Bionic fertilizer placer

A technology of fertilizing ditch openers and ditch openers, which is applied in the fields of excavation/covering ditches, agriculture, application, etc. It can solve the problems of large traction resistance and irregular ditch shape, and achieve the purpose of reducing soil resistance, reducing power consumption, The effect of reducing working resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

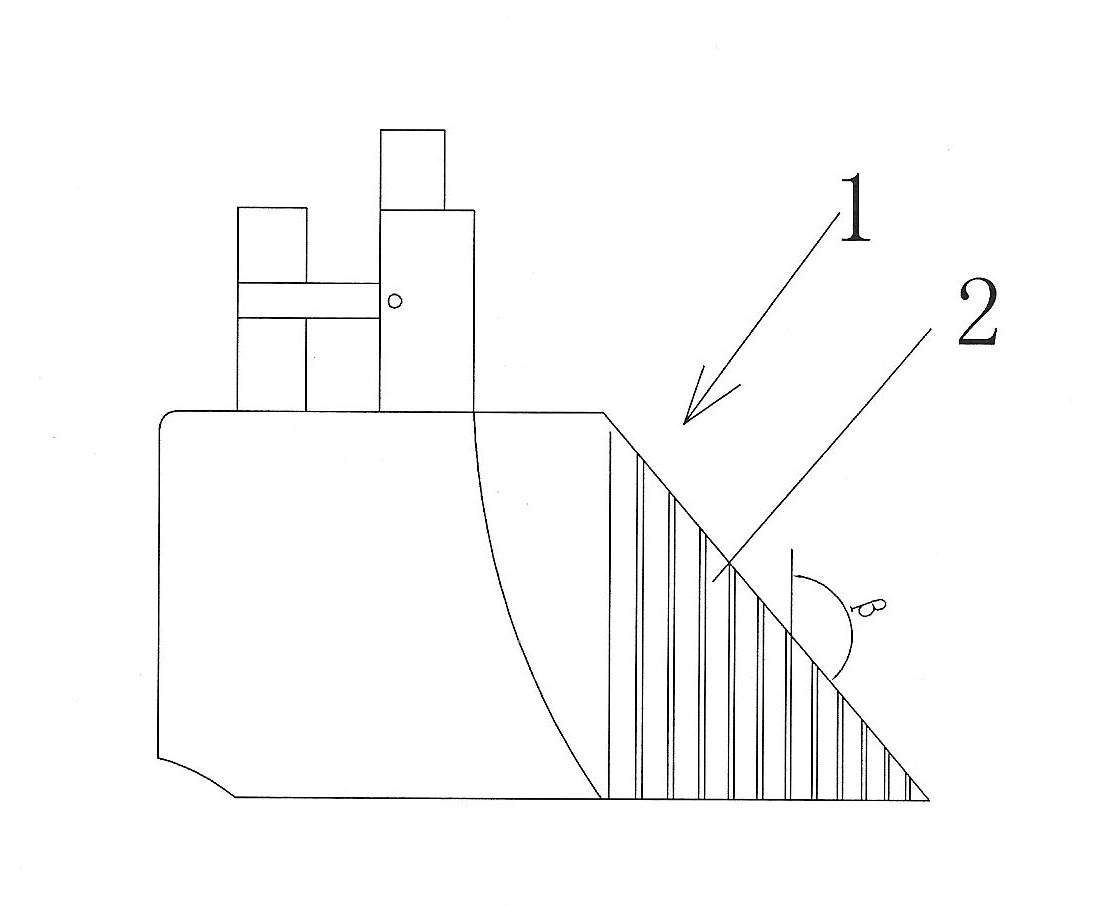

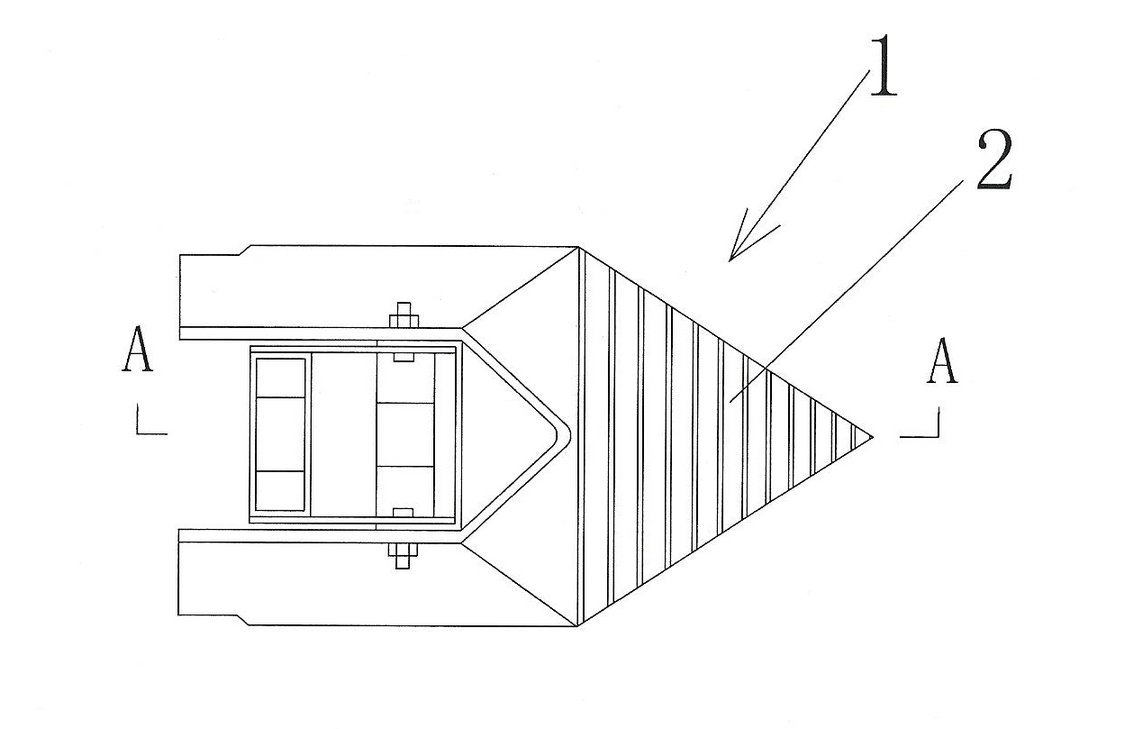

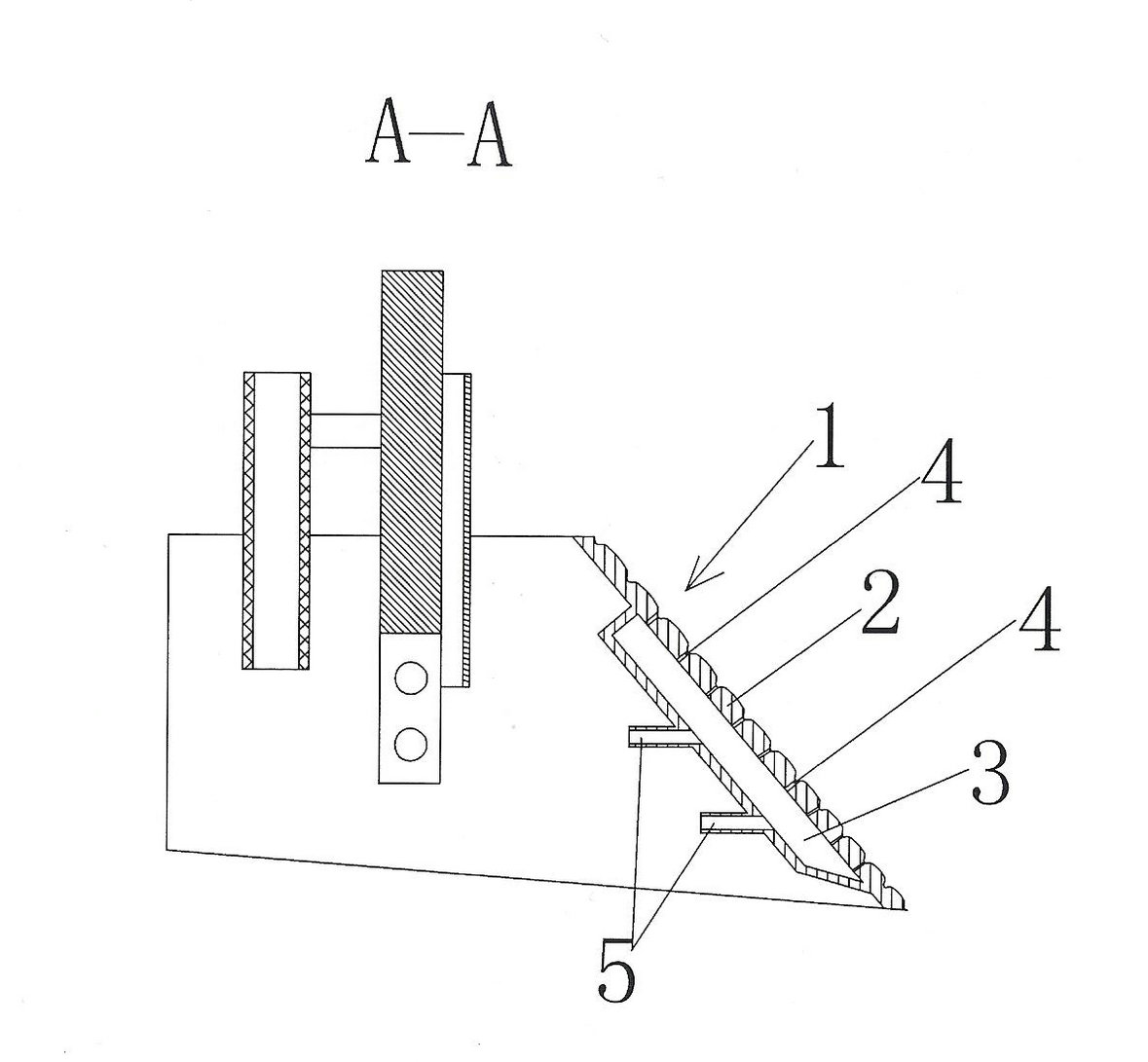

[0015] refer to Figure 1 to Figure 4 As shown, in this embodiment, the surface of the core share 1 of the opener is distributed with a bionic corrugated structure 2, the bionic corrugated structure 2 is a prismatic bionic geometric structure, and the prismatic bionic geometric structure unit and the core share 1. The matrix is made of hydrophobic materials such as ultra-high molecular weight polyethylene or composite materials. The back of the core share 1 has a cavity 3. The prismatic bionic geometric structure unit is provided with several through holes 4 that communicate with the cavity 3. The cavity 3 With air inlet and liquid inlet pipe 5.

[0016] The thickness D of the base body of the core share 1 is 2-4 mm; the height d of the convex rib is 1.7-2.6 mm, the width J is 4.6-7.4 mm, the width M of the groove is 1.1-1.8 mm, and the distance between the edge end of the convex rib and the shovel The distance between the body edge is 0-5mm, and the angle β between the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com