Novel full-automatic welding machine for mask ear ropes

A fully automatic, welding machine technology, applied to household components, tools for sewing clothes, household appliances, etc., can solve the problems of unguaranteed production quality, low production efficiency, high work intensity, etc., and achieve labor cost saving and production efficiency High, high welding efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

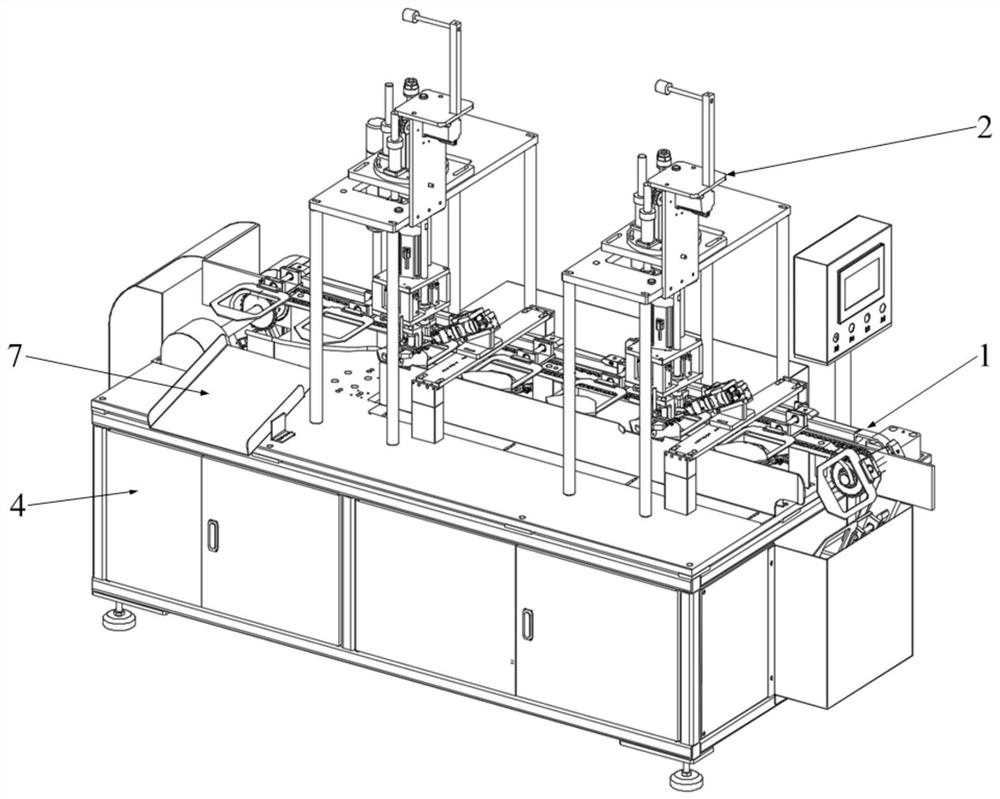

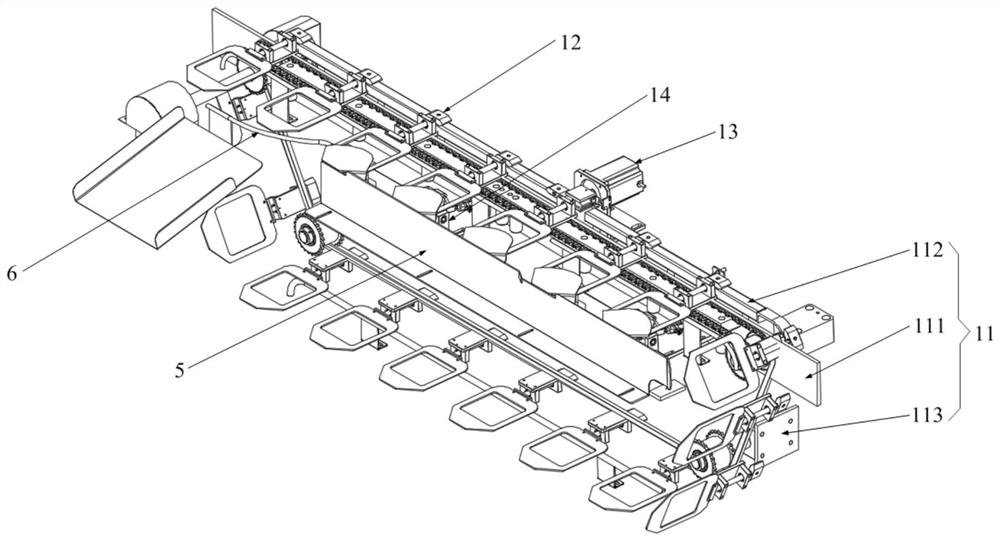

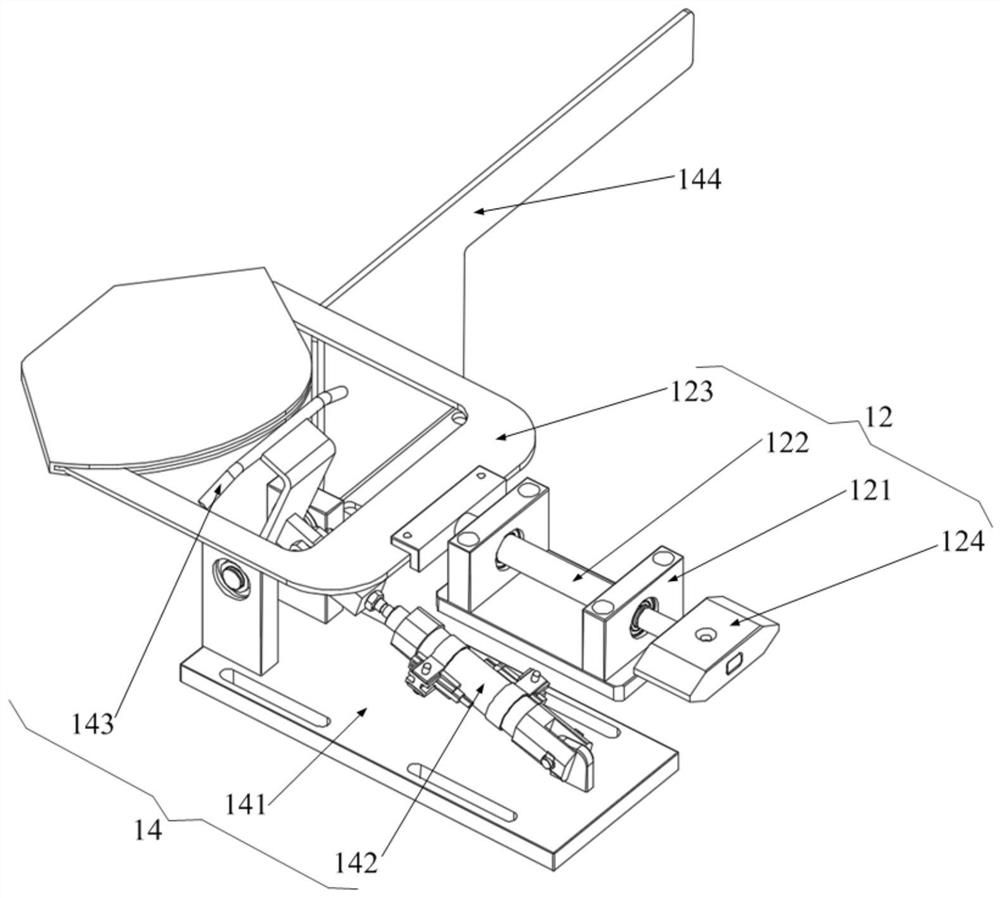

[0068] refer to Figures 1 to 11 As shown, the present invention provides a new type of full-automatic welding machine for mask ear straps, including a mask transmission device 1, two ear strap transfer devices 2, and two ultrasonic welding devices 3; the two ear strap transfer devices 2 are arranged in parallel intervals on the mask Above the transmission device 1, each ultrasonic welding device 3 corresponds to an ear belt conveyor 2 and is arranged below it; A number of supporting plate mechanisms 12 for inserting masks, and a flipping mechanism 13 fixedly installed on the chain plate transmission line mechanism 11 and between the two ear belt conveyors 2; the chain plate transmission line mechanism 11 is also fixedly installed There are two flanging mechanisms 14, and each flanging mechanism 14 is arranged near one side of the ear belt c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com