Novel intelligent regulating isobathic seeding device for wide seedling zone

A sowing device and wide seedling belt technology, which is applied in the field of deep sowing devices, can solve problems such as long lag time, large gap in soil depth, and difficulty in seedling emergence, and achieve the effects of overcoming mechanical profiling, ensuring the shape of furrows, and improving seeding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

[0015] Embodiments of the present invention are described below in conjunction with accompanying drawings:

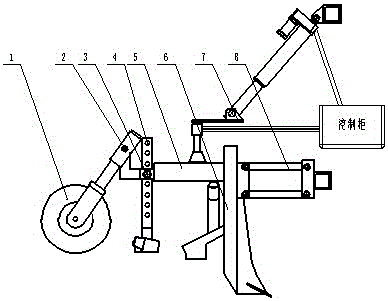

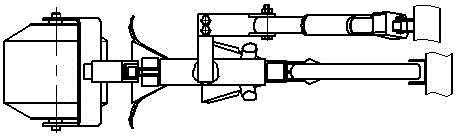

[0016] figure 1 Shown in: 1. Roller wheel system, 2. Adjusting bolt 1, 3. Adjusting bolt 2, 4. Ditch scraper preparation device after sowing, 5. Connecting plate, 6. High-position and wide-width sowing opener for deep fertilization, etc. 7. Intelligent control system, 8. Parallel four-bar mechanism;

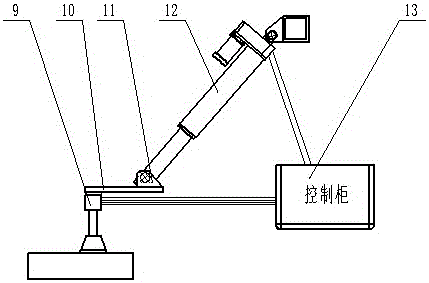

[0017] image 3 Shown in: 9. Pressure sensor, 10. Mounting plate, 11. Electric push rod support, 12. Electric push rod, 13. Control cabinet.

[0018] The high-position and wide-width sowing ditch opener (6) for deep fertilization is connected with the ditch scraper and preparation device (4) after sowing, adjusted by the intelligent control system (7), and the parallel four-bar structure (8) moves up and down to parallel The horizontal position of the four rods is the standard, and the vertical adjustment range is -70mm to 70mm, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com