Front-back synchronous steering active row control and posture adjustment device of no-tillage planter

A technology of adjusting device and planter, which is applied to adjusting device, lifting device of agricultural machinery, fertilizer and seeding equipment, etc., can solve the problems of large traverse resistance and reduced sowing quality, so as to ensure the quality and efficiency of sowing and avoid touching corn. The effect of stubble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] The present invention will be described in further detail below in conjunction with the accompanying drawings.

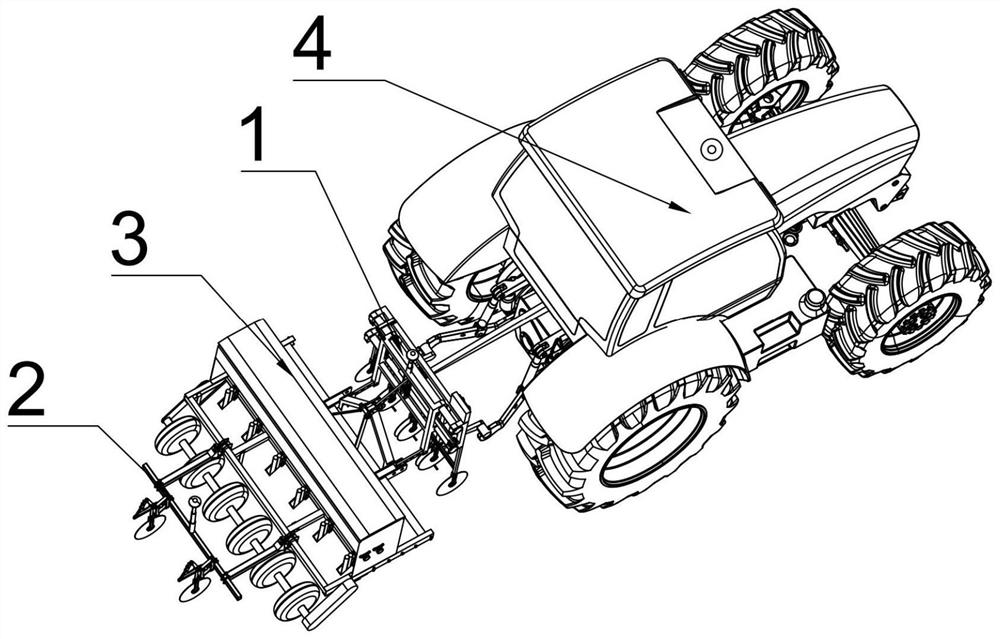

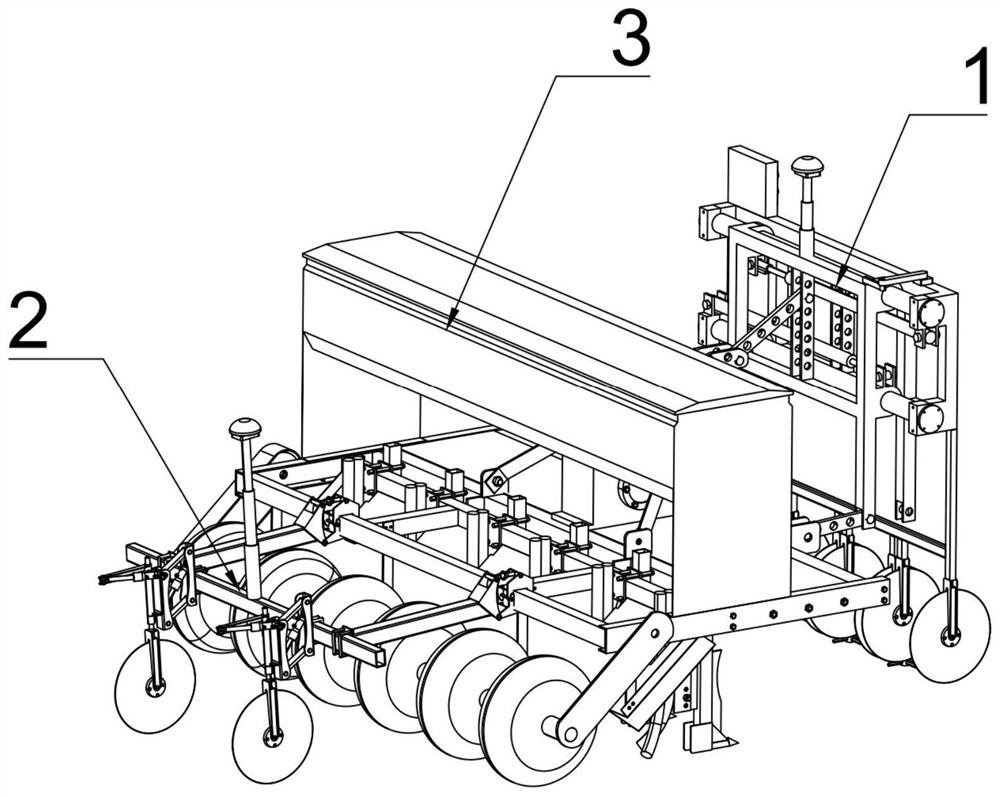

[0082] Such as figure 1 and figure 2 As shown, a no-tillage seeder front and rear synchronous steering active alignment and attitude adjustment device includes a traverse device 1 installed between the tractor 4 and the no-tillage seeder 3 and a profiling device installed at the rear end of the no-tillage seeder 3 Steering device 2.

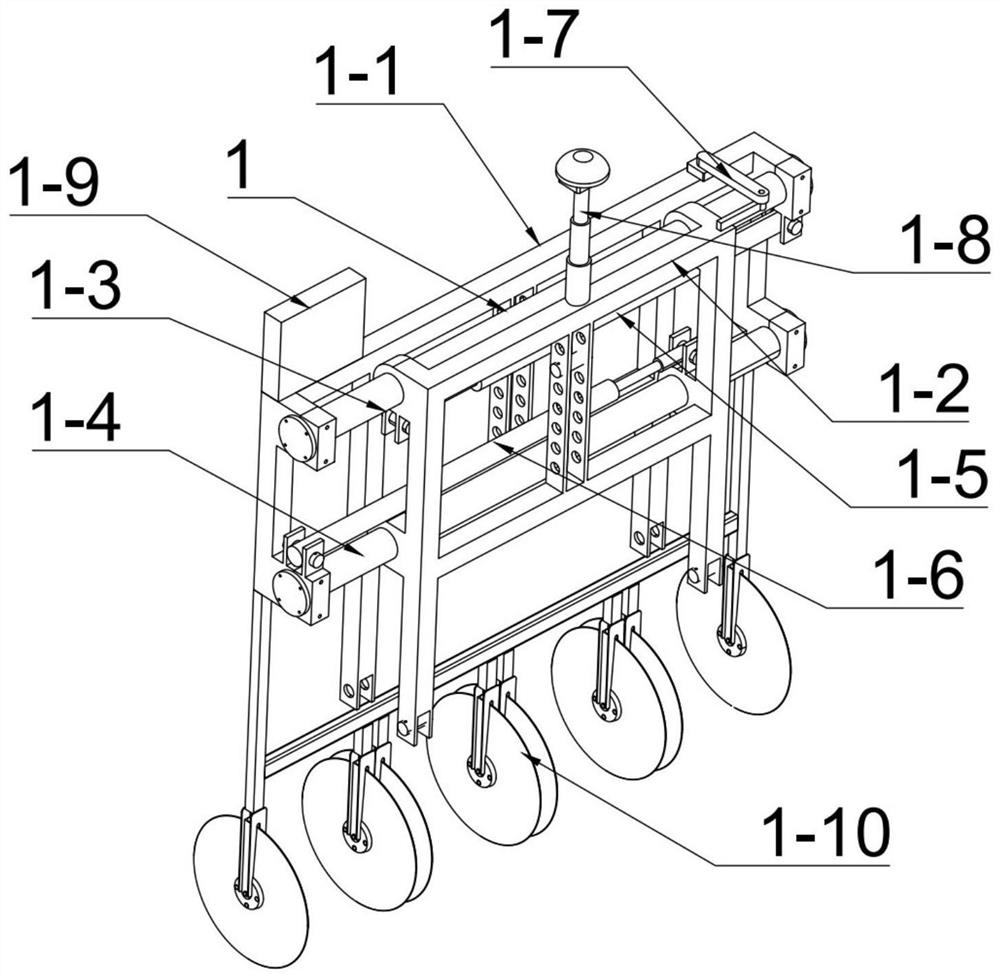

[0083] Such as image 3 As shown, the traversing device 1 includes a fixed frame 1-1, a traversing frame 1-2, an upper traversing optical axis 1-3, a lower traversing optical axis 1-4, an upper traversing hydraulic cylinder 1-5, Lower traverse hydraulic cylinder 1-6, traverse angle sensor 1-7, traverse navigation device 1-8, control system 1-9 and gravity stubble cutting device 1-10.

[0084] Such as Figure 4 As shown, the fixed frame 1-1 includes an upper fixed frame beam 1-1-1 and a lower fixed frame beam 1-1-3 arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com