field, and is also an effective way for construction of a reasonable arable layer on dry land and promotion of soil fertility.

Owner:SHENYANG AGRI UNIV

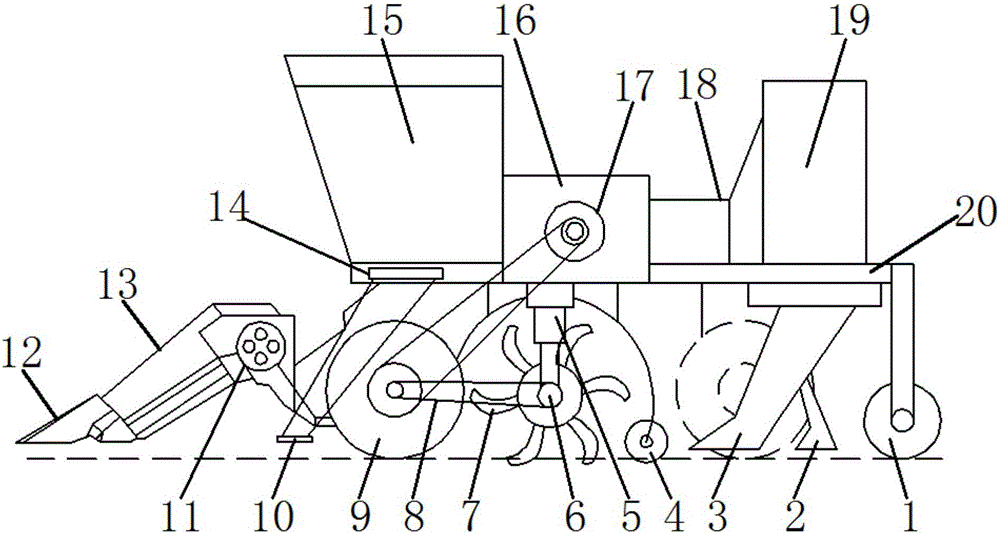

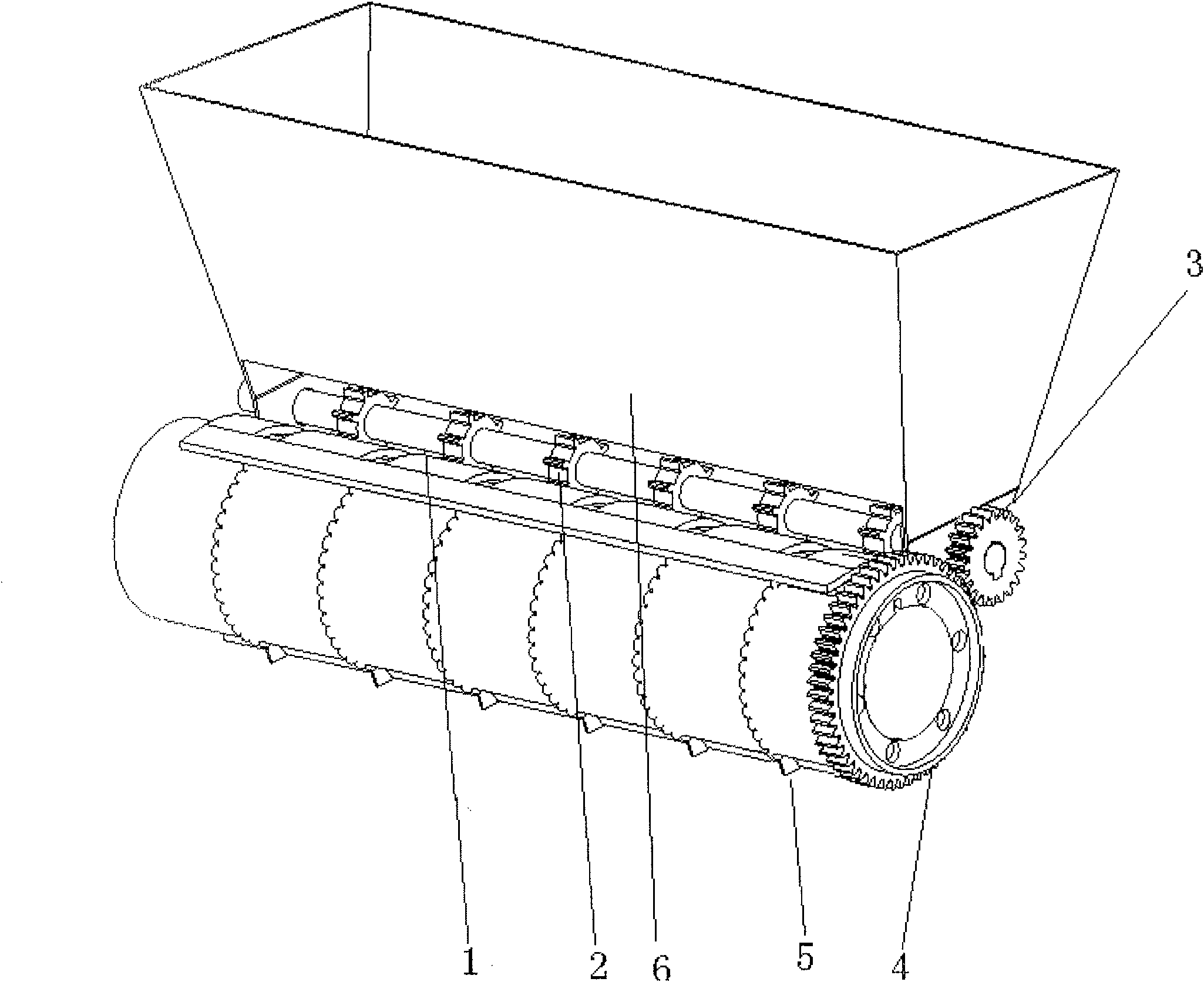

Agricultural rotary tillage sowing machine

The invention discloses an agricultural rotary tillage sowing machine. The agricultural rotary tillage sowing machine comprises seed falling devices, a rotary tillage knife roll, a fertilizer broadcasting hopper, a straw smashing disc, a fertilizer storage barrel, a seed box and a sowing rack. A header is arranged at the front end of the sowing rack, the header is provided with an upper hood, the straw smashing disc is installed at the tail of the hood, the fertilizer broadcasting hopper is arranged behind the straw smashing disc, the upper portion of the fertilizer broadcasting hopper is communicated with the fertilizer storage barrel, the rotary tillage knife roll is installed behind the fertilizer broadcasting hopper, multiple ditch pressing wheels are installed at the rear end of the rotary tillage knife roll, one seed falling device is arranged behind each ditch pressing wheel, and the upper portions of the seed falling devices are communicated with the seed box. The agricultural rotary tillage sowing machine is compact in structure and convenient to use, crop straw is effectively smashed, fertilizer is convenient to broadcast, the rotary tillage effect is good, sowing and seed earthing burying are convenient, the bottom flattening effect is good, one machine achieves multiple purposes, the sowing quality and efficiency are improved, and the cost of agricultural rotary tillage sowing is reduced.

Owner:万钰

Bionic wide-width leveling seed bed type opener

The invention relates to a bionic wide-width leveling seed bed type opener and belongs to the technical field of agricultural machinery. The bionic wide-width leveling seed bed type opener comprises a seed conveying pipe, a seed distribution box, a seed bed preparation curve surface, a sword type front cutting edge and the like, and can be used for working conditions of rotary tillage type tillage, blocking prevention, ditching and the like of a no-tillage seeder, a wide-seed band seeder and the like; the seed conveying pipe and the seed distribution box are welded so as to form a whole body; a swordfish gill type seed bed preparation curve surface is arranged below the seed distribution box; the sword type front cutting edge is embedded in front of the seed distribution box and the seed bed preparation curve surface to divide soil from the two sides; a seed distribution plate is arranged on the bottom face of the seed distribution box and an ejection bulge is arranged above the seed distribution plate, so as to be beneficial to uniform seed distribution; the equal-depth accurate seeding is realized; the seeding quality is guaranteed; a foundation is laid for the yield improvement of crops.

Owner:SHANDONG UNIV OF TECH

V-groove driving wheel type seed guiding device

InactiveCN107580837ANovel structural designReasonable structural designSeed depositing seeder partsDrive wheelDrive shaft

The invention relates to a V-groove driving wheel type seed guiding device, which belongs to agricultural machinery. The V-groove driving wheel type seed guiding device mainly comprises a seed-metering unit assembly, a driving system comprising a variable-frequency controlled motor and an electrically controlled transmission shaft, and a seed guiding system comprising a V-groove brachistochrone seed guiding tube and a flexible seed-driving wheel. The V-groove driving wheel type seed guiding device adopts the flexible seed-driving wheel to carry out even seed distribution, the V-groove brachistochrone seed guiding tube to carry out delivery and seed guiding and the variable-frequency controlled motor to drive the electrically controlled transmission shaft and the flexible seed-driving wheelto rotate in real time, the instantaneous horizontal relative velocity of a seed dropping into a seed furrow is decreased or counteracted by a secondary seed delivery method, the moving track, speedand direction of the seed in the seed guiding tube are controlled before the seed gets into the soil of a seedbed, consequently, the stable delivery of seeds is realized, the problems existing in theprior art, such as severe bouncing as the result of the collision between seeds and the tube wall and poor evenness and stability of seed delivery, are overcome, and the V-groove driving wheel type seed guiding device has the characteristics of novel and reasonable structural design, good seeding operation quality, high automation degree and wide application range.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Pneumatic seed protection type precision concentrated seeding device

ActiveCN104303651AGood pickupEasy to embedSeed depositing seeder partsAgricultural engineeringAtmospheric pressure

The invention discloses a pneumatic seed protection type precision concentrated seeding device, including a seed box, a seeding roller assembly and a seed divider provided with a seed discharge plug, a seed guide tube, a shunt tube, a seed clearing mouth, a protection room plate and a pressure nozzle. The seeding roller assembly is installed in the seed divider, the seed box and the seed divider are connected through a connecting plate, the inlet of the shunt tube is located in the seed box, and a seed protective air cushion is arranged between the protection room plate and the seeding roller assembly. The invention adopts the "inverted cone" or "inverted rectangular cone" shaped hole for facilitating seed picking, at the same time when shaped hole carrying seeds passes through the pneumatic seed protection zone, the seeds are not easy to embed into the shaped hole.

Owner:HUAZHONG AGRI UNIV

Compound spot planting mechanism

InactiveCN106973596AAvoid stickingGuaranteed accuracySeed depositing seeder partsRegular seed deposition machinesEngineeringCam

The invention relates to a compound spot planting mechanism which comprises a frame, a storage cabin, a walking mechanism, and a sowing guiding mechanism and a sowing mechanism which are separately arranged at the upper and lower ends of the storage cabin, wherein the sowing mechanism comprises a mixed conveying portion which is fixedly connected to the bottom end of the storage cabin and an hole insertion portion which is communicated with a mixing cabin and is located on one side of the fixing cabin; the mixed conveying portion comprises at least two mixing cabins which are arranged in the bottom of the storage cabin and communicated with the storage cabin, a conveying shaft which penetrates through the mixing chamber and is rotatably arranged in the bottom of the storage cabin which are arranged in the bottom of the storage cabin and communicate with the storage cabin, a conveying shaft which penetrates through the mixing chamber and is rotatably arranged in the bottom of the storage cabin and a conveying assembly which is communicated to one end of the bottom of the mixing cabin and is connected to the hole insertion portion; the hole insertion portion comprises a rotating shaft which is rotatably mounted on the frame and is separately connected to the walking mechanism, the sowing guiding mechanism and the conveying shaft, and a first cam which is arranged correspondingly to the mixing cabin and a hole inserting cone which is driven by the first cam to move up and down to be slidably communicated with the conveying assembly. The compound spot planting mechanism provided by the invention is simple in structure, accurate to proportion and thorough to mix, and agricultural production is improved while the sowing efficiency is increased.

Owner:FOSHAN HUAPU RUILIAN ELECTROMECHANICAL TECH CO LTD

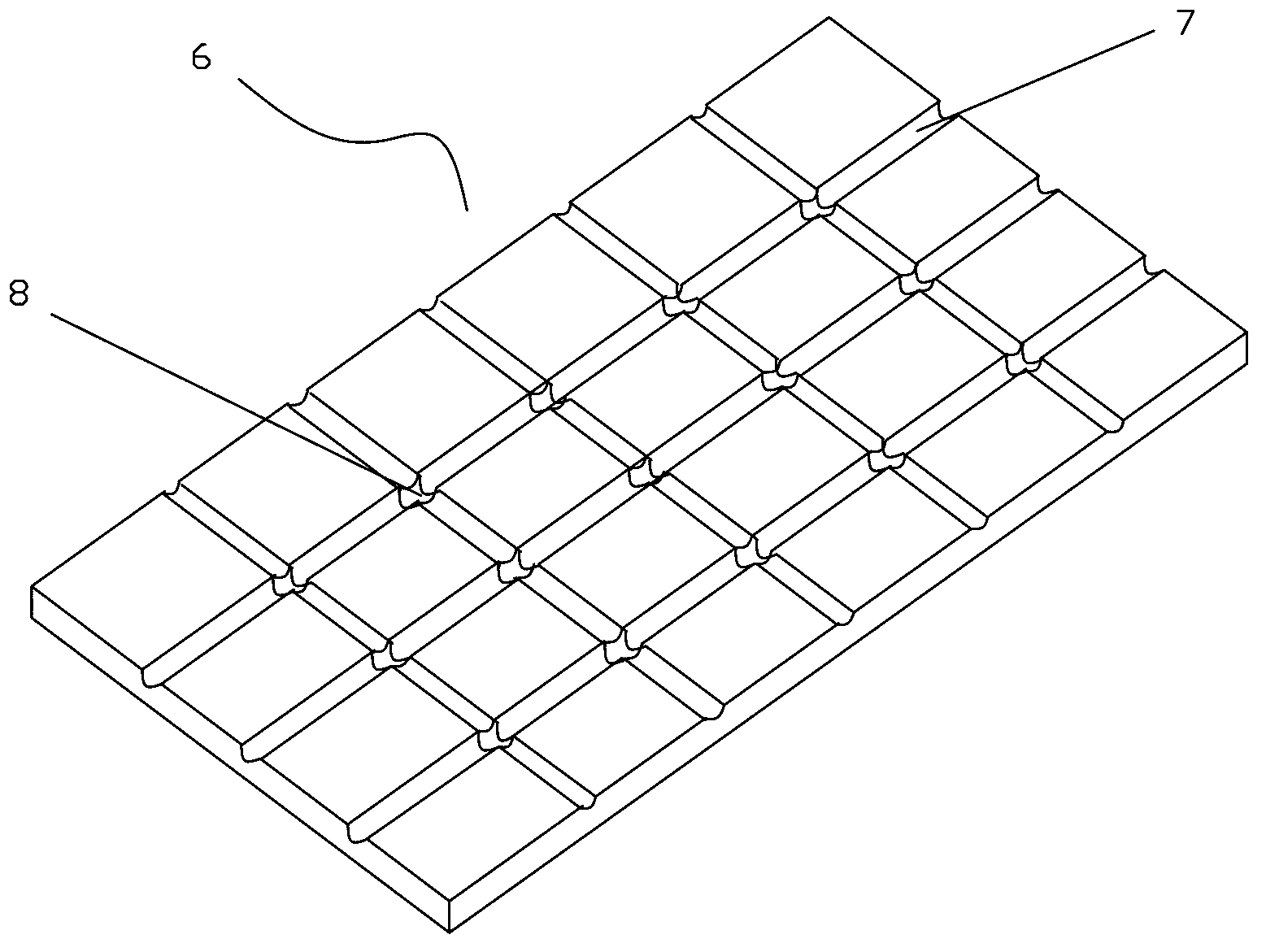

Fast-sprouting cynomorium songaricum seed mat and preparation method thereof

InactiveCN103229615AImprove utilization efficiencyIncrease germination rateClimate change adaptationSeed arrangmentsCynomorium songaricumEngineering

The invention relates to a fast-sprouting cynomorium songaricum seed mat and a preparation method thereof. The seed mat sequentially comprises a covering layer (1), a mixed slurry layer (2) and a mat type layer (4) which are adhered with one another and have basically identical shapes from top to bottom, wherein the cynomorium songaricum seeds are inlaid in the mixed slurry layer according to a random cluster shape or strip shape, and the ratio of the length to the width of the cynomorium songaricum seed mat is (1.5-2.5):1. The preparation method mainly comprises the steps of seed processing, slurry preparation and seed mat preparation. The cynomorium songaricum seed product provided by the invention has the advantages that the utilization efficiency of the cynomorium songaricum seeds and the seed spouting speed rate under the drought conditions can be improved obviously, the cynomorium songaricum seeds are more conveniently sowed in the desert environment, the sowing quality can be improved, and the seeds can be saved; and the roots of hosts such as nitraria tangutorum bobr, zygophyllum and the like can be promoted to sprout and grow towards the direction of the seed mat, and the parasitic efficiency can be enhanced.

Owner:甘肃凯源生物技术开发中心有限责任公司

Large-ridge double-row buckwheat sowing machine

InactiveCN103098592ARealize the sowing operationSimple structurePlantingFurrow making/coveringPolygonum fagopyrumDrive shaft

The invention discloses a large-ridge double-row buckwheat sowing machine, which comprises a frame, a seed box and a fertilizer box are arranged over the frame, an operation mechanism with 1-6 ridges is arranged at equal interval under the frame, the operation mechanism of each ridge comprises a fertilize opener, two sowing openers and a ; the fertilize opener of each ridge is arranged at the front part of the frame, two sowing openers are arranged at the rear part of the fertilize opener, the repressing roller is arranged at the rear part of two sowing openers; each fertilize opener is communicated with a fertilizer shifting device arranged at the bottom of the fertilizer box through a fertilizer discharge pipeline; each sowing opener is communicated with a seed shifting device arranged at the bottom of the seed box through a seed discharge pipeline; and the fertilizer shifting device and the seed shifting device are connected by driving a repressing shaft, a sprocket wheel, a chain and a transmission shaft through the repressing roller. The large-ridge double-row buckwheat sowing machine has the advantages of simple structure, uniform seed falling, consistent depth and good operation quality, and can realize the large-ridge double-row sowing.

Owner:赤峰市农牧科学研究院

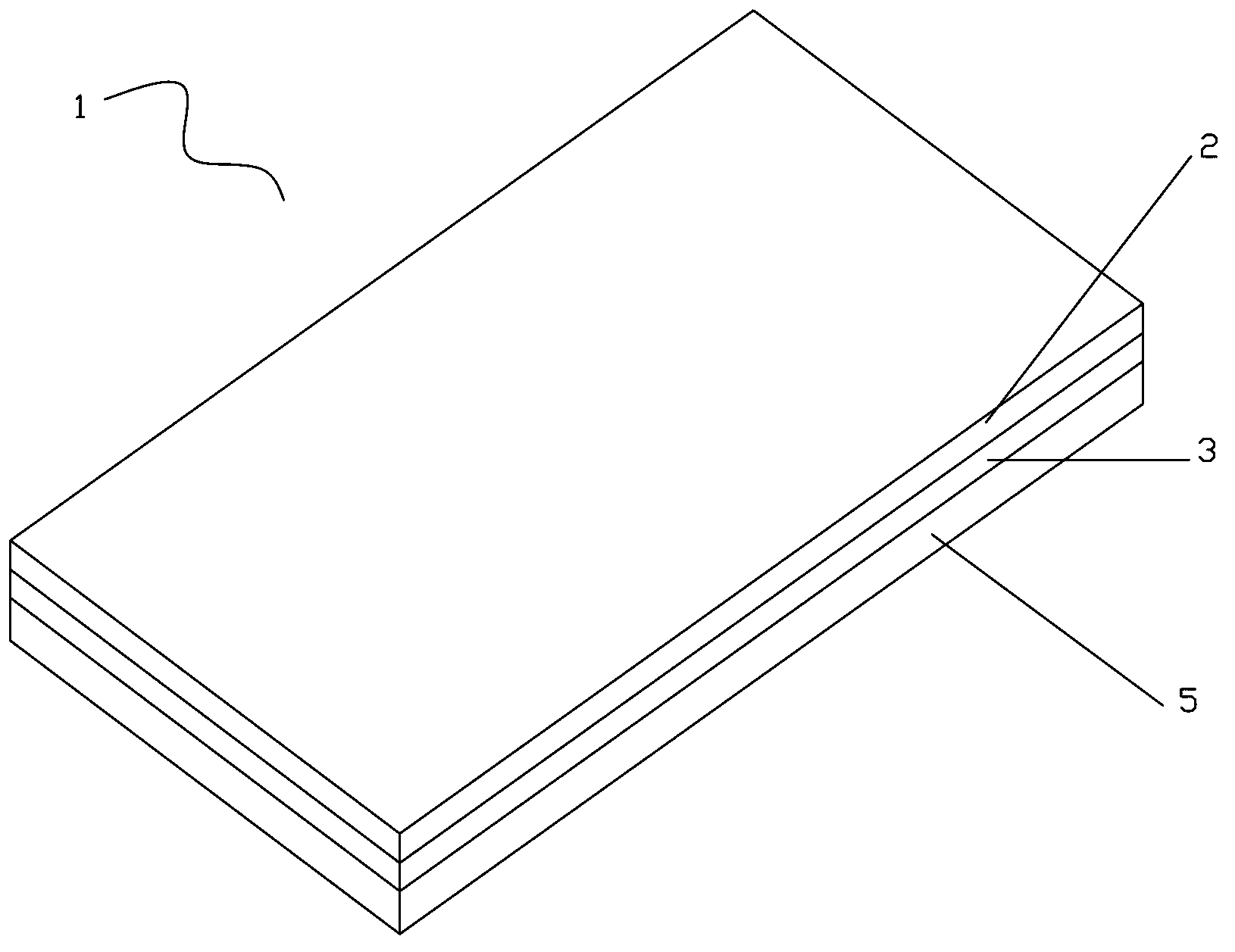

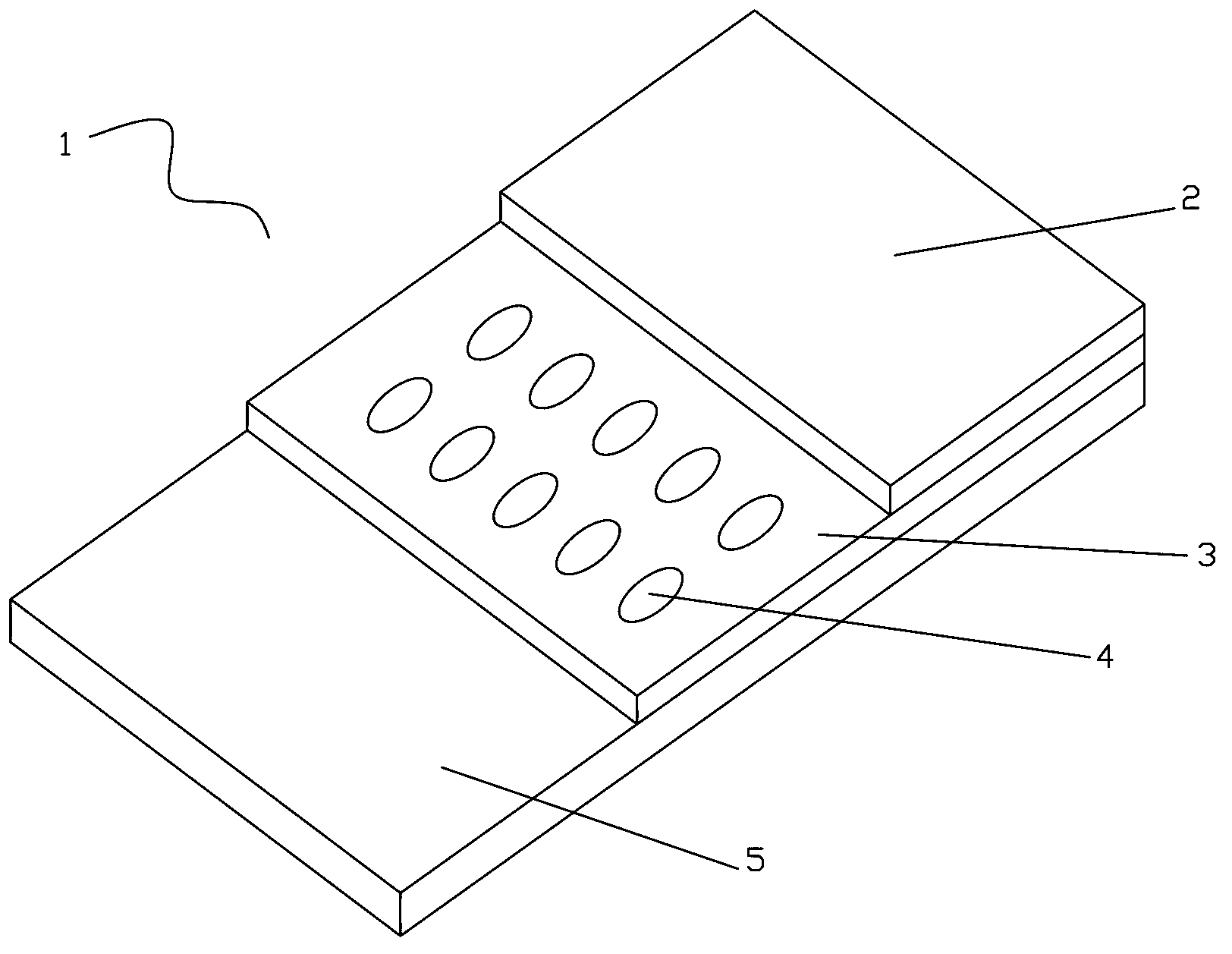

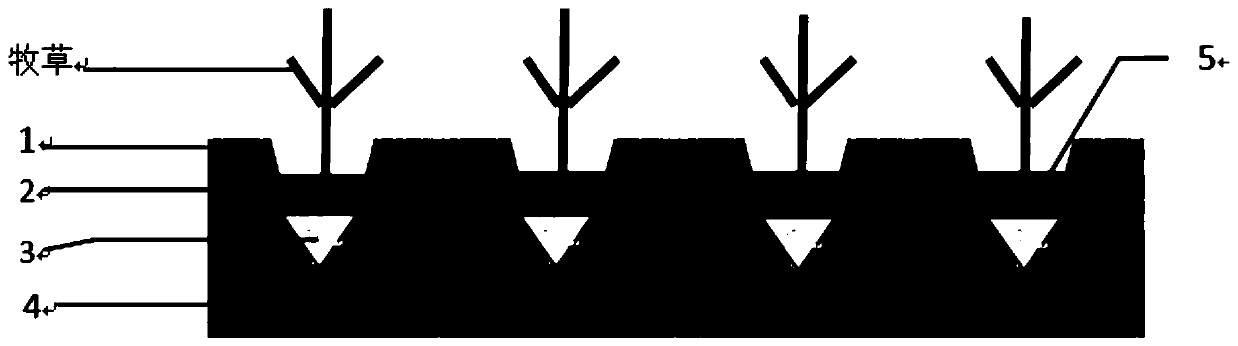

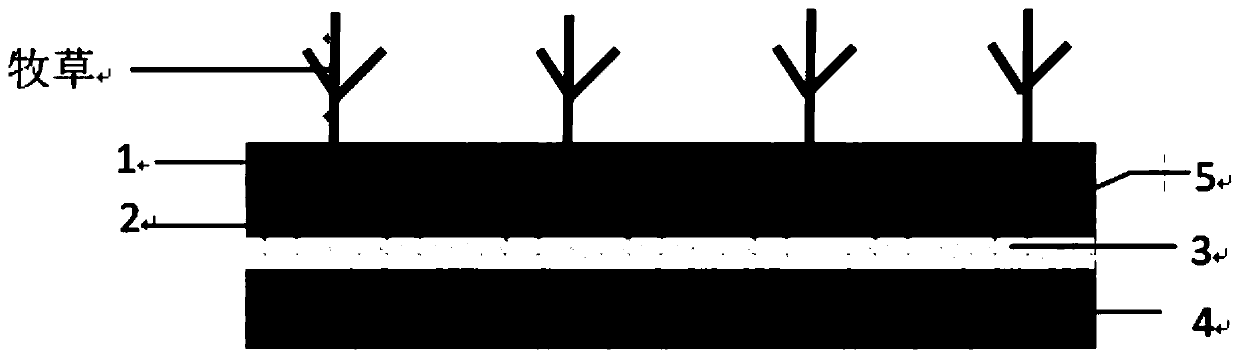

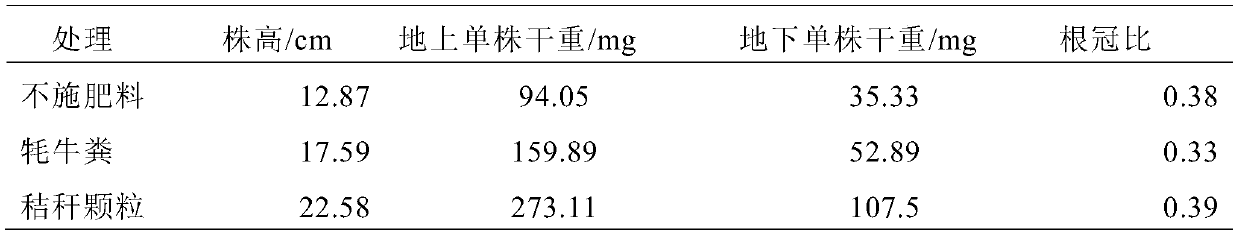

System and method for planting pasture grass in desertificated soil of alpine grassland

PendingCN110506467AImprove fertilityImprove physical and chemical propertiesSuperphosphatesHops/wine cultivationGrasslandFertility

The invention discloses a system and method for planting pasture grass in desertificated soil of alpine grassland. According to the system for planting the pasture grass in the desertificated soil ofthe alpine grassland, a pasture grass seeding row in the desertificated soil contains a first soil layer 1, a thin soil layer 2, a straw particle layer 3 and a second soil layer 4 from top to bottom from the earth's surface; the thin soil layer 2 is internally provided with a seeding layer 5; the pasture grass is planted in the seeding layer 5; the thickness of the first soil layer 1 is 9-11 centimeters; the thickness of the thin soil layer is 3-5 centimeters; the thickness of the straw particle layer is 2-3 centimeters; the straw particle layer is formed by gathering a large number of straw particle modifiers. The provided system and method solve the problems of the alpine grassland in northwestern Sichuan that the desertificated soil has poor fertility, water and fertilizers are leaked,organic materials are difficult to put, and seeds are wasted.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

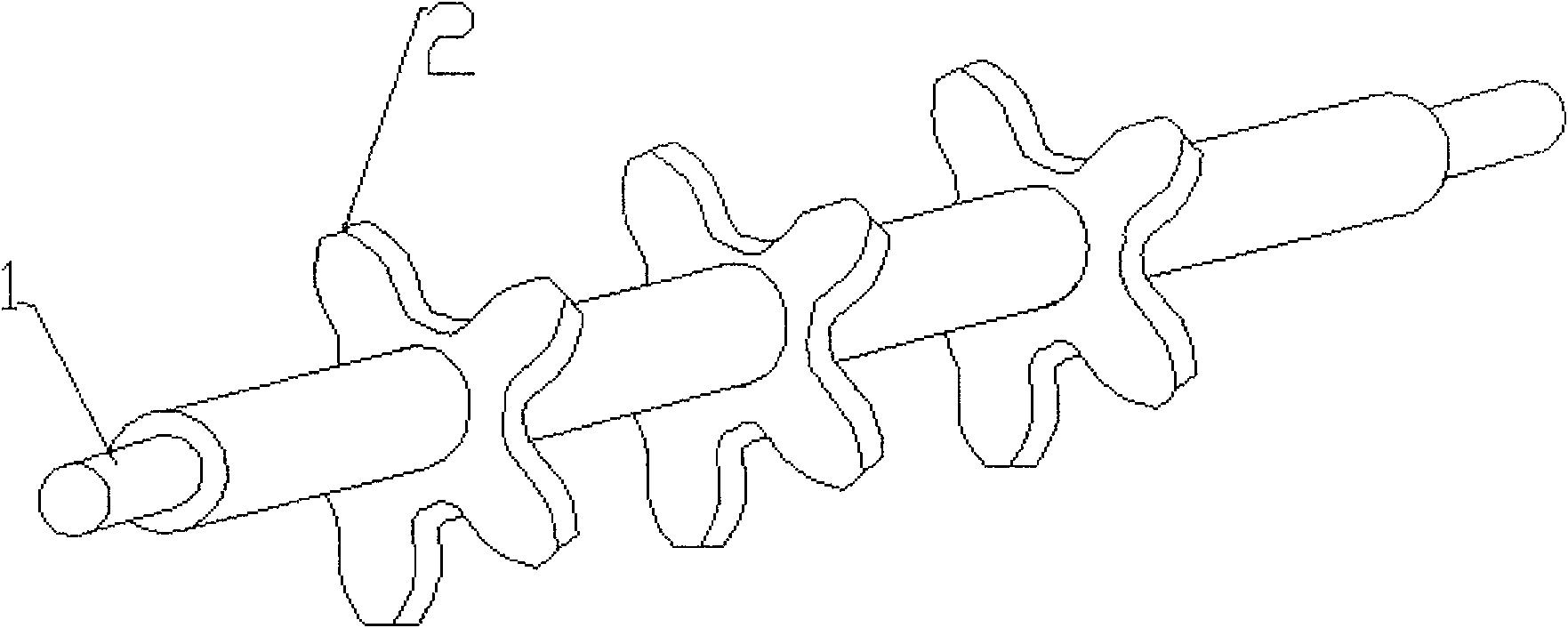

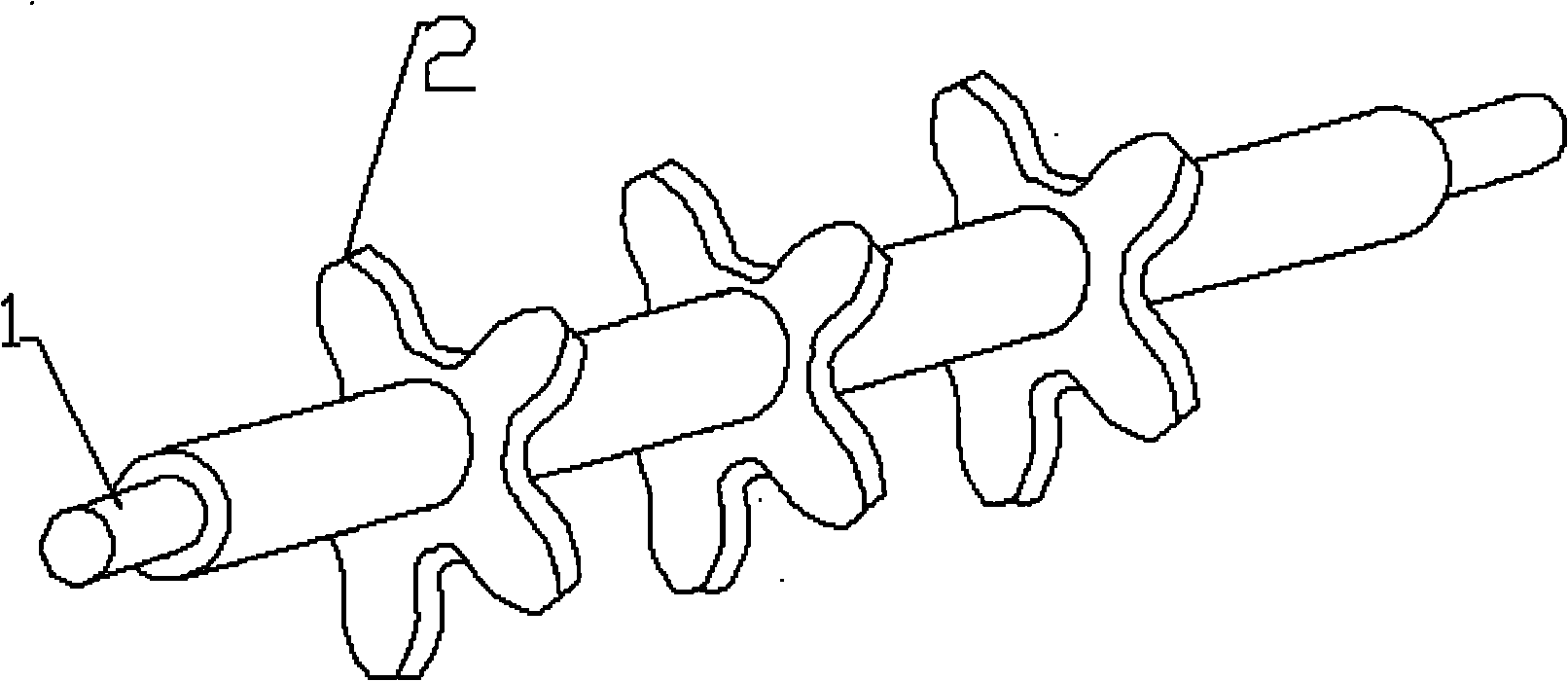

Stirring device for circular tube air-suction seeding unit

InactiveCN101766079AImprove liquidityImprove adsorption capacitySeed depositing seeder partsSingle grain seedersSeederAir volume

The invention relates to a main part of a seeder in agricultural machinery. Seeding quality depends on the seed charging rate of a seeding unit, and the seed charging rate of the circular tube air-suction seeding unit depends on the size of air volume and the fluidity of seeds. When the air volume is a fixed value, the fluidity of the seeds directly affects the seed charging rate. The invention provides a stirring device for the circular tube air-suction seeding unit, which can increase the fluidity of the seeds, increases the adsorption force of the seeding unit, and enhances the seed charging rate. The centered seed sucking seam on a shaft is provided with a stirring wheel, and the butt-seam installation of the stirring wheel can enhance the fluidity of the seeds in a seed charging area. The device is fixed on a seed box to continuously and smoothly work. One end of the shaft is provided with a gear wheel which is externally engaged with a gear wheel on a seeding unit, so that the stirring wheel is reversely rotated following the seeding unit.

Owner:HEBEI AGRICULTURAL UNIV.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com