Aluminum foil for 1100C lithium battery and preparation method of aluminum foil

A lithium battery and aluminum foil technology, applied in metal rolling and other directions, can solve the problems of low tensile strength and low elongation of aluminum foil, and achieve the effect of overcoming difficult control of plate shape, high degree of work hardening, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

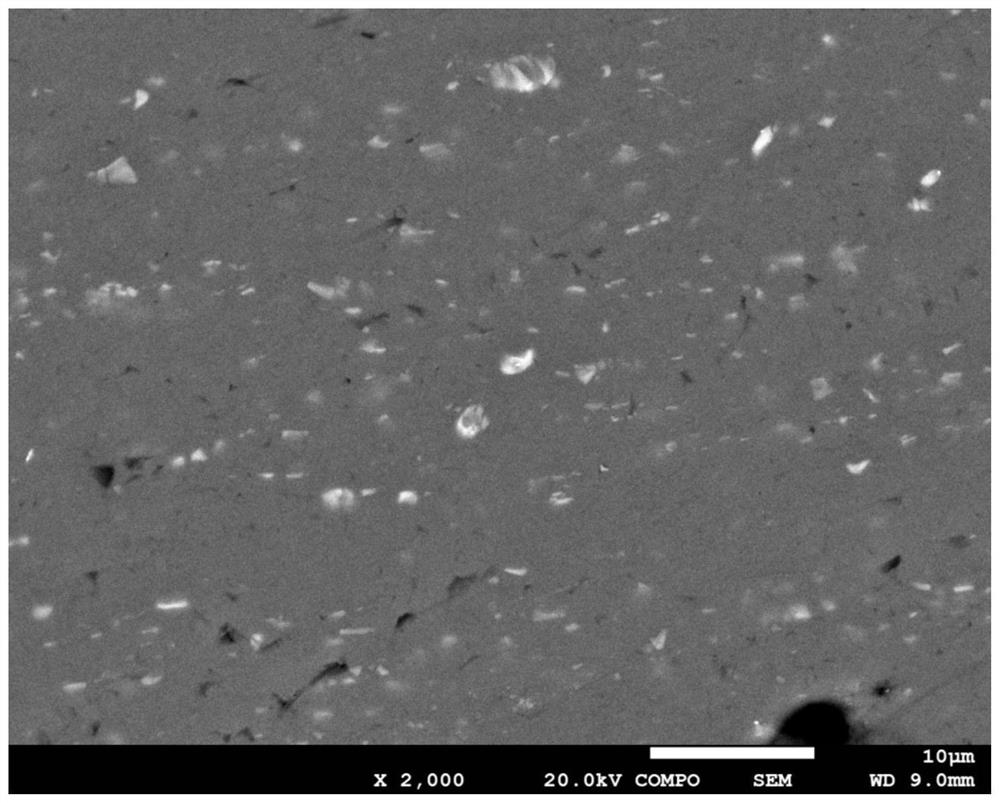

Image

Examples

preparation example Construction

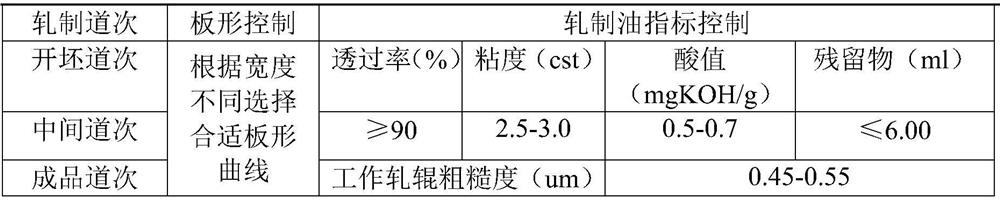

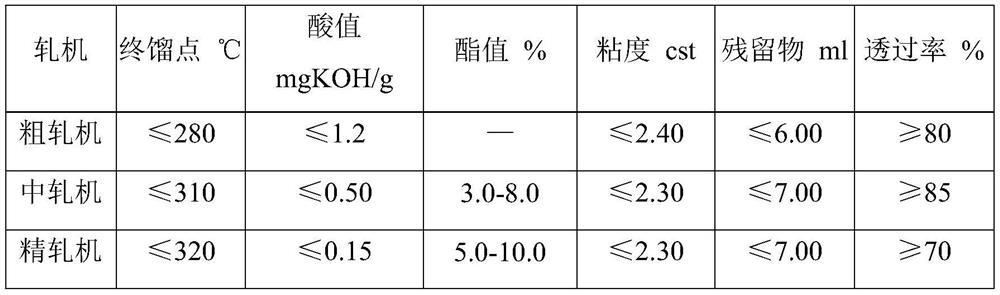

[0035] The preparation method of above-mentioned 1100C lithium battery aluminum foil, comprises the following steps:

[0036] S1. Ingredients, weigh the corresponding raw materials according to the composition design. The raw materials include aluminum alloy scrap with a mass percentage not higher than 25%, and the rest of the aluminum is pure aluminum ingots. The use of the aluminum alloy scrap can realize the reuse of the scrap and reduce the material cost.

[0037] S2, smelting, putting the prepared raw materials into a melting furnace for smelting, and refining the aluminum alloy liquid after the raw materials are completely melted. The hydrogen content in aluminum water is less than or equal to 0.12ml / 100gAl, and the refining agent is sprayed into the melt with pure argon for refining, refining in the melting furnace for 1-2 times, and the refining time in the melting furnace is more than 30min / time; refining in a static furnace for 1 time -2 times, the refining time in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com