Automatic rope release device for direct seeding machine

A technology of automatic rope release and direct seeding machine, which is applied in the direction of sowing, application, and seed treatment methods, and can solve problems such as difficult control of row spacing, plant spacing, inability to guarantee the quality of seedling emergence, and excessive density of planting, so as to ensure the consistency of sowing depth , Improve the quality of sowing, the effect of high seed prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

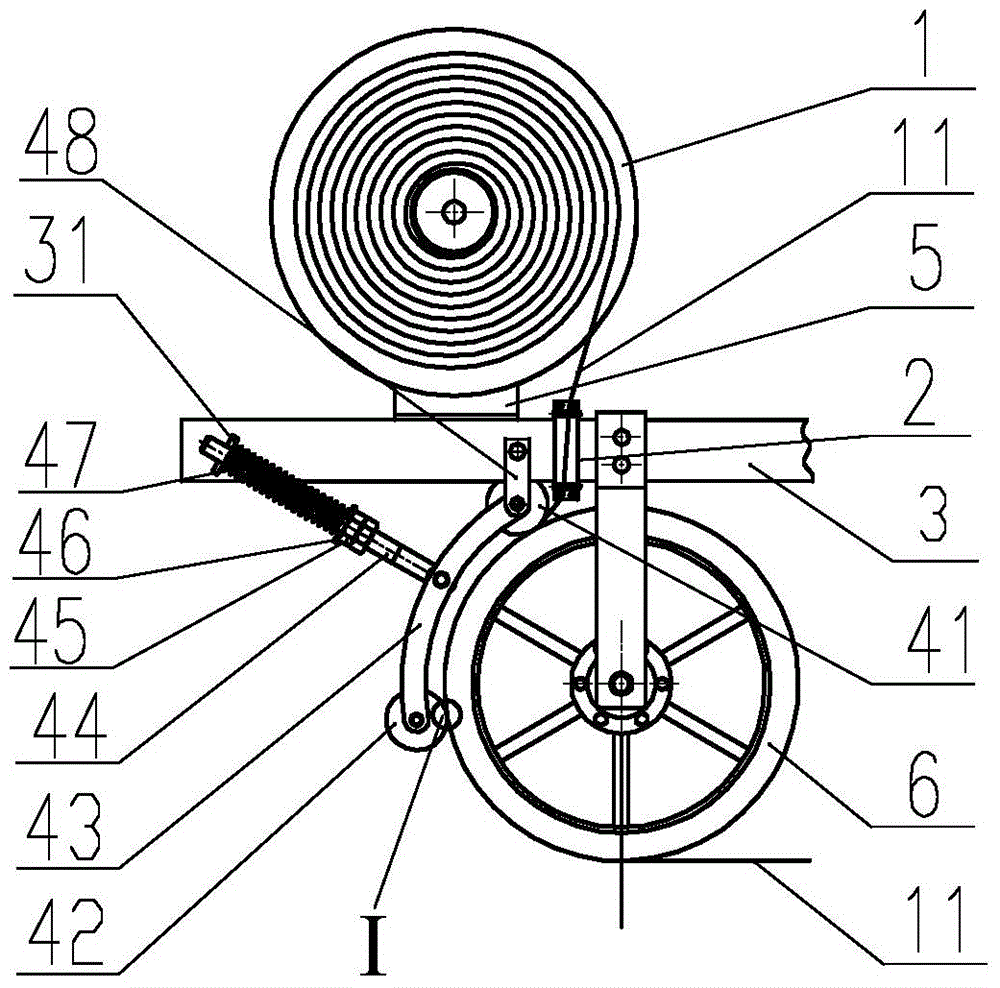

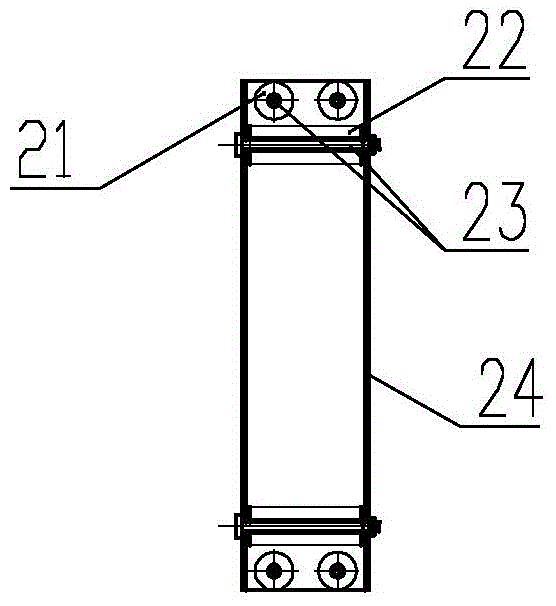

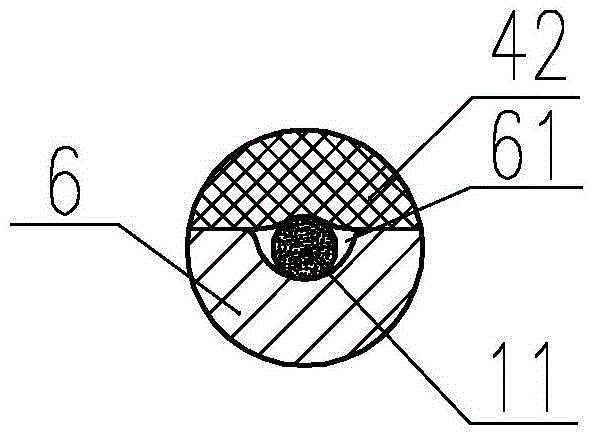

[0021] Example: such as figure 1 As shown, the present invention includes a rope guide tube 2, a seed rope reel 1, a ditch pressing wheel 6 and a rope pressing device. The rope guide tube 2 is fixed on the frame 3 on the lower side of the seed rope reel 1 and the ditch pressure wheel 6 Above, one end of the rope pressing device is connected to the frame 3, and the other end is pressed on the ditch pressing wheel 6. The end of the seed rope 11 of the seed rope reel 1 passes through the rope guide 2 and passes between the two rope pressure wheels and the groove pressure wheel 6 of the rope pressing device. The two pressure rope wheels rotate with the pressure groove wheel 6 under the action of friction. The rope pressing wheel and the ditch pressing wheel 6 can clamp and compress the seed rope 11 and roll forward with the ditch pressing wheel 6, so that the seed rope 11 is pressed into the seed groove.

[0022] Such as figure 1 As shown, the rope pressing device includes a pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com