Anti-blockage corn no-tillage seeder

A seeder and functional technology, which is applied to fertilizers and seeding equipment, planting methods, agricultural gas emission reduction and other directions, can solve the problems of poor adaptability of straw mulching, lengthened longitudinal distance of seeders, and poor adaptability of anti-blocking devices, etc. The effect of plugging the planter, saving power, and good weeding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

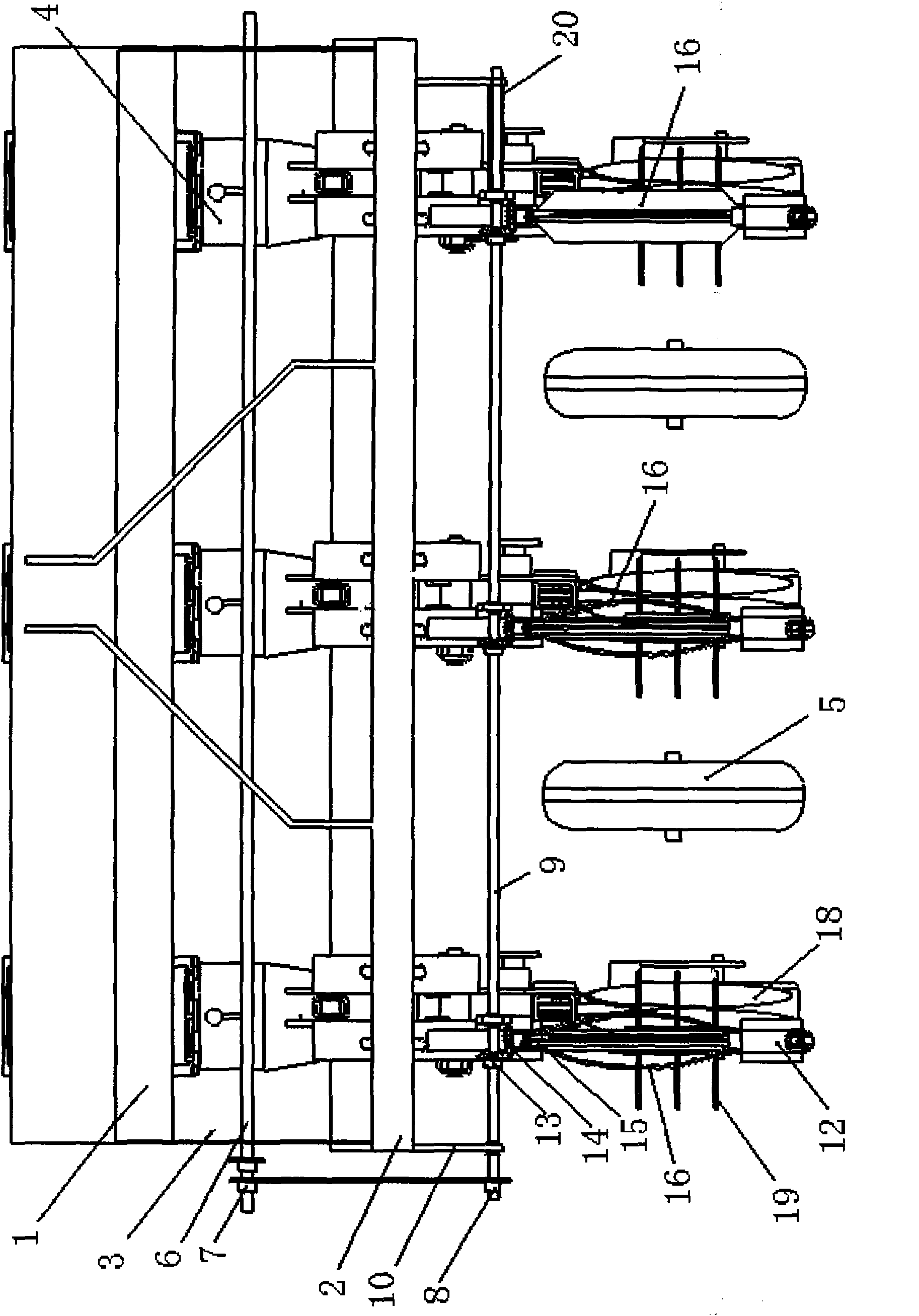

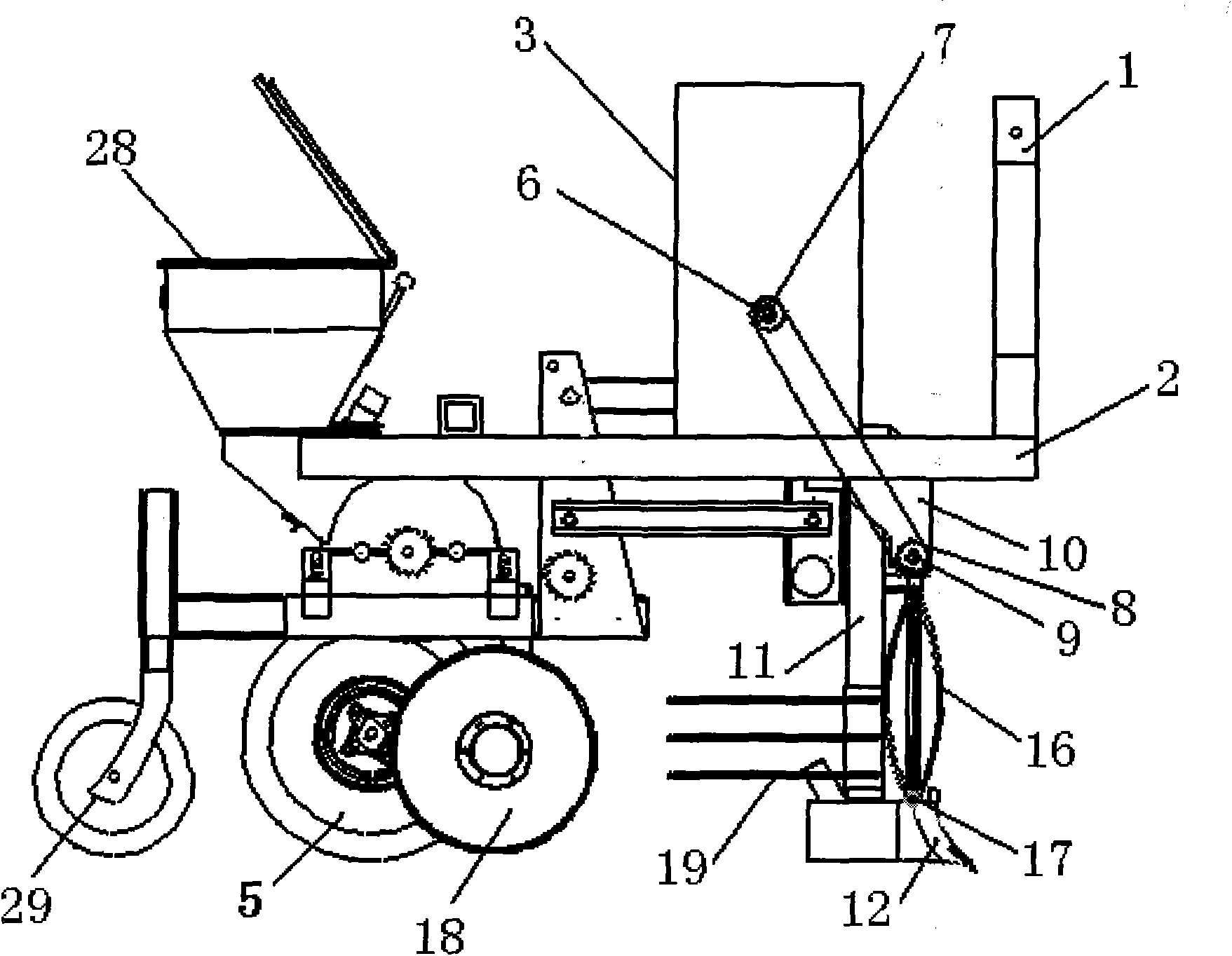

[0026] Such as figure 1 , figure 2 As shown, the present invention includes the no-tillage seeder 1 of the prior art, and the no-tillage seeder 1 is provided with an anti-blocking device. No-tillage seeder 1 comprises a frame 2 that is arranged in a conventional manner, and frame 2 is provided with a fertilizer box 3 and some no-tillage seeder units 4 arranged side by side, and each no-tillage unit 4 is provided with a Anti-blocking device. The no-tillage seeder 1 drives sowing through the ground wheel 5 arranged between the adjacent no-tillage planter units 4, and the ground wheel 5 is powered by a tractor (not shown) in front of it.

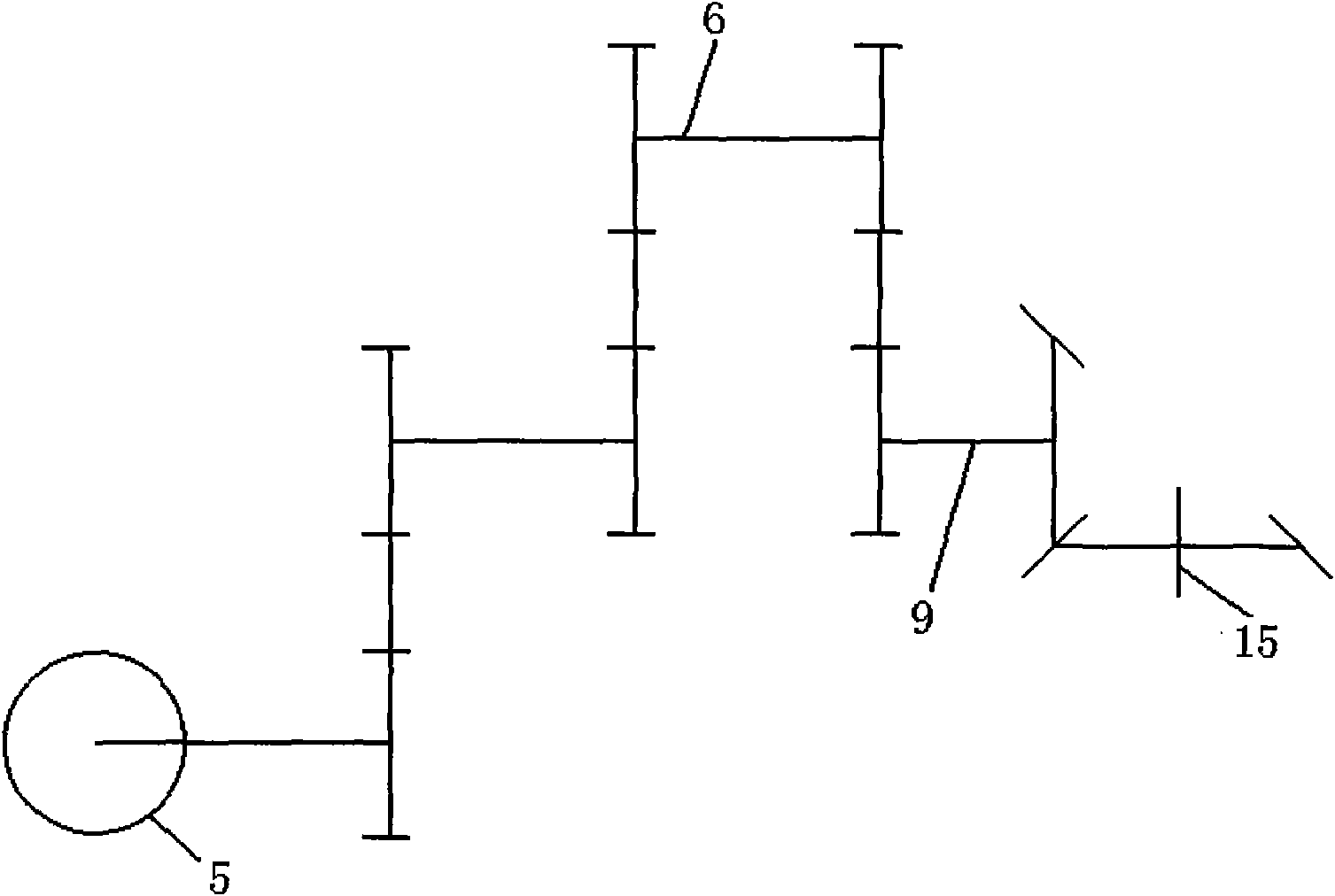

[0027] Such as Figure 1~3 As shown, the present invention includes a fertilizer discharge shaft 6 arranged on the fertilizer box 3, and the fertilizer discharge shaft 6 is connected to the ground wheel 5 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com