Intelligent precision corn drilling sowing single body

A precision and corn technology, applied in the direction of sowing, sowing planters, planter parts, etc., can solve the problems of real-time control of sowing depth, uncontrollable four-link profiling structure, and inability to realize plant spacing, etc. Achieve the effect of stepless adjustment, eliminate uneven plant spacing, and ensure the quality of sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

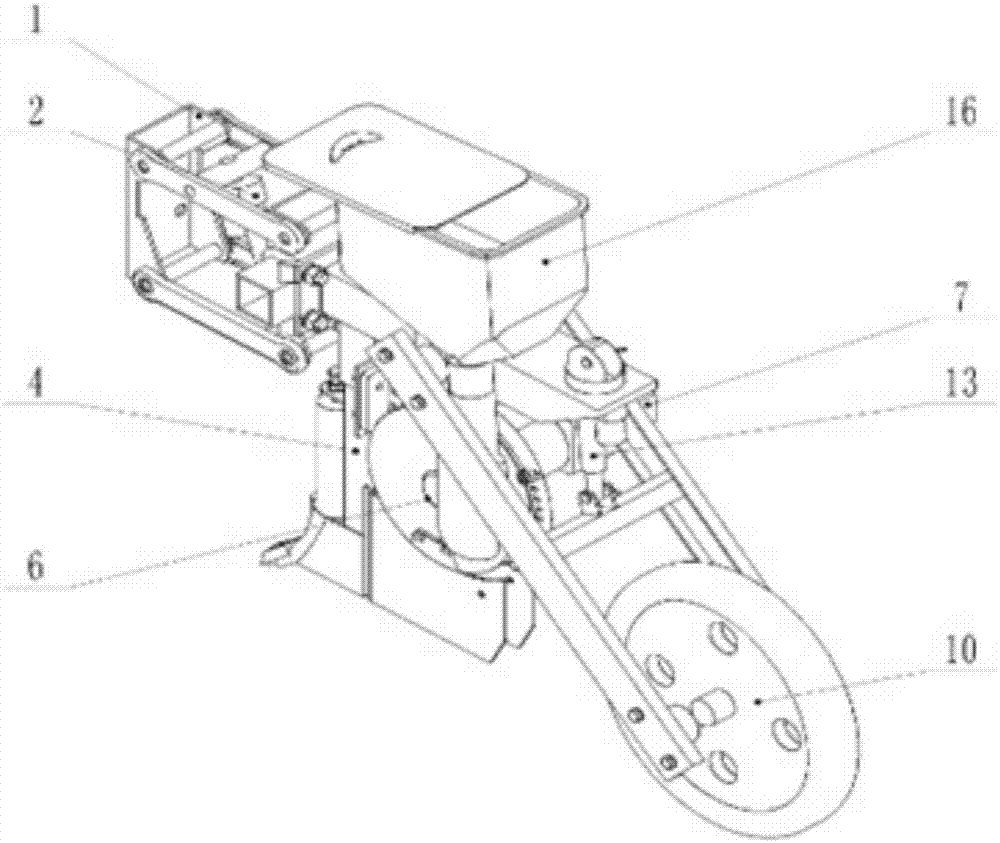

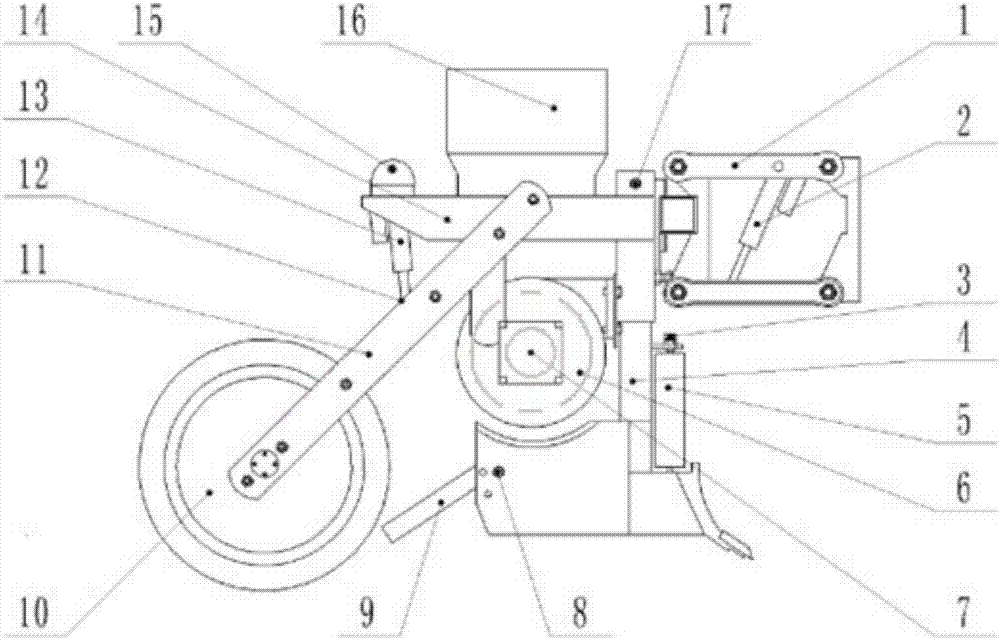

[0031] Such as Figure 1-4 As shown, an intelligent precision corn sowing unit includes: a mechanical part and a monitoring control part;

[0032] Such as Figure 2-4 As shown, the mechanical part includes: frame 14, seed box 16, ground wheel mounting frame 11, ground wheel 10, ditch opener 4, four-bar linkage mechanism 1, seed meter 6 and grass breaking roller 5;

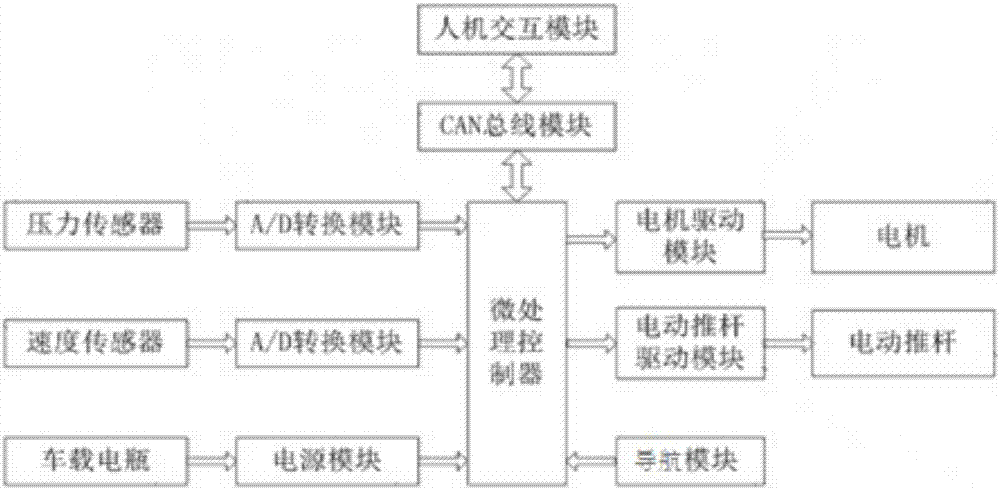

[0033] Such as figure 1 As shown, the monitoring control part includes: speed sensor 23, pressure sensor 12, A / D conversion module, microprocessor controller, human-computer interaction module, motor drive module, motor 7, electric push rod one 2, electric push rod two 13 , electric actuator drive module, navigation module, power module, vehicle battery, CAN bus module;

[0034] Such as Figure 2-4 As shown, the frame 14 is set horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com