Crop seed rope direct sowing machine

A direct seeding machine and crop technology, applied in sowing, agriculture, agricultural gas emission reduction, etc., can solve problems such as difficult to control row spacing, plant spacing, unsuitable for large-scale operations, excessive dense planting and density, etc., to ensure the consistency of sowing depth , Improving the quality of sowing, and the effect of strict hole spacing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

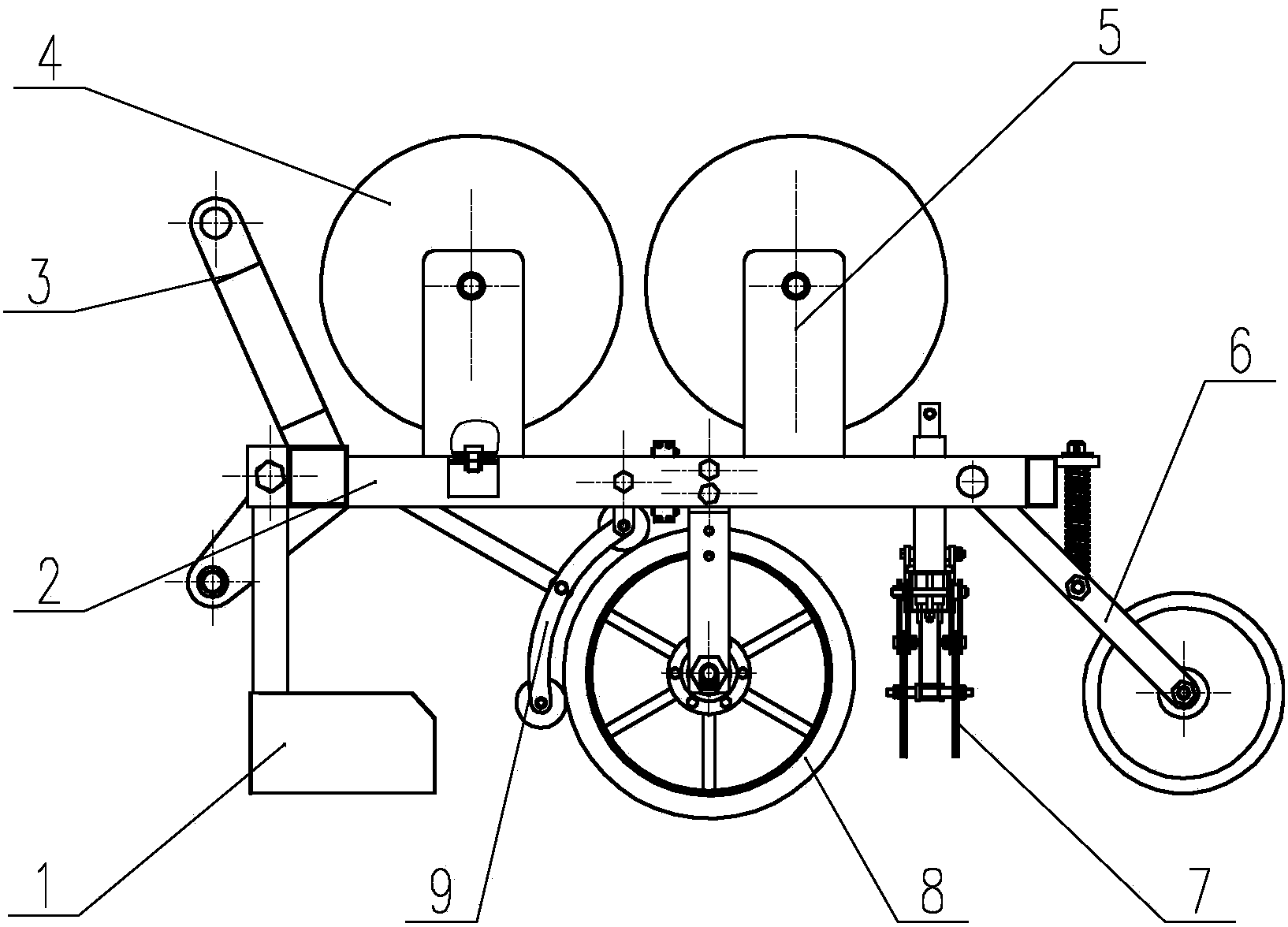

[0033] Embodiment 1: as figure 1 As shown, the present invention includes a frame 2, a kind of rope reel 4, an automatic rope release device 9, a ditching wheel 8 and a suppressing soil covering device 6, and the automatic rope releasing device 9, a ditching wheel 8 and a suppressing soil covering device 6 are sequentially Connected on the frame 2, the seeding rope reel 4 is fixed on the frame 2 through the seeding rope reel frame 5, and the end of the seeding rope 41 on it bypasses the groove wheel 8 through the automatic rope release device 9 and places it under the pressure of the groove wheel 8. When sowing, the frame 2 is connected to the tractor through the suspension frame 3, and the ditch wheel 8 and the suppressing soil covering device 6 are in contact with the field respectively; .

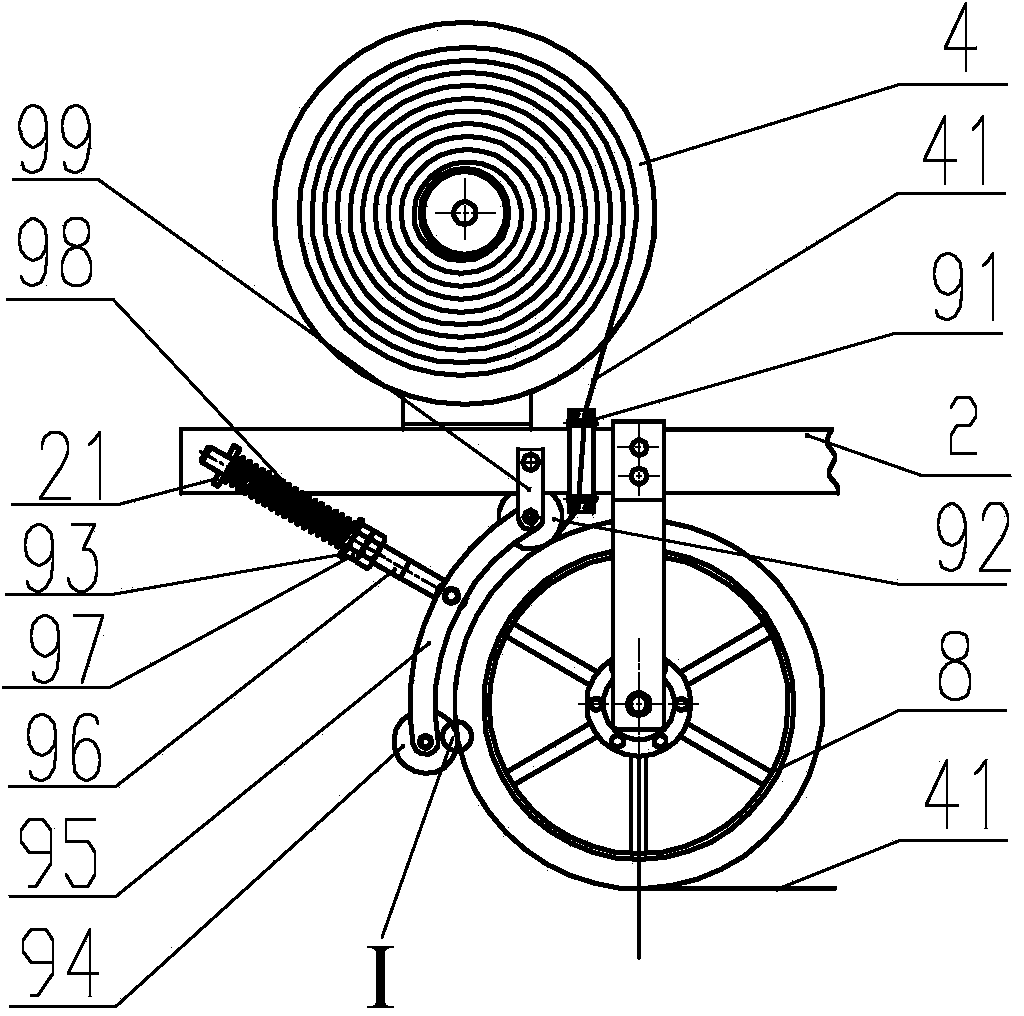

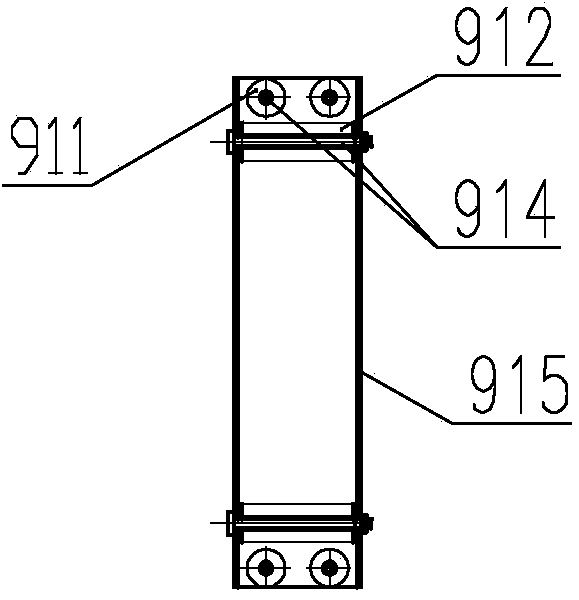

[0034] Such as figure 2 As shown, the automatic rope release device 9 includes a rope guide tube 91, a kind of rope reel 4, a groove wheel 8 and a rope pressing device, and the rope g...

Embodiment 2

[0038] Embodiment 2: The difference between this example and Embodiment 1 is that on the basis of Embodiment 1, this example is to realize the automatic cutting of the seed rope, and the groove wheel 8 on the frame 2 is connected with the soil covering device 6 There is a rope cutting device. Such as Figure 5 Shown, described kind of rope cutting device comprises fixed crossbeam 705, scissors drive crossbeam 708, drive bar 707, driving device, guiding device and multiple rows of scissors, described fixed crossbeam 705 is connected on the frame 2, fixed crossbeam 705 and scissors The driving beam 708 is connected by the driving rod 707, the guide device and the scissors. The scissors driving beam 708 is fixedly connected with the guide rod of the guiding device, or made into an integral form. Through the fixed beam 705, it is connected with the drag cable 709 of the driving device. The number of scissors is the same as that of the groove wheel 8, and they are respectively co...

Embodiment 3

[0043] Embodiment 3: the difference between this example and embodiment 2 is: this example is on the basis of embodiment 2, for leveling the ground surface, clearing stubble, and ensuring the quality of sowing, and the frame 2 at the connecting end of the suspension frame 3 is also connected There is a leveling shovel 1.

[0044] The usage method of the present invention:

[0045] The rope sowing planting technology divides the sowing operation of crops into two steps: the first step is to use the rope twisting equipment to roll the seeds, fertilizers and herbicides in the non-woven paper tape in the factory according to the requirements of agricultural technology. In the second step, go to the field and use the rope seeding machine to only open the ditch, put the seed rope and cover the soil to complete the field sowing operation.

[0046] During the work of the present invention, the live broadcast machine is articulated with the tractor through the suspension frame 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com