Pneumatic precise seeder

A planter and precision technology, applied in the field of agricultural machinery, can solve the problems of high operating cost, inaccurate sowing acupoints, high precision requirements of parts, etc., and achieve the effect of reducing operating cost, improving seeding quality, and good moisture retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

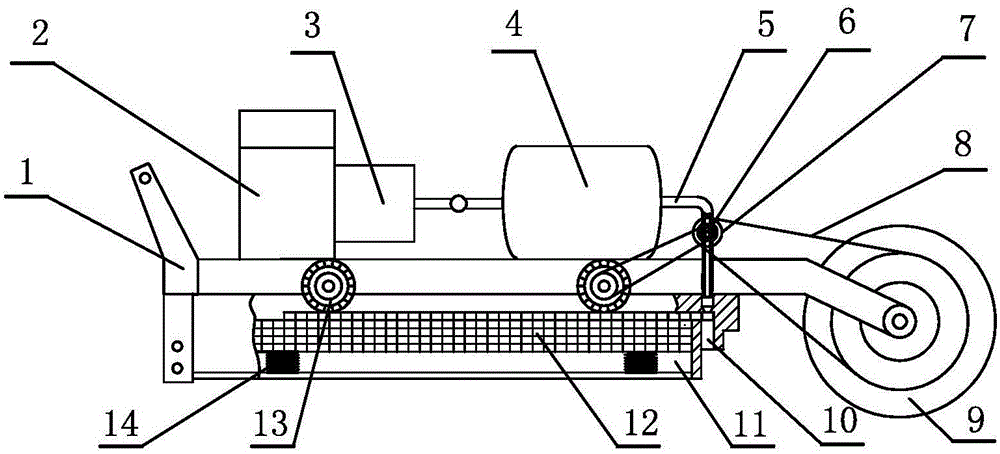

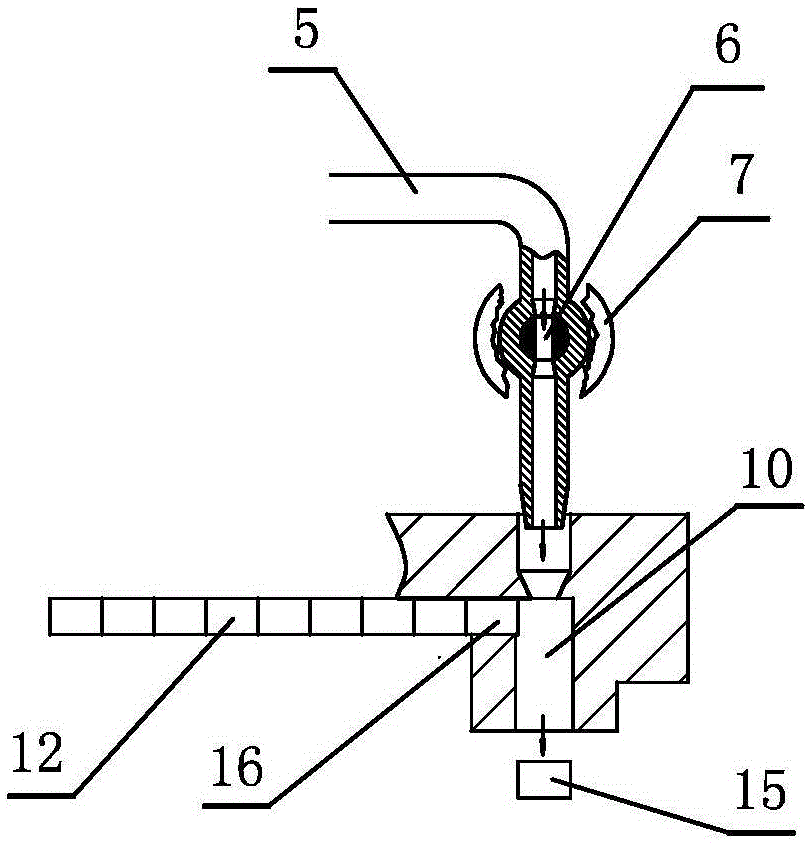

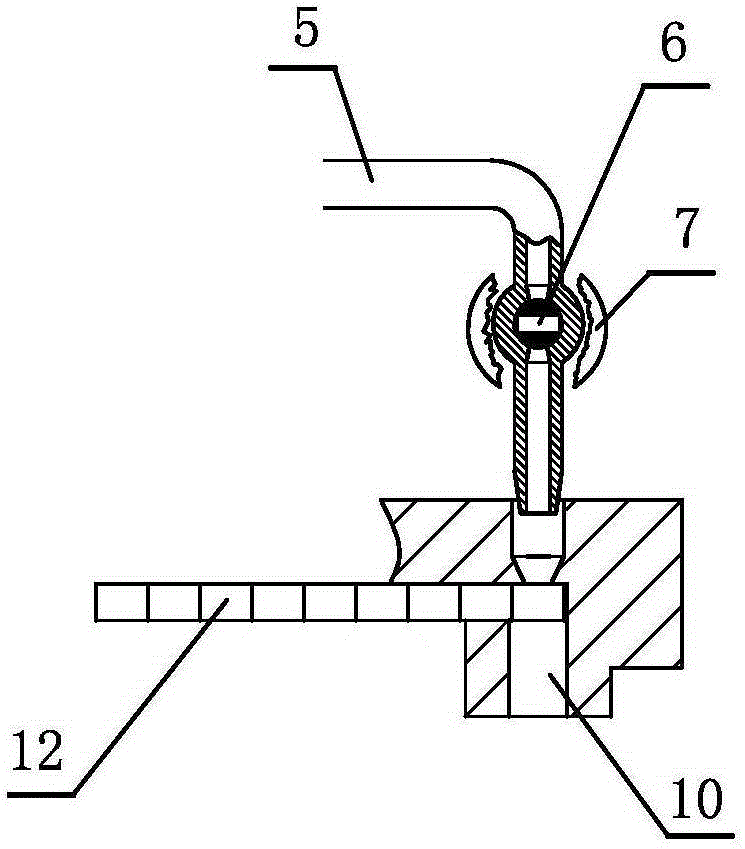

[0020] The general idea of the present invention is to learn from the structural principle of the nail gun, utilize high-pressure gas to shoot the seeds out, and complete the sowing operation. Two embodiments are described below in conjunction with the accompanying drawings around this idea.

[0021] The first embodiment: figure 1 A percussion-type precision seeder is introduced, which is characterized in that an airbag 4 that can be filled with high-pressure gas is provided on the frame 1, and an opening on one side of the airbag 4 is connected to an air injection pipe 5, and an on-off valve 6 is provided on the air injection pipe 5 , one end of the jet pipe 5 is opposite to the firing port 10, the frame 1 is provided with a seed box 11 and a seed injector for transporting seeds, and the seed port 16 of the seeds is opposite to the firing port 10.

[0022] The air bag 4 here can be inflated in advance, but preferably the front is provided with an air pump 3, and the air pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com