Environment-friendly automatic distributing robot and using method thereof

A technology of automatic cloth and robots, which is applied in the direction of furnaces, lighting and heating equipment, furnace components, etc., can solve the problems of large energy consumption, labor and time-consuming, non-conforming to energy conservation and environmental protection, etc., and achieve the effect of free movement and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

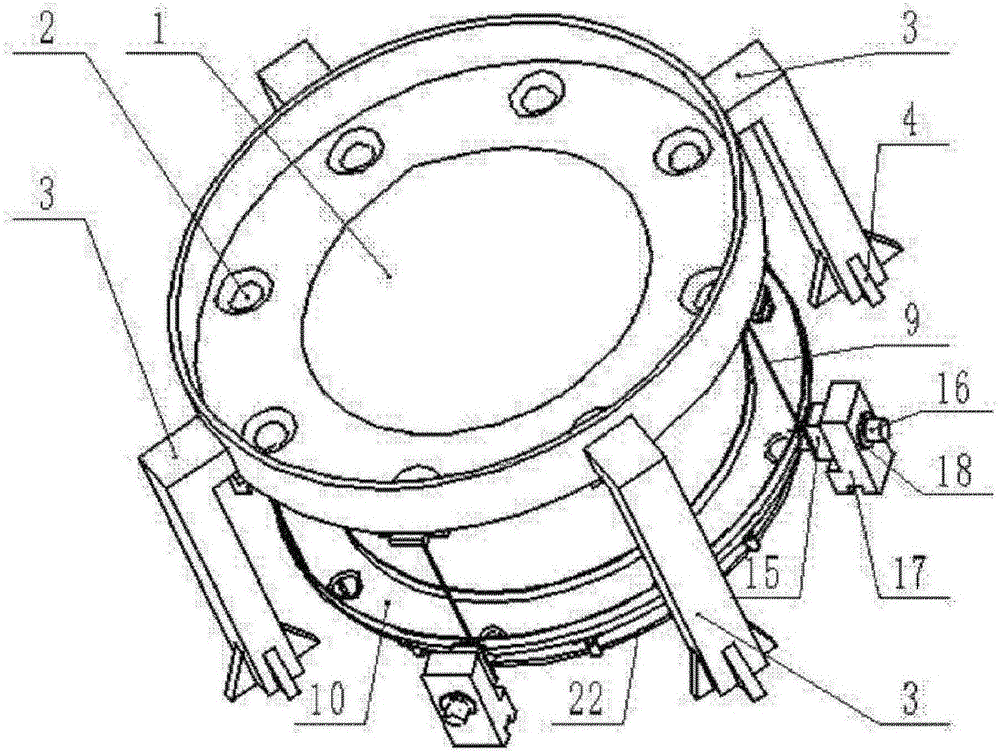

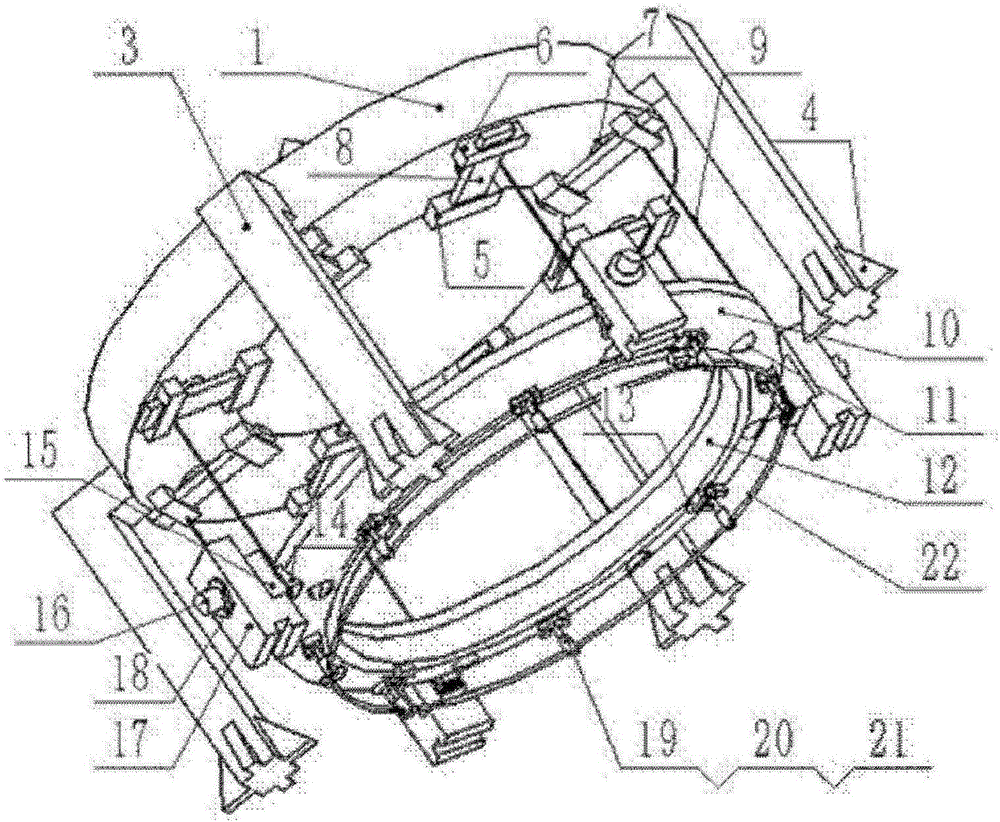

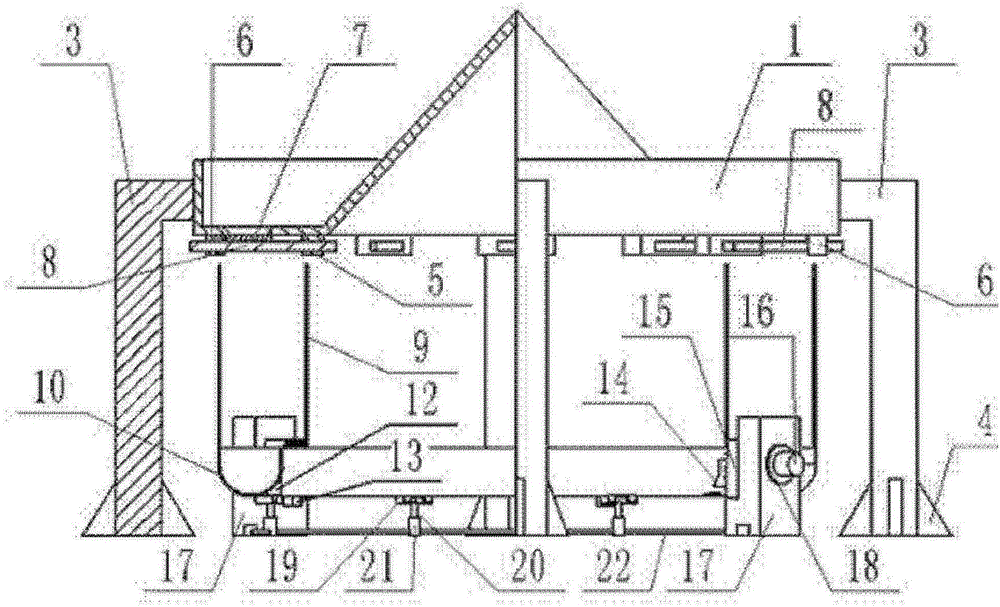

[0021] Such as Figure 1-Figure 8 As shown, an environment-friendly automatic distributing robot includes feeding bin 1, feeding port 2, feeding bin outrigger 3, outrigger tendon plate 4, baffle inner slide 5, baffle outer slide 6, baffle material circular plate 7, material retaining slide bar 8, vertical trigger lever 9, material receiving rocking plate 10, material pipe hole 11, water distribution pipe 12, generator 13, rocking plate gear 14, outrigger gear, outrigger gear seat 16 , outrigger base 17 , gear slideway lock clip 18 , rocking plate base 19 , special-shaped connecting rod 20 , plunger cylinder 21 , water flow hose 22 , feeding bin 1 is provided with evenly arranged feeding days 2 along the circumferen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com