A semi-automatic production device for oyster culture skewers

A semi-automated, production device technology, applied in fish farming, climate change adaptation, applications, etc., can solve the problems that restrict the sustainable development of the oyster farming industry, such as scarcity, to achieve a clear control circuit connection relationship, meet control needs, and control way simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

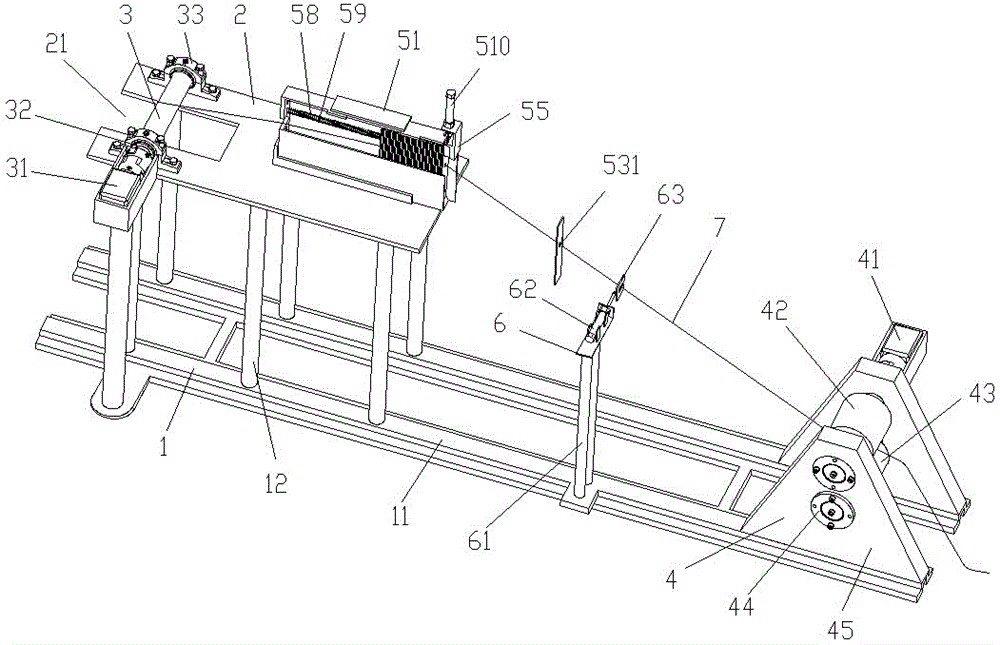

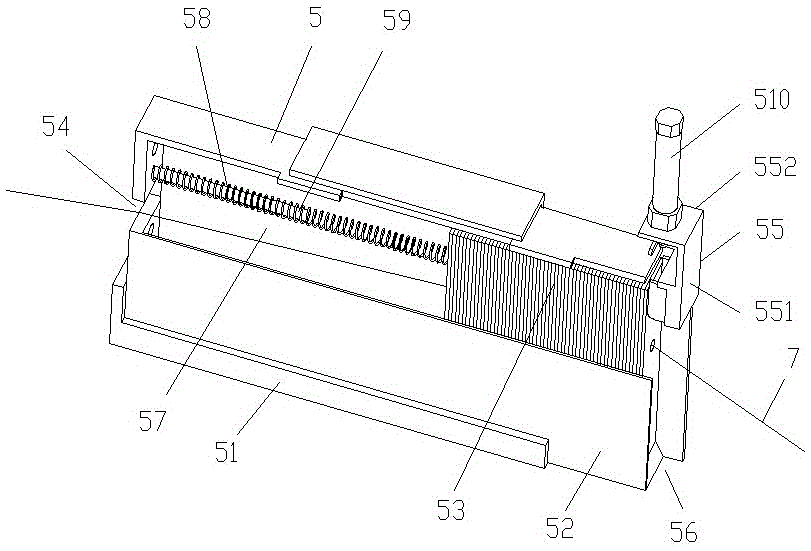

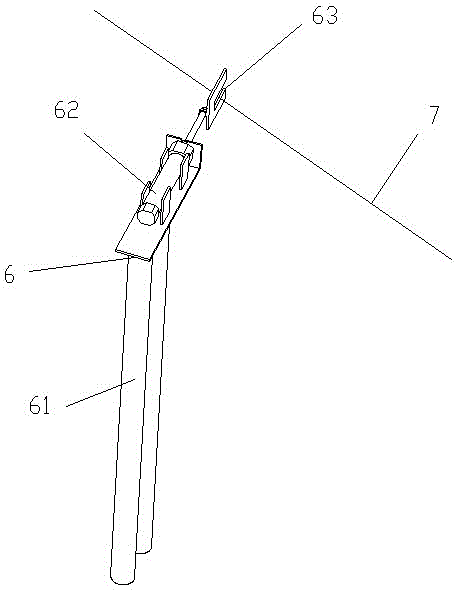

[0022] Such as Figure 1~5 As shown, a semi-automatic production device for oyster culture strings includes a vertically arranged slope-shaped support frame 1. The rope shaft 3, the operating table 2 is provided with a groove 21 around the bottom of the rope shaft 3, which is convenient for taking and placing the polyethylene rope 7, and at least a pair of rope receiving wheel groups 4 are arranged at the bottom of the slope-shaped support frame 1 , the operating table 2 is provided with a seedling-attached sheet output structure 5 between the rope winding shaft 3 and the rope receiving wheel group 4, and the slope-shaped support frame 1 is vertically positioned between the operating table 2 and the rope receiving wheel group 4 A positioning structure 6 for easy knotting is provided, one end of the polyethylene rope 7 is wound on the rope winding shaft 3, and the other end of the polyethylene rope 7 runs through the attached seedling sheet output structure 5, the positioning s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com