Front-back alternate type high-efficiency garlic seeding machine

The utility model relates to a planter and alternating technology, which is applied to the field of front and rear alternating high-efficiency garlic planters, which can solve the problems of heavy structure and low planting efficiency, and achieve the effects of ensuring the quality of sowing, simple structure and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

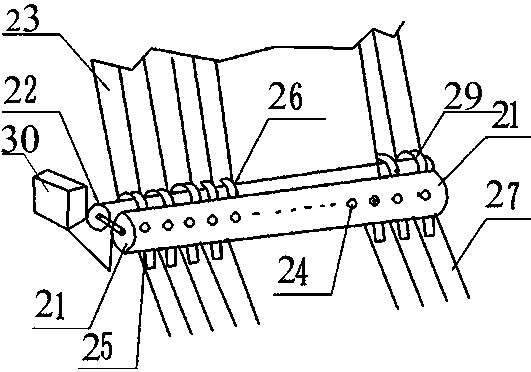

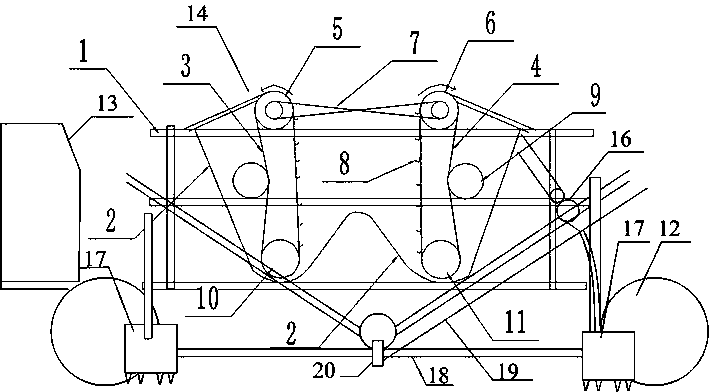

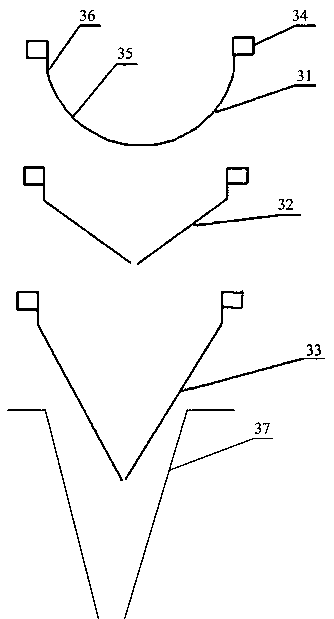

[0024] Accompanying drawing is a kind of specific embodiment of the present invention. as attached figure 1 Shown, comprise frame 1, engine, transmission mechanism, seeding mechanism, it is characterized in that: the bottom of described frame is fixed with 4 traveling wheels 12, and frame 1 front is provided with driver's cab, operating desk, and microcomputer control system , the middle part of the frame 1 is provided with a feeding device 14, and the feeding device 14 includes a "W" type feeding bin 2 fixed on the frame 1, a first feeding material located at the inner recesses at both ends of the feeding bin 2 The chain plate 3 and the second feeding chain plate 4, the first feeding chain plate 3 and the second feeding chain plate 4 are respectively connected to the distributor 15, and the air suction type distributor is connected below each distributor 15. The material device 16, the air suction type material distribution device 16 is connected with the guide cup assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com