Food pasting and baking device

A baking device and food technology, applied in food preparation, food science, application and other directions, can solve the problems of uneven manual paste, partial undrying, high production cost, shorten the product production cycle, reduce labor intensity, reduce The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

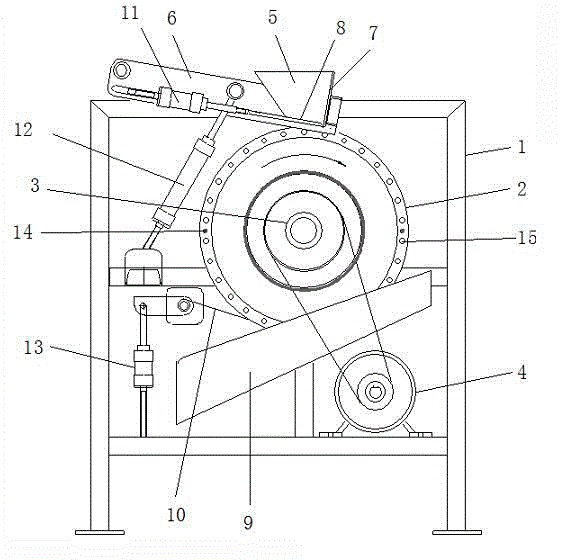

[0012] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

[0013] Such as figure 1 As shown, a food paste baking device provided by the embodiment of the present invention is characterized in that it includes a frame 1, a feeding bracket 6, and a control box (not shown in the figure);

[0014] A rotatable drum 2 is placed on the frame 1. The drum 2 is a cylindrical heat-conducting cylinder. A central cylinder 3 is coaxially inserted in the cylinder 2. One end of the central cylinder is equipped with a brush ring (Fig. not shown in the figure), the drum 2 and the central cylinder 3 are fixedly connected by a heat insulating member, the drive motor 4 for driving the central cylinder 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com