Preposed small seed sower

A small-grain and seeder technology, applied in the field of agricultural machinery research, can solve the problems of uneven soil compaction, insufficient water, and high labor intensity, so as to avoid uneven seeding depth, ensure seeding quality, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

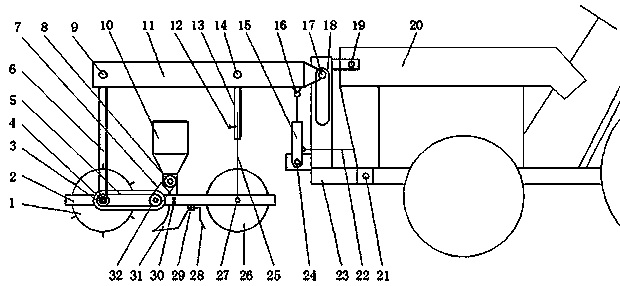

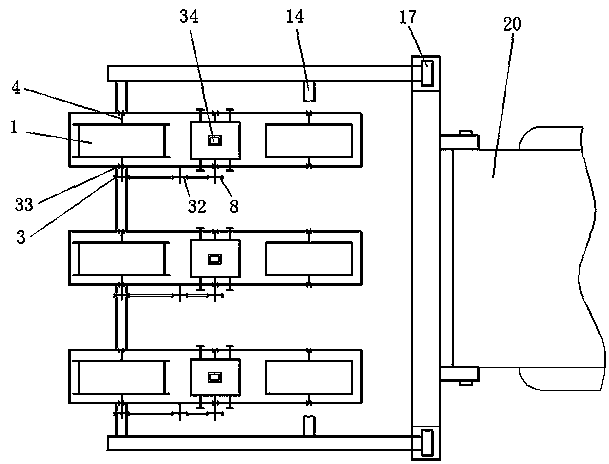

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

[0016] figure 1 It is a front view of a front-mounted small-grain seeder of the present invention, including the main frame (2), the sub-frame (23), the ground wheel (1), the pressing wheel (26), the front bracket (6), the beam ( 11), casing (13), connecting rod (25), oil cylinder (15), seed box (10), opener (32), cover plate (28), chain I (5), chain II (7) , sprocket I (3), sprocket II (32), sprocket III (8), the ground wheel (1) is installed on the front end of the main frame (2), and the suppression wheel (26) is installed on the main frame (2), the seed box (10) and the opener (32) are respectively installed above and below the frame (2), and the cover plate (28) is installed on the opener by screws (29) (32) backend;

[0017] The upper end of the main frame (2) is sequentially installed with a front bracket (6), a beam (11), a bushing (13) and a connecting rod (25)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com