Patents

Literature

122results about How to "Realize automatic blanking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

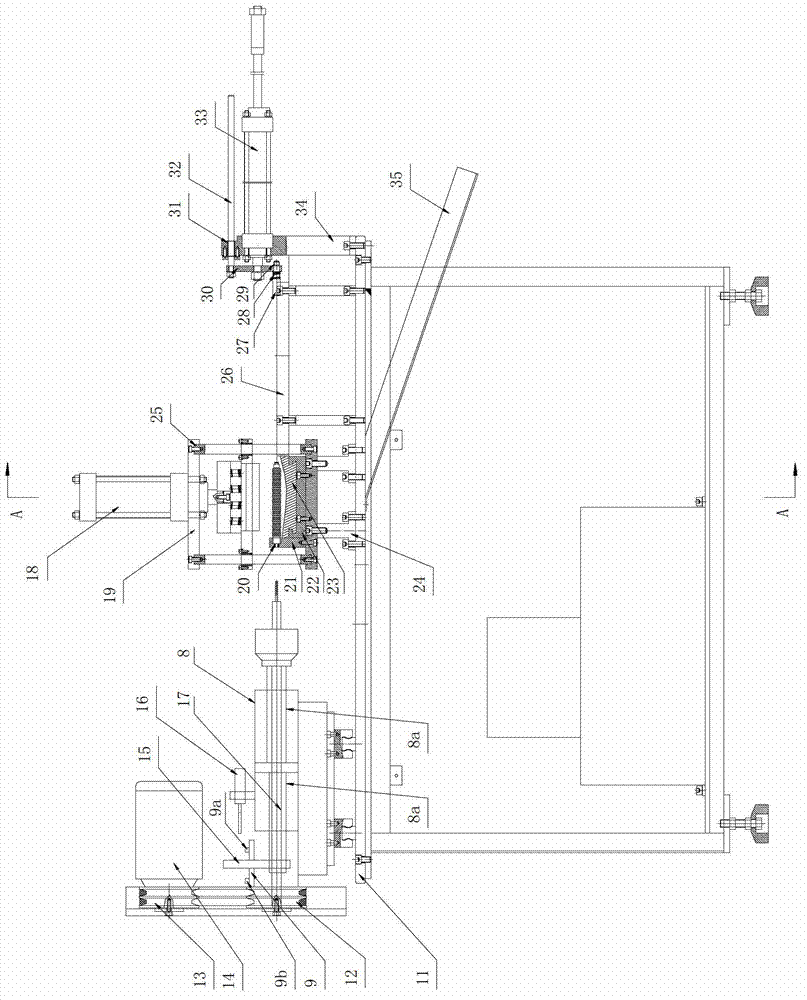

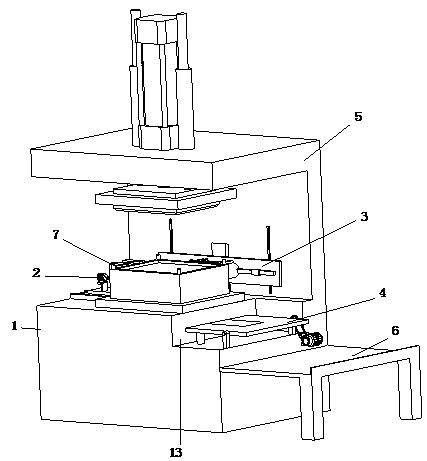

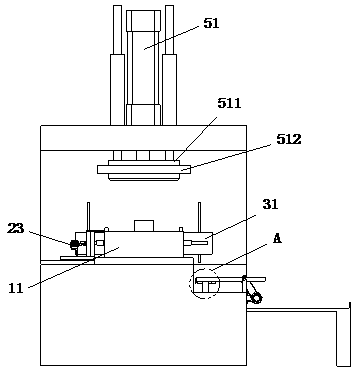

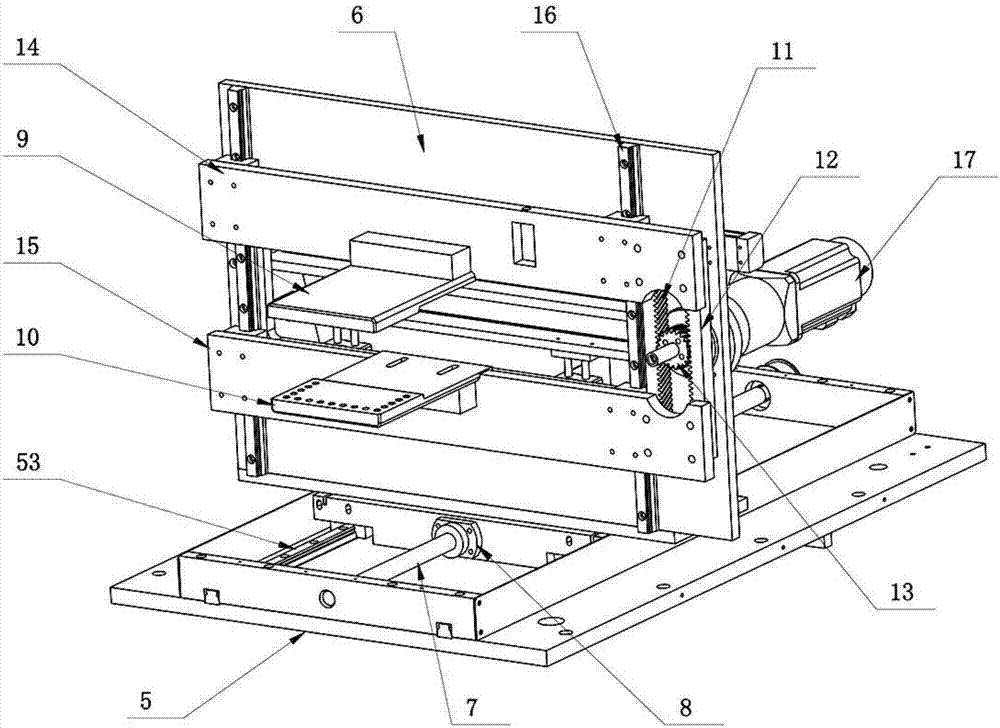

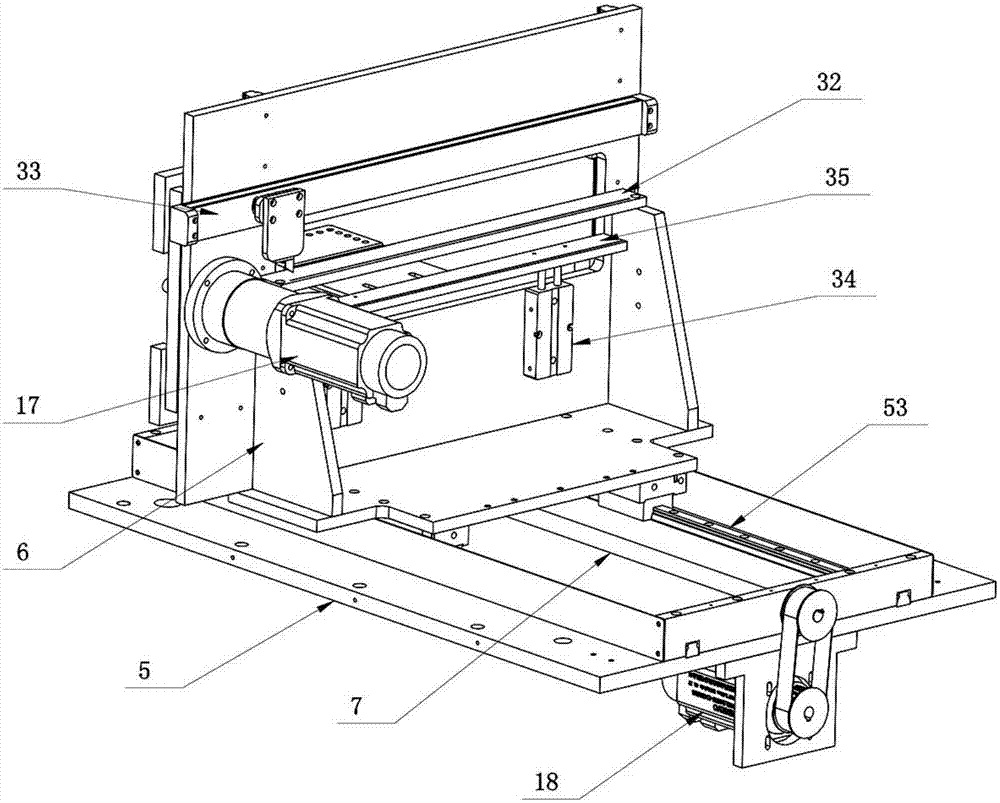

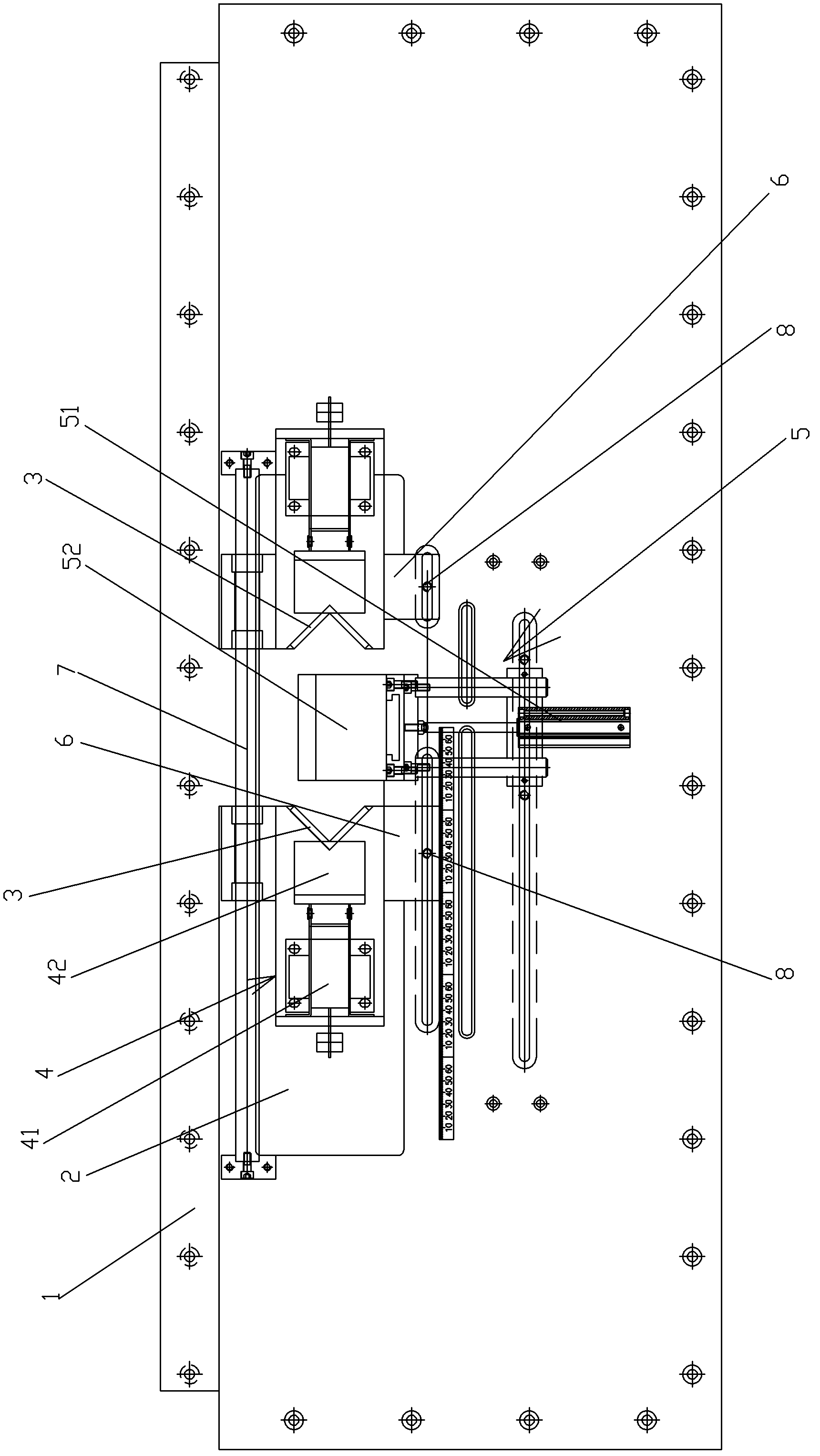

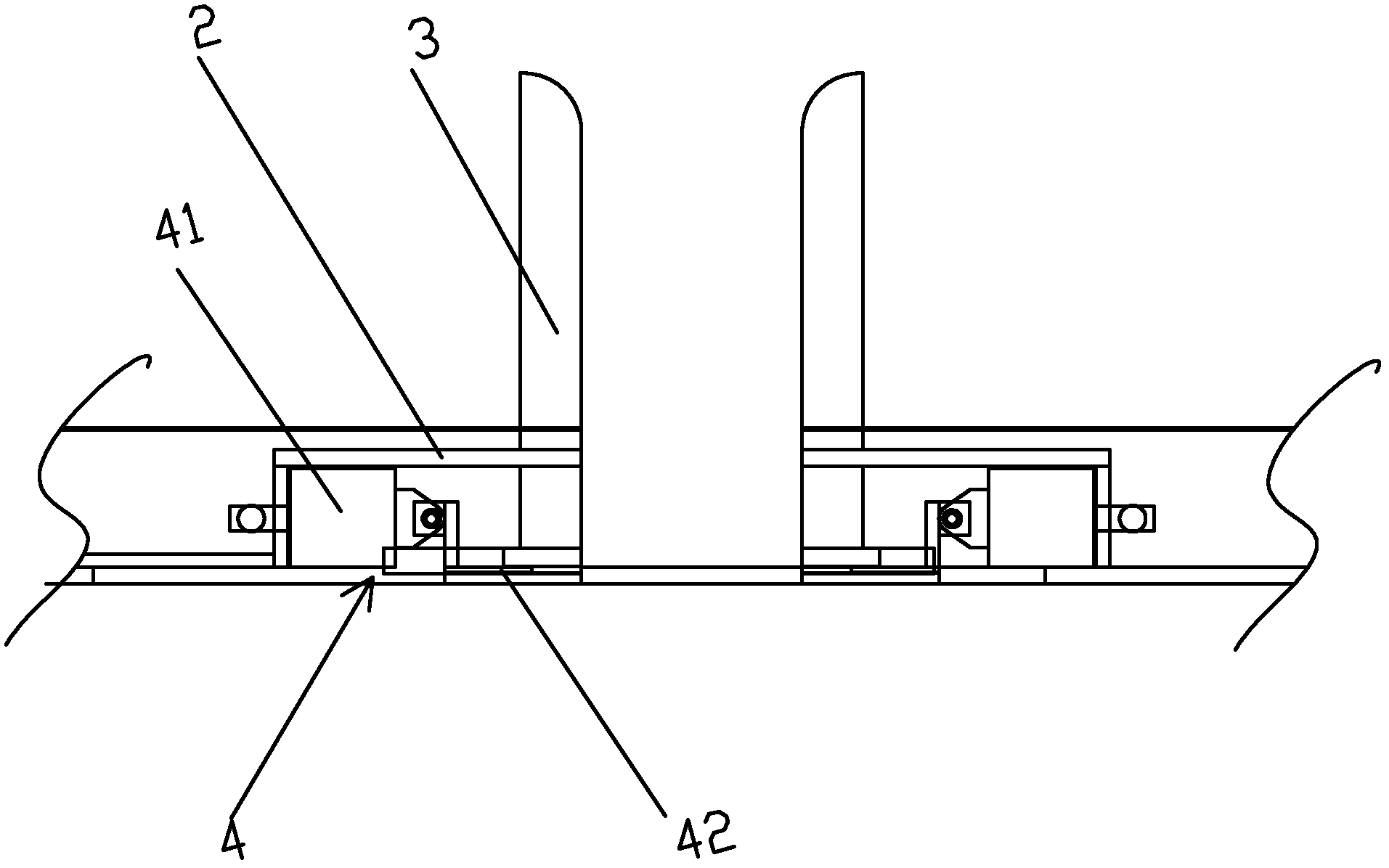

Automatic punching machine

InactiveCN103157822ARealize double-head drilling functionGuaranteed positioning accuracyPositioning apparatusMetal working apparatusPunchingEngineering

The invention relates to an automatic punching machine. A clamping mechanism opposite to a drilling cutting tool is placed on a work platform. The clamping mechanism comprises a support platform, a lower die device, a baffle, a guide column, a support plate, a pressing support platform, an upper die and a pressing oil cylinder. The lower surface of the support platform is fixed on the work platform, the lower die device is fixed on the upper surface of the support platform, the baffle is fixed on the upper surface of the support platform and is located on one side of the lower die device, and the baffle is provided with a through hole through which a workpiece to be machined penetrates. One end of the guide column is connected with the support platform, and the other end of the guide column is connected with the support plate. The pressing support platform is in sliding fit with the guide column. The upper die is connected with the lower portion of the pressing support platform, the upper portion of the pressing support platform is connected with the pressing oil cylinder which is fixed on the support plate, and both the lower die device and the upper die are provided with two material grooves for assembling the workpiece. By means of the automatic punching machine, two wirkpieces with the same axle can be automatically punched at the same time. The automatic punching machine has the advantages of being high in degree of automation, and improving product quality and production efficiency.

Owner:CHANGZHOU SHULE KITCHEN UTENSILS

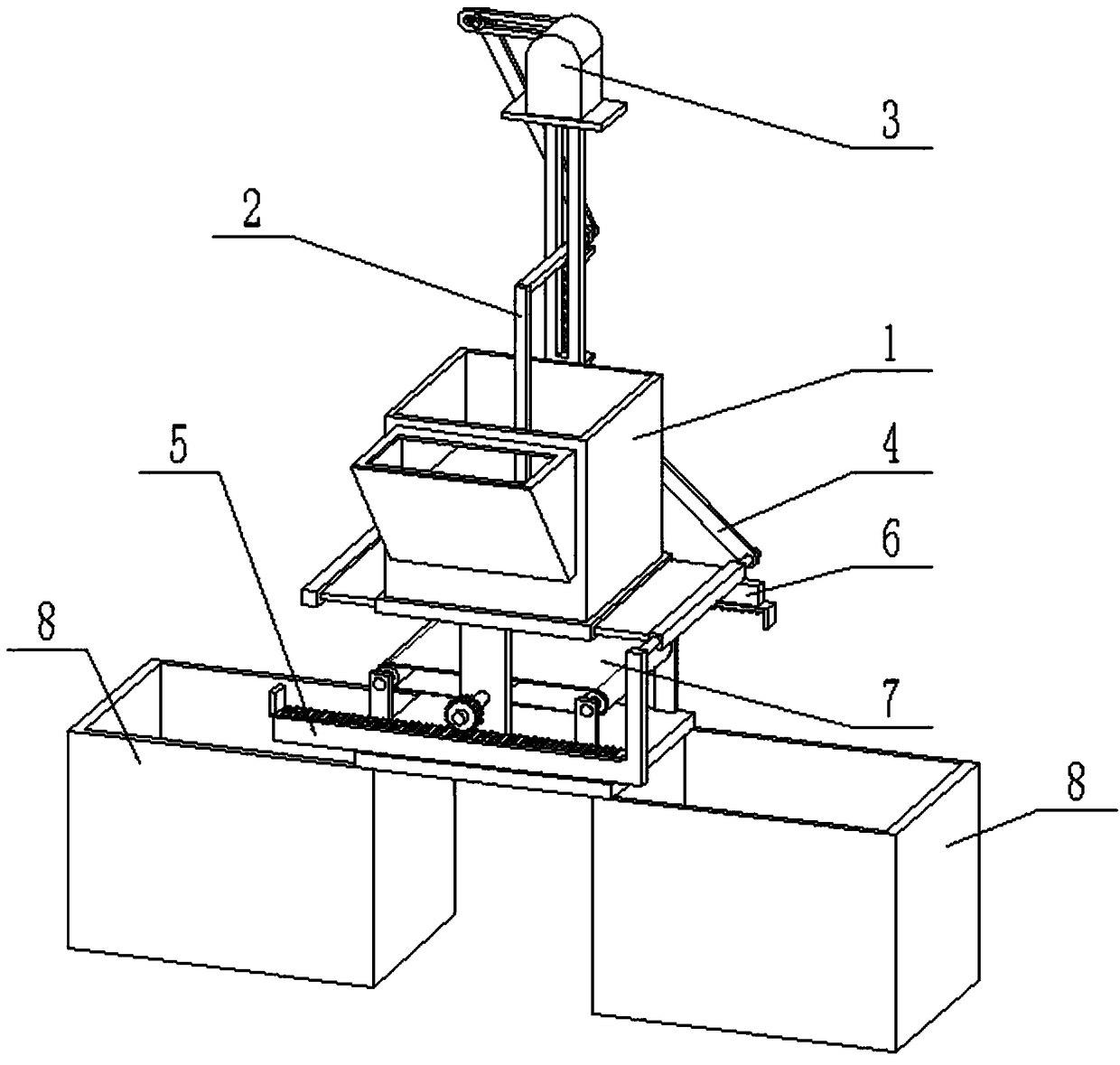

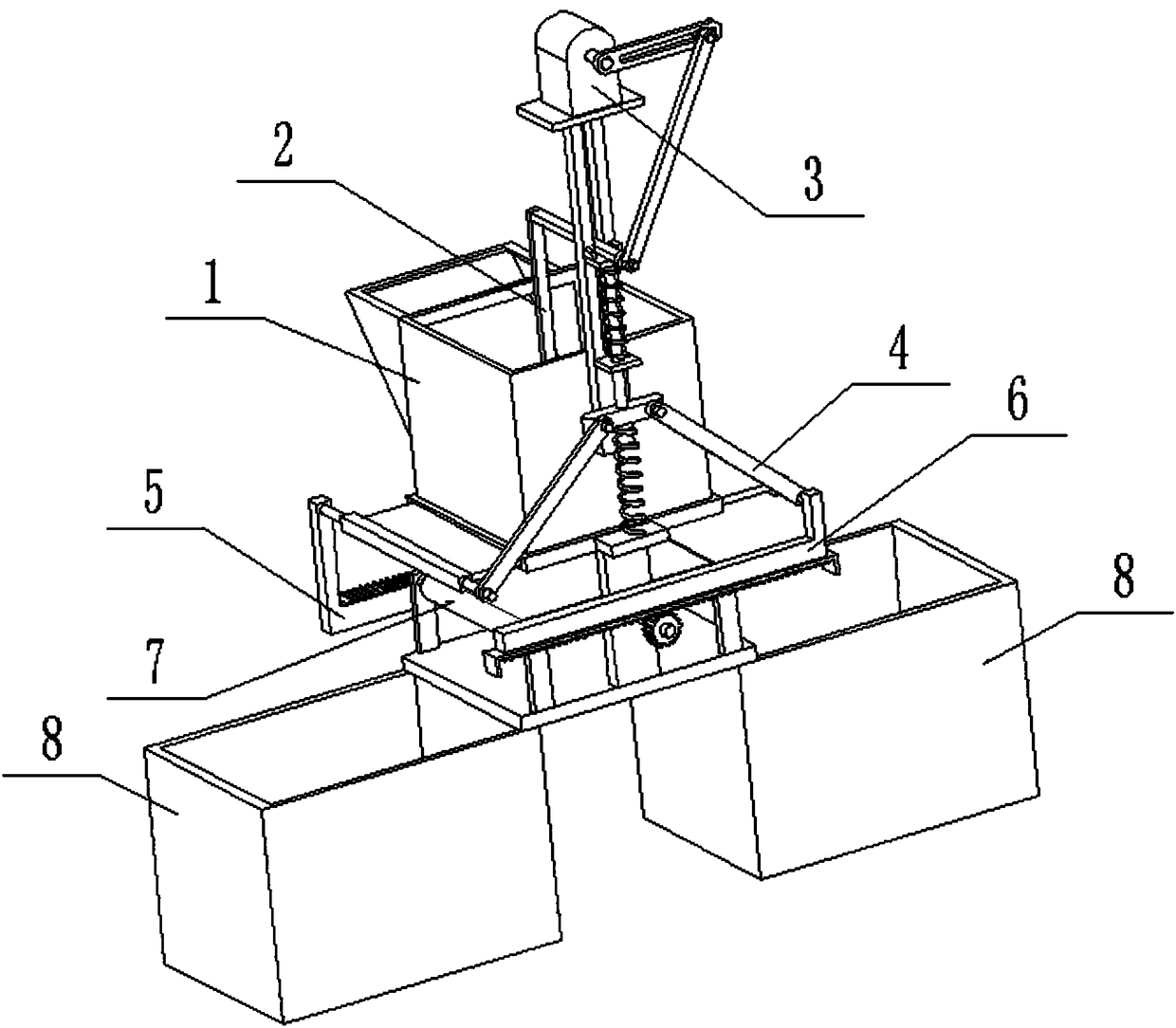

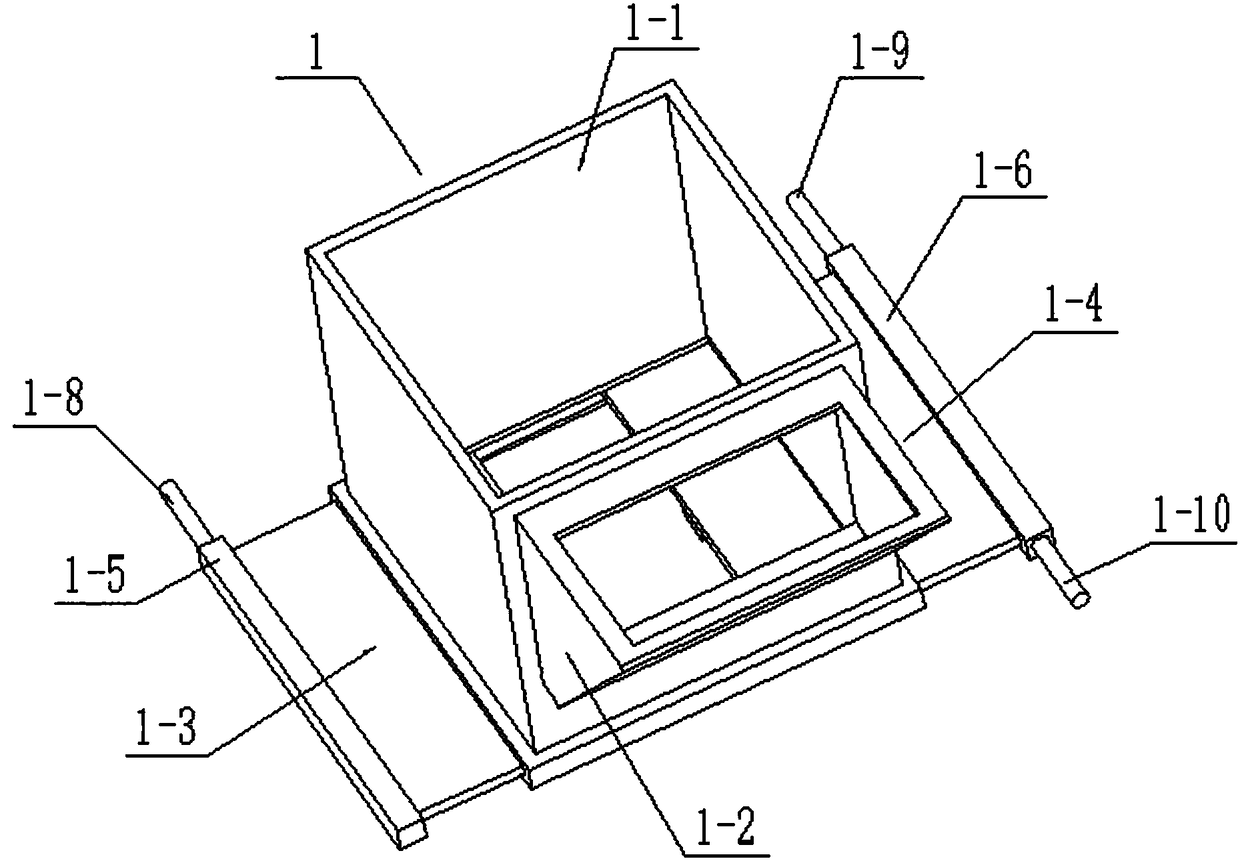

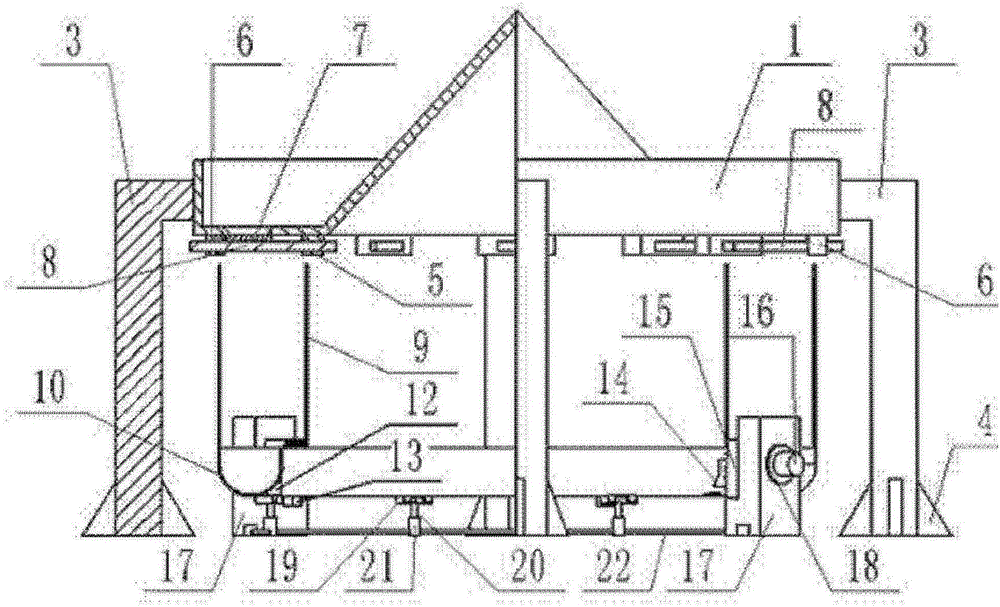

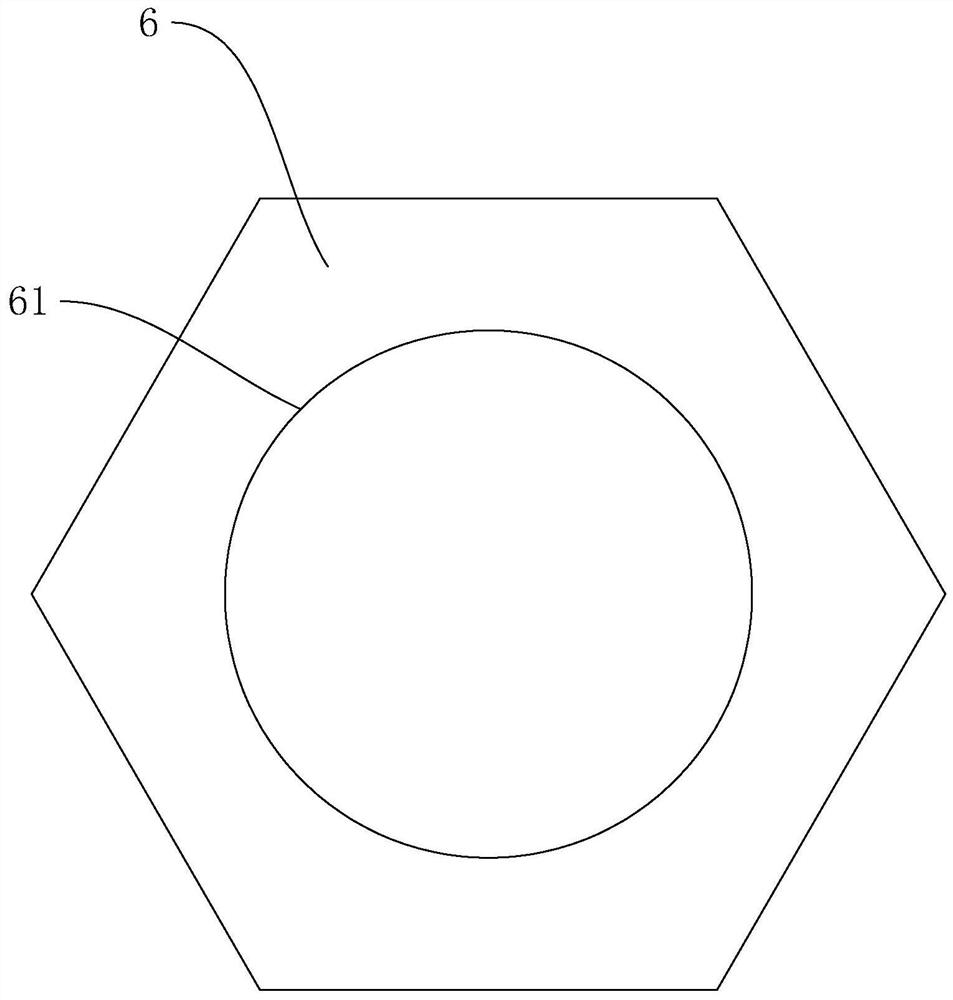

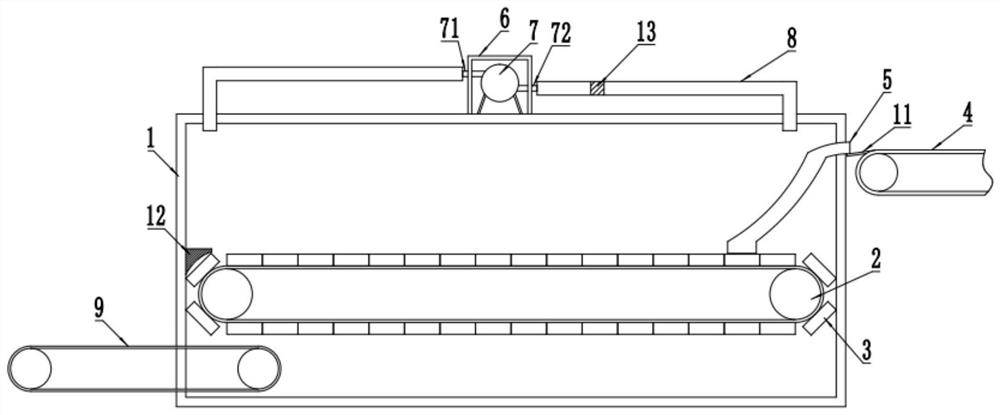

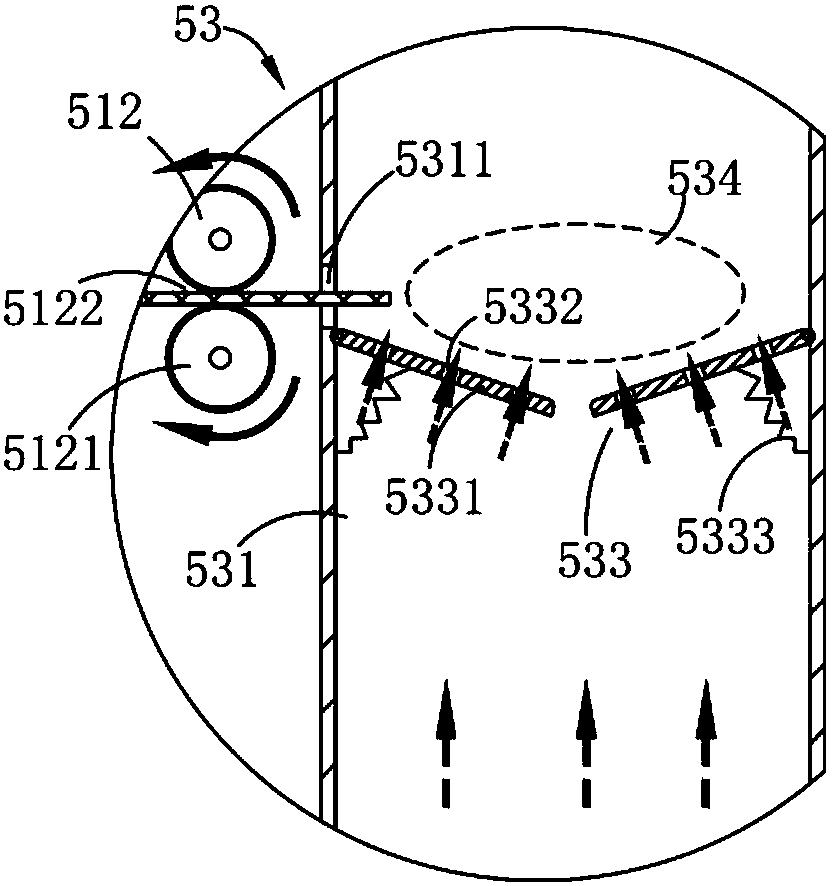

Compression and conveying device for rural garbage treatment

ActiveCN108582841AEfficient compressionRealize automatic blankingLoading/unloadingPressesEngineering

Owner:章雪霞

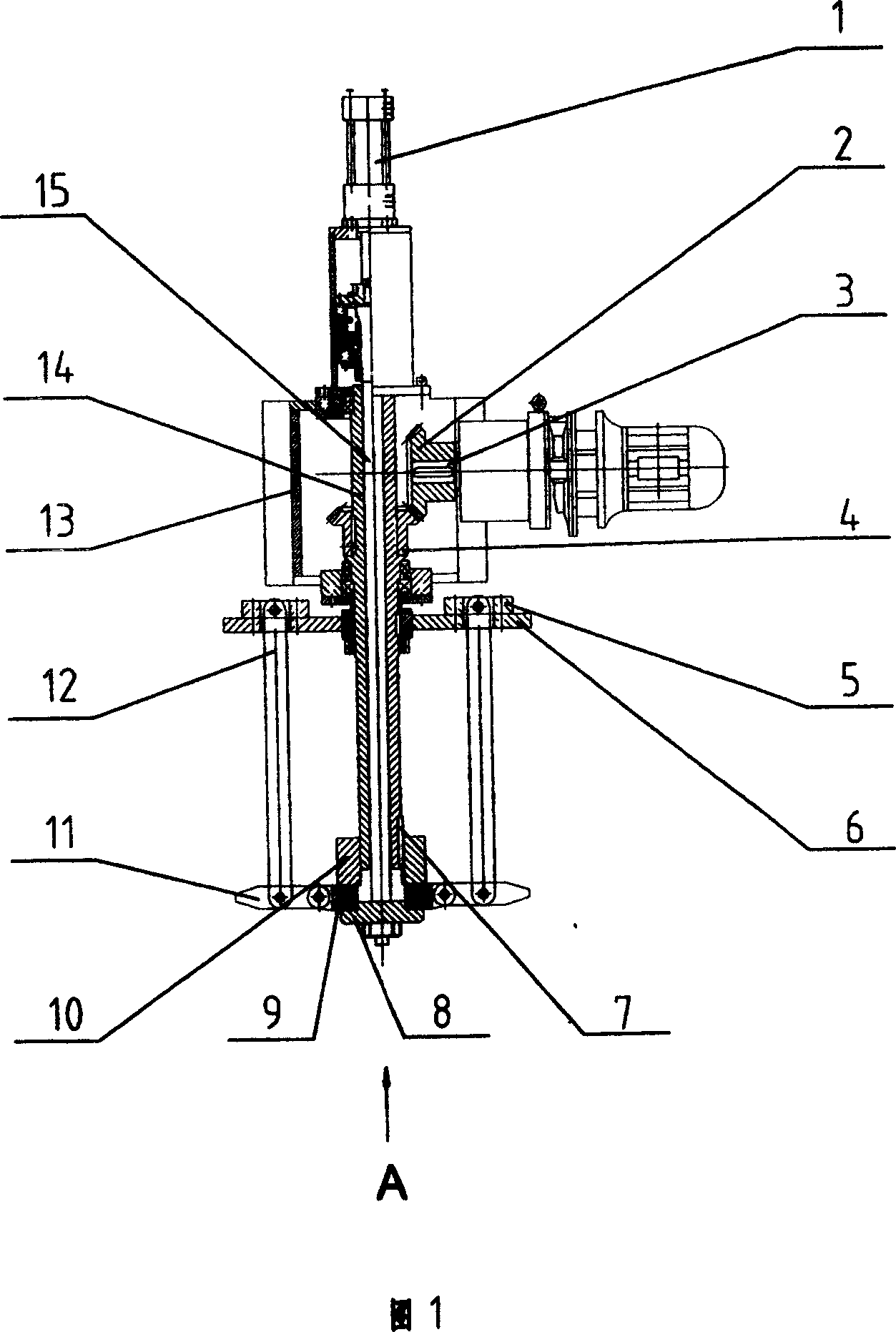

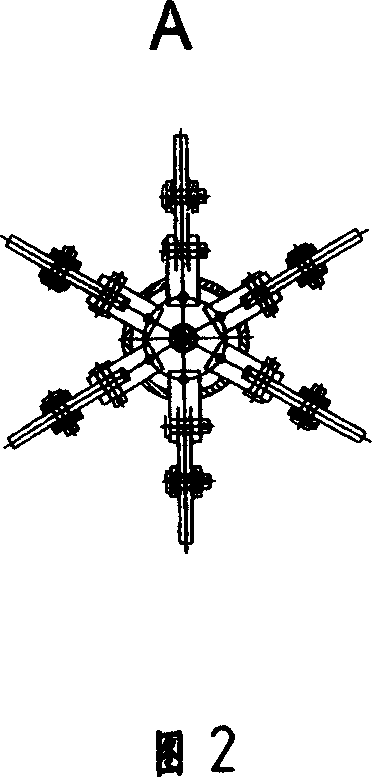

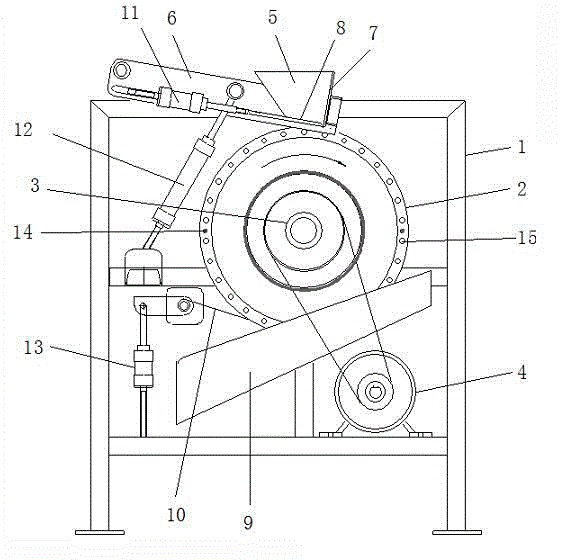

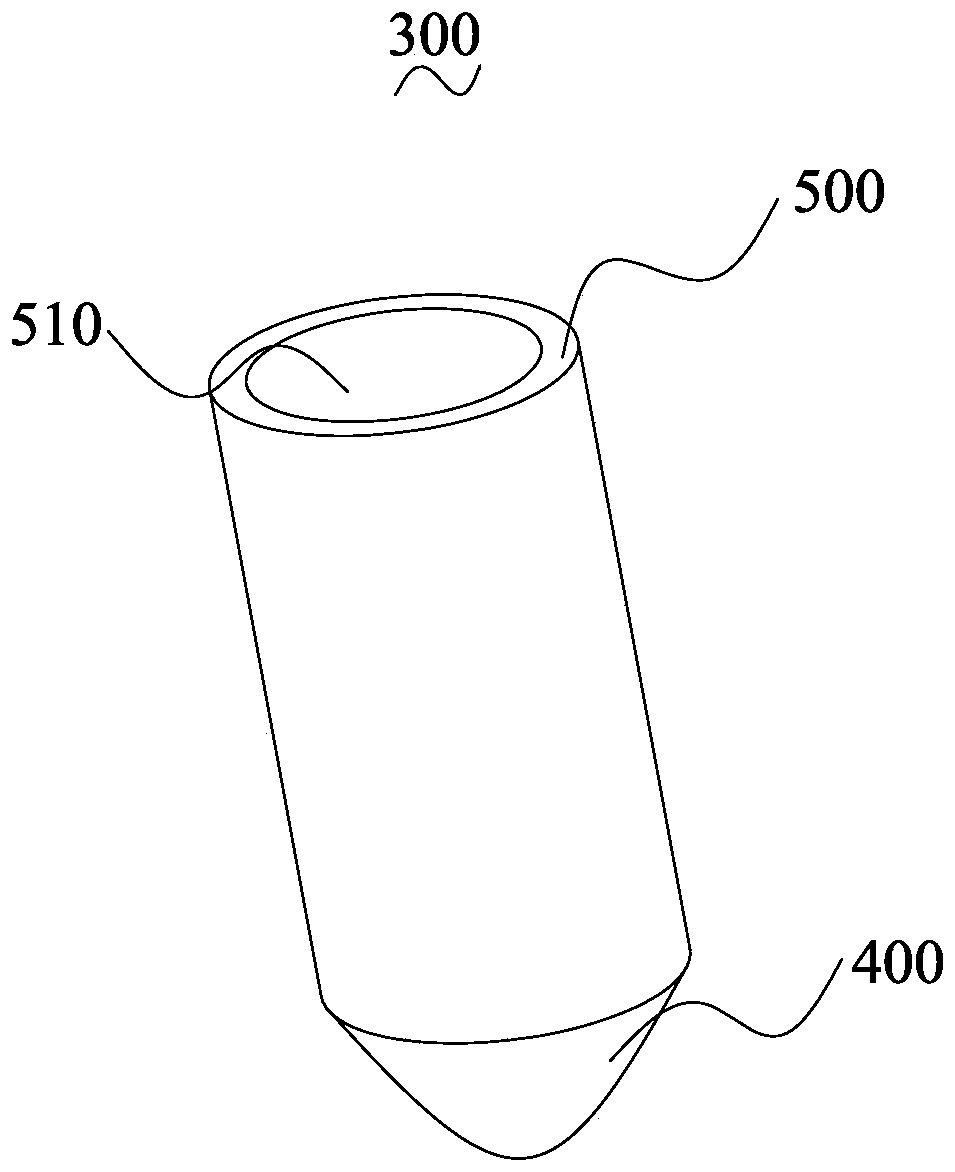

Curling machine for metal, slitter edge

A useless edge coiling machine for making the useless metal edge to become a value-added product is composed of machine frame, pilot unit, a case body on said machine frame, a hydraulic cylinder, a driver unit with a drive axle extended into said case body, a bevel gear on said drive axle, a hollow mainshaft in said case body and with another bevel gear engaged with the one on said drive axle, a perforated disk linked to the extended-out part of said mainshaft, several branch rods linked between said disk and a short rod, a sleeve on the lower end of said mainshaft and with a cover, etc.

Owner:JIANGSU YAWEI MACHINE TOOL

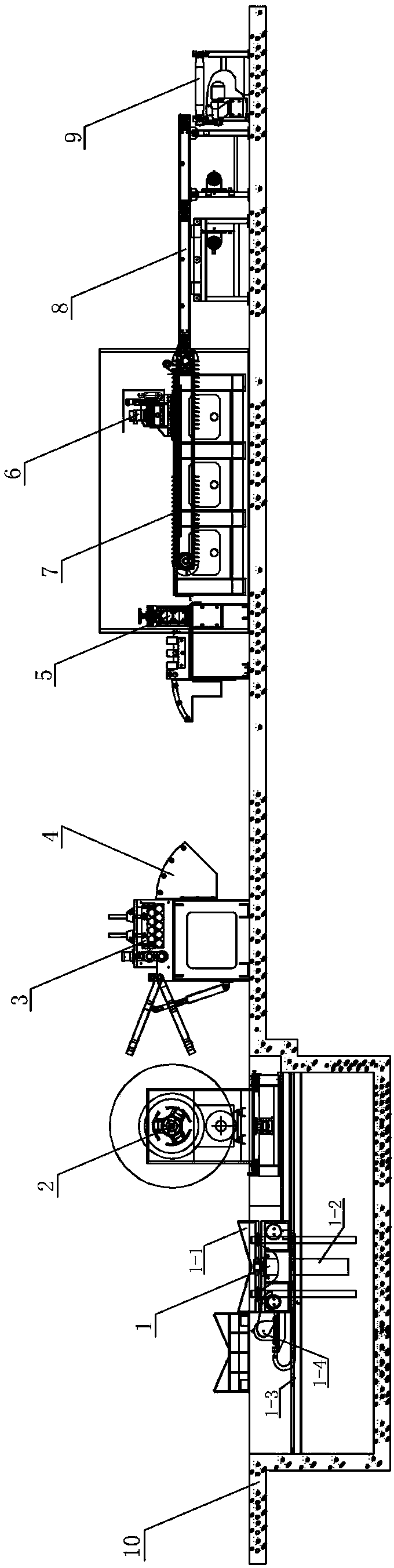

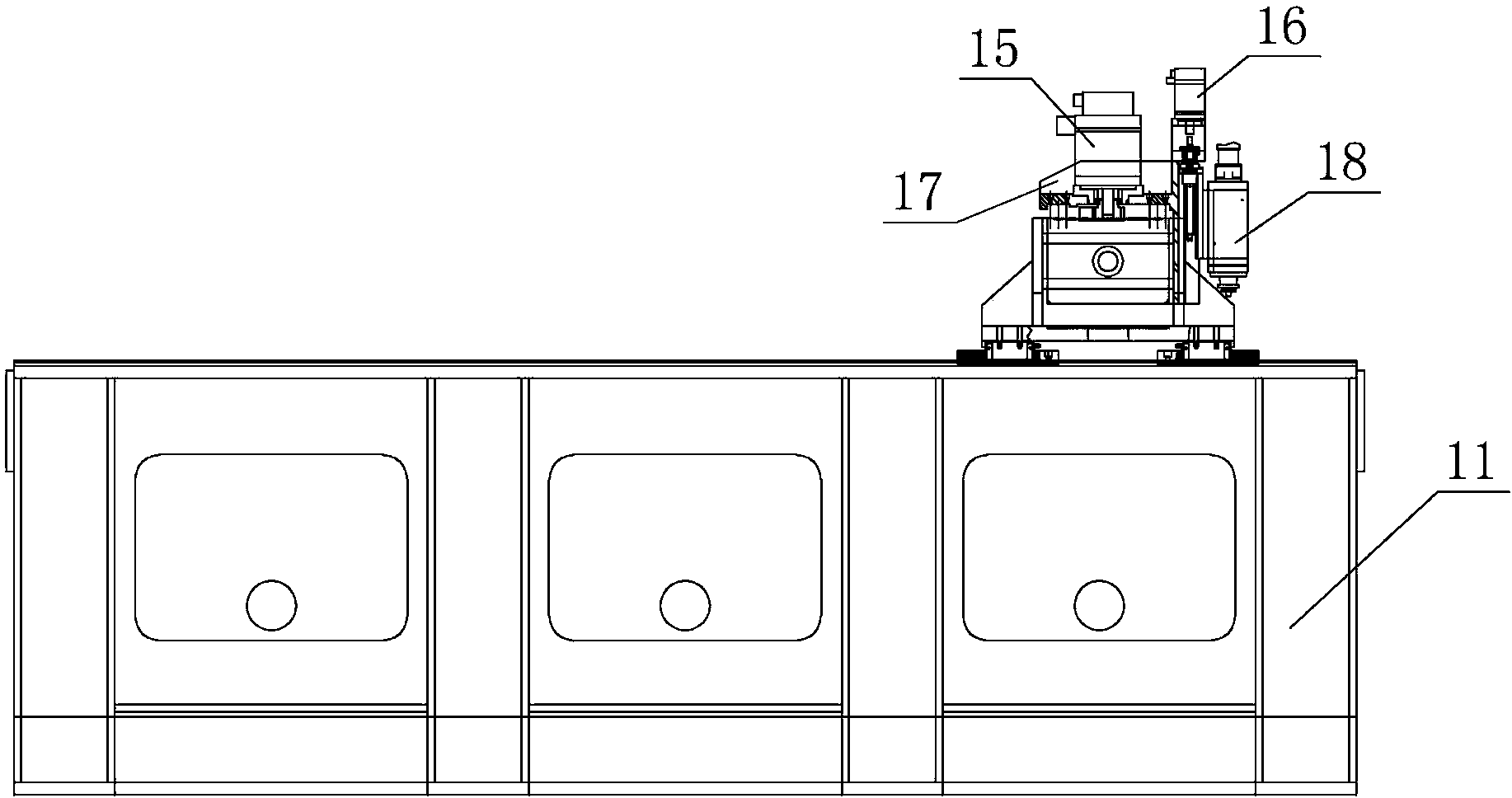

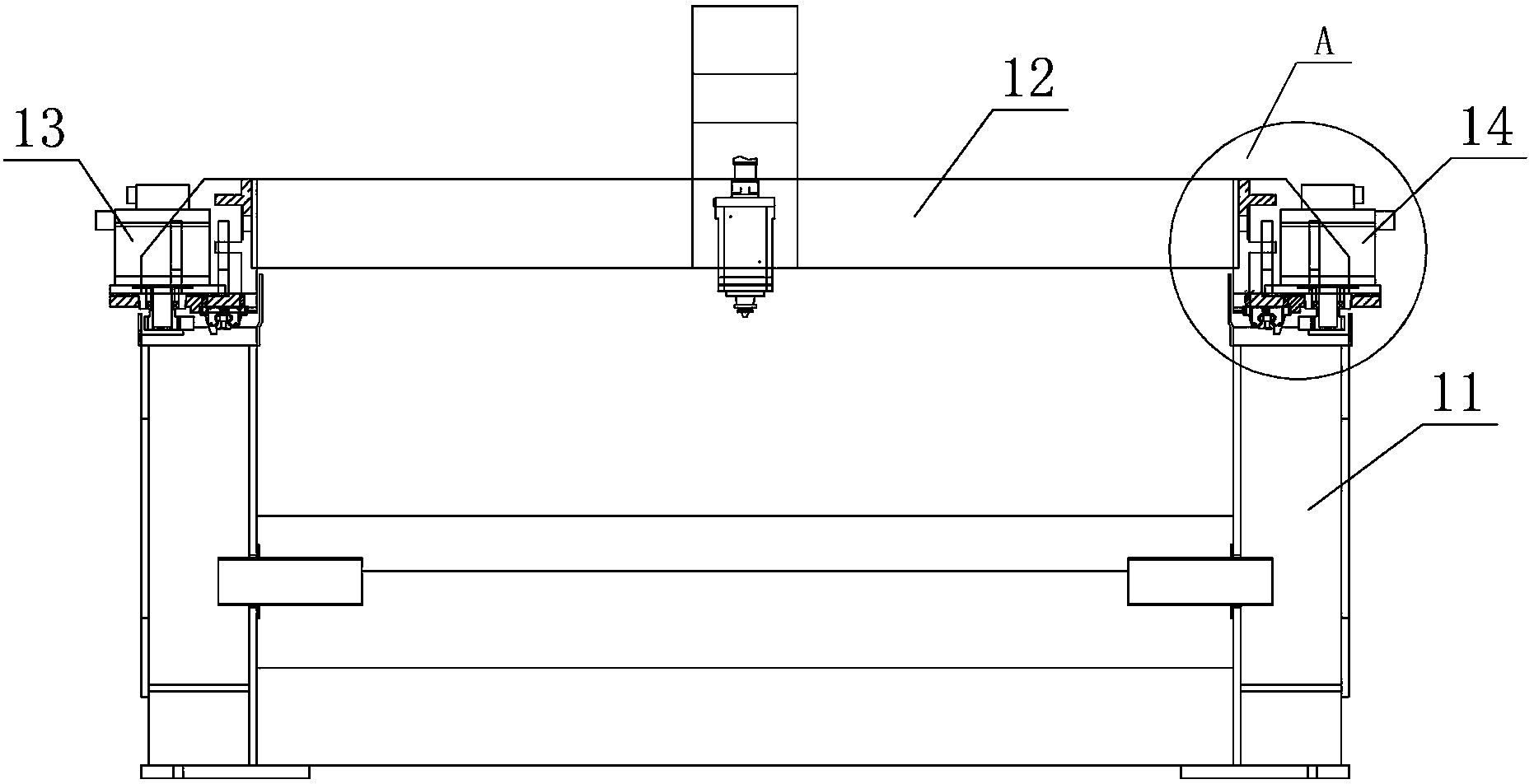

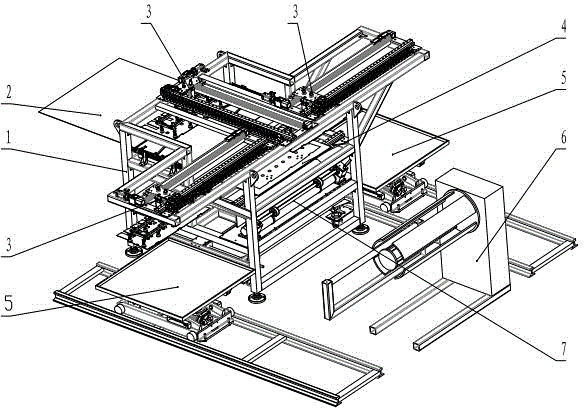

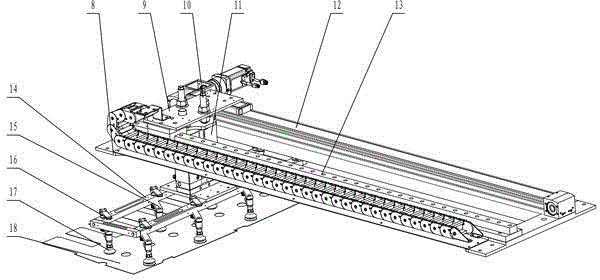

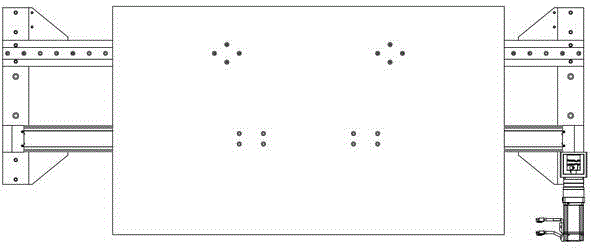

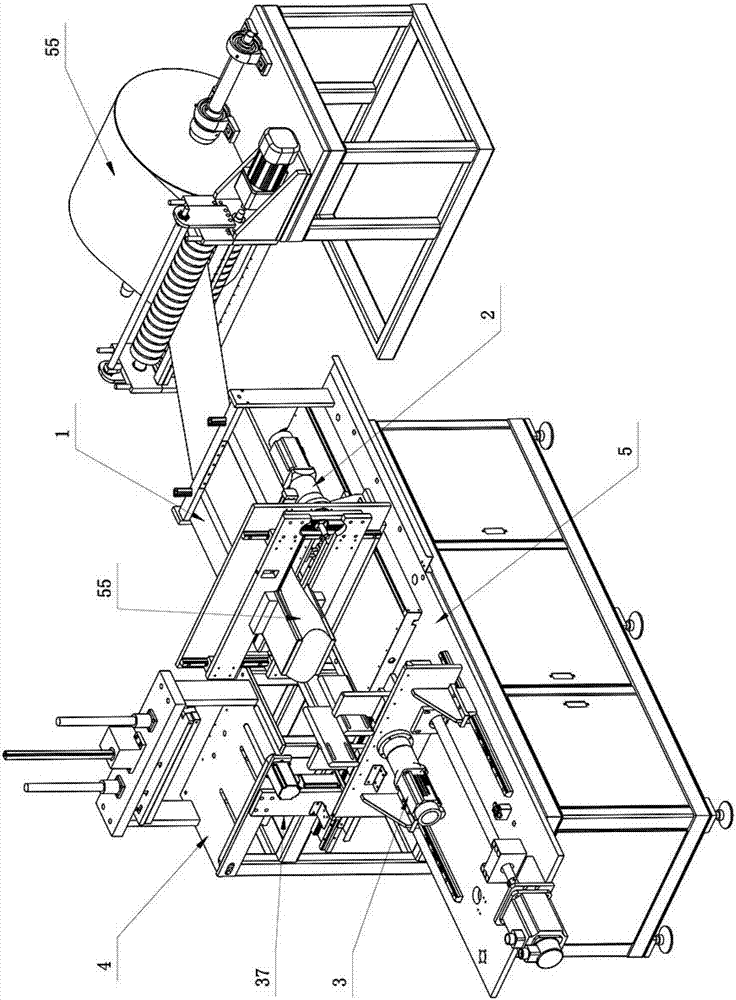

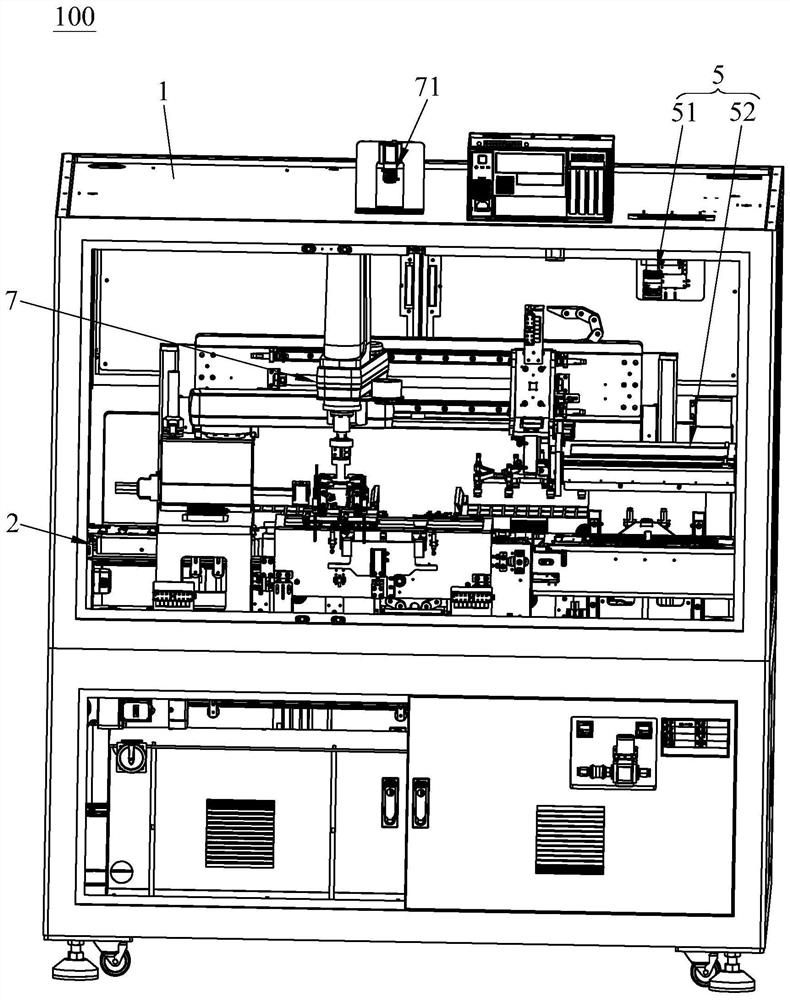

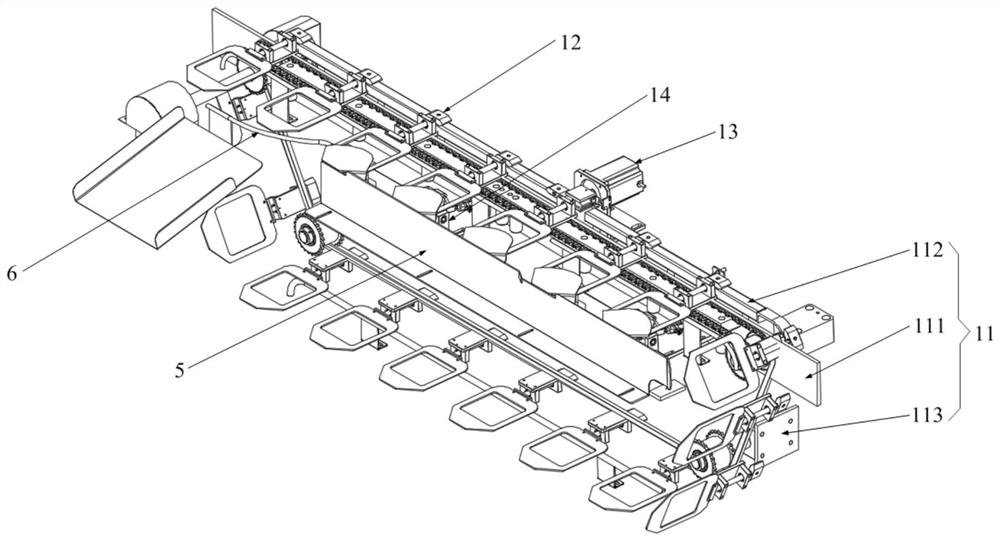

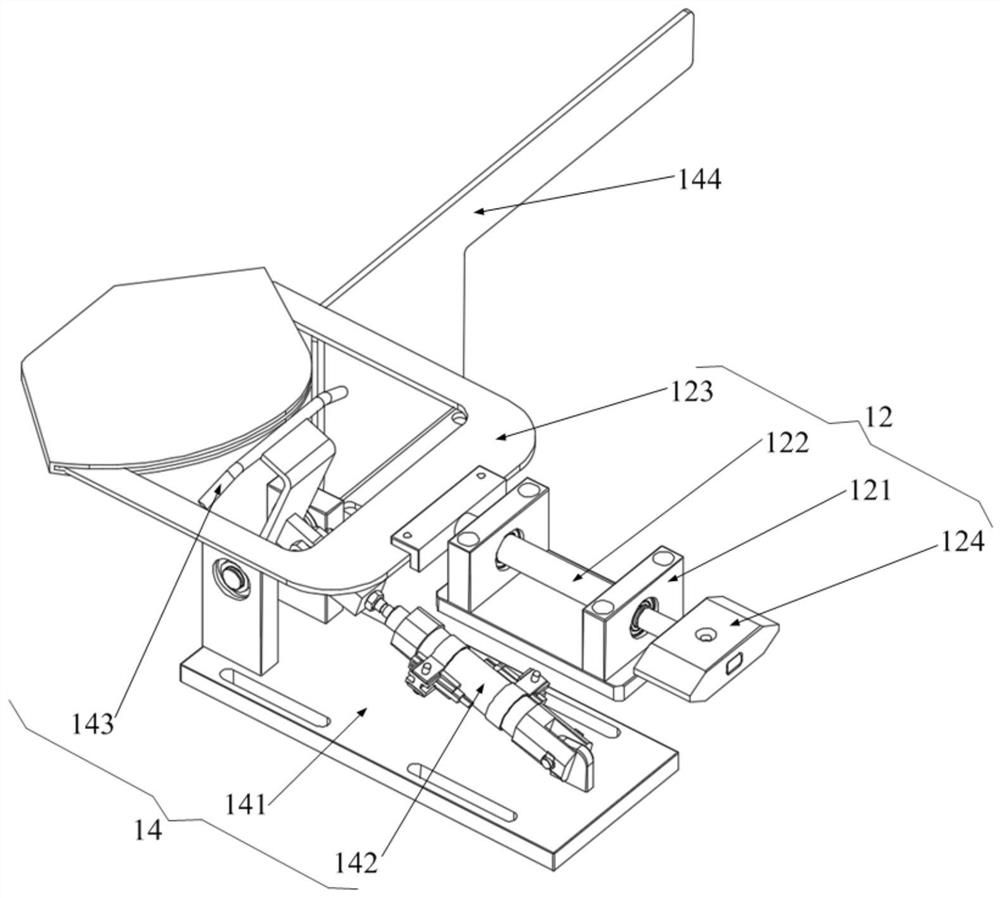

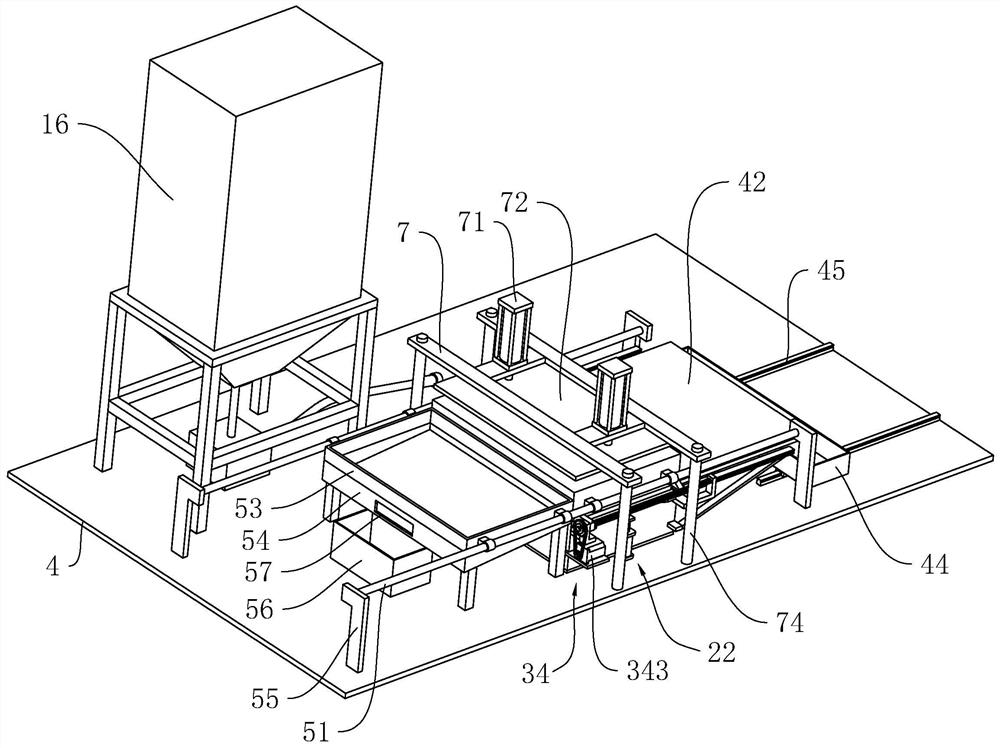

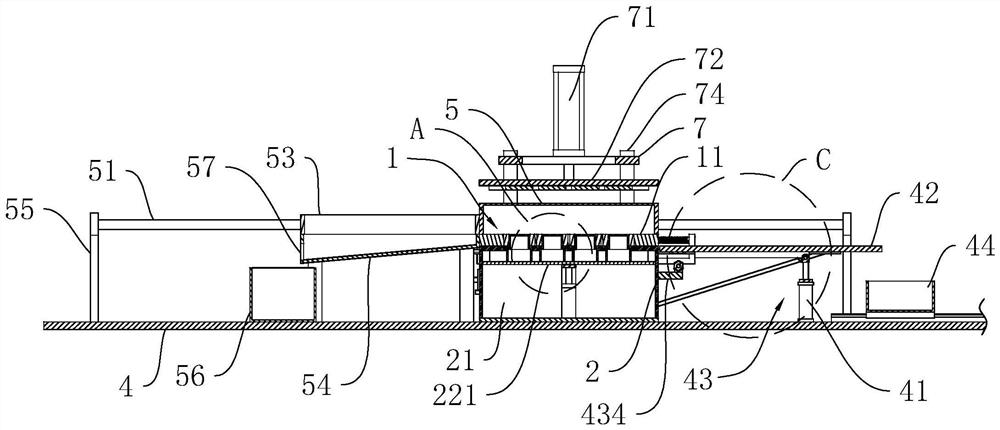

Uncoiling blanking production equipment and processing method by adoption of laser cutting technology

InactiveCN103394916AAchieve reductionTake advantage ofOther manufacturing equipments/toolsVehicle componentsMetal stripsLaser cutting

The invention discloses uncoiling blanking production equipment by the adoption of a laser cutting technology. The uncoiling blanking production equipment comprises an uncoiling machine, a leveler, a servo feeder, a palletizing system and a waste material processing system, and is characterized in that a laser cutting platform is fixed on a foundation between the servo feeder and the palletizing system, and a laser cutting device which can cut moving strips is fixed to the laser cutting platform. A processing method of the uncoiling blanking production equipment comprises the steps of (a) servo feeding, (b) positioning of a starting point of cutting, (c) velocity stacking, (d) implement of graph cutting, (e) returning to the starting point of cutting, and (f) repeating of the step (b), the step (c), the step (d) and the step (e) until the strips are processed completely. The equipment and method achieve the automatic blanking of the metal strips through the three-dimension movement cutting of a laser cutting head, and improve the utilization rate of materials; meanwhile, uncoiling blanking equipment composed of an expensive press machine and frequently-replaced dies is replaced, the cost of the equipment is lowered, the energy consumption is reduced, transformation of product specifications is rapid, and the uncoiling blanking production equipment and the processing method are suitable for all kinds of batch production.

Owner:江苏华工蓝天智能科技有限公司

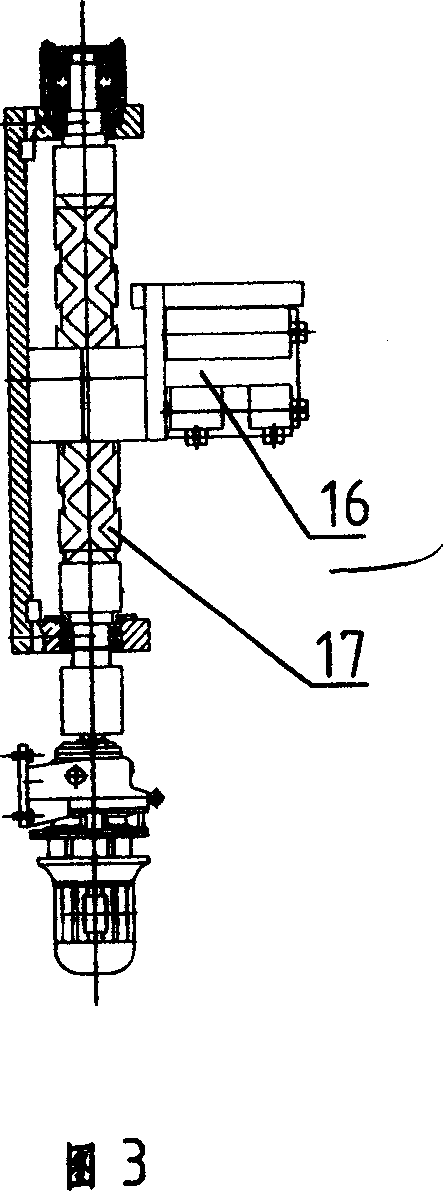

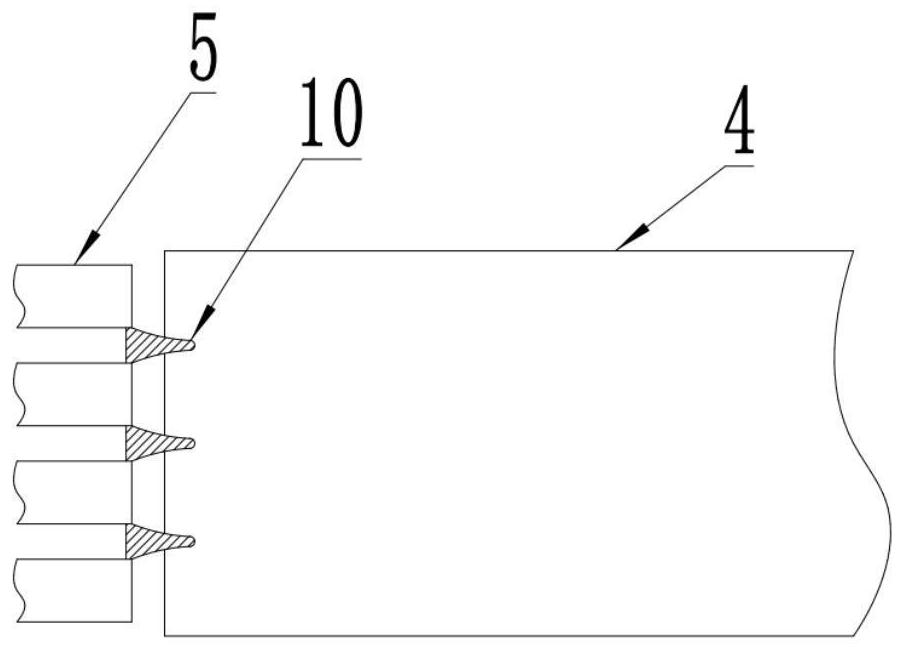

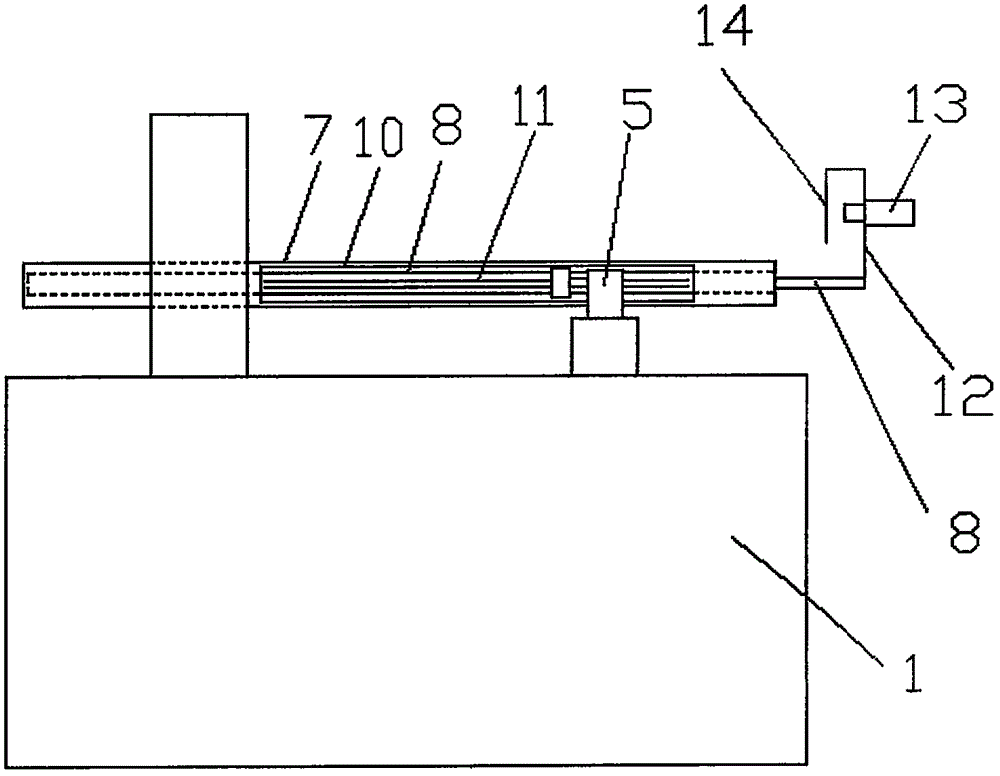

Processing machine tool for valve body connection hole

InactiveCN102357803ARealize automatic feedingRealize the processing effectOther manufacturing equipments/toolsPositioning apparatusMachine toolKnife holder

The invention provides a processing machine tool for a valve body connection hole, which belongs to the technical field of machinery and solves the problems that the existing valve body processing machine tool is small in processing range, cannot process the valve body connection hole and the like. The processing machine tool of the valve body connection hole comprises a machine tool body, a feeding hopper and a spindle box fixedly connected onto the machine tool body. A transverse guide rail is arranged on the machine tool body, a processing cutter rest used for processing the connection hole is arranged on the transverse guide rail, and a clamp used for clamping a valve body and enabling the end of the valve body to face the processing cutter rest is fixedly connected with the spindle end of the spindle box. A conveying mechanism used for conveying the valve body to be processed in the feeding hopper to the clamp of a spindle in positioning mode is arranged on the machine tool body,and a driving mechanism used for pushing the processing cutter rest to process the valve body when the valve body to be processed is located in the clamp is further arranged on the machine tool body.The processing machine tool for the valve body connection hole has the advantages of being convenient to operate, high in automation degree, good in product uniformity and the like.

Owner:杨建龙 +1

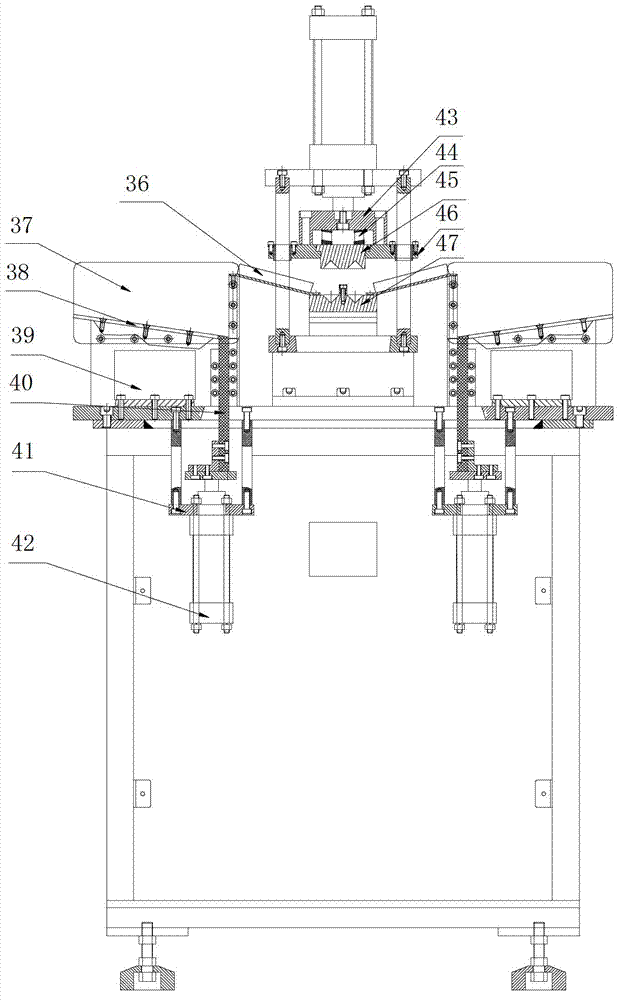

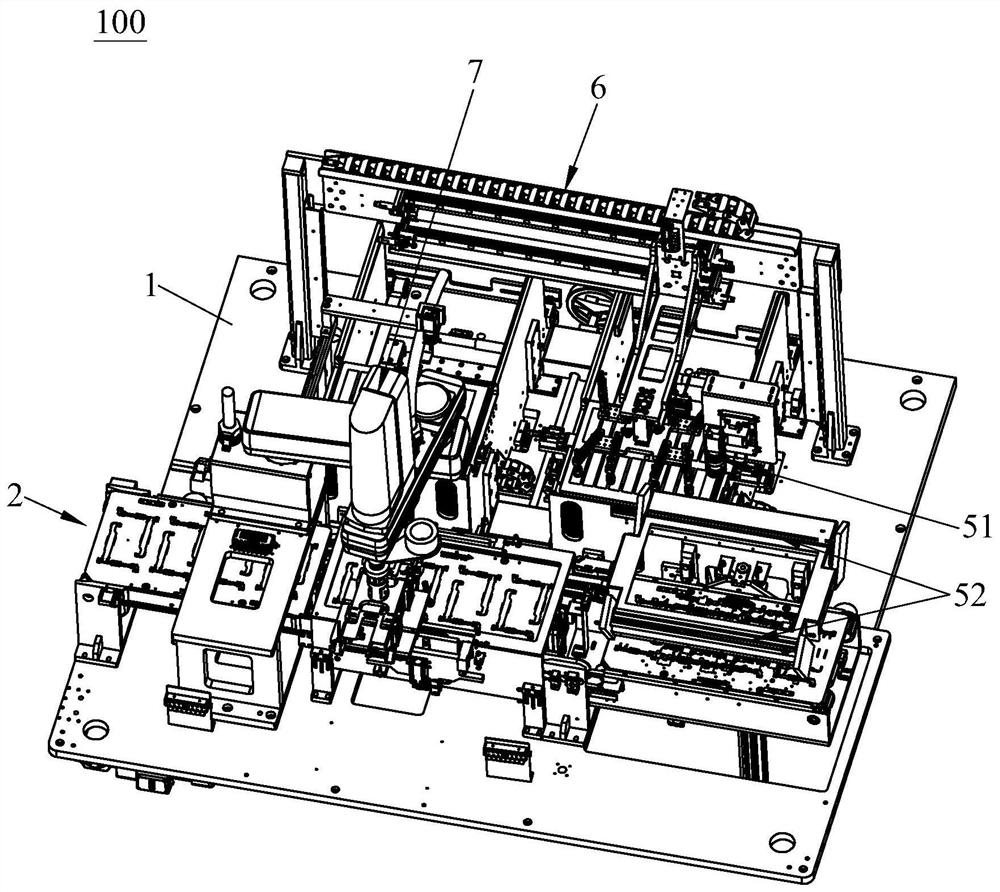

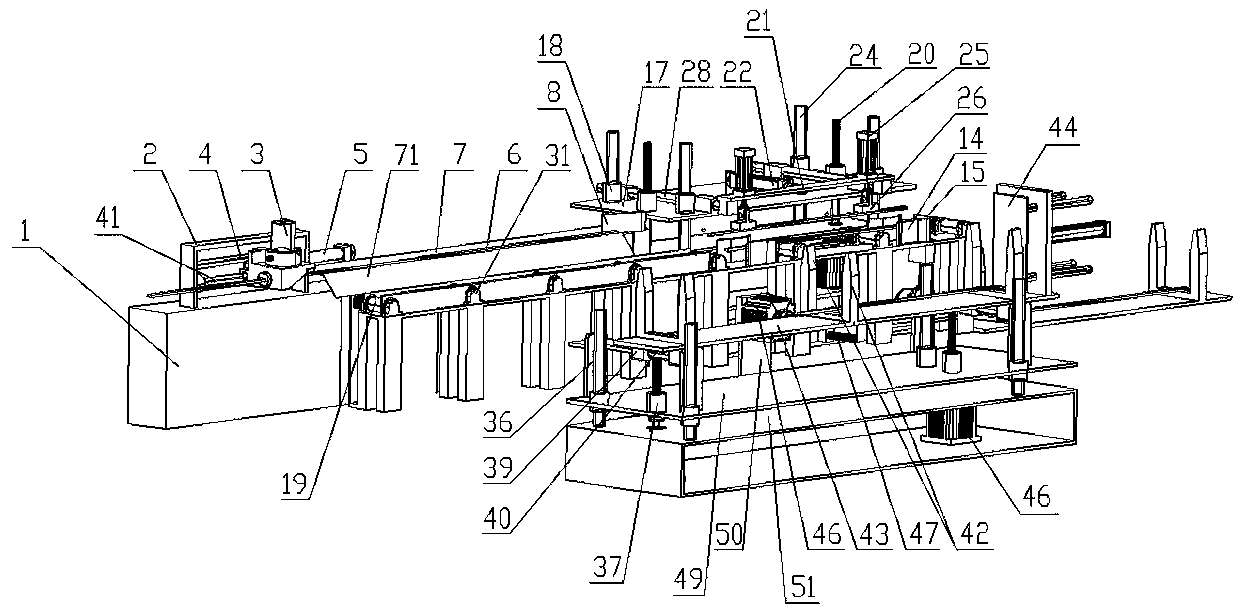

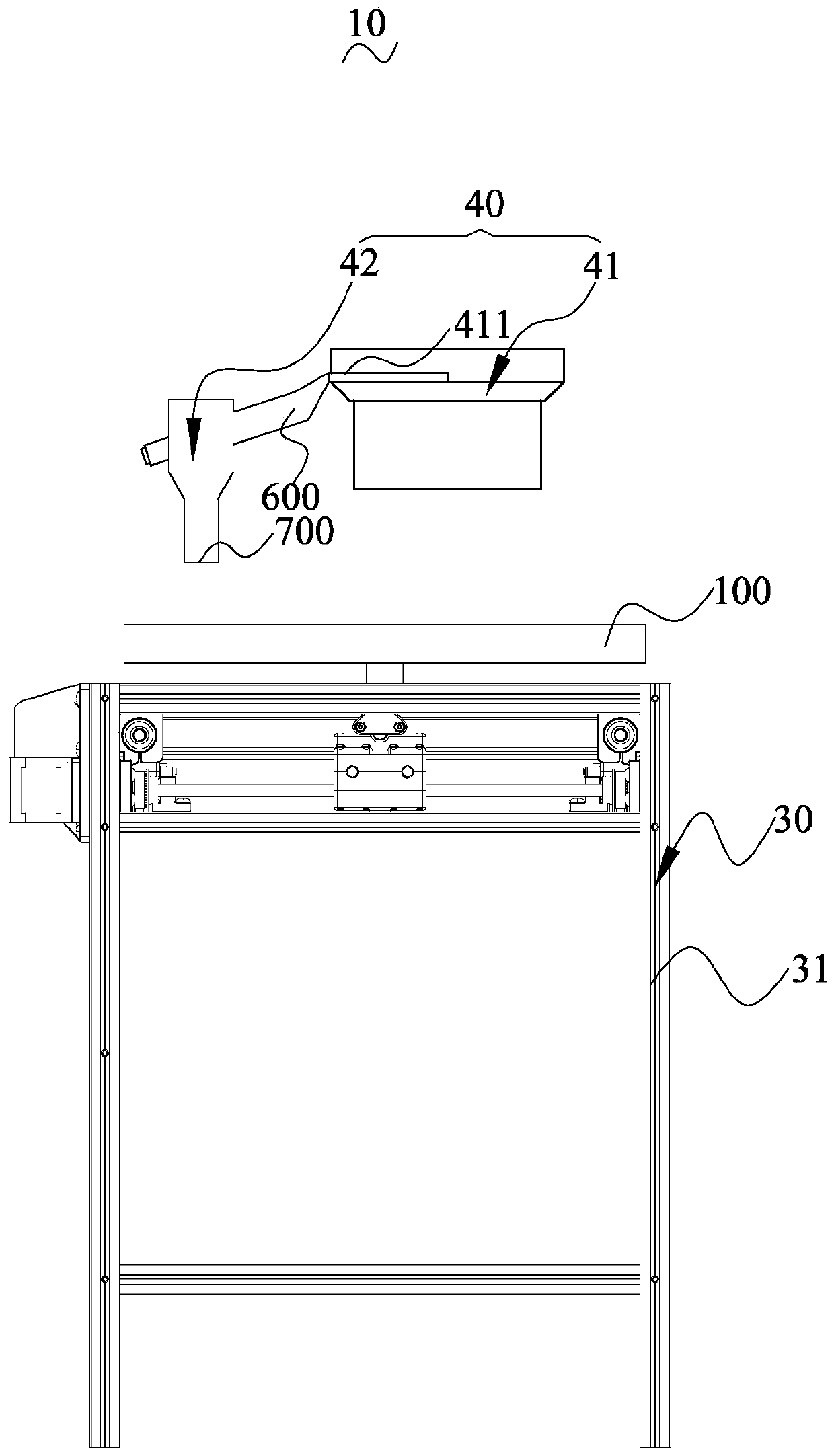

Automatic discharging system used for stamping production line

ActiveCN104815916ARealize automatic blankingEasy to adjustMetal-working feeding devicesPositioning devicesProduction linePunch press

The invention relates to the field of punching machine automation, and particularly relates to an automatic discharging system used for a stamping production line. The automatic discharging system comprises a framework, transportation and adsorption systems, a work-piece transfer system, stacking systems, a waste material traction system and a waste material collection system; the framework is provided with at least three transportation and adsorption systems, the work-piece transfer system and the waste material traction system; a stacking system is respectively arranged below the transportation and adsorption systems which are located at the left side and the right side of the framework. The systems are combined according to the way in the invention, automatic discharging of the stamping production line, including, separation of the work-piece and the waste material, work-piece stacking, waste material collection and the like, can be realized conveniently and rapidly. In the application, only one framework system is needed for separation and transportation of the work-piece waste material, and two-side stacking of the work-pieces can be realized.

Owner:中国东方电气集团有限公司

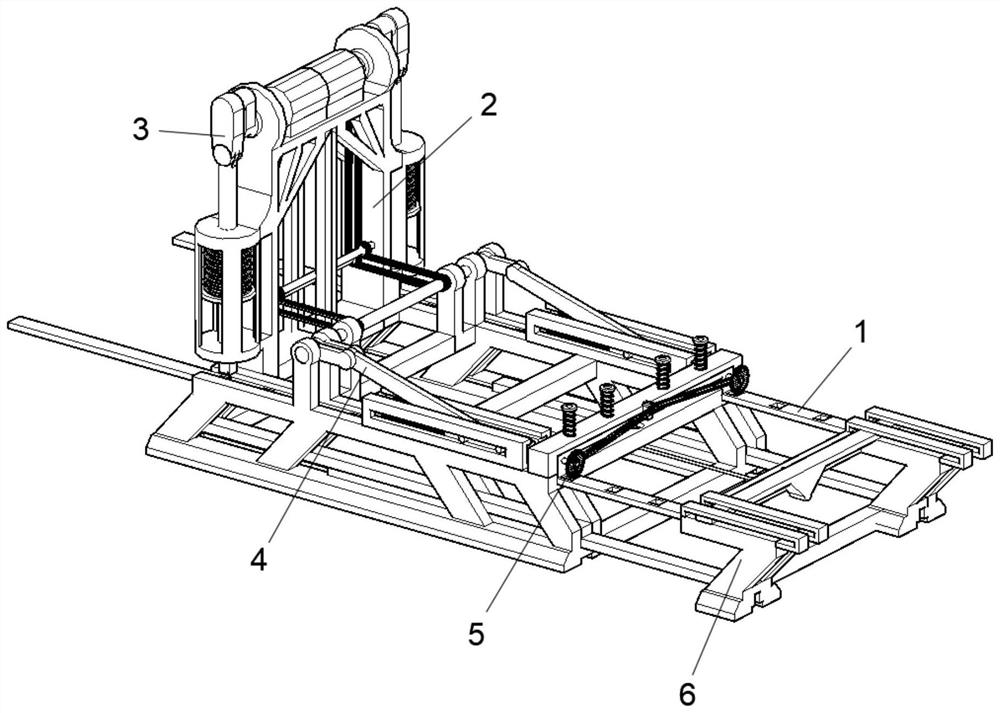

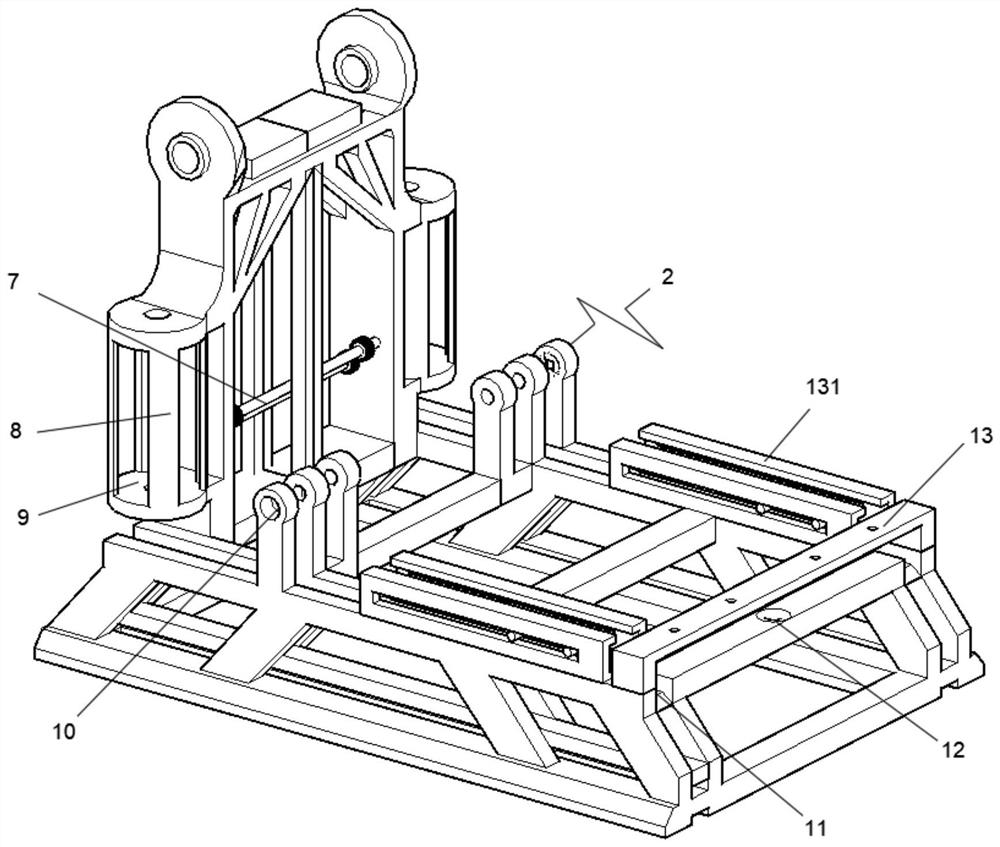

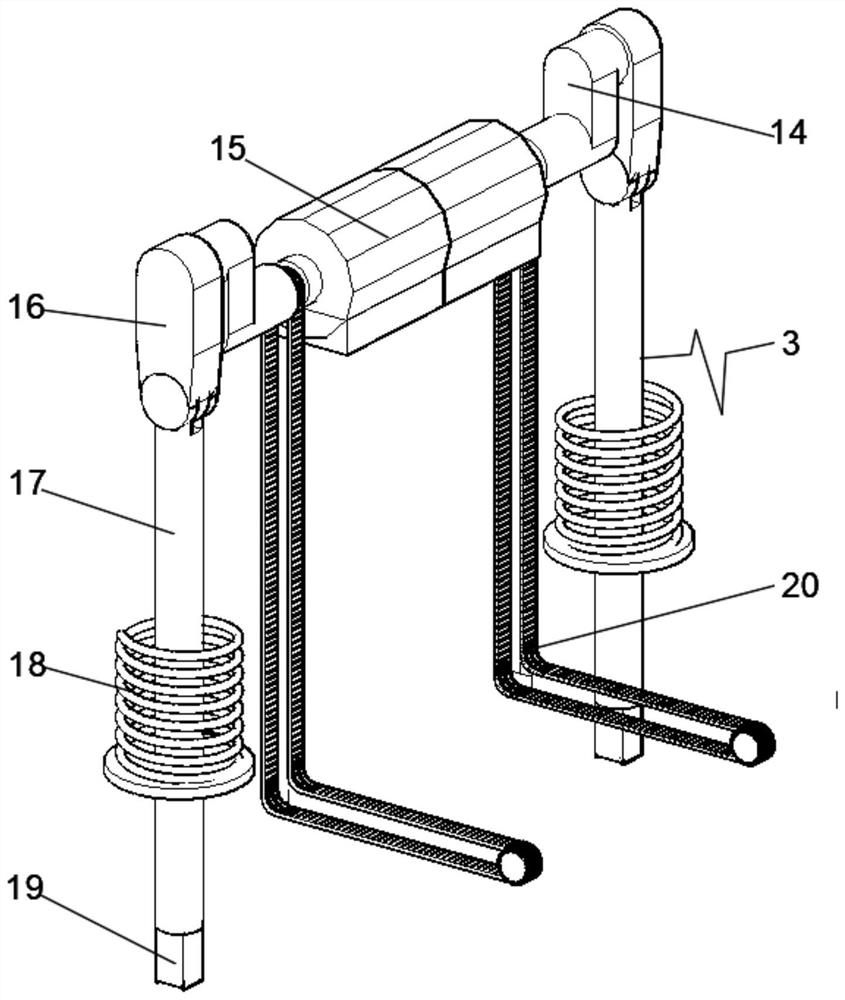

Falling device of stamping and drawing die

The invention relates to the technical field of die machining and manufacturing, in particular to a falling device of a stamping and drawing die. The falling device comprises a stamping platform, an ejection separation mechanism, a carrying mechanism and an auxiliary discharging mechanism, wherein the stamping platform is provided with an L-shaped auxiliary support, a stamping air cylinder which is vertically arranged is arranged at the top of the auxiliary support, a connecting plate is arranged at the output end of the stamping air cylinder, an upper die is arranged at the bottom of the connecting plate, and a lower die matched with the upper die is arranged at the top of the stamping platform; and the ejection separation mechanism and the auxiliary discharging mechanism are arranged atthe left end and the right end of the lower die respectively, the carrying mechanism is arranged on the auxiliary support, a material receiving platform is arranged on the side wall of the stamping platform, the material receiving platform is positioned beside the auxiliary discharging mechanism, and an auxiliary ejection component is arranged on the lower die. The falling device of the stamping and drawing die has the advantages that stamped plates can automatically fall, the machining efficiency is improved, and operators do not need to carry out discharging.

Owner:蓝茂生 +1

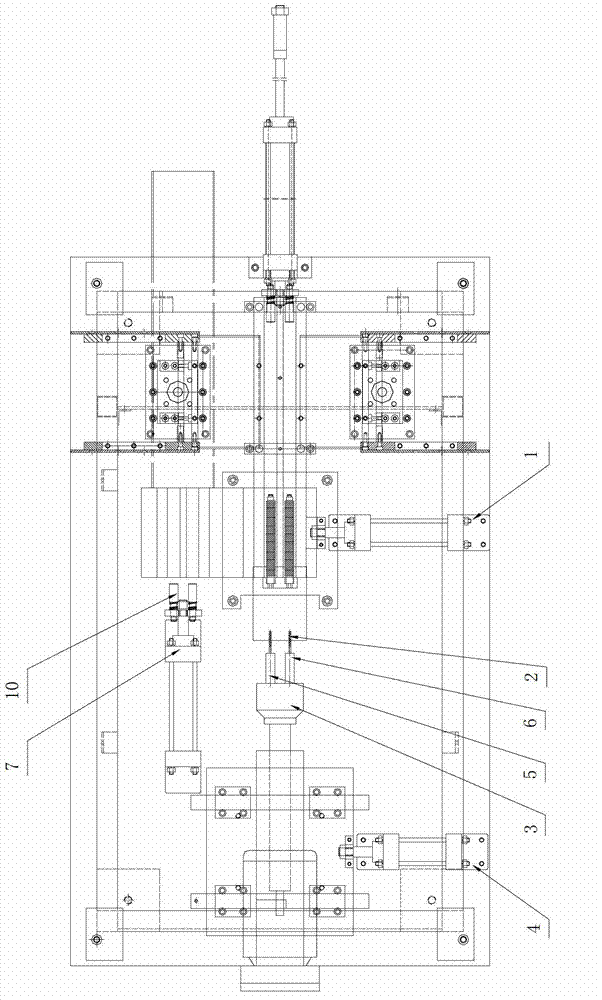

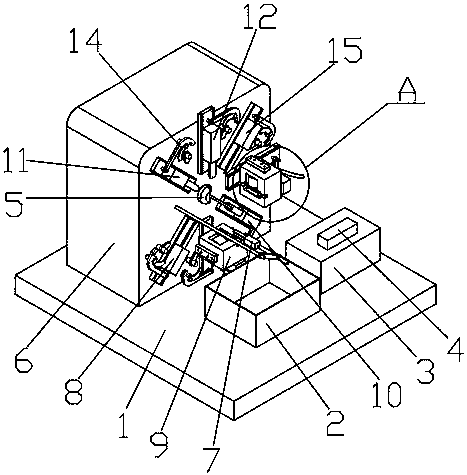

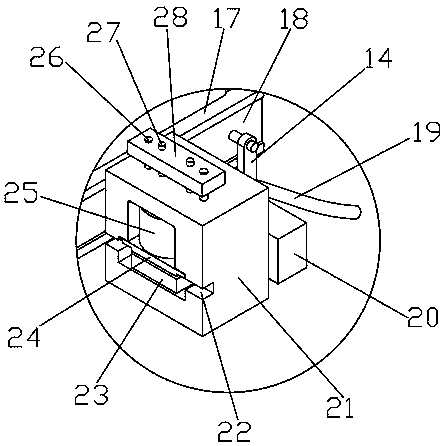

Spring machine for forming of pulling and pressing rod

The invention relates to a spring machine for forming of a pulling and pressing rod. The spring machine comprises a base and a case. A feeding shaft is arranged in the center of the case, a first cutter seat, a first stamping device, a second cutter seat, a second stamping device, a third cutter seat, a bending cutter seat and a fourth cutter seat are sequentially arranged at the front end of thecase and around the feeding shaft, the bending cutter seat is arranged right above the feeding shaft, the first stamping device is arranged right below the feeding shaft; the second stamping device isarranged on the right side of the feeding shaft, the left side of the feeding shaft is provided with a material taking device, the first cutter seat, the second cutter seat, the third cutter seat, the bending cutter seat, the fourth cutter seat, the first stamping device and the second stamping device all slide along the axis of the feeding shaft and are respectively matched with a driving devicearranged on the case, and the first stamping device and the second stamping device are both connected with a hydraulic oil tank arranged on the base. The spring machine is pulling and pressing rod forming equipment which can realize one-time forming and has high production efficiency by utilizing the bending cutter seat and combining with the stamping devices.

Owner:东莞市永强弹簧五金有限公司

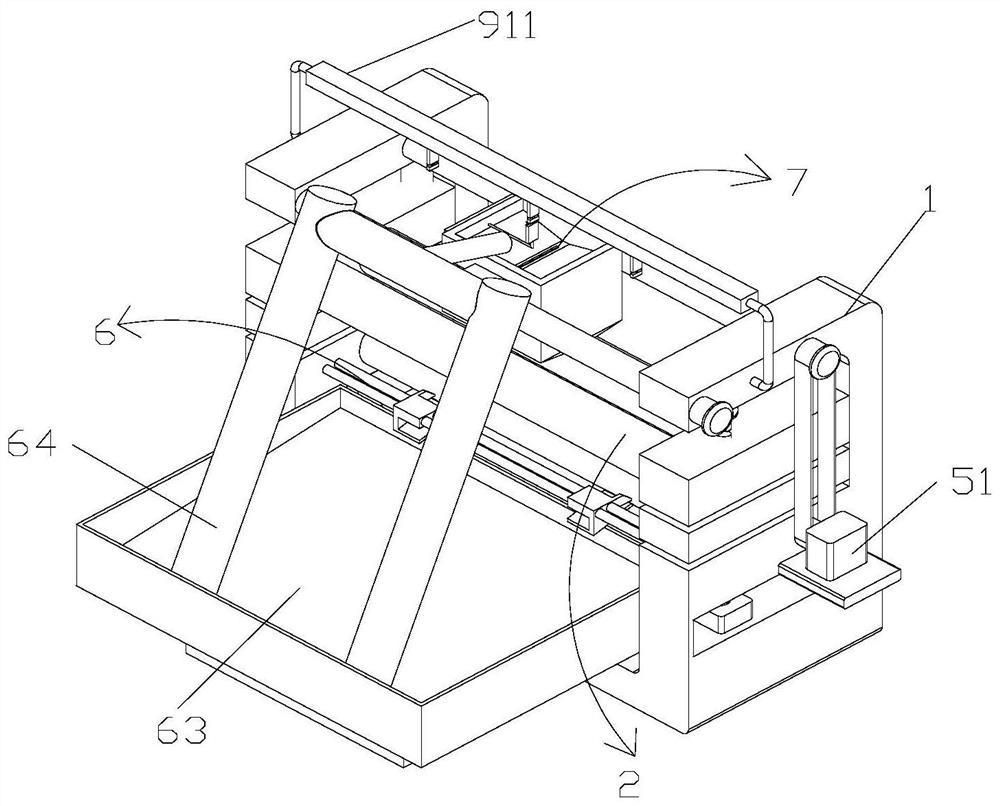

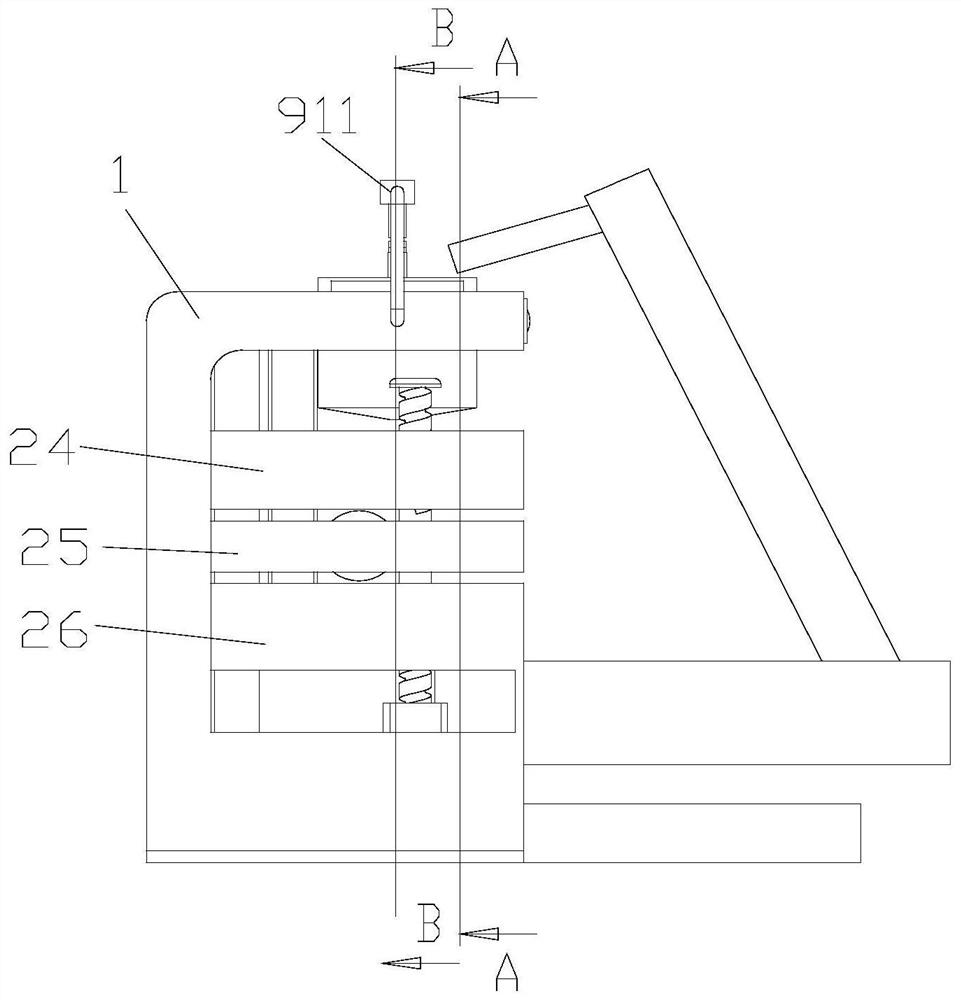

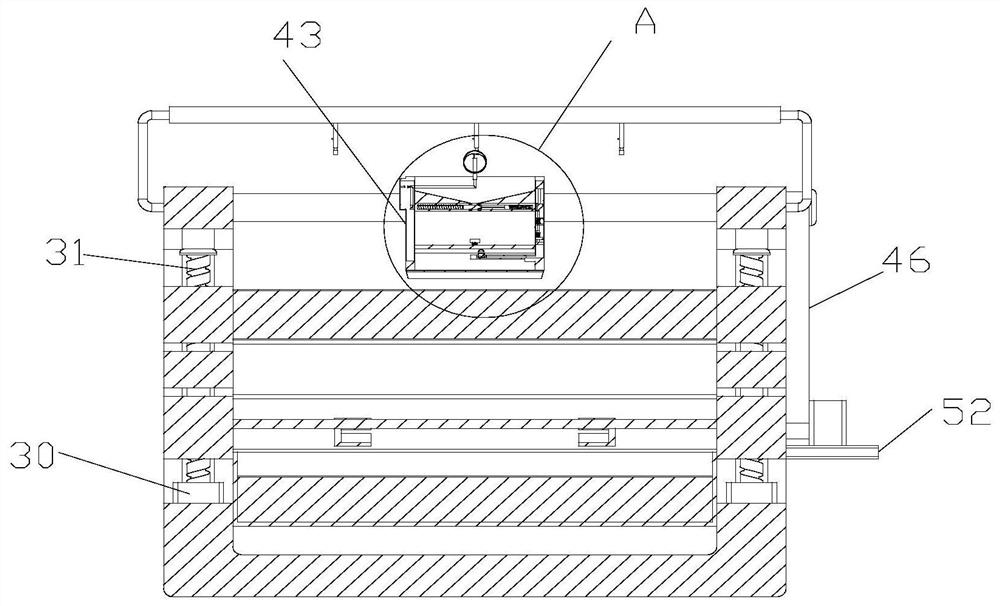

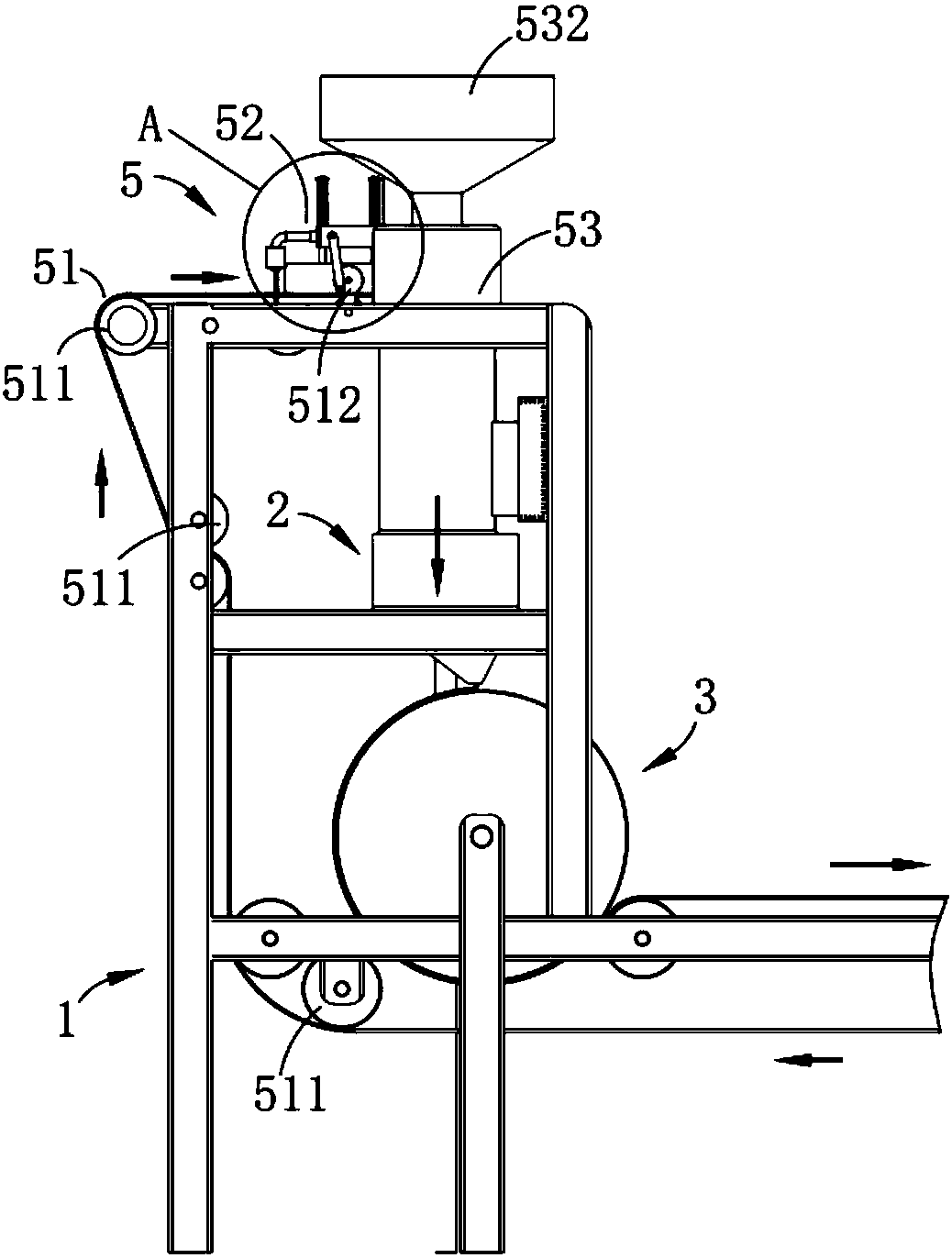

Full-automatic plastic bag film multilayer folding machine and method

ActiveCN107399105ARealize automatic feedingRealize automatic cuttingBag making operationsPaper-makingEngineeringWorkbench

The invention provides a full-automatic plastic bag film multilayer folding machine and method. The full-automatic plastic bag film multilayer folding machine comprises a feeding plate used for holding plastic bag films, a first folding device, a second folding device, a blanking device and a workbench. The feeding plate, the first folding device and the second folding device are mounted on the workbench. The first folding device and the second folding device are used for repeatedly folding the films at the feeding plate in the axial direction. The blanking device used for exhaust extruding treatment on the folded films. The full-automatic plastic bag film multilayer folding machine can achieve the functions of automatic folding, automatic cutting and automatic blanking of the plastic bag films, the automation degree is high, and the production efficiency is high.

Owner:龚林晖

Automatic discharging equipment

ActiveCN113387171AHigh degree of automationPromote refluxConveyorsFinal product manufactureRobot handEngineering

The invention provides automatic discharging equipment. The equipment comprises a machine frame, a carrier conveying mechanism, a carrier, a jacking mechanism, a defective material detecting mechanism, a material disc feeding mechanism and a mechanical arm, the carrier is located on the carrier conveying mechanism and used for loading workpieces, and the carrier conveying mechanism is used for conveying the carrier; the jacking mechanism and the defective material detection mechanism are sequentially arranged on the machine frame in the conveying direction of the carrier conveying mechanism, the jacking mechanism is used for jacking the carrier located on the carrier conveying mechanism, the material disc feeding mechanism is used for providing a material disc, and the mechanical arm is used for grabbing a workpiece located on the carrier of the jacking mechanism to the material disc of the material disc feeding mechanism; and the defective material detection mechanism comprises a first CCD visual detection assembly, the first CCD visual detection assembly is arranged on the machine frame and located above the carrier conveying mechanism, and the first CCD visual detection assembly is used for detecting whether residual workpieces exist on the taken carrier on the carrier conveying mechanism or not. According to the automatic discharging equipment, normal operation of the equipment can be guaranteed, and the automation degree is high.

Owner:GUANGDONG TOPSTAR TECH +1

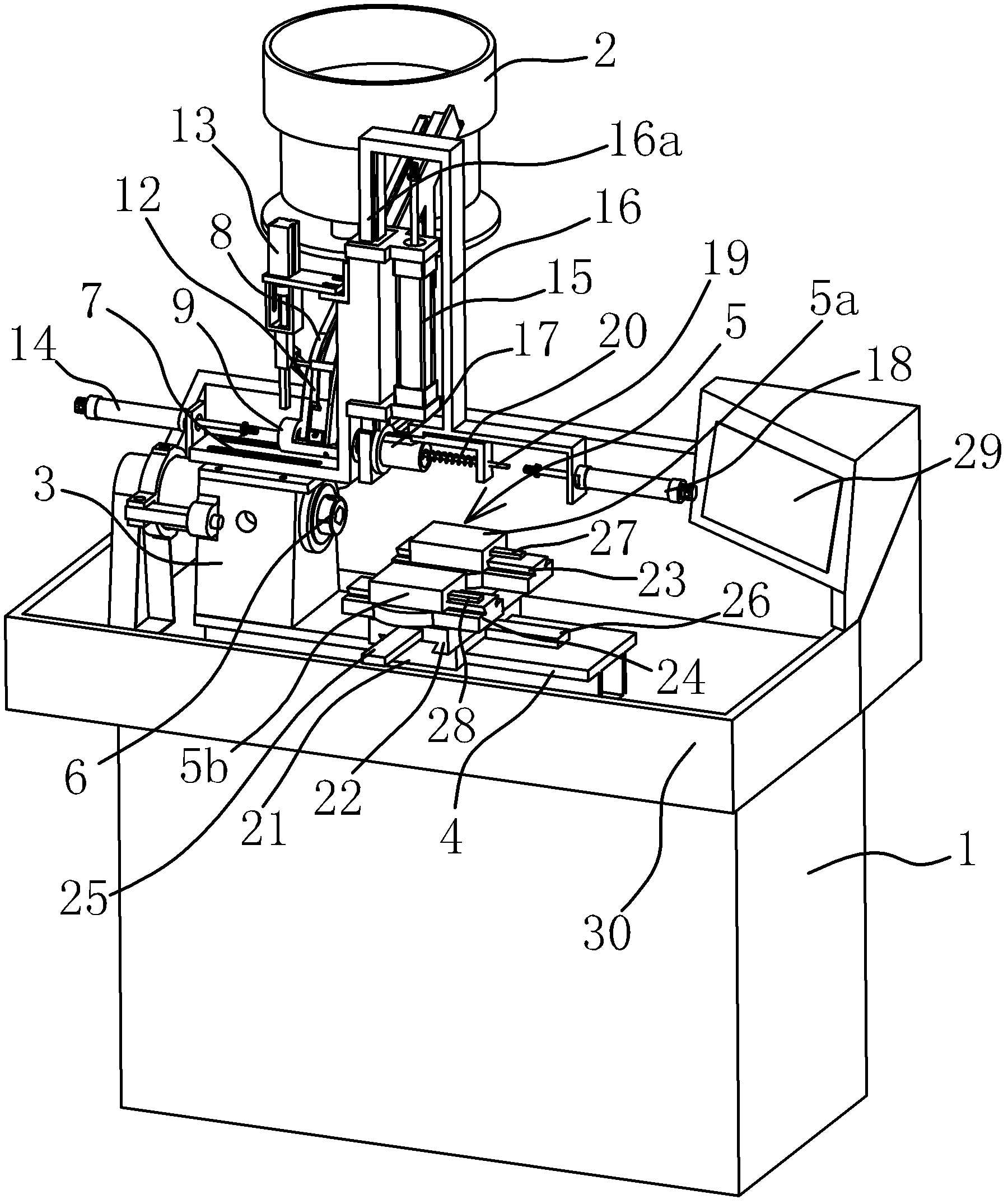

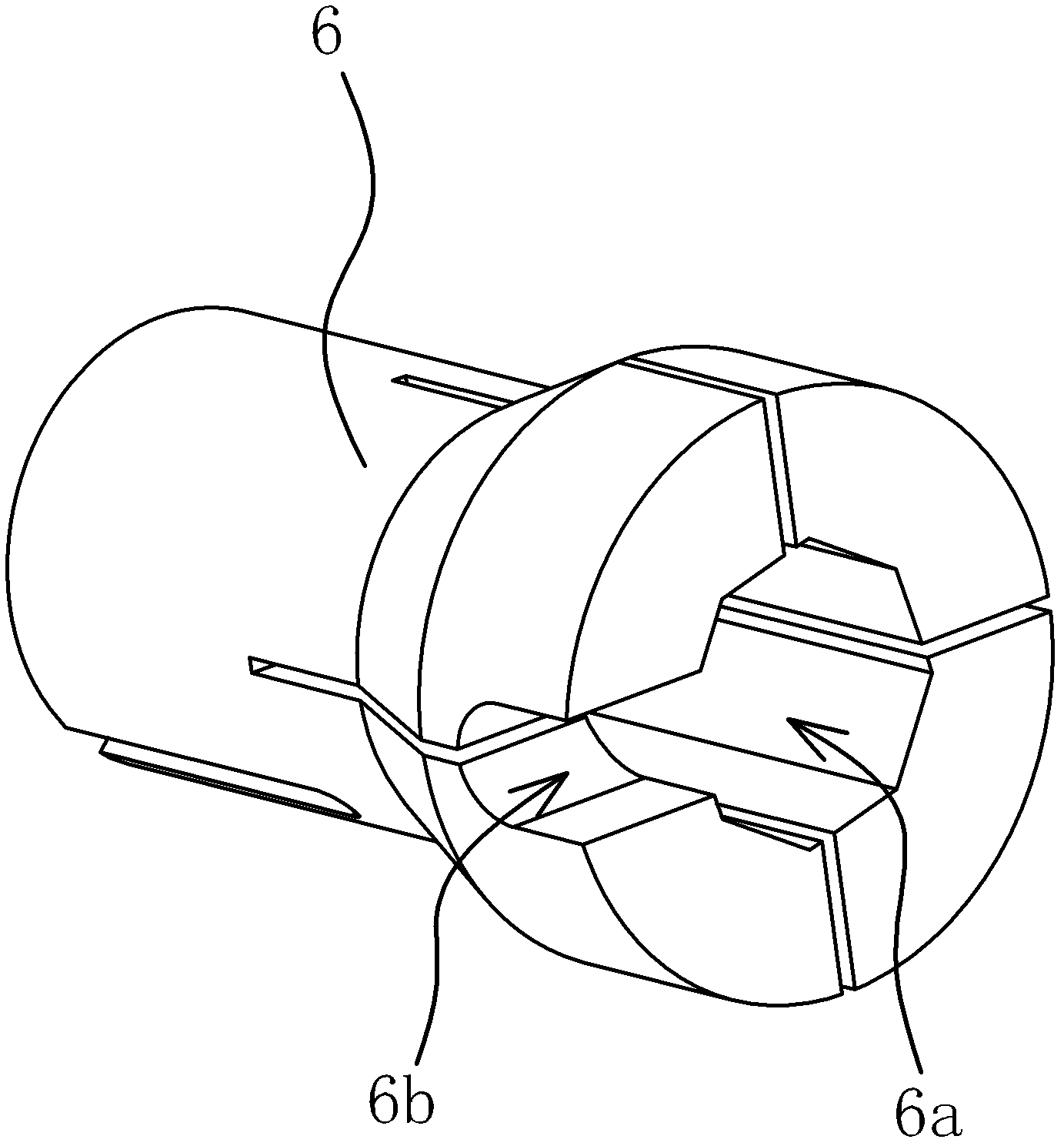

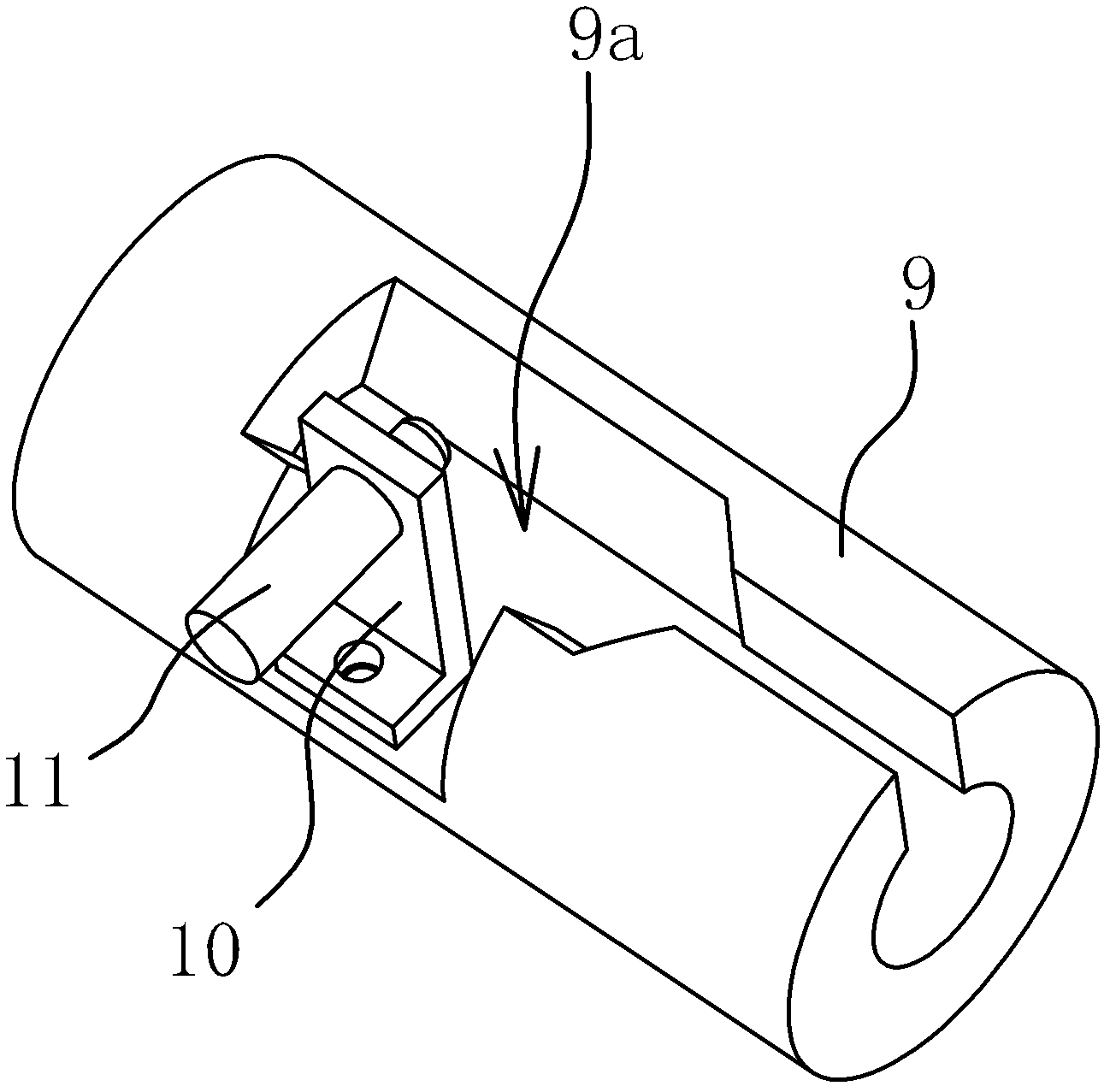

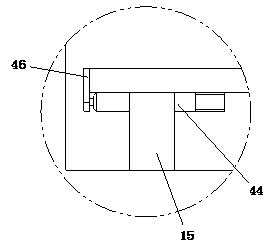

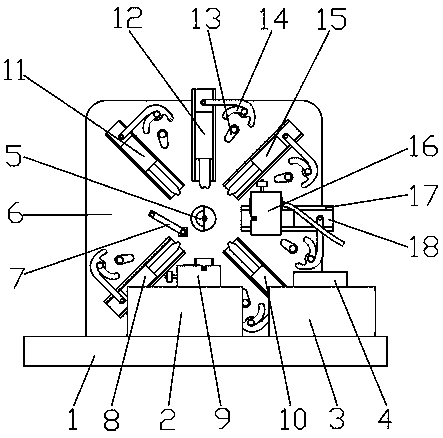

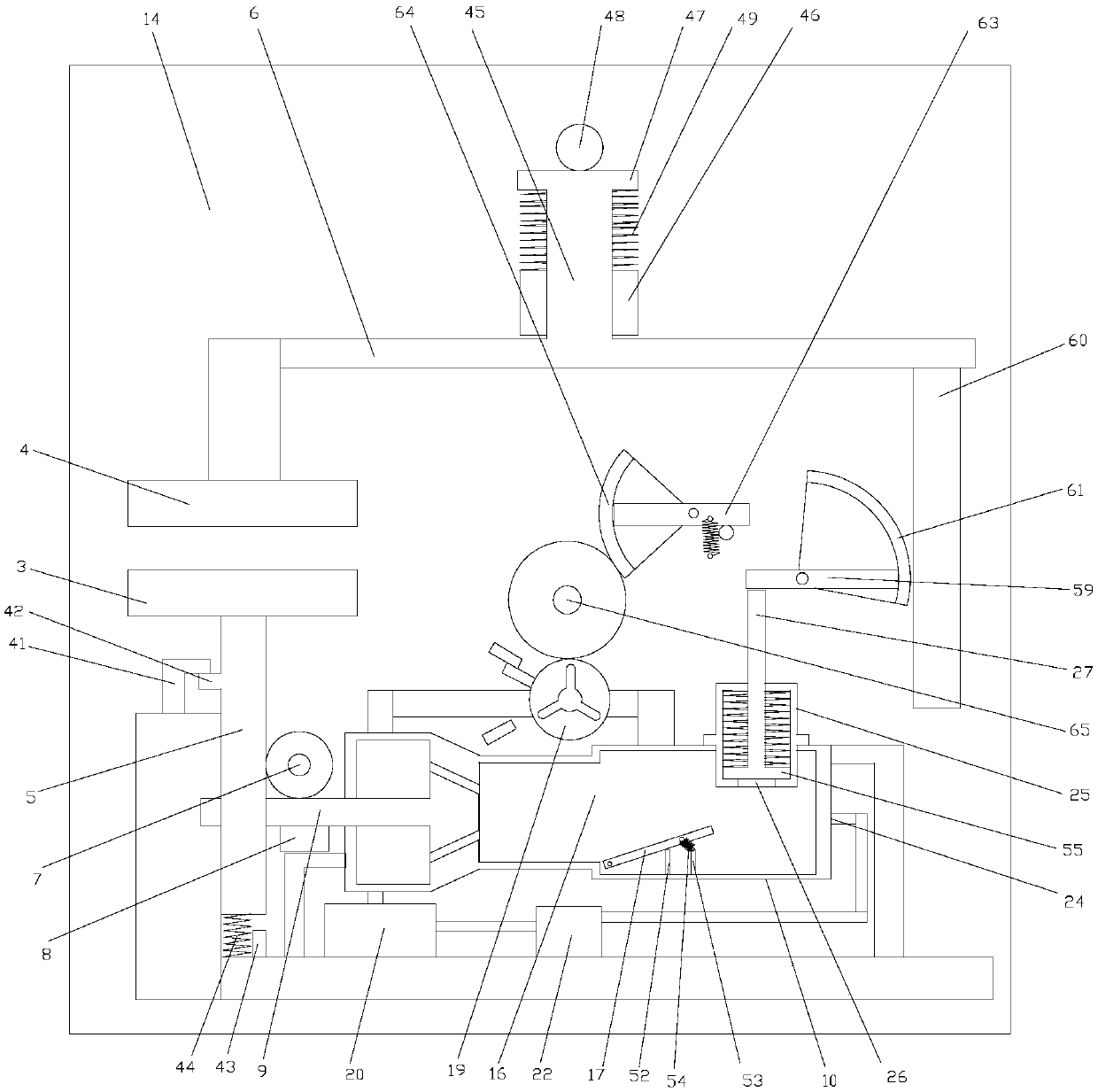

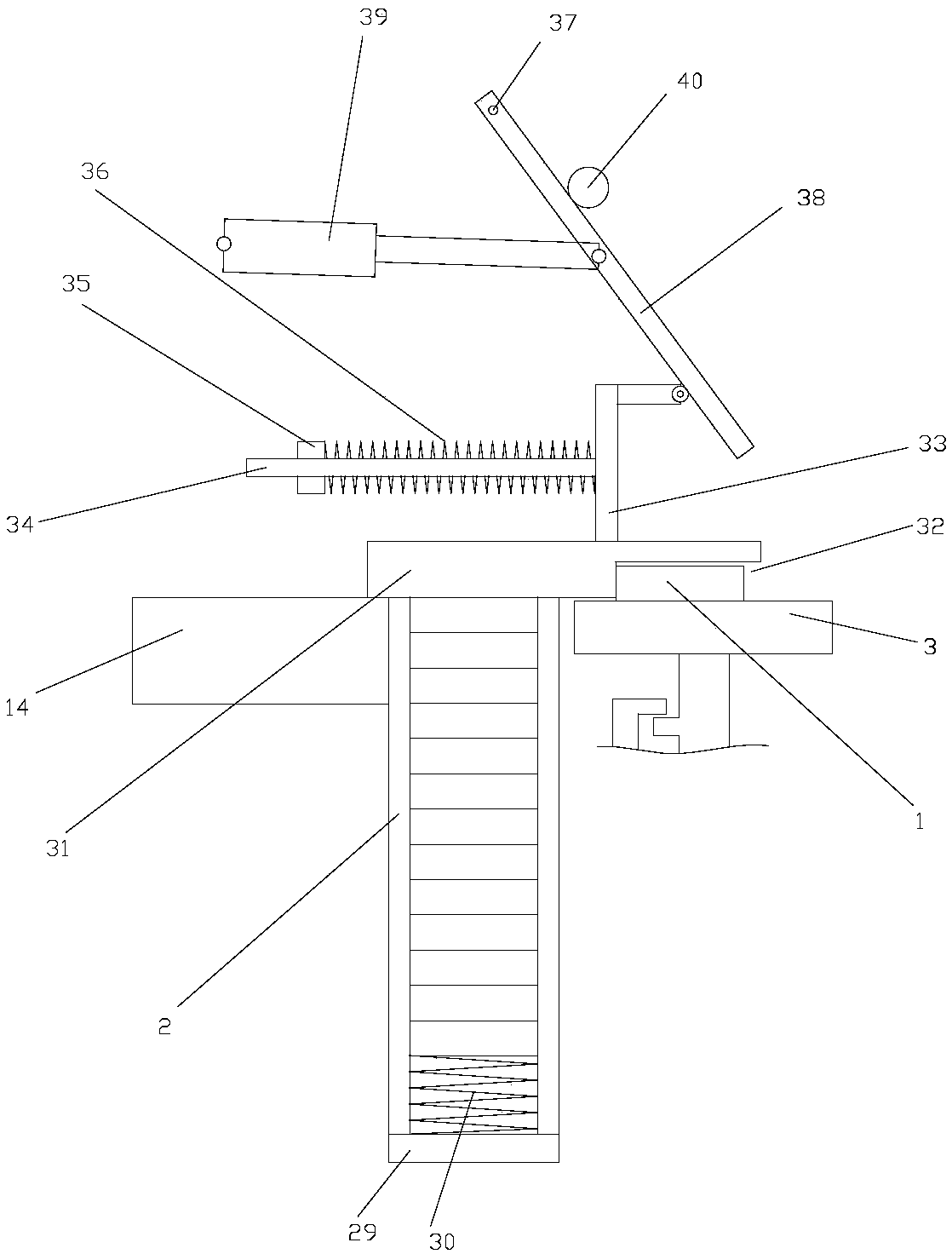

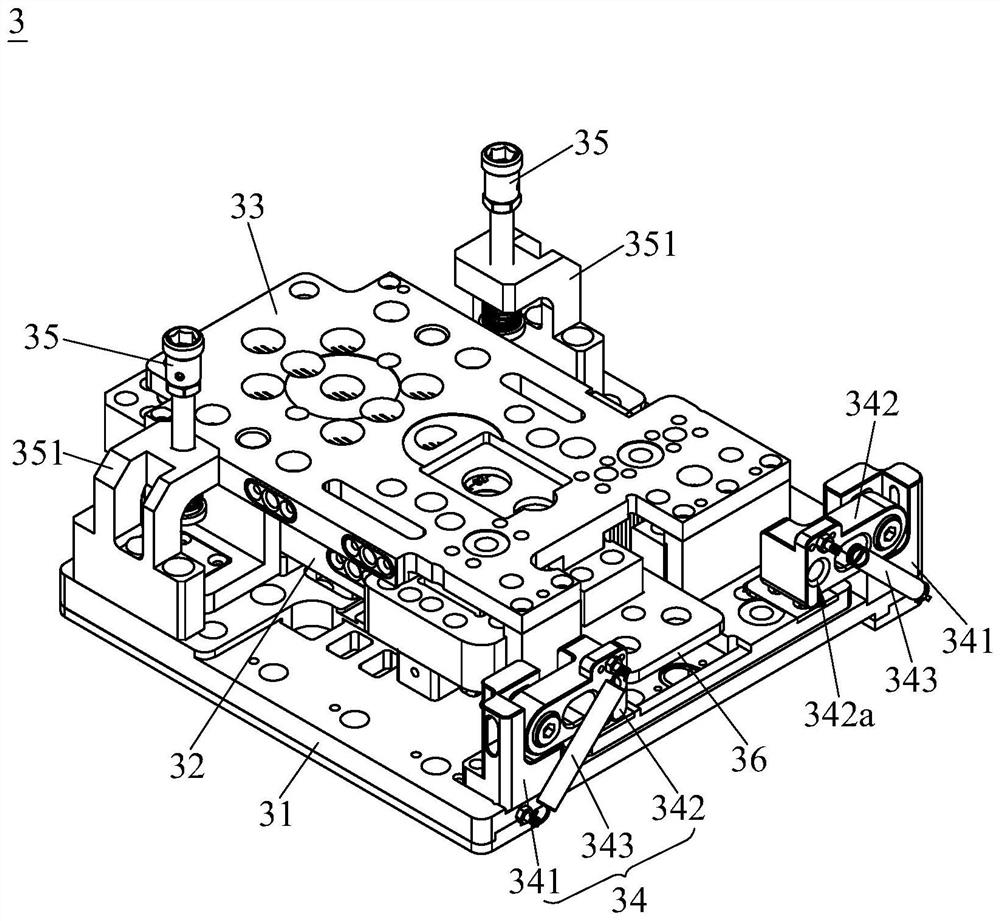

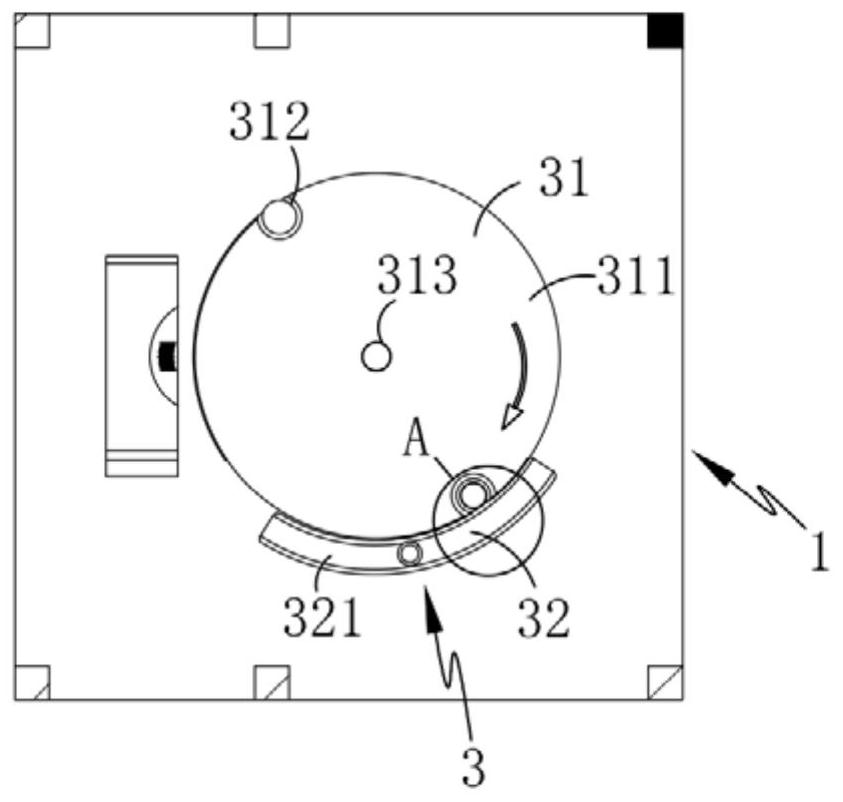

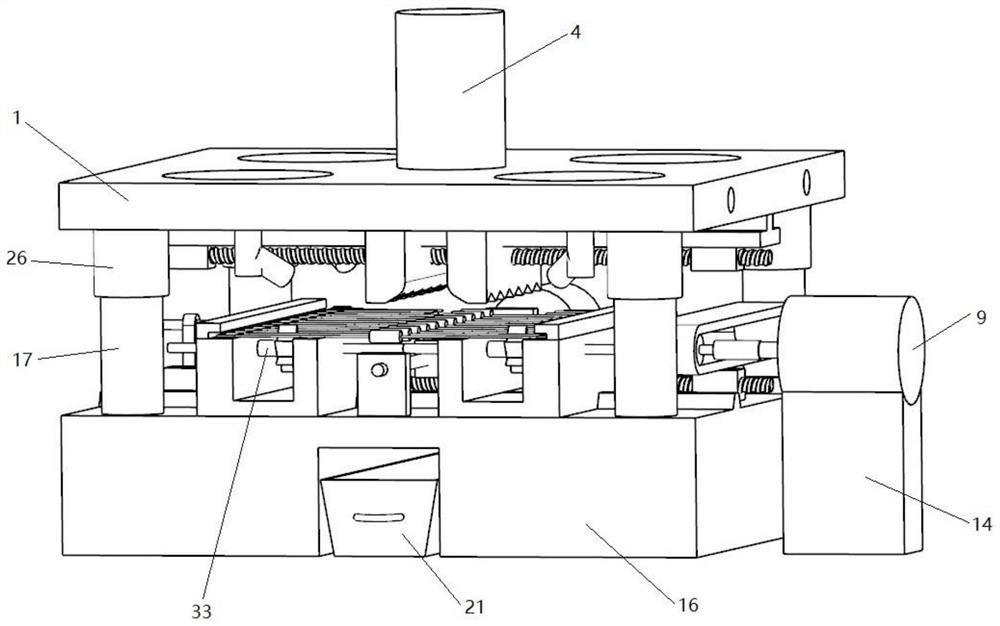

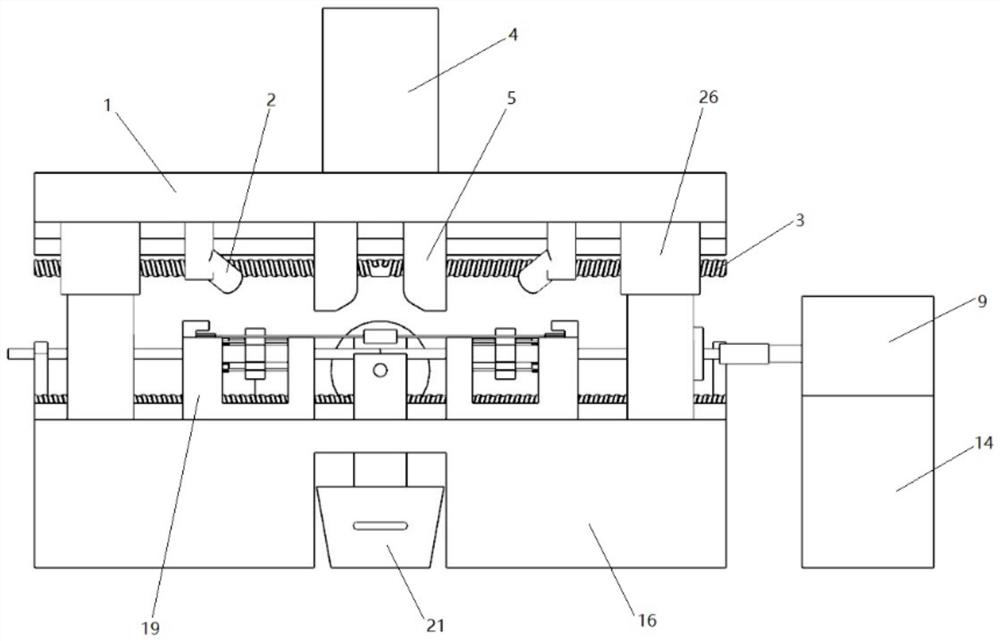

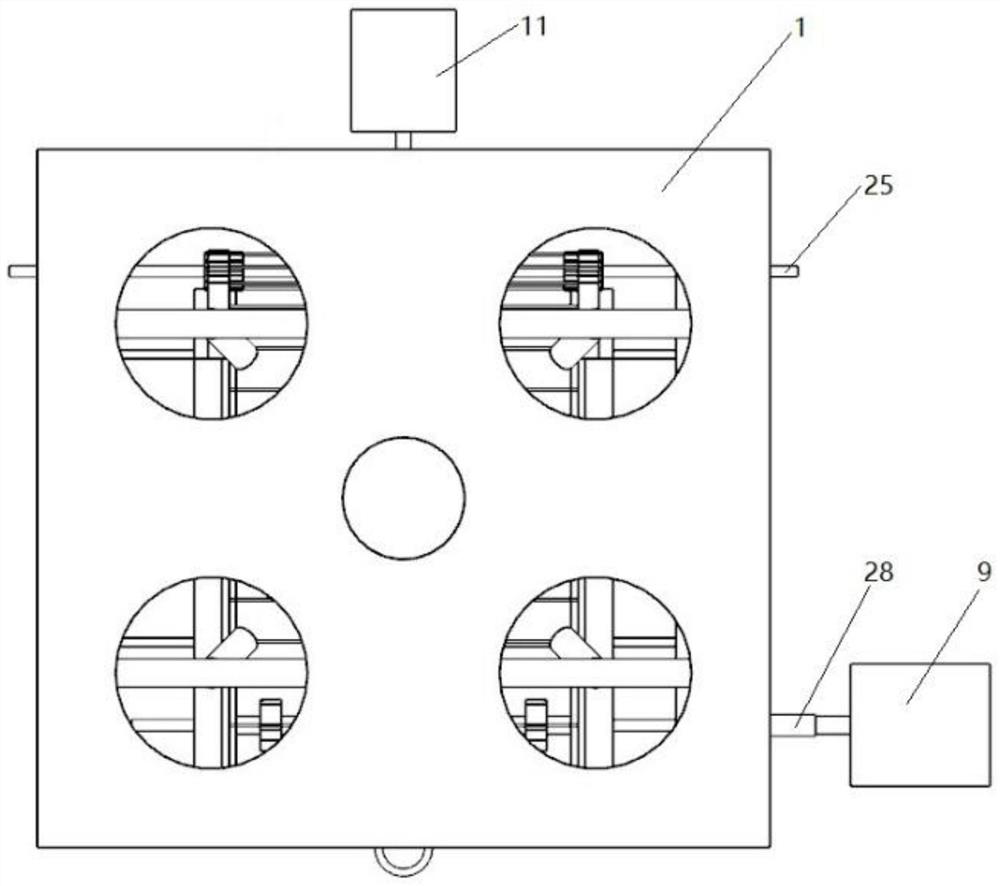

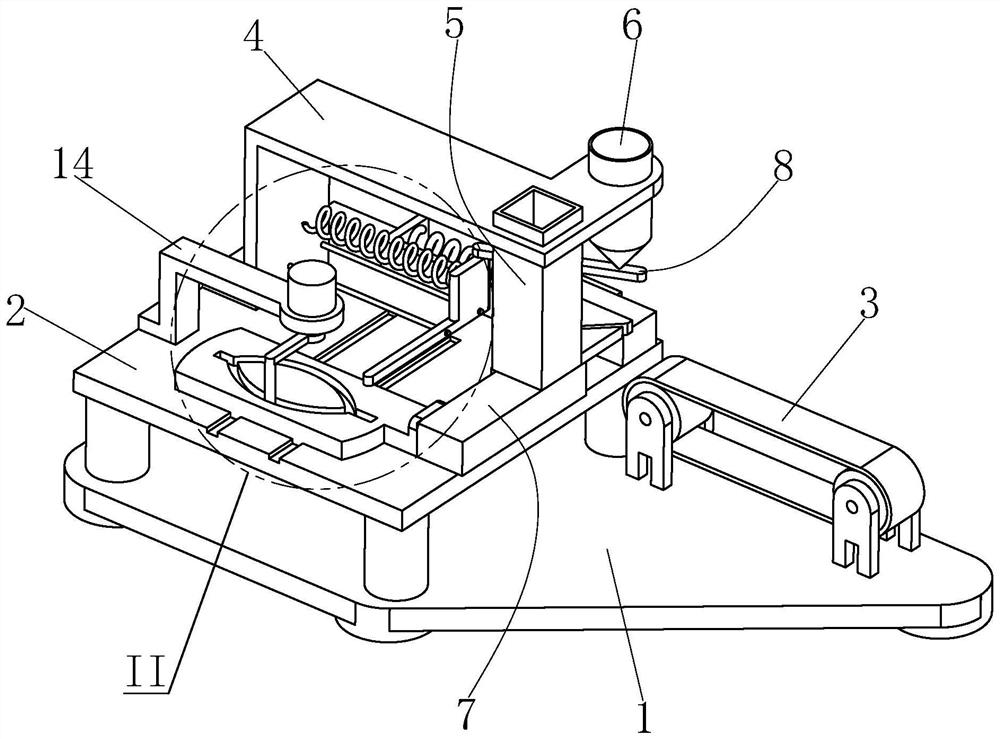

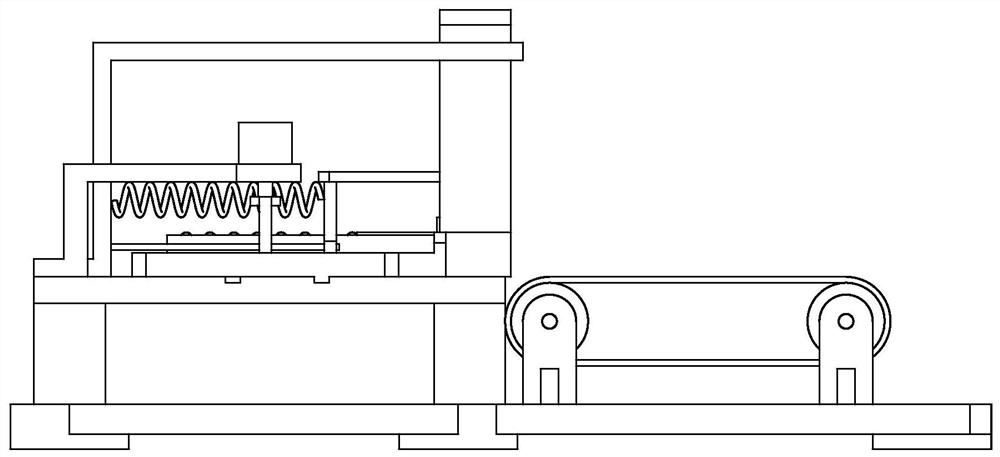

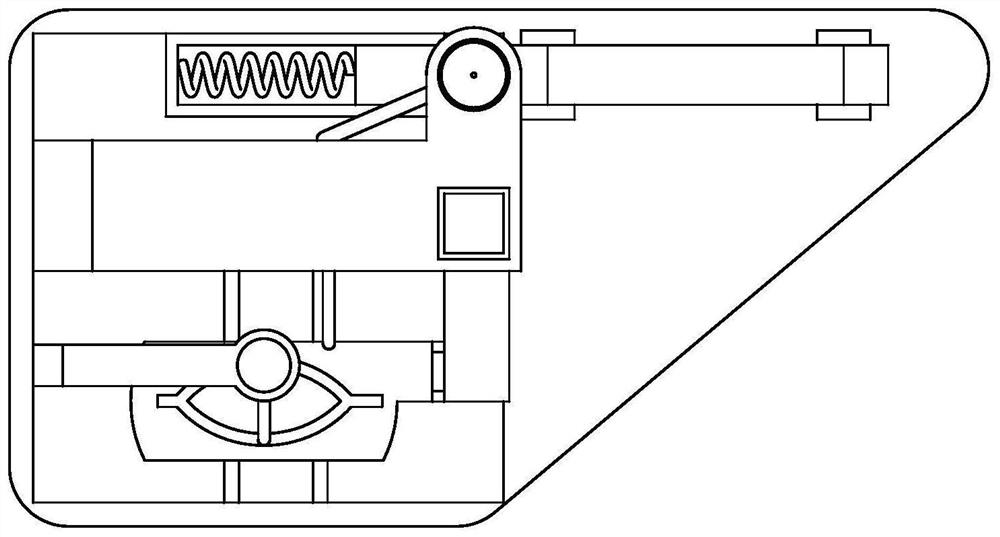

Intelligent punching die

InactiveCN108672577ASmall openingSpeed up the flowShaping toolsMetal-working feeding devicesEngineeringAutomation

The invention discloses an intelligent punching die. The intelligent punching die comprises a base 14, the base 14 is in sliding connection with an upper die base 4 and a lower die base 3, the base 14is provided with a material barrel 2 for storing blank pieces 1, and the base 14 is provided with a pushing assembly for pushing the blank pieces 1 in the material barrel 2 to the lower die base 3 one by one. The lower die base 3 and the upper die base 4 are provided with a supporting rod 5 and a sliding frame 6 correspondingly, wherein the supporting rod 5 and the sliding frame 6 slide in the vertical direction, accordingly, it is ensured that the upper die base 4 and the lower die base 3 can be subjected to die assembly, and the supporting rod 5 and the sliding frame 6 are in sliding connection to the base 14 through a first sliding assembly and a second sliding assembly in the vertical direction. The intelligent punching die higher in automation level and higher in machining precisionis provided.

Owner:安祖桂

Calendar for PVC film processing process

The invention discloses a calender for a PVC film processing process. The calender comprises a frame, a calendering device arranged on the frame and a scraping device arranged at the front part of theframe. The calendering device comprises a first pressing roller, a second pressing roller arranged on one side of the first pressing roller, a third pressing roller arranged below the second pressingroller, a fourth pressing roller arranged below the third pressing roller, first connecting blocks arranged on the left side and the right side of the first pressing roller and the second pressing roller, second connecting blocks arranged on the left side and the right side of the third pressing roller, third connecting blocks arranged on the left side and the right side of the fourth pressing roller, transmission devices arranged on the connecting blocks, a discharging device arranged on the first pressing roller, and the scraping device arranged at the front part of the fourth pressing roller. According to the calender, intermittent blanking is carried out through a blanking trough, so that the blanking is more uniform, two sides of a PVC film are the same in thickness, the PVC film isrolled and flattened through a flattening device, the consistent thickness can be realized by the scraping device, meanwhile, scraped materials can be recycled, and thus resources are saved.

Owner:杭州汇安建筑节能科技有限公司

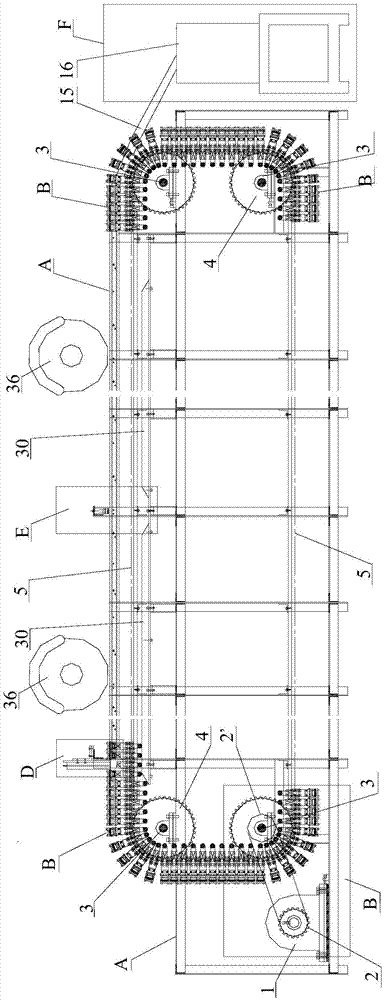

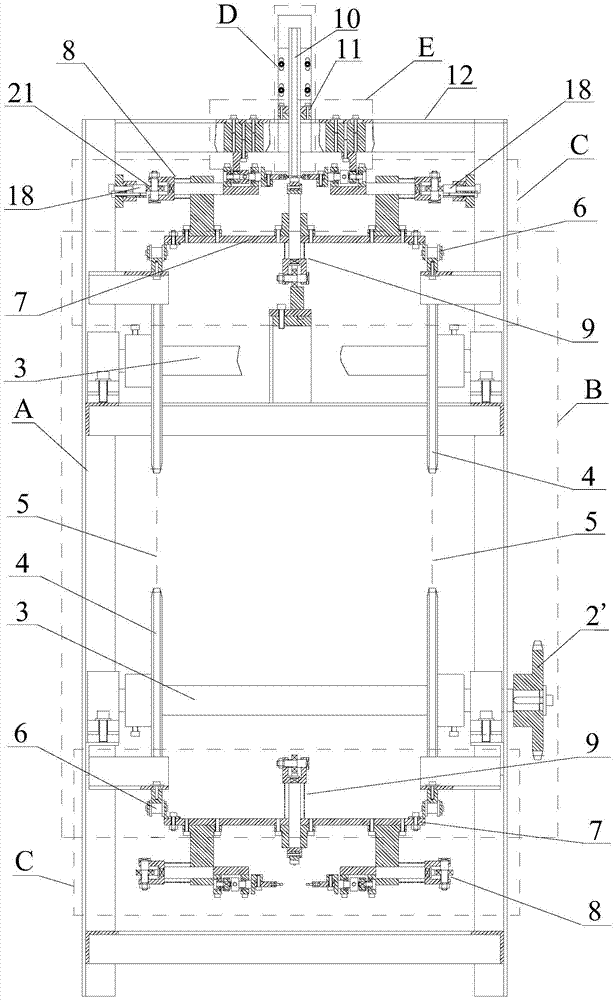

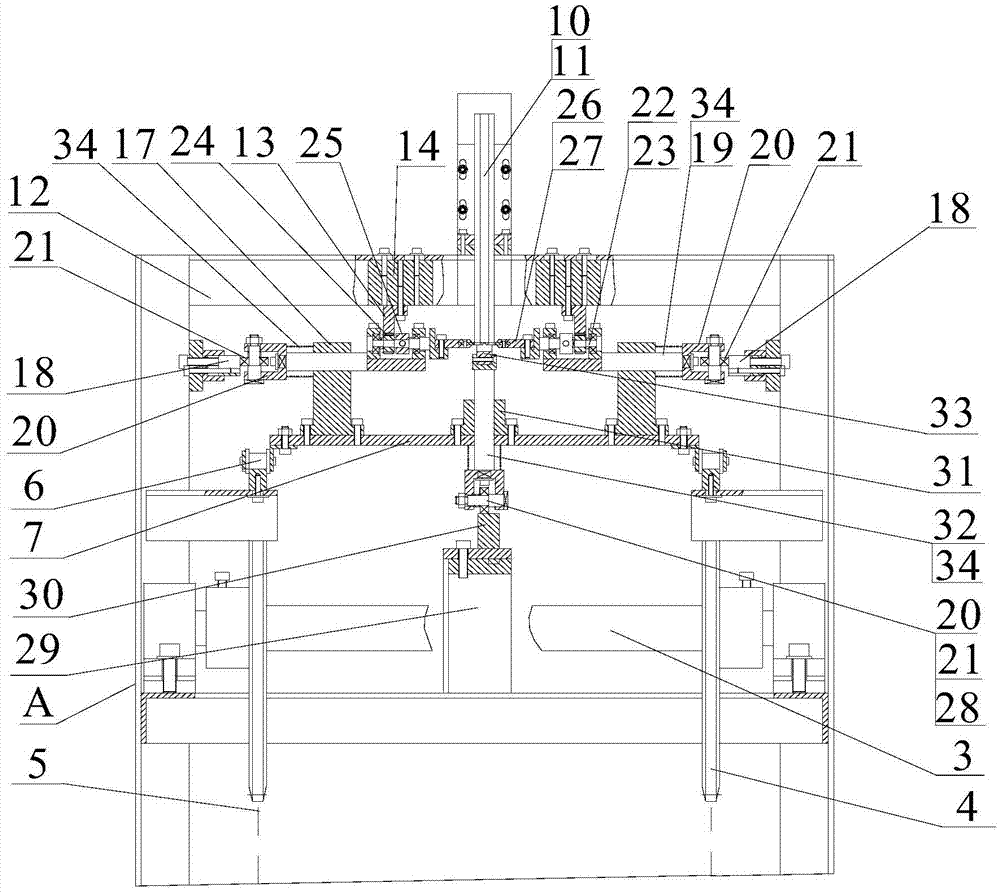

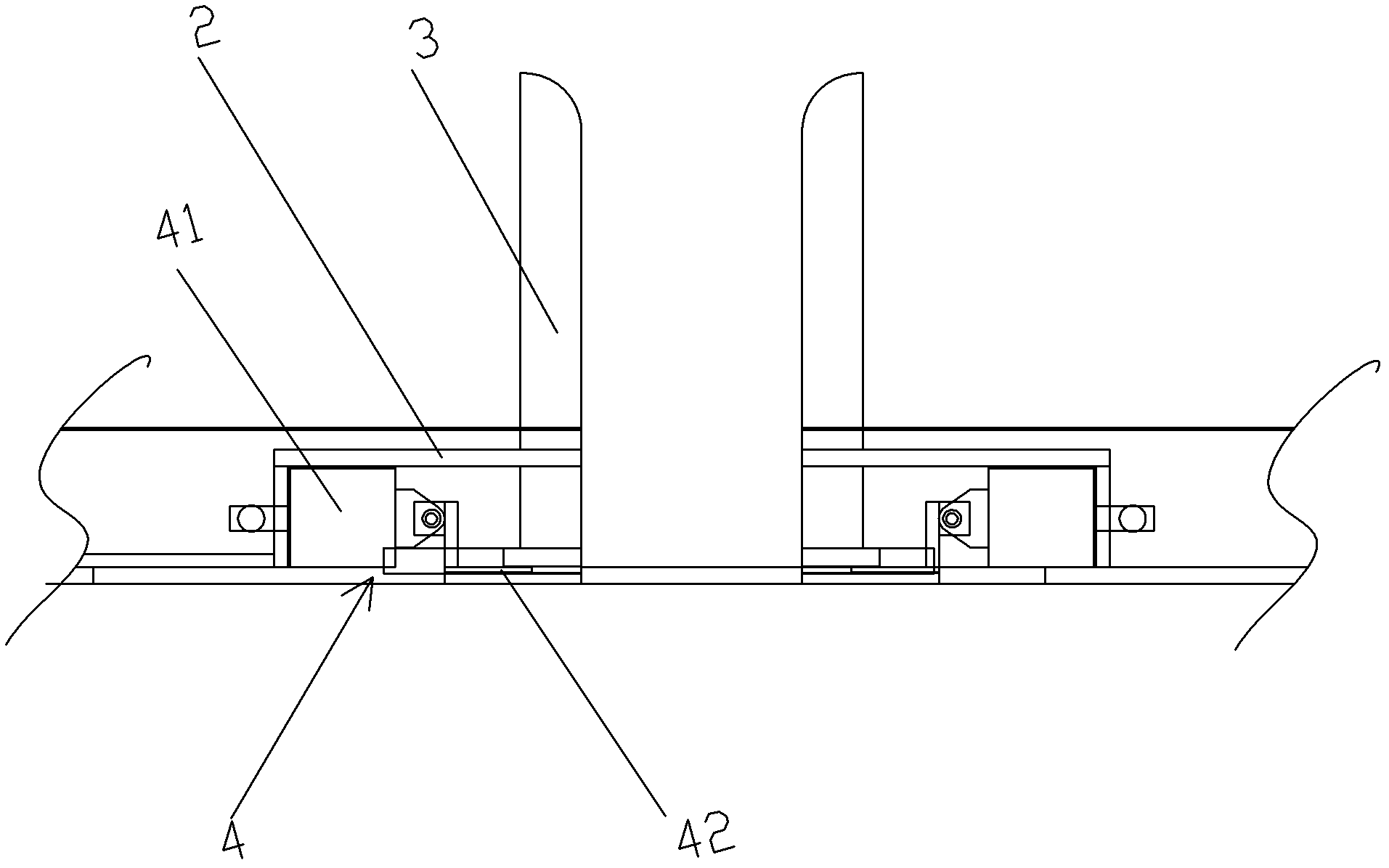

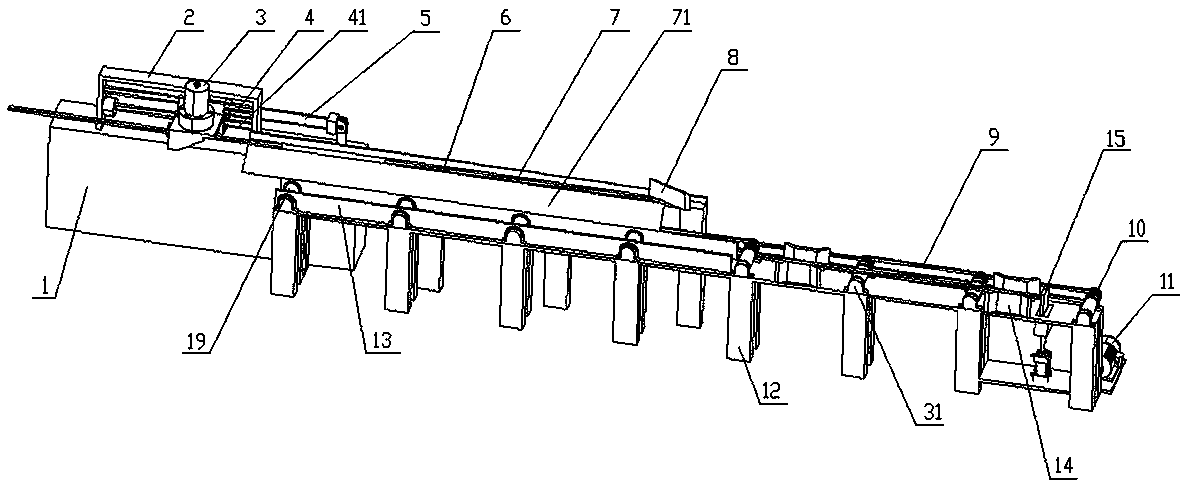

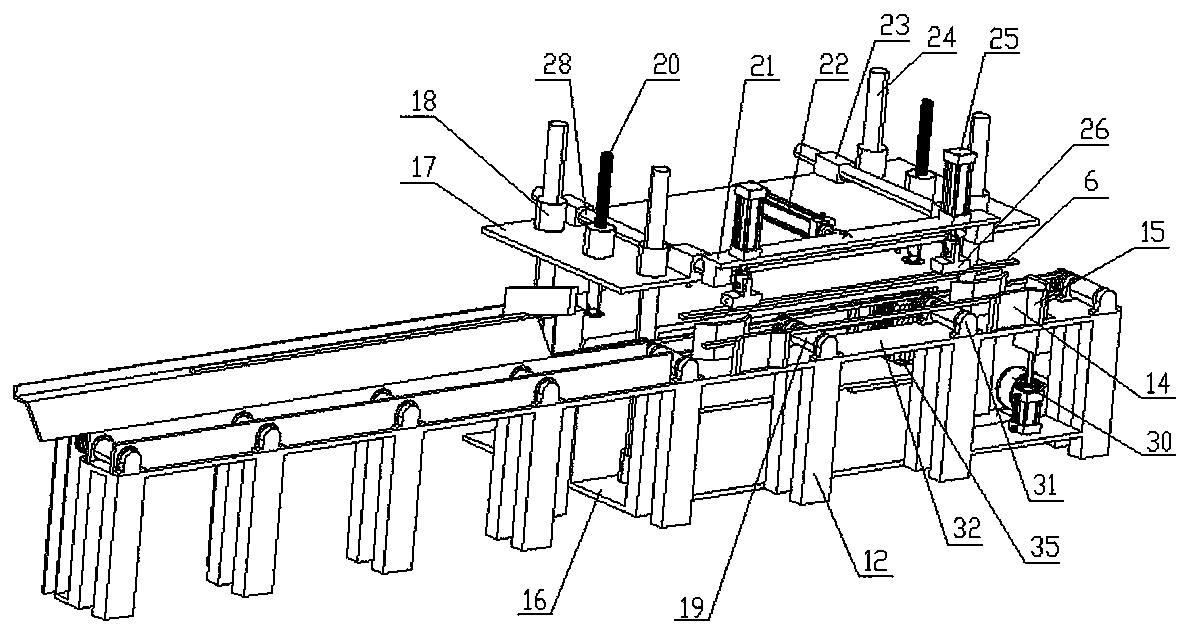

Automatic polishing and feeding device for watch band grains

InactiveCN105437048ARealize clamping transferRealize automatic blankingPolishing machinesGrinding machinesSprocketDrive motor

The invention discloses an automatic polishing and feeding device for watch band grains. Power is transmitted to a driven sprocket by a driving motor mounted on a rack, a main drive sprocket and a drive chain, the driven sprocket drives a sprocket shaft to rotate so as to drive the drive chain to rotate, and thus a follow-up clamping mechanism is driven to run forwards; when the follow-up clamping mechanism runs to a feeding position, the watch band grains are automatically fed to a workpiece positioning block of a longitudinal clamping component from a feeding mechanism, and are clamped by a workpiece clamping block of a transverse clamping component, so that clamped conveyance of the watch band grains is implemented; while the watch band grains continue running forwards, upper surfaces of the watch band grains are polished by a left polishing wheel; when the follow-up clamping mechanism runs to a steering mechanism, the longitudinal clamping component retracts, the steering mechanism drives the watch band grains clamped by the transverse clamping component to rotate at an angle of 180 degrees, and then the longitudinal clamping component upwards supports workpieces; when the watch band grains continue moving forwards, the other surfaces of the watch band grains are polished by a right polishing wheel; and when forwards moving to a discharging mechanism, the watch band grains are discharged automatically, and automatic polishing of the watch band grains is finished.

Owner:SOUTH CHINA UNIV OF TECH

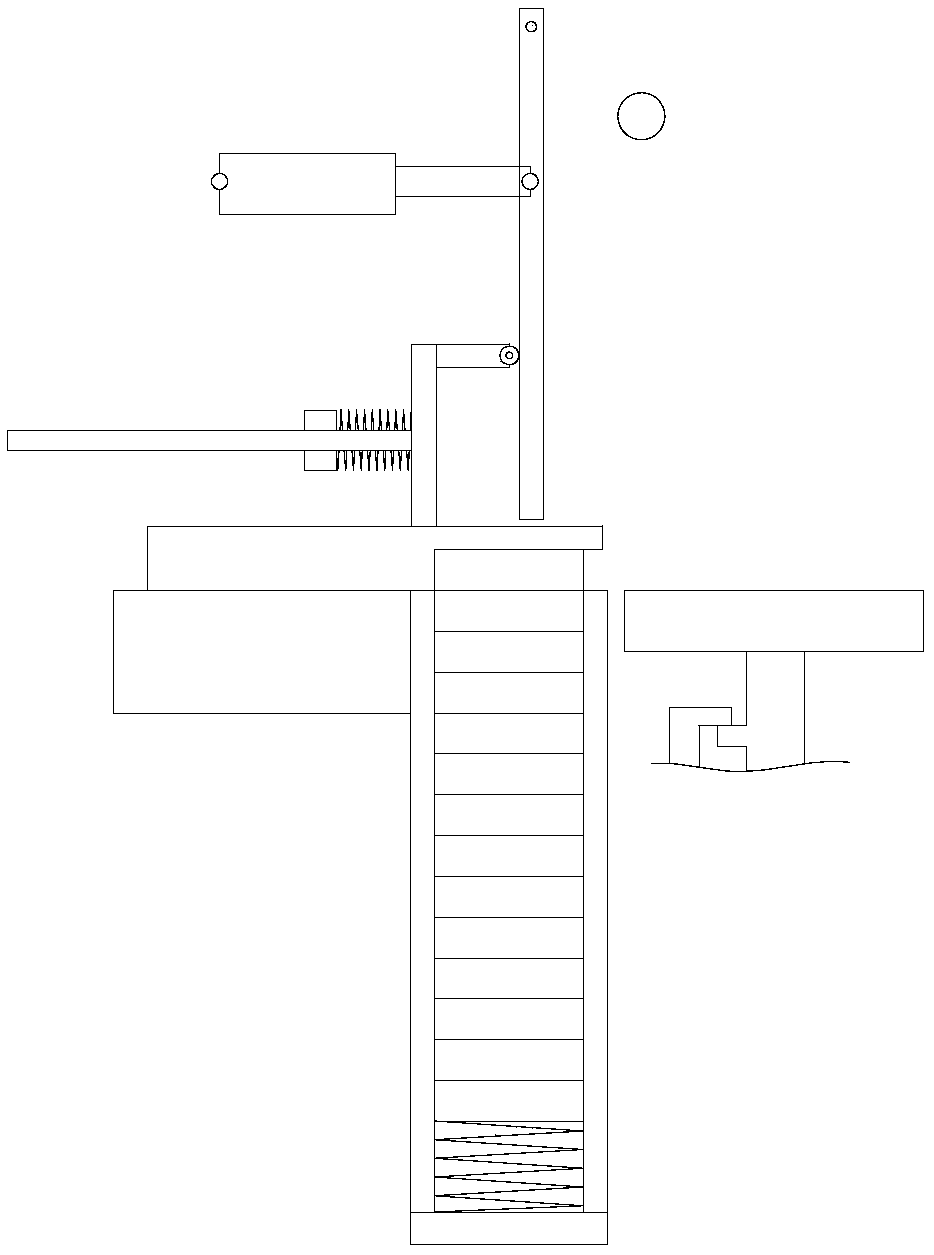

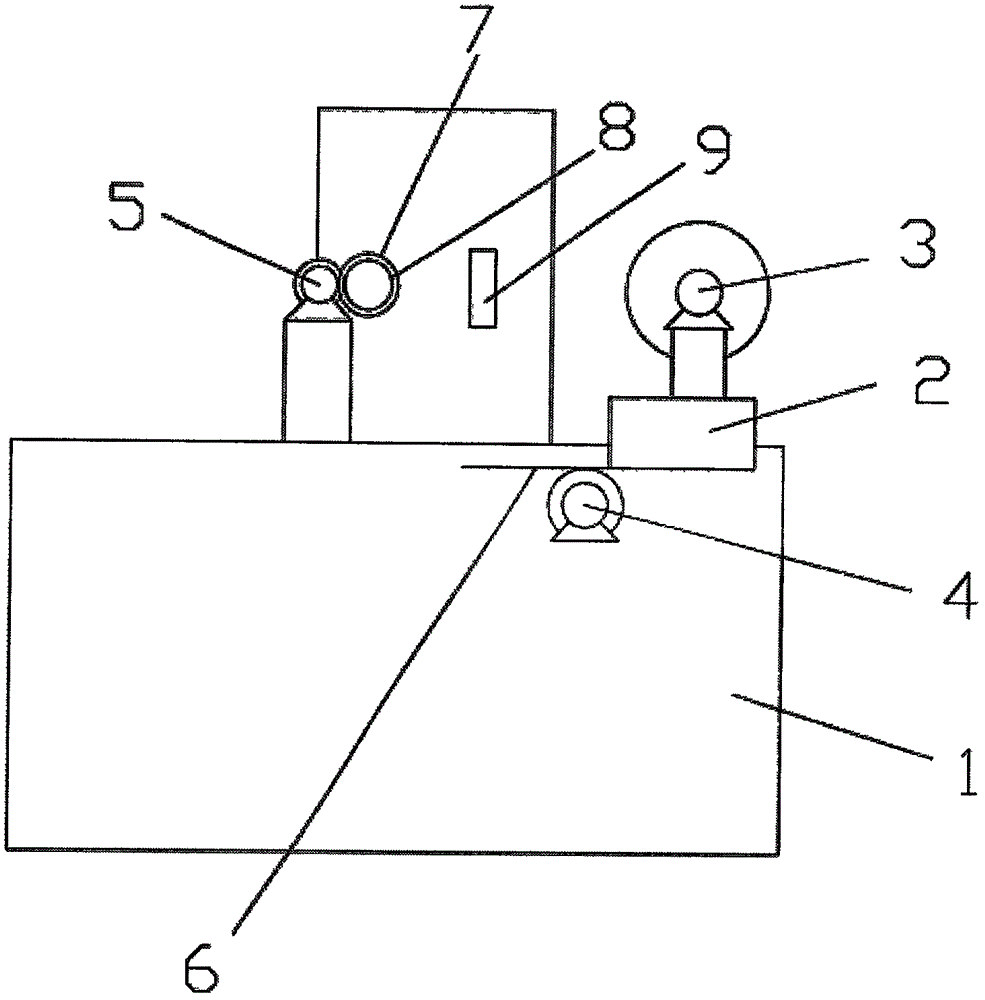

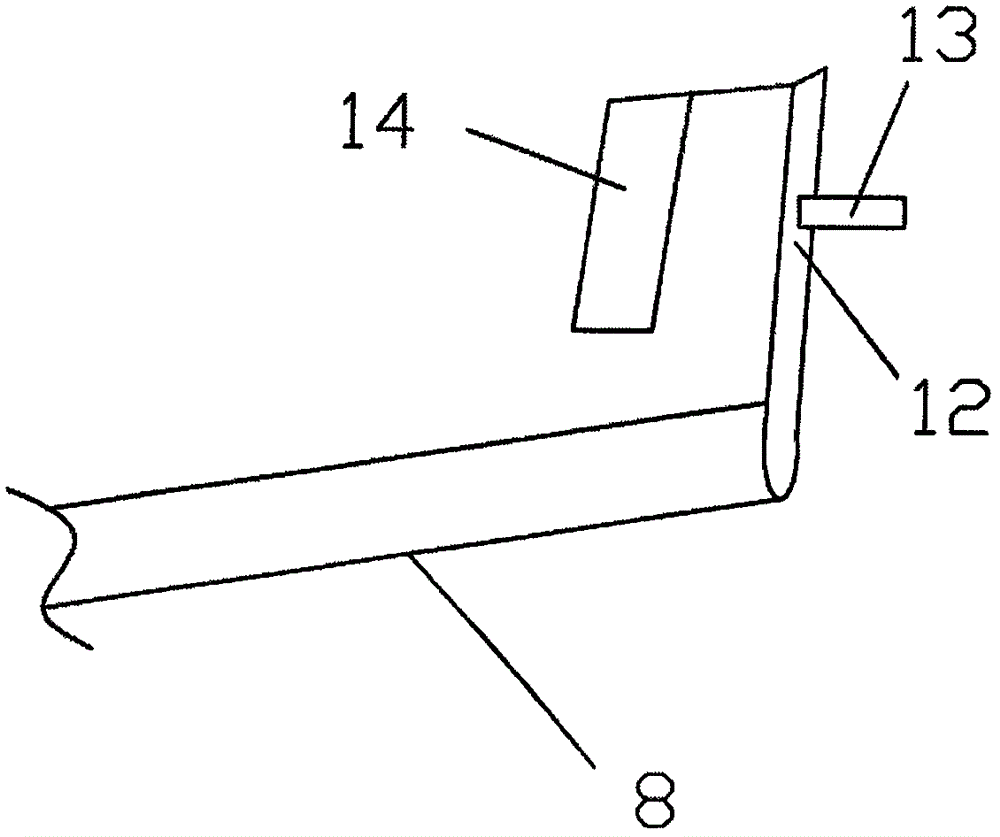

Blanking device with good use effect and high efficiency

InactiveCN102248472AClever realization of automatic blankingRealize automatic blankingPolishing machinesBurnishing machinesEngineeringMechanical engineering

The invention relates to a blanking device with good use effect and high efficiency. The device comprises a bracket, wherein a work platform is arranged on the bracket; a vertical feeding rod for holding workpieces to be processed is arranged on the work platform; and a main blocking component capable of preventing the lowest workpiece from falling down is arranged at the bottom of the work platform; and an auxiliary blocking component, used for enabling the lowest workpiece to fall for processing and preventing the workpiece in the feeding rod from falling when the main blocking component actuates, is arranged at the bottom of the work platform. The invention aims at overcoming the defects in the prior art, and provides the blanking device with simple structure, automatic blanking, high efficiency and good effect.

Owner:刘忠平 +1

Jig disassembling equipment

PendingCN112296668ARealize automatic disassemblyRealize automatic blankingAssembly machinesMetal working apparatusRobot handEngineering

The invention provides jig disassembling equipment. The jig disassembling equipment comprises a rack, first conveying lines, jigs, pressing plate opening mechanisms, a first manipulator and a second manipulator, wherein the rack is sequentially provided with a first station, a second station and a third station in the conveying direction of the first conveying lines; the jigs are placed on the first conveying lines and comprise jig bottom plates, jig limiting middle frames, jig upper covers and elastic pressing assemblies, the jig bottom plates are provided with placement stations for allowingradiators to be placed, the jig limiting middle frames are detachably stacked in the jig bottom plates, and the jig upper covers cover the jig limiting middle frames and are detachably stacked on thejig bottom plates, and the elastic pressing assemblies comprise first supporting seats, rotary pressing plates and first elastic pieces; the pressing plate opening mechanisms are arranged on the rackand located at the first station, and the pressing plate opening mechanisms can drive the rotary pressing plates to rotate to be disengaged from the jig upper covers; and the first manipulator is used for disassembling the jig upper covers, and the second manipulator is used for disassembling the jig limiting middle frames and taking out the radiators located on the jig bottom plates.

Owner:DONGGUAN WORLD PRECISION MACHINERY

Flat steel production device with cutting-off, blanking and discharging functions

PendingCN107755777ARealize automatic cut offRealize automatic nestingShearing machinesMetal working apparatusProduction lineEngineering

Owner:WUXI TIANCHI STEEL BAND CO LTD

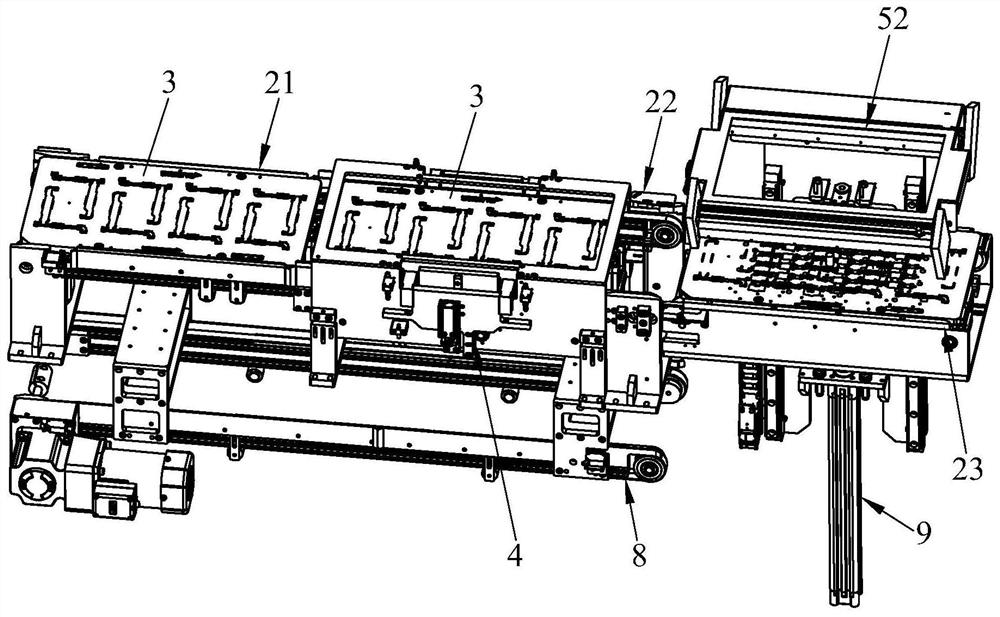

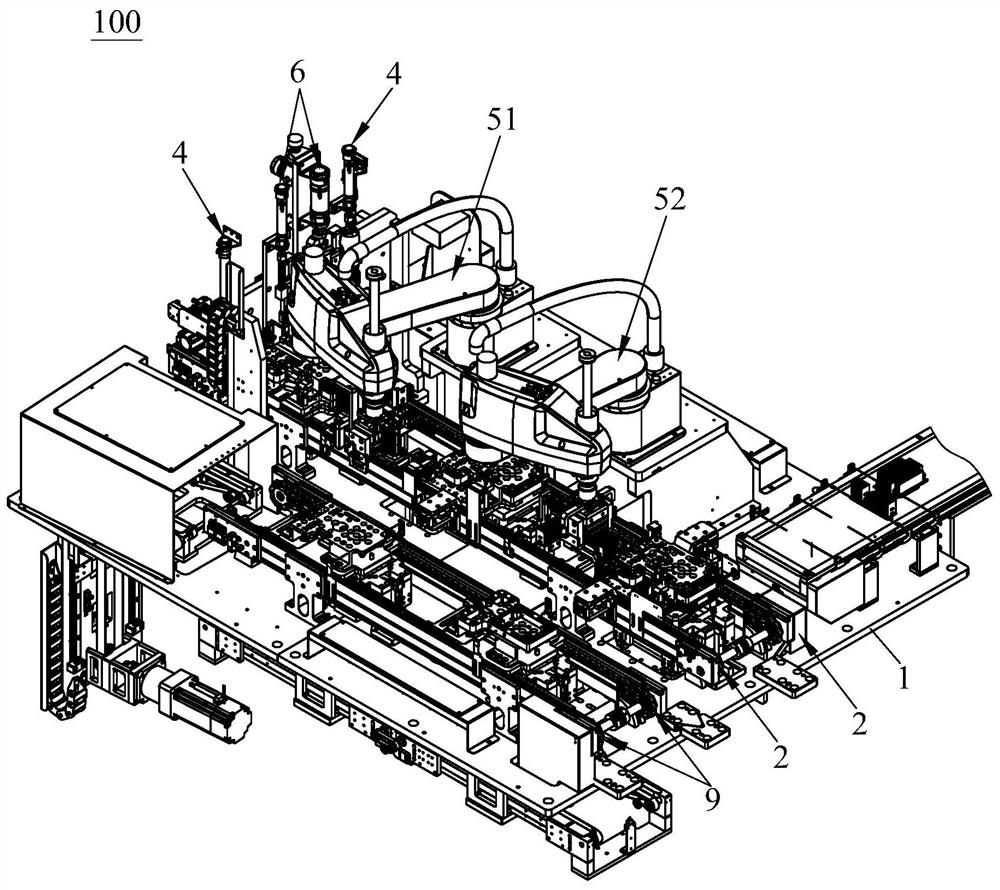

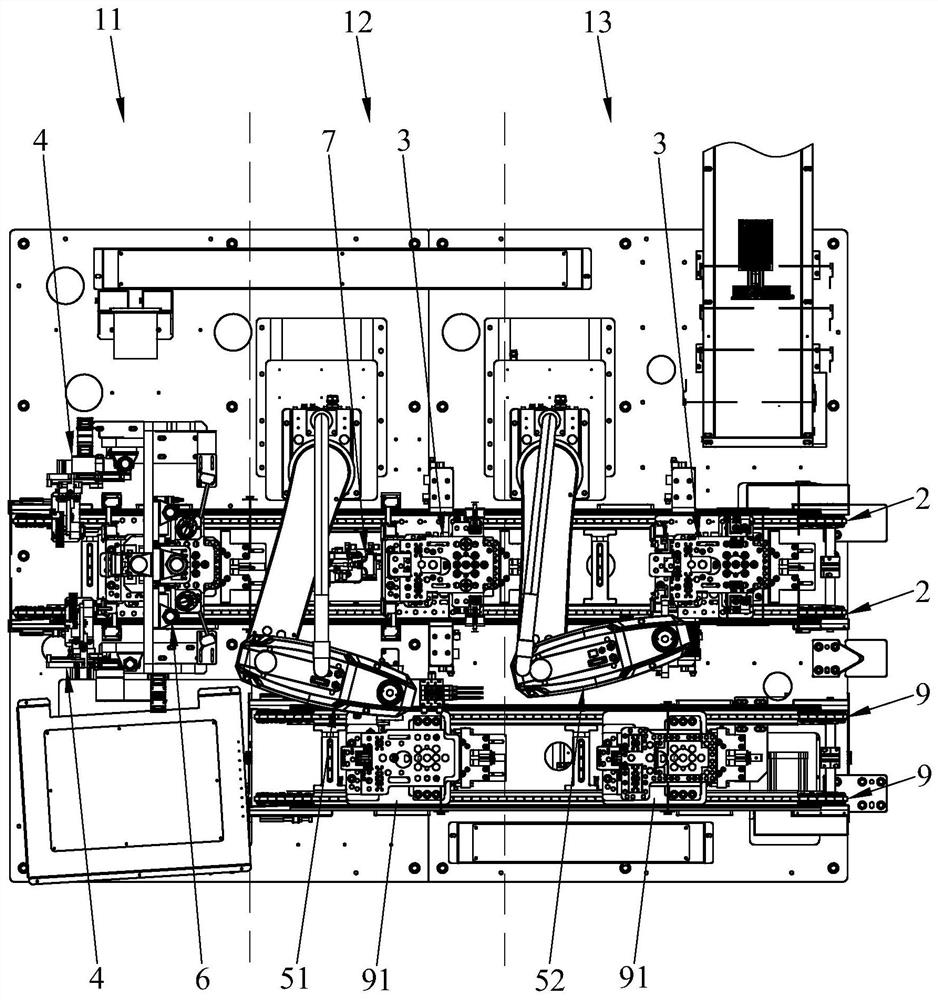

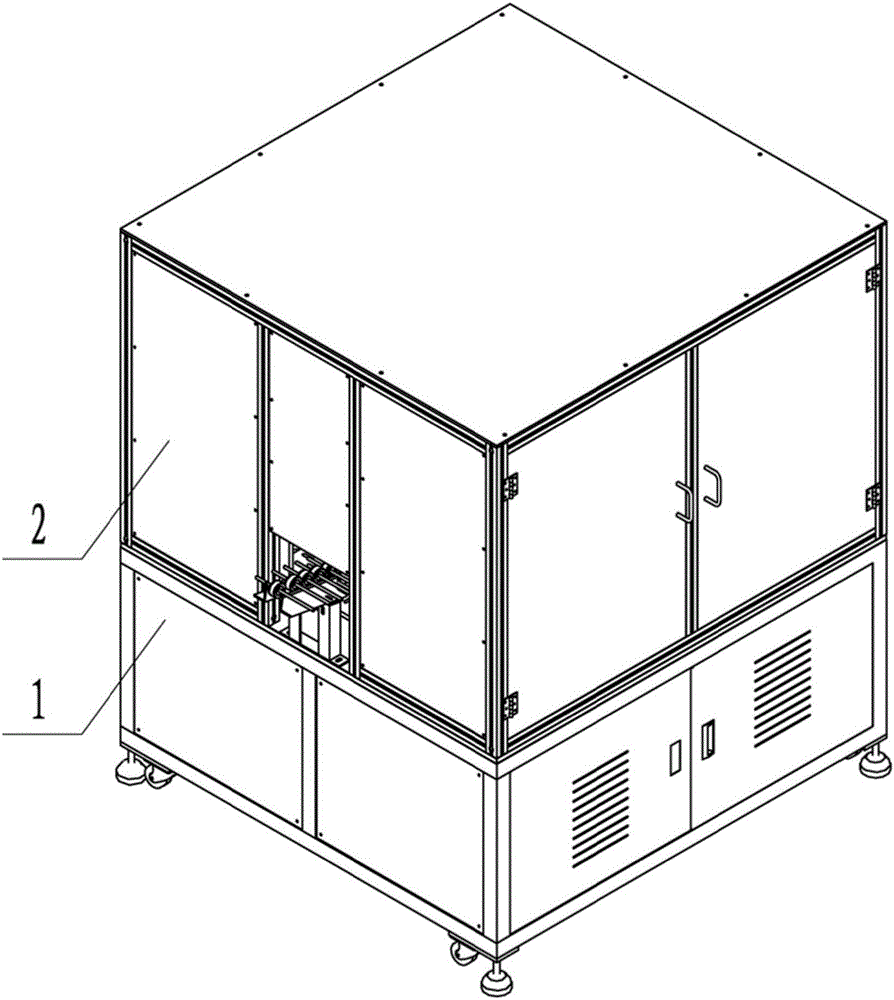

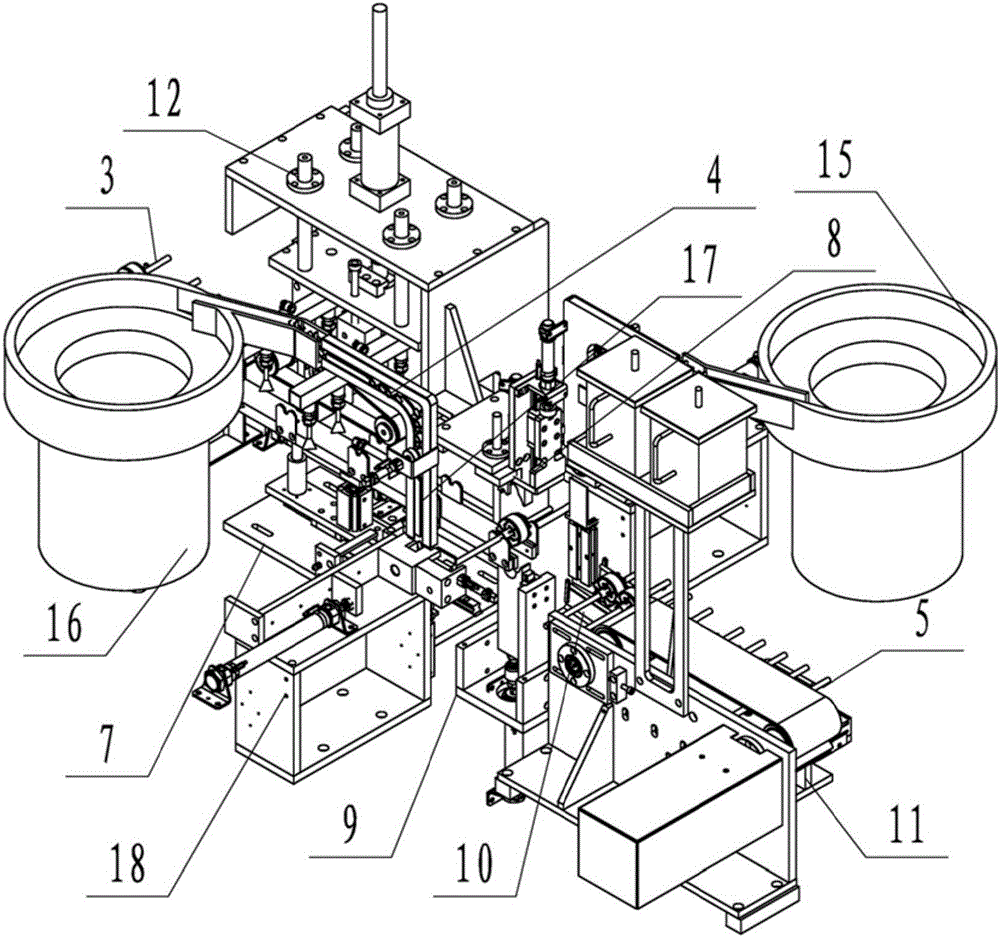

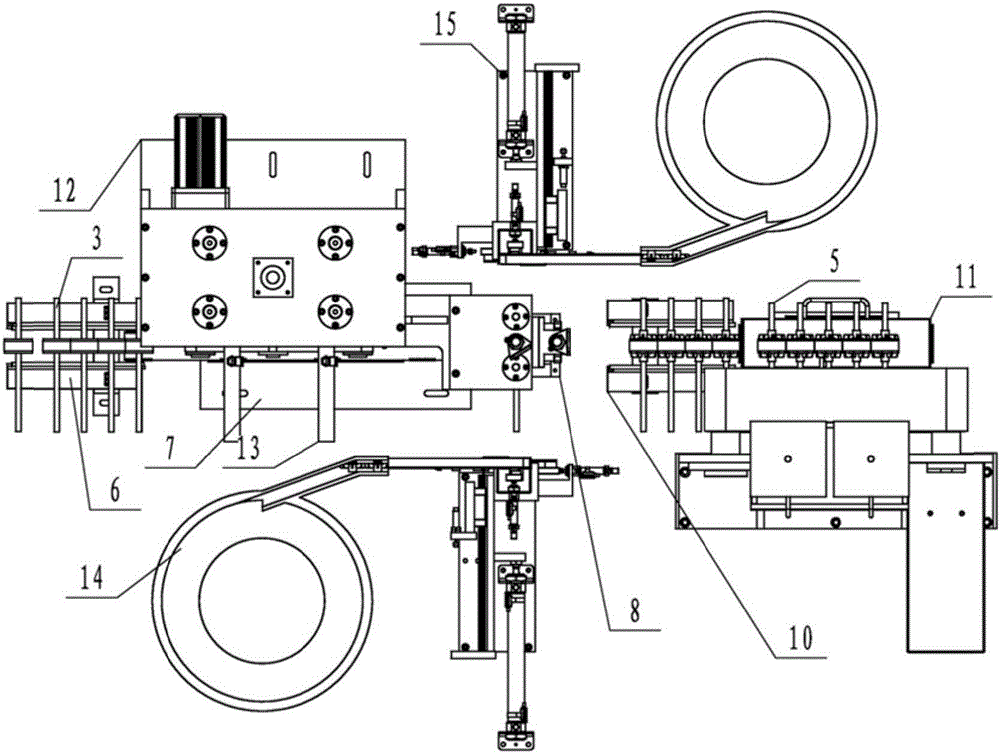

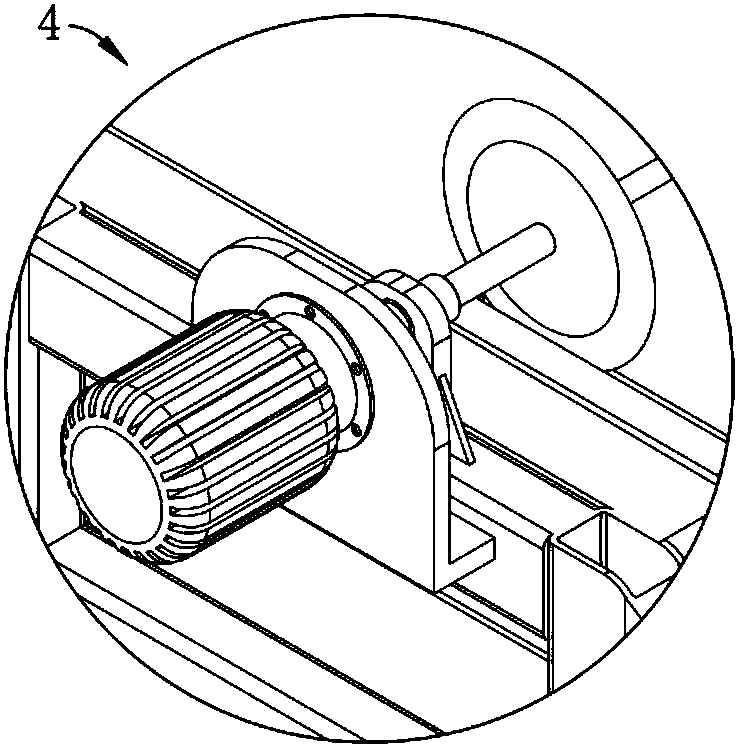

Automatic assembly device for rotating shaft and spiral fan blade wheels of electronic control motor

The invention relates to an automatic assembly device for a rotating shaft and spiral fan blade wheels of an electronic control motor. The automatic assembly device comprises a machine base, a working system arranged on the machine base and a protective cover arranged on the working system in a covering mode; the working system comprise a feed frame group carrying a center spindle to be assembled, a feeding device connected with the feed frame group process, a transition frame group connected with the feeding device process, an acid pickling device connected with the transition frame group process, a rotating driving device arranged at one side of the feeding device, a spray frame of which nozzles are located over spindle heads at the two ends of the center spindle placed on the feeding device, a first vibration feeding device, a second vibration feeding device, a jacking frame group and a rising frame group, wherein the first vibration feeding device and the second vibration feeding device are arranged at the two sides of the feeding device and each provided with one spiral fan blade wheel, and the jacking frame group and the rising frame group are located between the feeding device and the transition frame group. The automatic assembly device is reasonable in design, compact in structure and convenient to use.

Owner:济宁高新科达科技项目服务有限公司

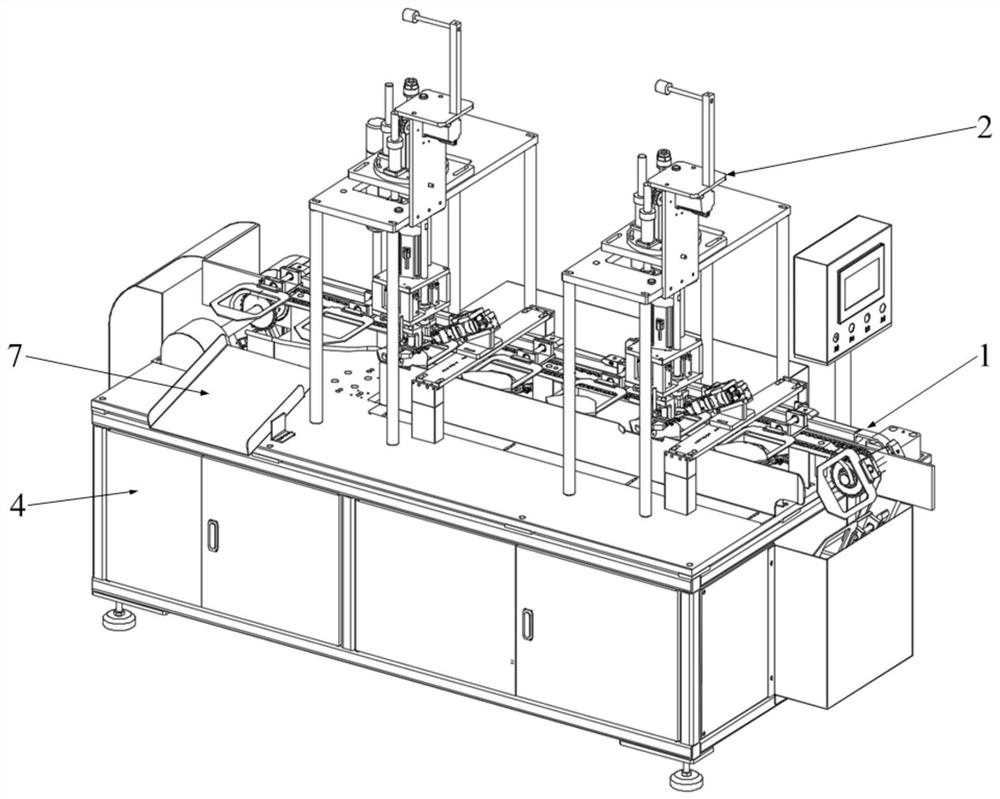

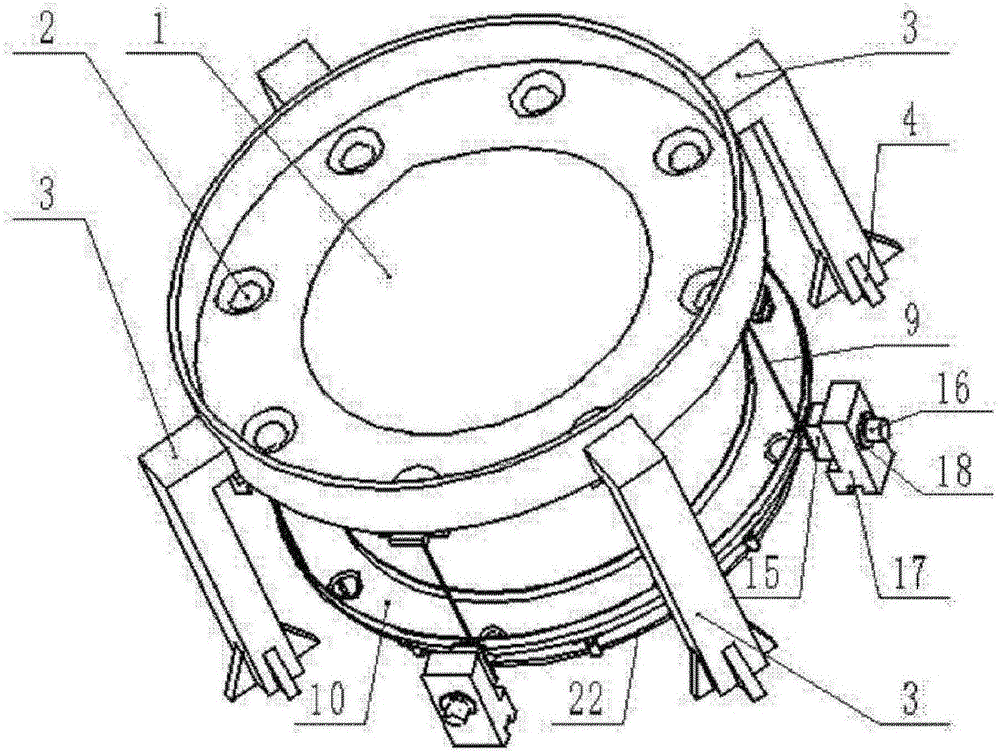

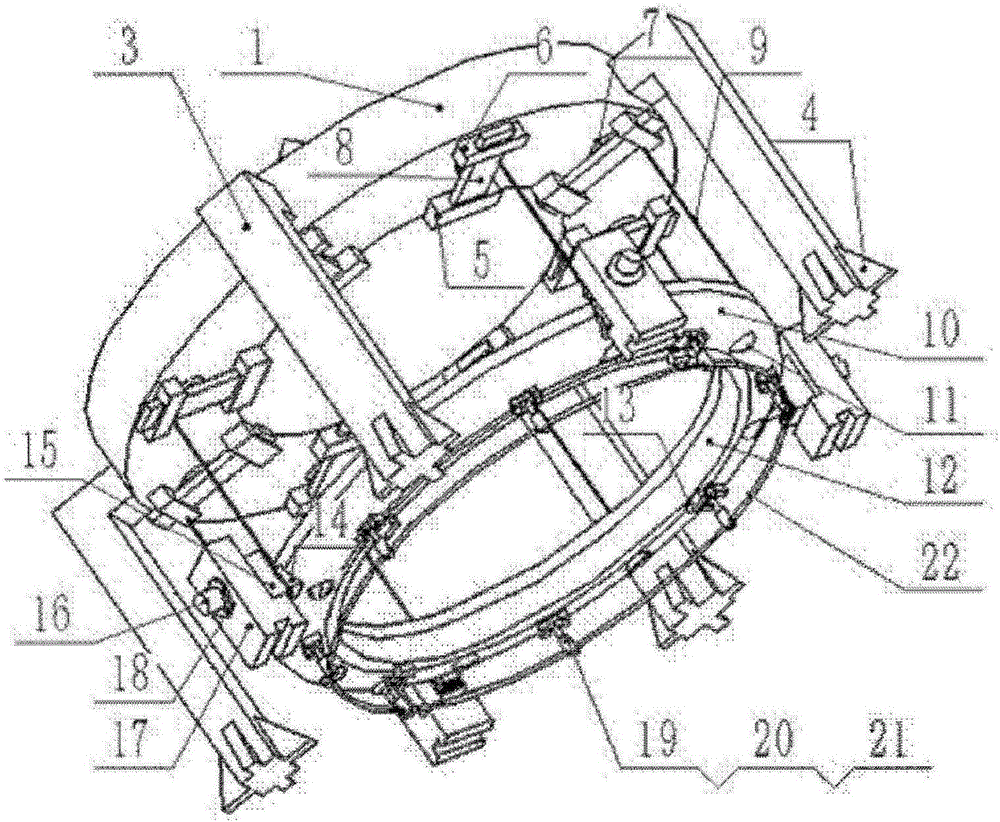

Novel full-automatic welding machine for mask ear ropes

PendingCN111844766AHigh degree of automationIncrease productivityDomestic articlesClothes making applicancesUltrasonic weldingEngineering

The invention discloses a novel full-automatic welding machine for mask ear ropes. The novel full-automatic welding machine comprises a mask conveying device, two ear rope conveying devices and two ultrasonic welding devices; the two ear rope conveying devices are arranged above the mask conveying device in parallel at intervals, and each ultrasonic welding device corresponds to one ear rope conveying device and is arranged below the ear rope conveying device; the mask conveying device comprises a chain plate conveying line mechanism, a plurality of supporting plate mechanisms and an overturning mechanism; the plurality of supporting plate mechanisms are arranged on the chain plate conveying line mechanism at intervals and used for being sleeved with masks, and the overturning mechanism isfixedly installed on the chain plate conveying line mechanism and located between the two ear rope conveying devices; two flanging mechanisms are further fixedly installed on the chain plate conveying line mechanism, and each flanging mechanism is arranged close to one side of one ear rope conveying device. The novel full-automatic welding machine can achieve the procedures of automatic conveying, bending, shearing, welding, discharging and the like of ear ropes, and is high in automation degree, high in production efficiency, reasonable in overall design, compact in structure, small in size,low in cost and high in practicability.

Owner:深圳市利和兴股份有限公司

Environment-friendly automatic distributing robot and using method thereof

InactiveCN106017106AReduce consumptionRealize automatic blankingCharge manipulationGear wheelControl engineering

The invention discloses an environment-friendly automatic distributing robot and a using method thereof. The environment-friendly automatic distributing robot comprises a feeding bin, a material receiving shaking plate, a water distribution pipeline, four electric generators, a shaking plate gear and the like; feeding holes are evenly formed in the feeding bin in the circumferential direction, the feeding bin is fixedly installed at the top ends of four evenly arranged feeding bin support legs, the material receiving shaking plate is arranged under the feeding bin, the water distribution pipeline is fixedly installed on the side face of the material receiving shaking plate, and the electric generators are evenly installed around the water distribution pipeline. The environment-friendly automatic distributing robot is reasonable in structure and saves energy intelligently; due to the fact that the shaking plate gear and a gear slideway are arranged, free motion is achieved when the material receiving shaking plate is stressed in an unbalanced mode, energy consumption of secondary carrying is reduced, and the intelligent energy-saving effect is achieved.

Owner:陈小华

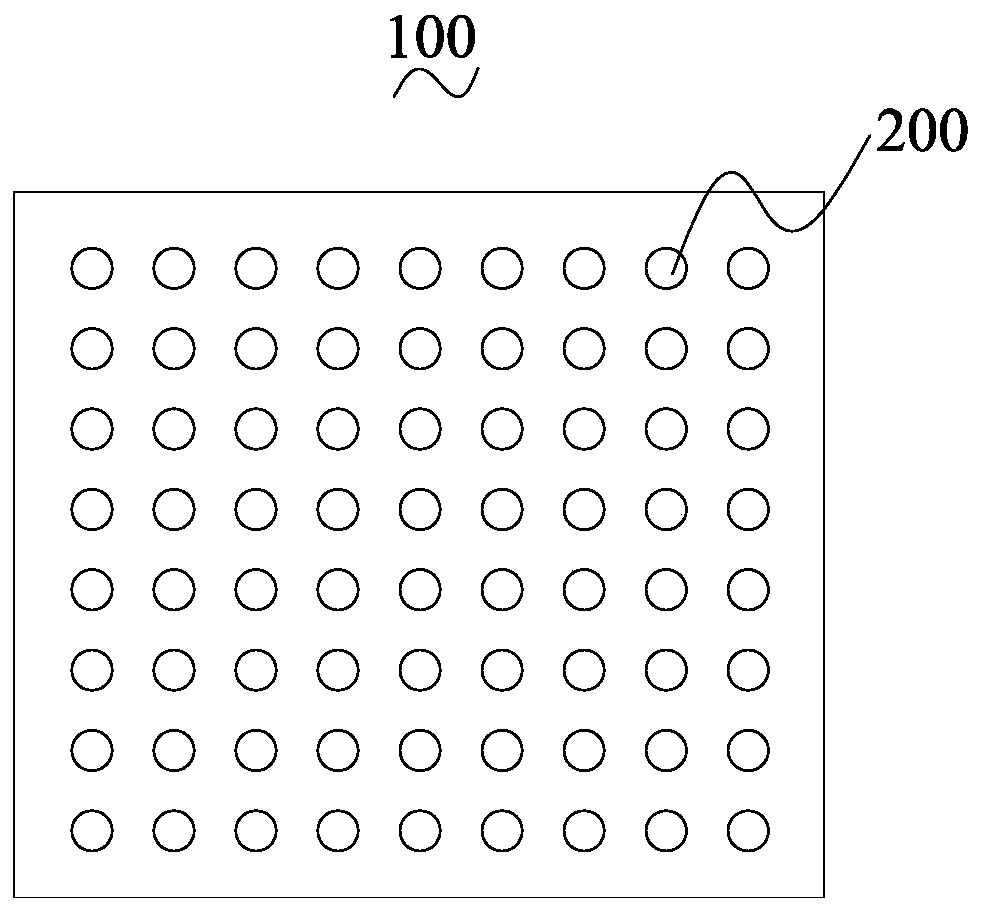

Concrete member production line

ActiveCN113799238AImprove efficiencyRealize automatic demouldingDischarging arrangementMouldsManufacturing lineStructural engineering

The invention relates to the technical field of concrete member machining, in particular to a concrete member production line. The concrete member production line comprises pouring equipment, a mold, a base, a curing device and a demolding device, wherein the mold comprises an outer mold and inner molds, the outer mold is arranged on the base, a plurality of pouring cavities are formed in the outer mold, the inner molds correspond to the pouring cavities in a one-to-one mode, and all the inner molds are arranged in the corresponding pouring cavities; and the demolding device comprises demolding plates, the demolding plates correspond to the pouring cavities in a one-to-one mode, all the demolding plates are embedded in the base, a cavity is formed in the base, and a lifting component used for driving the demolding plates to ascend and descend is arranged in the cavity. The concrete member production line has the effect of improving the production efficiency of concrete members.

Owner:南京交通工程有限公司

Equal-distance machining and synchronous conveying and cutting integrated device for strip-shaped plates

InactiveCN114102143AAct as a limiting supportPlay a buffer roleOther manufacturing equipments/toolsMetal working apparatusPunchingStructural engineering

The invention discloses a strip-shaped plate equidistant machining and synchronous conveying and cutting integrated device which comprises a strip-shaped plate, a machining bed, a machining device, a conveying device, a cutting device and a guiding device, the machining device is fixedly installed on the upper surface of the edge of one end of the machining bed, and the conveying device is rotatably installed on the edge of the center of the top of one end of the machining bed; the cutting device is slidably mounted on the edge of the top of one end of the machining bed, the guiding device is slidably mounted on one end face of the machining bed, and the strip-shaped plates are symmetrically slidably inserted into the edges of the two sides of the end face of the machining bed. The strip-shaped plates are conveyed through the conveying device, it can be guaranteed that the machining bed conducts cooperative punching on the strip-shaped plates, it can be guaranteed that the cutting device conducts equidistant cutting on the strip-shaped plates, continuous machining on the strip-shaped plates is facilitated, and automatic discharging can be achieved.

Owner:王德龙

Mould filling and drying device for flapjack production

InactiveCN111637721AIncrease productionImprove high yieldDrying gas arrangementsDrying chambers/containersProcess engineeringEngineering

One or more embodiments of the invention provide a mould filling and drying device for flapjack production. The mould filling and drying device for flapjack production comprises a drying chamber, wherein a mould feeding conveyor belt is arranged in the drying chamber, moulds are fixed on a conveying end surface of the mould feeding conveyor belt, used for being filled with flapjacks, and rotationally conveyed in the drying chamber along with the mould feeding conveyor belt, and the flapjacks are conveyed through a feeding conveyor belt on the outer side of the drying chamber, and sequentiallyfall into the conveyed moulds through an opening at the upper end of a feeding pipe. Two ends of a hot fan in a fan bin communicate with circulation air pipes, thereby communicating with the two endsof the drying chamber respectively, circulating hot air can be formed in the drying chamber to dry the flapjacks circularly conveyed in the drying chamber. Meanwhile, one end of a discharging conveyorbelt is arranged below one end, far away from the feeding conveyor belt, of the mould feeding conveyor belt, so that the flapjacks automatically fall onto the discharging conveyor belt when being conveyed downwards along with the mould feeding conveyor belt, and therefore automatic falling, mould filling, drying, demoulding and automatic recycling of the moulds are realized.

Owner:安徽德旺食品科技有限责任公司

Food pasting and baking device

ActiveCN104605216AQuality improvementRealize automatic unloadingFood processingFood preparationCooking & bakingDrive motor

The invention provides a food pasting and baking device, relates to the technical field of food processing, and aims to solve the technical problems related to food pasting and baking. The device comprises a rack, an electrically heated roller, a feeding bracket, a shaping scraping plate, a shoveling plate and a control box, wherein the heat conduction roller and a driving motor used for driving the roller to rotate are horizontally placed on the rack; a plurality of electrically heated tubes and temperature sensors, which are electrically connected with the control box, are placed on the inner wall of the roller; the feeding bracket is pivotally arranged on the rack; a lifting cylinder used for driving the feeding bracket to rotate pivotally is mounted on the rack; a feed hopper is fixed on the feeding bracket; the shaping scraping plate is placed on one side of the feed hopper, and a flashboard used for controlling the opening and closing of an opening in the lower end of the feed hopper and a cylinder used for controlling the flashboard to slide are placed on the feeding bracket; the shoveling plate used for shoveling attachments on the surfaces of the roller and a cylinder used for controlling the shoveling plate to rotate pivotally are pivotally arranged on the rack; a discharge hopper with an upward opening is placed on the rack and is positioned under the roller. The device provided by the invention is used for baking foods.

Owner:上海贸燊机电科技有限公司 +1

ABA cast film manufacturing equipment and manufacturing method

InactiveCN108453978ANot easy to scatterSolve technical problems prone to stratificationFlat articlesCoatingsFixed ratioEngineering

The invention relates to the technical field of cast film production, in particular to ABA cast film manufacturing equipment. The equipment comprises a machine frame, a fusing mechanism, a tape casting mechanism, a cutting mechanism and an edge material reuse mechanism, wherein the edge material reuse mechanism comprises a transmission part, a section cutting part and a mixing part; the transmission part comprises a plurality of guide rollers and a lead-in assembly; the mixing part comprises a mixing cabin, a storage part and a mixing assembly; the storage part is used for new material discontinuous quantitative lead-in; the mixing assembly is used for fixed ratio mixing of edge material sections and the new materials; the edge materials and the new materials are in contact mixing in the mixing region and are then transferred; meanwhile, the new materials are covered inside the edge materials to form a mixing unit by the edge material sections; then, the materials enter the fusing mechanism for liquification treatment; through the lead-in assembly, the edge materials are subjected to quantitative transmission; the section cutting part is controlled to perform equal distance sectioncutting treatment; then, the bonding proportioning of the mixing assembly and the edge material section in a way of coating the new materials by the edge material sections by using the mixing assembly is realized; the technical problem of easy delamination in the fusing process of the edge materials and the new materials in the prior art can be solved.

Owner:ZHEJIANG SHANLIAN NEW MATERIAL TECH CO LTD

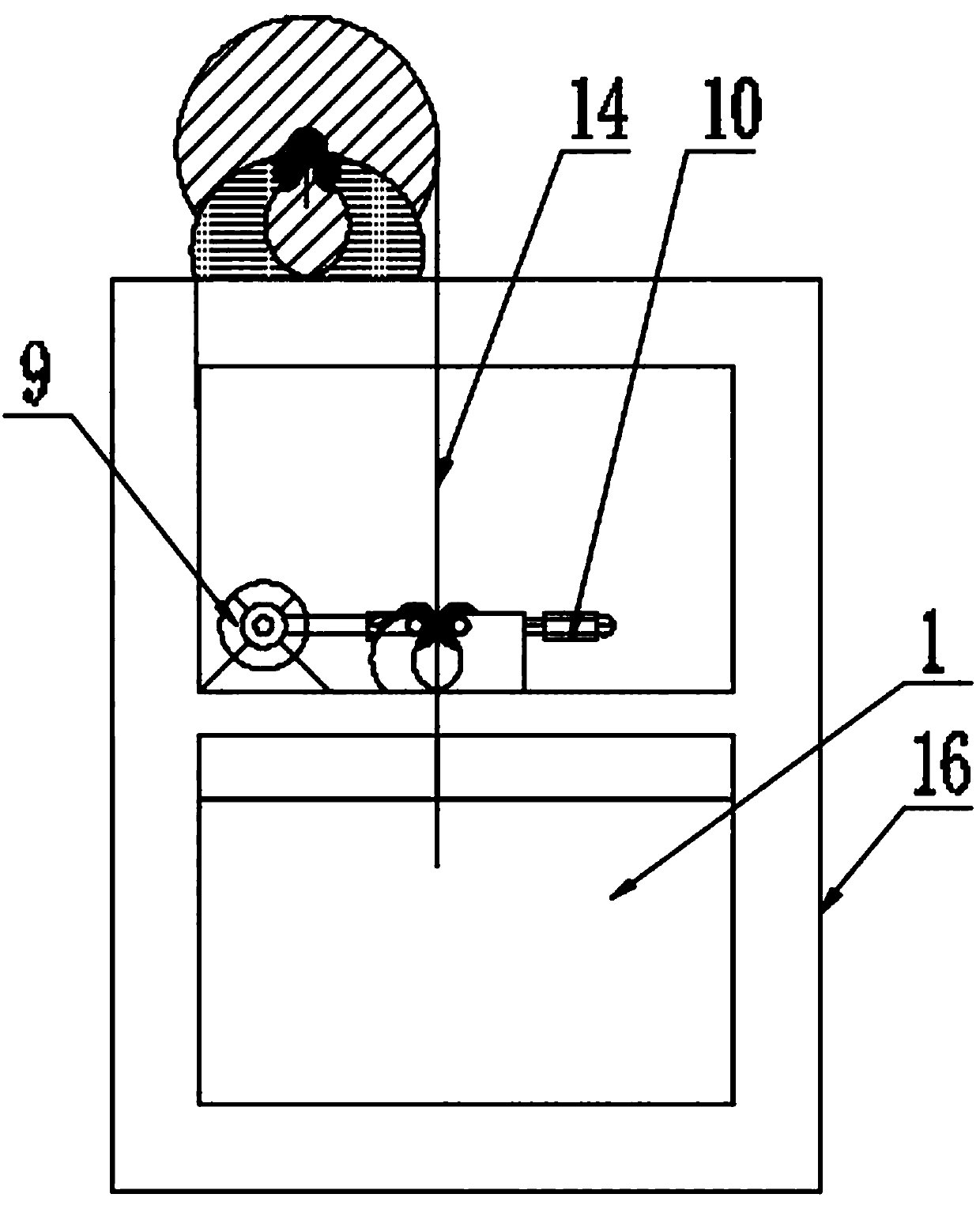

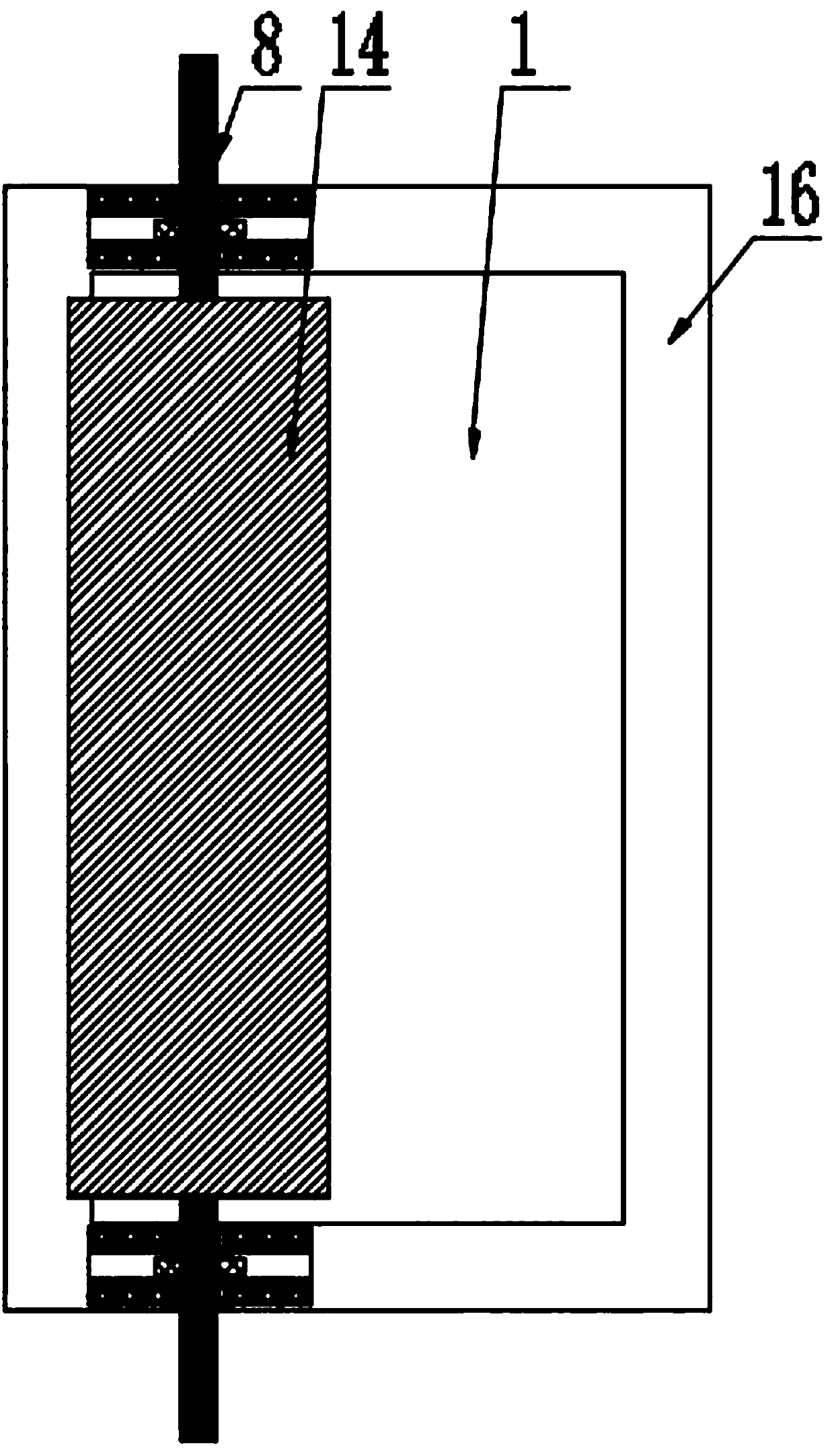

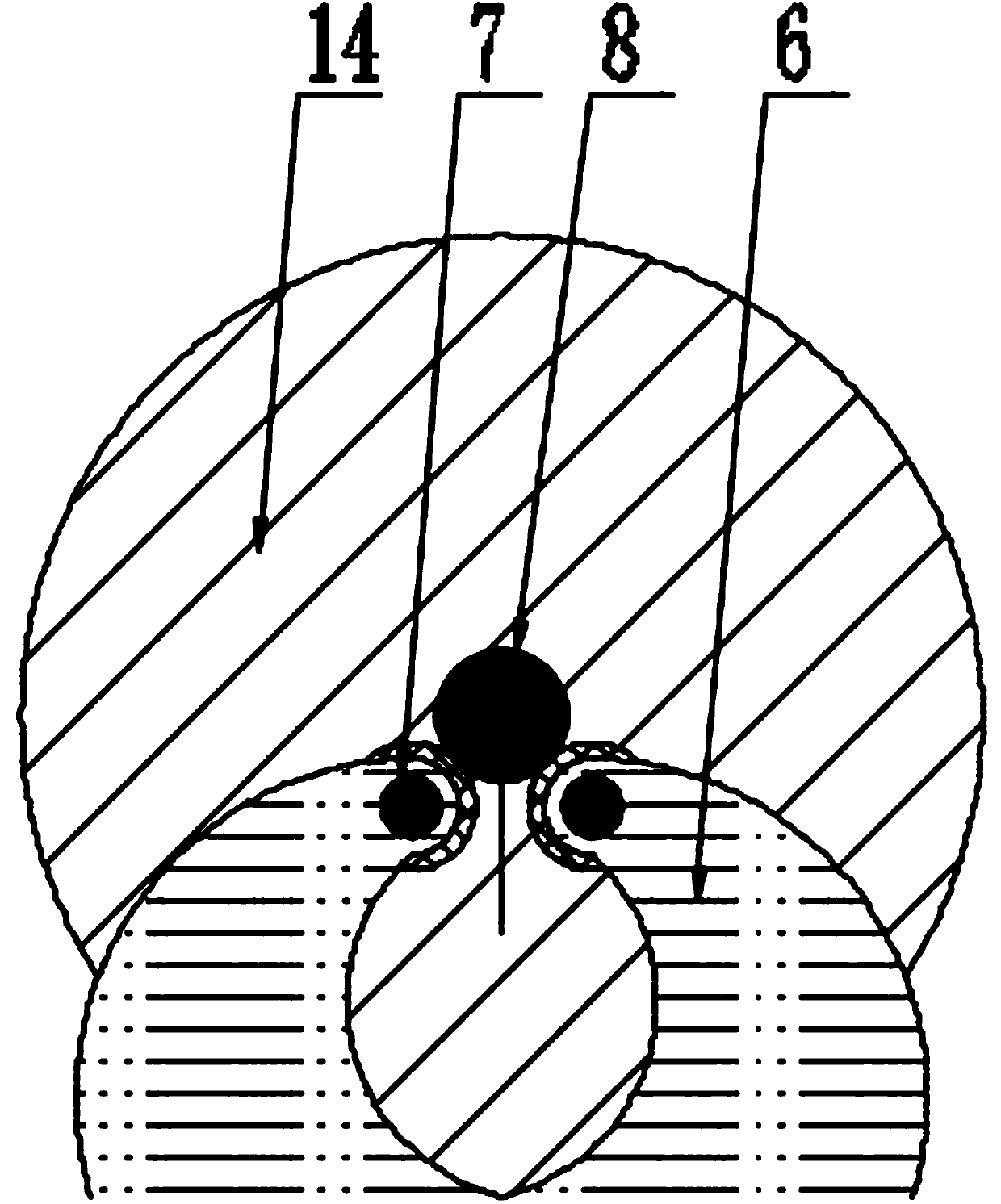

Electrolytic reaction device for preparing graphene

The invention discloses an electrolytic reaction device for preparing grapheme. The electrolytic reaction device for preparing the grapheme comprises an electrolytic cell, graphite plates, discharging mechanisms and graphite paper supporting mechanisms. Each discharging mechanism comprises a pressing roller and a graphite conducting roller connected with a power supply positive pole through a carbon brush. The pressing rollers and the graphite conducting rollers are symmetrically arranged above the electrolytic cell, each graphite paper supporting mechanism is fixed above the corresponding discharging mechanism, and the graphite plates serve as a negative pole and are arranged in the electrolytic cell. According to the purpose of the electrolytic reaction device for preparing the grapheme, the problem that an existing electrolytic device cannot be automated during large-scale preparation of the grapheme is solved.

Owner:DEYANG CARBONENE TECH

Hardware fitting falling and packaging equipment with fixed direction adjusting piece

InactiveCN111284762ARealize automatic blankingAt the same time high production efficiencyPackagingComputer hardwareMechanical engineering

Owner:杜藏恩

Automatic clipping device for server cabinet frame supporting rod

ActiveCN106378487AAutomatic cropping implementationRealize automatic blankingShearing machinesShearing machine accessoriesMotor driveEngineering

The invention discloses an automatic clipping device for a server cabinet frame supporting rod. The automatic clipping device comprises a base, a positioning rod, a motor, a cutter base, a cutter, a processor and a travel switch. The positioning rod comprises an outer rod body and an inner rod body. The inner rod body is arranged at the outer portion of the outer rod body in a sleeving manner, and the inner rod body and the outer rod body are coaxially arranged. The inner rod body can rotate relative to the outer rod body but cannot axially move. The outer rod body is provided with a notch hole extending in the axial direction. Teeth distributed around a center axis of the inner rod body are evenly arranged on the outer circumference of the inner rod body. The base is provided with a positioning rod clamping hole and a fastening device, the base is provided with motors, and the motors include the first motor, the second motor and the third motor. The travel switch is used for detecting whether the supporting rod is fed in place or not and sending signals to the processor. Instructions are sent to the first motor, the second motor and the third motor through the processor, the first motor is made to drive the cutter to conduct cutting, the second motor drives the cutter base to move, the third motor drives the inner rod body to rotate, accordingly, automatic clipping and automatic discharging on the supporting rod are achieved, and the work efficiency is improved.

Owner:EASTERN LIAONING UNIV

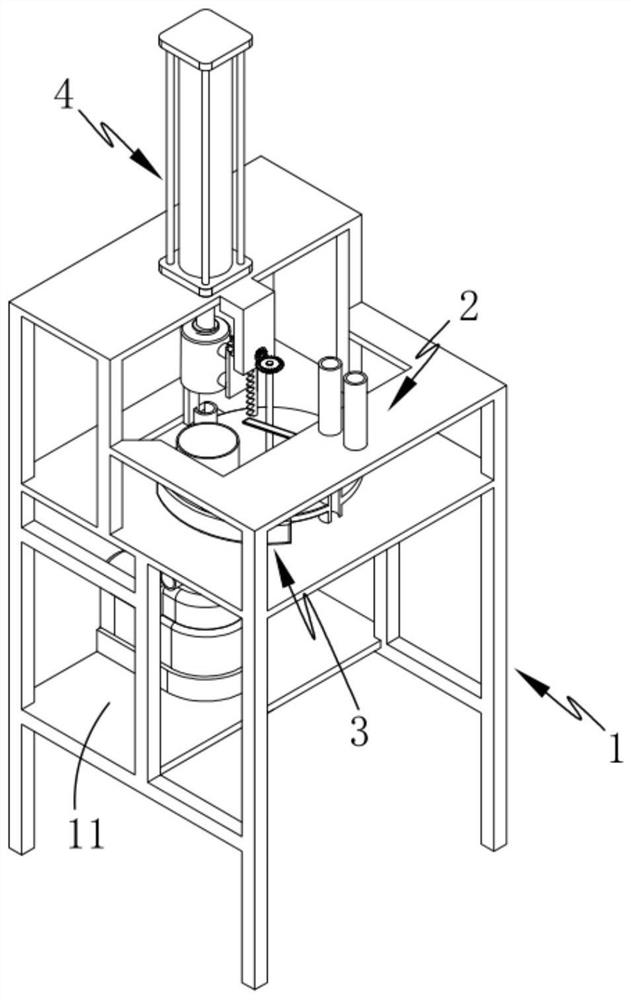

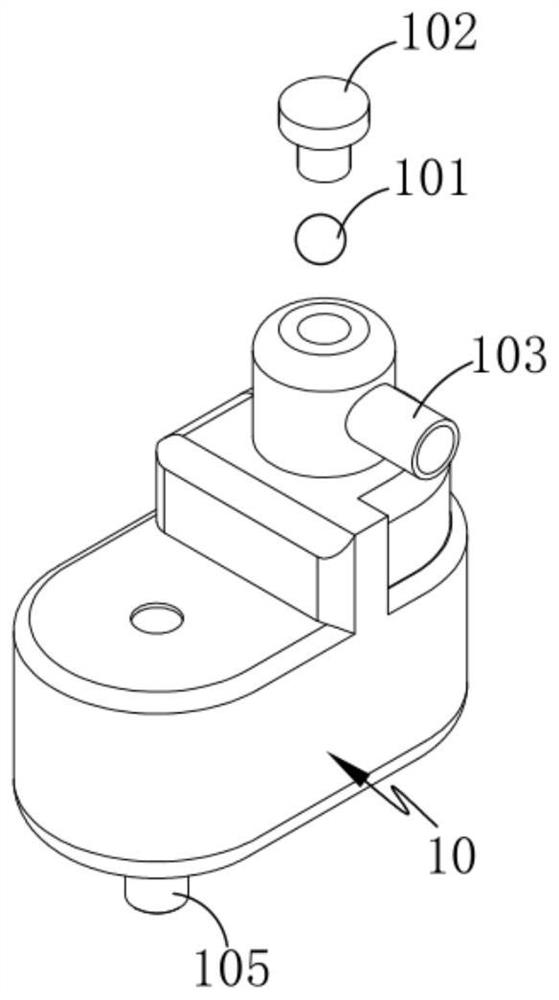

A continuous integrated pressure fitting equipment for oil pump

ActiveCN109366162BAvoid damageAchieving State StabilityLiquid surface applicatorsAssembly machinesProcess engineeringSteel ball

The invention relates to the technical field of oil pump assembly and production, in particular to a continuous integrated pressure-fitting equipment for oil pumps, which includes a frame, an operating table, a batching mechanism, an oiling mechanism, and a press-fitting mechanism. The batching mechanism is used for sorting steel balls and plugs; The oiling mechanism includes a transfer assembly and an oiling assembly. The transfer assembly includes a turntable, a transfer chamber and a rotating shaft. The oil application assembly includes an oiling brush containing oil. When transferring through the transfer chamber, the oiling brush drives the steel ball and the plug to rotate; The press-fitting mechanism is used to press-fit the plugs and steel balls transferred to the press-fitting station through the transfer components into the oil pump body; the steel balls and plugs are automatically batched through the batching mechanism, and then oiled by the oiling mechanism during the transfer process At the same time, the plug is vertically corrected, and then the automatic feeding mechanism for the next set of steel balls and plugs is automatically transferred by the press-fit mechanism during the press-fit process, realizing multi-functional automatic press-fit production and solving the problem of existing technologies The technical problem that the oil pump pressure matching function exists in the unit is single.

Owner:CHANGXING BEST MASCH CO LTD

Vision-based batch axial component pin cutting and bending device

ActiveCN113458280AAutomatic quick cutImprove processing efficiencyMetal working apparatusControl cellEngineering

The invention provides a vision-based batch axial component pin cutting and bending device. The vision-based batch axial component pin cutting and bending device comprises an upper die base, a lower die base, a position monitoring device, a press machine, a driving unit and a control unit; a linear fixed clamping groove, guide sleeves and two grooved cutting and bending punch-die bodies are arranged on the upper die base, and the two grooved cutting and bending punch-die bodies are connected with the linear fixed clamping groove in a sliding mode; guide columns, linear guide rails, a grooved bending male die body and two cutting female die bodies are arranged on the lower die base, and the two cutting female die bodies are connected with the linear guide rail in a sliding mode; a plurality of first concave grooves are formed in the upper surface of the grooved bending male die body, axial components are placed in the first concave grooves, and the left side face and the right side face of the grooved bending male die body are planes; and the position monitoring device and the driving unit are both connected with the control unit, and the control unit controls the driving unit according to signals transmitted by the position monitoring device, so that the positions of the grooved cutting and bending punch-die bodies and the cutting female die bodies are controlled. The vision-based batch axial component pin cutting and bending device is used for bending and cutting axial component pins on a large scale.

Owner:JIANGSU UNIV

Distributor capable of achieving split charging after mixing of various organic fertilizers

ActiveCN113002870AEasy to useGood practical valueBio-organic fraction processingSolid materialAgricultural engineeringElectrical and Electronics engineering

The invention relates to a distributor capable of achieving split charging after mixing of various organic fertilizers. The distributor comprises a base, and a left support and a conveying belt are arranged on the base; a main driving assembly, a hanging bracket and an auxiliary driving assembly are installed on the left support; a boxing barrel and a charging barrel are installed on the upper portion of the hanging bracket; the lower end of the boxing barrel abuts against a feeding block, and the lower end of the loading barrel abuts against a blocking plate; and the feeding block and the blocking plate are both matched with the main driving assembly. The distributor is convenient to use, on the basis that the feeding block is controlled to do left-right intermittent reciprocating sliding, automatic supply and transportation of square boxes and automatic falling of the mixed organic fertilizers can be effectively achieved in sequence, therefore, automatic quantitative split charging and distributing of the mixed organic fertilizers can be achieved, and the distributor has good practical value.

Owner:安徽惠禾壮生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com