Electronic control gear drive on-membrane copying hill planter

A gear transmission mechanism and gear transmission technology are applied in the direction of interval quantitative planting machinery, fertilization devices, applications, etc., and can solve the problems of lack of mature equipment for on-demand seeding operations on the film, tractors that cannot enter the ground twice, and high labor costs. , to achieve the effect of ensuring the quality of seeding, ensuring reliability and light design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

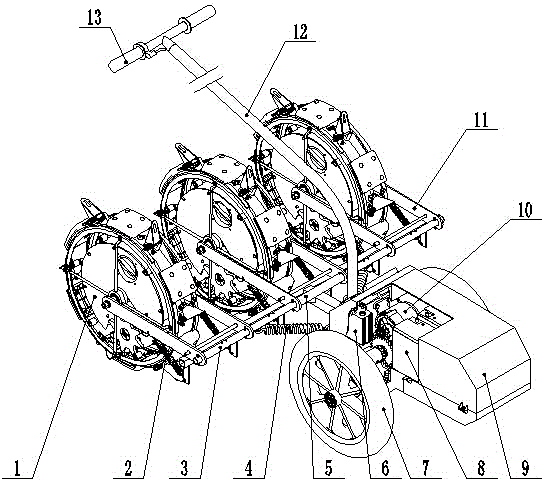

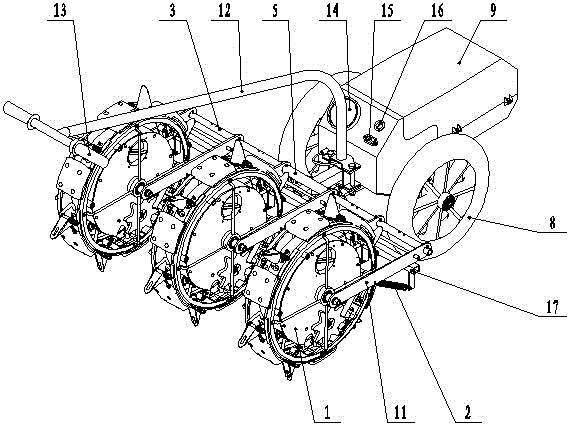

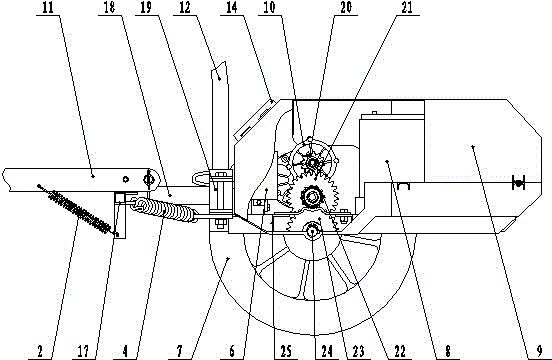

[0017] like figure 1 , figure 2 , image 3 , Figure 4 As shown, a profiling hole sowing machine on an electronically controlled gear transmission film includes a frame 25, a walking wheel shaft 24 is installed below the middle part of the frame 25, and walking wheels 7 are installed at both ends of the walking wheel shaft 24, and the walking wheels 7 are positioned at both sides of the frame 25. . The top of the frame 25 is provided with an electric control mechanism and a gear transmission mechanism cooperating with the electric control mechanism. The electric control mechanism includes a controller 6, a storage battery 8, a motor 10, a power meter 14, a charging port 15 and an electric door lock 16, and the controller 6 is installed On the rear upper part of the frame 25, the accumulator 8 is installed on the front upper part of the frame 25, the motor 10 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com