Unmanned aerial vehicle quantitative spreading device and method for green manure seeds

A machine-quantitative, seed-based technology, which is applied in the direction of launching devices, sowing seeders, and seeder parts, can solve problems such as low compatibility, unbalanced weight, and inability to achieve quantitative seeding, and achieve the effect of ensuring the quality of seeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The so-called quantitative sowing means that during the operation process, no matter how the flying height and speed of the drone change, for a certain variety of green manure seeds, the amount of seeds per unit area of the field always maintains a fixed value.

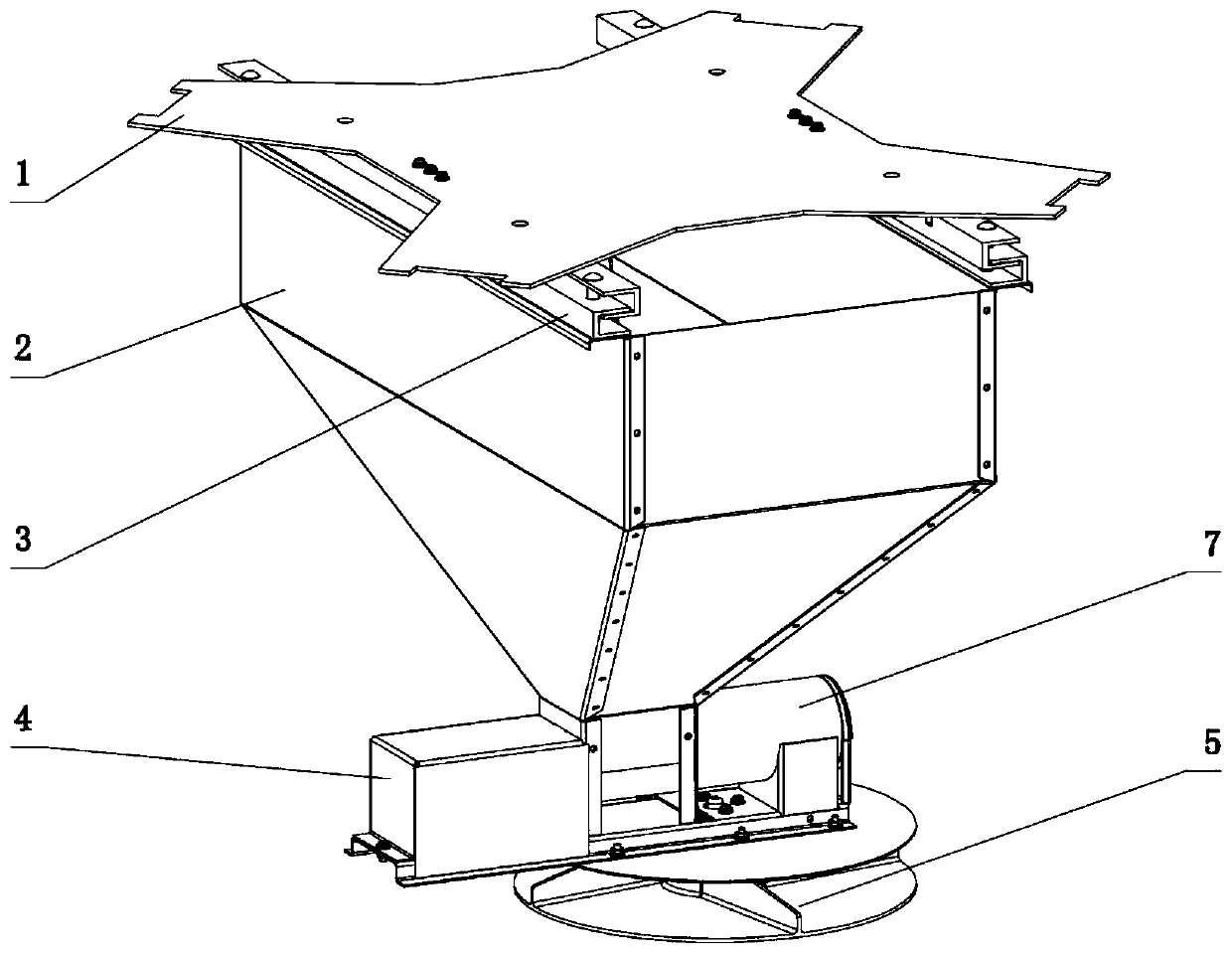

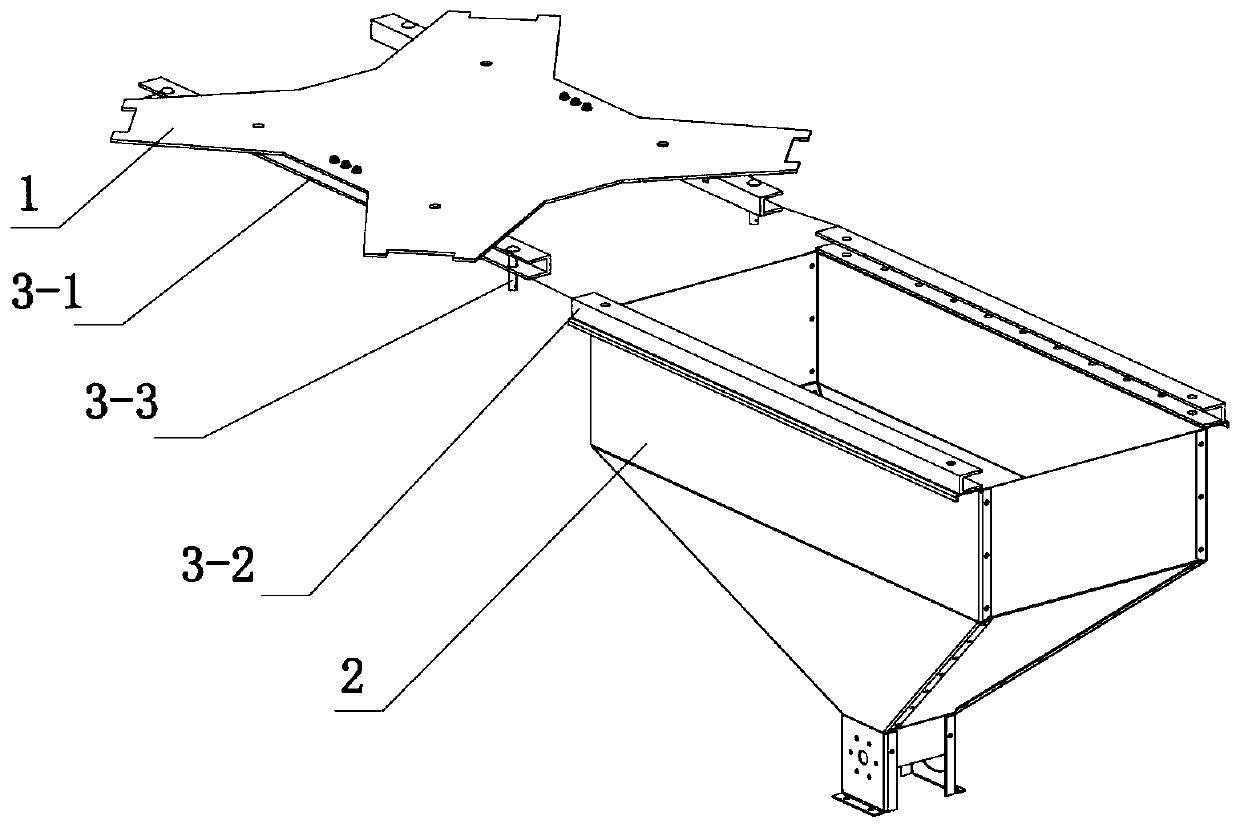

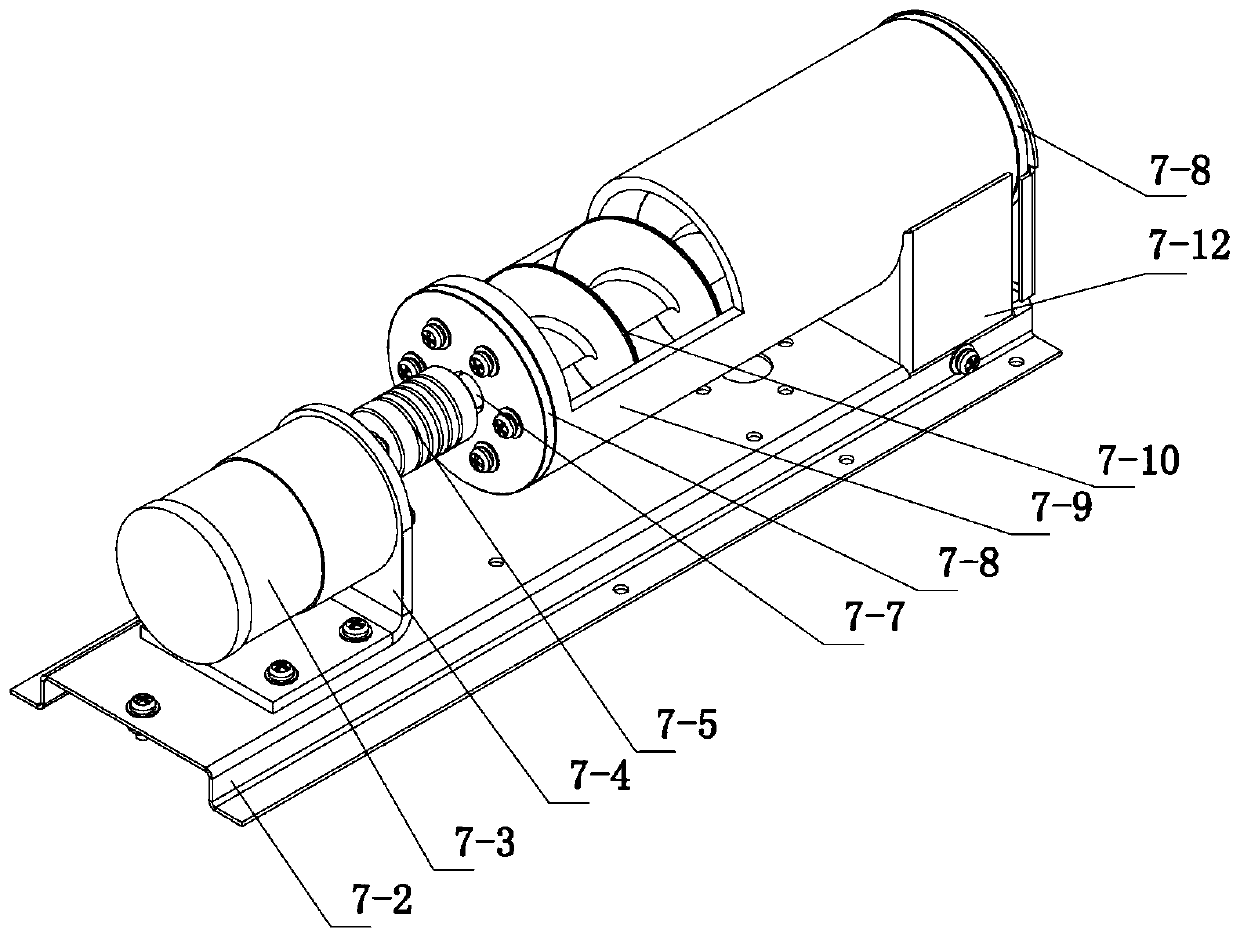

[0045] The green manure seed unmanned aerial vehicle quantitative sowing device of the present embodiment is as figure 1 and figure 2 As shown, its basic composition is: the funnel-shaped seed box 2 is placed under the UAV base plate 1 through the hook assembly 3, the quantitative seeding mechanism 7 is installed at the lower end of the seed box 2, and the seeding mechanism 5 is installed at the bottom of the quantitative seeding mechanism 7. 4 among the figure is the sorting motor cover.

[0046] Specifically, the seed box 2 is composed of four front, rear, left and right side plates with a straight upper part and an inwardly folded lower part, and the horizontal section is rectangular. In order to ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com