Hand rope release mechanism and hand rope release method

A handle and adjustment mechanism technology, which is applied in the direction of container manufacturing machinery, paper/cardboard containers, box production operations, etc., can solve the problems of poor accuracy of the end of the handle rope, large distance error of the handle rope, and large error of the length of the handle rope and other problems, to achieve the effect of high production efficiency, good automation and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

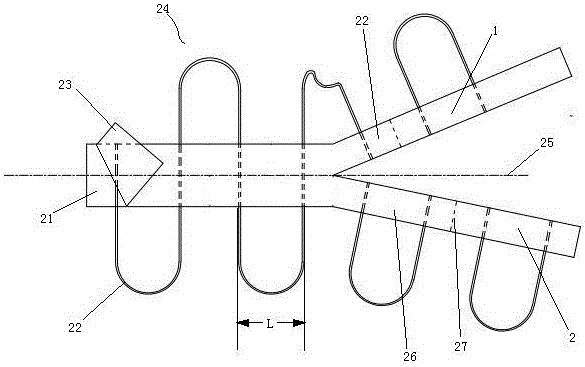

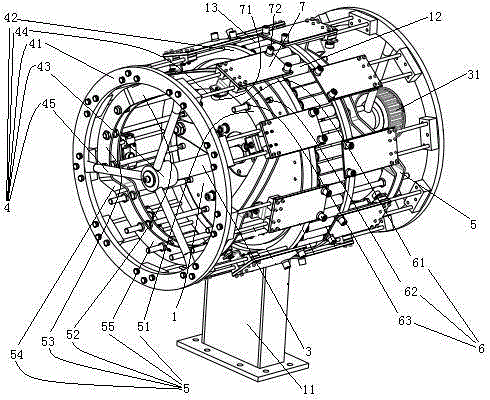

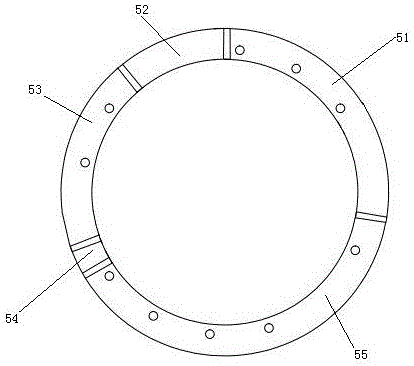

[0025] Embodiment one, see figure 1 , a handle rope release mechanism, characterized in that it includes a seat 1. The seat 1 is disc-shaped. The seat is designed to be disc-shaped, and any part of the peripheral surface of the seat can be used as a support surface for the handle rope, so that the positioning guide groove and the butt joint with the fitting structure are convenient. The seat 1 is provided with supporting feet 11 . A portion of the peripheral surface of the seat 1 constitutes a handle cord supporting surface 13 . Several drag-reducing rollers 12 are arranged on the peripheral surface of the seat 1 , and the drag-reducing rollers 12 are distributed along the circumferential direction of the seat 1 . The drag reducing roller 12 extends along the axial direction of the seat 1 .

[0026]A rotating shaft 3 is rotatably connected to the fixed seat 1 . The rotating shaft 3 runs through the fixed seat 1 and is coaxial with the fixed seat 1 . A transmission wheel ...

Embodiment 2

[0033] Embodiment 2, the difference from Embodiment 1 is that the guide groove is not provided with the hook head detachment guide section and the hook rope plate avoidance section, and an inlet is provided at the entrance end of the hook rope preparation section, so that the slider can be accurately Enter the hook rope preparation section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com