Concrete member production line

A production line and concrete technology, applied in the field of concrete component production line, can solve the problems of low degree of automation, affecting the efficiency of concrete component production, and spending a lot of time, so as to achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

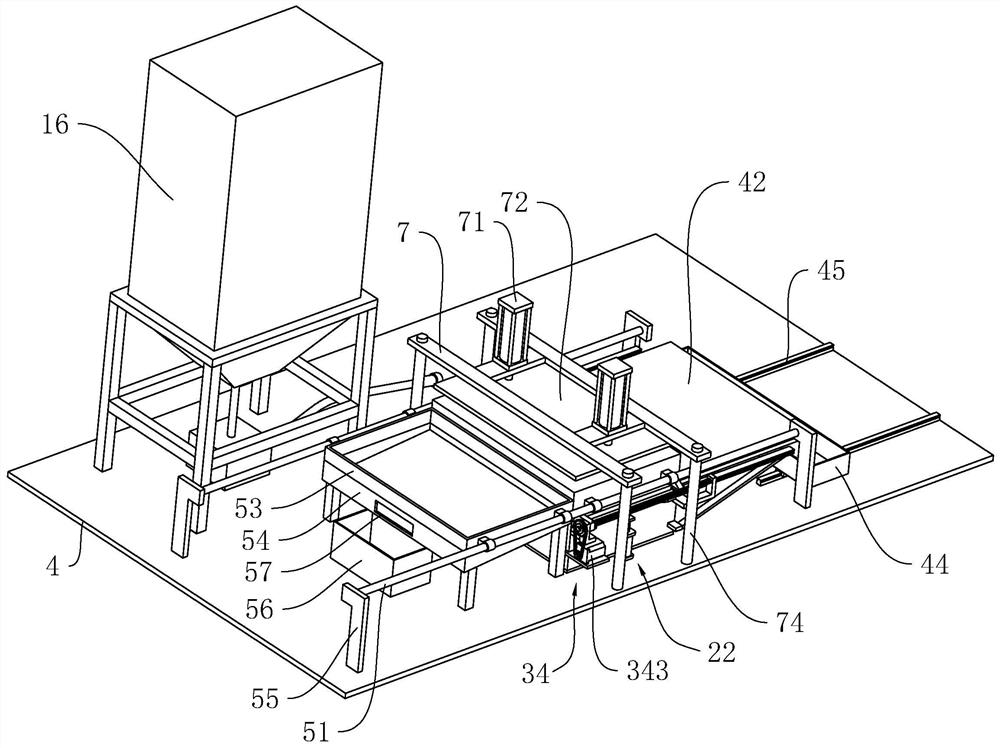

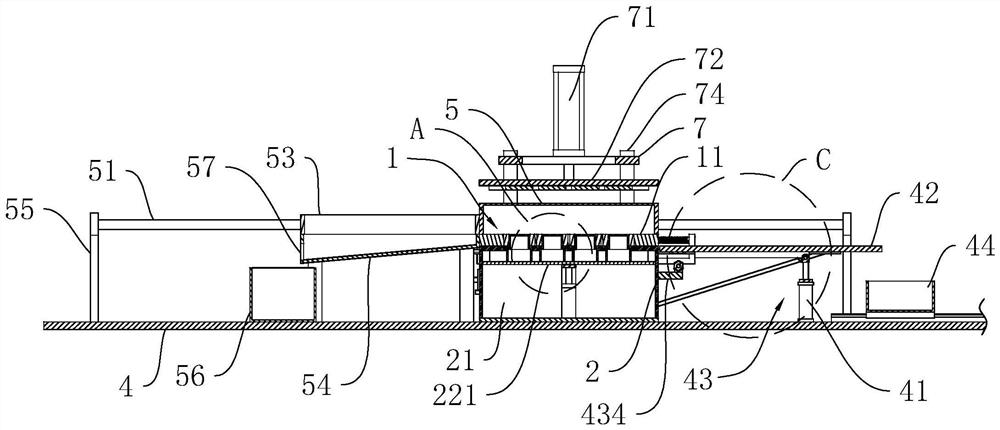

[0041] The following is attached Figure 2-8 The application is described in further detail.

[0042] The embodiment of the application discloses a concrete member production line. Such as figure 2 and image 3 , the concrete member production line includes a bottom plate 4 horizontally arranged on the ground, a rectangular base 2 is arranged on the bottom plate 4, a mold 1 is arranged on the upper surface of the base 2, a curing device is arranged on the mold 1, and a mold 1 is arranged on the ground. The pouring equipment 16 for pouring concrete, the base 2 is provided with a blanking device along one side of its width direction, and the base 2 is provided with a demoulding device, wherein the pouring equipment 16 is a prior art and will not be described too much.

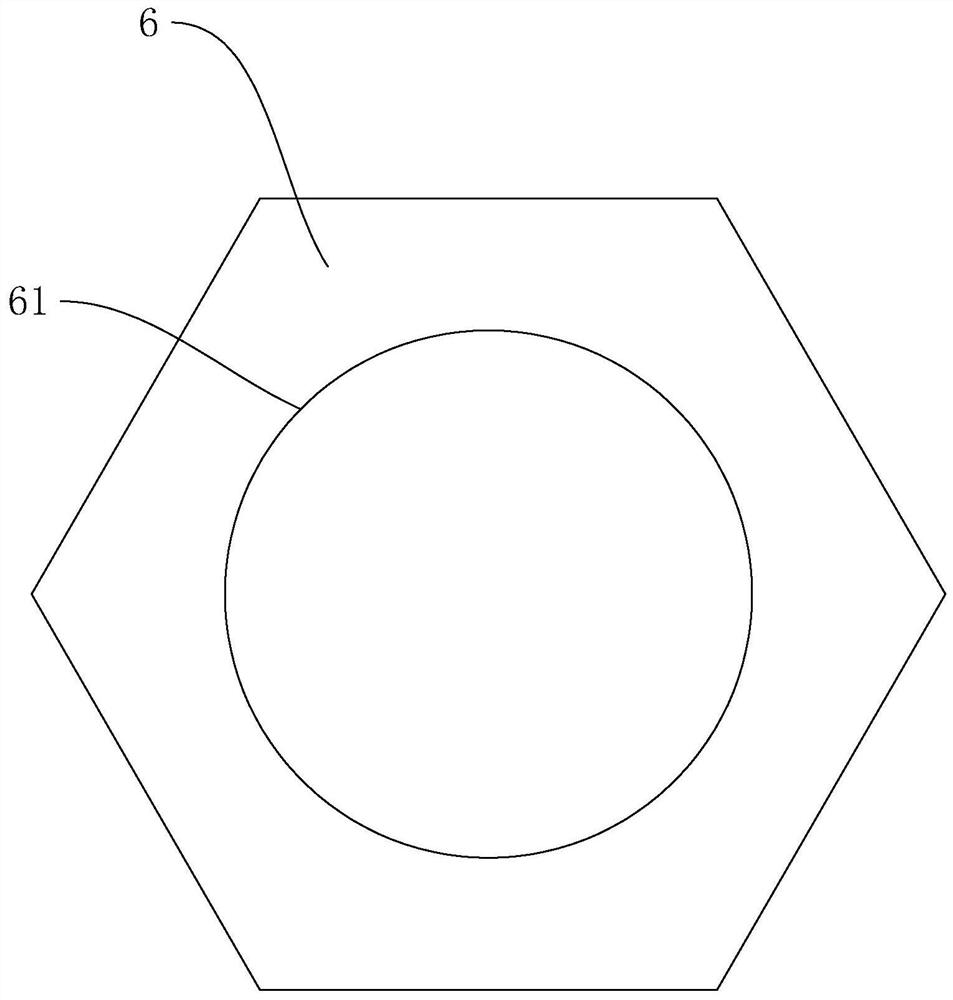

[0043] Such as Figure 4 , Figure 5 as well as Figure 6 , the mold 1 includes a rectangular outer mold 11, the base 2 is fixedly connected with slide rails 32 on both sides along its own length direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com