Patents

Literature

72results about How to "Guarantee the quality of sowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

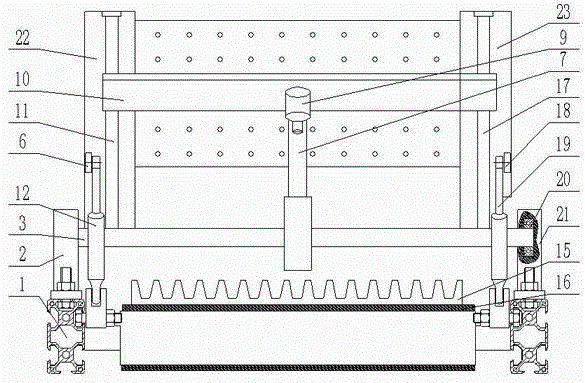

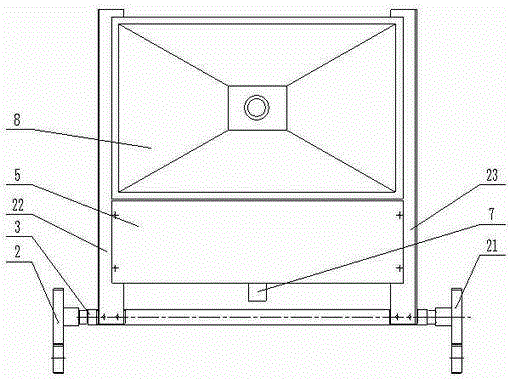

Air suction plate type seeder

InactiveCN103141191ASmooth motionImprove adsorption capacitySeed depositing seeder partsRegular seed deposition machinesEngineeringSmall particles

The invention discloses an air suction plate type seeder. The air suction plate type seeder mainly comprises a rack, a seed suction plate, a seed box, a guide rod, a pneumatic vibrator, a rotating shaft, an air cylinder I, and an air cylinder II. The pneumatic vibrator is arranged on the seed box; the seed box is driven by the air cylinder I to move up and down along the guide rod; and the seed suction plate is driven by the air cylinder II to turn over. The seeder can be used for air suction type precise seeding of small-particle seeds, the seed suction plate moves steadily, and the seed falling caused by shock vibration can be avoided, so that the miss-seeding rate can be reduced and the seedling cultivation cost is lowered.

Owner:JIANGSU UNIV

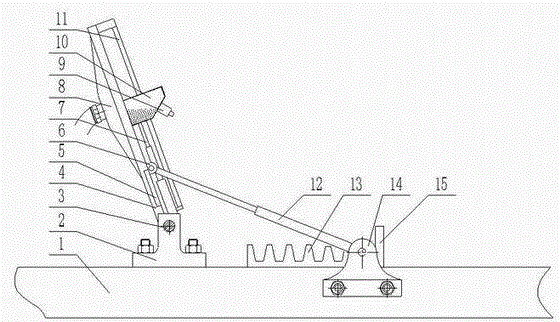

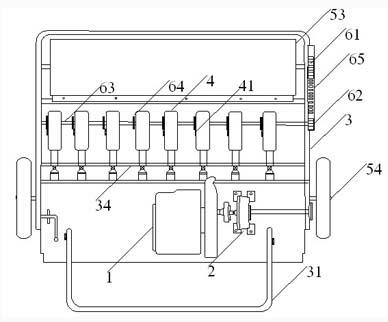

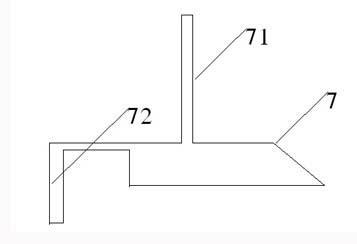

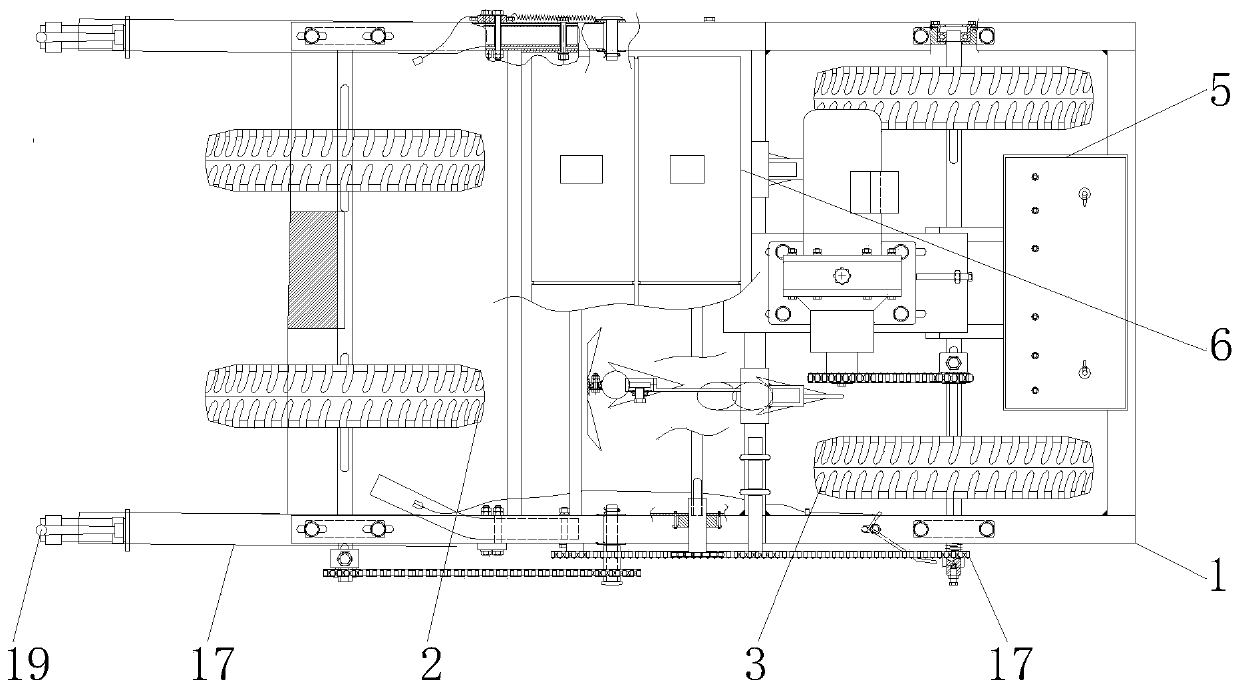

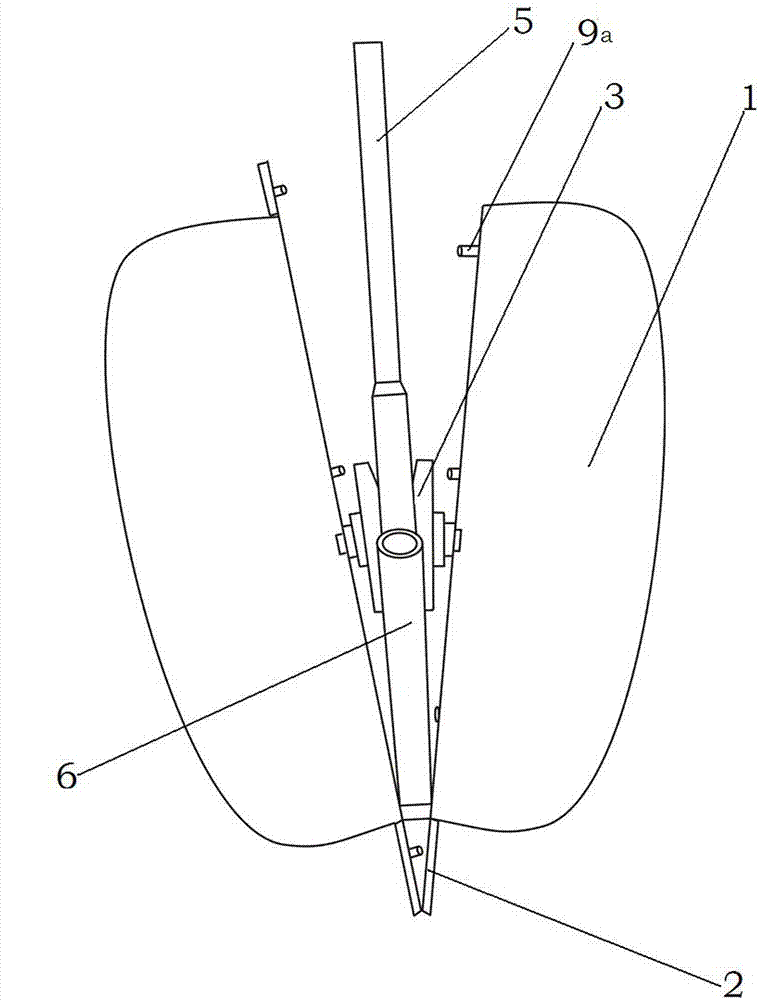

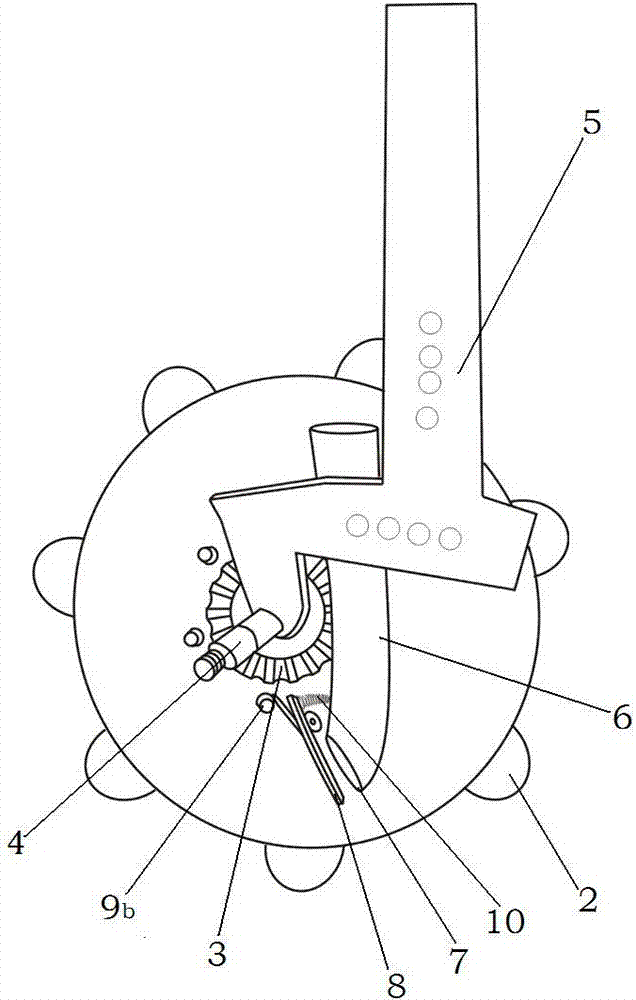

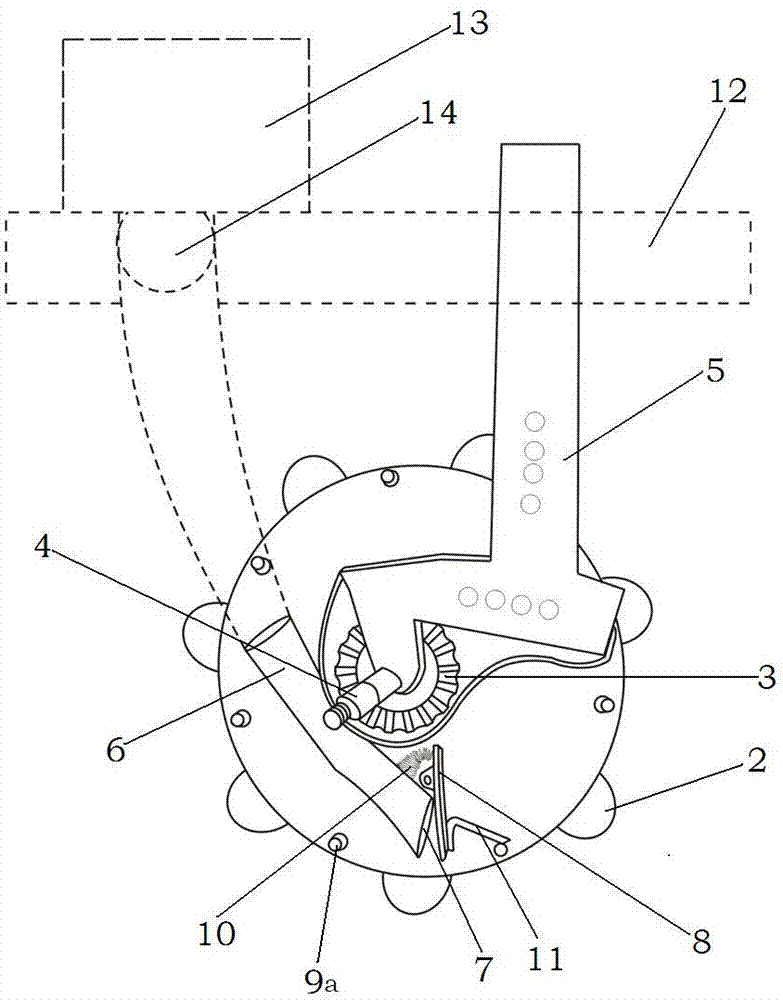

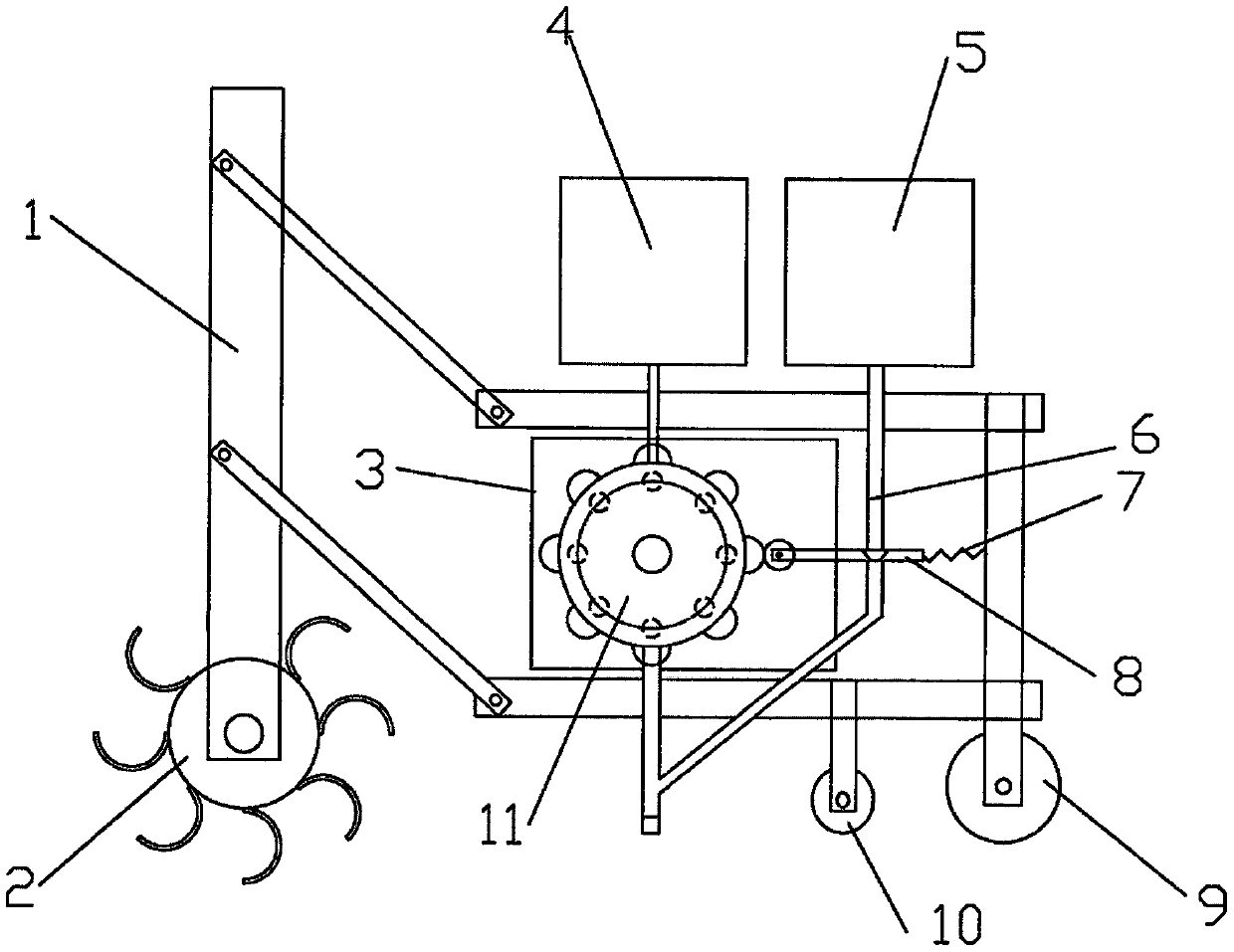

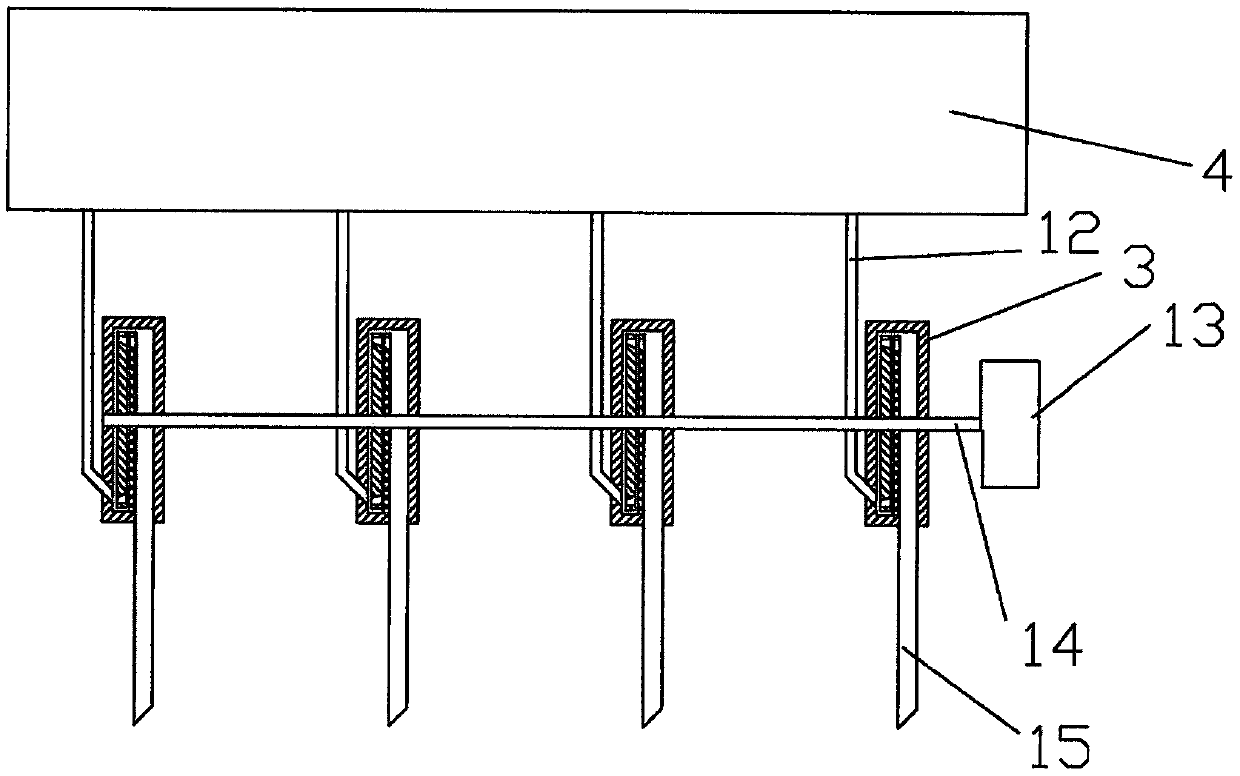

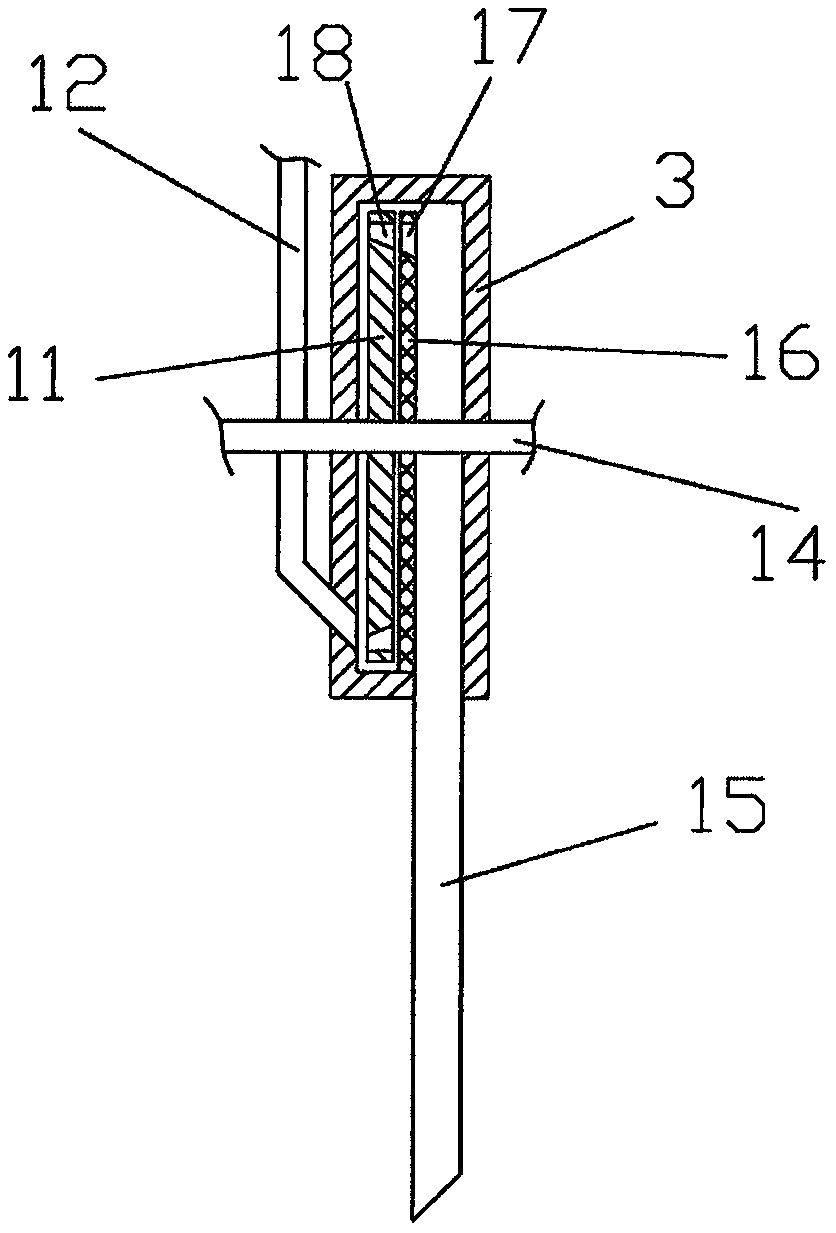

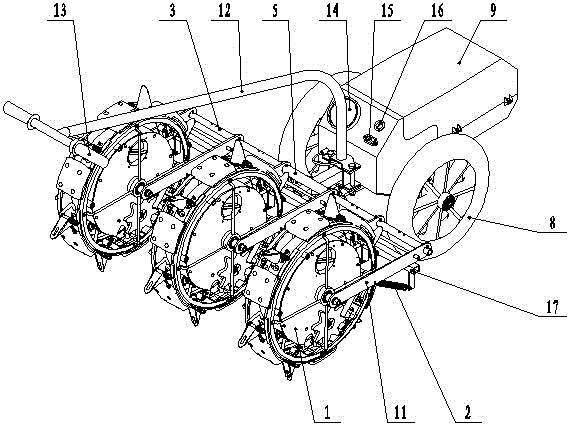

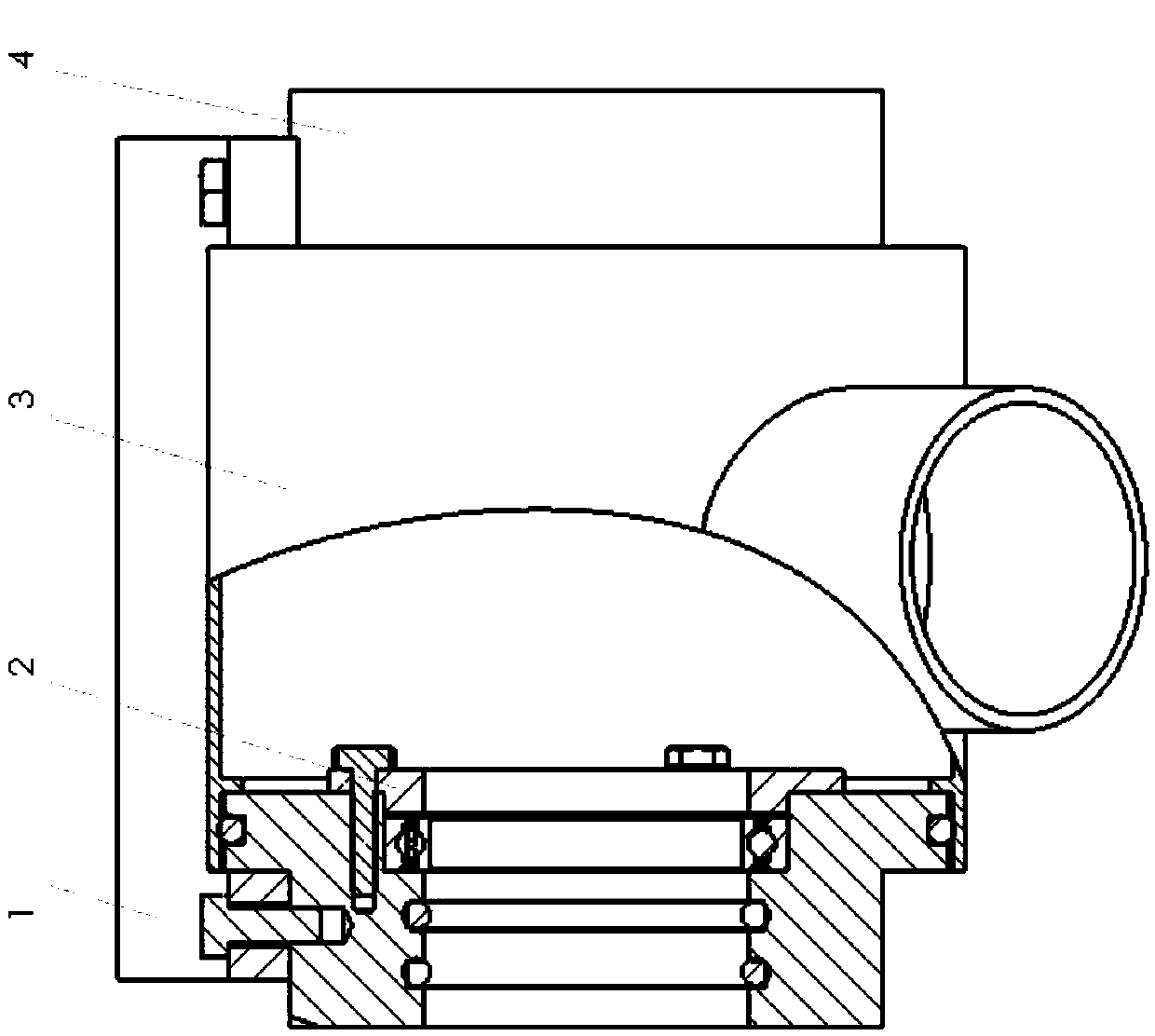

Minimal-tillage and sub-soiling precise wheat tiller

InactiveCN102656969AImprove adhesionGuarantee the quality of sowingSpadesPloughsAgricultural engineeringShovel

The invention discloses a minimal-tillage and sub-soiling precise wheat tiller, comprising a suspension support, wherein a gearbox and a rotary tillage cutter are installed on the suspension support, and the rotary tillage cutter is located below the suspension support; an output shaft of the gearbox is connected with a shaft of the rotary tillage cutter via a transmission mechanism; a transmission shaft is installed on the output shaft of the gearbox, an eccentric bearing is installed on the transmission shaft, and a connection rod sleeve is installed at the periphery of the eccentric bearing; a connection rod is installed on the connection rod sleeve, a swing arm is installed on the suspension support, and the swing arm is hinged with the suspension support via a swing arm shaft; one end of the swing arm is hinged with the connection rod, and a break shovel is installed at the other end of the swing arm; and the break shovel is located below the suspension support and behind the rotary tillage cutter. The minimal-tillage and sub-soiling precise wheat tiller is installed with the break shovel, and can realize a deep soil breaking operation via the swing of the break shovel, thus solving the problem existing in the prior art.

Owner:窦乐智

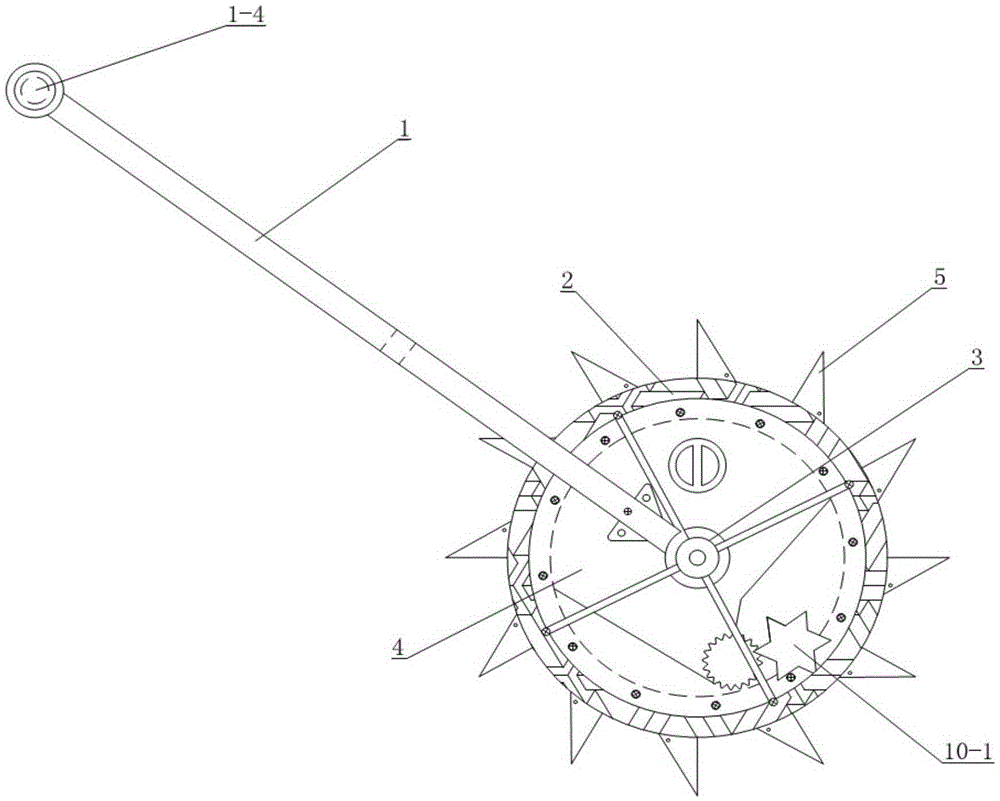

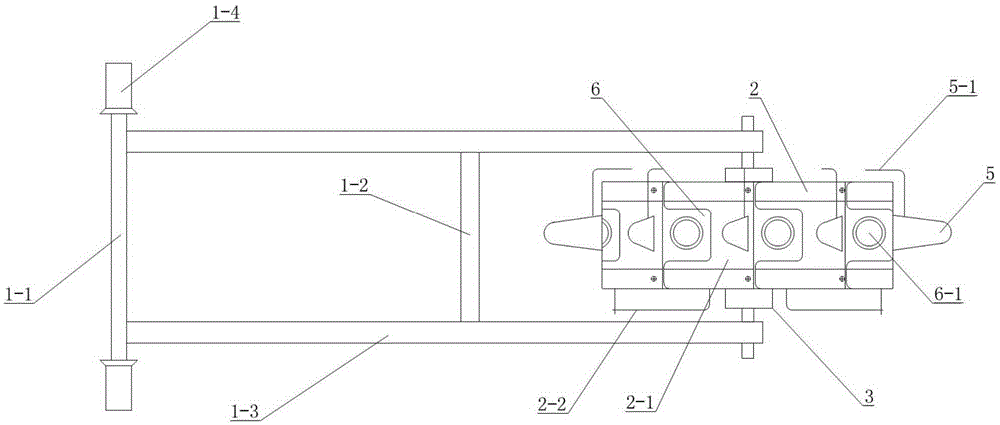

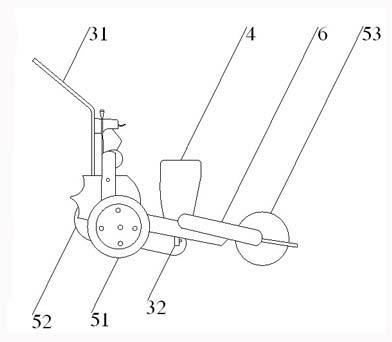

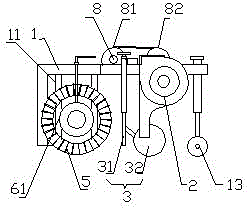

Hand-push type single grain corn planter

ActiveCN105210505AAvoid cloggingTimely spittingSeed depositing seeder partsSingle grain seedersEngineeringCochlea

Owner:CHANGZHOU UNIV

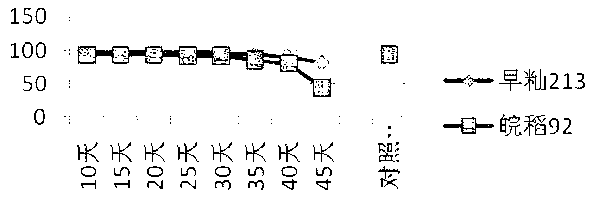

Paddy rice seed pregermination method

InactiveCN103004321APass smoothlyImprove sowing qualitySeed and root treatmentAgricultural scienceGermination

The invention discloses a paddy rice seed pregermination method. When radical buds of paddy rice grow up to a specified standard, a physical method is used to control the growth of the radical buds, thereby widening the optimal period of seeding, so that the aims of labor conservation, cost conservation, effect enhancement and labor intensity relief are achieved. Compared with the traditional paddy rice pregermination seeding, the method can improve the seeding quality remarkably, and in particular to applying the method to mechanized direct seeding of paddy rice, the resistance of the machinery transmission of the seeds can be reduced obviously, so that the sprouts can pass through a seed passage smoothly and the seeding quality is guaranteed; when the paddy rice seed sprouts are prepared, the 'seed soaking-germination accelerating' process does not need to be repeated everyday; and the method has the characteristics of simplicity, convenience, easiness for mastering the technology and the like, and can be widely applied to paddy rice cultivation.

Owner:程太平

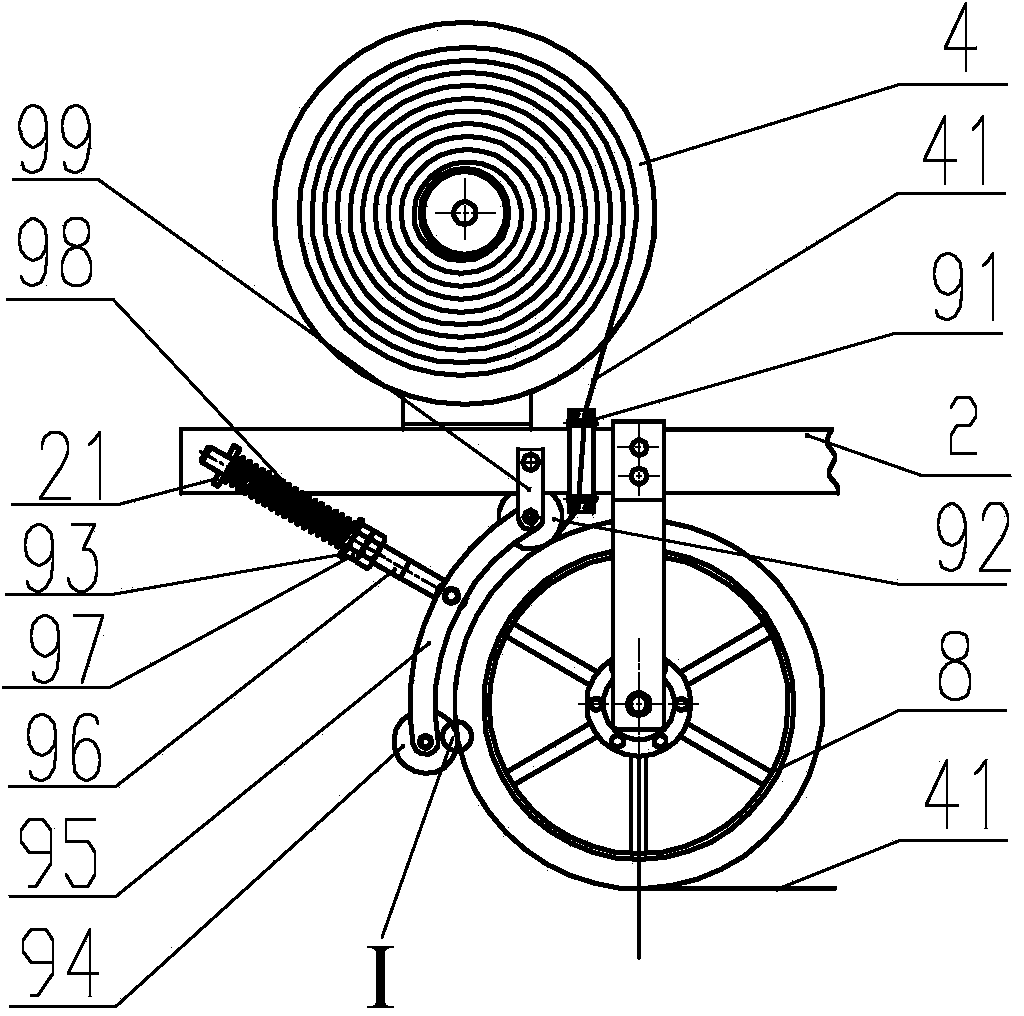

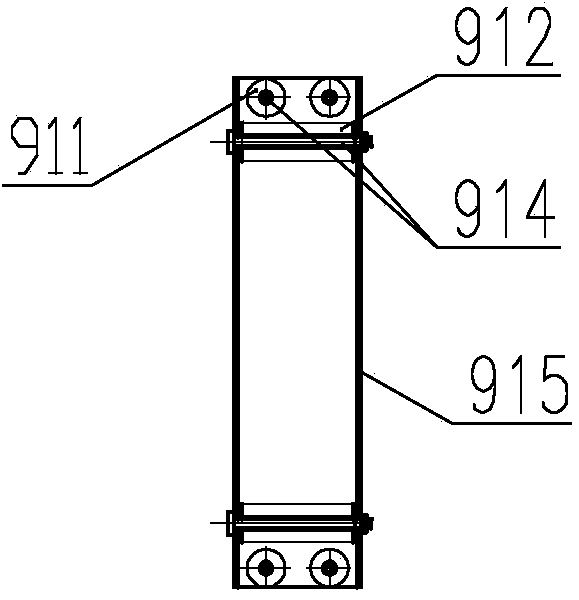

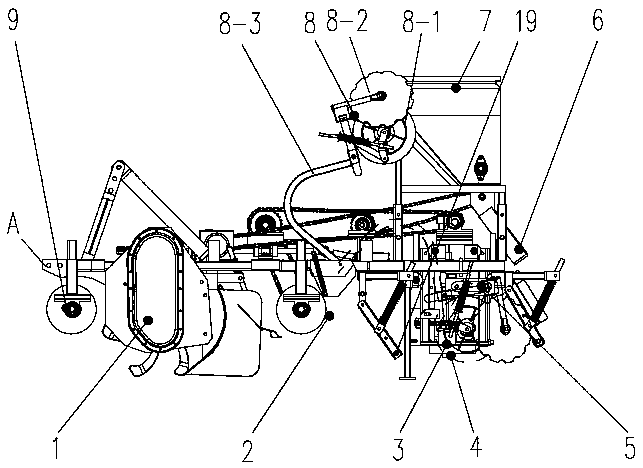

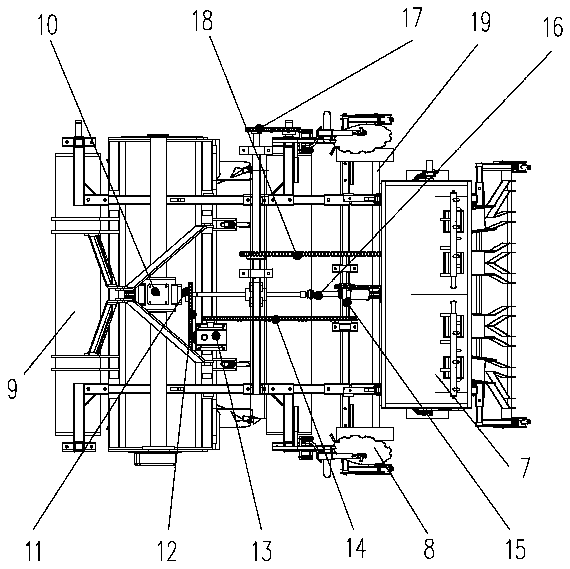

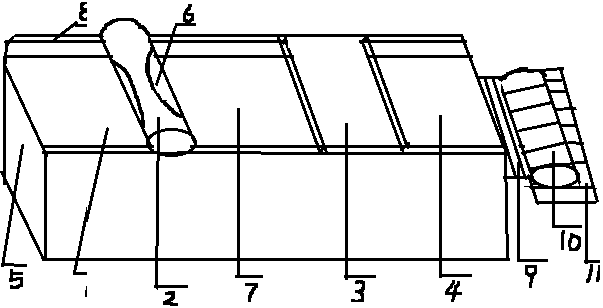

Crop seed rope direct sowing machine

ActiveCN103858566ASolve the problem of manual rope release and pressureRealize automatic rope releaseSowingAgriculture gas emission reductionAgricultural engineeringSowing

The invention relates to a crop seed rope direct sowing machine, belonging to the technical field of an agricultural sowing machine. The crop seed rope direct sowing machine comprises a stand, a seed rope coil, an automatic rope releasing device, a furrow pressing wheel and a compacting soil covering device, wherein the automatic rope releasing device, the furrow pressing wheel and the compacting soil covering device are sequentially connected with the stand; the seed rope coil is arranged on the stand; a seed rope end on the seed rope coil comes round the furrow pressing wheel by the automatic rope releasing device and is arranged in a seed furrow formed by the furrow pressing wheel; when seeds are sown, the stand is connected with a tractor by a suspension bracket, and the furrow pressing wheel and the compacting soil covering device are respectively contacted with the field; the compacting soil covering device is used for compacting the seed furrow so as to cover soil on the seed rope and compact. The crop seed rope direct sowing machine is provided with the automatic rope releasing device, so that the problem of manually releasing and pressing the rope at the edge of the field can be solved, and the degree of automation is improved. The crop seed rope direct sowing machine is provided with a seed rope shearing device, so that the problem of manually shearing the rope at edge of the field can be solved, and the degree of automation is improved. The crop seed rope direct sowing machine is provided with a flattening shovel which is used for flattening the surface of the ground, cleaning stubbles and the like, so that the sowing quality is guaranteed.

Owner:SHENYANG AGRI UNIV

Articulated multifunctional celery planting integrated machine

ActiveCN105325083AReduce extrusion deformationAvoid deformationSpadesPlantingAgricultural engineeringAgricultural machinery

The invention relates to an articulated multifunctional celery planting integrated machine, which belongs to the technical field of agricultural machinery. A compaction wheel, a rotary-tillage ridging device, a film mulching device, a land wheel, a perforating device and a seed discharge device are arranged on an articulation frame of the machine from front to rear, the perforating device comprises a liftable film-pressing plate driven by a lifting drive device, a sponge mat is attached to the lower surface of the film-pressing plate, perforated holes are distributed at certain interval on the film-pressing plate in a direction perpendicular to the forward direction of the articulation frame, a rotatable circular-tube perforating tool of which the lower end is provided with a cutting edge is inserted in each perforated hole, the upper end of the circular-tube perforating tool is coaxially connected with a chain wheel driven by a transmission chain, and the chain is in transmission connection with an output shaft of a gearbox fixedly connected on the film-pressing plate. According to the invention, regular circular holes can be cut on a film, so that the deformation of the film is completely avoided; and the perforated holes are completely consistent in depth.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

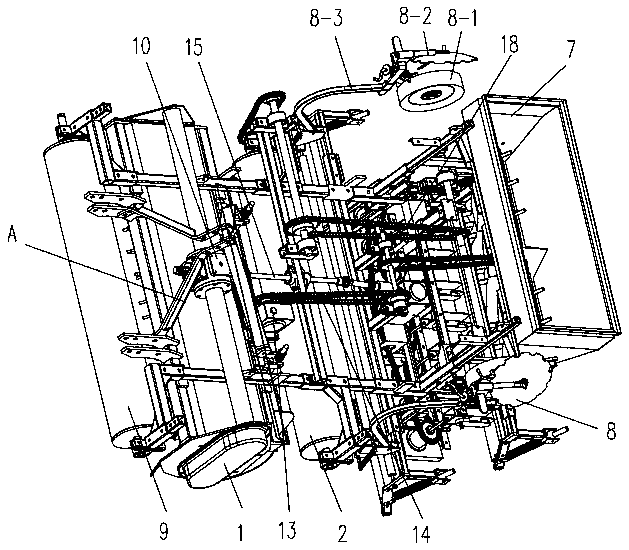

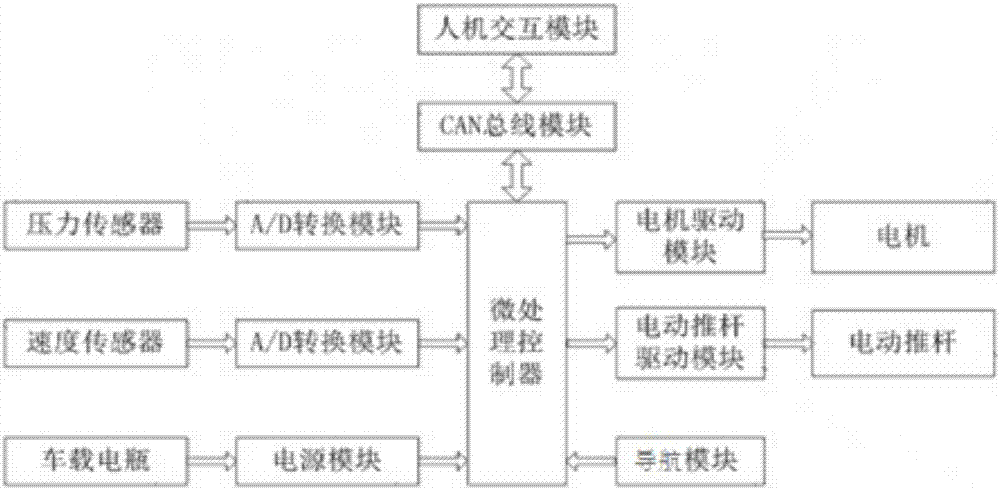

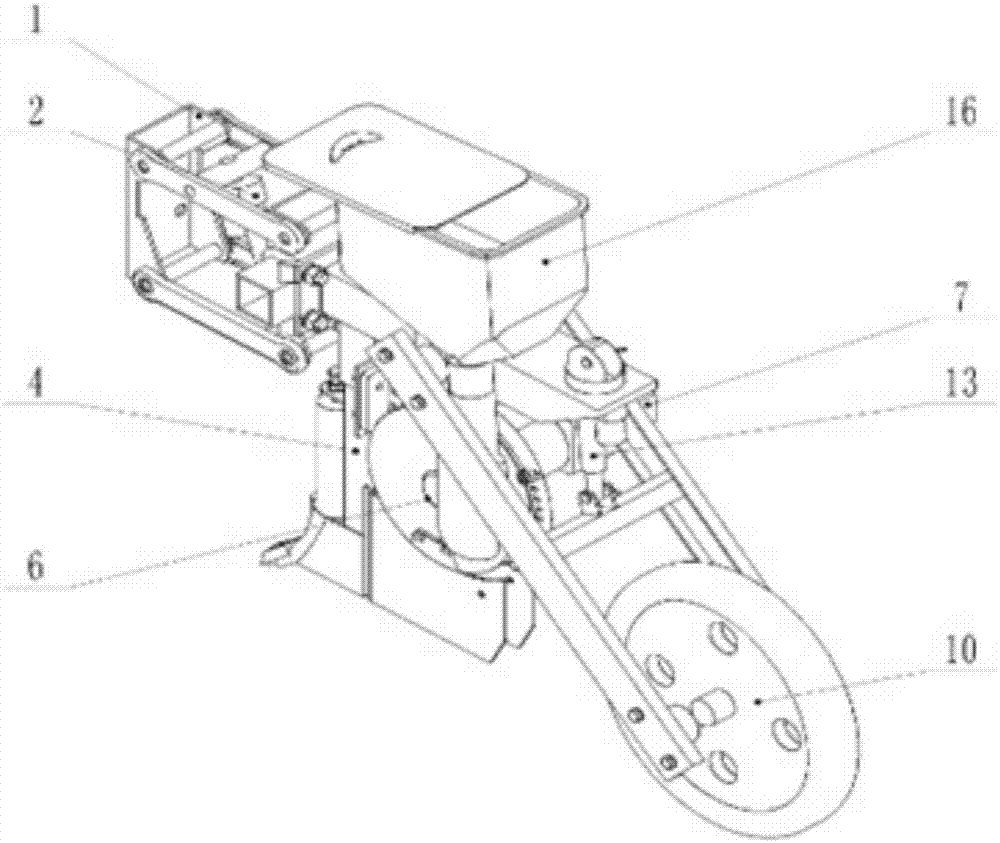

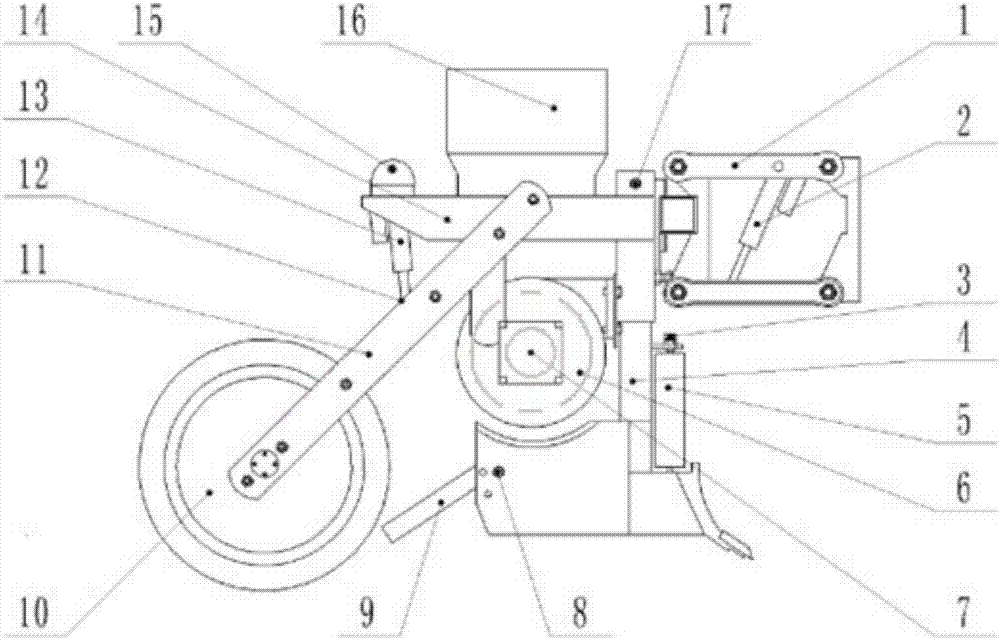

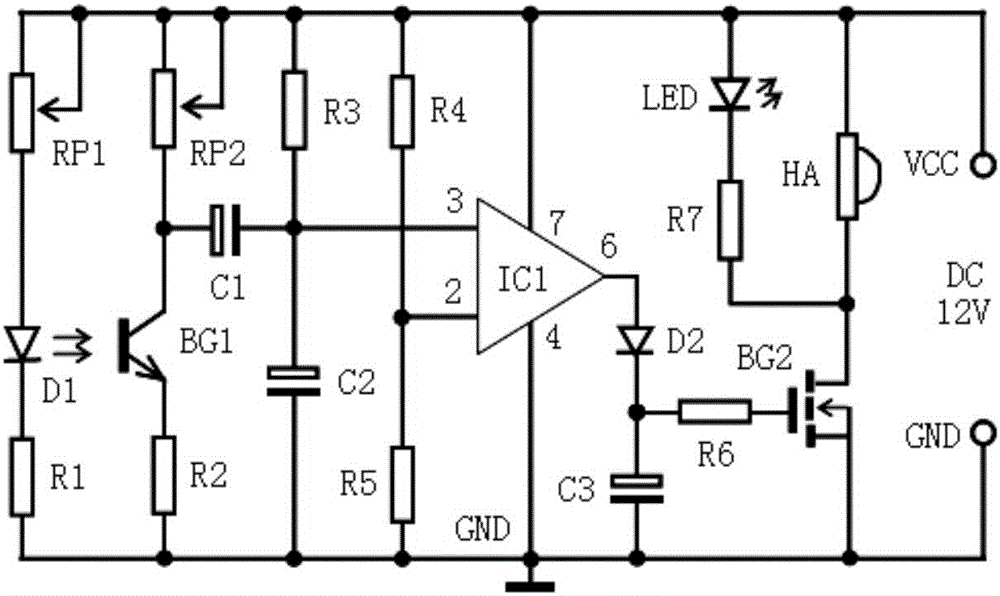

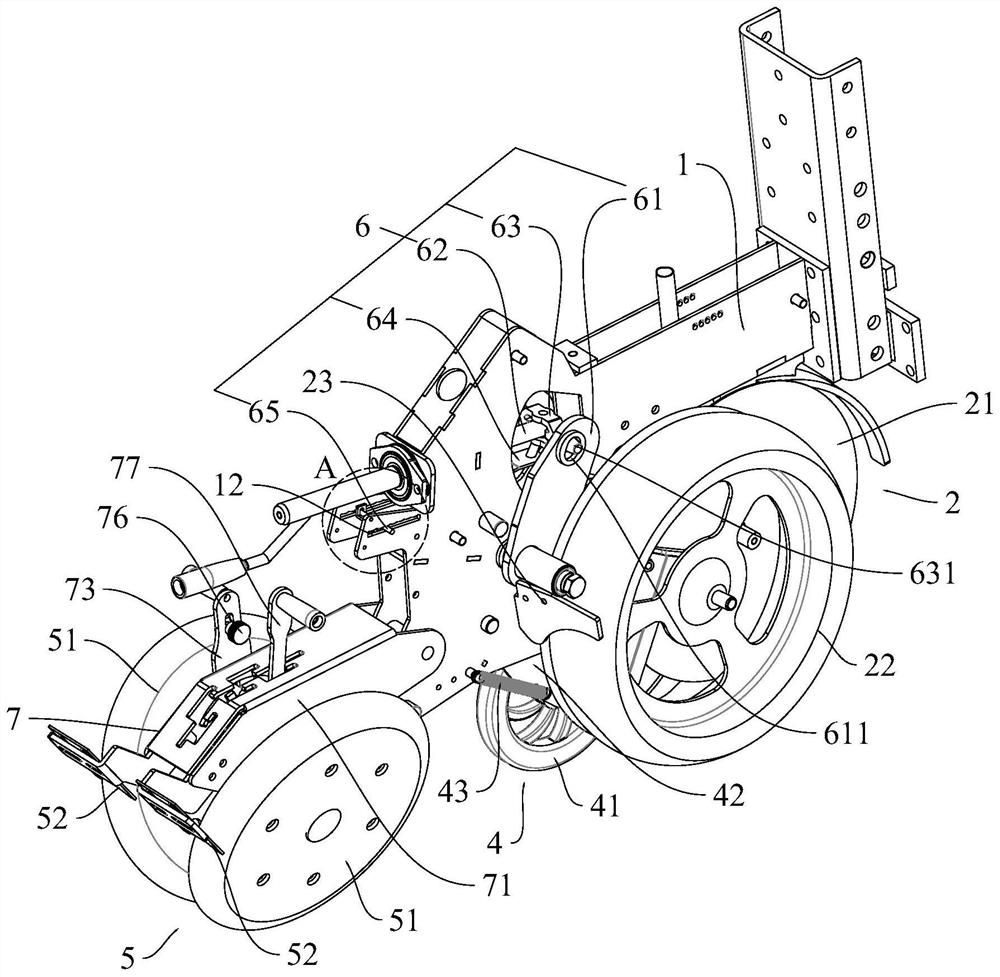

Intelligent precision corn drilling sowing single body

ActiveCN107182385AOvercome uncontrollableOvercoming the limitation that it is impossible to realize the infinite adjustment of plant distanceSeed depositing seeder partsBroadcast seedersBrushless motorsArea network

The invention relates to an intelligent precision corn drilling sowing single body, which belongs to the field of agricultural machinery. The intelligent precision corn drilling sowing single body comprises a mechanical part and a monitoring control part; a human-computer interaction module sends preset planting distance and preset sowing depth to a microprocessing controller through a CAN (Controller Area Network) bus module; the microprocessing controller controls the revolving speed of a direct current brushless motor and the elongation amount of an electric push rod according to the preset sowing length and planting distance, the value of a speed sensor, a speed value collected by a navigation module and the value of a pressure sensor through the direct current brushless motor and an electric push rod pushing module so as to realize the accurate control over the planting distance and the real-time control over the sowing depth; the microprocessing controller sends the real-time working condition of a sowing single body to the human-computer interaction module through the CAN bus module. By use of the intelligent precision corn drilling sowing single body, the accurate control over the planting distance and the real-time control over the sowing depth can be directly and effectively realized, sowing quality and working efficiency are improved, and sowing cost and labor intensity are lowered.

Owner:CHINA AGRI UNIV

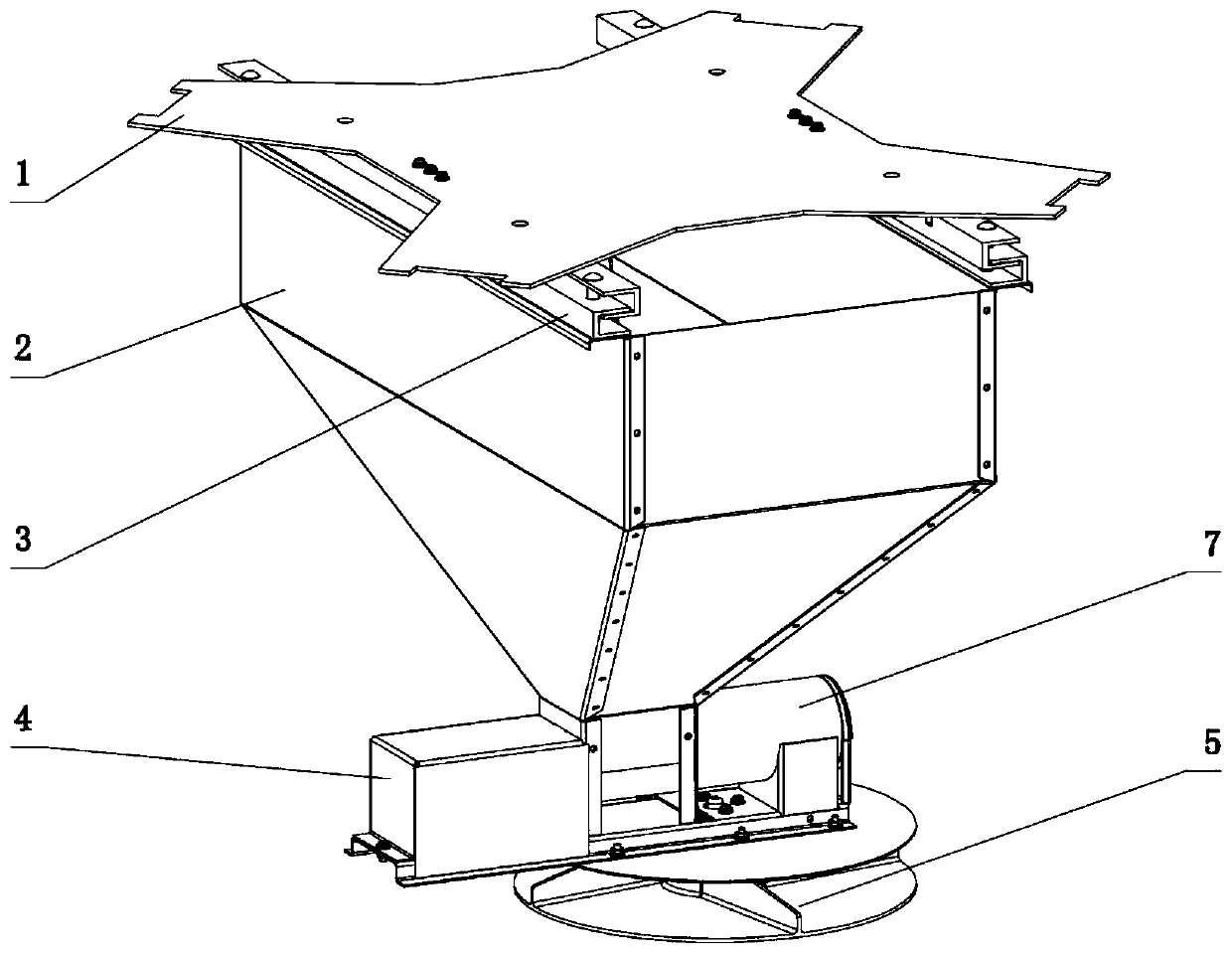

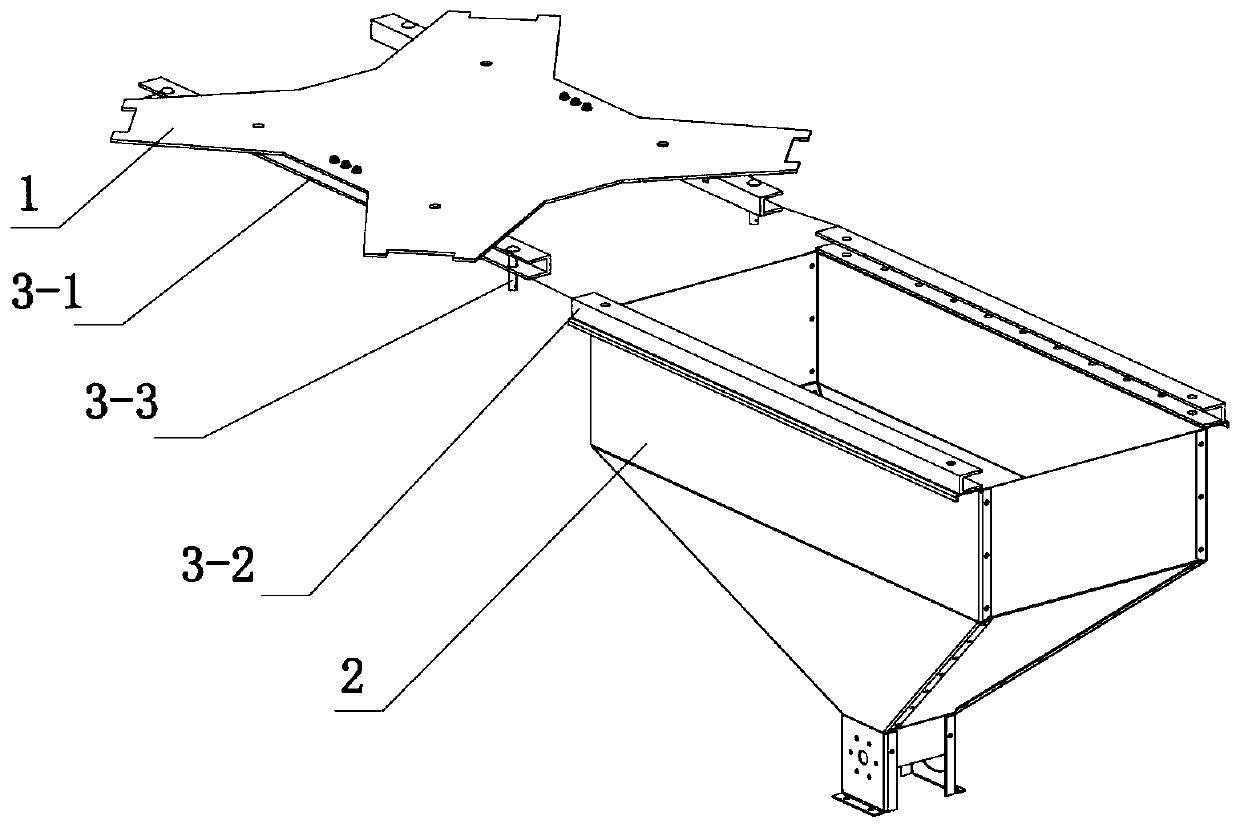

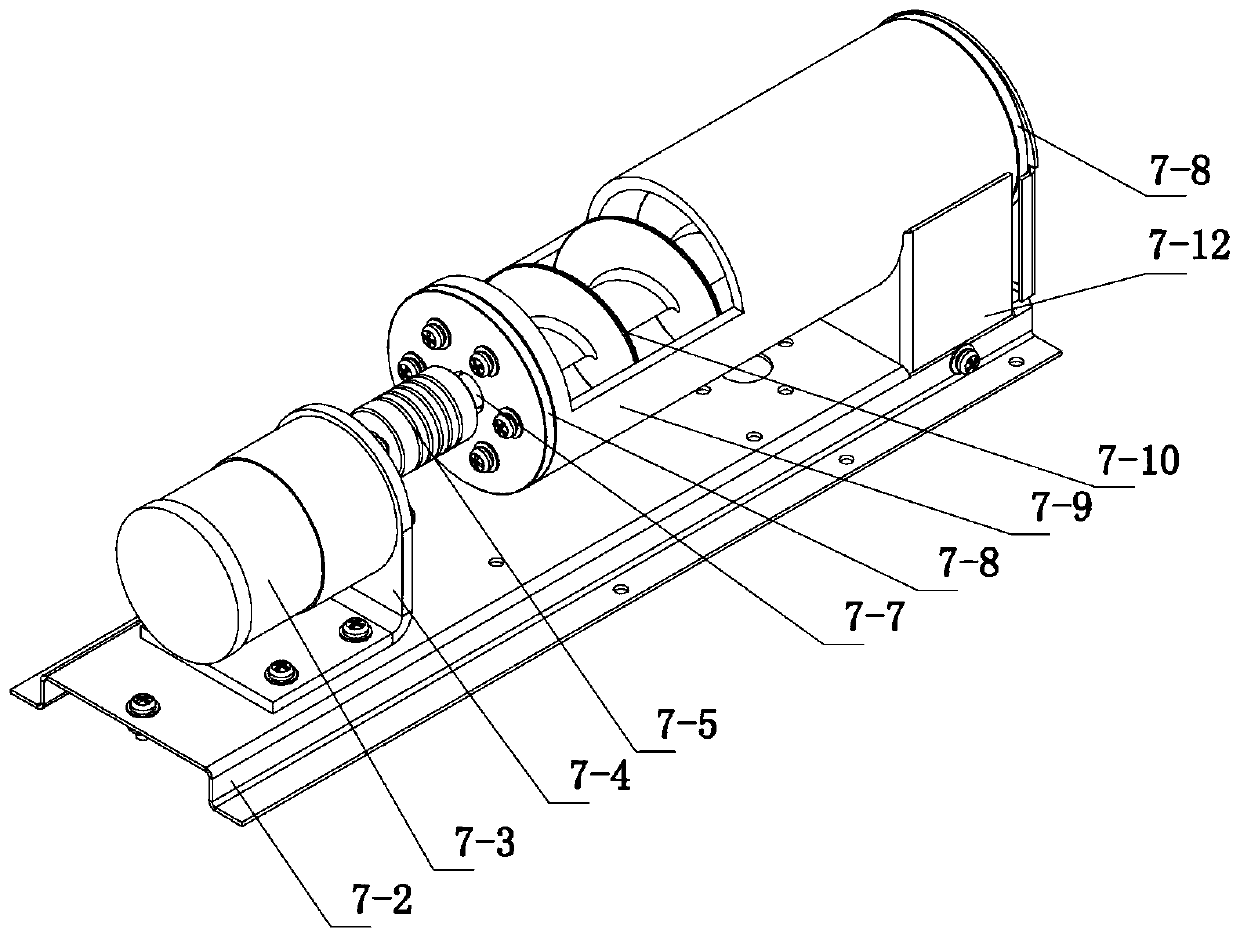

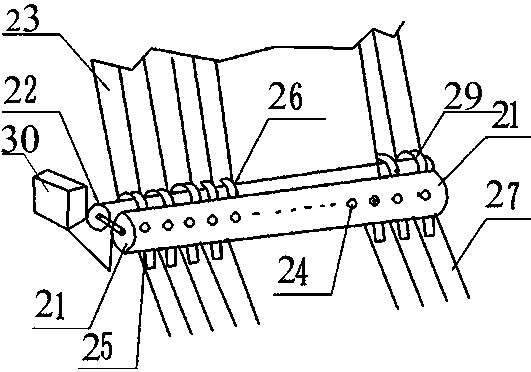

Unmanned aerial vehicle quantitative spreading device and method for green manure seeds

PendingCN111284698AGuarantee the quality of sowingAircraft componentsSeed depositing seeder partsAutomatic controlAgricultural engineering

The invention relates to an unmanned aerial vehicle quantitative sowing device for green manure seeds, and belongs to the technical field of agricultural automation. The device comprises a sowing control circuit and a seed box, a quantitative seeding mechanism and a seeding mechanism are mounted at the lower end of the seed box; a seed-metering pipe is supported on a mounting support of the quantitative seed-metering mechanism; a horizontal shaft auger is arranged in the seed-metering pipe; one end of the seed metering pipe is provided with a feeding hole right opposite to the leakage hole ofthe seed box, and the other end is provided with a downward discharging hole; a seed throwing disc is arranged below a disc cover of the seeding mechanism; seed throwing blades are fixed on the seed throwing disc; an automatic sowing control module of the sowing control circuit is in communication connection with a flight control system of the unmanned aerial vehicle and is provided with a selection input end, a current sampling input end and respective control output ends. By the adoption of the device, no matter how the flight height and speed change within a certain range, it can be guaranteed that the unit seeding rate of various green manure seeds within the preset operation breadth is unchanged, and the field seeding quality is practically guaranteed.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Corn straw total crop straw return protective farming method

InactiveCN108476651AEffective protectionReduce wind erosionAgriculture gas emission reductionSoil-working methodsGround temperatureReturn function

The invention discloses a corn straw total crop straw return protective farming method. A corn harvester with the straw crushing and returning function is adopted for harvesting during the autumn harvest in first year, meanwhile, the crushed corn straws are uniformly thrown into the field, and the ground surface is covered; ploughing and soil preparation operation is carried out; stubble ploughing, straw cutting and mix burying, subsoiling, soil preparation, compacting and the like are completed at one time; in the spring period in the second year, direct seeding is carried out, multiple worksuch as fertilization, precision seeding, soil covering, compacting and the like can be completed at one time; a nitrogen fertilizer is applied between the seedlings by a topdressing machine during the growth period of the corns. According to the method, the straw cutting segments are uniformly mixed in the soil of the tilling layer, so that the ground temperature can be improved, the straw rotting is accelerated, the diseases and pests are reduced, and meanwhile a certain surface straw coverage rate can be guaranteed, wind erosion and water erosion are reduced, and the purpose of protecting the soil is achieved, the method is especially suitable for being applied and popularized in regions with low winter and spring temperature in the northeast, and a technical support is provided for large-area popularization and protection of the regions.

Owner:JILIN ACAD OF AGRI MACHINERY

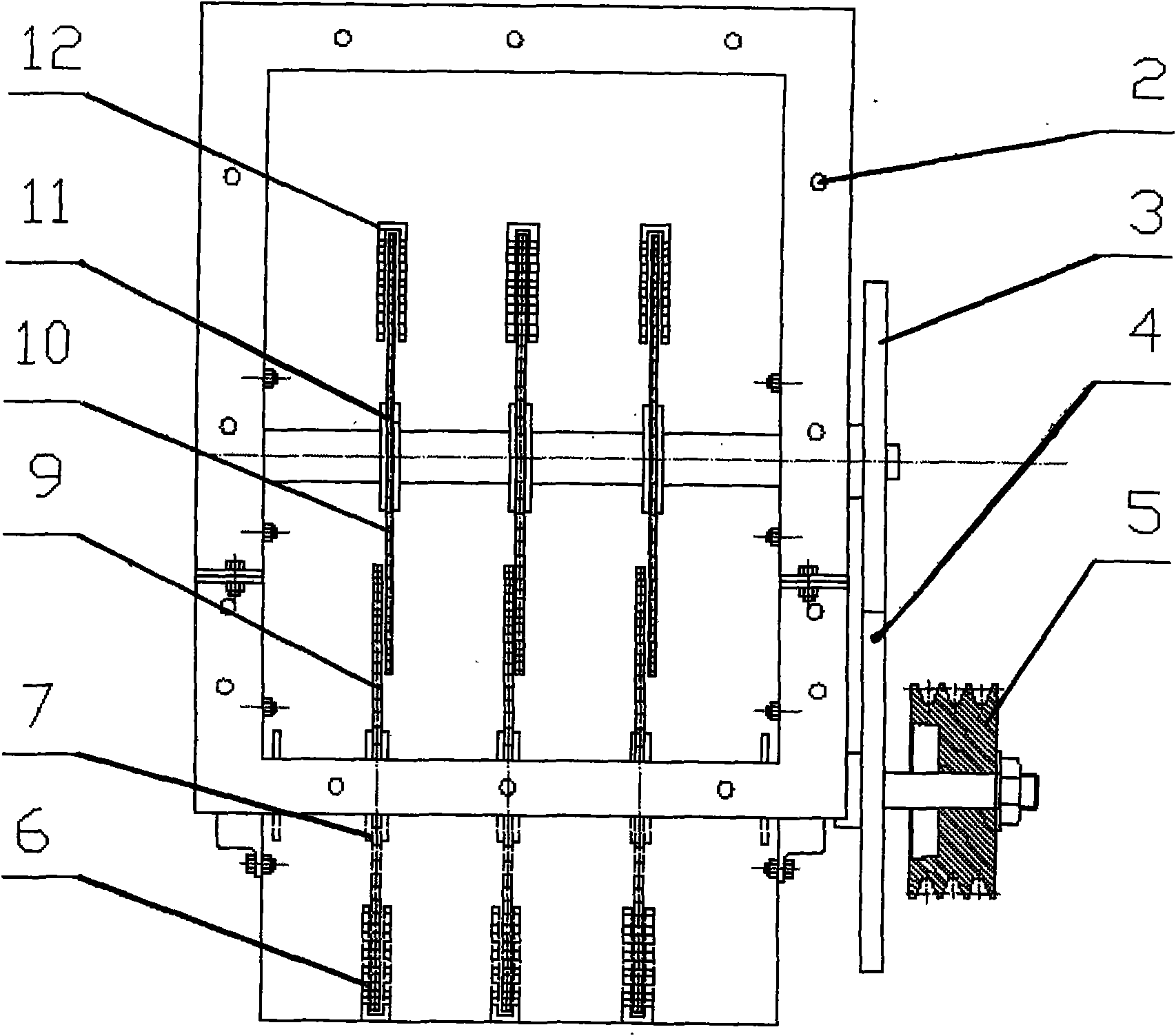

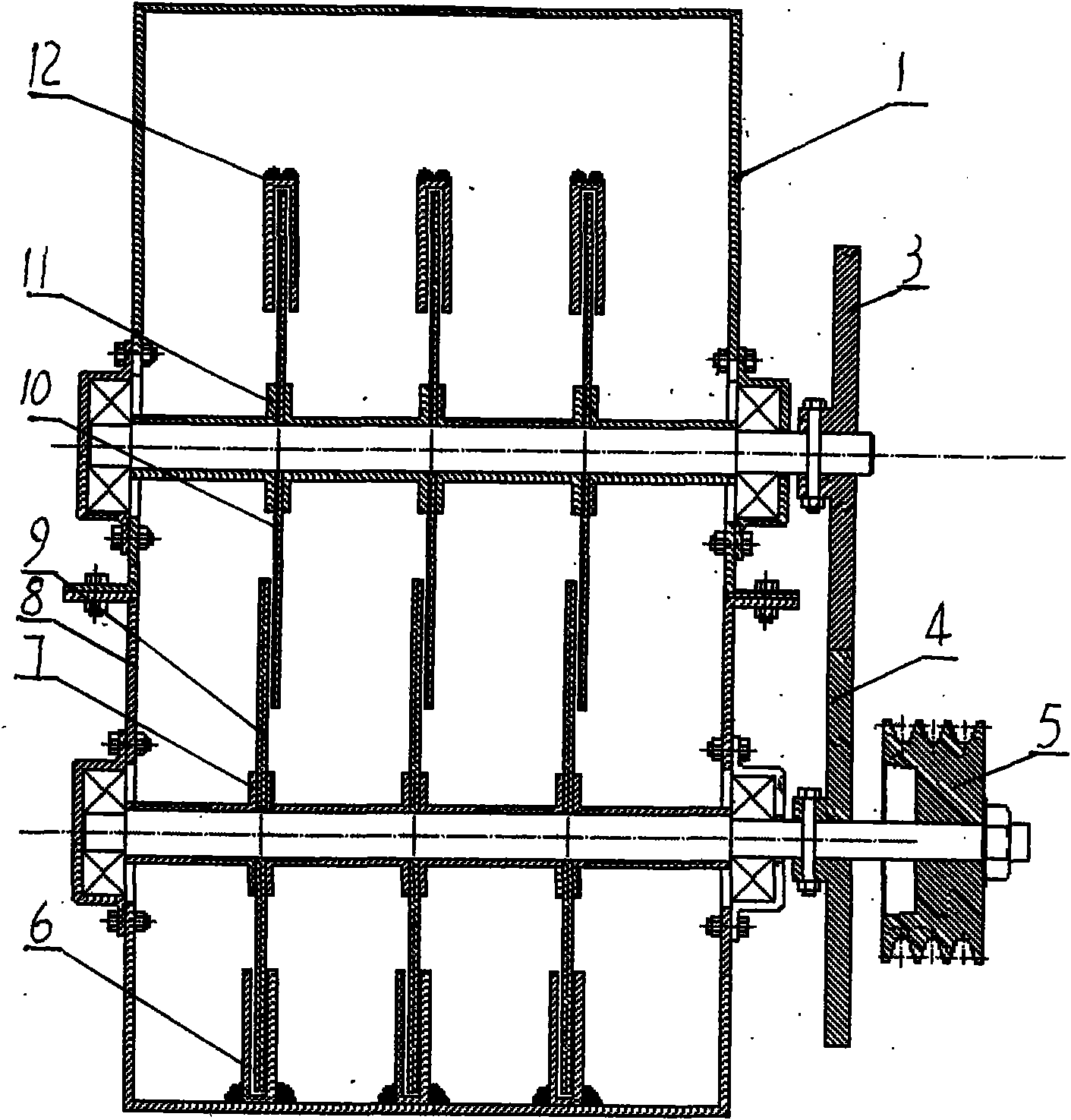

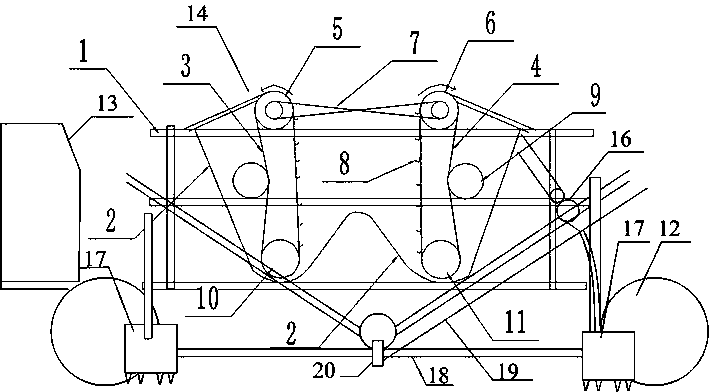

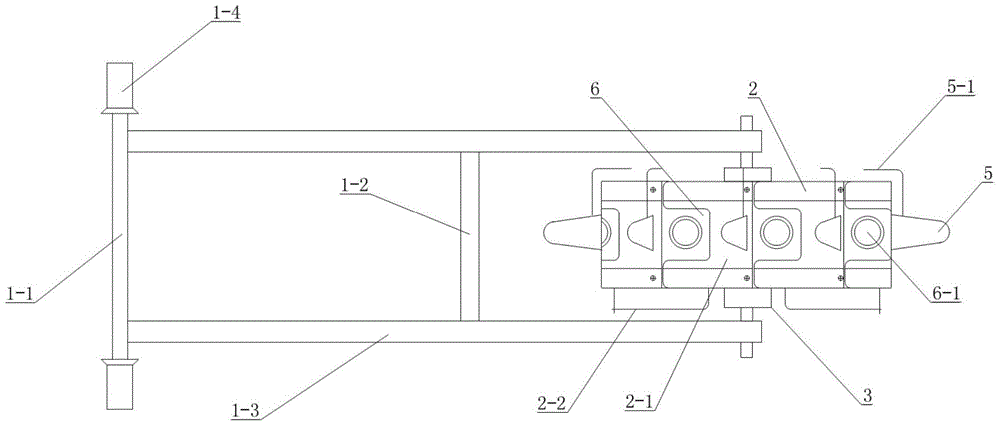

Plant/line spacing-adjustable detachable multifunctional seeding device

InactiveCN102379179AReduce labor intensityImprove labor productivityPlantingAgriculture gas emission reductionPlanting seedAgricultural engineering

Owner:应华

Straw crusher used for whole-feed combine harvester

InactiveCN101558711AConducive to return to fieldNo change in mechanical structureCrop conditionersMowersDrive shaftCrusher

A straw crusher used for a whole-feed combine harvester belongs to the technical field of agricultural tools. The invention aims to provide a straw crusher that is capable of matching with a whole-feed combine harvester for use and has simple structure, little power consumption, good crushing effect and convenient use. The key technical points are as follows: a driven shaft and a driving shaft are respectively fixed with a group of saw bits (10, 9) and respectively composed of three saw bits; an upper cover (1) and a lower cover (8) of an enclosure are respectively correspondingly fixed with an upper cutter tooth (12) and a lower cutter tooth (6) matched with the three saw bits on the driven shaft and the driving shaft, and the ends of the saw bits are arranged in a partially coincident way between the saw bits on the driven shaft and the saw bits on the driven shaft. Two groups of saw bits from three cutting rolls of between the saw bits and the upper cutter tooth, between the saw bits which are opposite in rotary direction and coincident on the driven shaft and the driving shaft, and between the saw bits on the driving shaft and the lower saw tooth. The straw crusher matches with the whole-feed combine harvester domestically used at present for use.

Owner:ANHUI AGRICULTURAL UNIVERSITY

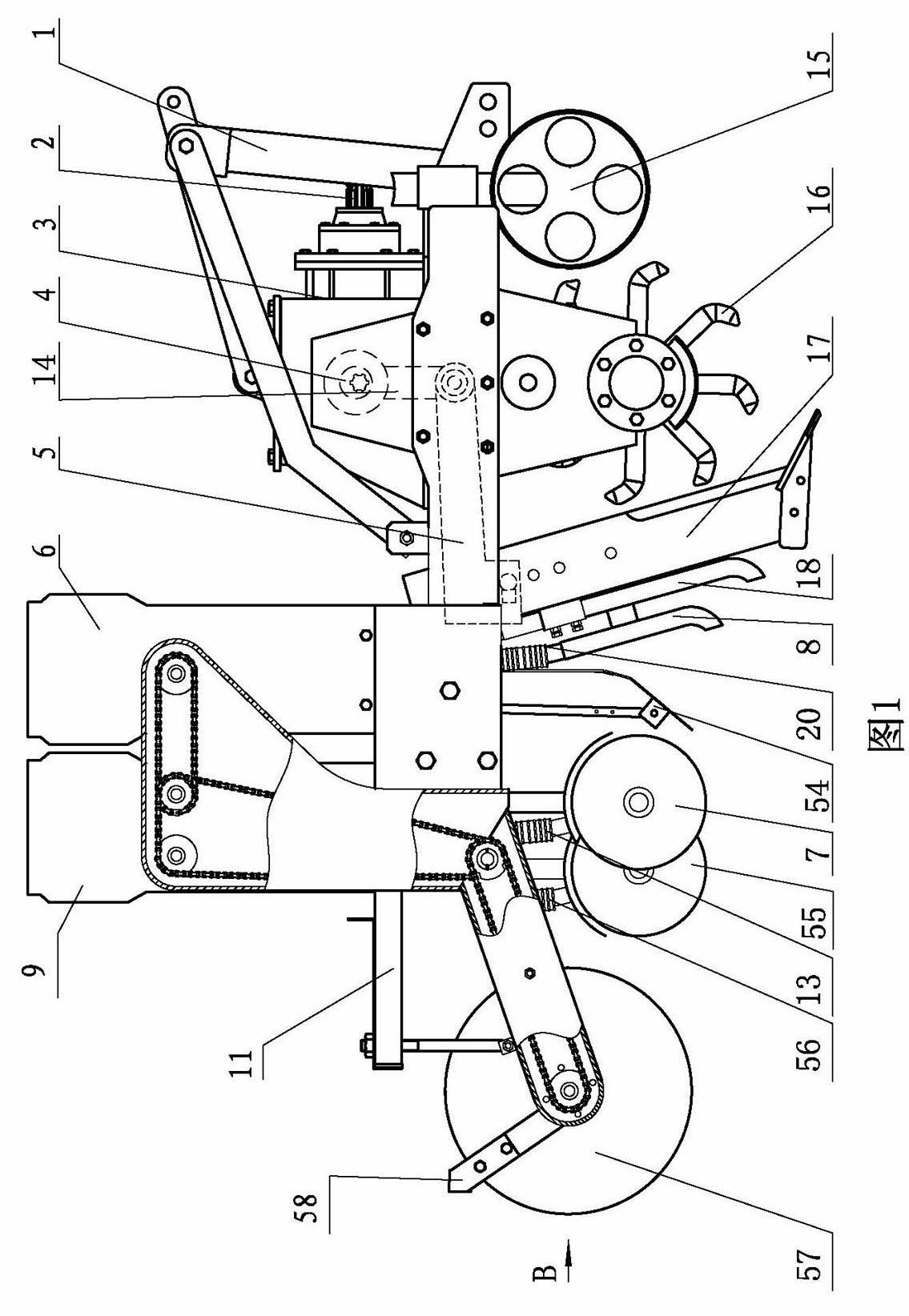

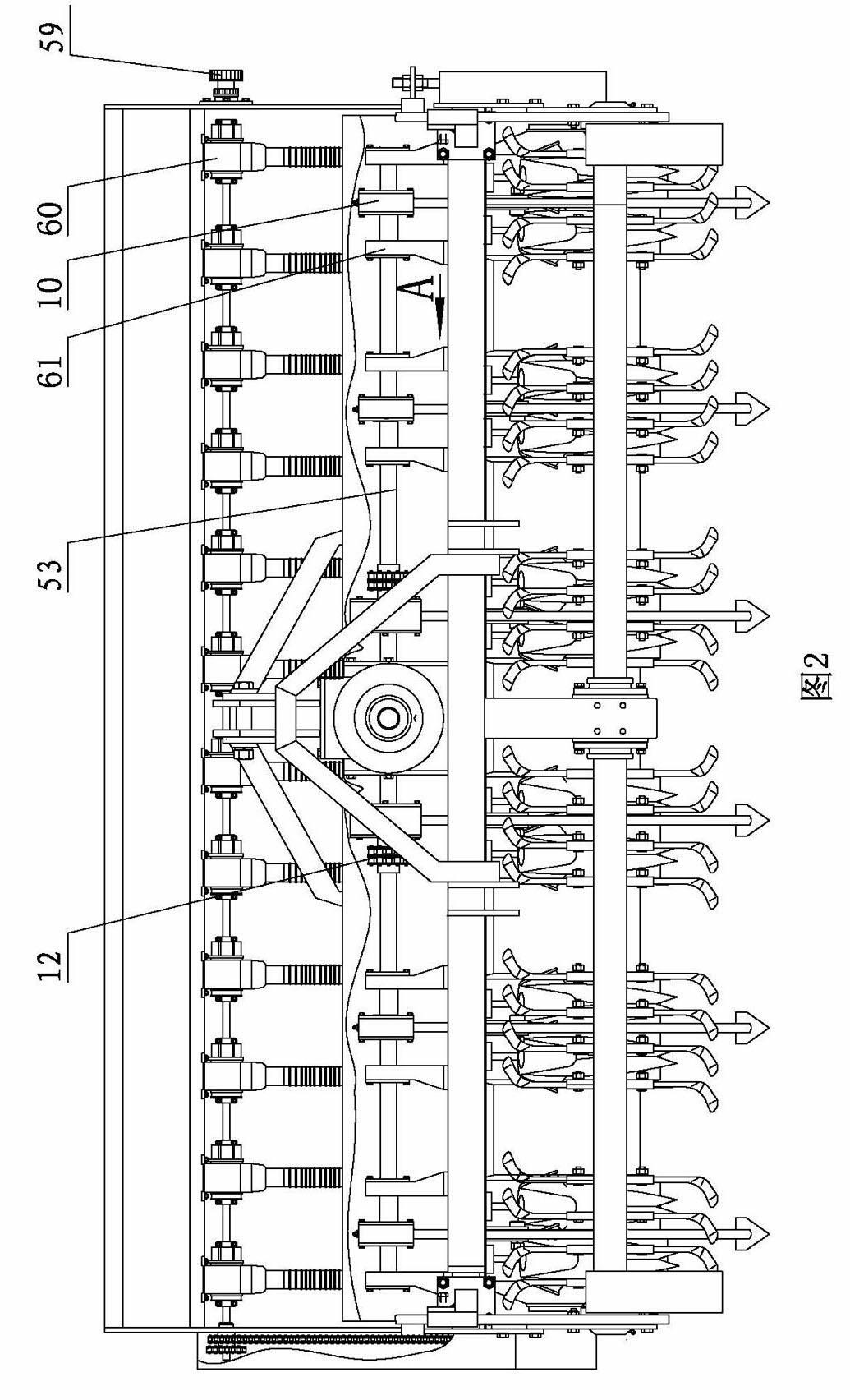

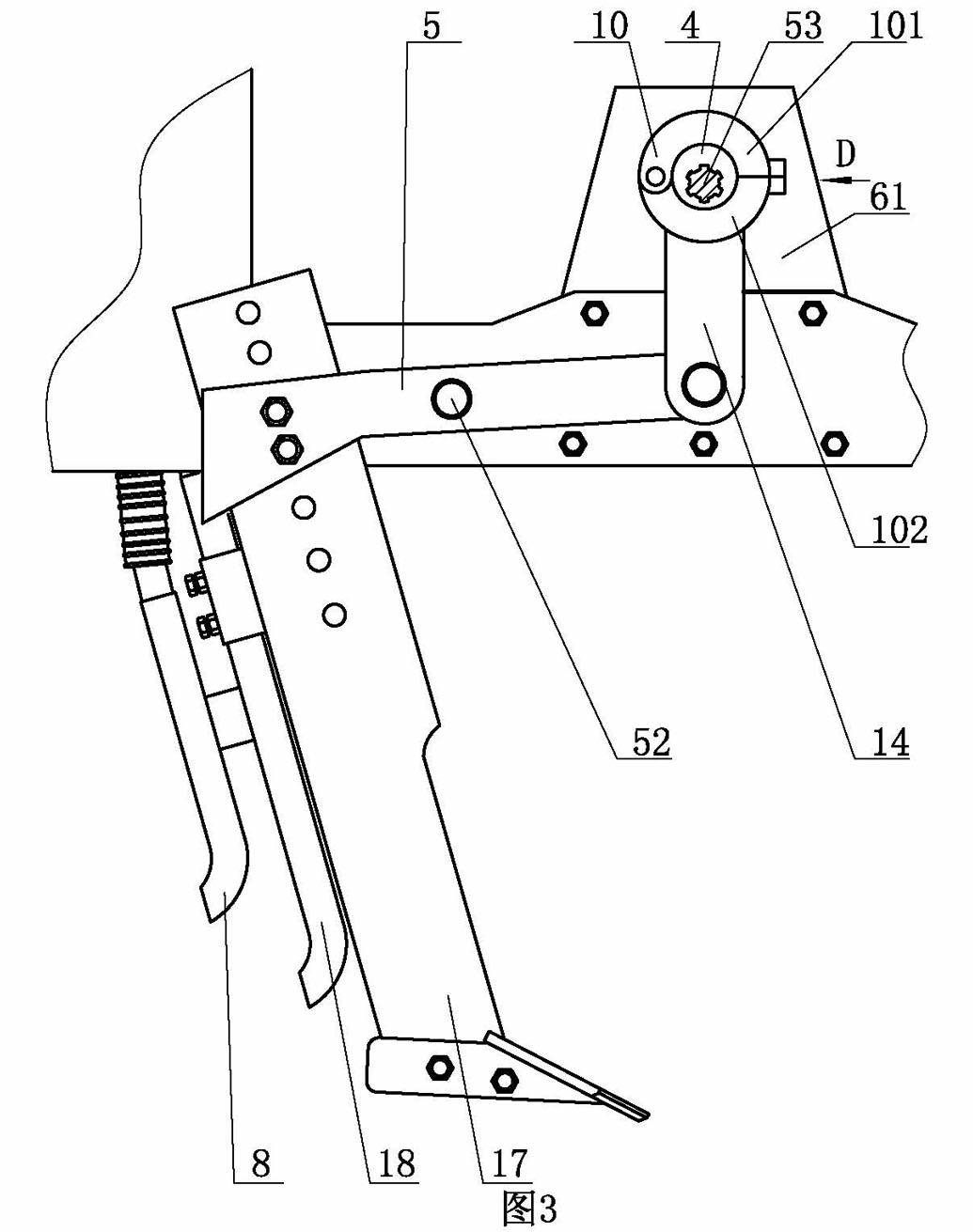

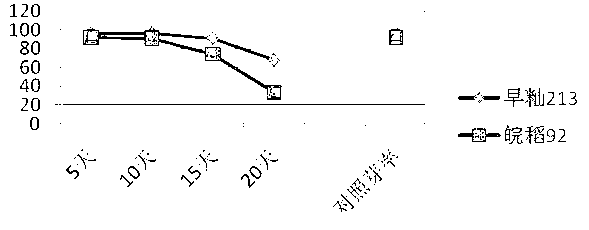

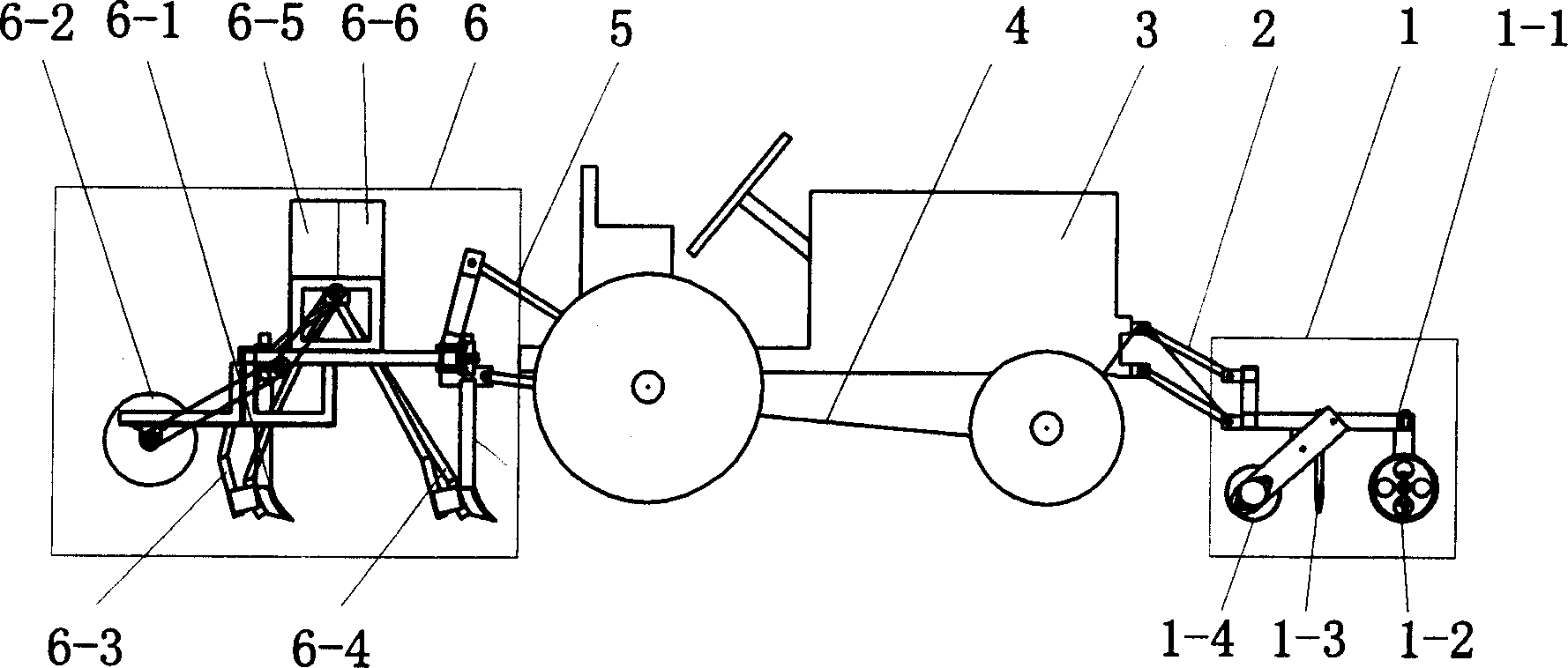

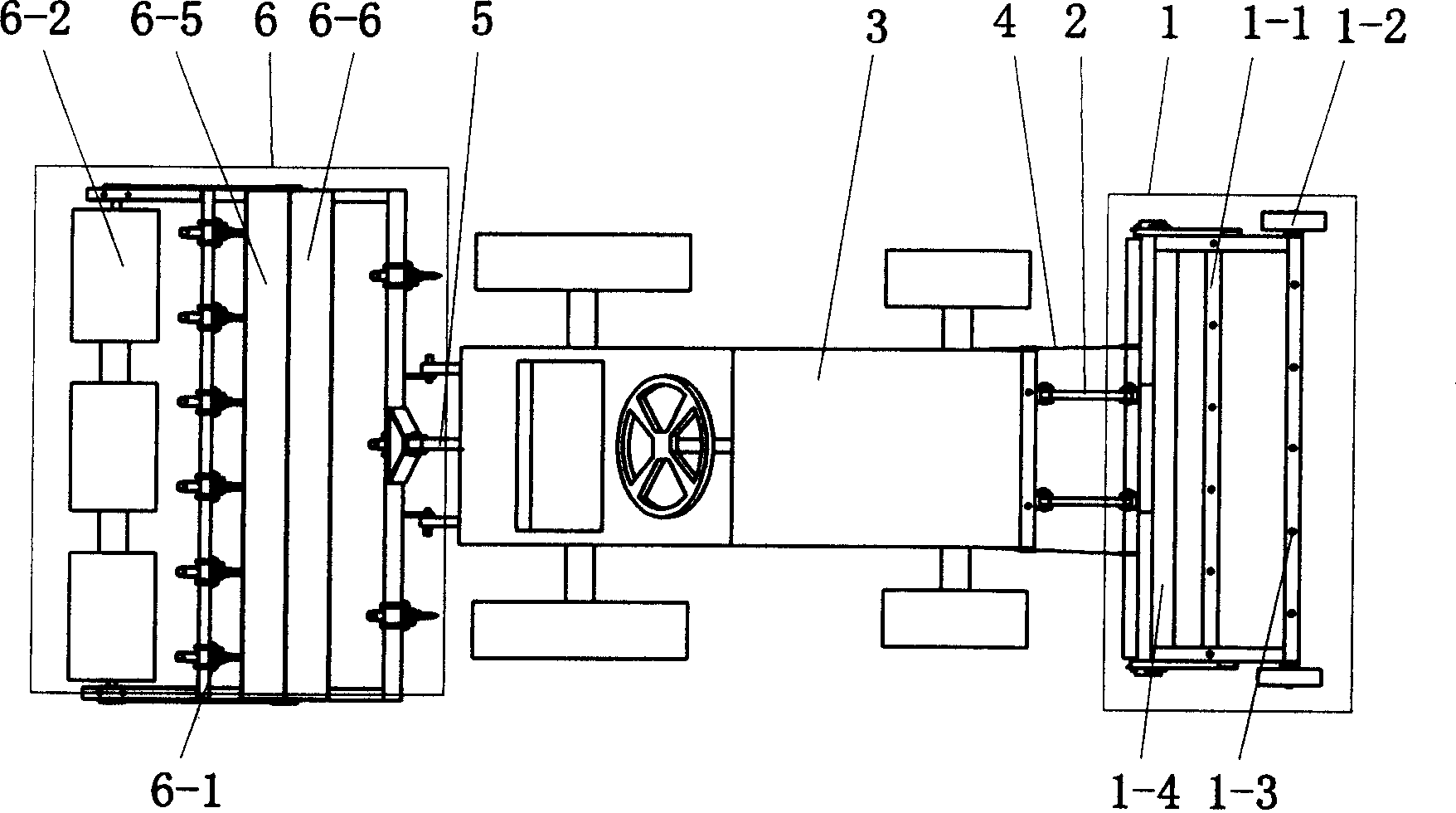

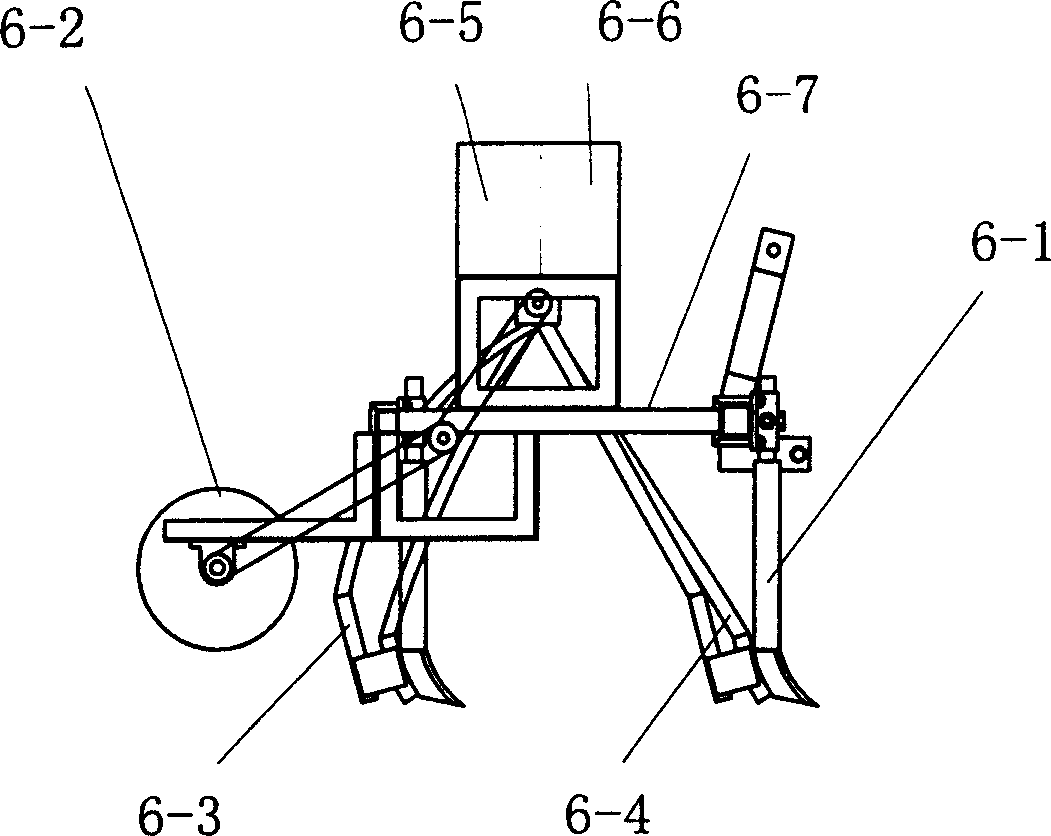

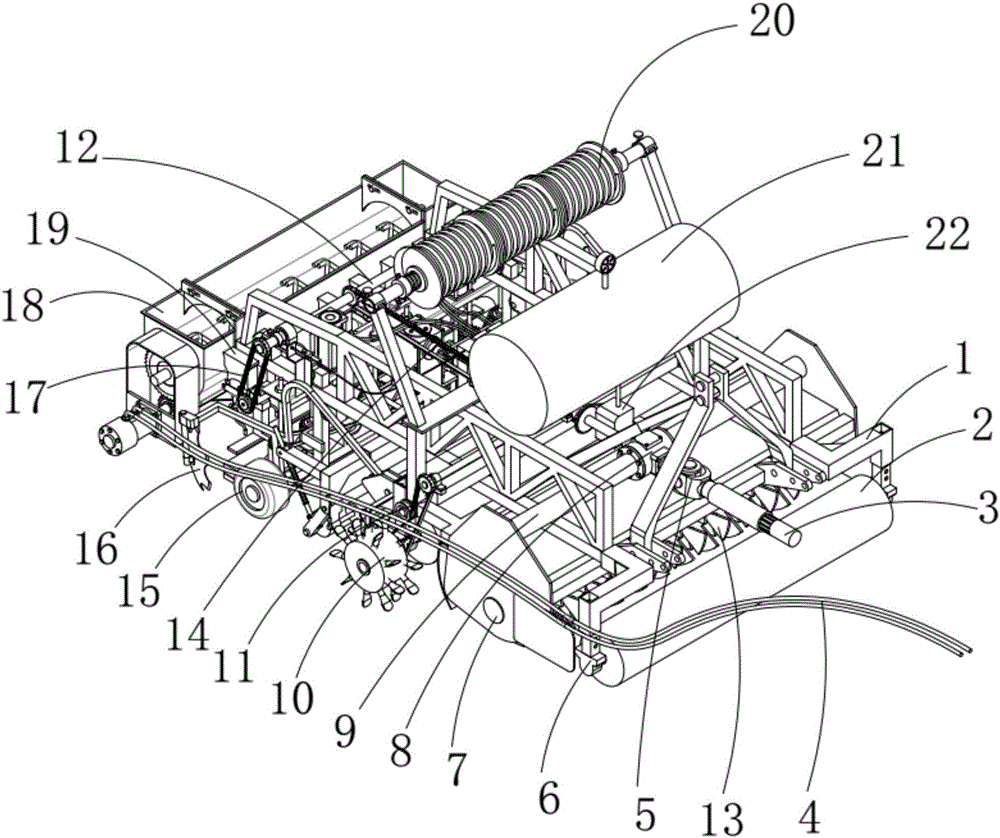

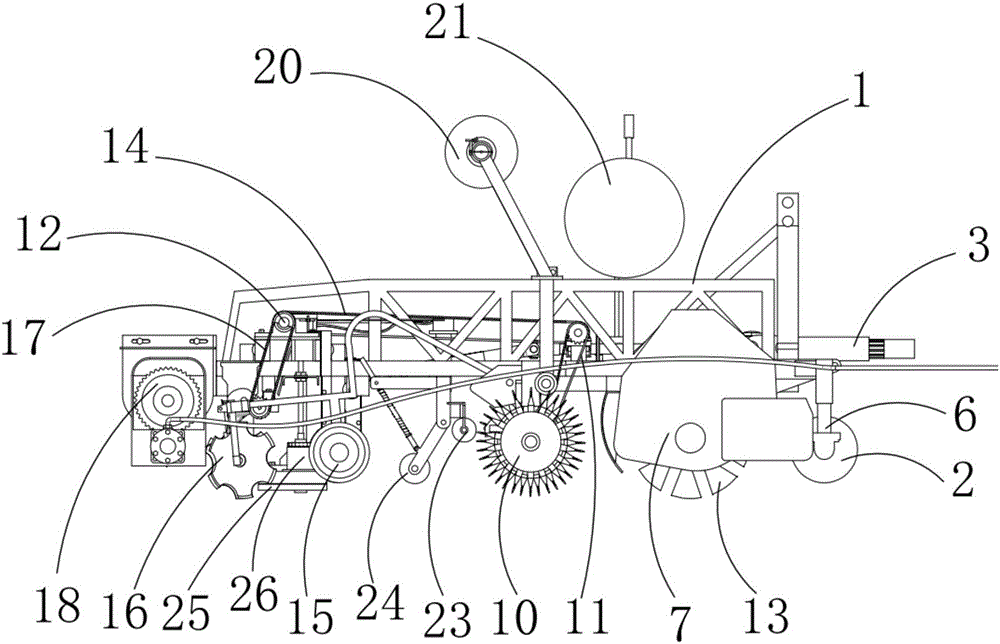

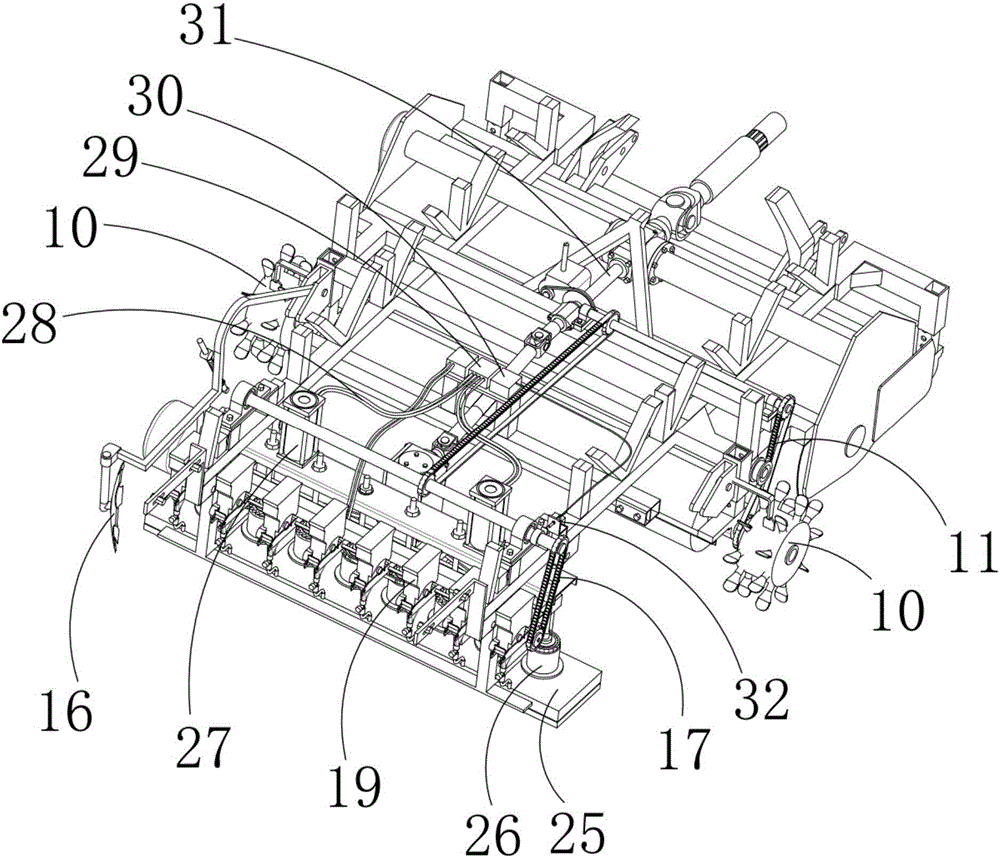

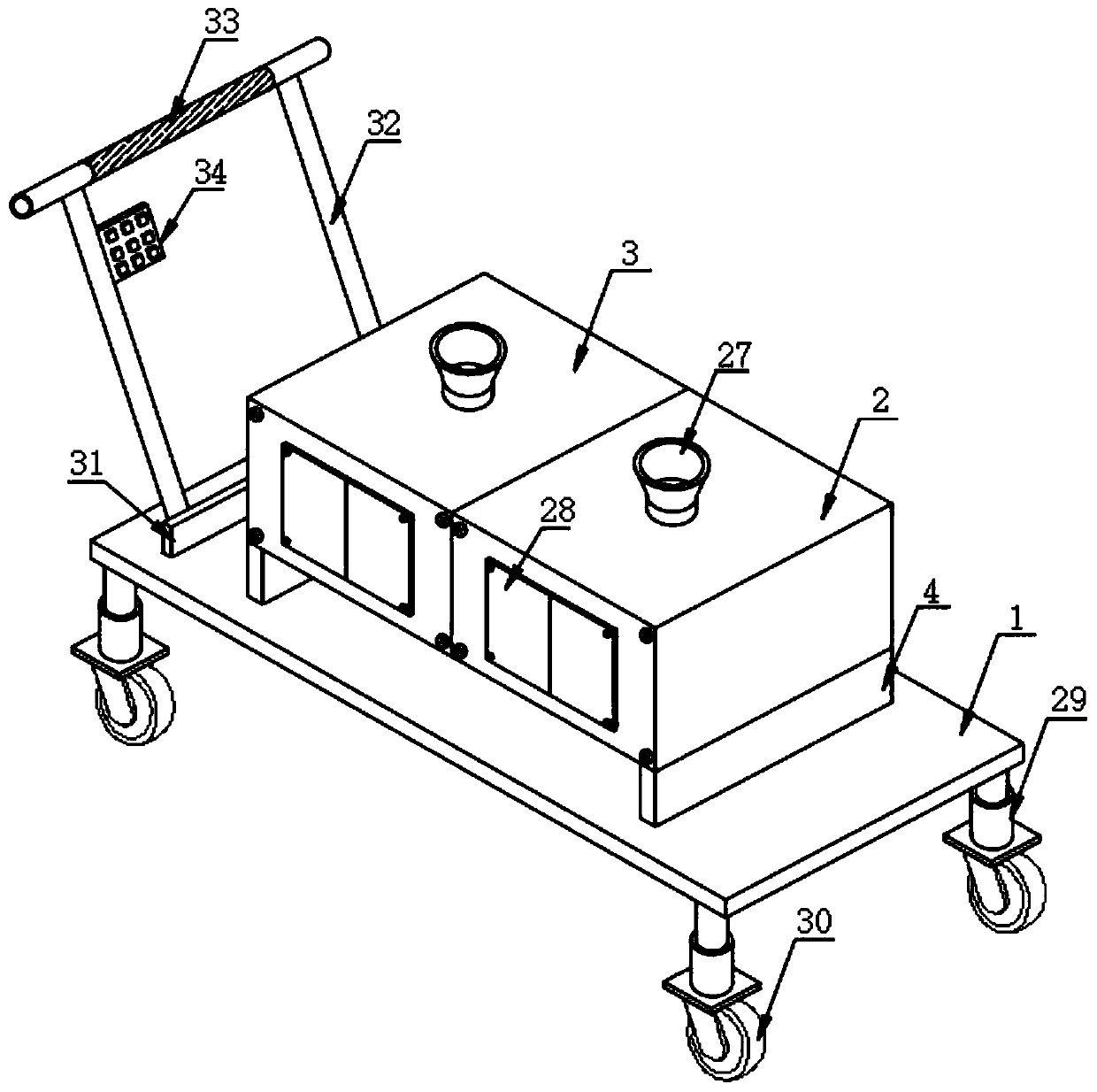

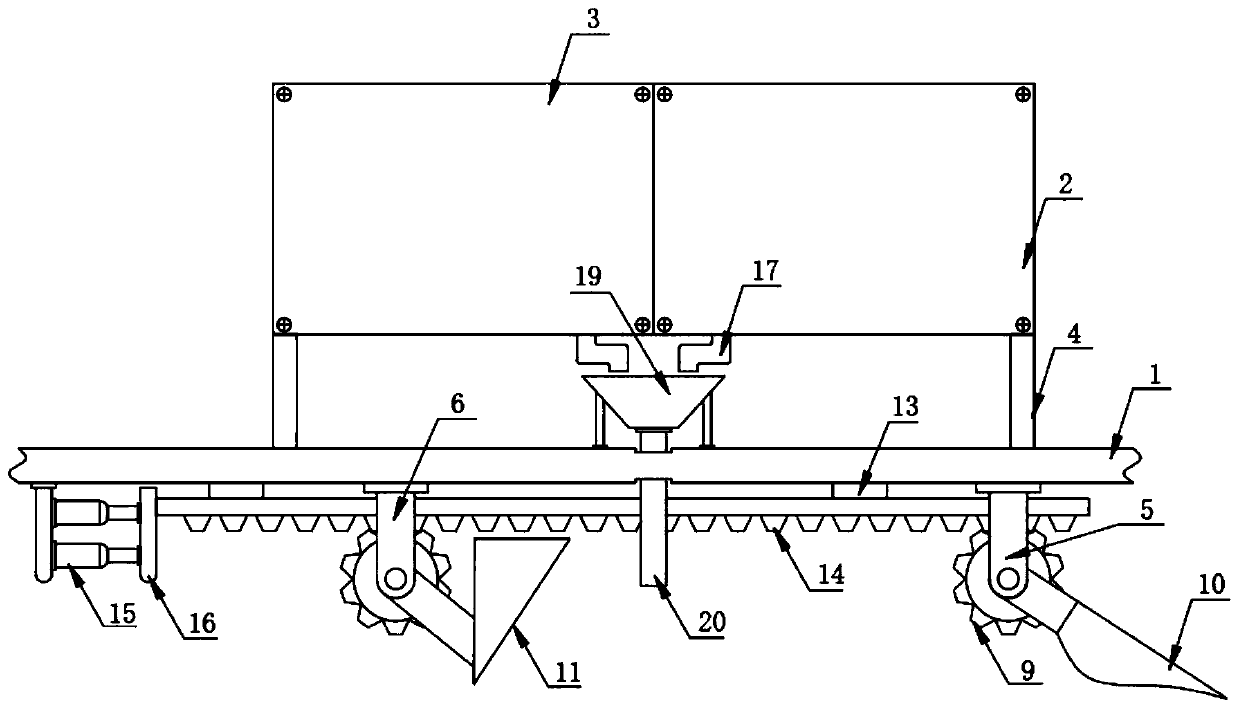

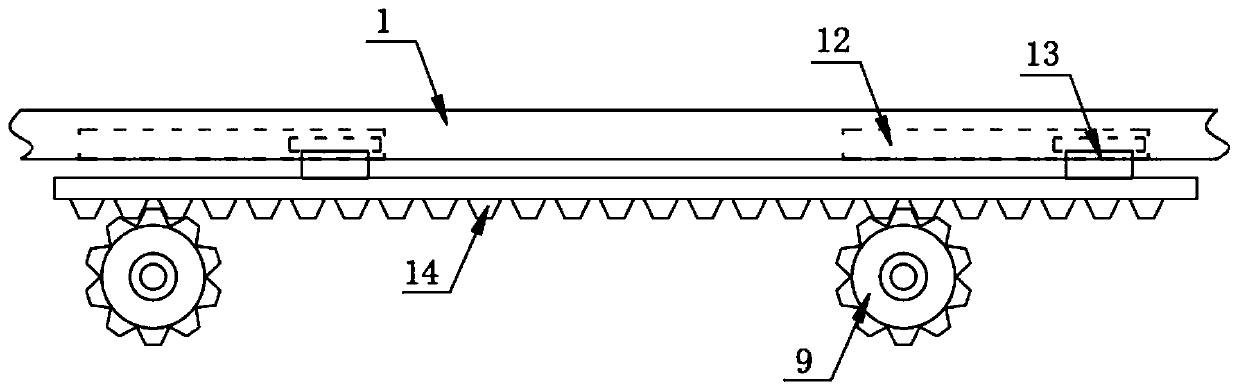

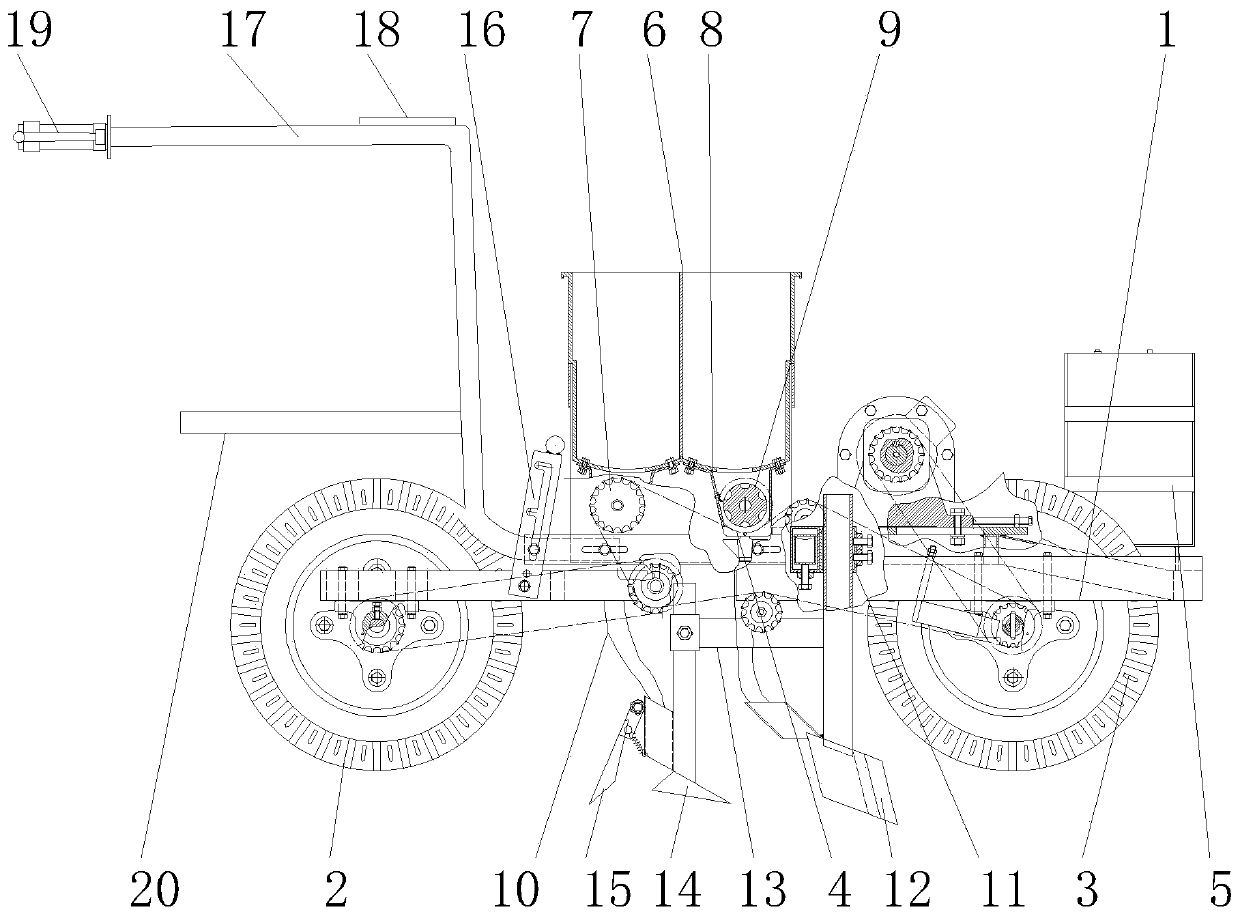

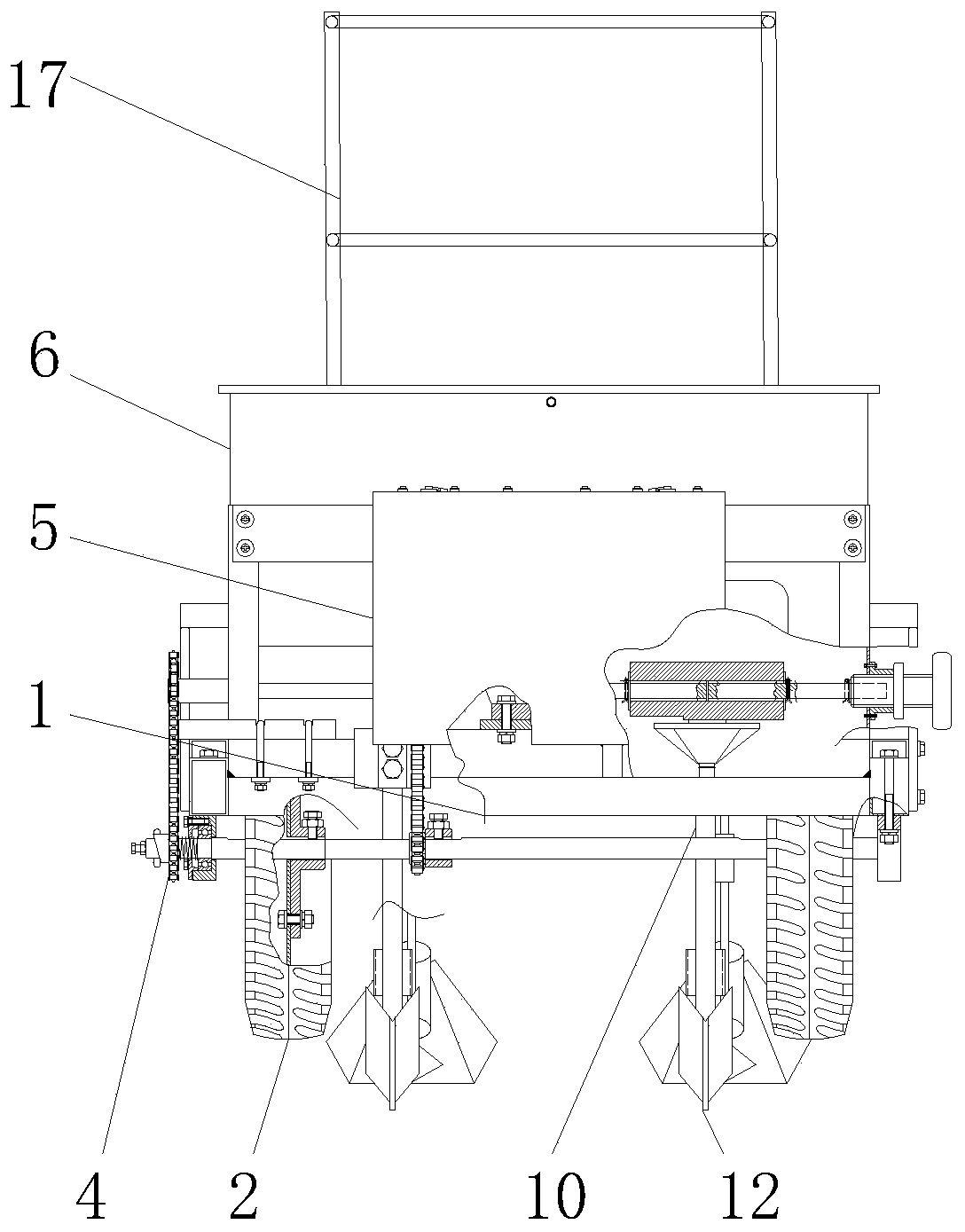

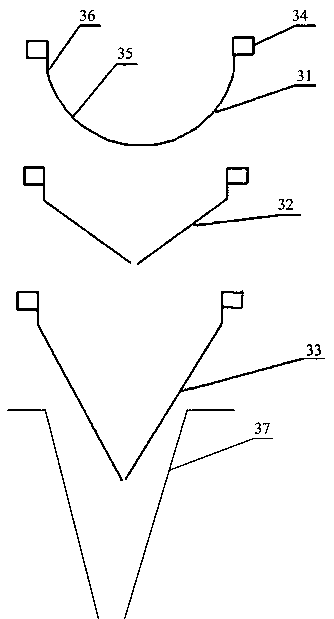

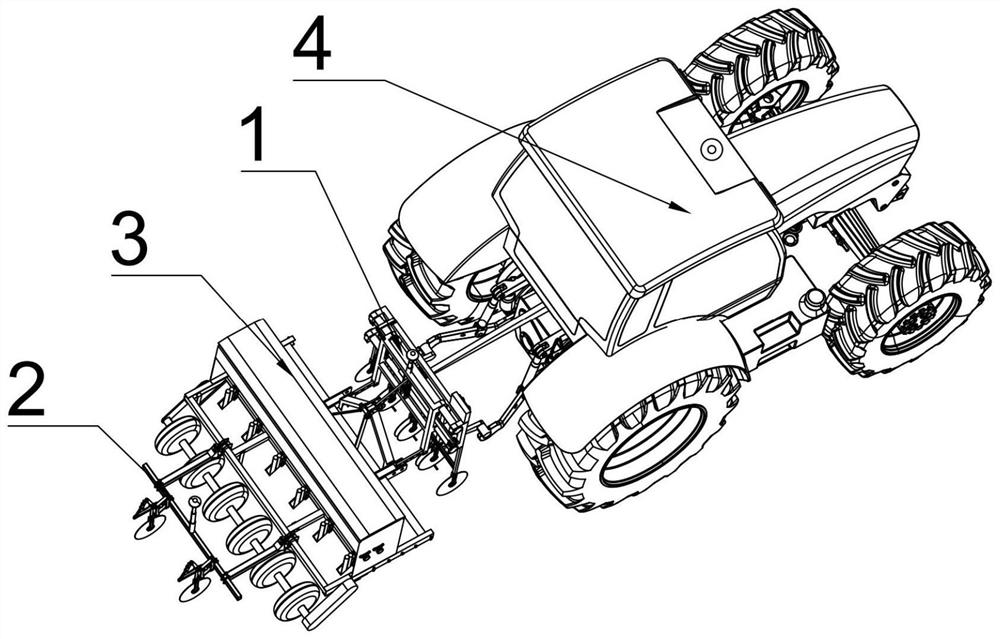

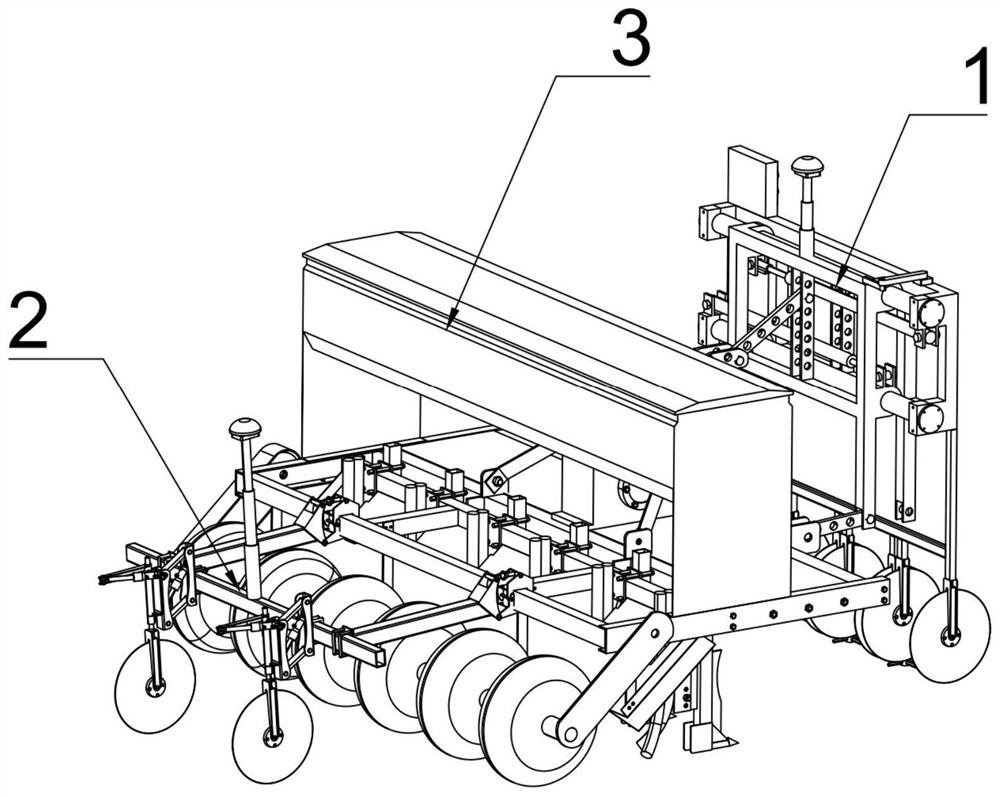

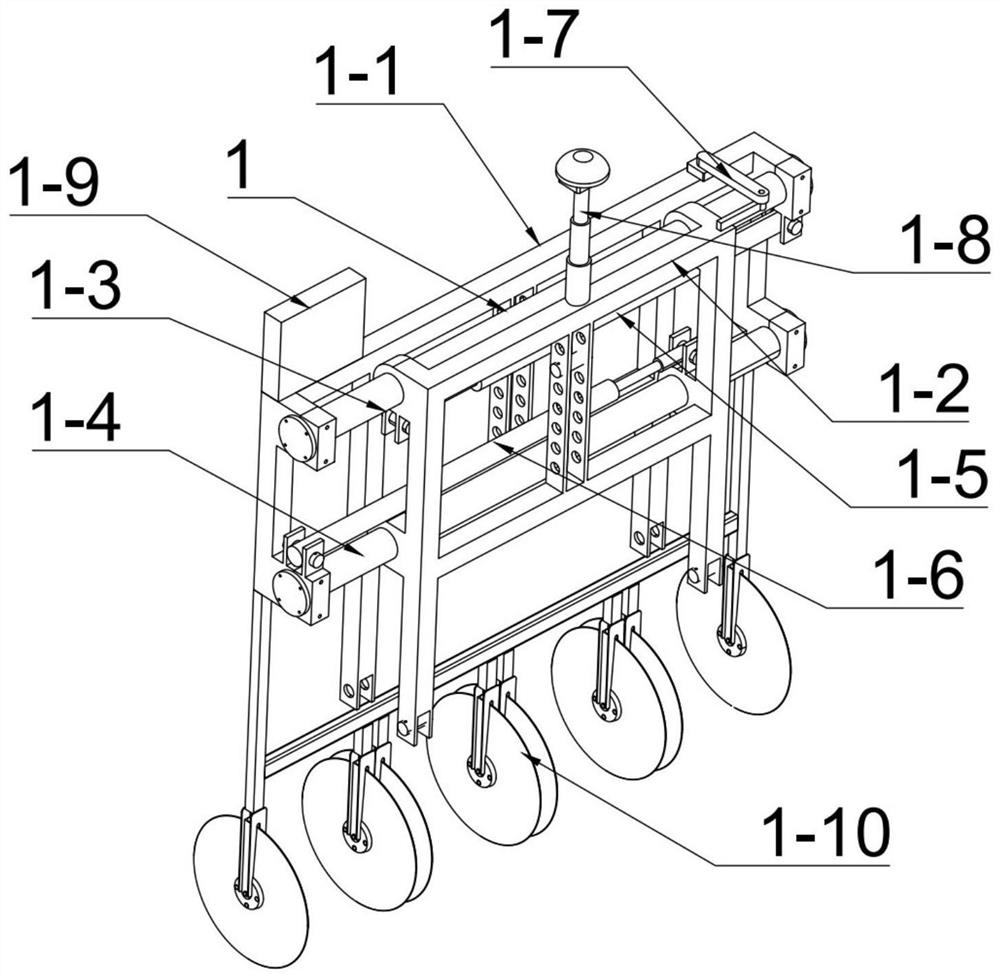

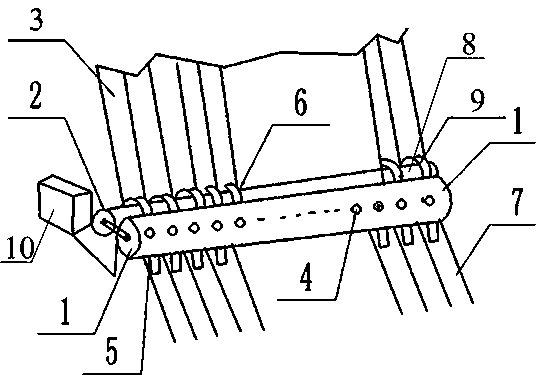

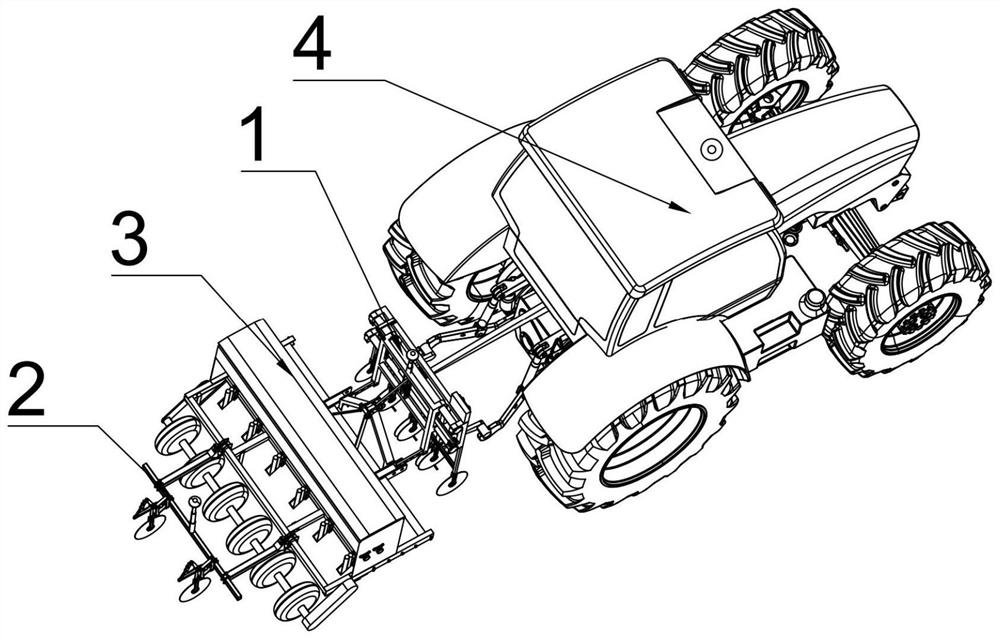

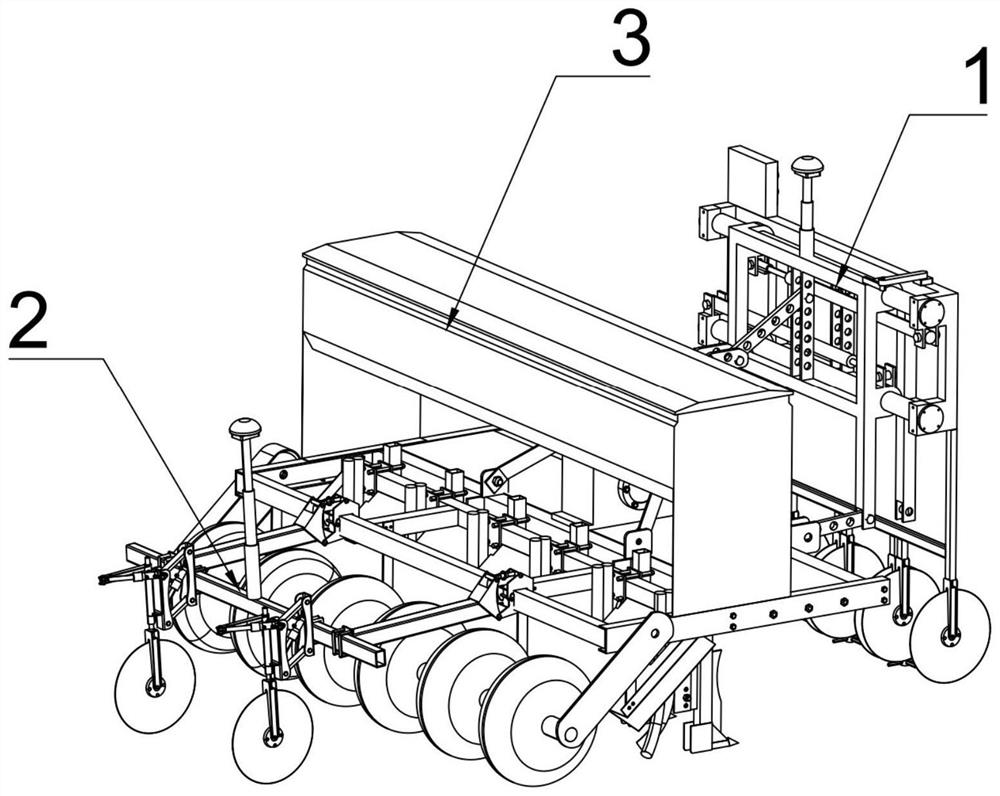

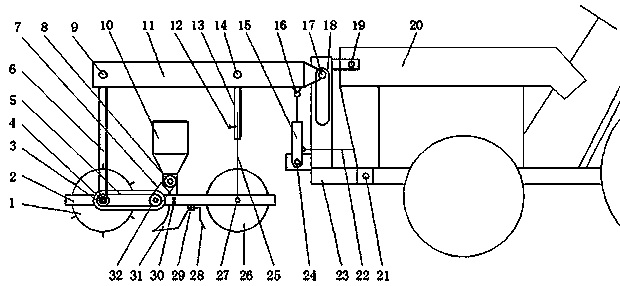

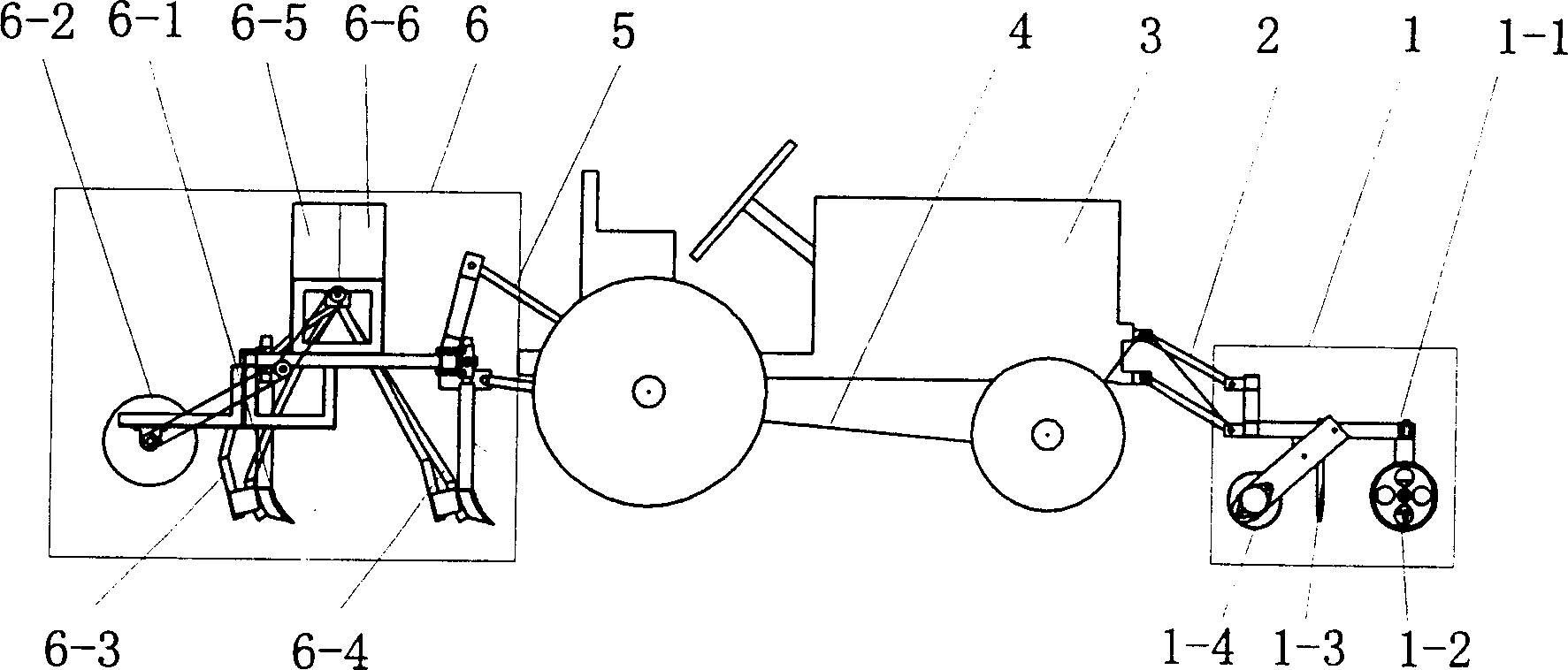

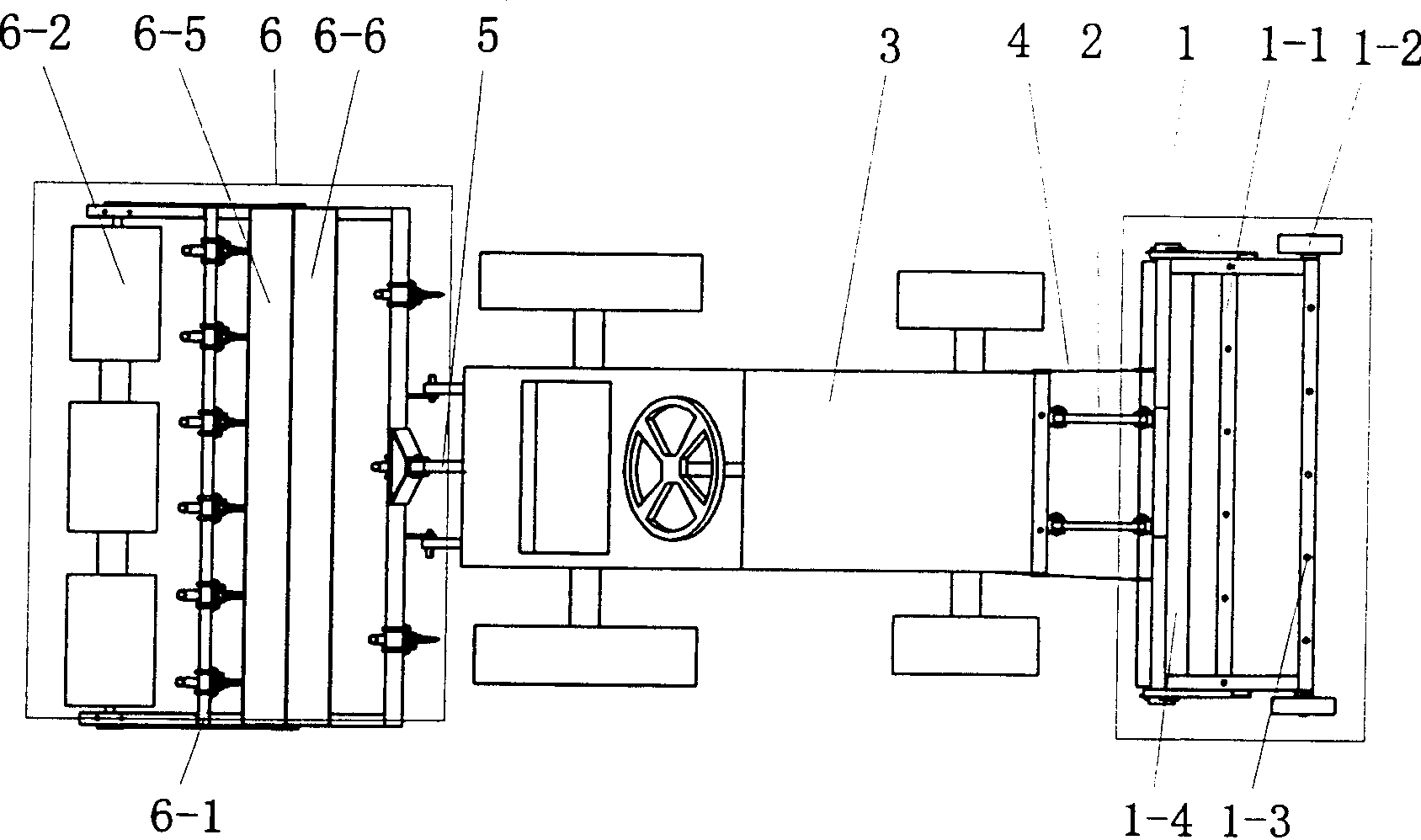

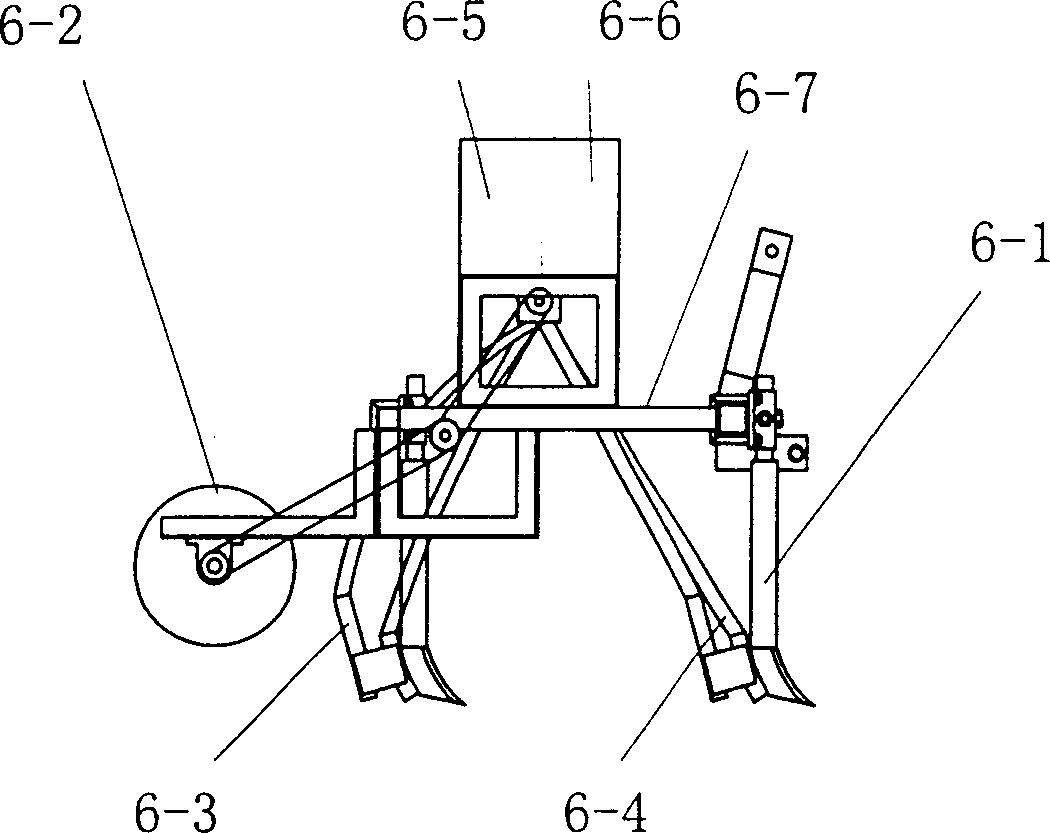

Mealie whole straw coverage wheat full no-tillage planting method and equipment thereof

The invention provides a method and apparatus for total no-tillage planting operation through blanketing wheat with overall maize stalks, wherein the complete stalks of the harvested maize are pulled down in situ in the field, and the wheat seeds are planted through trench digging between the maize planting rows. The maize complete stalk blanketing wheat no-tillage planting and fertilizer applicator set provided by the invention can realize the operations of upright maize stalk pulling down, combing, wheat seeding, fertilizing, suppressing and stalk compression.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

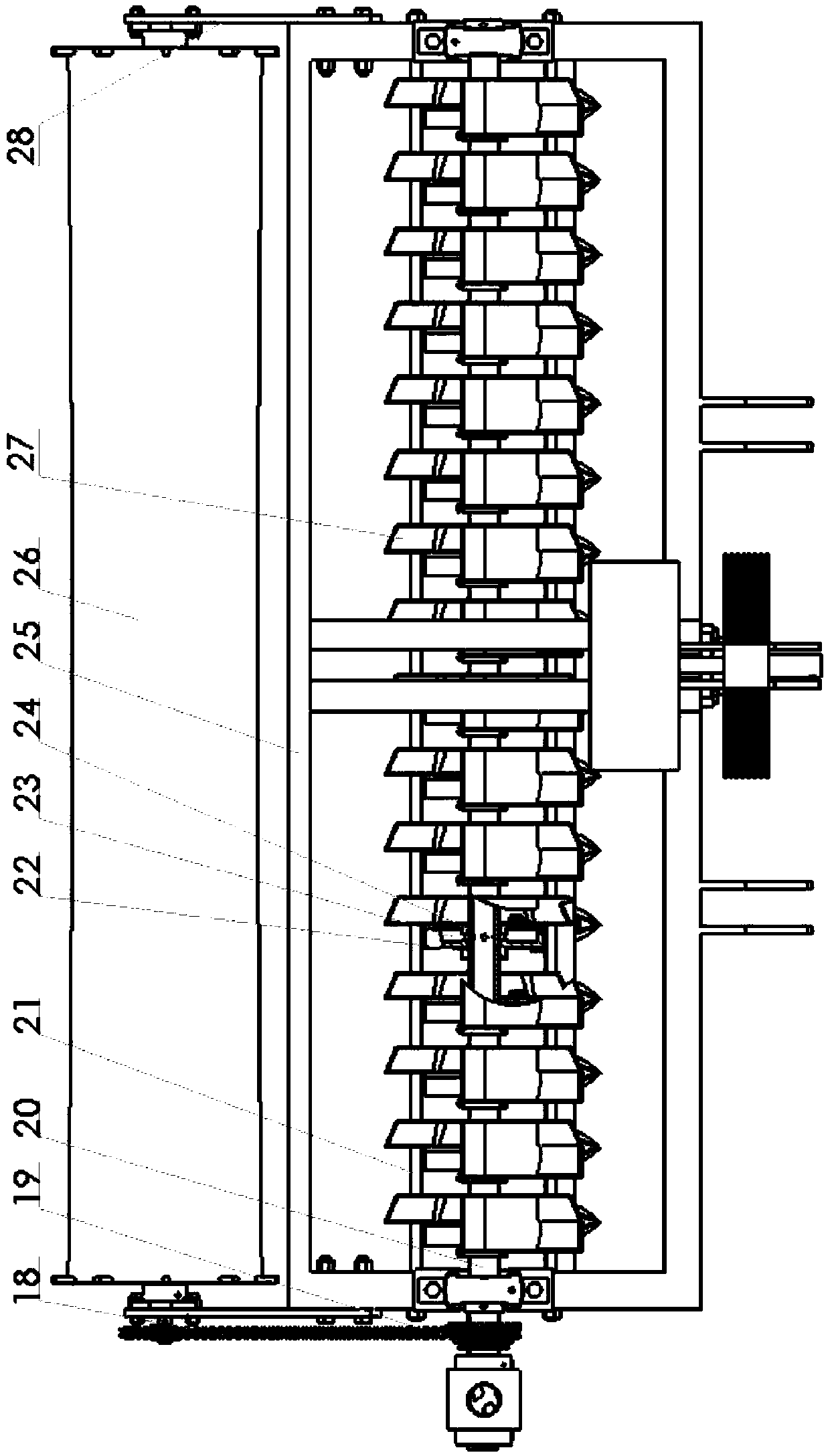

Multifunctional celery seeding all-in-one machine

InactiveCN106489325AGuarantee the quality of sowingKeep moistureSpadesPloughsSeederProduction effect

The invention discloses a multifunctional celery seeding all-in-one machine, and belongs to the field of agricultural machinery. The multifunctional celery seeding all-in-one machine comprises a rack, a pressing roller, a rotary tillage ridging device, a ground wheel device, a film laminating device, a sand pressing device and a seeder, wherein the pressing roller, the rotary tillage ridging device, the ground wheel device, the film laminating device and the seeder are fixedly mounted on the rack from front to back. The machine advances under the traction of a tractor or other agricultural machinery; rotation of ground wheels of the machine is realized through a first-stage chain in a transmission manner; and rotation of a film laminating shaft in the film laminating device and transmission of an output shaft of a speed change box of a perforation device are realized through second-stage and third-stage chains in a transmission manner. According to the multifunctional celery seeding all-in-one machine, the sand pressing device and the ground wheel device are improved, and a drop irrigation device is additionally arranged, so that the sand stirring and production effect is enhanced, the advancing resistance of the all-in-one machine is reduced, and the seeding precision is improved.

Owner:NINGXIA ACADEMY OF AGRI & FORESTRY SCI +1

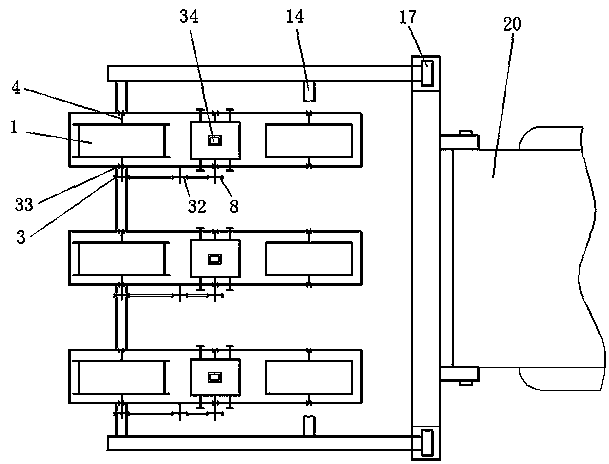

Planting seeder for facility agriculture

ActiveCN111264143AImprove seeding efficiencyReduce labor intensitySeed depositing seeder partsFertiliser and seeding apparatusSeederAgricultural engineering

The invention discloses a planting seeder for facility agriculture. The planting seeder comprises a bottom plate, a seed storage chamber and a fertilizer storage chamber, wherein the seed storage chamber and the fertilizer storage chamber are fixedly arranged at the top part of the bottom plate through supporting plates; the seed storage chamber and the fertilizer storage chamber are fixedly connected; and a first fixed plate and a second fixed plate are fixedly arranged at two sides of the bottom part of the bottom plate correspondingly. The invention relates to the technical field of facility agriculture equipment. The planting seeder for facility agriculture provided by the invention has the following advantages: during seeding, a ditch channel used for seeding can be automatically formed in a facility greenhouse for soil cultivation along with the movement of the seeder, and after seeding is finished, the ditch channel can be automatically buried along with the movement of the seeder, so the seeding efficiency is improved to a great extent; and during seeding, seeds and required chemical fertilizers can be simultaneously applied and scattered, and the seeds and the required chemical fertilizers are well mixed, so two procedures are not required for operation during seeding, and the seeding efficiency is improved to a great extent.

Owner:广东省农业科学院农业科研试验示范场

Agricultural sowing vehicle with watering function

InactiveCN110100533AImprove job stabilityAvoid shakingPlantingWatering devicesVehicle frameAgricultural engineering

The invention relates to an agricultural sowing vehicle with a watering function. The agricultural sowing vehicle comprises a sowing mechanism and a watering unit, the sowing mechanism comprises a vehicle frame, a storage battery box, a seed manure tank, a fixing frame and furrow openers; the seed manure tank is installed in the middle side above the vehicle frame, the front furrow opener is liftably connected with the vehicle frame through the fixing frame, handlebars are installed at the rear end of the vehicle frame, and the watering unit is arranged below the handlebars; the watering unitcomprises a water tank, an installing connector, a watering mechanism and a damping unit, the damping unit comprises a first damping mechanism and a second damping mechanism, and the water tank is connected with the installing connector through the first damping mechanism and the second damping mechanism; the watering mechanism comprises a rotary shaft and a roller, and the surface of the roller is provided with water outlet mesh holes; one end of the roller is communicated with a water feeding pipe, and the other end of the roller is connected with a transmission belt and a motor. According to the agricultural sowing vehicle with the watering function, the problems can be effectively solved that an existing agricultural sowing vehicle cannot adjust the furrow opening depth according to planting demands, and another device is needed for watering operation when watering is not timely.

Owner:YANCHENG INST OF TECH

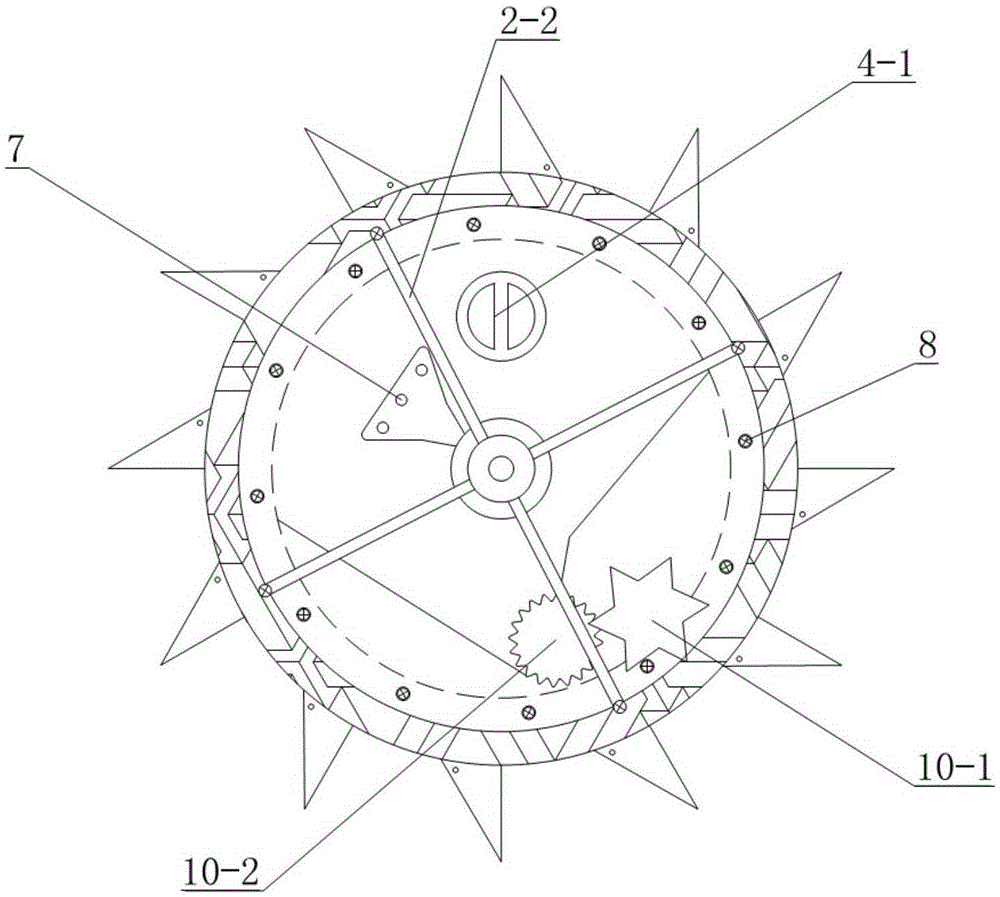

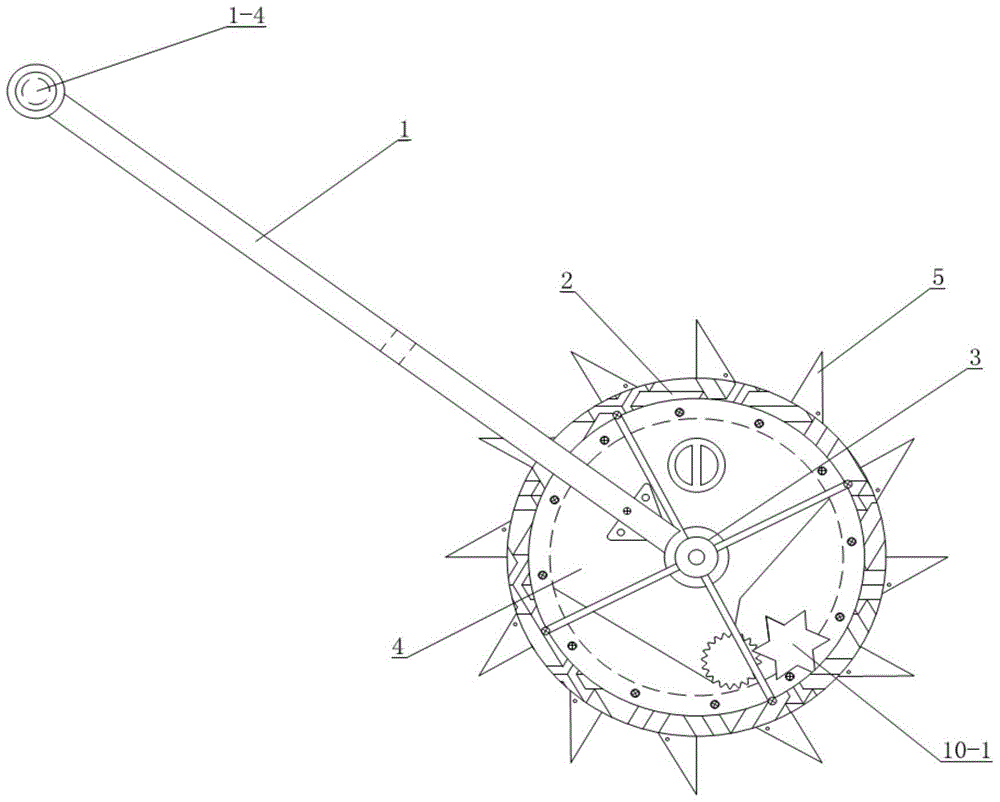

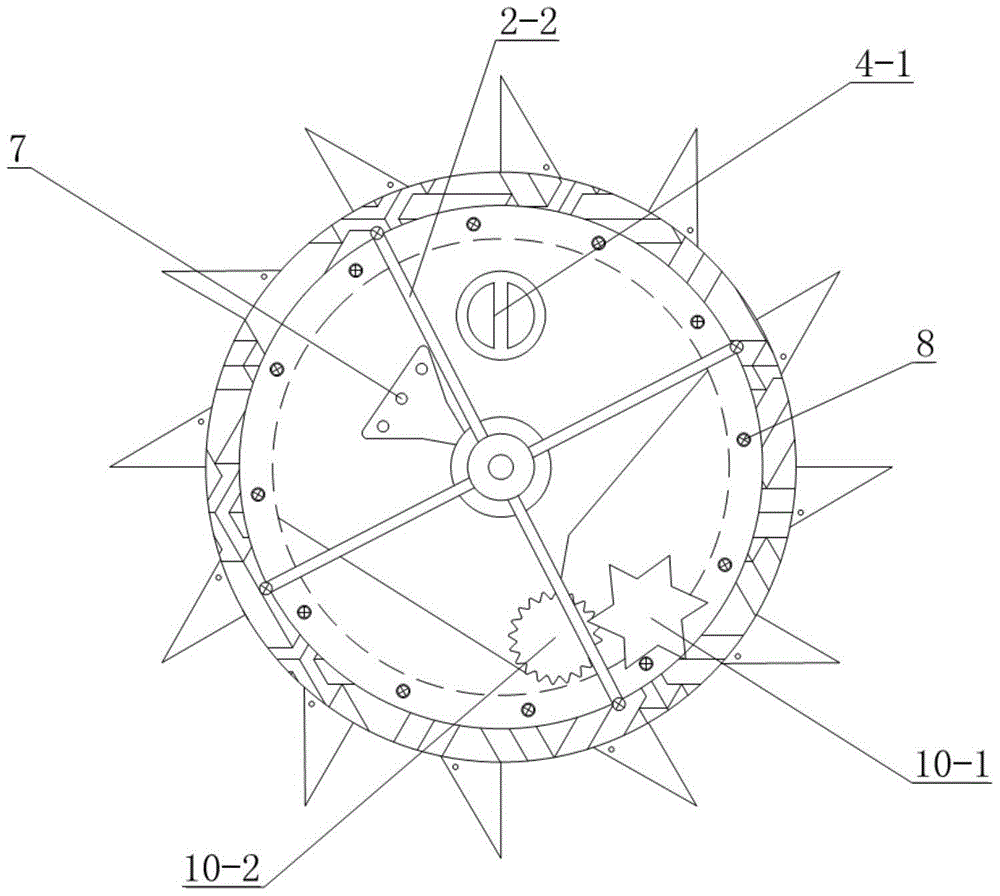

Drum-type mulch puncture and under-mulch precision seeder

InactiveCN107302860AReduce resistancePrecise perforation positionPlantingFurrow making/coveringSeederQuality assurance

A drum-type mulch puncture and precision seeder under the film, comprising: two V-shaped drums with opposite ends, gears distributed on the circumference of the drums, a pair of bevel gears at the opposite ends of the two drums, fixed on the drawbar, Connect the seed introduction tube of the seed box seed metering device, the seed injection valve arranged at the lower port of the seed introduction tube, and the seed injection valve on the circumference of the drum to open the dial. Seed valve return spring. The positive effect of the invention is that the synchronous rotation of the double rollers is used to hold the mulch film, and the mulch film is stable. The gears on the drum are relatively angled, the puncture resistance is small, and the position is accurate. The seeding port does not touch the ground, will not be blocked by soil, and will not be affected by soil dryness or wetness. The tangential speed along the circumference of the drum forms a tendency for the seeds to fly horizontally and leave the seed hole. The rate of seed entry into the hole is 100%, and the accuracy of the position of the seed is not affected by the speed of the planter. Under the condition of ensuring the seeding quality, it is better than the existing one. The seeding speed of the class seeder can be increased by 2‑4 times.

Owner:刘清春

Cotton seeding device

PendingCN109983869AAccurate control of seeding rateGuarantee the quality of sowingSpadesPlantingAgricultural engineeringTillage

The invention discloses a cotton seeding device and relates to the technical field of seeding devices. The device mainly structurally comprises a rack, a rotary tillage cutter, a seeding disc and a fertilizing machine, wherein the rotary tillage cutter, the seeding disc and the fertilizing machine are arranged on the rack. After rotary tillage is carried out on soil, seeding and fertilizing can bedirectly carried out, the power for seeding and fertilizing is provided by a tractor, and seeding and fertilizing can be synchronously completed. Moreover, the seeding disc and the fertilizing machine can accurately control the seeding amount, the fertilizing amount and the seeding spacing, thereby ensuring the seeding quality.

Owner:ZHEJIANG UNIV

Electronic control gear drive on-membrane copying hill planter

InactiveCN104871696AWill not polluteChange speedRegular seed deposition machinesFertiliser equipmentsGear driveCopying mechanism

The invention relates to an electronic control gear drive on-membrane copying hill planter which comprises a stand; two travelling wheels are respectively arranged at the two sides of the middle part of the stand; an electronic control mechanism and a gear transmission mechanism matched with the electronic control mechanism are arranged above the stand; the gear transmission mechanism is matched with the traveling wheels; a hitching frame is arranged at the rear end of the stand; a support beam is arranged at the rear of the hitching frame; a sleeve is arranged at the middle upper part of the support beam; a limiting rod is arranged at the rear of the support beam; hill planters are arranged on the sleeve; a copying mechanism is arranged on the hill planters and the hitching frame; an armrest is arranged above the hitching frame; the other end of the armrest is positioned at the rear upper parts of the hill planters; a speed control handle is arranged on the armrest; the speed control handle is connected with the electronic control mechanism. The electronic control gear drive on-membrane copying hill planter adopts a storage battery as a power source, thus being free from pollution to the environment; two-stage gear transmission is adopted, so that the reliability of transmission is guaranteed, machines and tools do not slip in the operation process, and the consistency of sowing row spacing can be guaranteed; each hill planter is provided with a copying tension spring, so that the copying of earth surface can be realized, and the sowing quality is guaranteed. The complete machine is suitable for completing hole sowing operation on a mulching film without damaging the mulching film.

Owner:GANSU TAOHE TRACTOR MFG

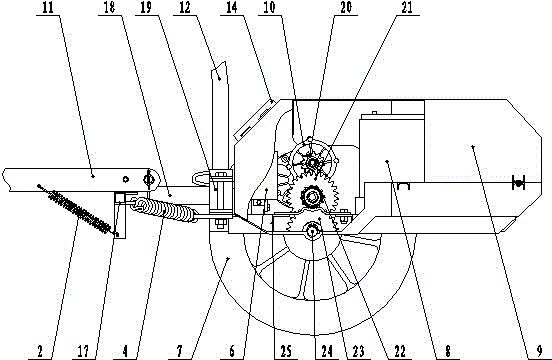

Mechanical planter seed granule falling blocking audible-visual alarm apparatus

InactiveCN106385884AGuarantee the quality of sowingImprove sowing qualityAlarmsSeed depositing seeder partsAudio power amplifierOperational amplifier

The invention discloses a mechanical planter seed granule falling blocking audible-visual alarm apparatus. The mechanical planter seed granule falling blocking audible-visual alarm apparatus comprises a 12V direct-current power source, an infrared ray emission circuit, an infrared signal receiving circuit, a negative pulse forming circuit, a voltage comparing circuit, a high electrical level power amplification and audible-visual alarm circuit; and in the voltage comparing circuit, the model of an adopted operational amplifier IC1 is <mu>A741. The mechanical planter seed granule falling blocking audible-visual alarm apparatus is capable of ensuring crop sowing quality, and is designed for farmers. The mechanical planter seed granule falling blocking audible-visual alarm apparatus can be used for monitoring falling situations of seed granules in a pipeline constantly; once blocking is caused in seed granule falling process, the mechanical planter seed granule falling blocking audible-visual alarm apparatus is capable of alerting operation staff to perform corresponding dredging measures in time, so that large area miss-seeding is avoided, crop sowing quality and farming area working efficiency are increased effectively.

Owner:周芸

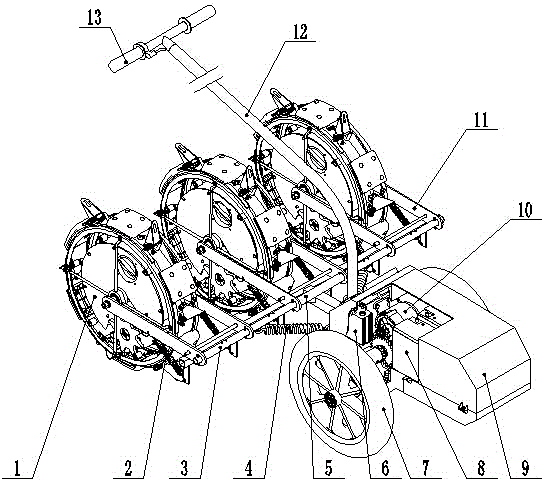

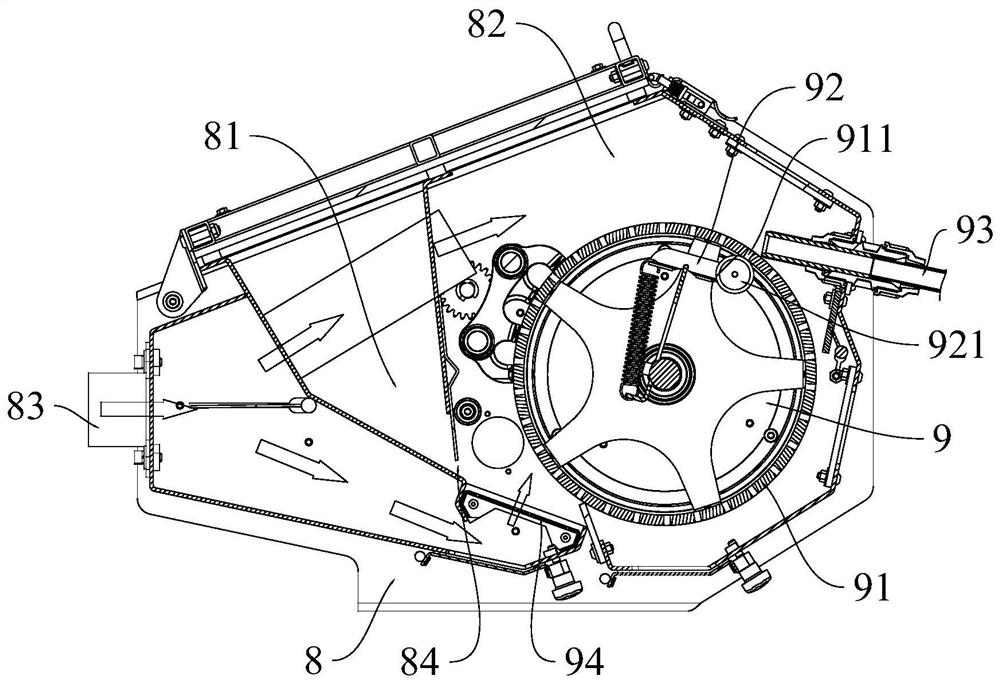

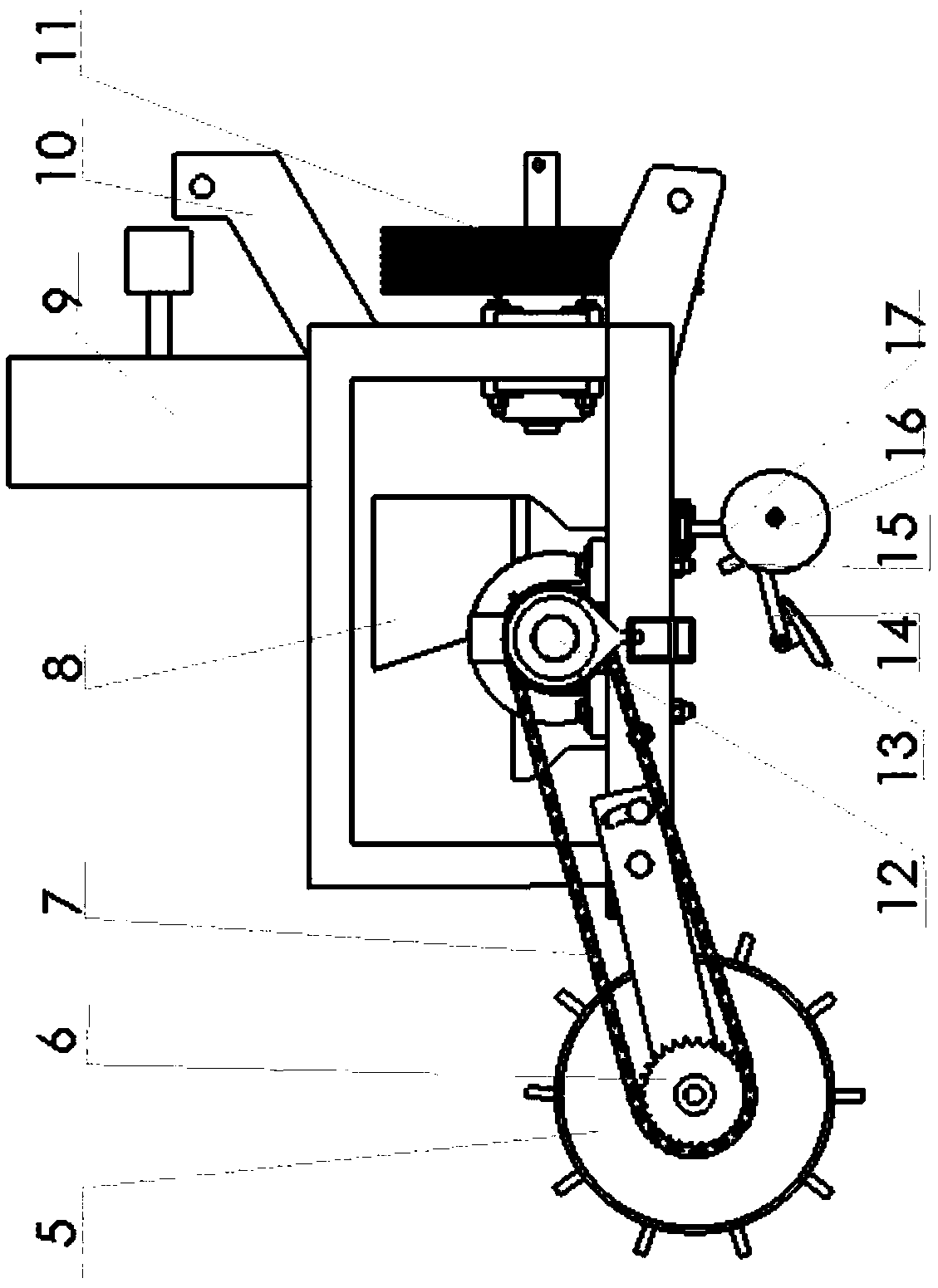

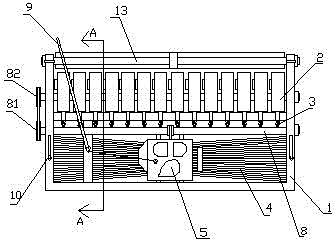

Front-back alternate type high-efficiency garlic seeding machine

ActiveCN109429639ASimple structureReasonable designPotato plantersAgricultural engineeringType distribution

The invention relates to garlic sowing equipment and especially relates to a front-back alternate type high-efficiency garlic seeding machine. The seeding machine comprises a machine frame, an engine,a transmission mechanism and a seeding mechanism, wherein four walking wheels are evenly distributed at the bottom of the machine frame; a driving device, an operating floor and a microcomputer control system are arranged in front of the machine frame; a feeding device is arranged in the middle of the machine frame; the feeding device comprises a W-shaped feeding cabin, a first feeding chain plate and a second feeding chain plate; the W-shaped feeding cabin is fixed to the machine frame, the first feeding chain plate and the second feeding chain plate are arranged at the concave positions ofthe two ends of the feeding cabin, the first feeding chain plate and the second feeding chain plate are respectively connected with distributors, and an air suction type distribution device is connected under each distributor; the air suction type distribution devices are connected with the bottoms of distribution pipes and guiding material cup assemblies, the guiding material cup assemblies are symmetrically arranged at the bottom of the machine frame through connection rods, and the two guiding material cup assemblies can finish front-back alternate rise and fall through push rods.

Owner:JINAN HUAQING AGRI MACHINERY TECH CO LTD

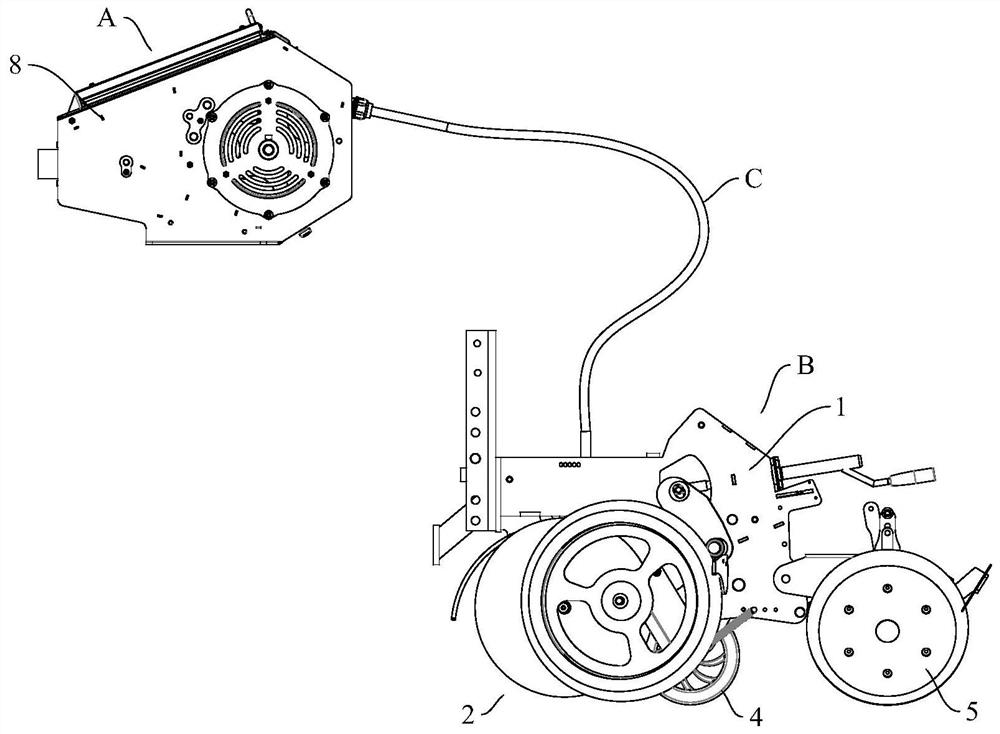

Airflow-assisted precise seeder

ActiveCN113179714AReduce collisionImprove seeding speedPlantingAgriculture gas emission reductionSeederAgricultural science

The invention discloses an airflow-assisted precise seeder. The airflow-assisted precise seeder comprises a precise seed metering device and a tail end tilling and seeding device which are connected through a seed metering pipe. The precise seed metering device comprises a case, and a differential pressure type precise device is mounted in the case. The case is provided with a seed cabin and an air cabin, and an air inlet pipe for introducing airflow into the air cabin is mounted on the case. The differential pressure type precise device is arranged in the air cabin. On one hand, airflow injected by the air inlet pipe enables the differential pressure type precise device to operate so that seeds in the seed cabin are discharged into a seed discharging pipe, and on the other hand, the airflow enters the seed discharging pipe so as to assist seed discharging. The tail end tilling and seeding device comprises a seed feeding pipe and a seed pressing wheel, and the seed pressing wheel is used for pressing seeds fed by the seed feeding pipe. According to the airflow-assisted precise seeder, through airflow assistance, collision between seeds and the pipe wall of the seed feeding pipe is reduced, the fed seeds are pressed through the seed pressing wheel so that the seeds cannot bounce after falling to the ground, and the seeding quality is guaranteed while the seeding efficiency is improved.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

A hand-push single corn seeder

ActiveCN105210505BAvoid cloggingTimely spittingSeed depositing seeder partsSingle grain seedersGear wheelEngineering

Owner:CHANGZHOU UNIV

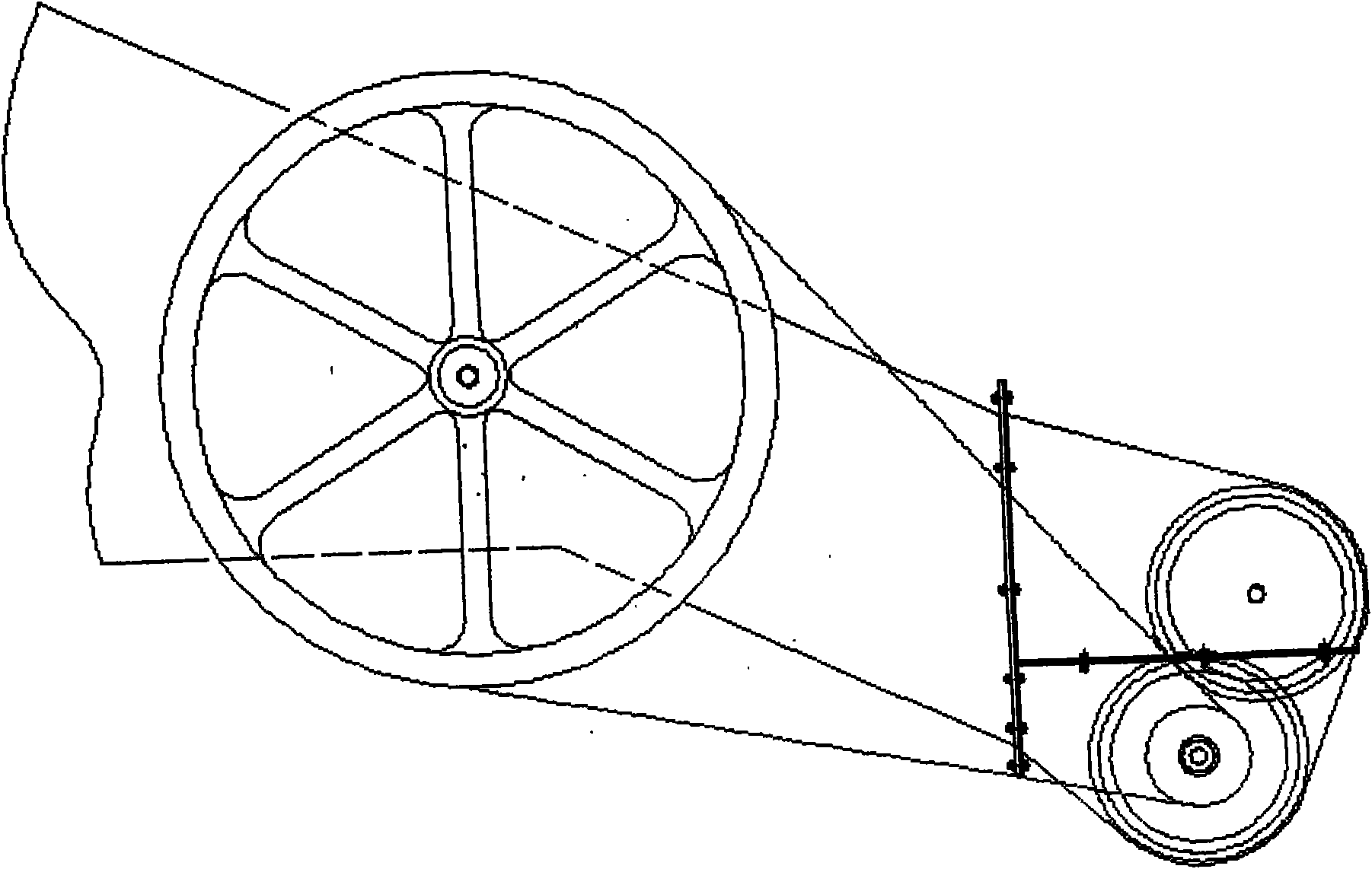

Paddy seedling growing machine

The invention relates to a paddy seedling growing machine. The paddy seedling growing machine comprises a machine body which is provided with a sowing wheel, a flexible hair brush, transmission wheelsand walking wheels. The paddy seedling growing machine is characterized in that a machine case is arranged outside the machine, a seed (soil) inlet is formed in the front part on the machine case, the sowing wheel is arranged below the seed (soil) inlet, the flexible hair brush is arranged at the front part of the machine below the sowing wheel, and an outlet is formed below the front part of theflexible hair; the walking wheels are arranged at the corners of the bottommost part of two sides of the machine case; and two transmission wheels are arranged at the parts, corresponding to two sides of the machine case, of the sowing wheel and the flexible hair brush and are connected through a belt. The paddy seedling growing machine is reasonable in design, the time and the labor are saved, the efficiency is extremely high, and the paddy seedling growing machine is suitable for being used by paddy planting famers or used in large-scale farms.

Owner:万玉花

American ginseng seeder

ActiveCN105493698AImprove planting efficiencyReasonable structurePlantingSowingEngineeringAmerican ginseng

The invention discloses an American ginseng seeder. The American ginseng seeder comprises a rack, a three-point suspension device used for being connected with a traction device is arranged at the front end of the rack, and a press wheel device is arranged at the rear end of the rack and rotates along with advancing of the rack; the rack is further movably provided with a seed storage device, a seed suction device, a seed discharging device, a ditching and earthing device and a transmission device; the seed suction device sucks seeds located in the seed storage device and transfers the seeds to the seed discharging device, the seed discharging device discharges the seeds into seed ditches ditched by the ditching and earthing device, the seeds fall into the ditches, then the ditching and earthing device covers the seeds with earth, and finally, the press wheel device flattens the land, so that sowing is completed, and the transmission device provides power passing and receiving for a gas suction device, the seed storage device, the seed suction device, the seed discharging device and the ditching and earthing device. The American ginseng seeder is reasonable in structure and convenient to operate, sowing operation can be conducted according to the plantation characteristics of American ginseng, sowing quality is guaranteed, and American ginseng plantation efficiency can be remarkably improved.

Owner:QINGDAO AGRI UNIV

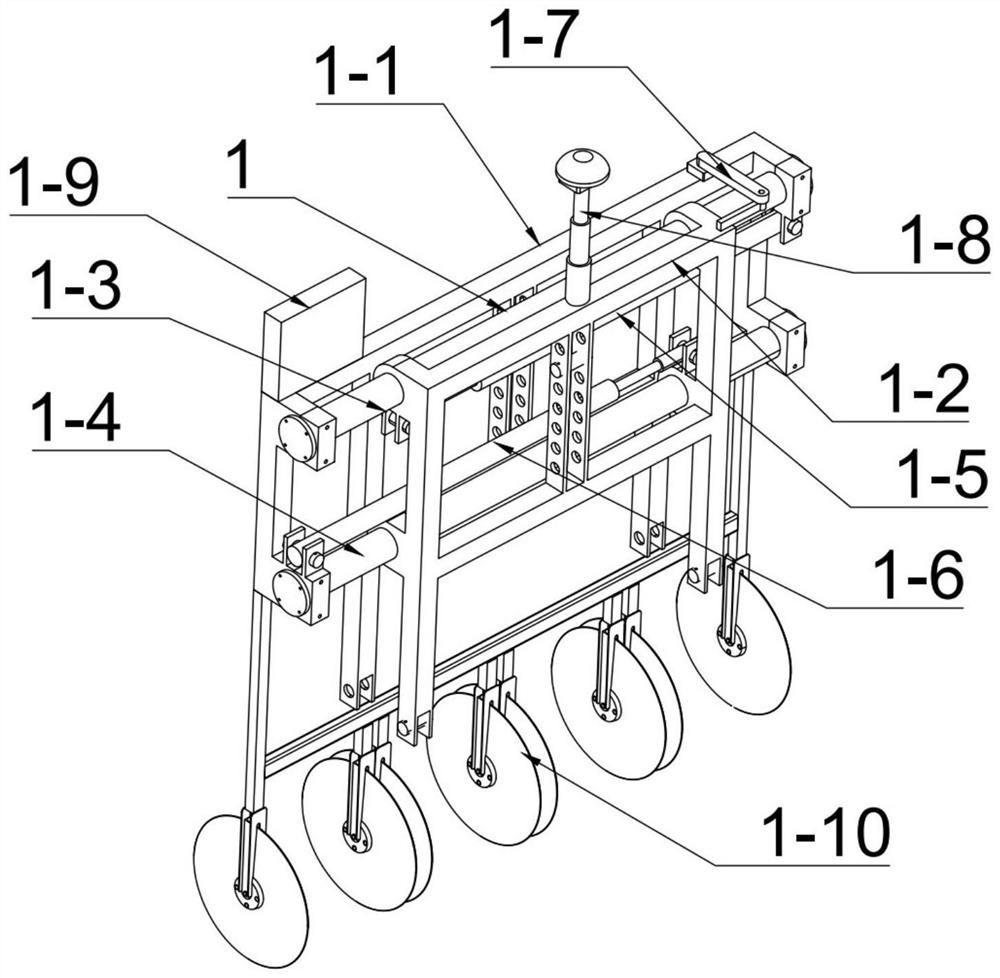

Front-back synchronous steering active row control and posture adjustment device of no-tillage planter

ActiveCN112154749AAvoid touchingSolve the problem that it is difficult to move quickly and stably in the soilAgricultural machinesPlantingHydraulic cylinderCircular disc

The invention relates to a front-back synchronous steering active row control and posture adjustment device of a no-tillage planter. The front-back synchronous steering active row control and postureadjustment device comprises a transverse moving device installed between a tractor and the no-tillage planter and a profiling steering device installed at the rear end of the no-tillage planter. The transverse moving device comprises a fixed frame, a transverse moving frame, an upper transverse moving polished shaft, a lower transverse moving polished shaft, an upper transverse moving hydraulic cylinder, a lower transverse moving hydraulic cylinder, a transverse moving angle sensor, a transverse moving navigation device, a control system and a gravity stubble cutting device. The profiling steering device comprises jaw type fixed frames, horizontal supporting rods, a horizontal cross beam, disc deflection profiling moving devices and a steering navigation device. The disc deflection profiling moving devices comprise four-rod profiling devices and steering devices. By means of the device, the no-tillage planter has independent transverse moving capacity, the problems that transverse moving resistance is too large due to the fact that the no-tillage planter is provided with a soil penetrating component, and the seeding quality is reduced due to the fact that the no-tillage planter only depends on transverse moving of the front portion or the rear portion of an agricultural implement are solved, and the instantaneous quick response is achieved when the implement conducts row control work and posture adjustment.

Owner:CHINA AGRI UNIV

Air suction type garlic seed distribution device

The invention relates to the technical field of garlic planting and especially relates to an air suction type garlic seed distribution device. The air suction type garlic seed distribution device is characterized by comprising a seed sucking pipe and a seed guiding wheel, wherein the seed guiding wheel is arranged in front of the seed sucking pipe and is in contact with the seed sucking pipe, a plurality of seed sucking holes are evenly arranged on the seed sucking pipe, seed guiding rollers are arranged on the seed guiding wheel and at the positions corresponding to the seed sucking holes, seed guiding grooves are arranged on the seed guiding rollers, air sucking pipes are arranged in the seed sucking pipes, openings are arranged on the air sucking pipes and at the positions correspondingto air sucking holes, the air sucking pipes are connected with an air tank, and electromagnetic valves are arranged on the air sucking pipes. The device has a simple structure and a reasonable design, can achieve accurate material distribution, can ensure sowing quality and is suitable for being applied and popularized to a garlic sowing machine.

Owner:JINAN HUAQING AGRI MACHINERY TECH CO LTD

No-tillage seeder front and rear synchronous steering active opposite and attitude adjustment device

ActiveCN112154749BAvoid touchingSolve the problem that it is difficult to move quickly and stably in the soilAgricultural machinesPlantingHydraulic cylinderSeeder

The invention relates to a front and rear synchronous steering active opposite and attitude adjustment device for a no-tillage seeder, which includes a lateral movement device installed between the tractor and the no-tillage seeder and a profiling steering device installed at the rear end of the no-tillage seeder; The moving device includes a fixed frame, a traversing frame, an upper traversing optical axis, a lower traversing optical axis, an upper traversing hydraulic cylinder, a lower traversing hydraulic cylinder, a traversing angle sensor, a traversing navigation device, a control system and gravity stubble cutting The device; the profiling steering device includes a jaw-type fixed frame, a horizontal support rod, a horizontal beam, a disc deflection profiling mobile device and a steering navigation device; the disc deflection profiling mobile device includes a four-bar profiling device and a steering device. The invention enables the no-tillage seeder to have independent lateral movement capability, solves the problem of too large lateral movement resistance caused by the soil-entry parts of the no-tillage planter and the problem of sowing quality degradation caused by the front or rear lateral movement of the agricultural machine tool alone, and realizes the machine tools. Instantaneous and fast response when adjusting the working attitude.

Owner:CHINA AGRI UNIV

Preposed small seed sower

InactiveCN108781619AAvoid uneven seedingGuarantee the quality of sowingPlantingFurrow making/coveringAgricultural engineeringSeed drill

The invention discloses a preposed small seed sower. The preposed small seed sower comprises a main machine frame, an auxiliary machine frame, a ground wheel, a suppressing wheel, a cross beam, an oilcylinder, a seed box, a furrow opener and a soil covering plate, wherein the ground wheel is mounted at the front end of the main machine frame; the suppressing wheel is mounted at the back end of the mainmachine frame; the seed box and the furrow opener are mounted above and below the main machine frame respectively; the soil covering plate is mounted at the back end of the furrow opener; and the auxiliary machine frame is mounted at the front end of the tractor. A sowing mechanism is mounted in a preposed manner, so that the sowing quality is guaranteed; and after sowing, under the rollingaction of the tractor, the preposed small seed sower also plays a compacting role.

Owner:NORTHWEST A & F UNIV

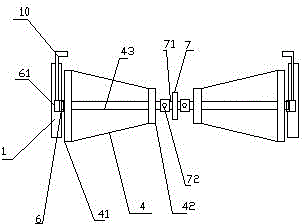

Panax quinquefolius seeder

InactiveCN104969694AImprove planting efficiencyReasonable structurePlantingSowingDrive wheelBarrel Shaped

The present invention relates to agricultural machinery. A purpose of the present invention is to solve the technical problem in the current panax quinquefolius planting process. The present invention provides a panax quinquefolius seeder, which comprises a rack, wherein the rack is provided with rotary seed discharging devices, ditching spades are fixed in the front of the seed discharging devices, the plurality of the seed discharging devices and the plurality of the ditching spades are uniformly arranged along the rack width direction, two walking wheels are arranged on the bottom portions of the rack in front of the ditching spades, present tapered barrel shapes, and comprise large wheel hubs and small wheel hubs, the shaft centers of the large wheel hubs and the small wheel hubs are provided with shaft sleeves, the wheel shaft penetrates through the shaft sleeves of the large wheel hubs and the small wheel hubs, the one wheel shaft end penetrating through the shaft sleeve of the large wheel hub and the side wall of the rack are supported and fixed through a bearing, the one wheel shaft end penetrating through the shaft sleeve of the small wheel hub is connected with a drive wheel, the two walking wheels are distributed on both sides of the drive wheel, the small wheel hub is closed to the drive wheel, and the drive wheel and the seeder are driven through a power machine. The panax quinquefolius seeder of the present invention has characteristics of reasonable structure, easy operation, and substantial panax quinquefolius planting efficiency improving.

Owner:RONGCHENG JIAXIN AGRI MACHINERY

Mealie whole straw coverage wheat full no-tillage planting method and equipment thereof

The invention provides a method and apparatus for total no-tillage planting operation through blanketing wheat with overall maize stalks, wherein the complete stalks of the harvested maize are pulled down in situ in the field, and the wheat seeds are planted through trench digging between the maize planting rows. The maize complete stalk blanketing wheat no-tillage planting and fertilizer applicator set provided by the invention can realize the operations of upright maize stalk pulling down, combing, wheat seeding, fertilizing, suppressing and stalk compression.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com